Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Avoid spallation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

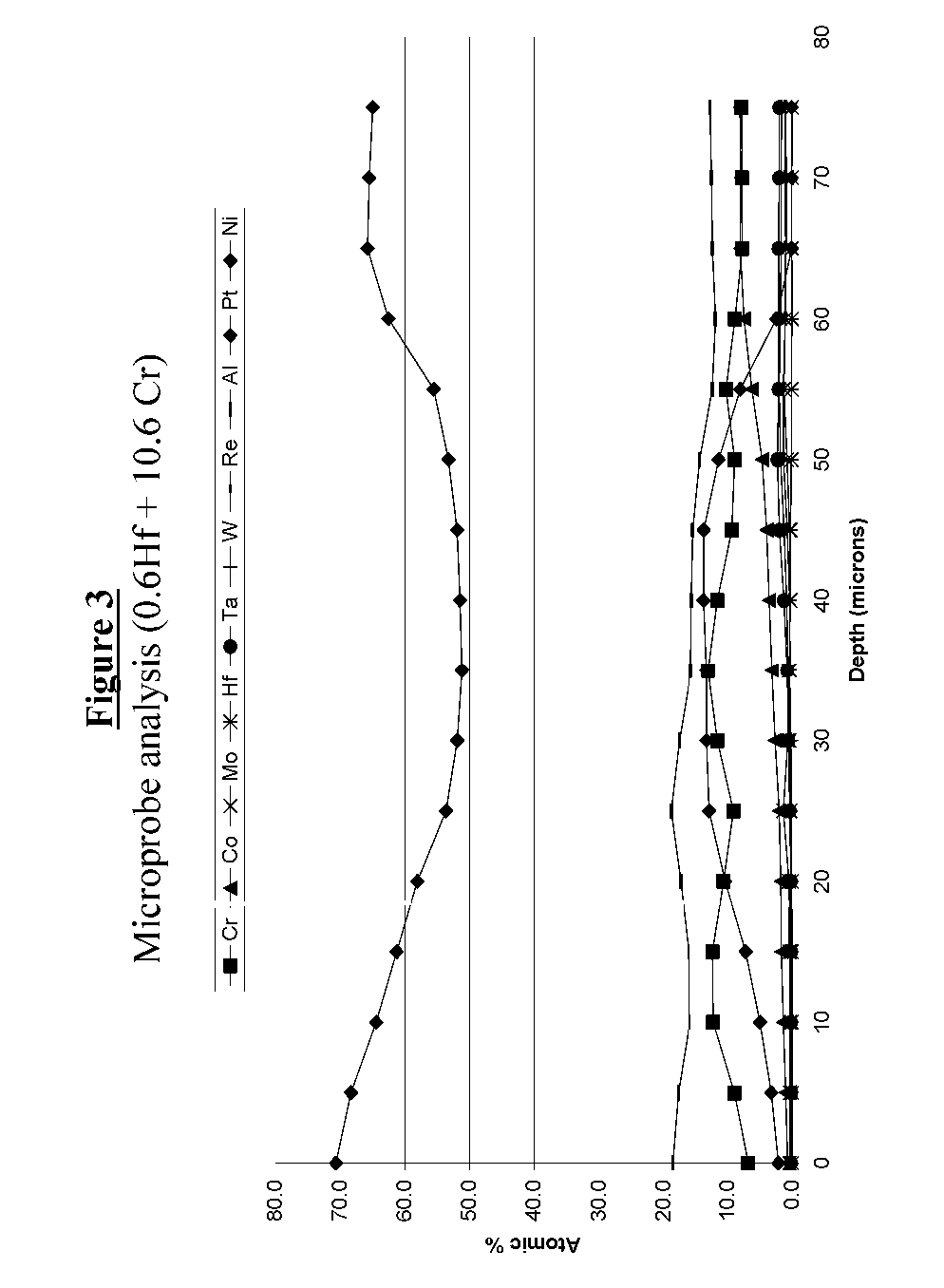

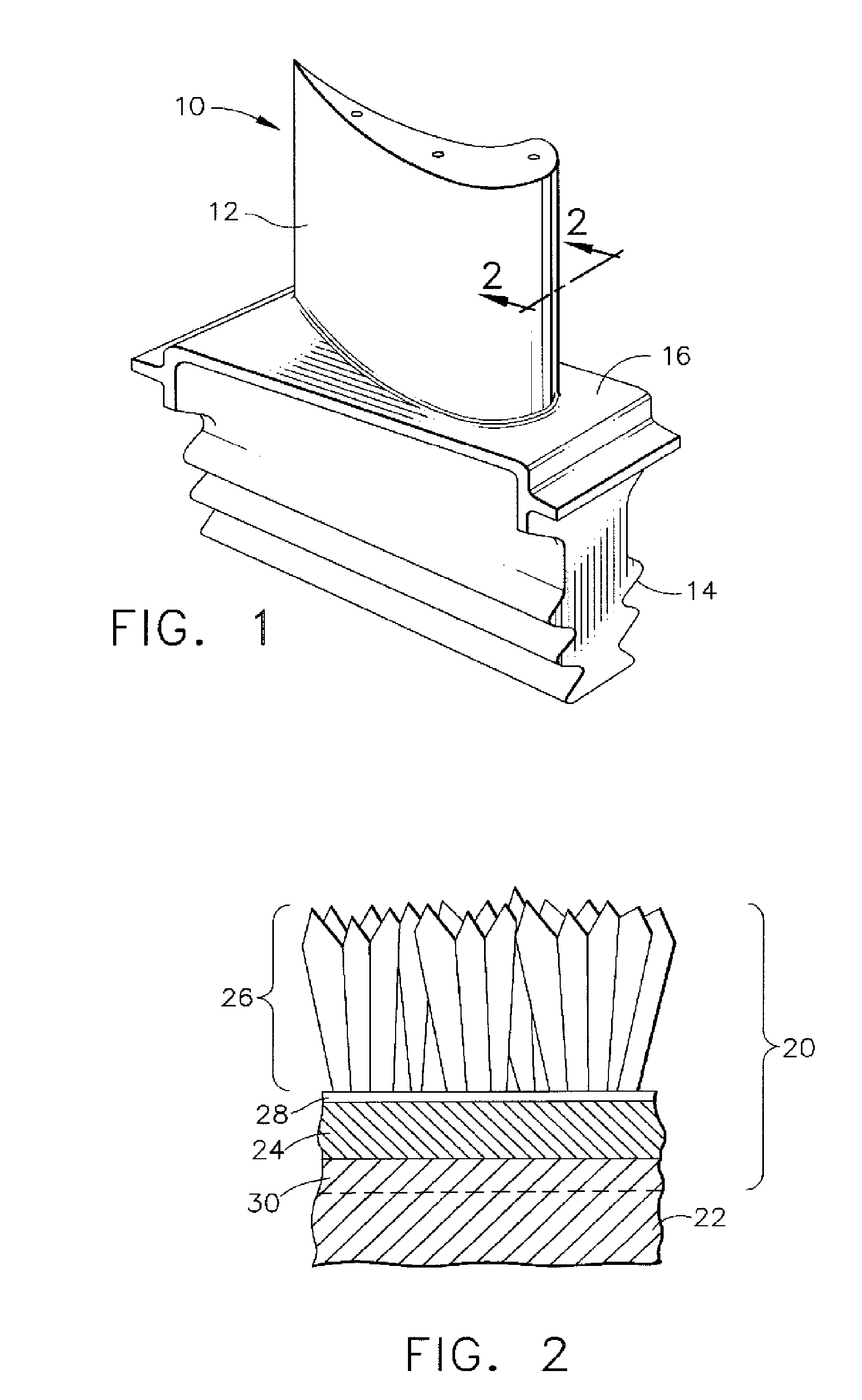

Methods for depositing gamma-prime nickel aluminide coatings

ActiveUS20060093752A1Reduce tendencyReduce the possibilityBlade accessoriesVacuum evaporation coatingChromiumNickel aluminide

Methods for depositing an overlay coating on articles intended for use in hostile thermal environments. The coating has a predominantly gamma prime-phase nickel aluminide (Ni3Al) composition suitable for use as an environmental coating and as a bond coat of a thermal barrier coating system. The coating further contains at least one platinum group metal, preferably chromium, optionally one or more reactive elements, and optionally silicon. The coating is deposited by a process that entails forming a platinum group metal layer and at least one separate layer of other constituents of the coating, and then performing a diffusion heat treatment to yield the coating.

