Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Avoid softening and deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

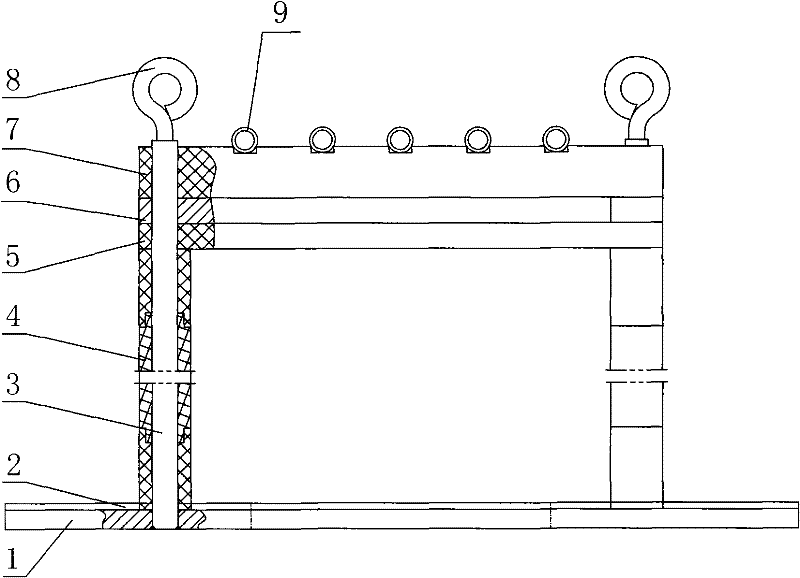

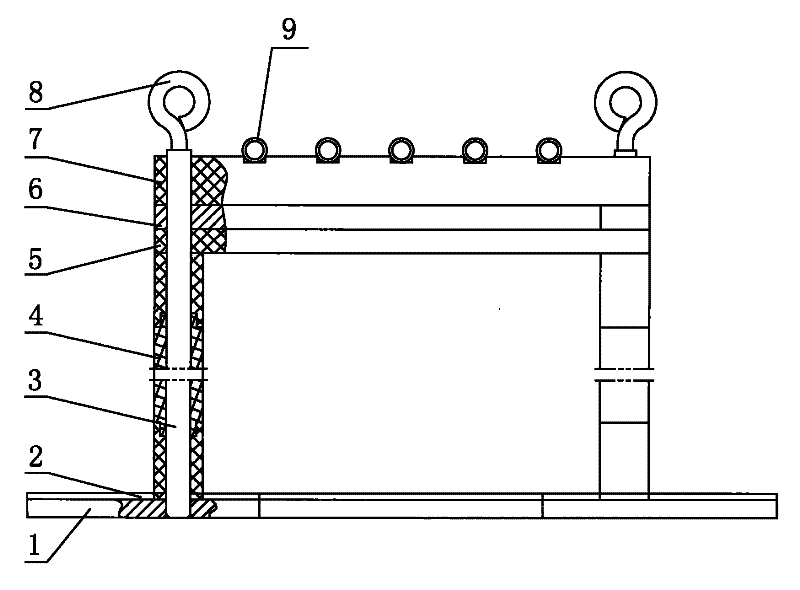

Lost foam casting method for heavy casting

ActiveCN102825215AHigh strengthGood high temperature resistanceFoundry mouldsFoundry coresStationary modelLost-foam casting

The invention discloses a lost foam casting method for a heavy casting. The method comprises the following steps of: a. manufacturing a foam model; b. mounting a counter-deformation bracket: manufacturing the steel-structured counter-deformation bracket according to the size and the length of a workpiece and placing the counter-deformation bracket on the bottom of the foam model; c. painting: the thickness of the paint is not less than 4mm; d. drying: placing the painted foam model in a drying room for drying at the constant temperature of 50 DEG C; e. fixing core: placing the steel-structured bracket in an inner cavity of the foam model so as to fix the model, and putting the whole foam model into a sandbox together; f. boxing: enabling the sandbox containing the foam model to drop sand evenly, vibrating the sandbox during sand dropping, gradually enhancing the vibration amplitude with the increasing of added sand quantity, mounting a main runner and a branch runner of a ceramic tube, and placing a pouring cup; g. pouring: opening a vacuum pump for vacuum pumping before pouring; h. releasing negative pressure: after pouring, keeping the negative pressure for 8 to 15 minutes until solidification of an iron liquid, and then releasing the negative pressure; and i. cleaning.

