Manufacturing method of laminated aluminum matrix composite for electronic packaging

An aluminum-based composite material and electronic packaging technology, applied in the field of aluminum-based composite material preparation, can solve the problems of poor weldability, low plasticity and toughness, and achieve the effects of low cost, good welding performance, and avoiding spalling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

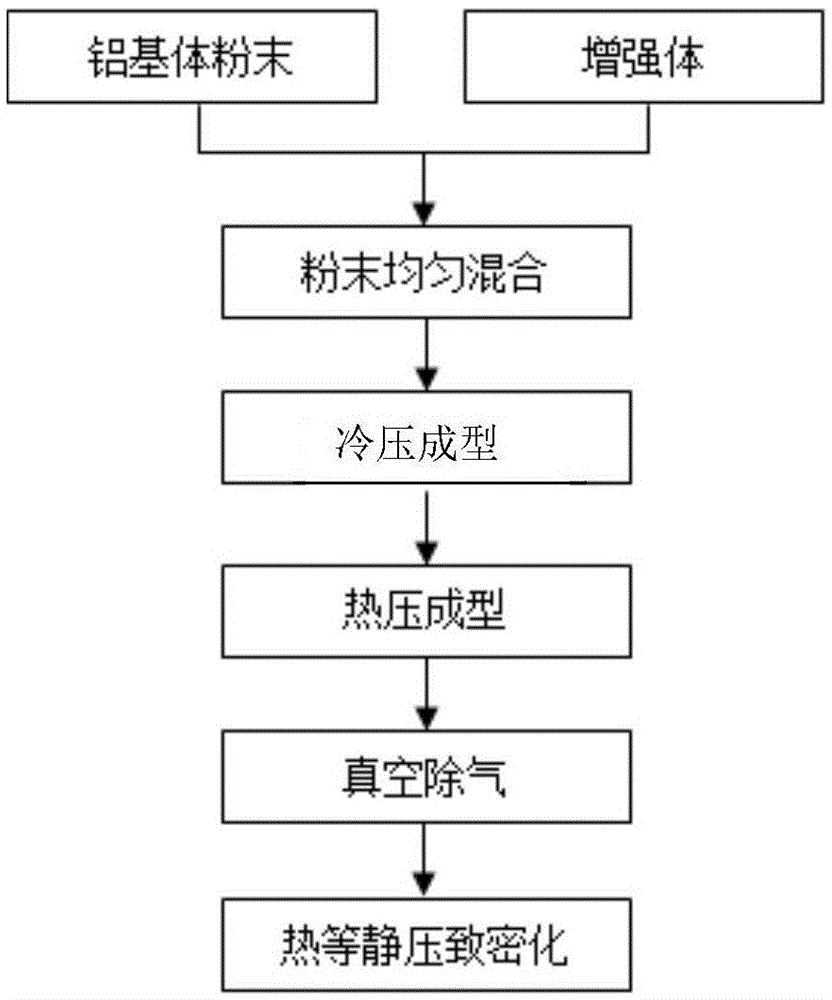

[0026] According to this embodiment figure 2 The preparation process of the layered aluminum-based composite material shown is carried out; the prepared silicon particle-reinforced layered aluminum-based composite material is composed of a 50% Si / Al layer, a 25% Si / Al layer and an Al layer. The preparation method adopts the following technical scheme: (1) uniformly mix silicon powder and aluminum powder according to a certain ratio, and the average particle size of silicon powder and aluminum powder is d 0.5 Both are 5.5μm; 50% Si / Al layer, powder according to mass ratio m Si :m Al = 1:1 mixed, 25% Si / Al layer, powder according to mass ratio m Si :m Al = 1:3 mixing; (2) Encapsulate the mixed powder in a cylindrical steel mold for cold pressing, the pressure is 10MPa, the thickness of each layer is about 3mm, the 50% Si / Al layer is in the upper part, and the 20% Si / Al layer is in the middle , the Al layer is in the lower part; (3) hot-press forming the billet formed by col...

Embodiment 2

[0029] According to this embodiment figure 2 The preparation process of the layered aluminum matrix composite material shown is carried out; the prepared silicon particle reinforced layered aluminum matrix composite material is composed of a 60% Si / Al layer, a 30% Si / Al layer and an Al layer. The preparation method adopts the following technical scheme: (1) uniformly mix silicon powder and aluminum powder according to a certain ratio, and the average particle size of silicon powder and aluminum powder is d 0.5 Both are 3μm; 60% Si / Al layer, powder according to mass ratio m Si :m Al = 3:2 mixed, 30% Si / Al layer, powder according to mass ratio m Si :m Al = 3:7 mixing; (2) Encapsulate the mixed powder in a cylindrical steel mold for cold pressing, the pressure is 10MPa, the thickness of each layer is about 5mm, the 60% Si / Al layer is in the upper part, and the 30% Si / Al layer is in the middle , the Al layer is in the lower part; (3) hot-pressing the cold-pressed billet, prot...

Embodiment 3

[0031] According to this embodiment figure 2 The preparation process of the layered aluminum-based composite material shown is carried out; the prepared silicon carbide particle-reinforced layered aluminum-based composite material is composed of a 70% SiC / Al layer, a 35% SiC / Al layer and an Al layer. The preparation method adopts the following technical scheme: (1) uniformly mix silicon powder and aluminum powder according to a certain ratio, and the average particle size of silicon carbide powder and aluminum powder is d 0.5 Both are 10μm; 70% SiC / Al layer, powder according to mass ratio m Si :m Al = 7:3 mixed, 35% SiC / Al layer, powder according to mass ratio m Si :m Al=7:13 mixing; (2) Encapsulate the mixed powder in a cylindrical steel mold for cold pressing, the pressure is 10MPa, the thickness of each layer is about 10mm, the 70% SiC / Al layer is on the upper part, and the 35% SiC / Al layer is in the middle , the Al layer is in the lower part; (3) hot-press forming the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com