Owner:GENERAL ELECTRIC CO

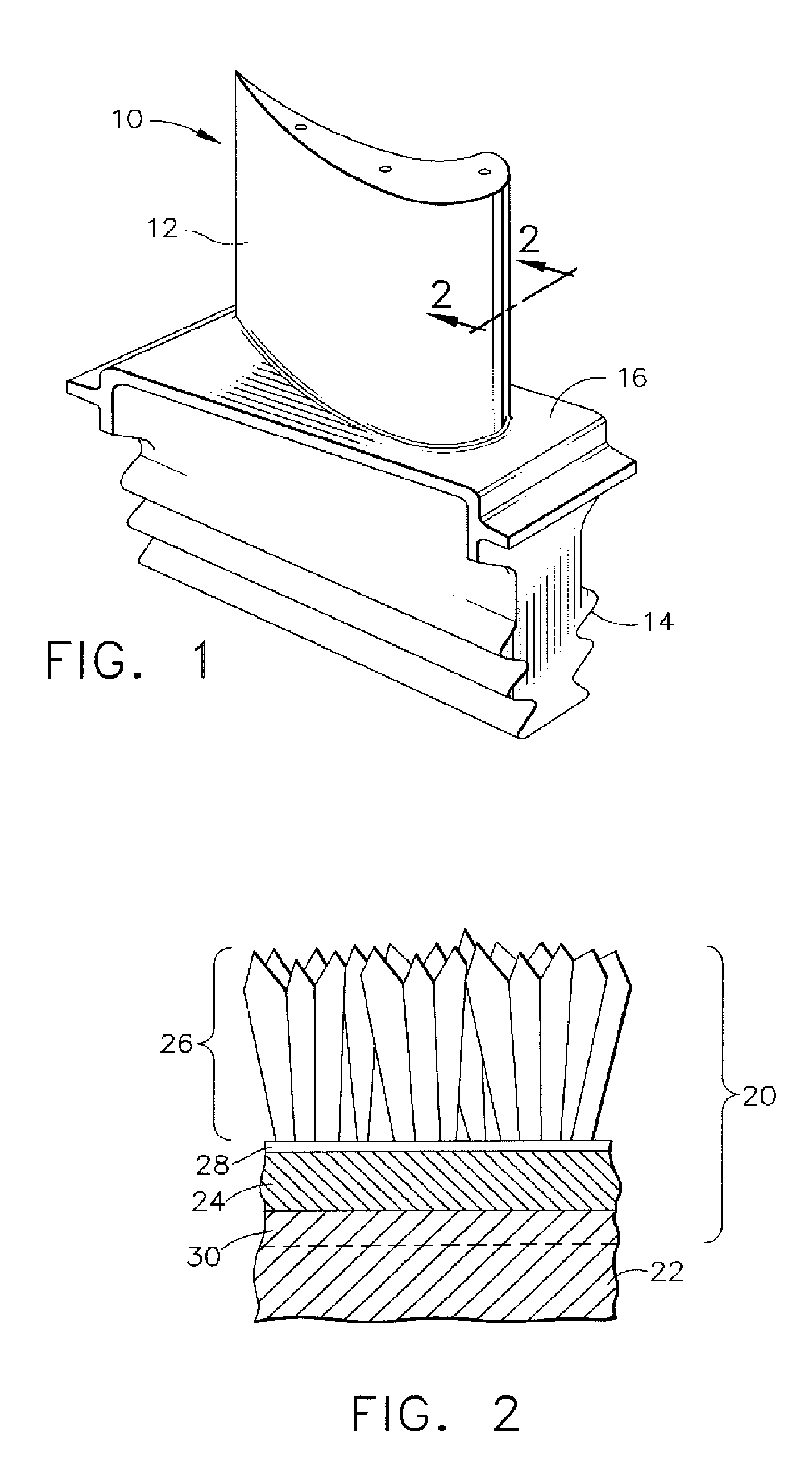

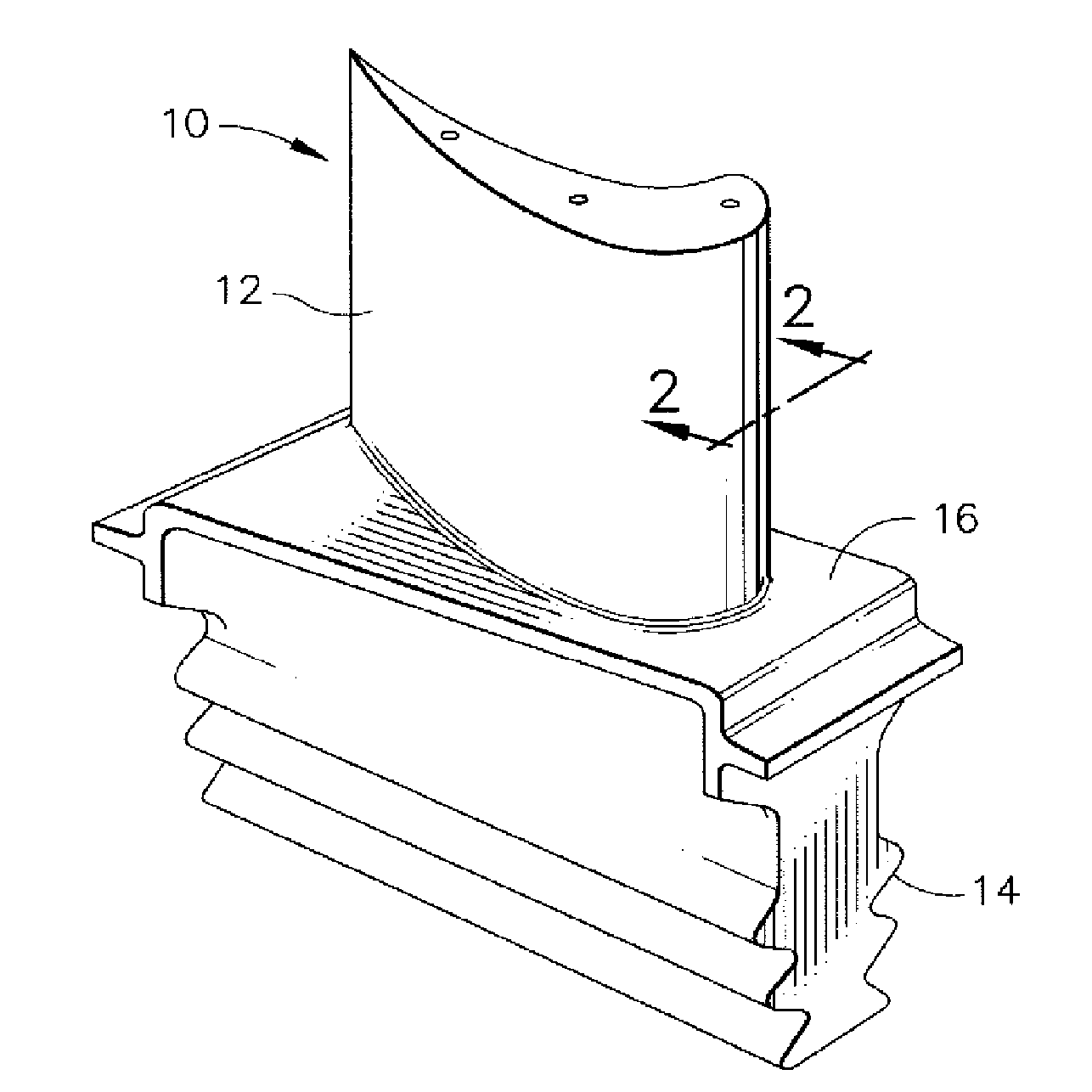

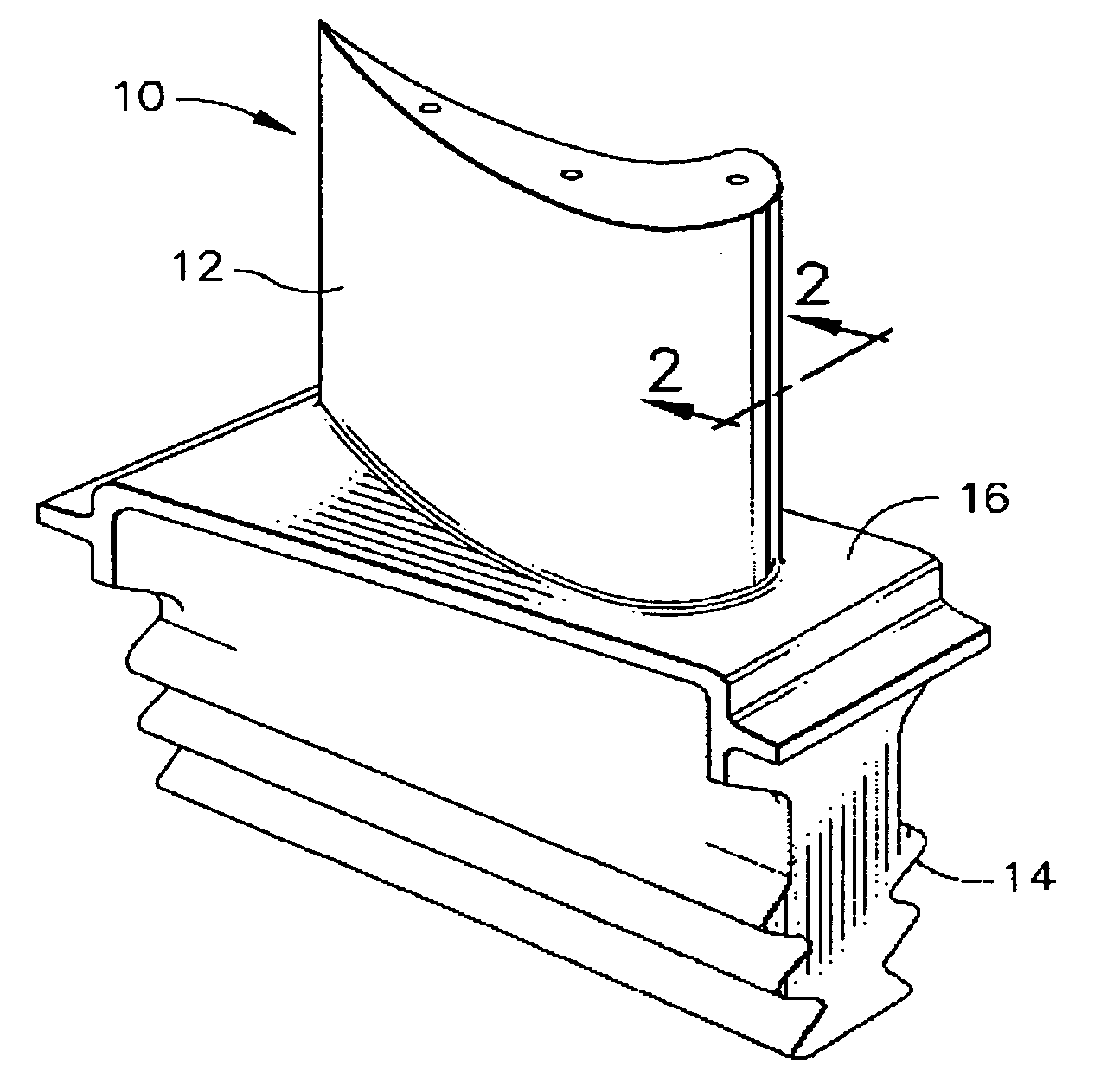

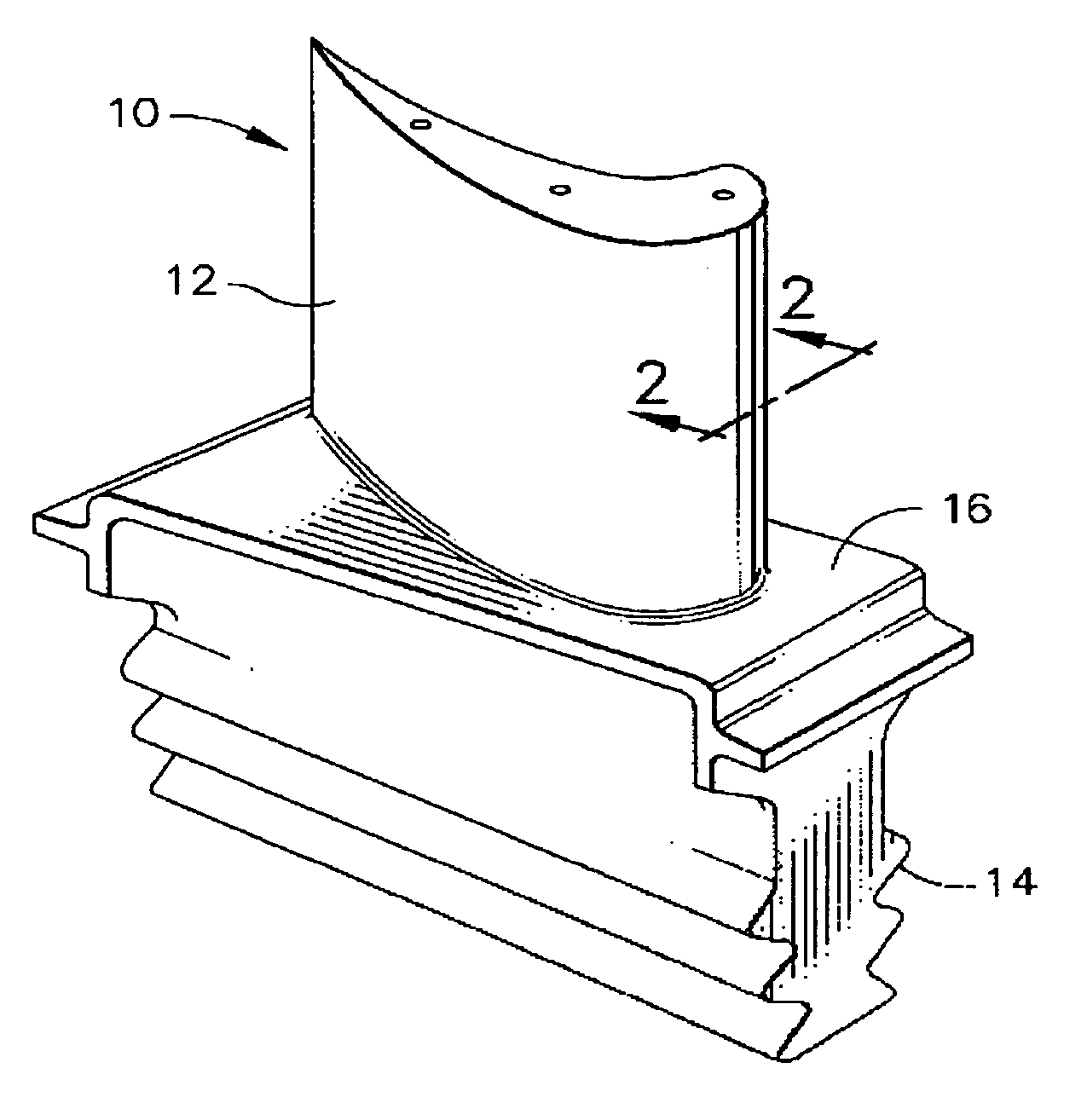

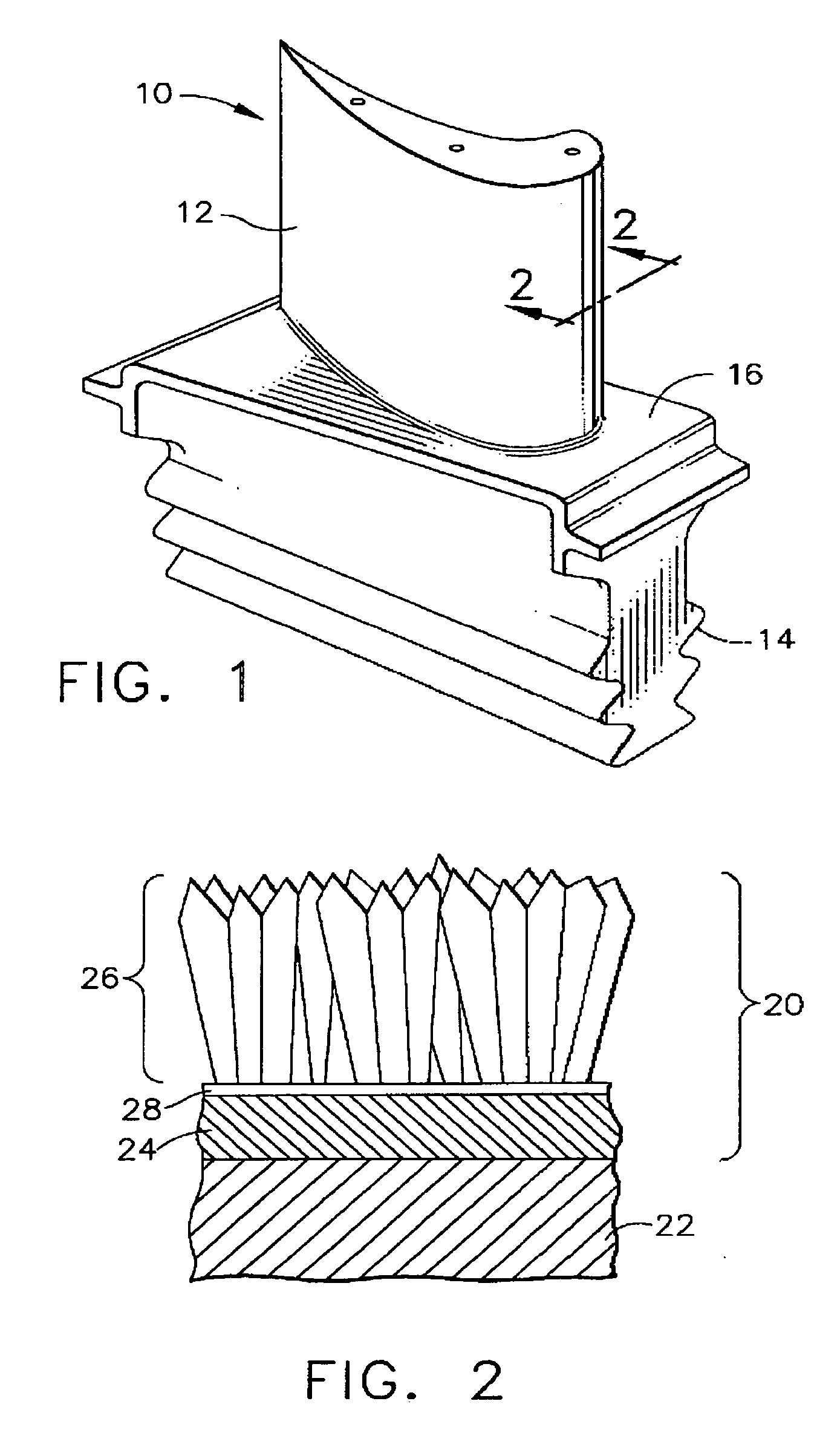

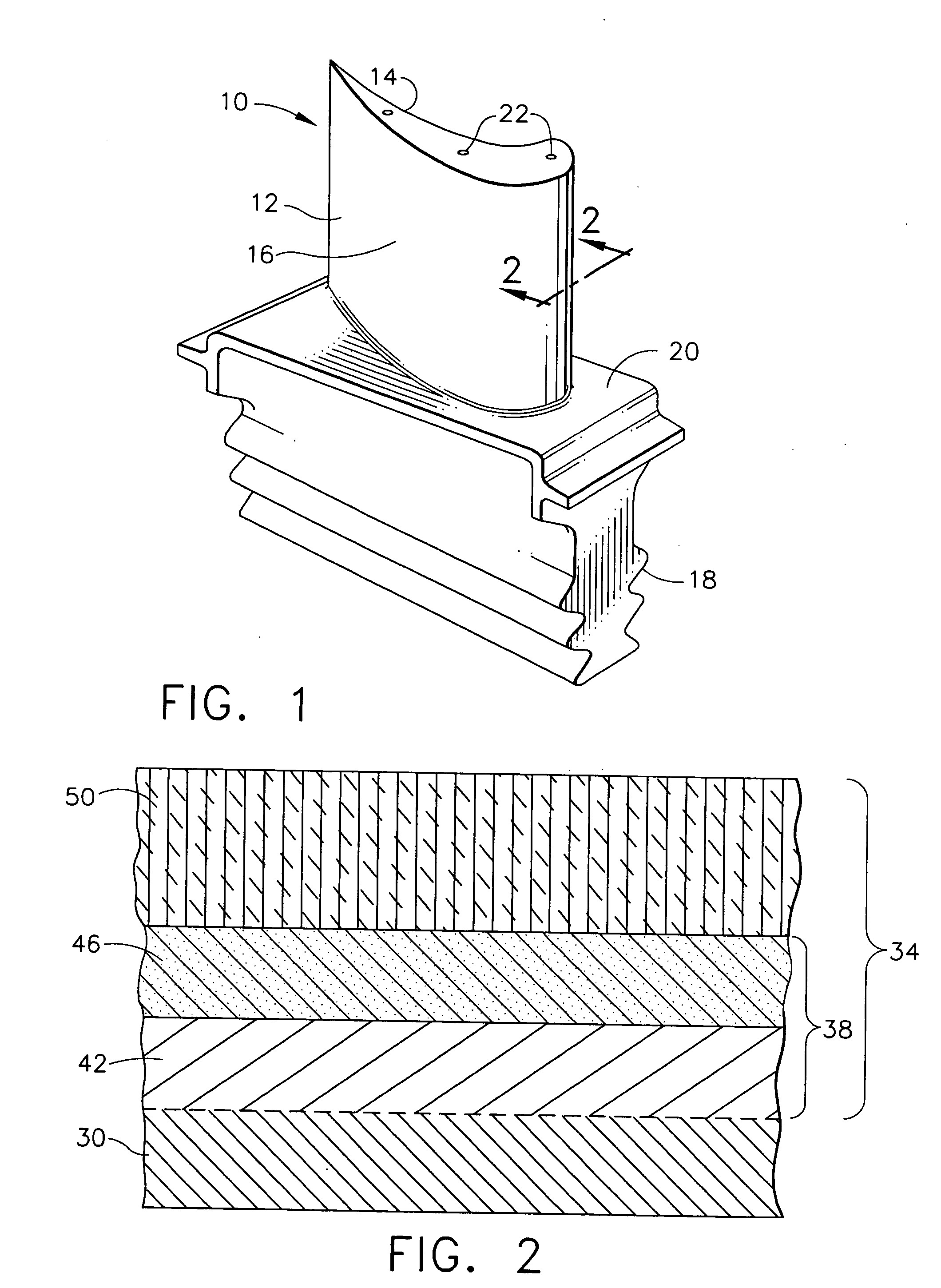

Strengthened bond coats for thermal barrier coatings

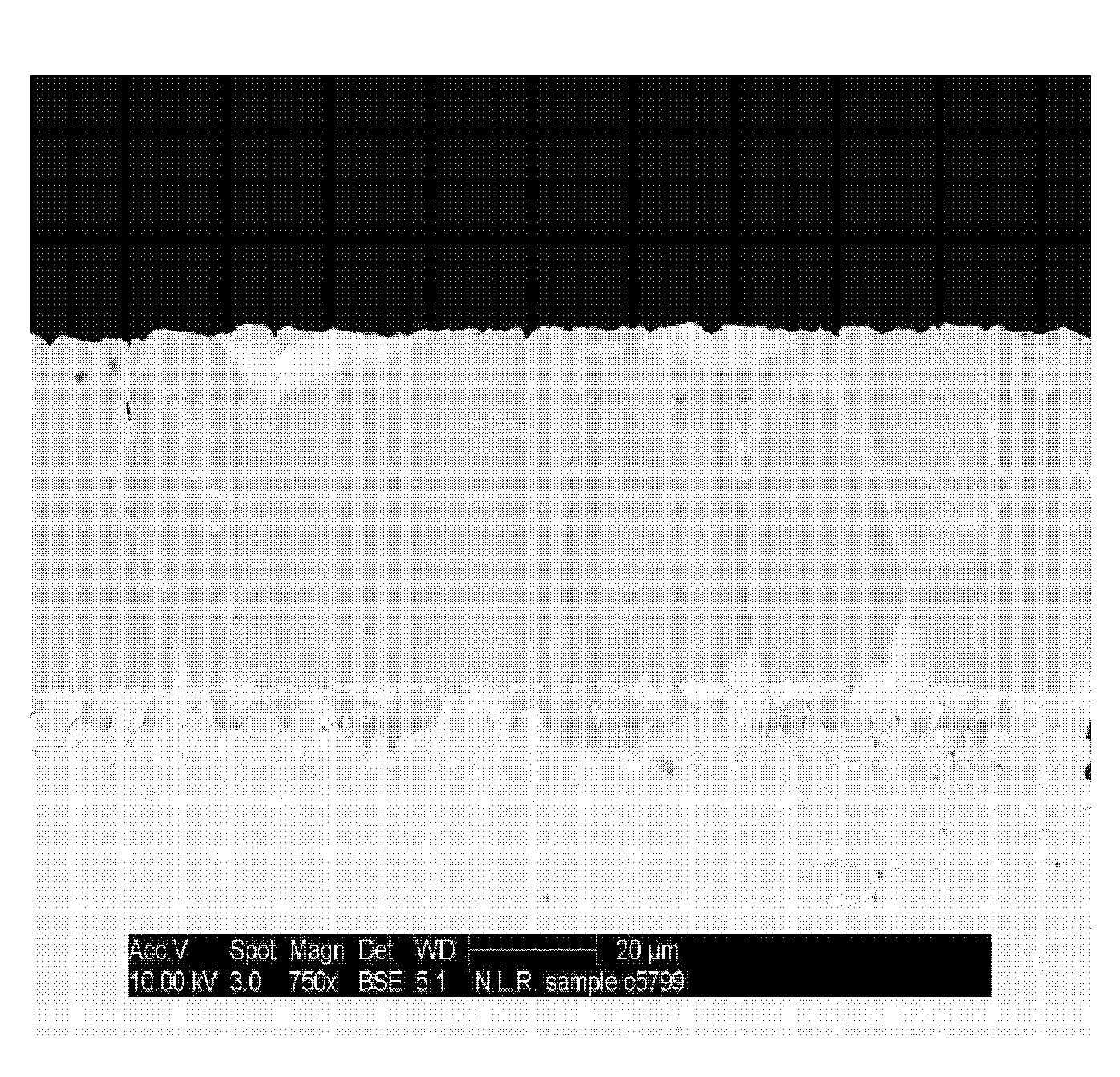

InactiveUS6979498B2Increase heightCoating is limitedPropellersRecord information storageBond coatingAlloy coating

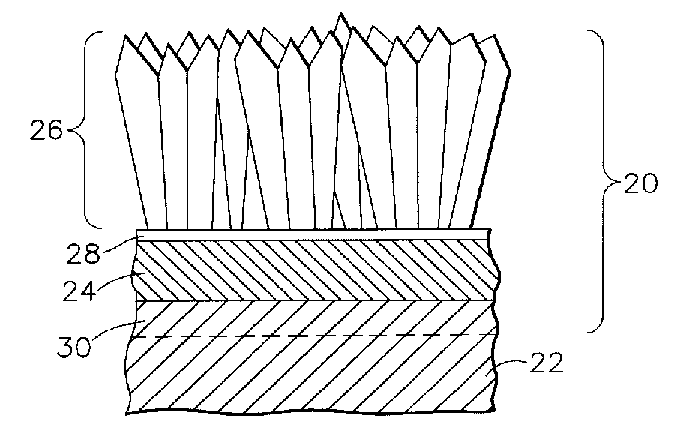

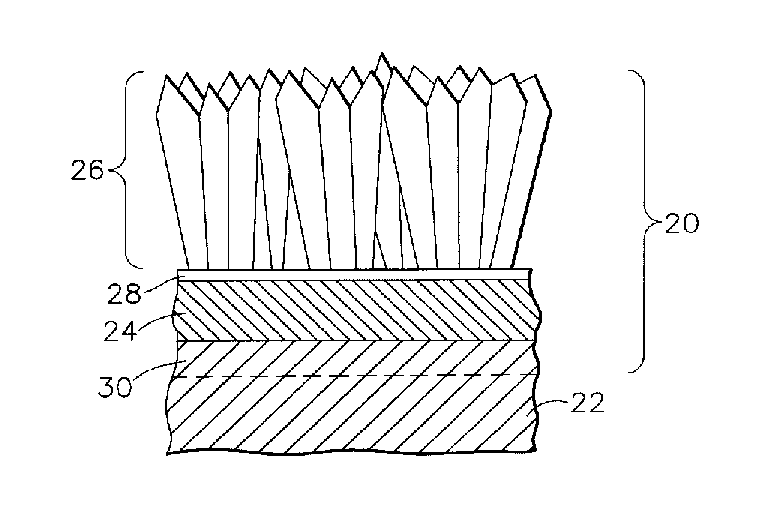

A strengthened bond coat for improving the adherence of a thermal barrier coating to an underlying metal substrate to resist spallation without degrading oxidation resistance of the bond coat. The bond coat comprises a bond coating material selected from the group consisting of overlay alloy coating materials, aluminide diffusion coating materials and combinations thereof. Particles comprising a substantially insoluble bond coat strengthening compound and having a relatively fine particle size of about 2 microns or less are dispersed within at least the upper portion of the bond coat in an amount sufficient to impart strengthening to the bond coat, and thus limit ratcheting or rumpling thereof.