Owner:东莞市巨高机床有限公司

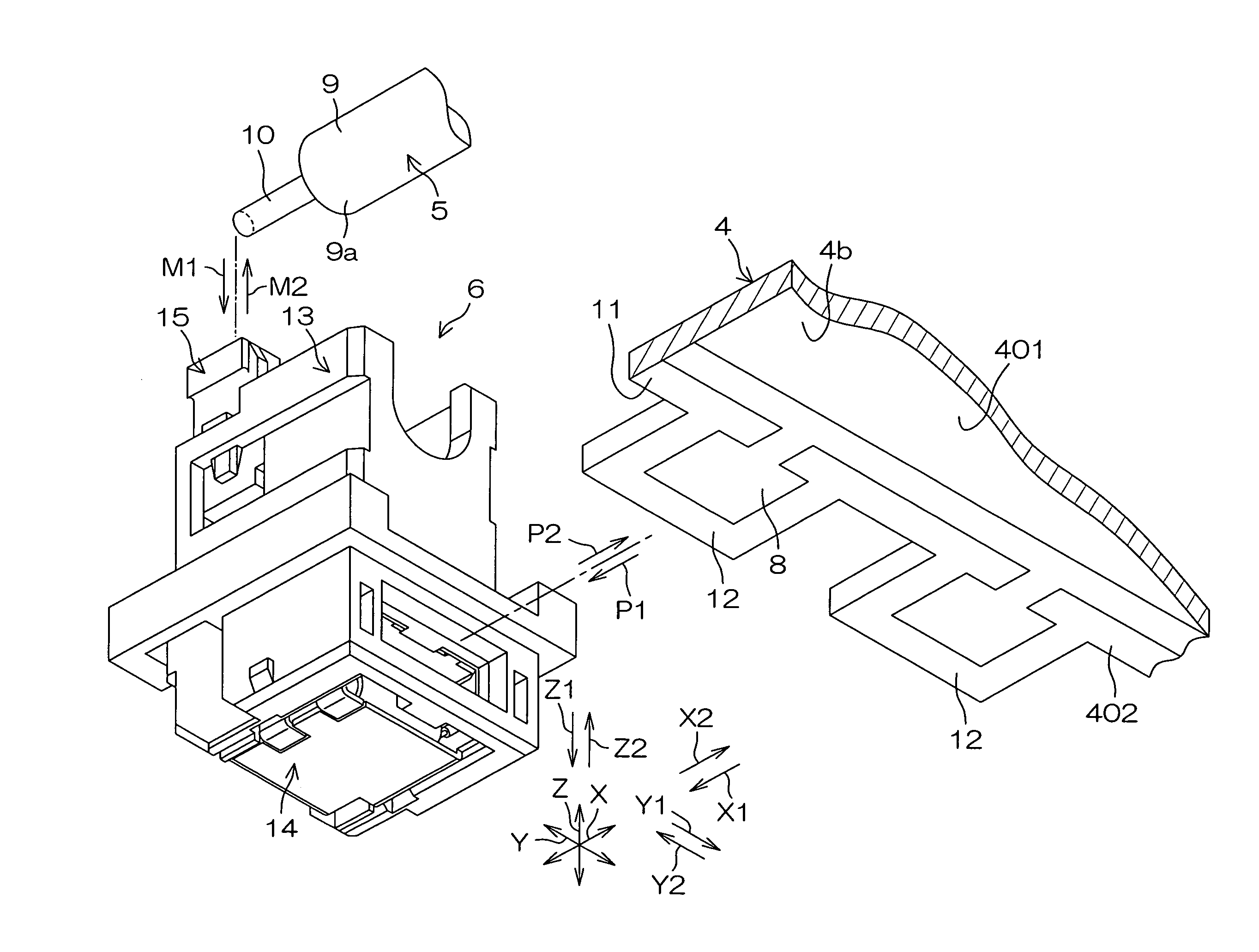

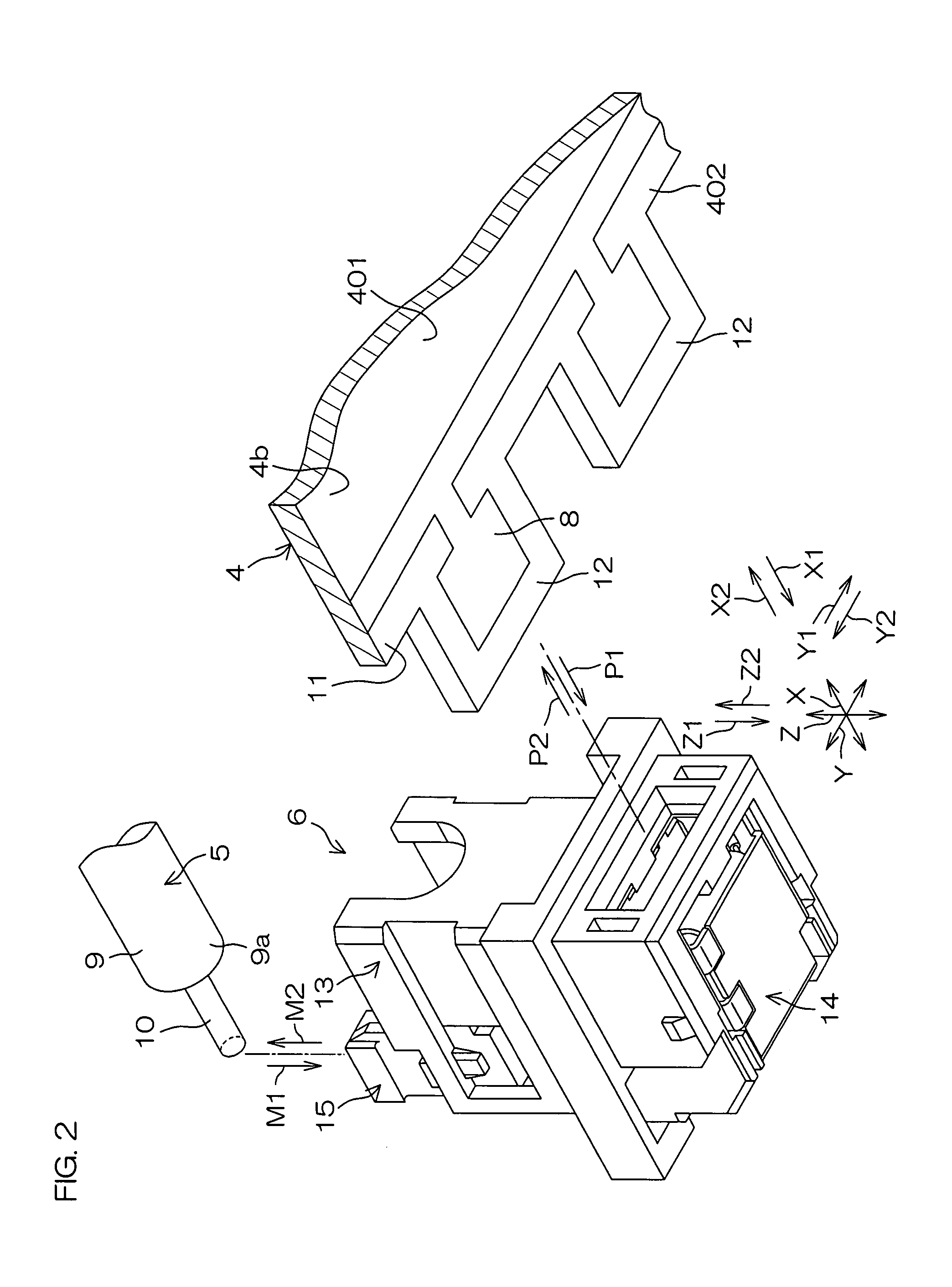

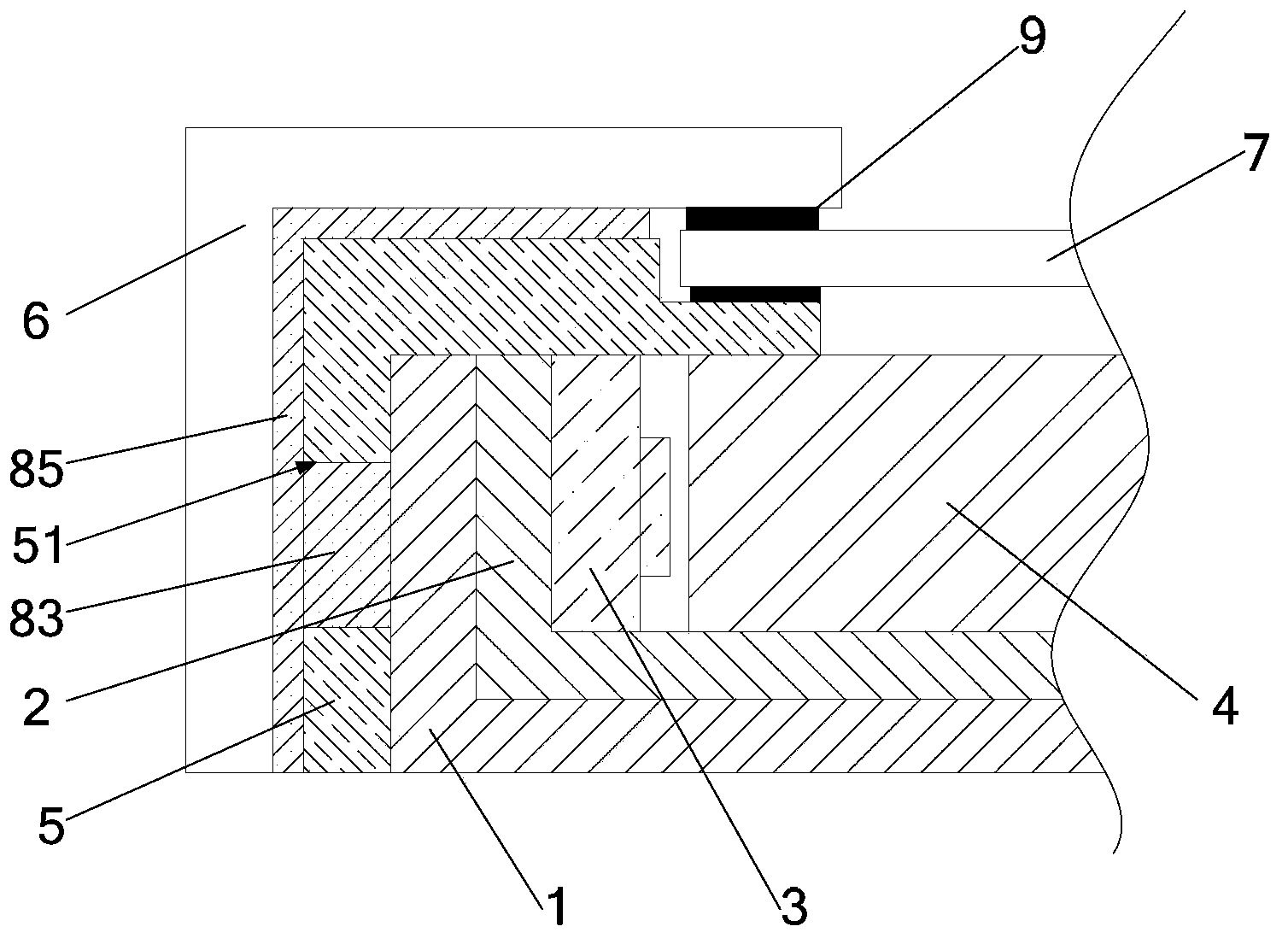

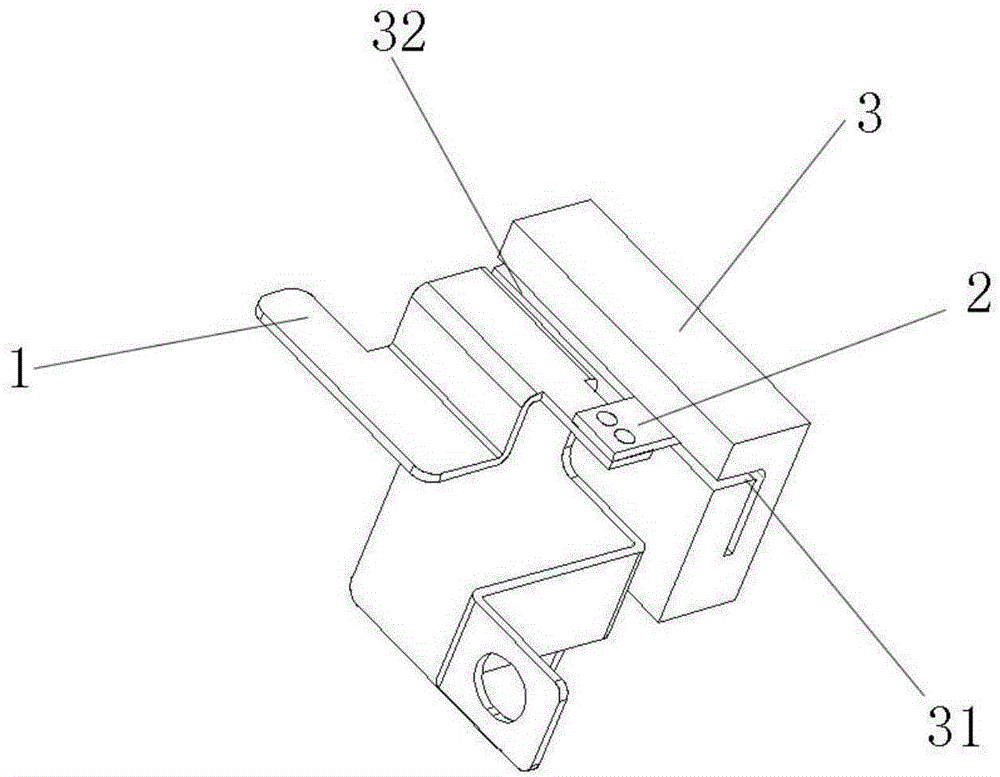

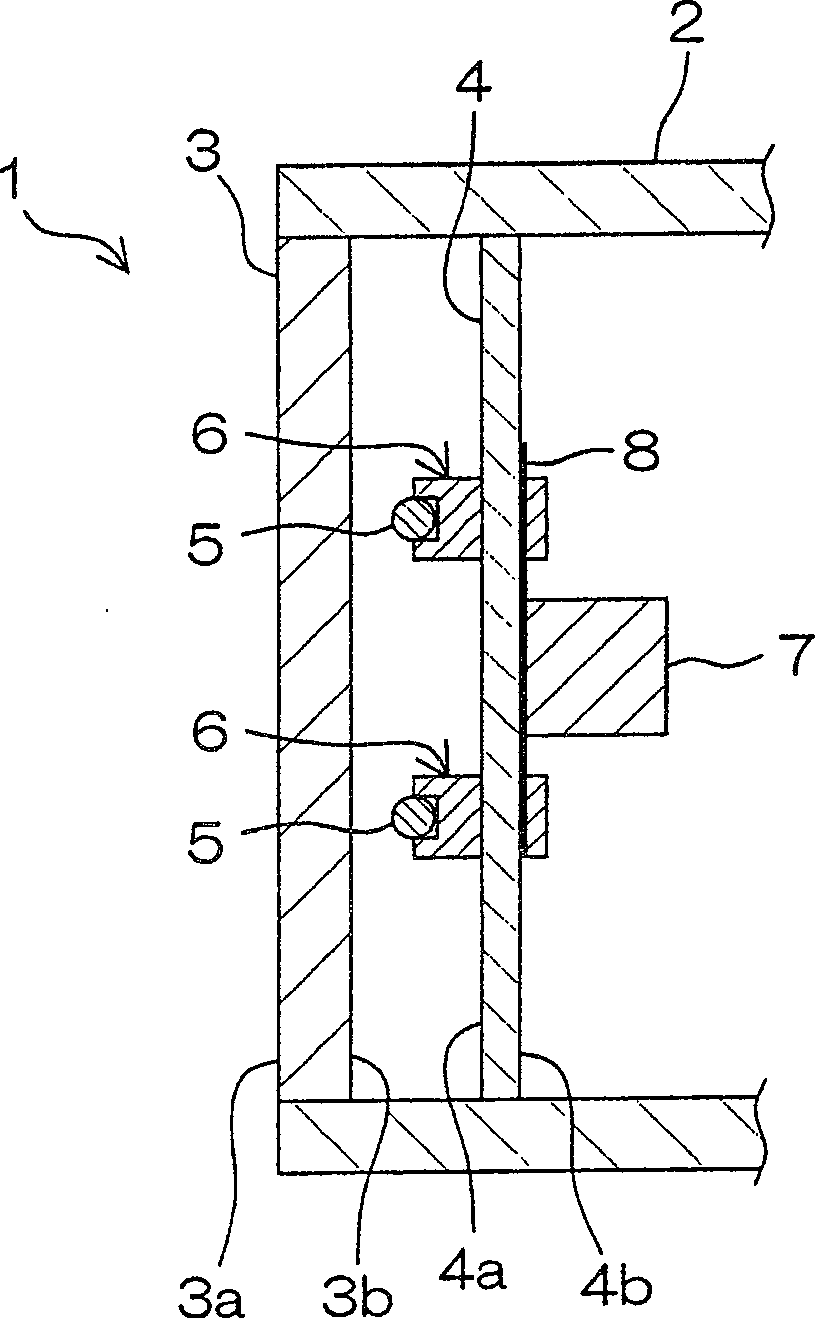

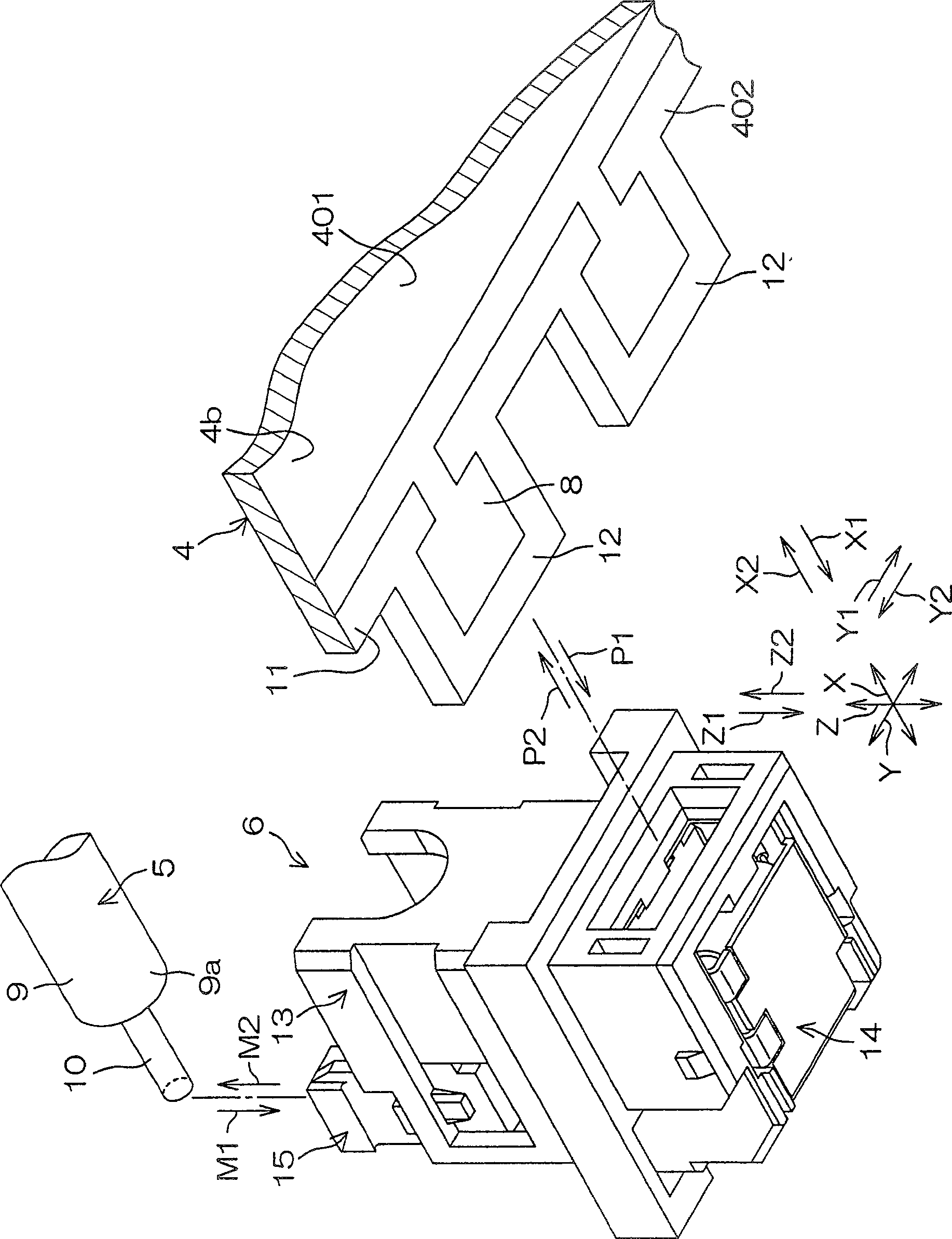

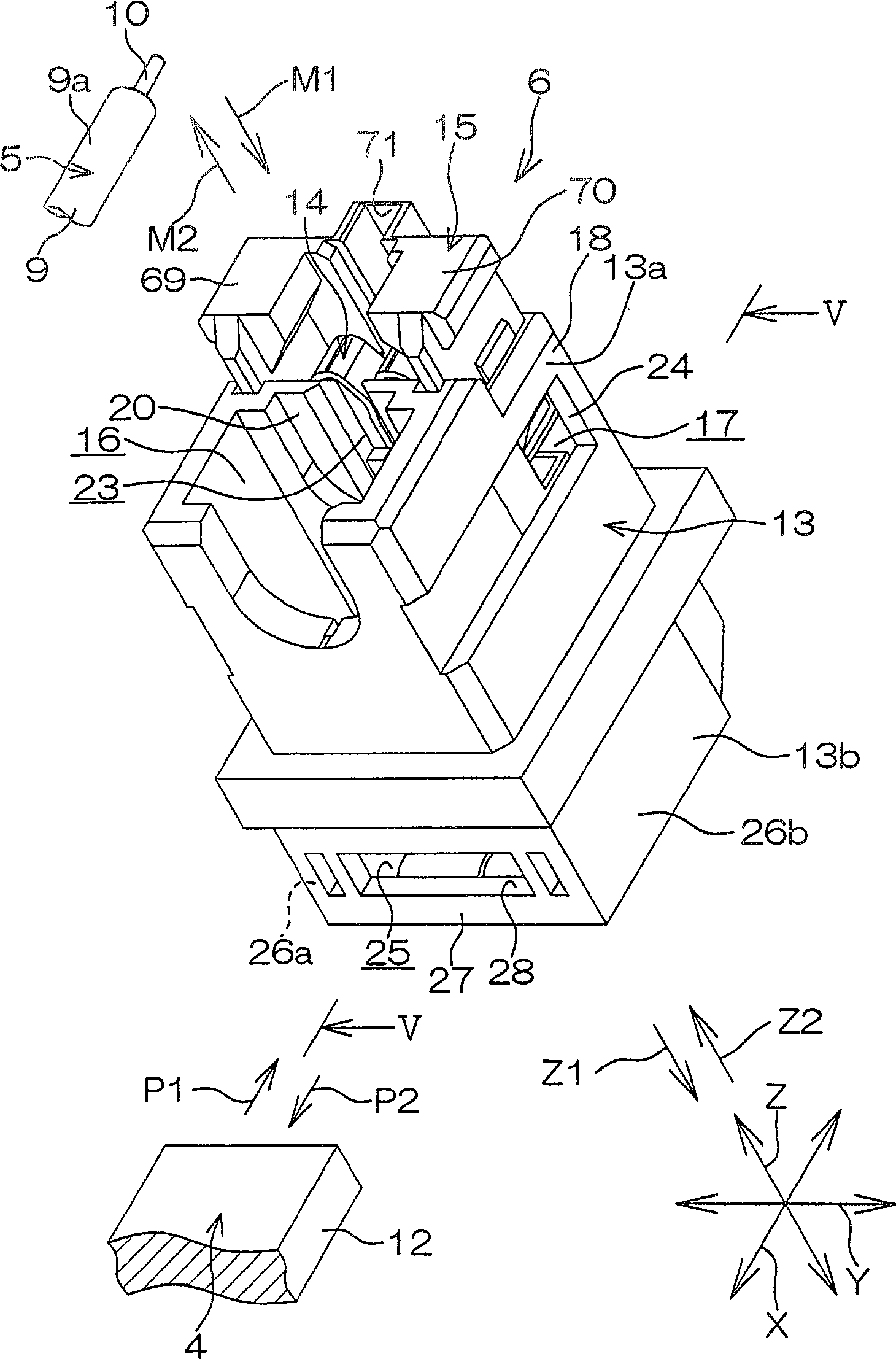

Electric connector and connection structure for electric connector

InactiveUS20080207063A1Prevent be soften and deformStably maintainCoupling contact membersTwo-part coupling devicesEngineeringMechanical engineering

An electric connector to be attached to a plate-like connection member having an edge portion, a plurality of insertion convex portions formed sideways at the edge portion, and a conductive portion formed on at least one of the front surface and the back surface of each insertion convex portion includes an insulating housing and a contact forming member made of a metal and held in the housing. The contact forming member includes a box-like portion having four walls and a connection member connecting contact extended from at least one of the walls of the box-like portion. The four walls define an insertion concave portion into which the insertion convex portion corresponding thereto is inserted along a predetermined insertion direction. The connection member connecting contact includes a contact portion that makes contact with the conductive portion of the corresponding insertion convex portion inserted into the insertion concave portion.

