Rotary hearth furnace and method for producing reduced metal

A technology of rotating hearth and metal, applied in the direction of hearth furnace, rotary drum furnace, furnace type, etc., can solve the problems of reducing the yield of reduced iron products, stopping the rotation of hearth 1, etc., to improve the yield and prevent low Strength problem, spallation prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

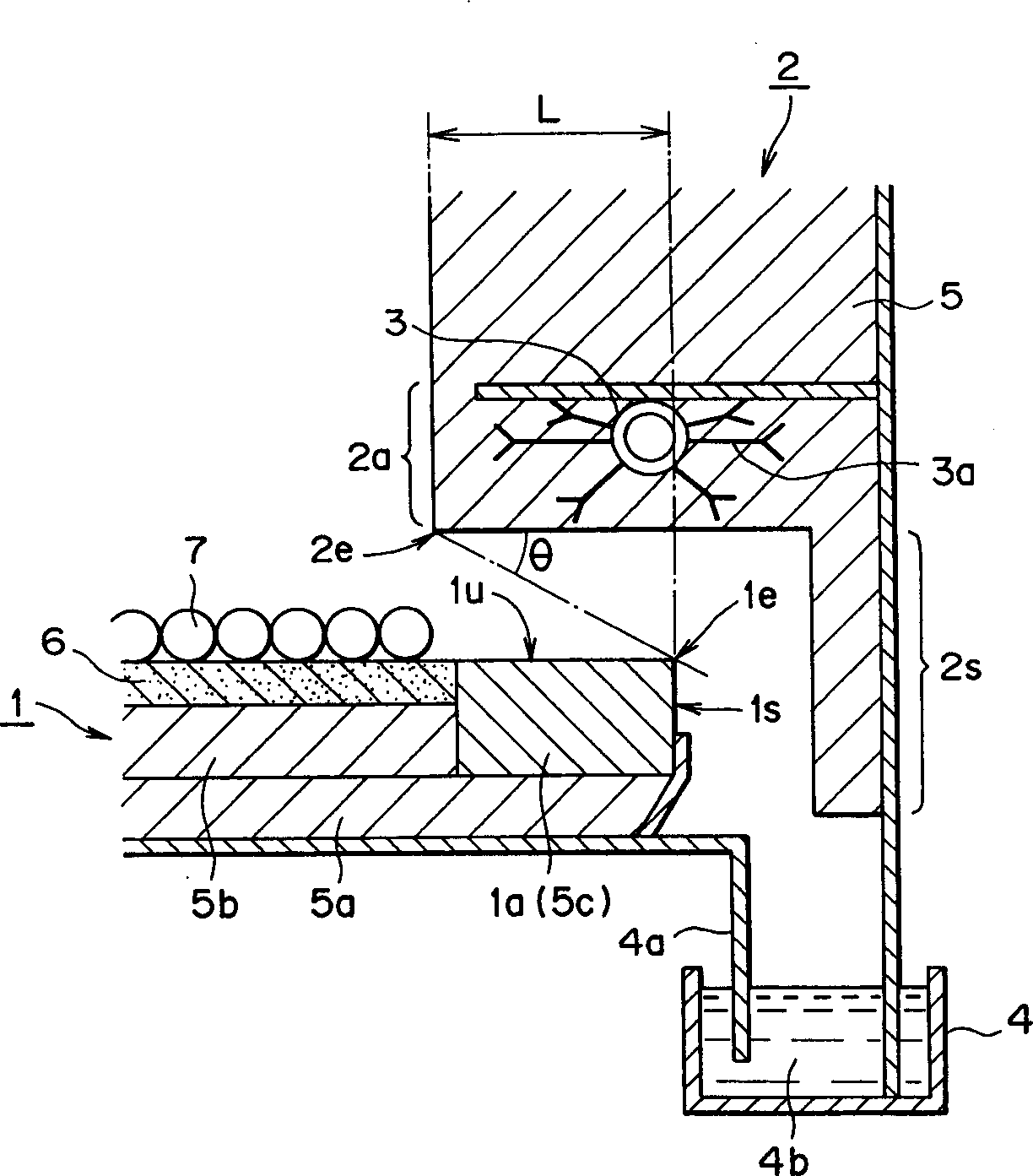

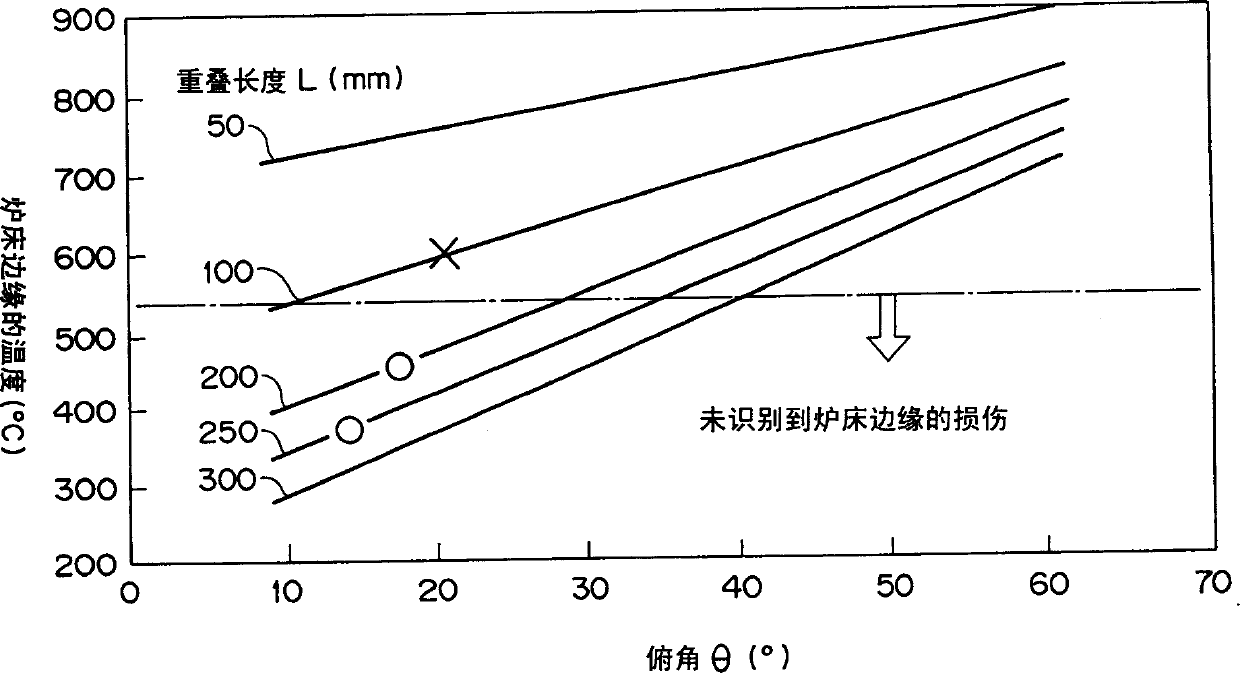

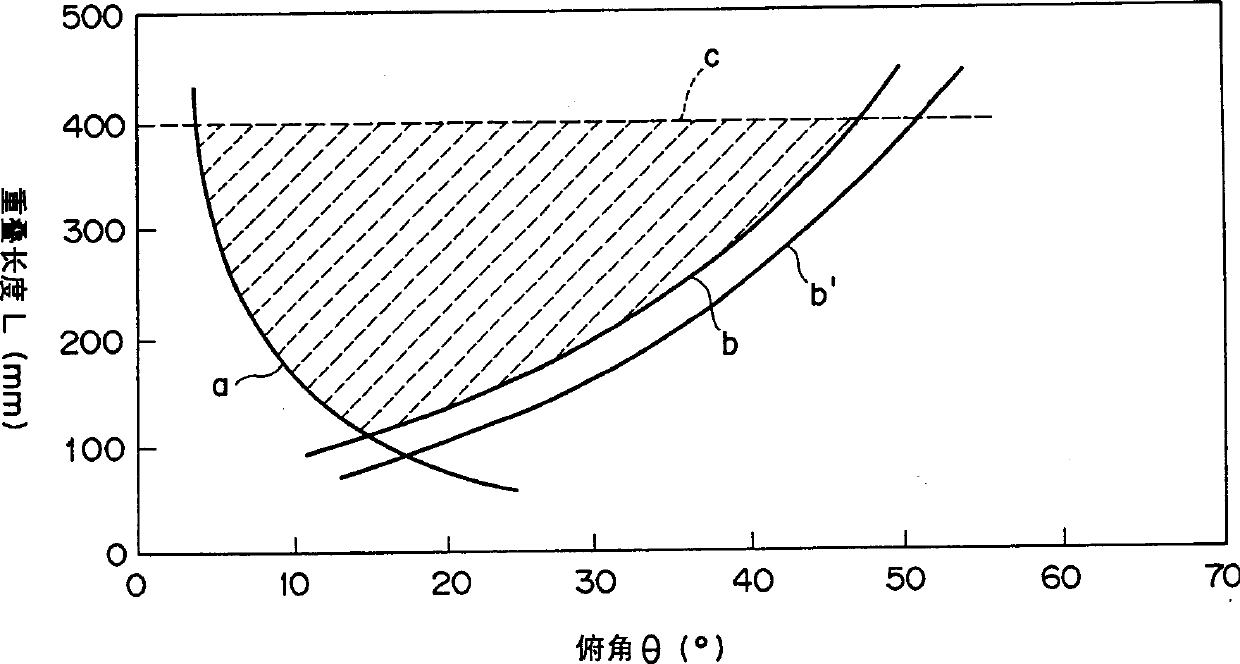

[0058] In the furnace structure, the hearth diameter of the rotary hearth type furnace is 8.5m, and the hearth width is 1.25m, and there is an inclination with an upward gradient toward the edge of the hearth (side front end) with respect to the overlapping length L, depression angle θ The surface, the embedded cooling water pipe at the lower end of the side wall, the type and installation method of the horizontal edge refractory have been modified differently, and the furnace atmosphere temperature is set at 1400°C or 1200°C and the predetermined time period under each condition (approximately 30 After producing reduced iron within 2 days), the extent of damage to the edge of the hearth and the increase in sludge in the seal tank were investigated. The results are shown in Table 1 below.

[0059]

sample

No

Hearth structure

run

condition

Operation result

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com