Owner:GENERAL ELECTRIC CO

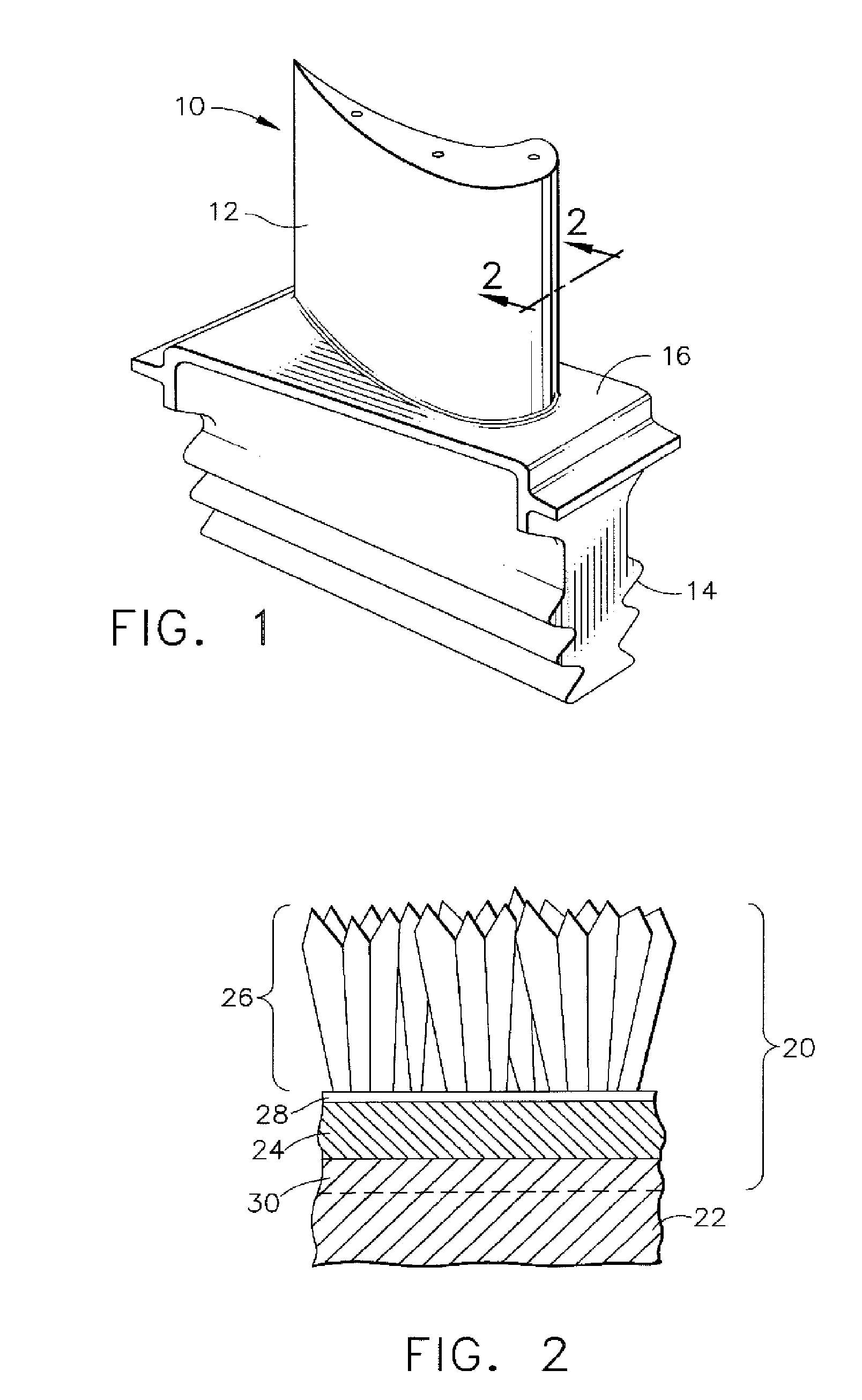

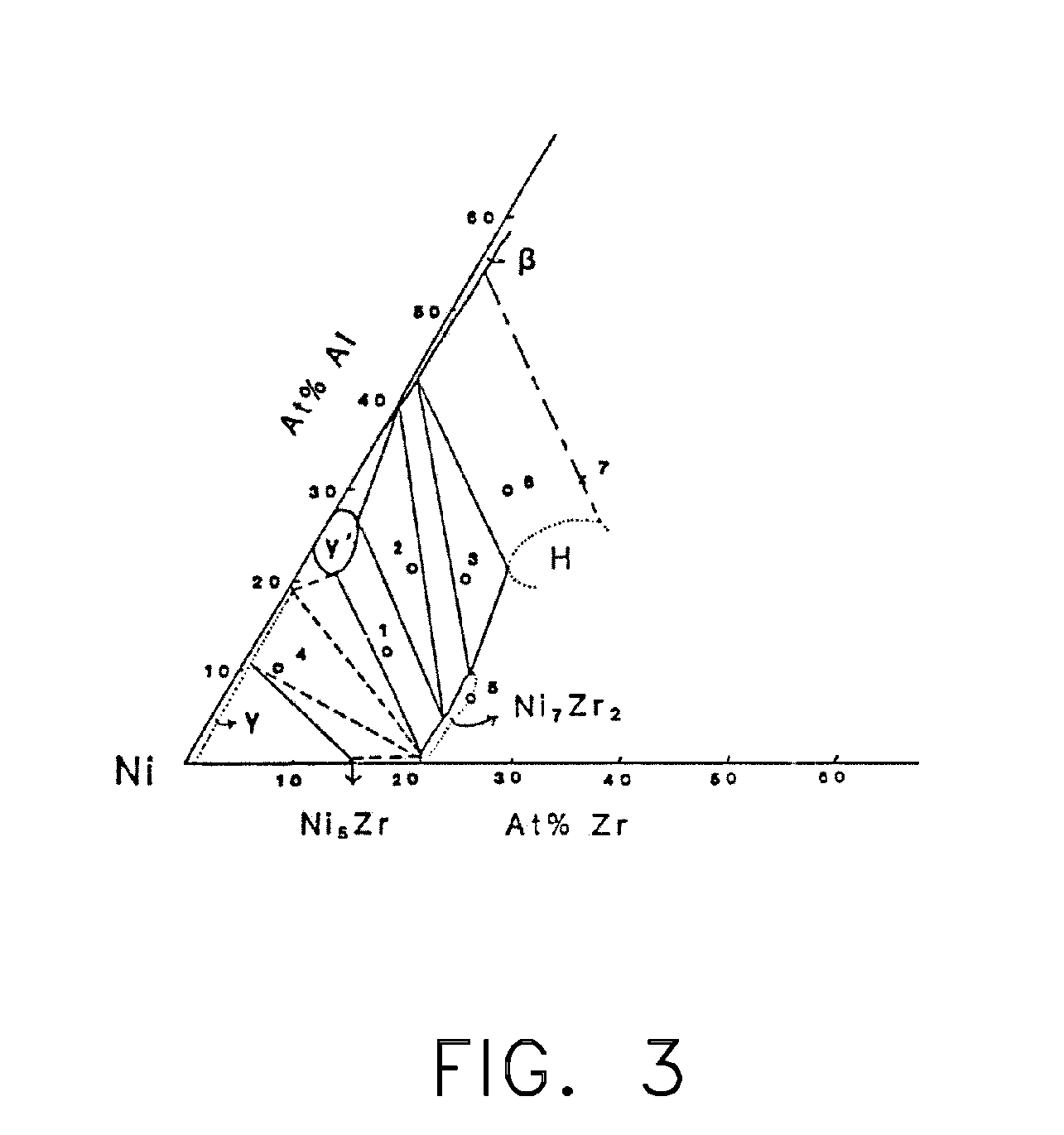

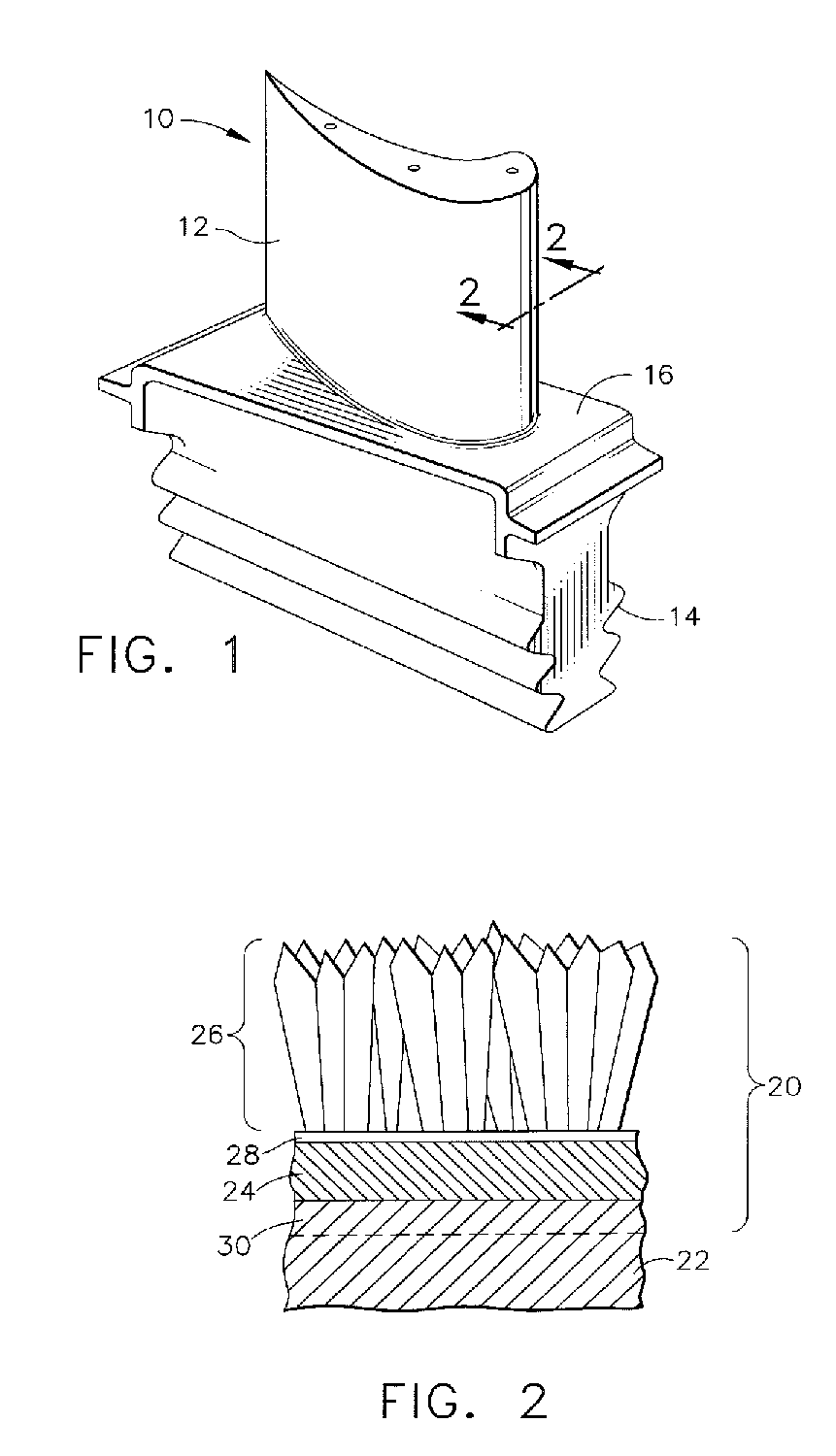

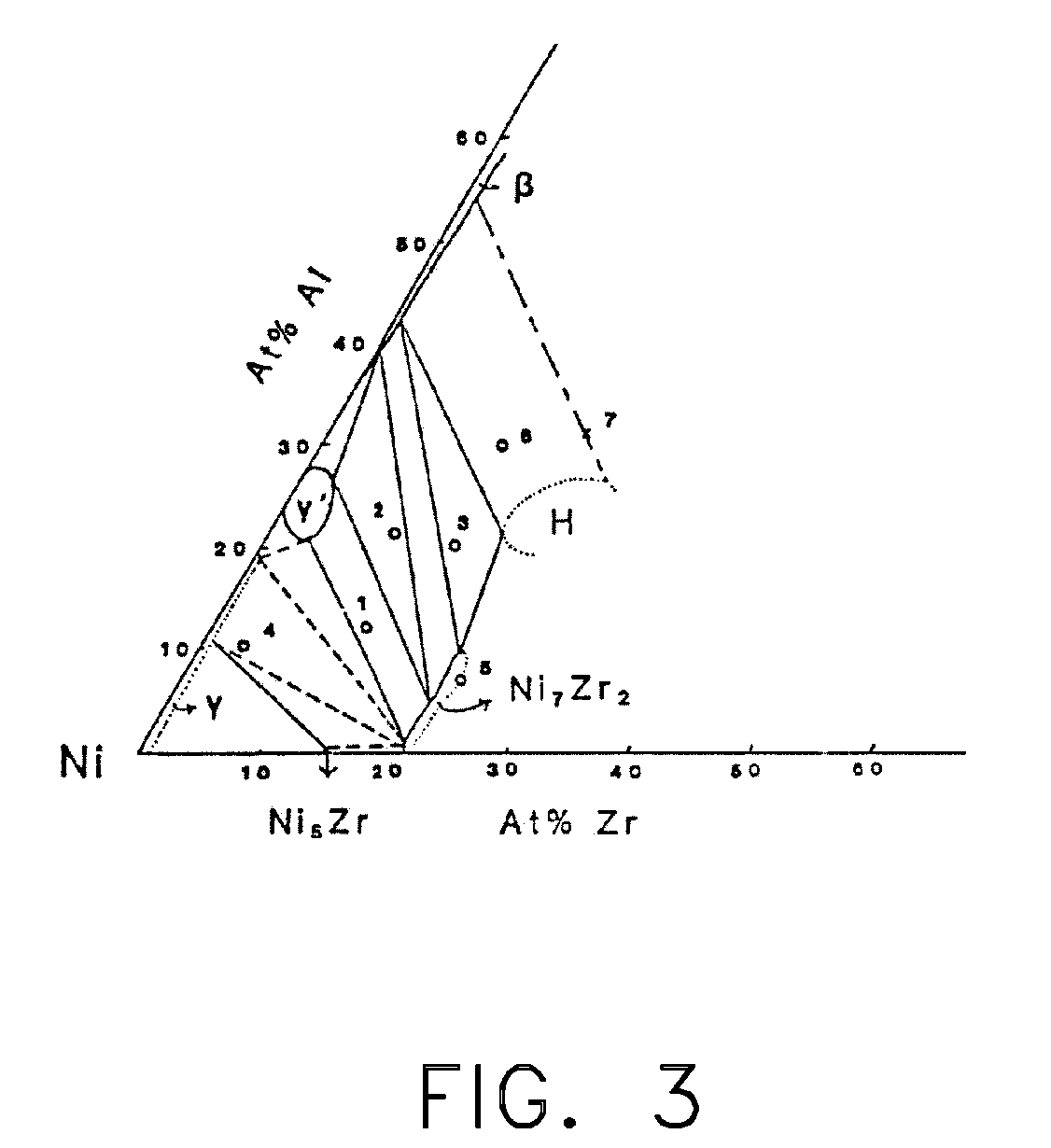

Coating systems containing beta phase and gamma-prime phase nickel aluminide

ActiveUS20060093801A1High solubility limitIncrease resistanceMolten spray coatingPropellersGreek letter betaBeta phase

A coating and process for depositing the coating on a substrate. The coating is a nickel aluminide overlay coating of predominantly the beta (NiAl) and gamma-prime (Ni3Al) intermetallic phases, and is suitable for use as an environmental coating and as a bond coat for a thermal barrier coating (TBC). The coating can be formed by depositing nickel and aluminum in appropriate amounts to yield the desired beta+gamma prime phase content. Alternatively, nickel and aluminum can be deposited so that the aluminum content of the coating exceeds the appropriate amount to yield the desired beta+gamma prime phase content, after which the coating is heat treated to diffuse the excess aluminum from the coating into the substrate to yield the desired beta+gamma prime phase content.

Owner:GENERAL ELECTRIC CO

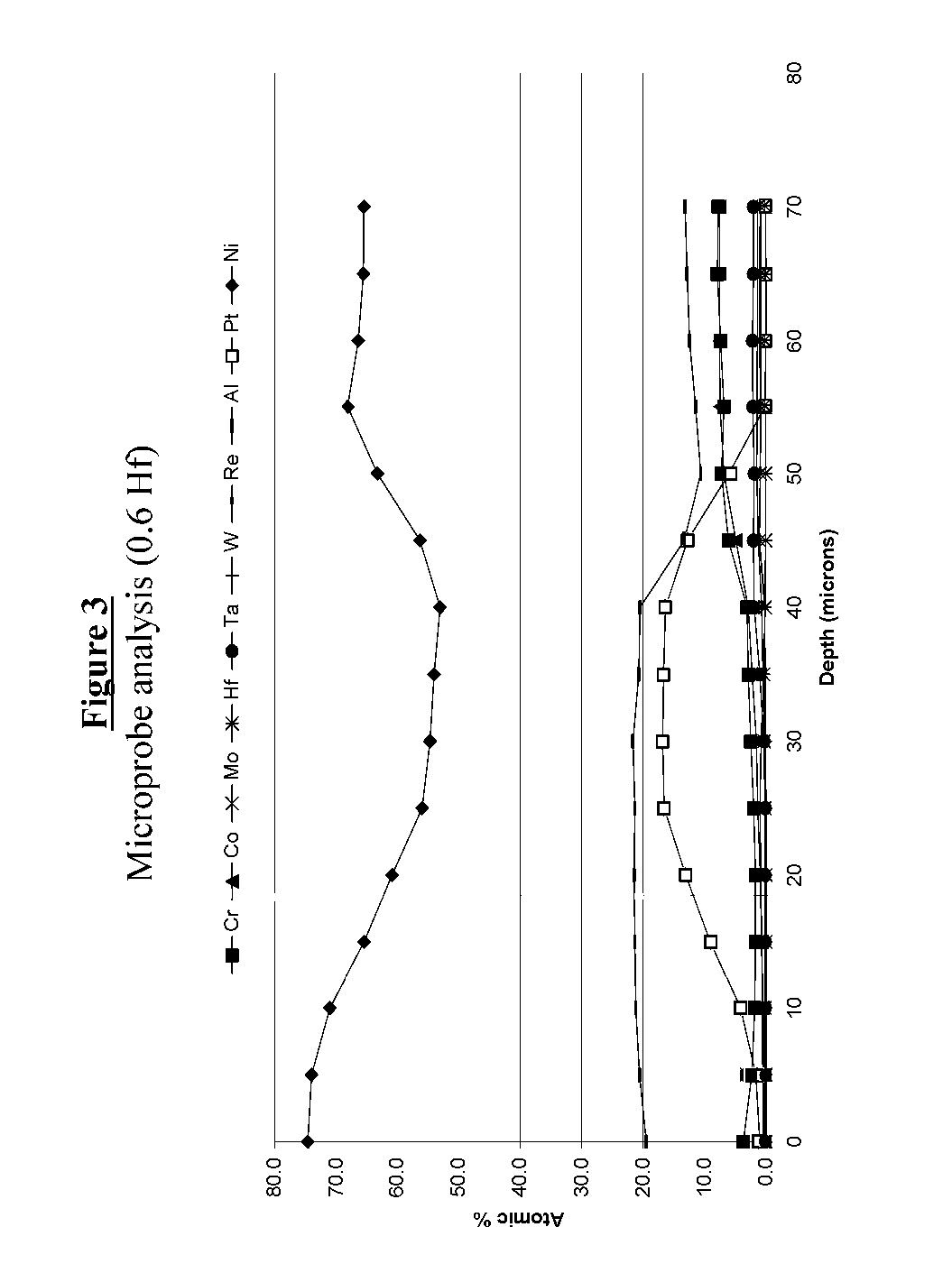

Gamma prime phase-containing nickel aluminide coating

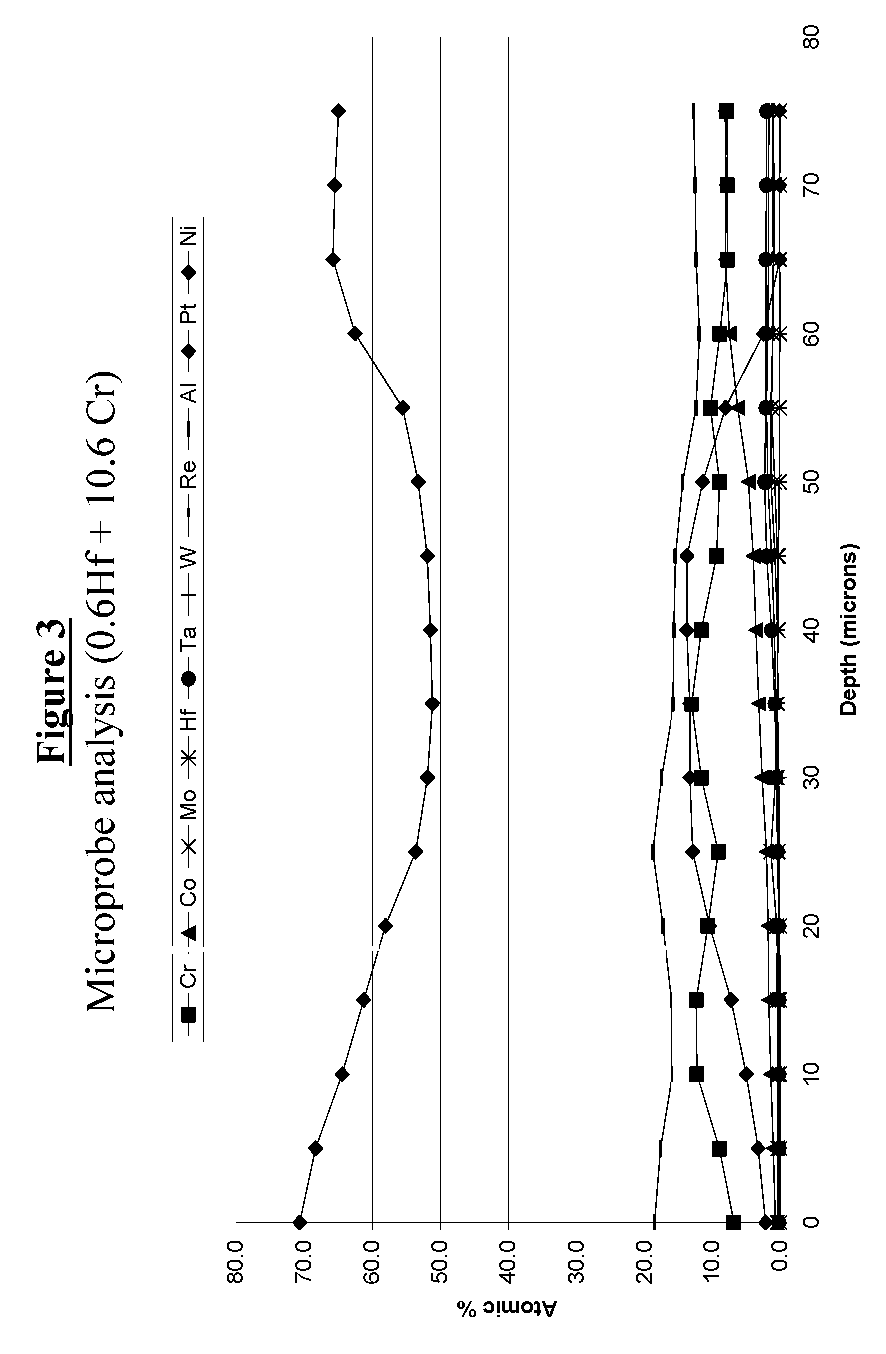

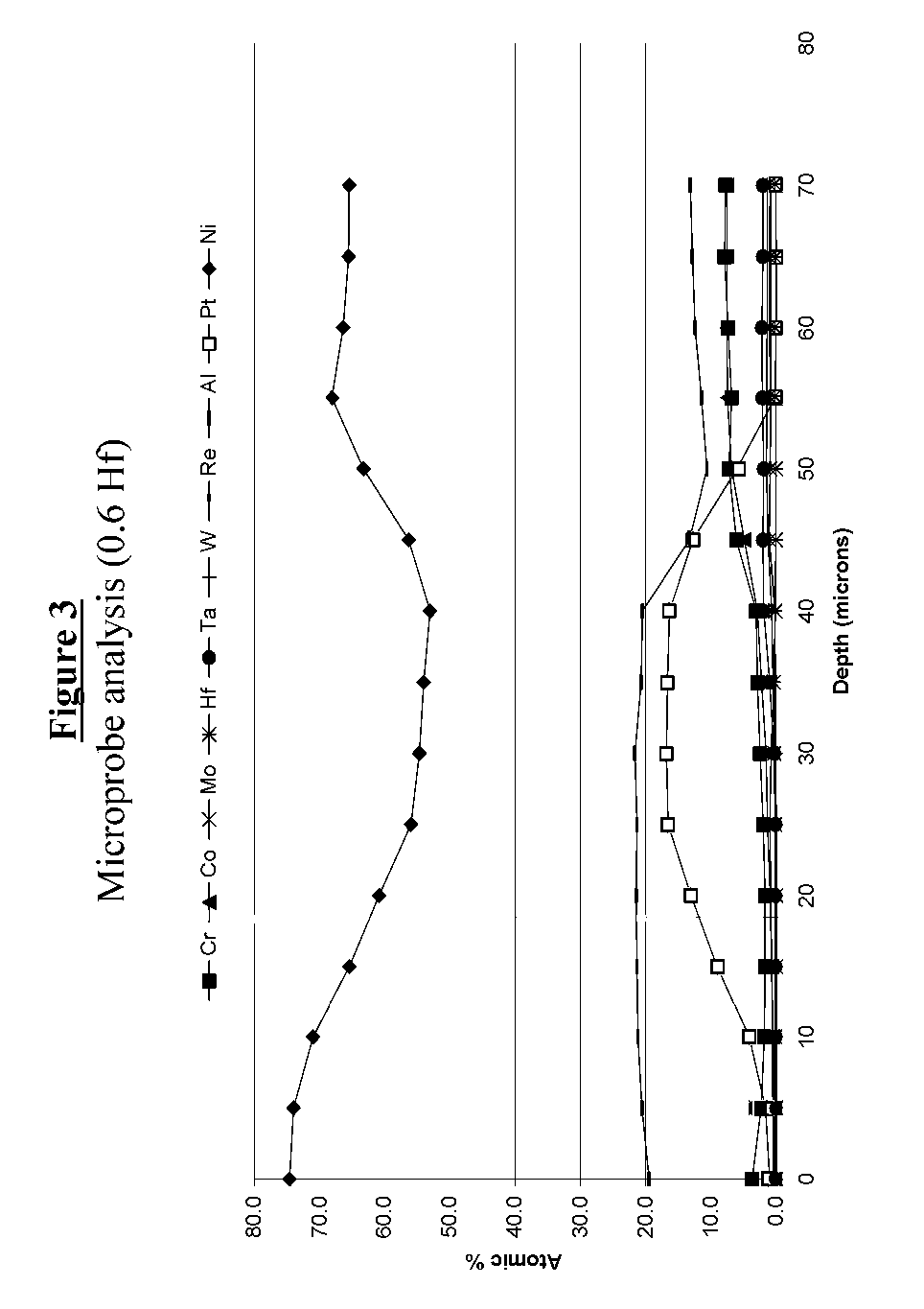

ActiveUS20070071996A1Desirable environmental and mechanical propertyOxidation resistance can be improvedPropellersReaction enginesCeriumHafnium

An intermetallic composition suitable for use as an environmentally-protective coating on surfaces of components used in hostile thermal environments, including the turbine, combustor and augmentor sections of a gas turbine engine. The coating contains the gamma-prime (Ni3Al) nickel aluminide intermetallic phase and either the beta (NiAl) nickel aluminide intermetallic phase or the gamma solid solution phase. The coating has an average aluminum content of 14 to 30 atomic percent and an average platinum-group metal content of at least 1 to less than 10 atomic percent, the balance of the coating being nickel, one or more of chromium, silicon, tantalum, and cobalt, optionally one or more of hafnium, yttrium, zirconium, lanthanum, and cerium, and incidental impurities.

