A New Type of Automatic Marble Composite Panel Manufacturing System

A manufacturing system and marble technology, applied in building structures, chemical instruments and methods, building components, etc., can solve the problems of low degree of automation, troublesome transfer processing, poor quality, etc., to improve production efficiency and glue quality. Standardized, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

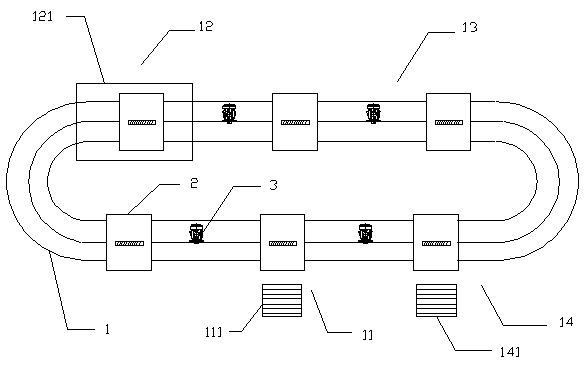

[0020] Such as figure 1 A new type of automatic marble composite panel manufacturing system shown includes a guide rail 1 , a pressing device 2 and a driving mechanism 3 .

[0021] The guide rail 1 is connected end to end to form a ring structure, and the guide rail 1 is sequentially divided into a gluing area 11, a drying area 12, a cooling area 13 and a lower plate area 14;

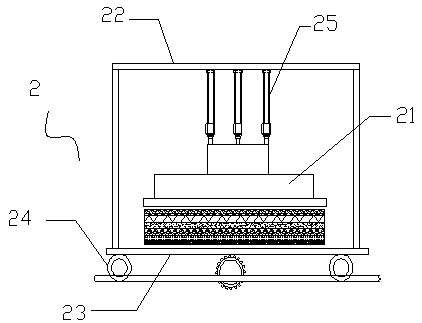

[0022] Such as figure 2 As shown, there are several pressing frame devices 2 and they are placed in series on the guide rail 1. The pressing frame device 2 moves circularly along each area of the guide rail 1 under the drive of the driving mechanism 3. The driving mechanism 3 is a motor and a device installed on the guiding rail 1 The fixed gear below the press frame device 2; the adjacent press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com