Purification method and purification system of chlorosilicate

A purification method and silicide technology, which is applied in the direction of silicon halide compounds, halosilanes, etc., can solve problems such as difficulty in effectively reducing the impurity concentration of chlorosilicides, and achieve the goal of avoiding unqualified polysilicon quality, good separation effect, and high separation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

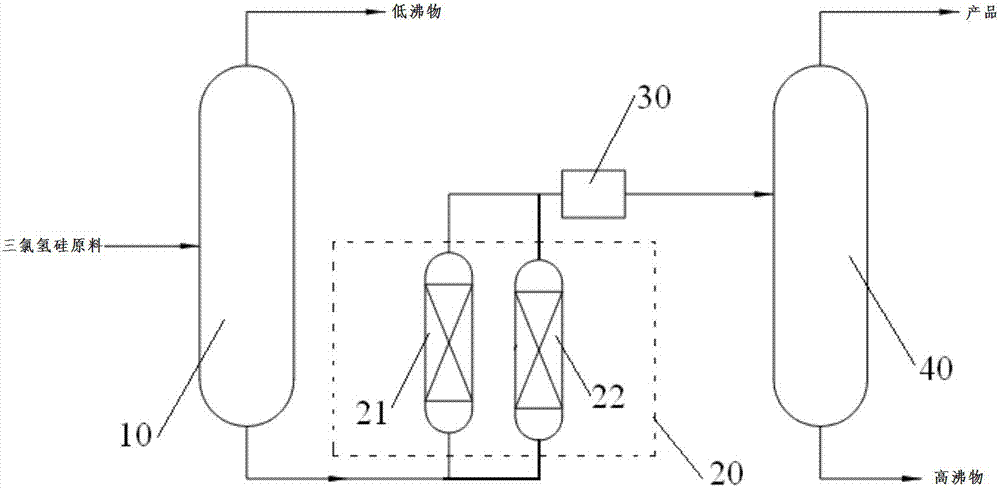

Embodiment 1

[0050] Put the trichlorosilane raw material into the first rectification tower, the B impurity content is 20ppb, the P impurity content is 13ppb, the pressure of the tower is controlled at 0.2MPa, and the temperature of the tower kettle is at 50°C to ensure the reflux of the tower, and the product is extracted from the tower kettle The rectification liquid phase trichlorosilane enters the reaction adsorber; the adsorption reactor is controlled at 20KPa, the temperature inside the adsorption reactor is controlled to be 35°C, and the rectification liquid phase trichlorosilane enters the adsorption reactor from the bottom of the first rectification tower In the reactor, a packed bed is set in the adsorption reactor, and an adsorbent is arranged in the packed bed, wherein the main body of the adsorbent is porous silica gel, the free water content is 10%, the aspect ratio of the equipment is controlled at 15:1, and the top outlet is adsorbed Liquid phase trichlorosilane; the gas pha...

Embodiment 2

[0052] Put the trichlorosilane raw material into the first rectification tower, the B impurity content is 22ppb, the P impurity content is 15ppb, the pressure of the tower is controlled at 0.3MPa, and the temperature of the tower kettle is at 65°C to ensure the reflux of the tower, and the product is extracted from the tower kettle The rectification liquid phase trichlorosilane enters the reaction adsorber; the adsorption reactor is controlled at 10KPa, the temperature inside the adsorption reactor is controlled at 10°C, and the rectification liquid phase trichlorosilane enters the adsorption reactor from the bottom of the first rectification tower In the reactor, a packed bed is set in the adsorption reactor, and an adsorbent is arranged in the packed bed, wherein the main body of the adsorbent is porous silica gel, the free water content is 10%, the aspect ratio of the equipment is controlled at 10:1, and the top outlet is adsorbed Gas-phase trichlorosilane; the adsorbed liqu...

Embodiment 3

[0054] Put the trichlorosilane raw material into the first rectification tower, the B impurity content is 23ppb, the P impurity content is 12ppb, the pressure of the tower is controlled at 0.05MPa, and the temperature of the tower kettle is at 45°C to ensure the reflux of the tower, and the product is extracted from the tower kettle The rectification liquid phase trichlorosilane enters the reaction adsorber; the adsorption reactor is controlled at 50KPa, the temperature inside the adsorption reactor is controlled at 45°C, and the rectification liquid phase trichlorosilane enters the adsorption reactor from the bottom of the first rectification tower In the reactor, a packed bed is set in the adsorption reactor, and an adsorbent is arranged in the packed bed, wherein the main body of the adsorbent is porous silica gel, the free water content is 2%, the aspect ratio of the equipment is controlled at 20:1, and the top outlet is adsorbed Gas-phase trichlorosilane; the adsorbed liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com