Owner:GENERAL ELECTRIC CO

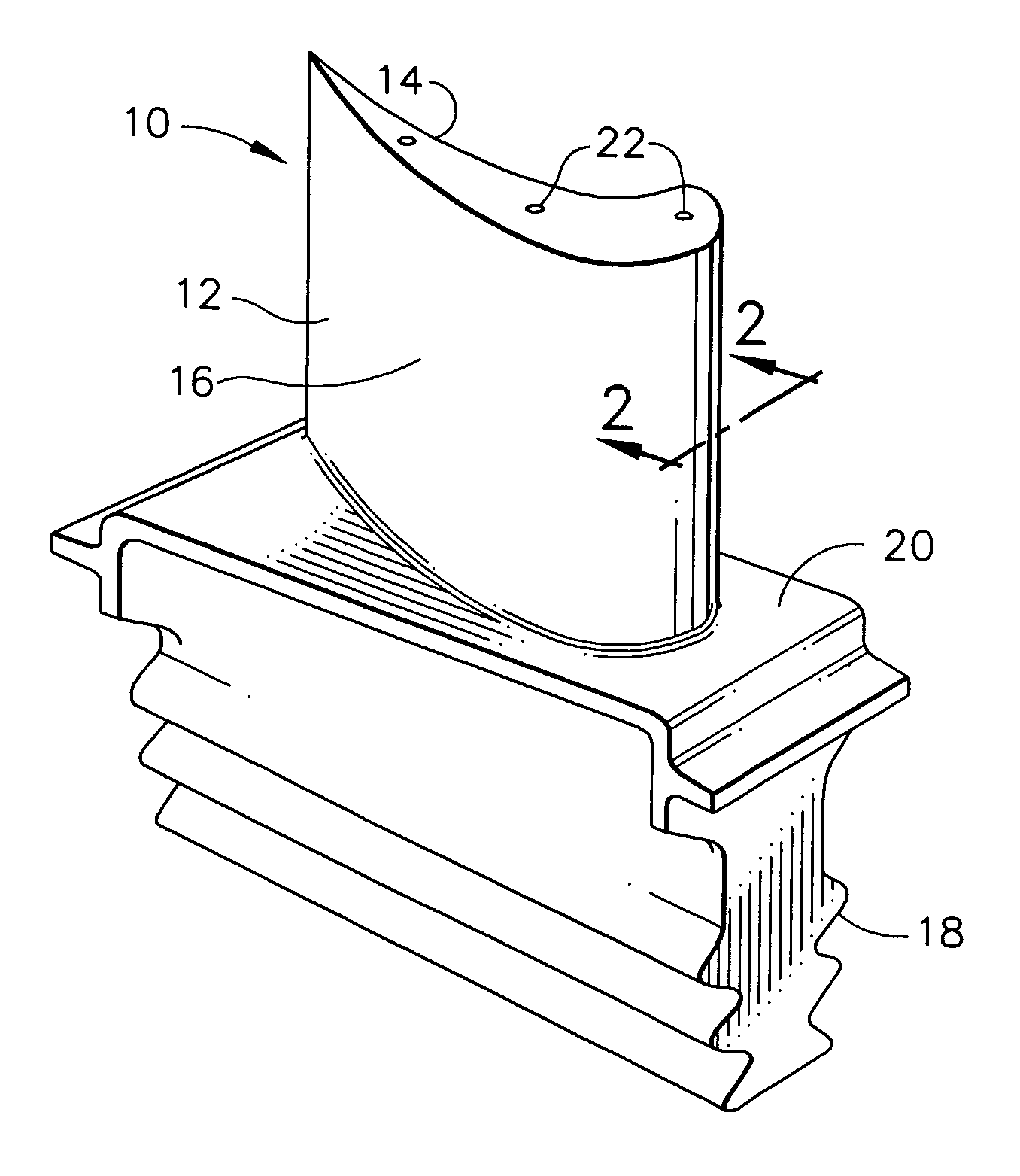

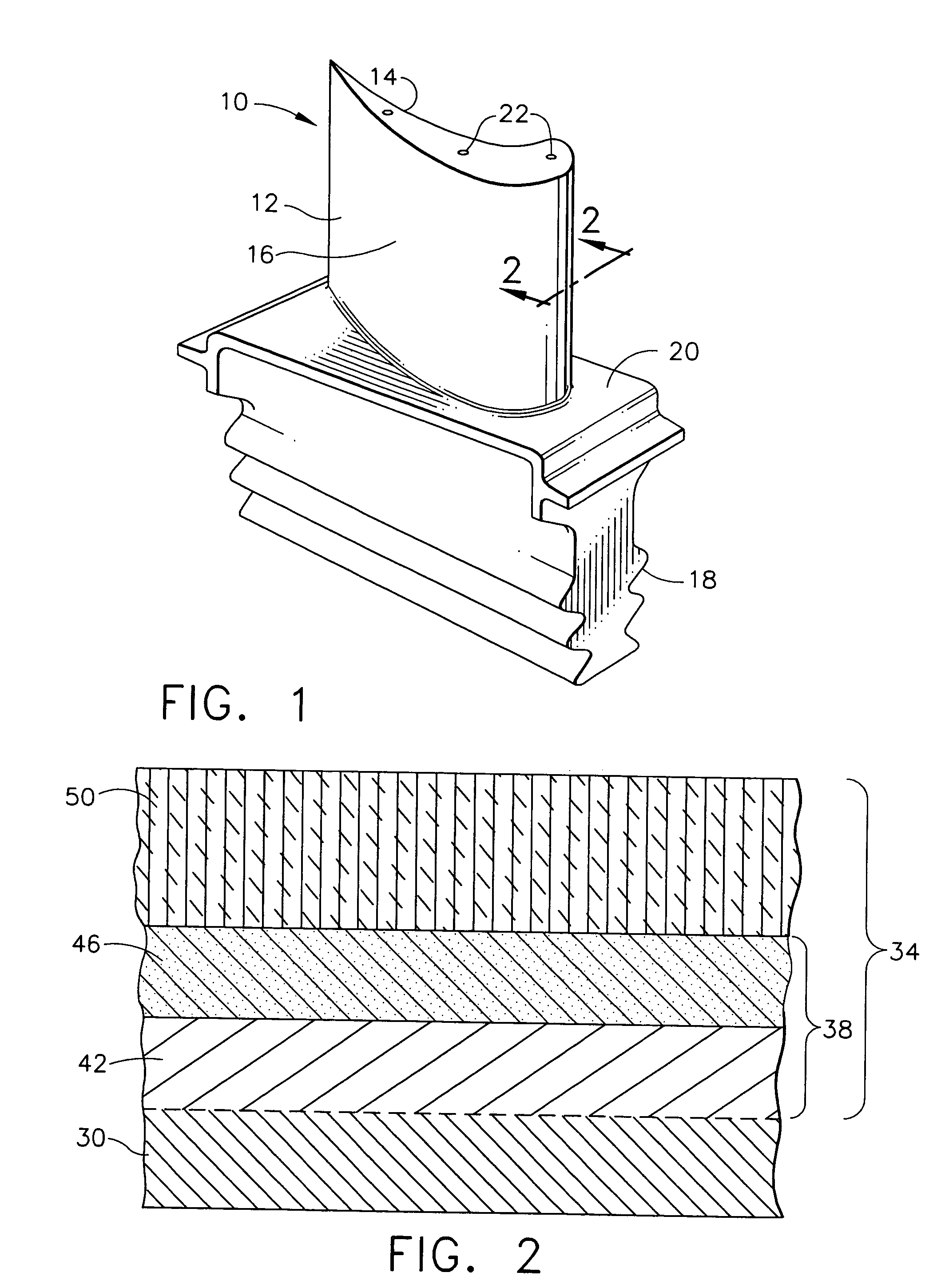

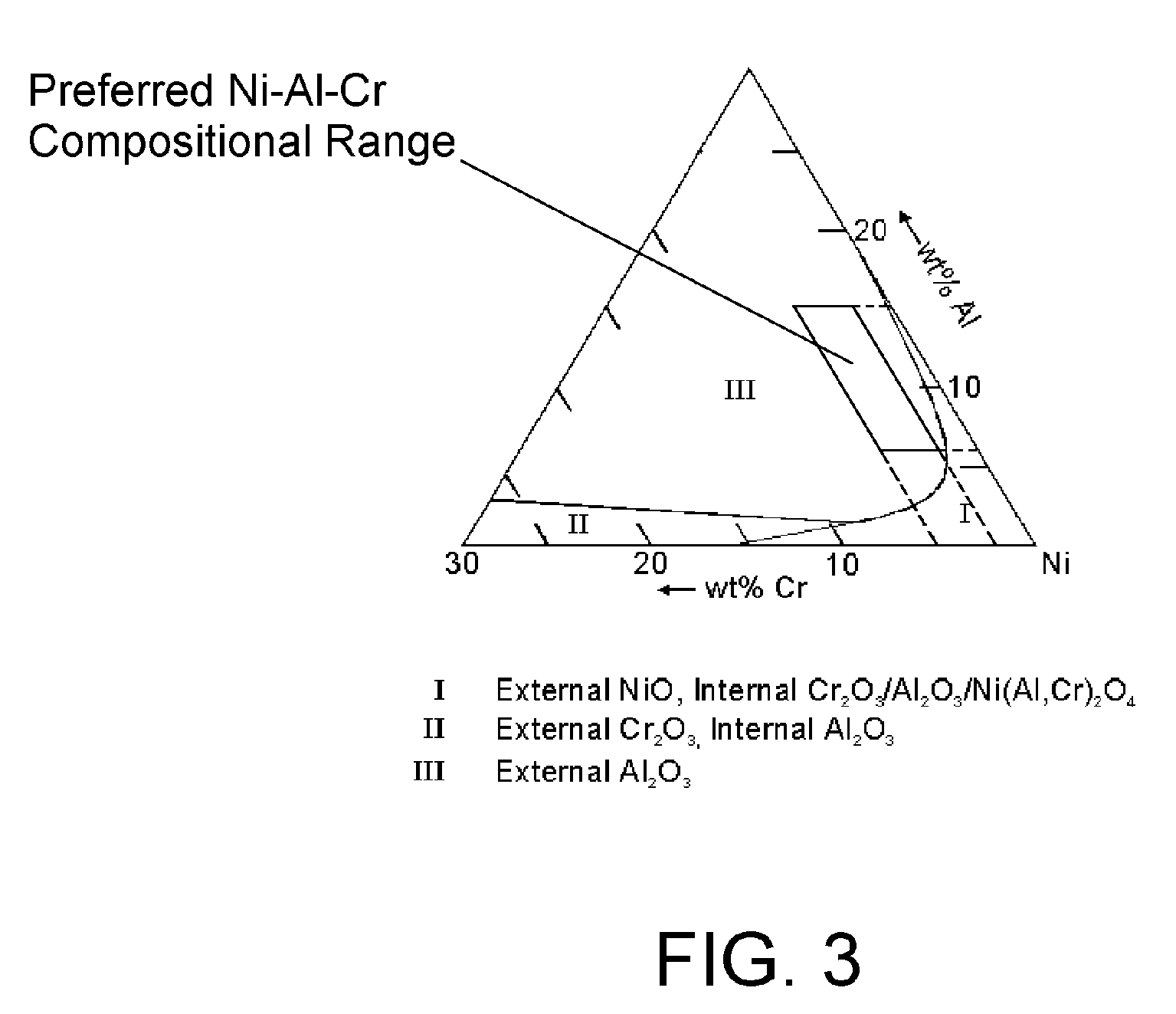

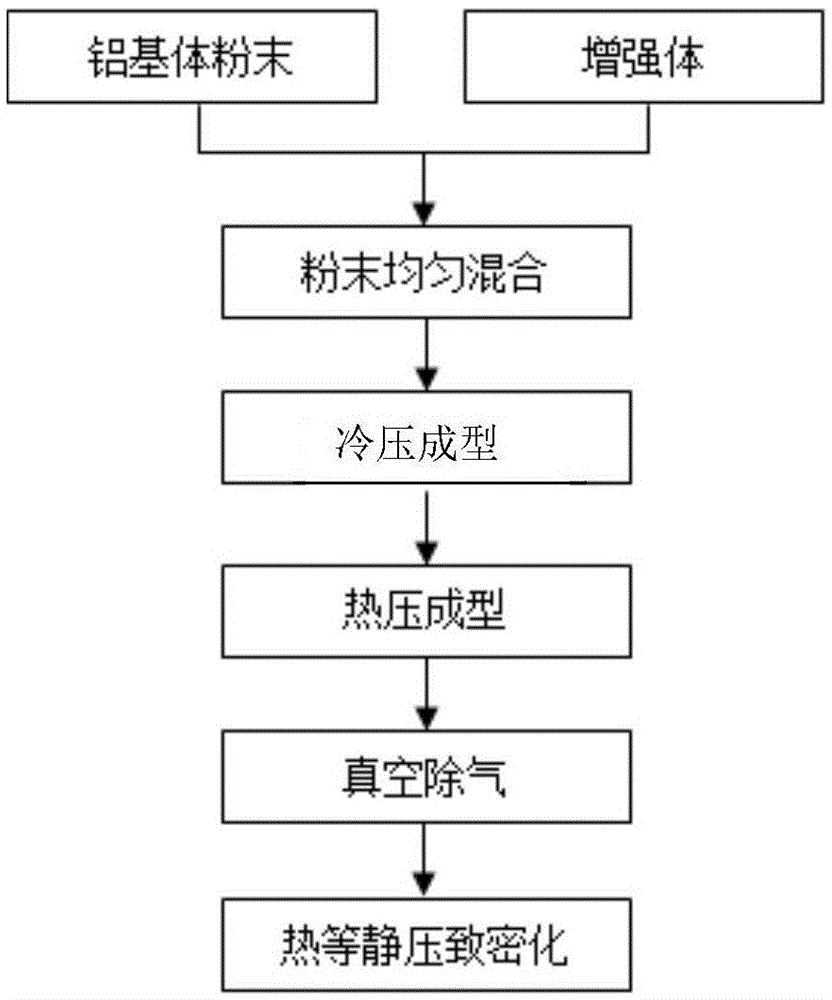

Coating systems containing gamma-prime nickel aluminide coating

ActiveUS7264888B2Promote formationImprove environmental resistance and strengthPropellersPump componentsBond coatSilicon

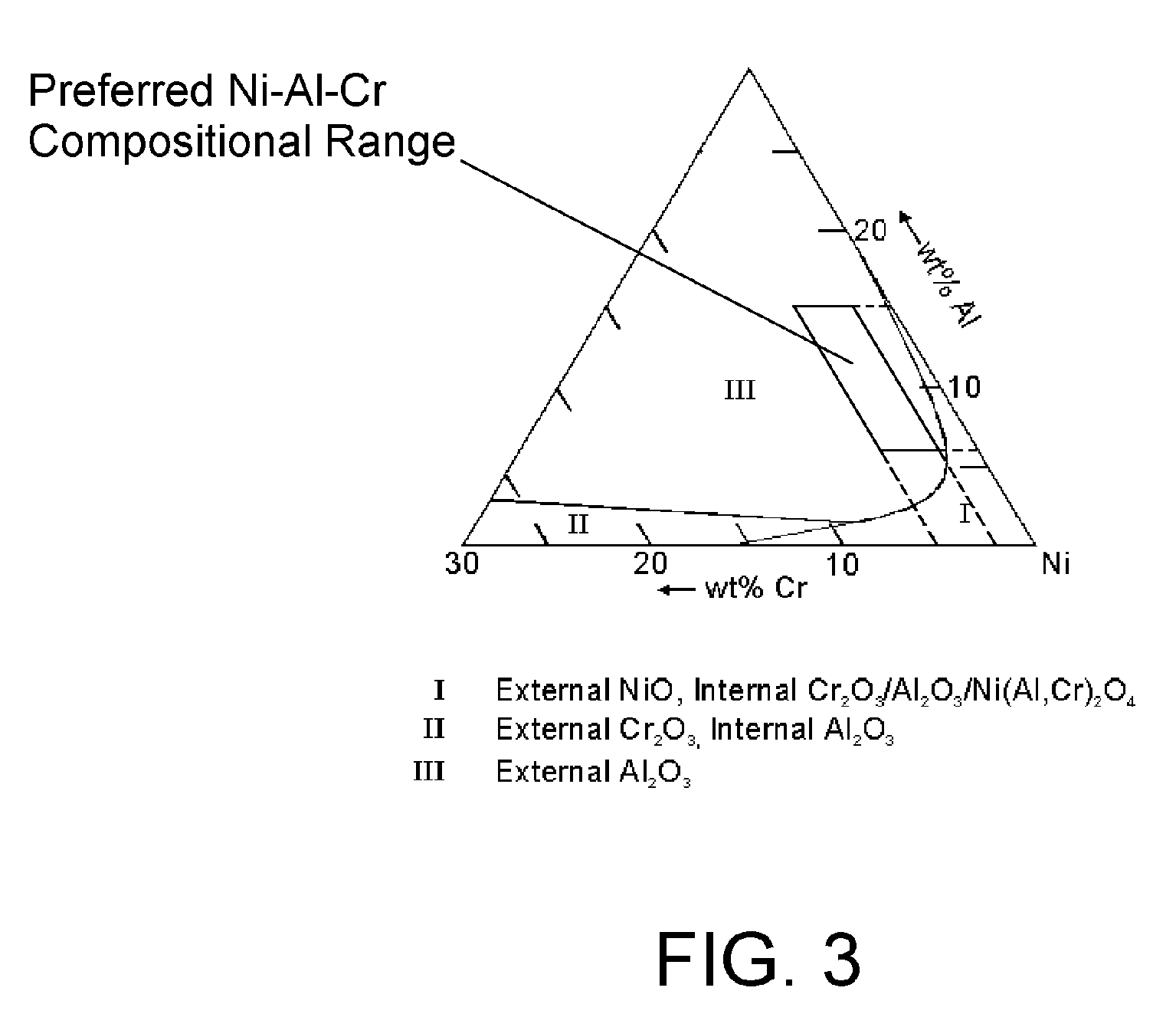

An overlay coating for articles used in hostile thermal environments. The coating has a predominantly gamma prime-phase nickel aluminide (Ni3Al) composition suitable for use as an environmental coating and as a bond coat for a thermal barrier coating. The coating has a composition of, by weight, at least 6% to about 15% aluminum, about 2% to about 5% chromium, optionally one or more reactive elements in individual or combined amounts of up to 4%, optionally up to 2% silicon, optionally up to 60% of at least one platinum group metal, and the balance essentially nickel. A thermal-insulating ceramic layer may be deposited on the coating.

Owner:GENERAL ELECTRIC CO

Coating systems containing gamma-prime nickel aluminide coating

ActiveUS20060093850A1Promote formationImprove environmental resistance and strengthBlade accessoriesMachines/enginesCoating systemBond coat

An overlay coating for articles used in hostile thermal environments. The coating has a predominantly gamma prime-phase nickel aluminide (Ni3Al) composition suitable for use as an environmental coating and as a bond coat for a thermal barrier coating. The coating has a composition of, by weight, at least 6% to about 15% aluminum, about 2% to about 5% chromium, optionally one or more reactive elements in individual or combined amounts of up to 4%, optionally up to 2% silicon, optionally up to 60% of at least one platinum group metal, and the balance essentially nickel. A thermal-insulating ceramic layer may be deposited on the coating.

Owner:GENERAL ELECTRIC CO

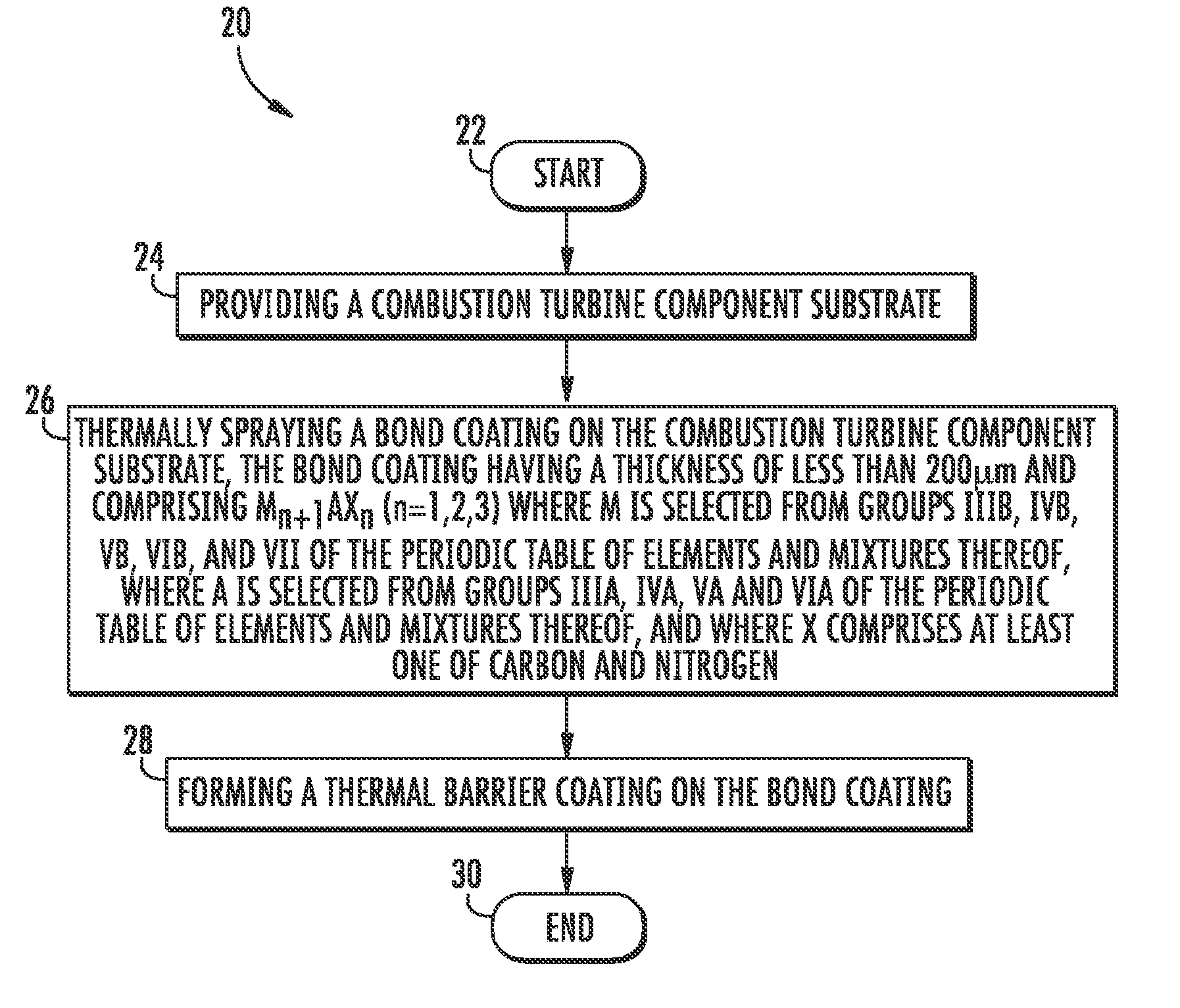

Combustion turbine component having bond coating and associated methods

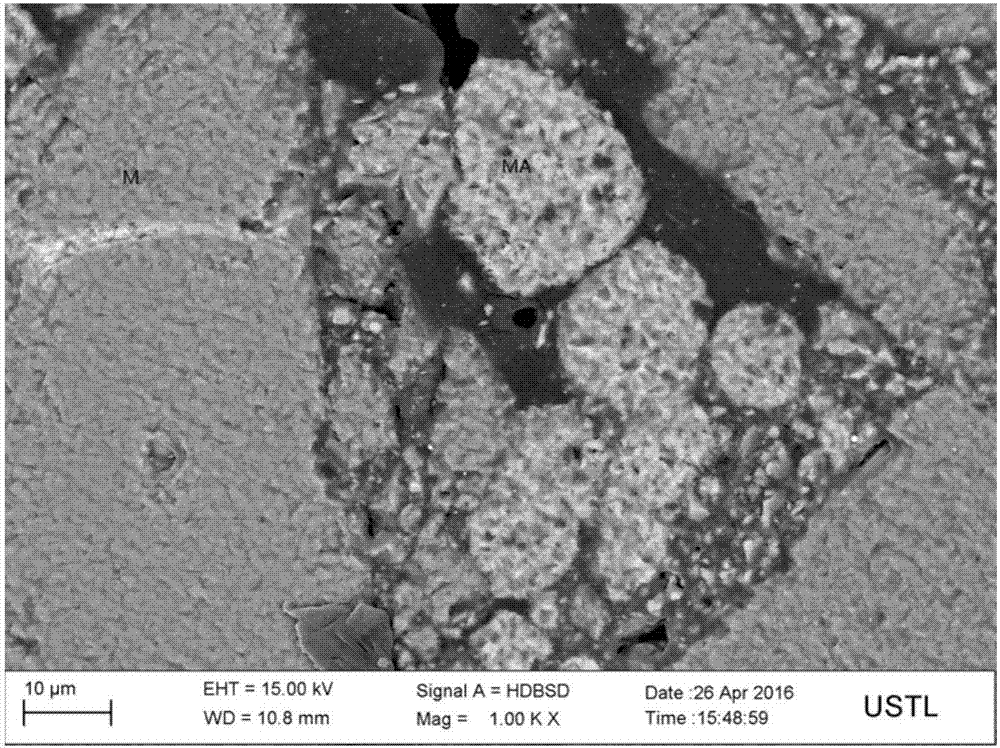

InactiveUS8192850B2Avoid spallationImprove the immunityMolten spray coatingBlade accessoriesCombustionBond coating

A combustion turbine component includes a combustion turbine component substrate and a bond coating on the combustion turbine component substrate. The bond coating may include Mn+1AXn (n=1,2,3) where M is selected from groups IIIB, IVB, VB, VIB, and VII of the periodic table of elements and mixtures thereof, where A is selected from groups IIIA, IVA, VA, and VIA of the periodic table of elements and mixtures thereof, and where X includes at least one of carbon and nitrogen. A thermal barrier coating may be on the bond coating.

Owner:SIEMENS ENERGY INC

Strengthened bond coats for thermal barrier coatings

InactiveUS20050112398A1Increase heightCoating is limitedPropellersRecord information storageBond coatingAluminide

A strengthened bond coat for improving the adherence of a thermal barrier coating to an underlying metal substrate to resist spallation without degrading oxidation resistance of the bond coat. The bond coat comprises a bond coating material selected from the group consisting of overlay alloy coating materials, aluminide diffusion coating materials and combinations thereof. Particles comprising a substantially insoluble bond coat strengthening compound and having a relatively fine particle size of about 2 microns or less are dispersed within at least the upper portion of the bond coat in an amount sufficient to impart strengthening to the bond coat, and thus limit ratcheting or rumpling thereof.