Owner:JST MFG CO LTD

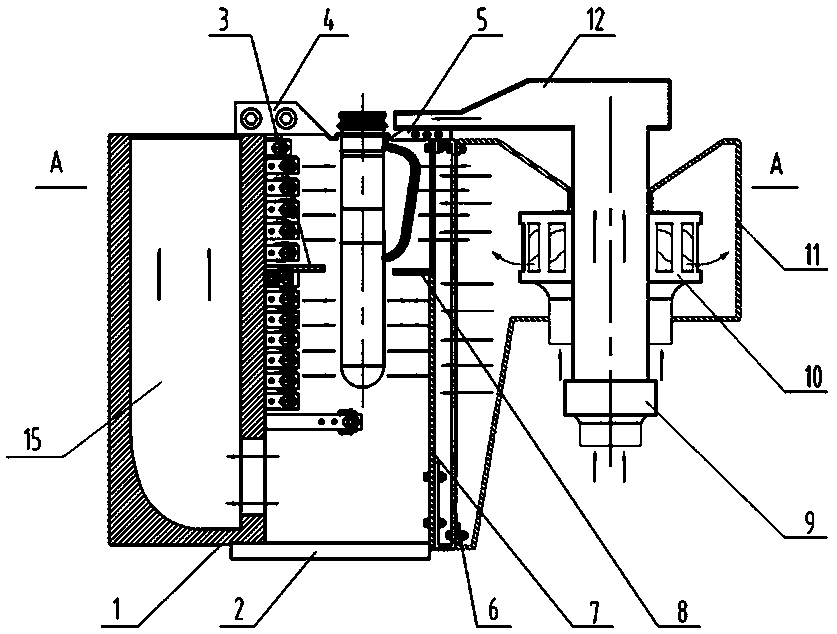

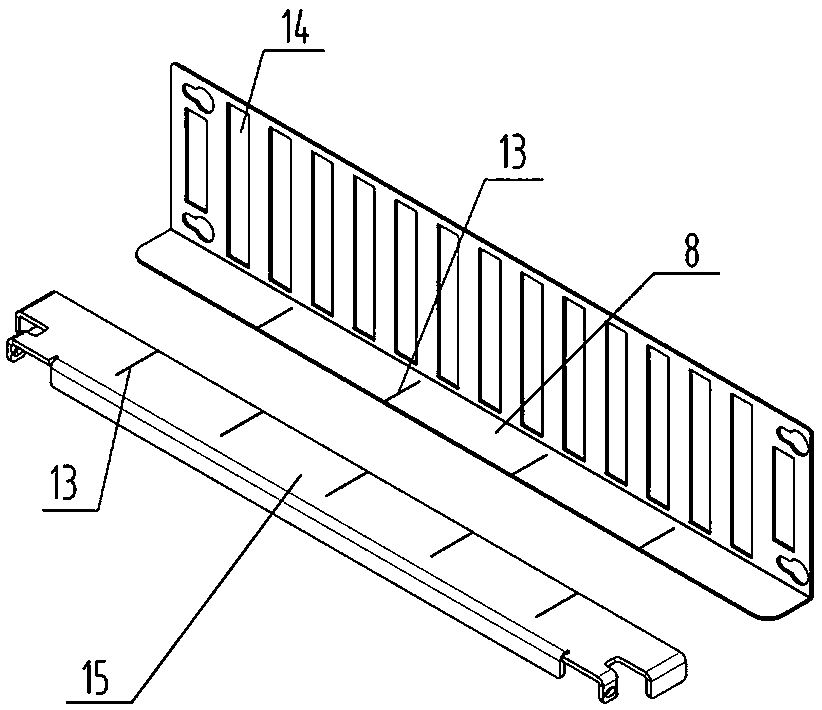

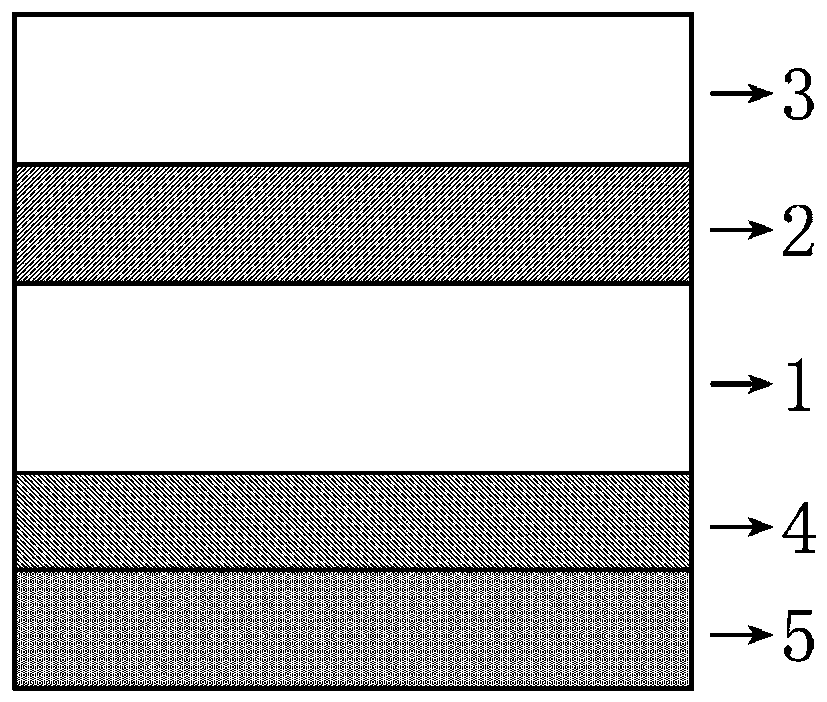

Sidelight type liquid crystal module, direct type liquid crystal module and television

InactiveCN103439831ASimple structureImprove cooling effectTelevision system detailsLighting heating/cooling arrangementsLuminosityEngineering

The invention provides a sidelight type liquid crystal module, a direct type liquid crystal module and a television. The sidelight type liquid crystal module comprises a back plate, a heat radiation plate, a lamp strip, a rubber frame and a surface frame, wherein the heat radiation plate is mounted on the back plate; the lamp strip is mounted on the side face of the heat radiation plate; the rubber frame and the back plate are fixedly connected; the surface frame and the rubber frame are fixedly connected; the sidelight type liquid crystal module further comprises a heat-conduction sheet; one side of the heat-conduction sheet is connected with the lamp strip, the heat radiation plate and / or the back plate and the other side of the heat-conduction sheet is connected with the rubber frame and / or the surface frame; the heat generated by the lamp strip can be transmitted to the surface frame. The liquid crystal module provided by the invention is simple in structure; the liquid crystal module is internally provided with the heat-conduction sheet so that the heat generated by the lamp strip can be simultaneously dissipated from the back plate and the surface frame; the heat radiation effect is effectively enhanced, the luminosity of the lamp strip is improved and the service life of the lamp strip is prolonged; the quality of a picture displayed by the liquid crystal module is ensured; and furthermore, the picture quality of the television is ensured.

