Anti-yarn-winding device

An anti-tangle and yarn technology, applied in spinning machines, textiles, papermaking, drafting equipment, etc., can solve problems such as end breakage, waste of resources, and inability to preliminarily determine the quality of yarns, etc., to reduce production costs , to avoid the effect of unqualified quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

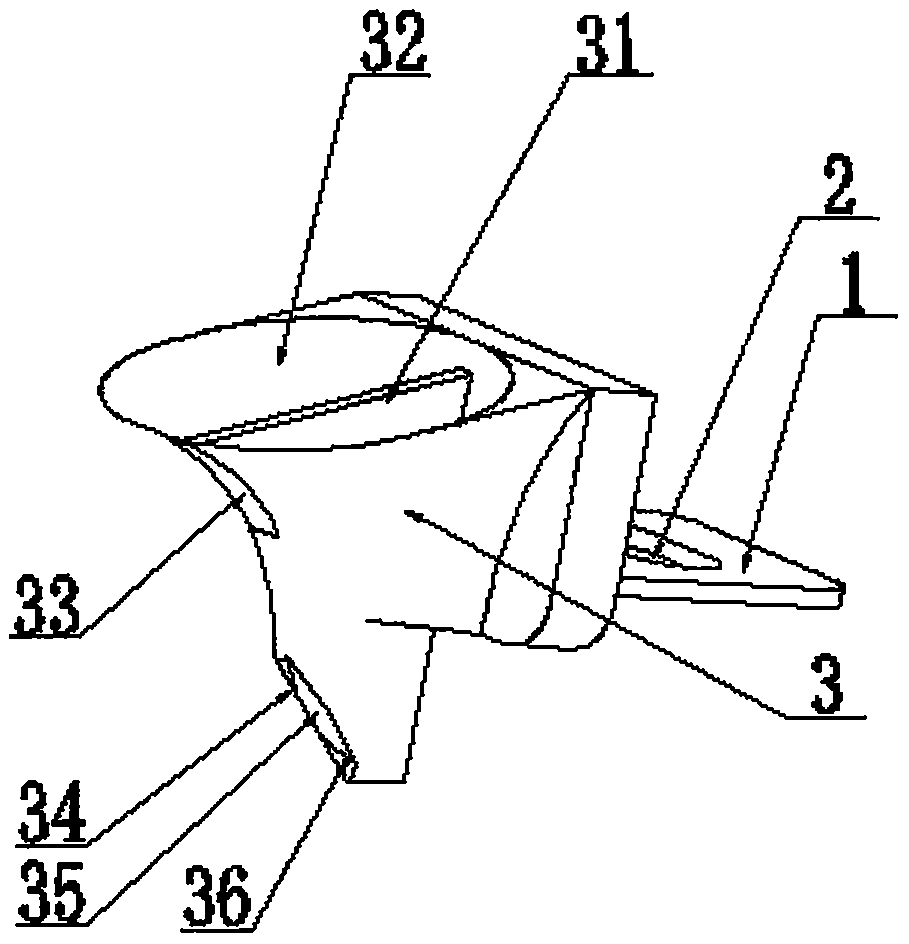

[0009] Referring to the accompanying drawings, the present invention includes a yarn anti-winding device, including a trumpet-shaped bell mouth main body 3, the back of the bell mouth main body 3 is integrated with the installation plate 1, and the installation plate 1 is provided with a groove-shaped The installation hole 2, the bell mouth main body 3 is made of plastic material, and an isolation plate 31 is arranged inside it to divide the inside of the bell mouth main body 3 into two. There is a vertical yarn groove 33 at the front most of the front, and the length of the yarn groove 33 is 1 / 2 of the length 3 of the main body of the horn; The angle is 45 degrees; the separation plate 31 extends from the middle of the bell mouth body 1 to 3 / 4 from the top to the bottom, and forms a viewing port 35 together with the oblique cut surface.

[0010] The present invention innovates on the existing yarn bell mouth technology, by opening a vertical, non-penetrating yarn groove 33 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com