Owner:GENERAL ELECTRIC CO

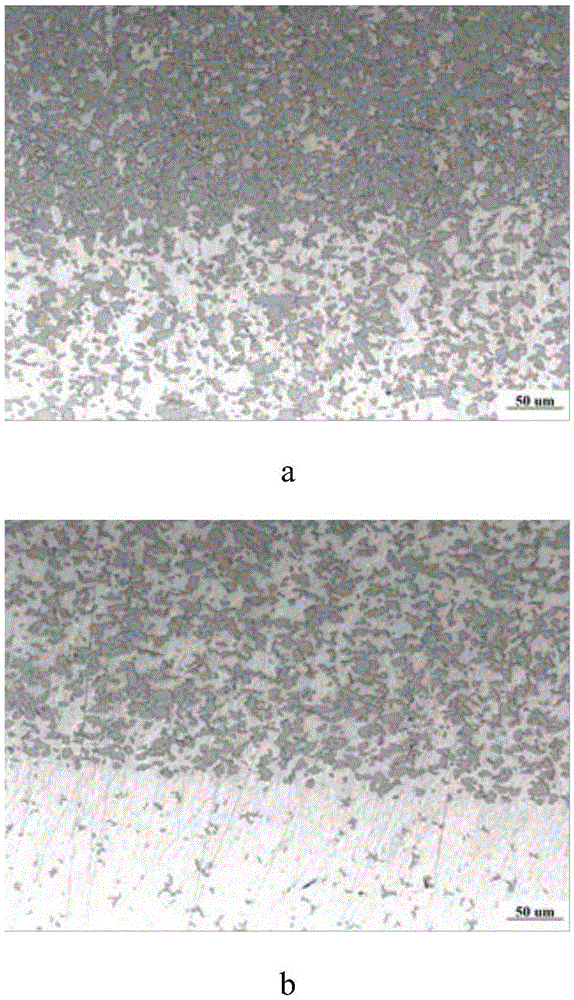

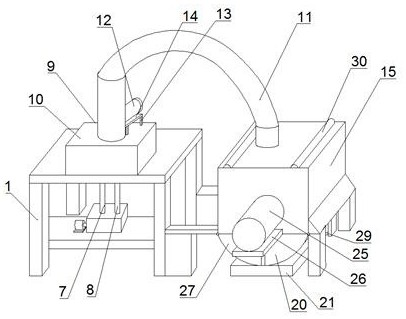

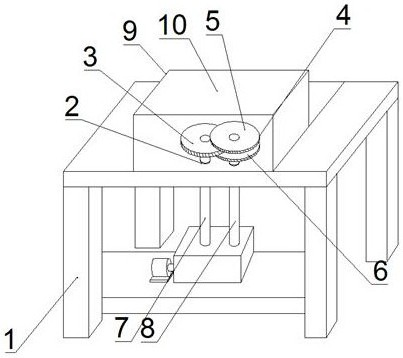

Manufacturing method of laminated aluminum matrix composite for electronic packaging

ActiveCN105483454AWill not oxidizePrecise content controlElectronic packagingCeramic matrix composite

The invention relates to a manufacturing method of a laminated aluminum matrix composite for electronic packaging. The method includes the steps that reinforcement powder and aluminum matrix powder are evenly mixed according to different proportions, obtained composite powder with different reinforcement contents is sequentially packaged to cylindrical steel dies to be subjected to cold press molding, and cold press billets are subjected to hot press molding in the inert gas atmosphere, so that the density of the billets is increased, the hot press billets are degassed in a high-temperature vacuum manner and then subjected to hot isostatic pressing densification, and the completely-dense billets are manufactured. The manufacturing method is simple and low in cost, the quality is stable, and the composite has the characteristics of being high in strength and tenacity and good in welding performance and can be applied to the electronic packaging field.

Owner:有研金属复材技术有限公司

Gamma prime phase-containing nickel aluminide coating

ActiveUS20070071995A1Improve oxidation resistanceImprove corrosion resistancePropellersRotary propellersGreek letter betaCombustor

An intermetallic composition suitable for use as an environmentally-protective coating on surfaces of components used in hostile thermal environments, including the turbine, combustor and augmentor sections of a gas turbine engine. The coating contains the gamma-prime (Ni3Al) nickel aluminide intermetallic phase and either the beta (NiAl) nickel aluminide intermetallic phase or the gamma solid solution phase. The coating has an average aluminum content of 14 to 30 atomic percent and an average platinum-group metal content of at least 1 to less than 10 atomic percent, the balance of the coating being nickel, incidental impurities, and optionally hafnium.

Owner:GENERAL ELECTRIC CO

Gamma prime phase-containing nickel aluminide coating

ActiveUS7247393B2Desirable environmental and mechanical propertyOxidation resistance can be improvedPropellersReaction enginesCeriumHafnium

An intermetallic composition suitable for use as an environmentally-protective coating on surfaces of components used in hostile thermal environments, including the turbine, combustor and augmentor sections of a gas turbine engine. The coating contains the gamma-prime (Ni3Al) nickel aluminide intermetallic phase and either the beta (NiAl) nickel aluminide intermetallic phase or the gamma solid solution phase. The coating has an average aluminum content of 14 to 30 atomic percent and an average platinum-group metal content of at least 1 to less than 10 atomic percent, the balance of the coating being nickel, one or more of chromium, silicon, tantalum, and cobalt, optionally one or more of hafnium, yttrium, zirconium, lanthanum, and cerium, and incidental impurities.

Owner:GENERAL ELECTRIC CO

Methods for depositing gamma-prime nickel aluminide coatings

ActiveUS7357958B2Reduce the possibilityTrend downBlade accessoriesVacuum evaporation coatingBond coatSilicon

Methods for depositing an overlay coating on articles intended for use in hostile thermal environments. The coating has a predominantly gamma prime-phase nickel aluminide (Ni3Al) composition suitable for use as an environmental coating and as a bond coat of a thermal barrier coating system. The coating further contains at least one platinum group metal, preferably chromium, optionally one or more reactive elements, and optionally silicon. The coating is deposited by a process that entails forming a platinum group metal layer and at least one separate layer of other constituents of the coating, and then performing a diffusion heat treatment to yield the coating.

Owner:GENERAL ELECTRIC CO

Gamma prime phase-containing nickel aluminide coating

ActiveUS7250225B2Desirable environmental and mechanical propertyOxidation resistance can be improvedPropellersRotary propellersCombustorHafnium

An intermetallic composition suitable for use as an environmentally-protective coating on surfaces of components used in hostile thermal environments, including the turbine, combustor and augmentor sections of a gas turbine engine. The coating contains the gamma-prime (Ni3Al) nickel aluminide intermetallic phase and either the beta (NiAl) nickel aluminide intermetallic phase or the gamma solid solution phase. The coating has an average aluminum content of 14 to 30 atomic percent and an average platinum-group metal content of at least 1 to less than 10 atomic percent, the balance of the coating being nickel, incidental impurities, and optionally hafnium.

Owner:GENERAL ELECTRIC CO

Coating systems containing beta phase and gamma-prime phase nickel aluminide

ActiveUS7326441B2Improve solubilityHigher reactive element contentMolten spray coatingBlade accessoriesGreek letter betaBeta phase

A coating and process for depositing the coating on a substrate. The coating is a nickel aluminide overlay coating of predominantly the beta (NiAl) and gamma-prime (Ni3Al) intermetallic phases, and is suitable for use as an environmental coating and as a bond coat for a thermal barrier coating (TBC). The coating can be formed by depositing nickel and aluminum in appropriate amounts to yield the desired beta+gamma prime phase content. Alternatively, nickel and aluminum can be deposited so that the aluminum content of the coating exceeds the appropriate amount to yield the desired beta+gamma prime phase content, after which the coating is heat treated to diffuse the excess aluminum from the coating into the substrate to yield the desired beta+gamma prime phase content.

Owner:GENERAL ELECTRIC CO

Anti-erosion magnesia-carbon bricks and preparation method therefor

The invention discloses anti-erosion magnesia-carbon bricks. The magnesia-carbon bricks are prepared from the following ingredients in parts by weight: 65-70 parts of magnesia, 3-5 parts of basalt granules, 0.25-0.5 part of nano zirconium boride, 1-3 parts of nickel citrate, 1-3 parts of copper sulfate pentahydrate, 0.3-0.5 part of hexamethylene tetramine, 15-18 parts of graphite, 3-5 parts of ceramic granules Al4SiC4 and 3-5 parts of binder. According to the anti-erosion magnesia-carbon bricks, the proportioning of the magnesia-carbon bricks is subjected to optimization and improvement, particularly, the basalt granules, the nano zirconium boride, the nickel citrate, the copper sulfate pentahydrate and the ceramic granules Al4SiC4 are added, and all the ingredients are synergistic mutually, so that the quality of the bricks is high, the carbon loss can be greatly lowered, the spalling of the bricks is avoided, the slag erosion resistance of the magnesia-carbon bricks is improved obviously, and the service lives of the magnesia-carbon bricks are prolonged. The invention further discloses a preparation method for the anti-erosion magnesia-carbon bricks. The preparation method is simple in processing steps and high in operability, has low requirements on equipment and is applicable to large-batch industrial production.

Owner:长兴长恒耐火材料股份有限公司

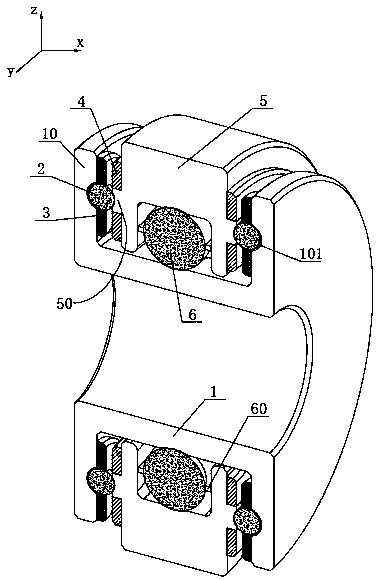

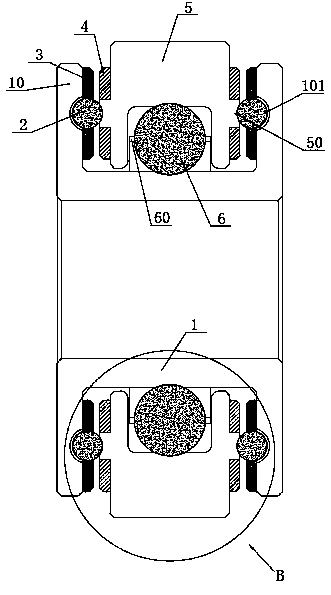

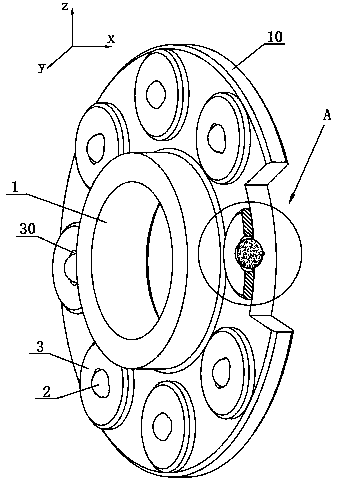

Anti-lateral-collision bearing with ball oil storage mechanism

InactiveCN108278270AReduce maintenance costsReduce replacement costsRolling contact bearingsBearing componentsFriction reductionEmbedment

An anti-lateral-collision bearing with a ball oil storage mechanism is disclosed. The anti-lateral-collision bearing is provided with a collision-resistant mechanism, the collision-resistant mechanismcomprises an embedment groove, an outer roll groove, an outer ball, an outer magnetic block for fixing of the outer ball, and an inner magnet with a magnet pole being repellant with that of an outermagnet. The outer ball is embedded between the embedment groove and the outer magnetic block. A hole for enabling the outer ball to be exposed is formed in the outer magnetic block, inner magnetic rings are located on the two sides of the outer roll groove, and the outer ball is made of a non-magnetic attraction material. The collision-resistant mechanism rolls on the outer roll groove through theball and can counteract most axial collision force. Repulsive force exists between an inner magnetic block and the outer magnetic block and enables a certain gap to exist between the ball and the outer roll groove, and abrasion caused by friction is reduced. The ball oil storage mechanism is further arranged, two oil passing holes are formed in the ball oil storage mechanism, lubricating oil brought out through rolling of the ball can be stored temporarily, the brought-out lubricating oil is prevented from being stacked on the interface, particles such as dust falling into the bearing are stored temporarily, deformation and abrasion are avoided, and the service life of the bearing is prolonged.

Owner:郑帆

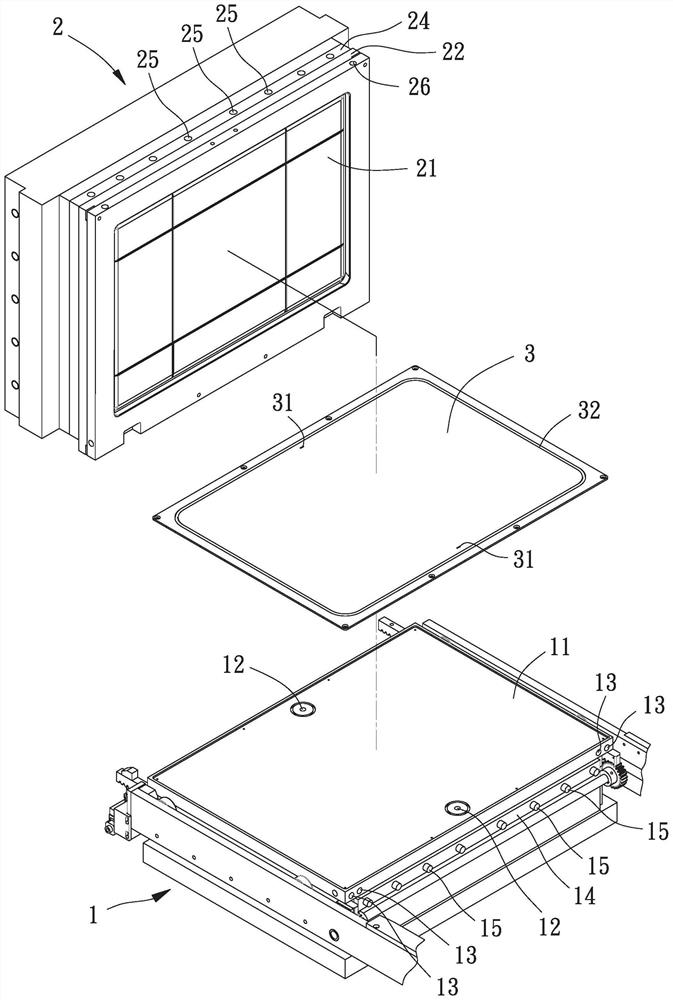

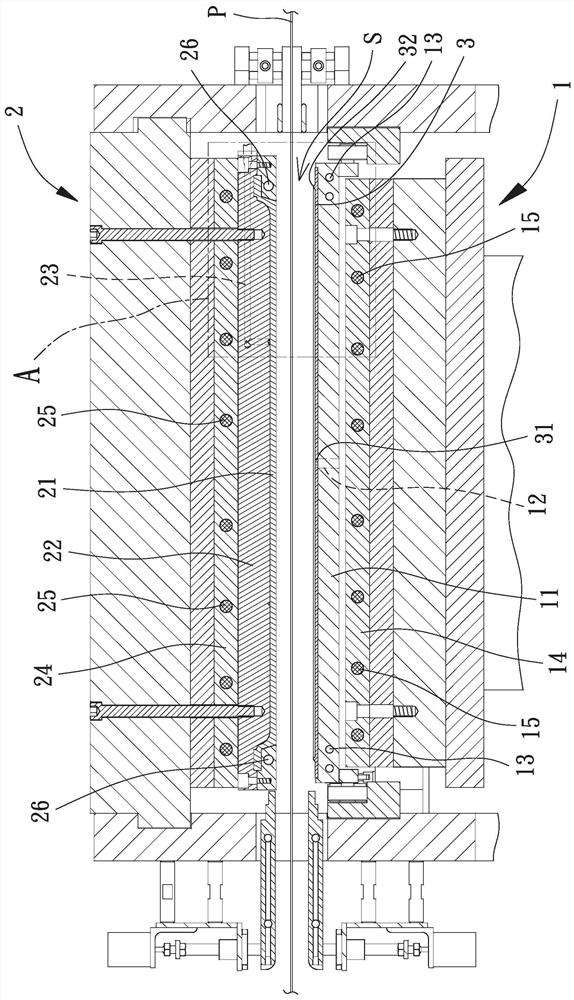

Vacuum pressing machine

ActiveCN112020241AAvoid uneven heatingAvoid spallationMultilayer circuit manufactureEngineeringPhysics

A vacuum pressing machine used for solving a problem that existing vacuum pressing machines cause defects formed on edges of plates is disclosed. The vacuum pressing machine includes an object carrying platform having an air extraction layer and a plurality of apertures arranged in the air extraction layer; a pressing platform having an aerating layer and a pressing pad arranged on a face of the aerating layer and parallel to the air extraction layer; and a vacuum pad arranged on a surface of the air extraction layer facing the pressing pad. The vacuum pad includes a stopper and a plurality ofholes corresponding to and intercommunicating with the plurality of apertures of the air extraction layer. The stopper wall protrudes from another surface of the vacuum pad opposite to the air extraction layer, and surrounds an outer periphery of the vacuum pad. Both the platform and the pressing platform include a plurality of cooling units arranged corresponding to the stopper wall.

Owner:TOP RANGE MACHINERY

Thermal gel emulsifier composition for plant meat and application thereof

PendingCN113575923AStir wellEffective bondingFood ingredient as gelling agentFood ingredient as coating agentBiotechnologyCellulose

The invention belongs to the technical field of food, and relates to a thermal gel emulsifier composition and application thereof, in particular to an emulsifier composition for plant meat and application thereof. The composition comprises the following components in percentage by weight: 0.3 to 1 percent of methyl cellulose, 0.1 to 0.5 percent of guar gum and 0.1 to 0.5 percent of Arabic gum. The composition can effectively bond plant high-humidity tissue protein (the moisture content is higher than 55%), and the chewiness and texture of plant meat in cold and hot environments are effectively improved; the taste is very close to the taste of the same product of real meat.

Owner:苏陀科技深圳有限公司

Unburned magnesia-carbon brick and preparation method thereof

The invention belongs to the technical field of high-duty refractory for electric furnace and converter linings and ladle linings and in particular relates to an unburned magnesia-carbon brick and a preparation method thereof. The unburned magnesia-carbon brick is characterized by comprising the following components in parts by weight: 80-90 parts of fused magnesite (more than or equal to 97% of MgO, the granularity of 0.1-5mm and the moisture content of less than or equal to 4%), 12-16 parts of graphite (more than or equal to 98% of C, the granularity of less than or equal to 400 meshes, and the moisture content of less than or equal to 0.15%), 0.5-1.5 parts of metal aluminum powder (more than or equal to 98% of Al and the granularity of less than or equal to 400 meshes), 1-3 parts of an aluminum magnesium alloy (more than or equal to 98% of Al+Mg and the granularity of less than or equal to 400 meshes), 0.2-0.8 part of boron carbide (more than or equal to 99% of BC4 and the granularity of 200-325 meshes), 1-2.5 parts of high temperature pitch (softening temperature of more than or equal to 150 DEG C, more than or equal to 50% of residual carbon and the granularity of 100-200 meshes), 0.2-0.5 part of a rare earth oxide (the granularity of 300-350 meshes), 3-5 parts of ceramic bond, 3-4 parts of a complex magnesium-aluminum cementing agent and 1-3 parts of water. The unburned magnesia-carbon brick disclosed by the invention has the advantages of simple and safe preparation method, low cost, no need of high-temperature firing, high density, high strength, high corrosion resistance, molten metal resistance, high oxidation resistance, energy conservation and emission reduction and the like.

Owner:孙光 +3

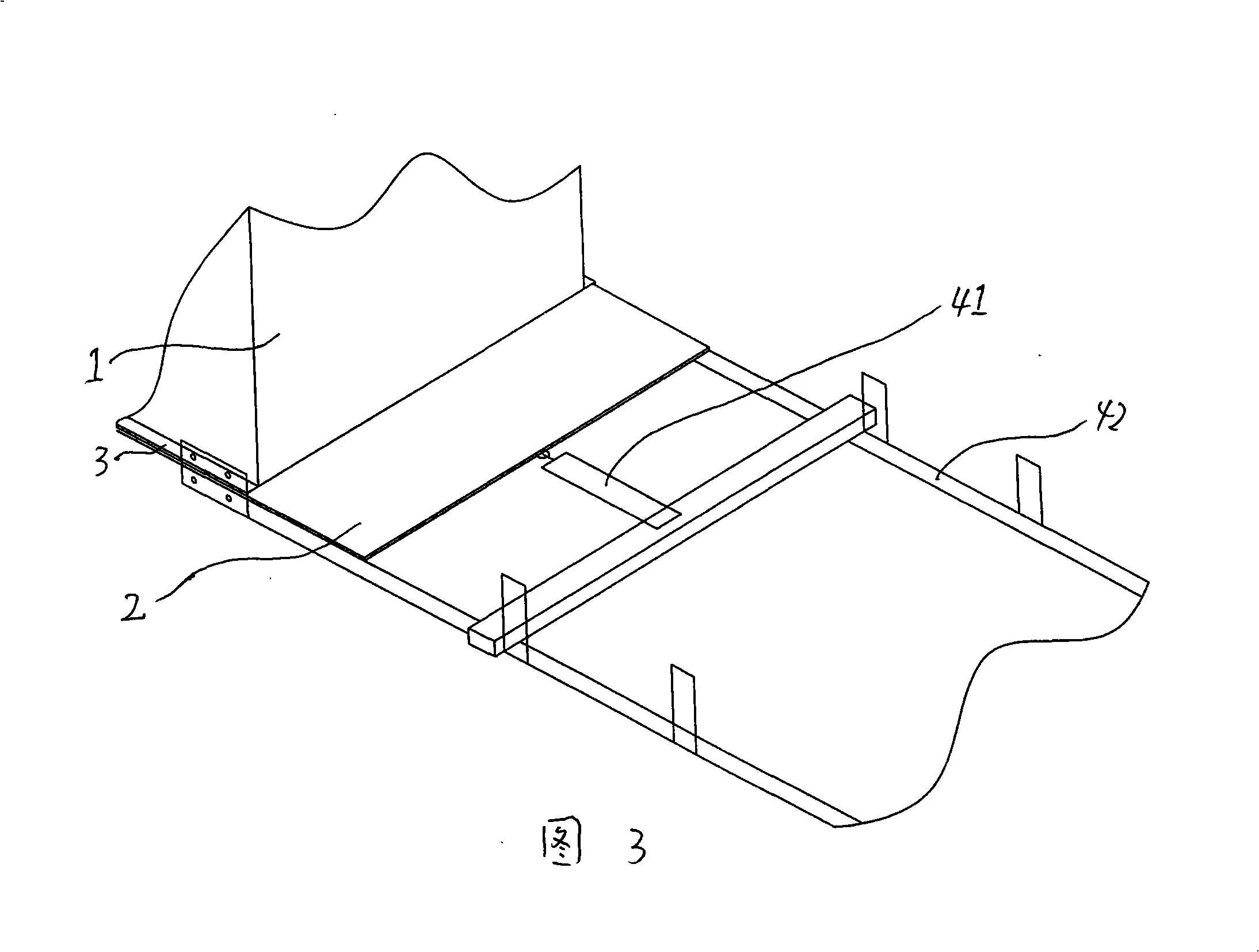

Method for relocation and seamless homing of undisturbed soil

InactiveCN101554104AReduce resistanceAvoid squeezingSoil-working equipmentsRigid containersForest industryNormal growth

The invention discloses a method for soil relocation and returning, in particular to a method for the relocation and returning of undisturbed soil, belonging to the technical field of agricultural and forestry. The method comprises the following steps of: firstly adopting a drill and a chain saw to carry out non-extrusion / impact-type cutting to the soil to be relocated; subsequently adopting a combined movable-plate-type earthwork special die and a special hydraulic machine to take the earthwork by a certain flow; transporting the die containing the earthwork to the destination; and finally returning the relocated earthwork according to the repeated sequence of the design. By adopting the homing method of moving soleplate, the method realizes seamless butting to the soil, avoids cracking and loosing the earthwork or damaging pores due to internal deformation caused by directly pushing the earthwork, avoids cracking, loosing and fallout of the soil, quickly melts and recovers the adjacent earthworks after homing, ensures the original state of soil and normal growth of plant, is applied to the relocation of agricultural and forestry experimental plots and has excellent generalization and application prospect.

Owner:王亮 +2

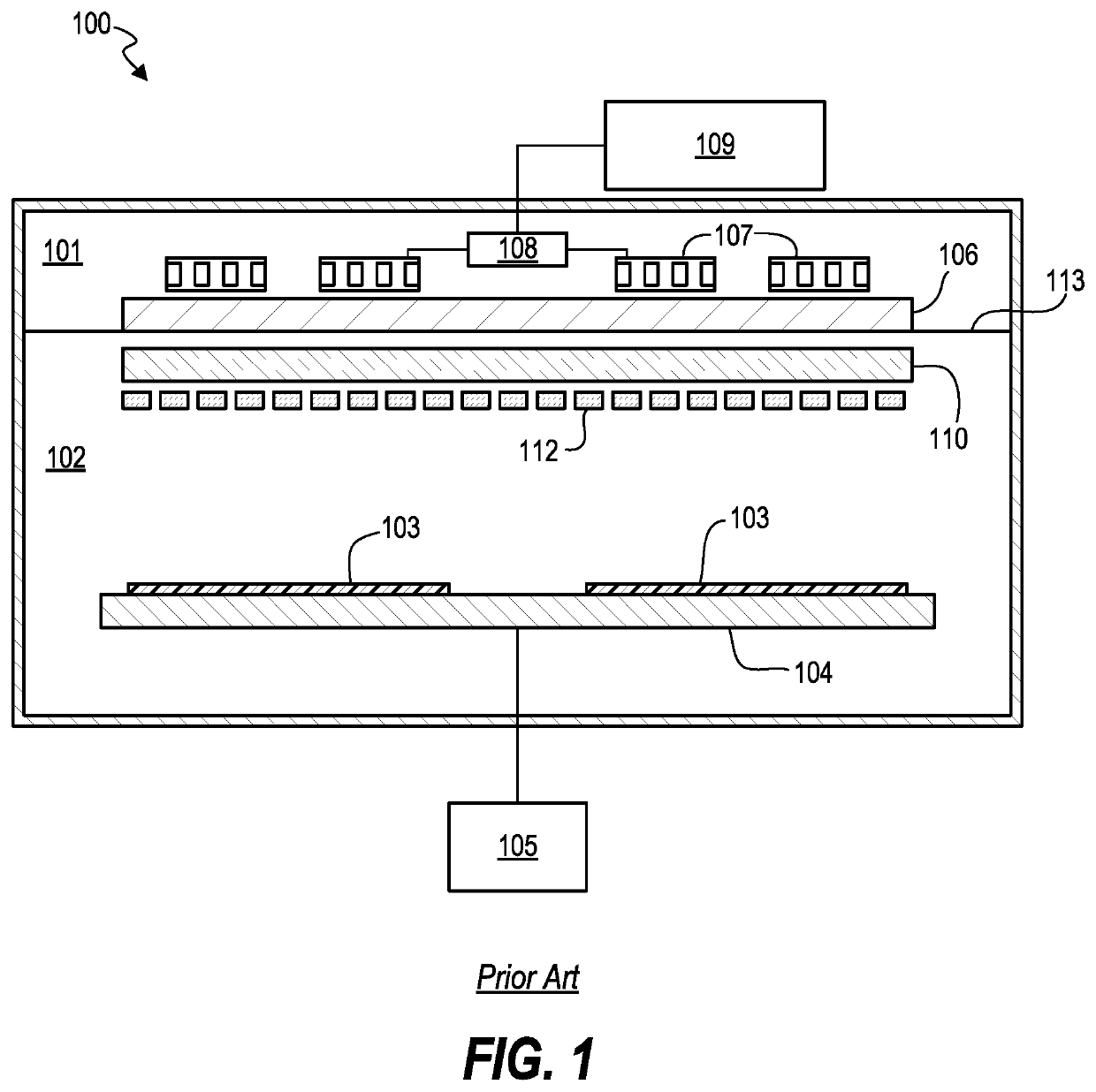

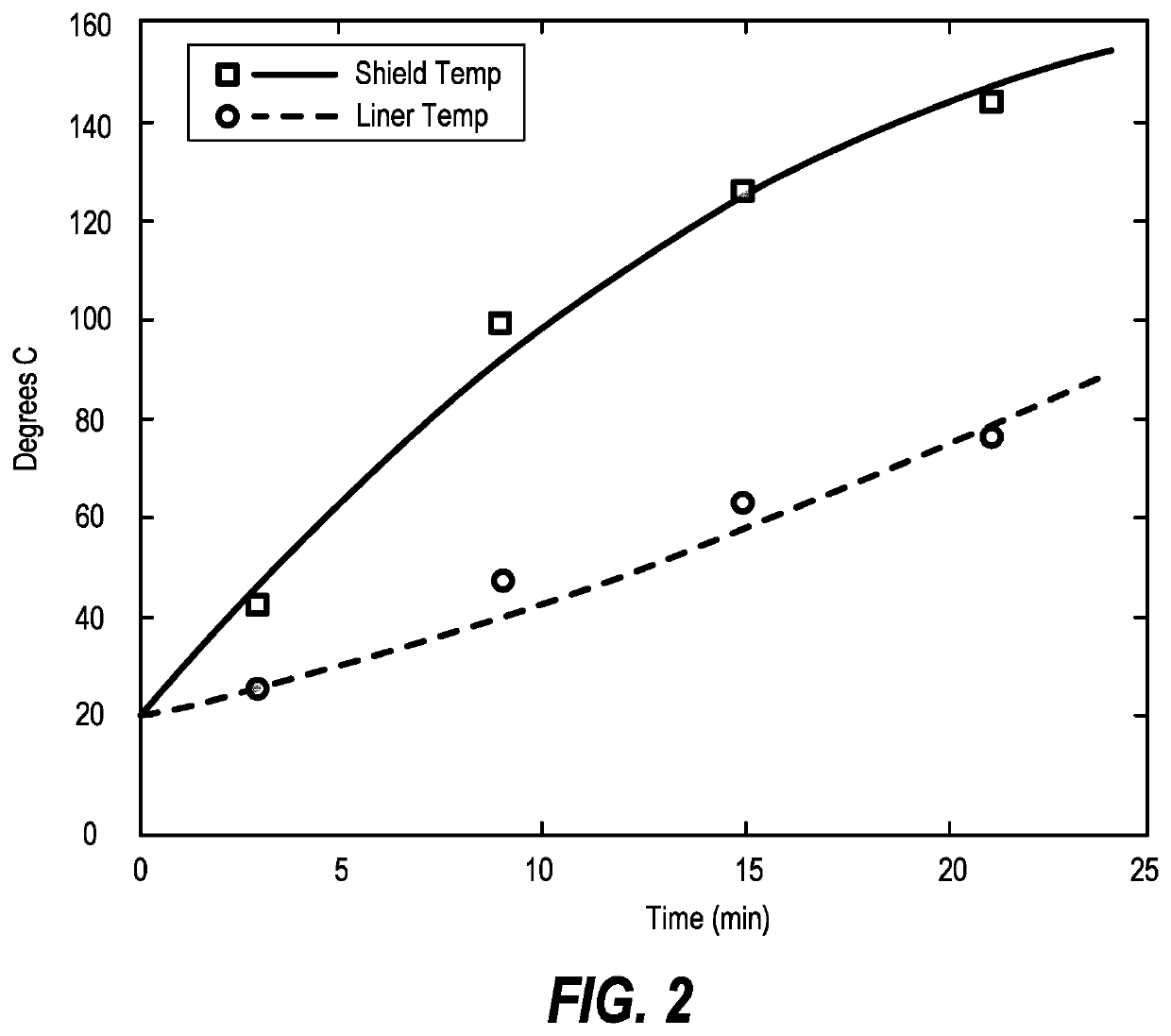

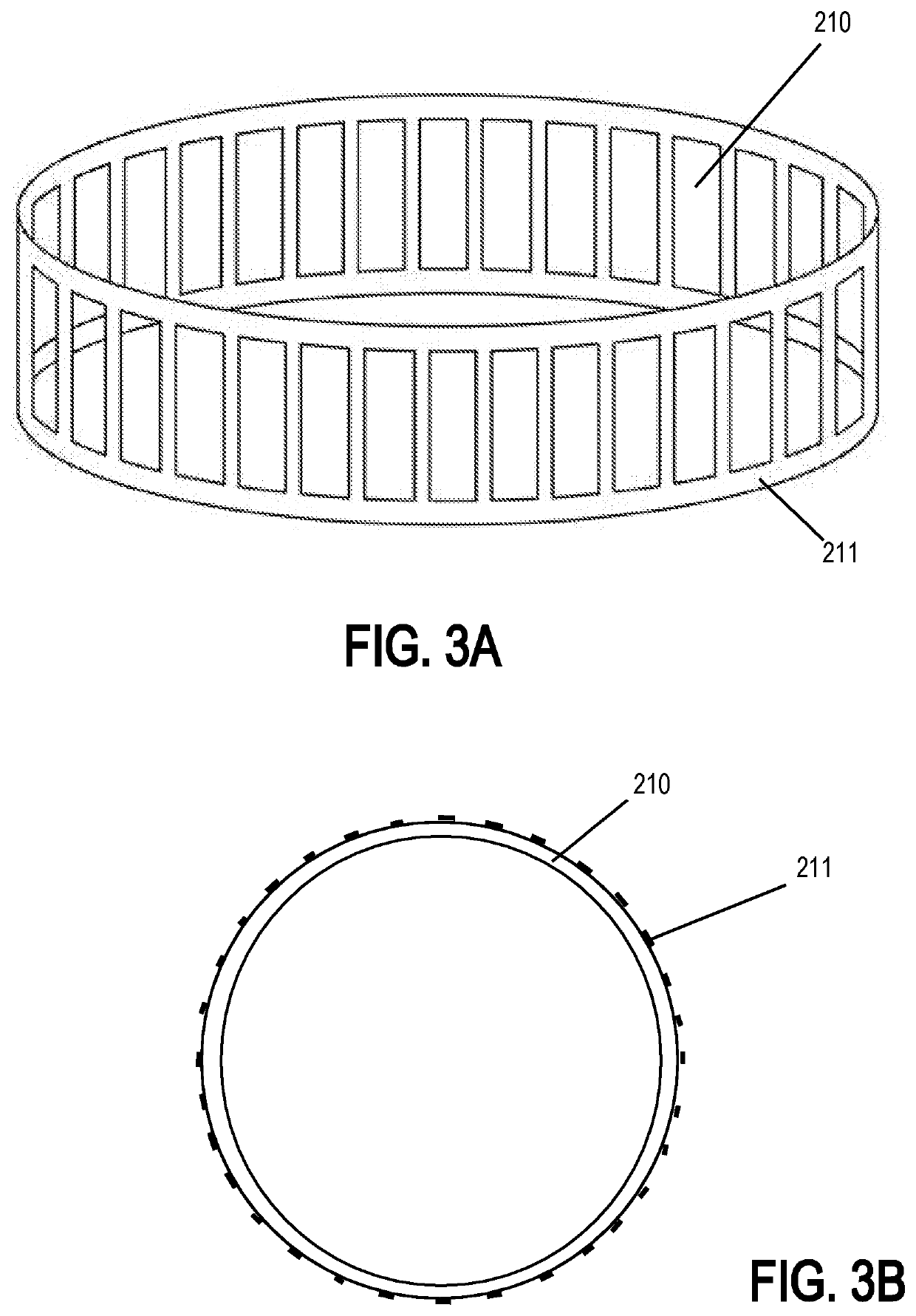

Ceramic liner with integrated faraday shielding

InactiveUS20190341230A1Prevent particle spallationInhibit productionElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringDelivery system

A plasma processing system for processing a semiconductor substrate, the system including a plasma processing chamber having a substrate support member configured for receiving a semiconductor substrate within the plasma processing chamber; a process gas delivery system configured to deliver process gas to the plasma processing chamber; a power source configured to energize process gas within the plasma processing chamber to create plasma; and a component positioned between the power source and the substrate support member, the component including a ceramic liner and a Faraday shield in contact with a surface of the ceramic liner.

Owner:ASMPT NEXX INC

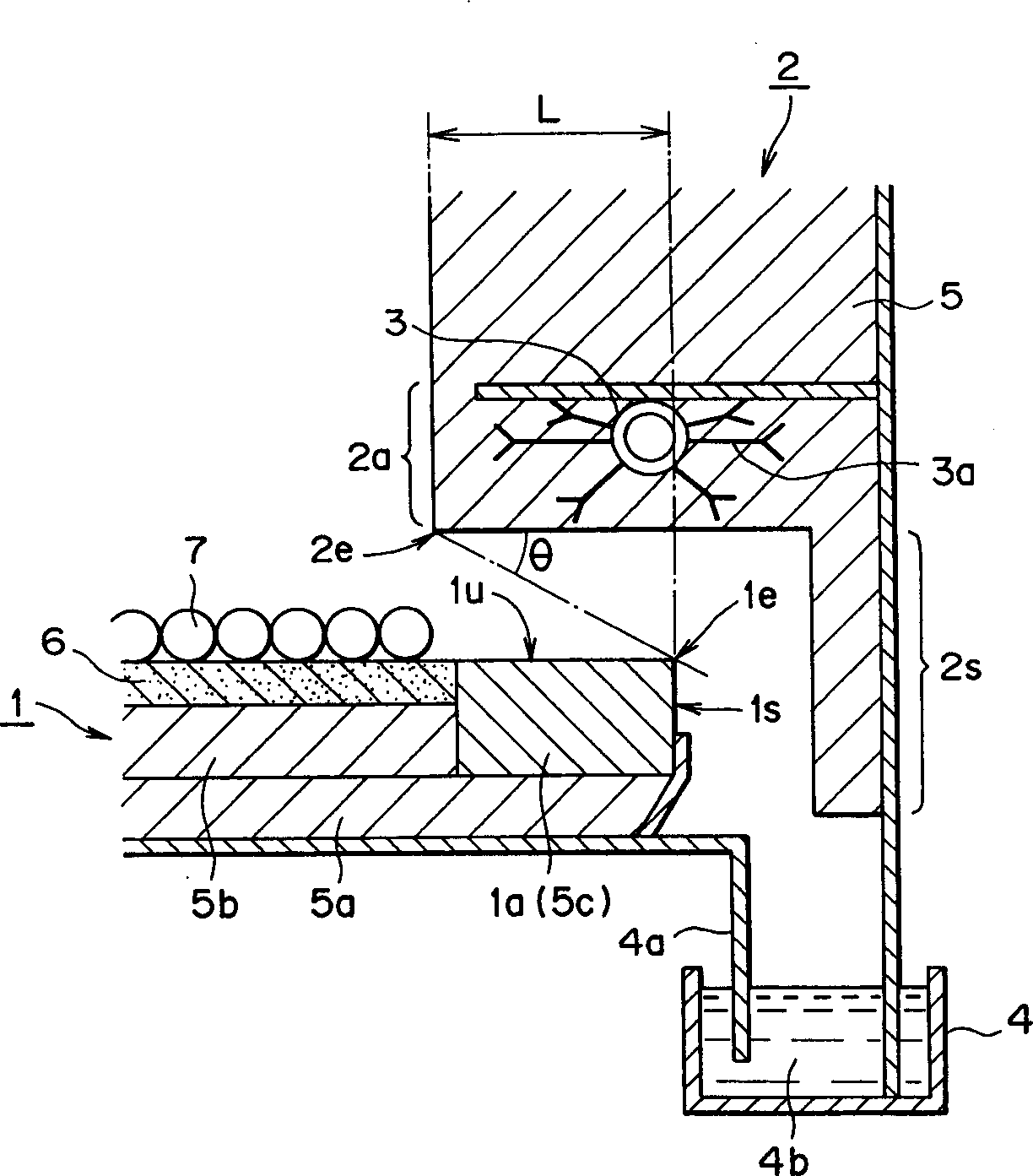

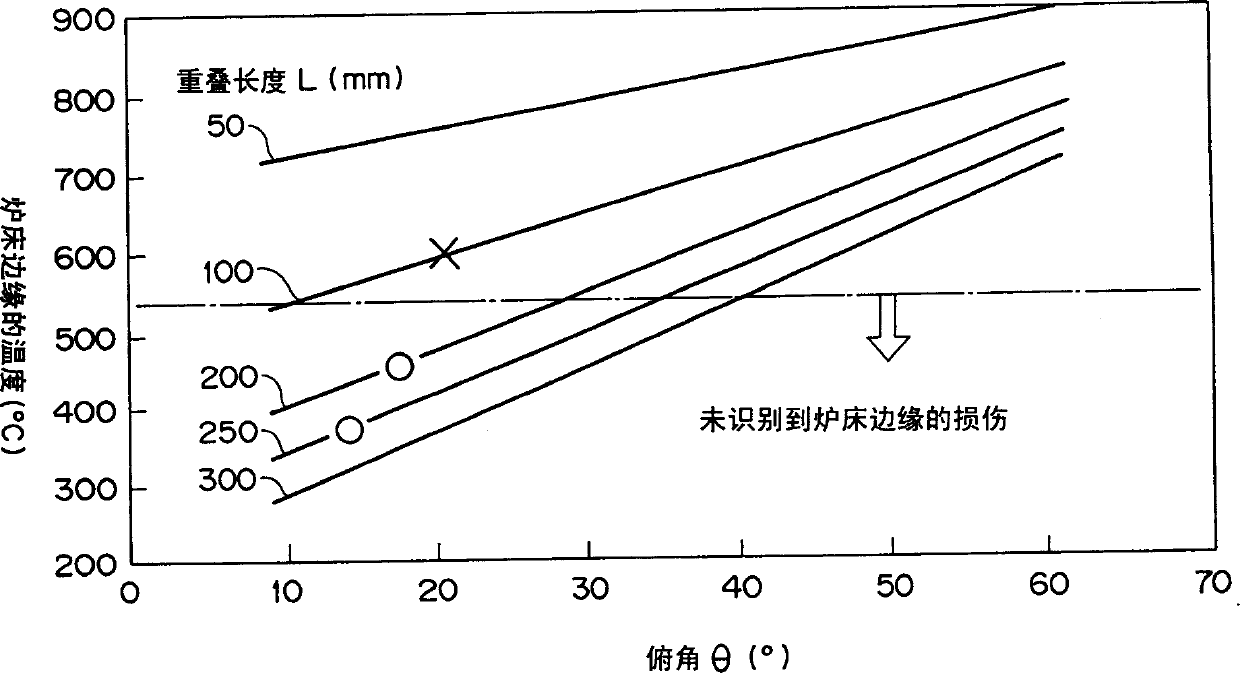

Rotary hearth furnace and method for producing reduced metal

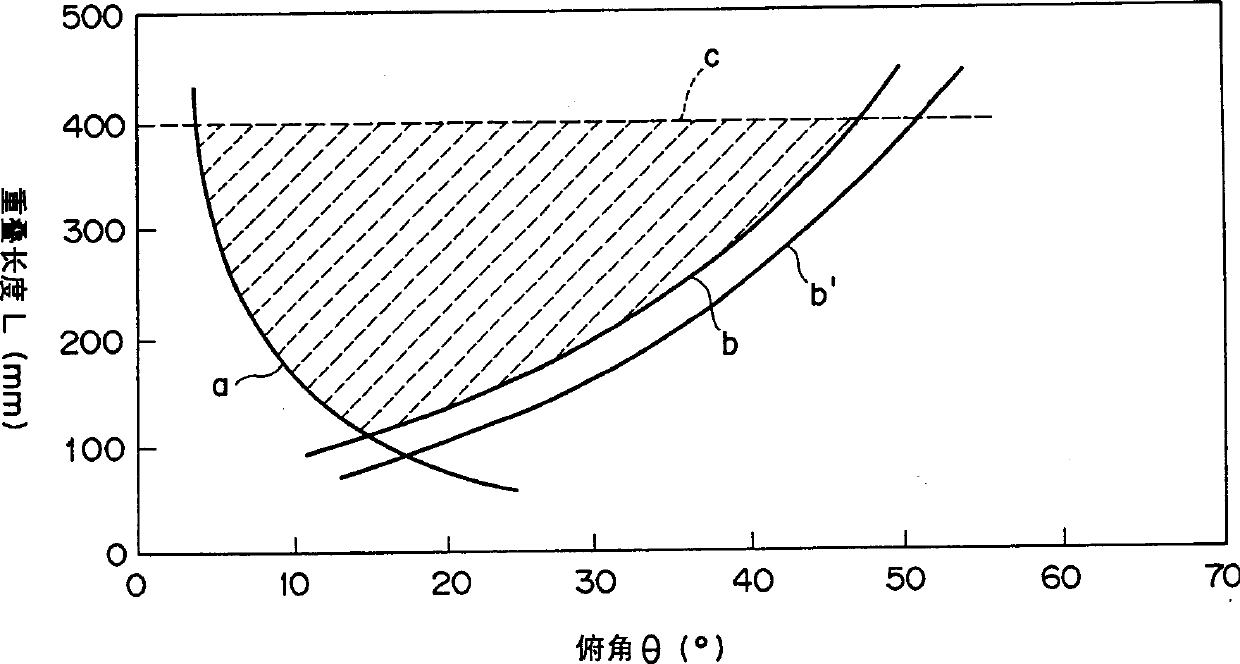

InactiveCN1360061AReduce the extent to which spallation cannot occurDoes not interfere with rotationRotary drum furnacesFurnace cooling arrangementsRefractoryHearth

In a rotary hearth furnace for producing reduced metal through heating and reducing carbon containing materials composed of at least metal oxide-containing material and carbon-containing reduction material, a hearth structure is provided by which a refractory in a hearth lateral end is not damaged and carbon containing materials do not fall down to a water sealing section of the rotary hearth furnace. The upper part of a hearth lateral end (1a) is covered with the lower end (2a) of a side wall (2) of a hood covering the whole hearth, and a cooling means (3) is installed in the side wall lower end (2a).

Owner:KOBE STEEL LTD

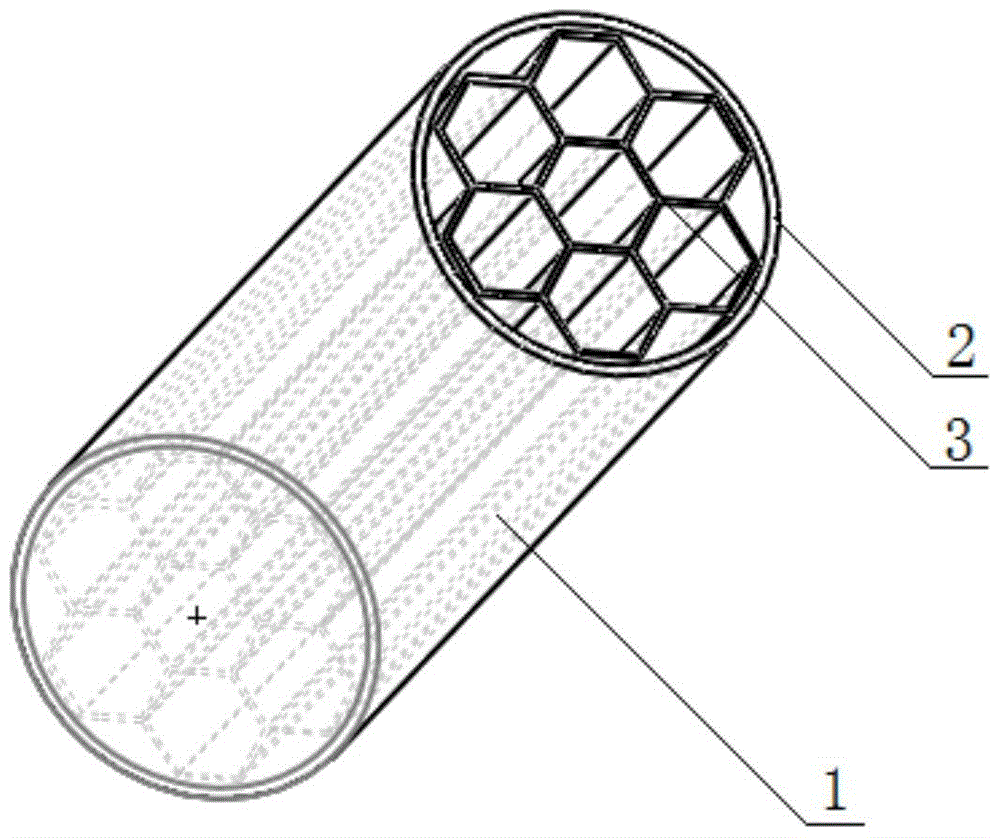

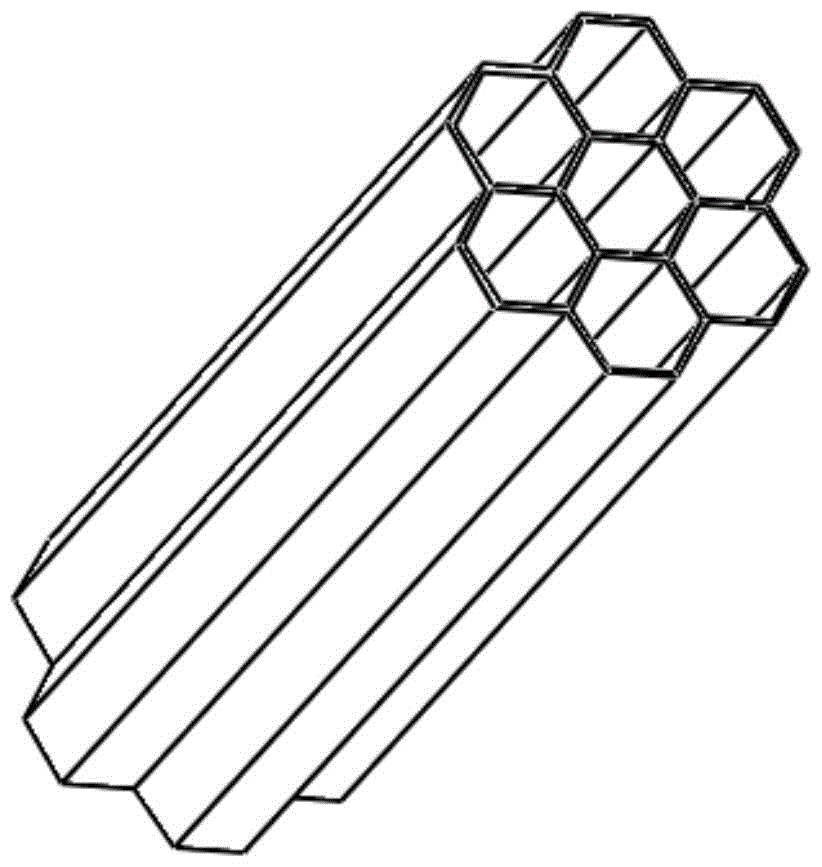

A high-strength steel transmission tower with a honeycomb structure

ActiveCN104047462BEasy to processAvoid spallationFoundation engineeringTowersTransmission towerSheet steel

Owner:STATE GRID CORP OF CHINA +2

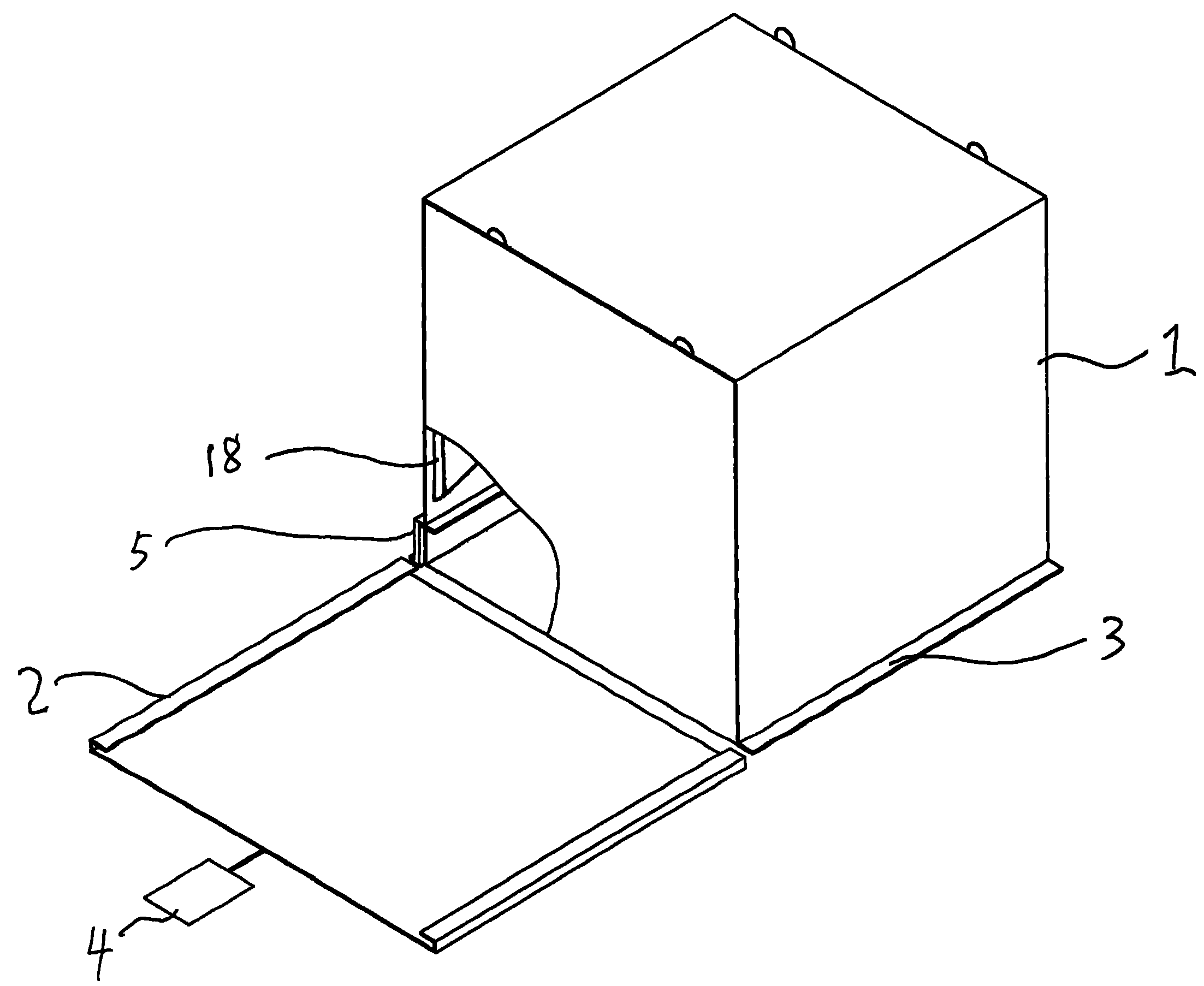

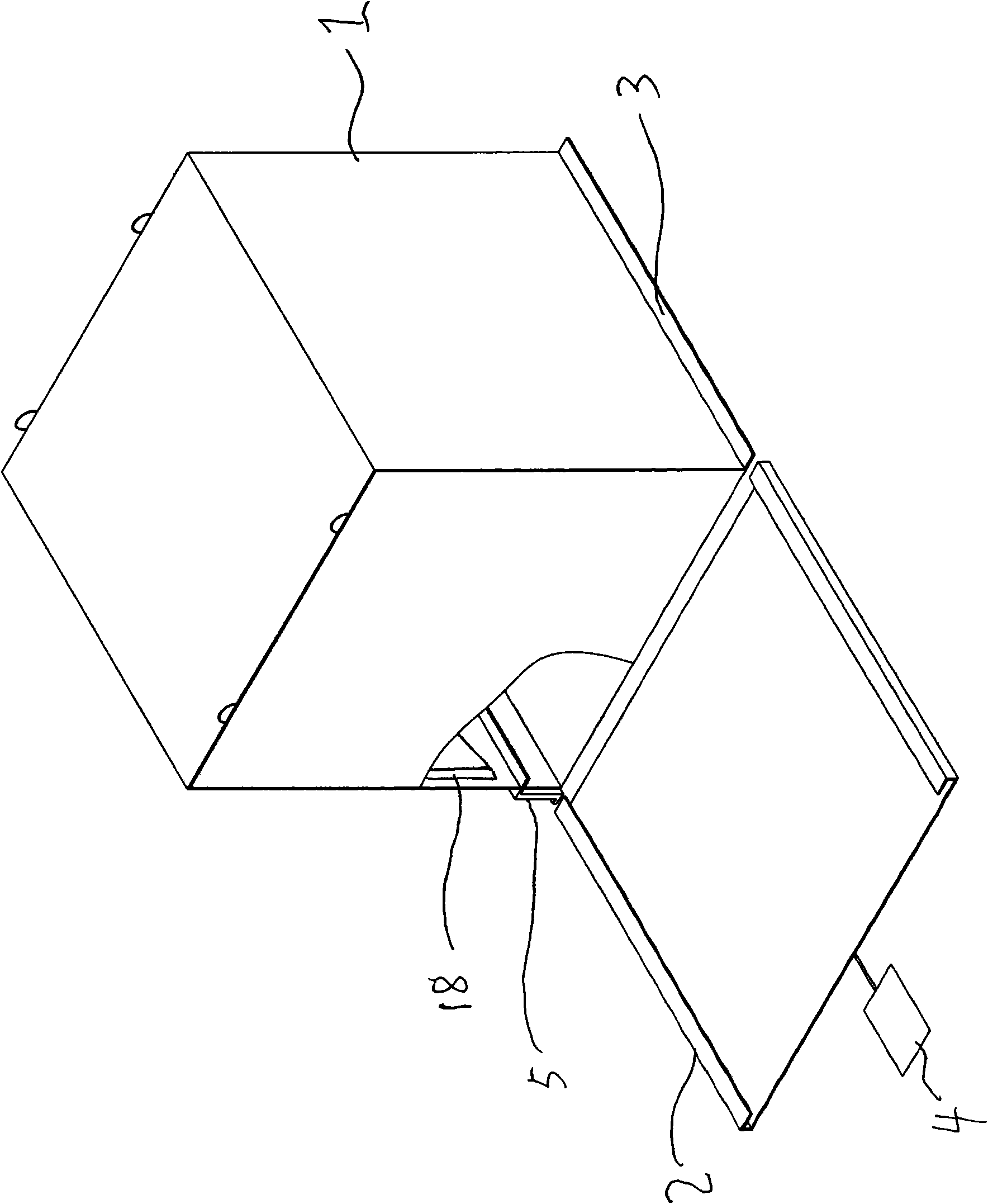

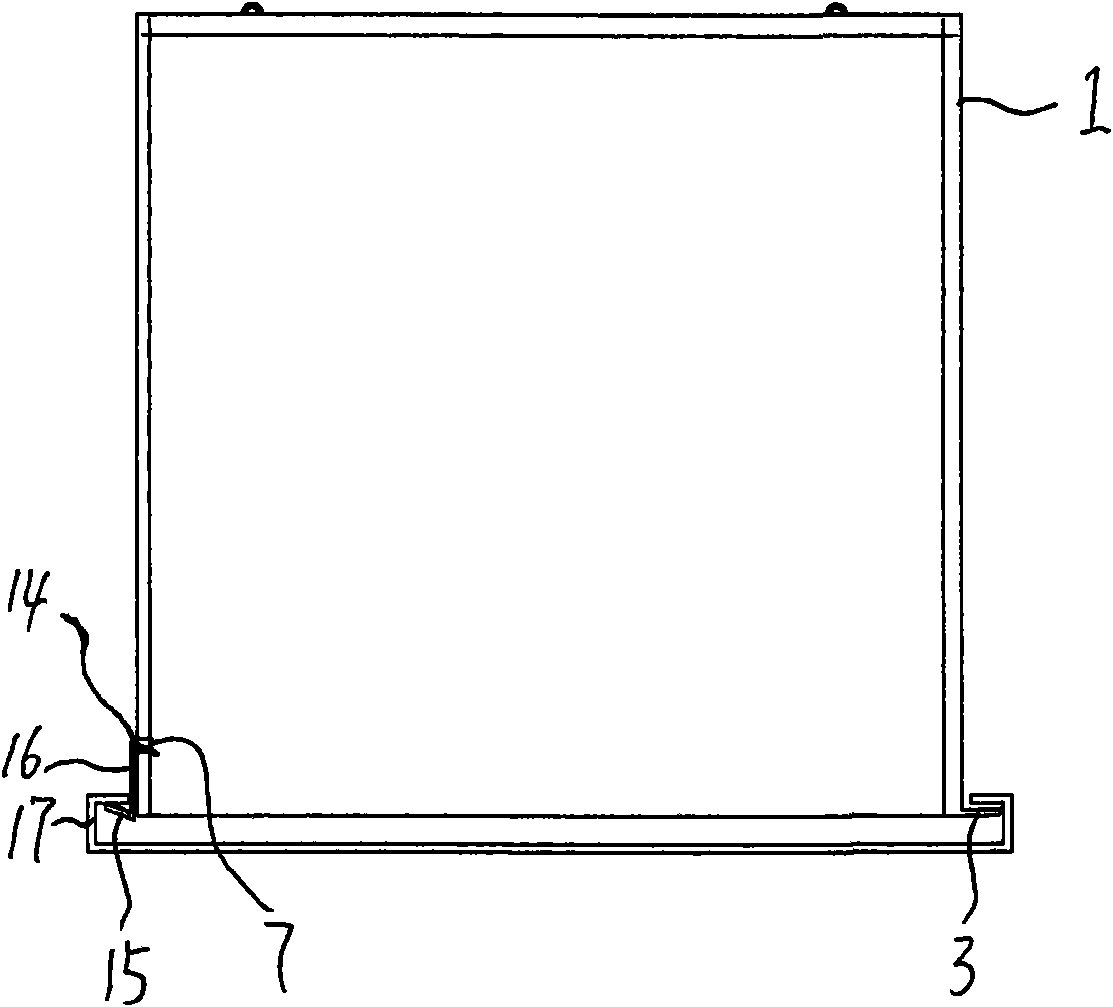

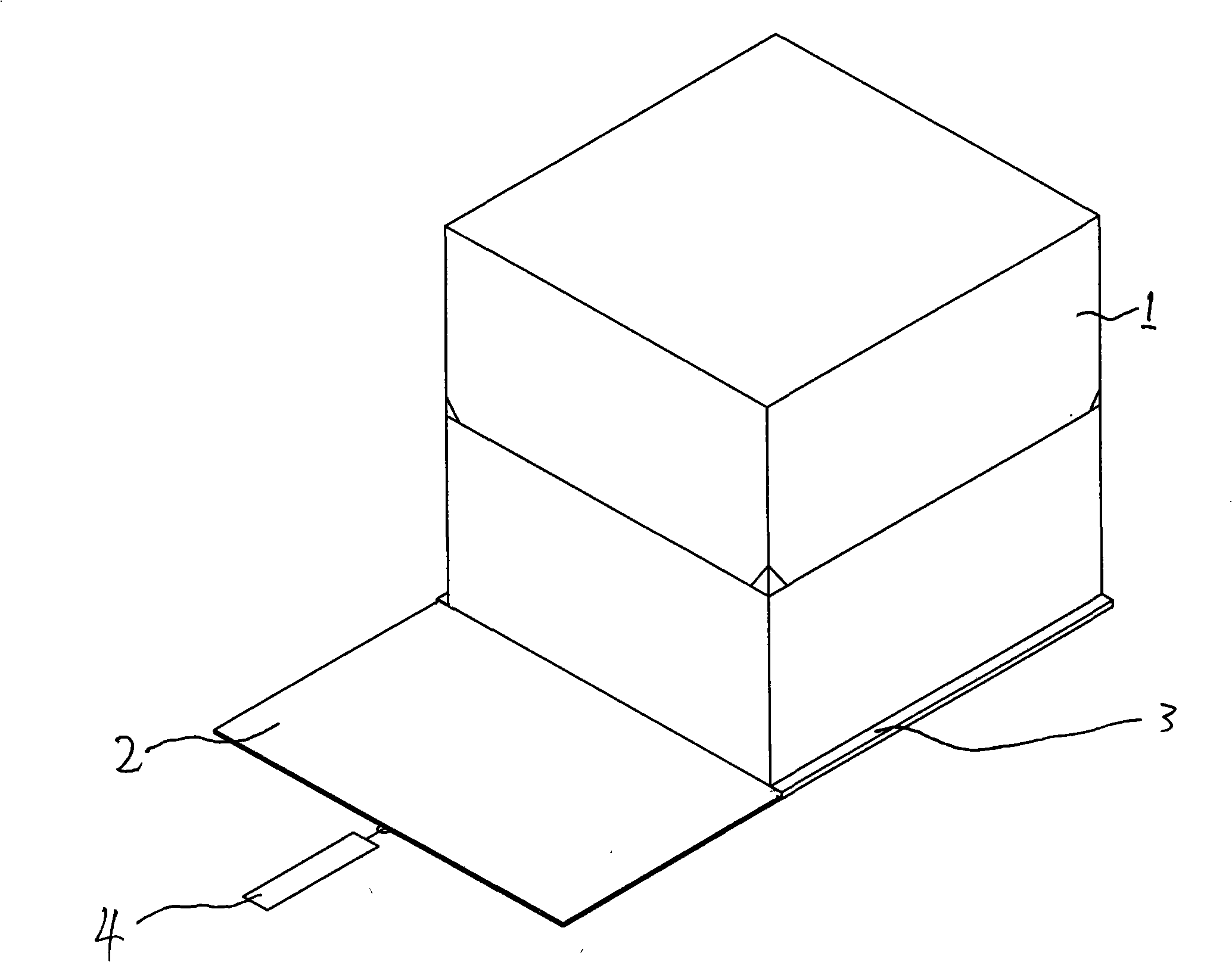

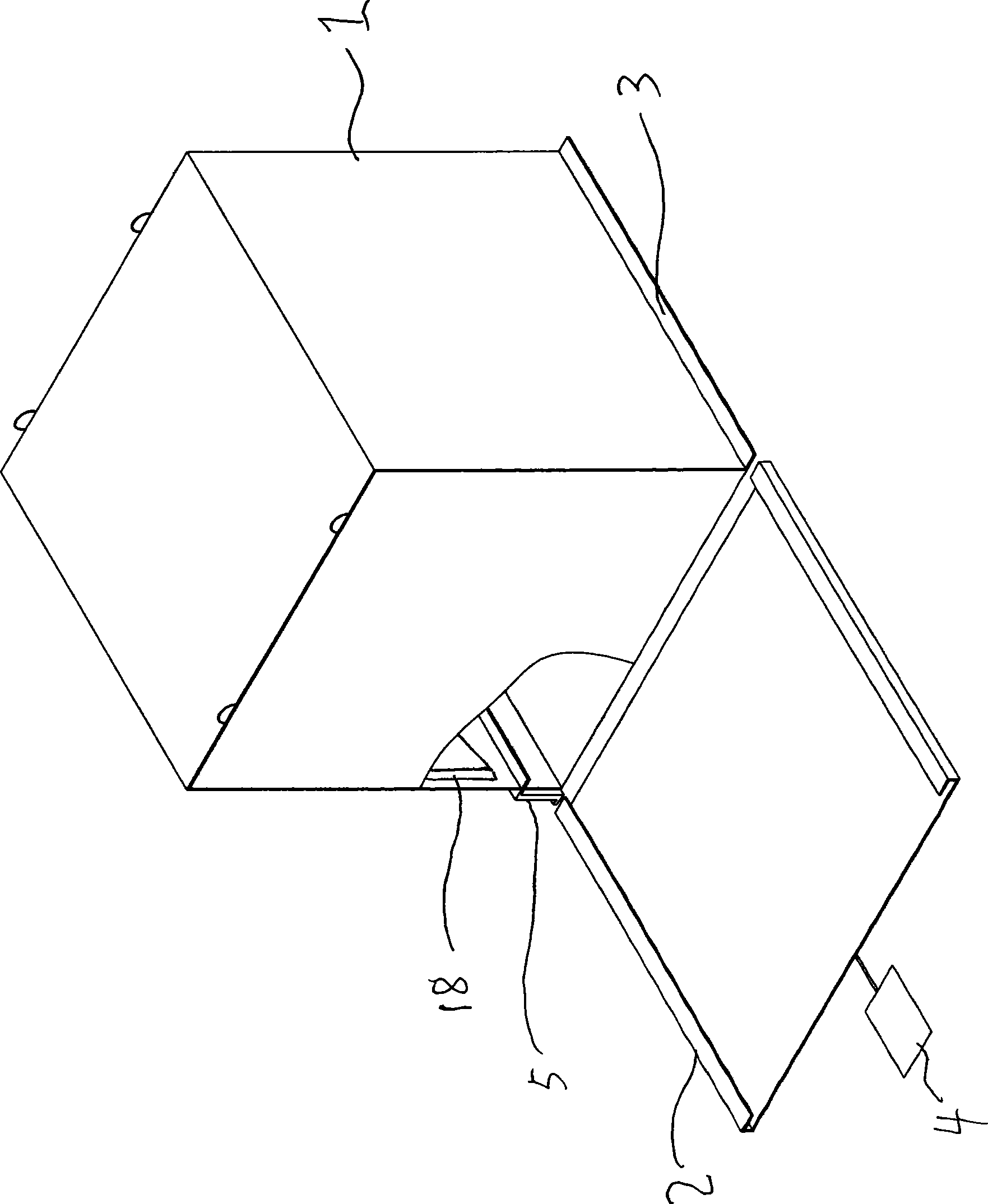

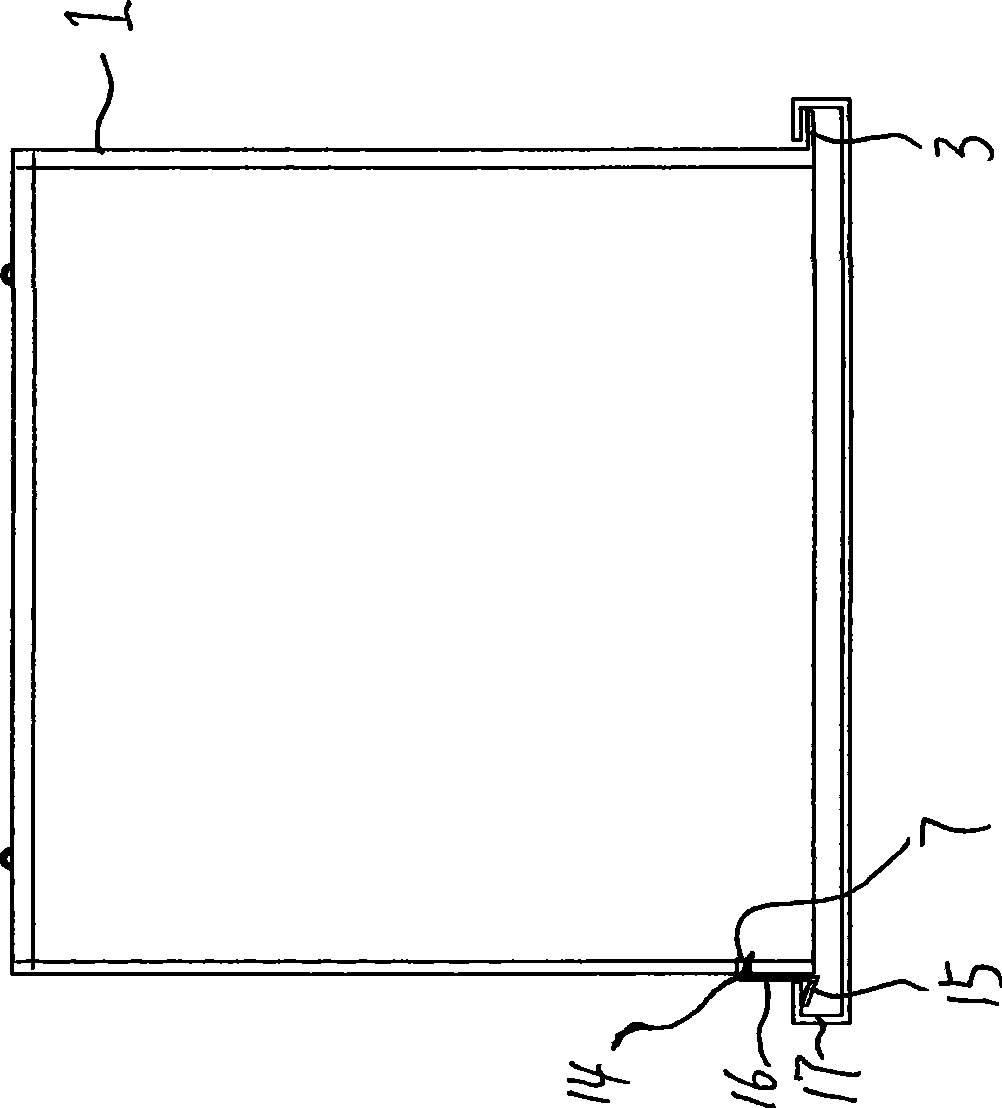

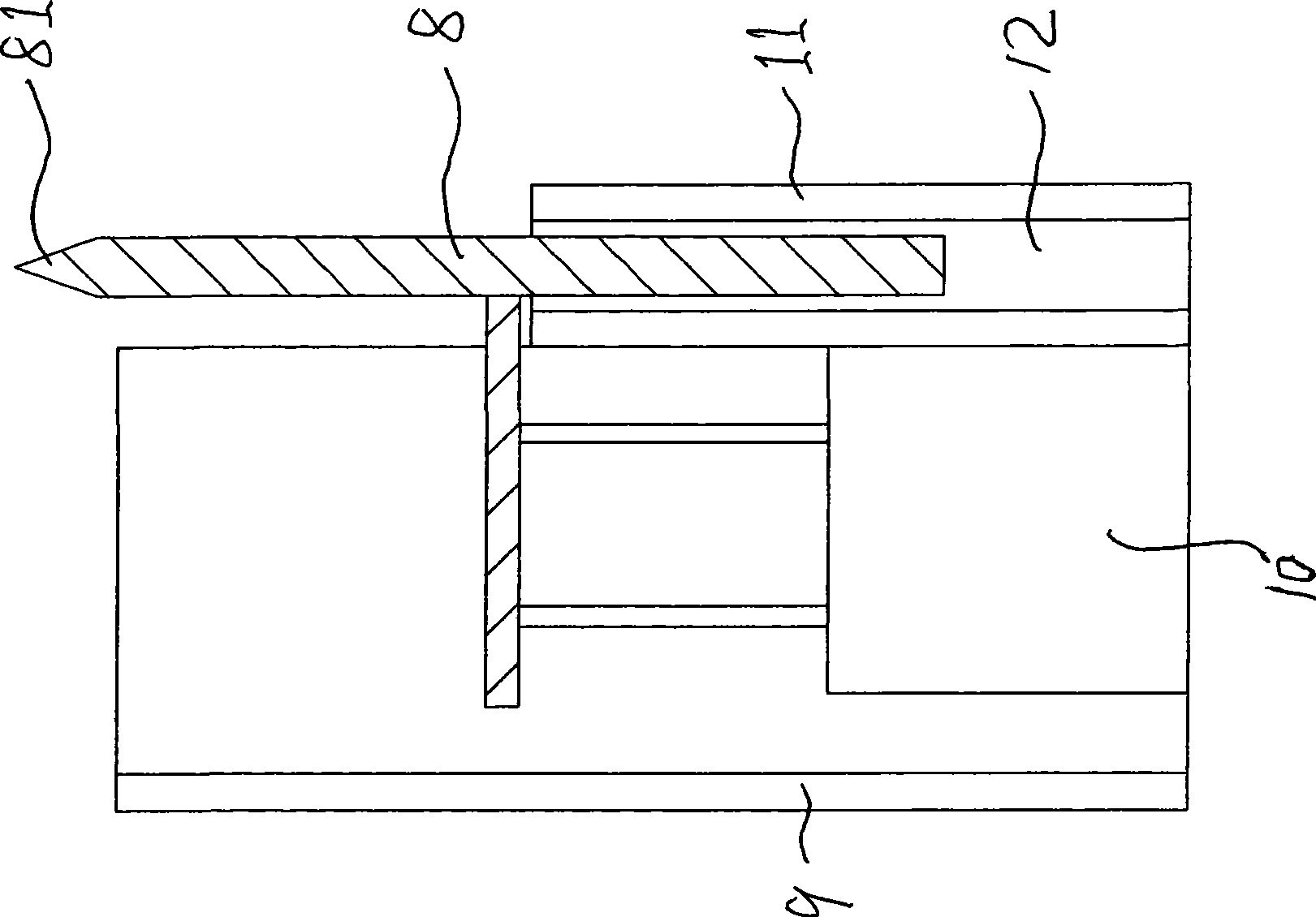

Plot movement device for maintaining undisturbed soil free from loss, and method for plot movement using device

InactiveCN101531262BReduce damageReduce effective thicknessSoil-working equipmentsRigid containersEngineering

The invention discloses a plot movement device and a special cutter maintaining undisturbed soil free from loss, and a method for plot movement using the device, belonging to the technical field of plot movement devices and implementation of plot movement using the devices. The plot movement device has the main technical characteristics that the device comprises a box body; box bottom which can be pulled is arranged at the bottom of the box body; the bottom edge of one side wall of the box body is an L-shaped first track; one side of the box bottom is clamped on the L-shaped first track and can slide forward and backward along the first track; the other side wall of the box body is provided with a connecting mechanism connected with the box bottom; the box bottom is connected with a pushing pulling mechanism thereof. The method has the main technical characteristics that the cutter is used for cutting large clods needing to be moved into a plurality of small plots slightly smaller than the box body, and the box bodies with movable box bottoms are used for moving the small plots to the destinations, therefore, position movement of the soil body can be finished on the basis that theundisturbed soil is maintained free from loss.

Owner:马洪彬

Fireproof inorganic quartz stone and preparation method thereof

The invention discloses fireproof inorganic quartz stone and a preparation method thereof. According to the preparation method, the raw materials are lightly sintered and sintered, so that a part of physical and chemical reactions of the raw materials can be completed, cremation of ore is realized, lattice defects are increased, sintering is promoted effectively, therefore, the preparation efficiency can be effectively improved; a double-sided hot-pressing mode is adopted for extrusion molding to obtain a green body, so that the green body is compact in structure, high in strength and small indrying and firing shrinkage, the size is easy to control, the layer density phenomenon of the green body can be effectively reduced, the total porosity of the green body is reduced, the fireproof performance can be effectively improved, and the using efficiency is increased; a plurality of times of extrusion is adopted, and extrusion time is prolonged, so that gas in the green body can be effectively and smoothly exhausted, the elasticity of the green body can be effectively improved, the strength of the green body can be effectively improved, the green body can be effectively prevented fromcracking, and the preparation efficiency of the green body can be effectively improved.

Owner:山东康洁利新材料有限公司

Land parcel transferring device for retaining soil construction and method for using the same to transfer land parcel

InactiveCN101259881AReduce soil resistanceEven by forceDrawer-and-shell containersExternal fittingsPush and pullDitch

The invention belongs to a block migration device and the technical field in which the device is used for block migration. The invention discloses a block migration device which keeps the structure of soil and a method by which the block is migrated with the block migration device. The block migration device which keeps the structure of soil has the main the technical characteristic that a box body with an extendable box bottom arranged at the bottom and a box bottom pushing and pulling mechanism which is connected with the box bottom are included; the bottom side of the side surface of the box body is provided with a box bottom advancing and backing track. The method has the main technical characteristic that the block required to be migrated is divided into a plurality of small blocks which are slightly less than the box body and ditches among the small blocks; the excavated soil is taken as spare soil; the box body with the movable box bottom is used for moving the small blocks to the destination; therefore, the positioning migration of the soil can be completed and the soil structure is maintained to be unchanged.

Owner:DRY LAND FARMING INST OF HEBEI ACAD OF AGRI & FORESTRY SCI

Plot movement device and special cutter maintaining undisturbed soil free from loss, and method for plot movement using device

InactiveCN101531262AReduce damageReduce gapSoil-working equipmentsRigid containersAgricultural scienceAgricultural engineering

The invention discloses a plot movement device and a special cutter maintaining undisturbed soil free from loss, and a method for plot movement using the device, belonging to the technical field of plot movement devices and implementation of plot movement using the devices. The plot movement device has the main technical characteristics that the device comprises a box body; box bottom which can be pulled is arranged at the bottom of the box body; the bottom edge of one side wall of the box body is an L-shaped first track; one side of the box bottom is clamped on the L-shaped first track and can slide forward and backward along the first track; the other side wall of the box body is provided with a connecting mechanism connected with the box bottom; the box bottom is connected with a pushing pulling mechanism thereof. The method has the main technical characteristics that the cutter is used for cutting large clods needing to be moved into a plurality of small plots slightly smaller than the box body, and the box bodies with movable box bottoms are used for moving the small plots to the destinations, therefore, position movement of the soil body can be finished on the basis that the undisturbed soil is maintained free from loss.

Owner:马洪彬

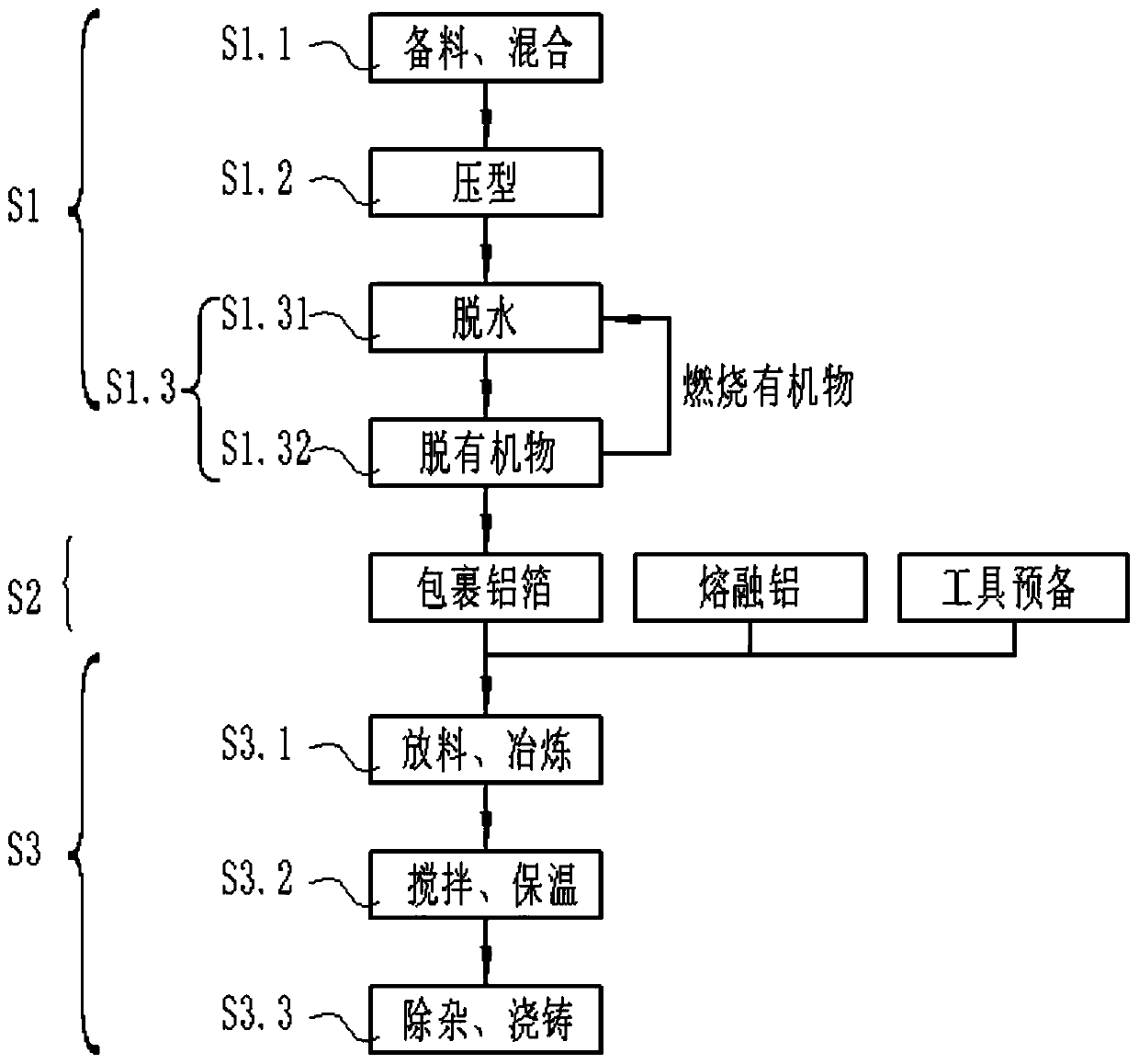

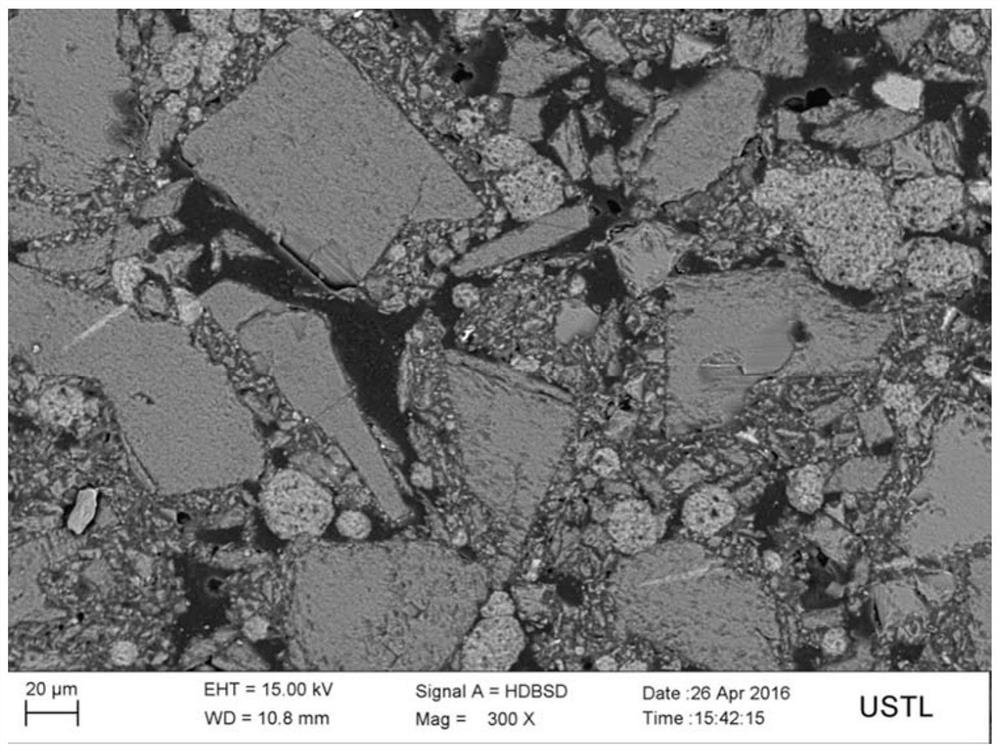

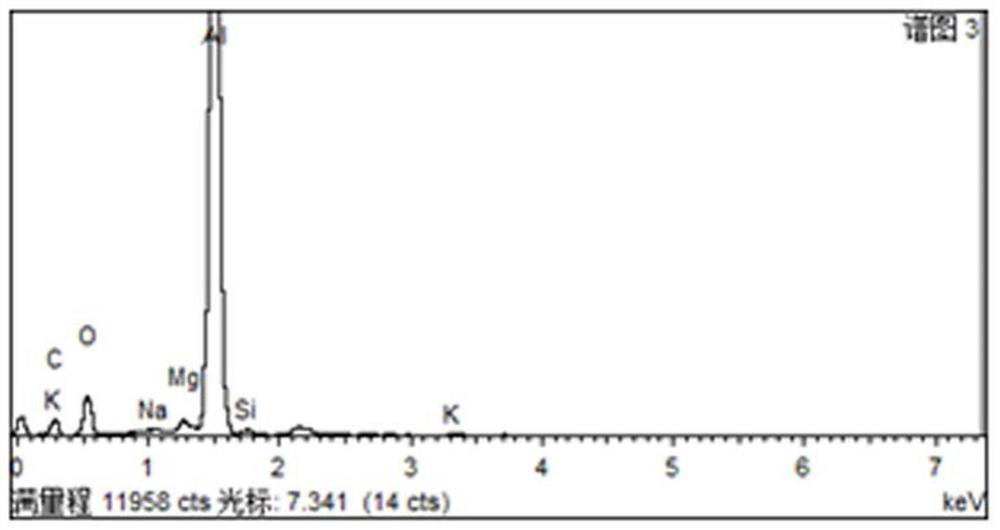

Silicon material prepared by photovoltaic cutting waste and preparation method thereof

The invention relates to a method for preparing an aluminum-silicon alloy by using photovoltaic cutting waste. The method comprises the steps that S1.1, photovoltaic cutting waste, water and adhesiveare mixed evenly by a mass ratio of 100 to (10-30) to (2-8), and a mixture is obtained; S1.2, the mixture is pressed into a material block; and S1.3, the material block is subjected to dehydration andorganic matter removal, a material block which is subjected to dehydration and organic matter removal is obtained, and the material block which is subjected to dehydration and organic matter removalis a silicon material. The method for preparing the silicon material by using the photovoltaic cutting waste realizes recycling of waste in the photovoltaic industry and turns waste into treasure. Inthe process of processing the waste, the pressing can reduce the total volume, transportation and subsequent operation are facilitated, and process loss is reduced; the adhesive is used for shaping toprevent spalling. Low-temperature dehydration and high-temperature organic matter removal are performed to conveniently collect water and organic matter separately, and water and organic matter are separately discharged and used. The material block is processed to be used for smelting.

Owner:NORTHEASTERN UNIV

A kind of unfired alumina-magnesia-carbon brick and preparation method thereof

The invention belongs to the technical fields of advanced fireproof materials for electric furnaces, converter linings and steel ladle linings and preparation thereof, and relates to an unfired alumina-magnesite carbon brick and a preparation method thereof. The unfired alumina-magnesite carbon brick is prepared from aggregate, powder, an additive and a binding agent in parts by weight: 60 to 70 parts of brown aluminum oxide and / or special alumina; 1 to 3 parts of magnesium aluminate spinel, 9 to 11 parts of high-purity magnesia, and 11 to 13 parts of sub-white corundum; 2 to 4 parts of the additive; 5 to 7 parts of graphite, 1 to 3 parts of high-temperature pitch, 0.2 to 0.5 part of rare earth oxide, 3 to 5 parts of a ceramic binding agent, 3 to 4 parts of a complexing magnalium grouting agent and 1 to 3 parts of water. The unfired alumina-magnesite carbon brick has the advantages that the preparation method is simple and safe, the cost is low, high-temperature firing is not needed, the density is large and the strength is high.

Owner:大石桥市冠诚耐火材料有限公司

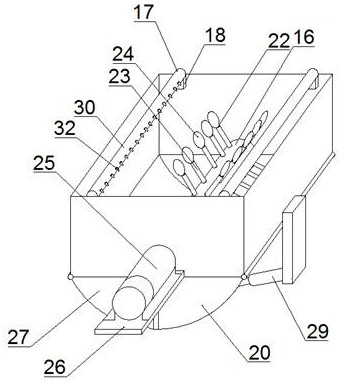

Control system for manufacturing shaving boards by using plywood cutting materials

PendingCN113510818AMix well and evenlyGuaranteed DustRotary stirring mixersProfiling/shaping machinesControl systemStructural engineering

The invention discloses a control system for manufacturing shaving boards by using plywood cutting materials. The system comprises a bottom frame, a cutting device is mounted on the bottom frame, the cutting device comprises a first cutting wheel and a second cutting wheel, the second cutting wheel comprises an upper cutting wheel and a lower cutting wheel, the first cutting wheel is embedded between the upper cutting wheel and the lower cutting wheel, the first cutting wheel is installed on a first rotating shaft, the second cutting wheel is installed on a second rotating shaft, the upper cutting wheel and the lower cutting wheel are installed on the second rotating shaft, a cutting material collecting device is installed above the cutting device, the cutting material collecting device comprises a collecting cover, a mixed material is fully stirred, the stirring efficiency is improved, meanwhile, a stirring piece on a stirring spoon can fully mix the cutting materials and a glue solution, uniform bonding of glue and the cutting materials is improved, plate blank spalling during later manufacturing is prevented, the quality and the service life of a product are guaranteed, meanwhile, the stirring efficiency is improved during stirring and mixing, and time is saved.

Owner:山东中亿木业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com