Owner:HISENSE VISUAL TECH CO LTD

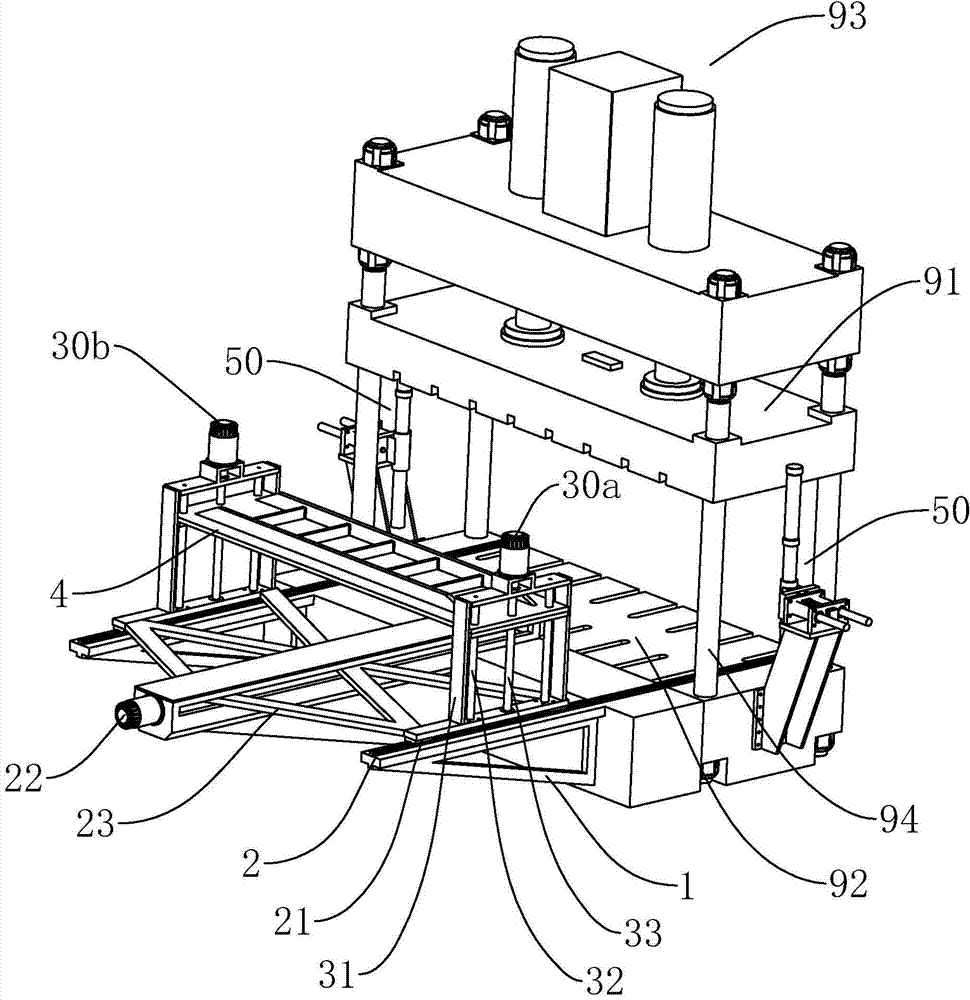

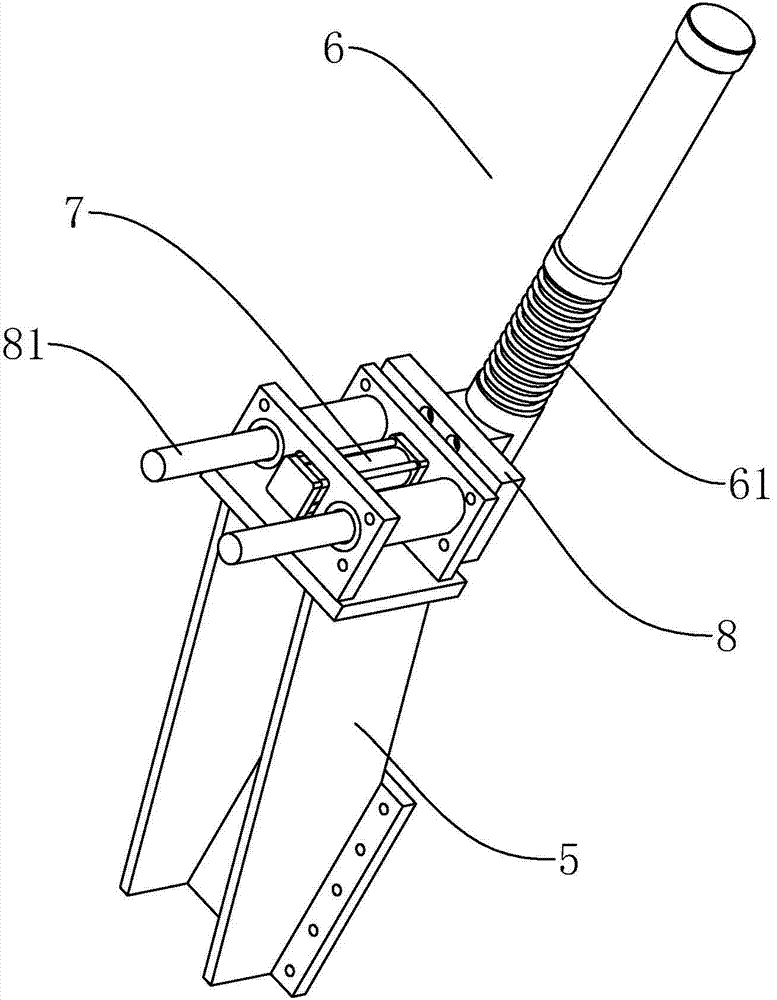

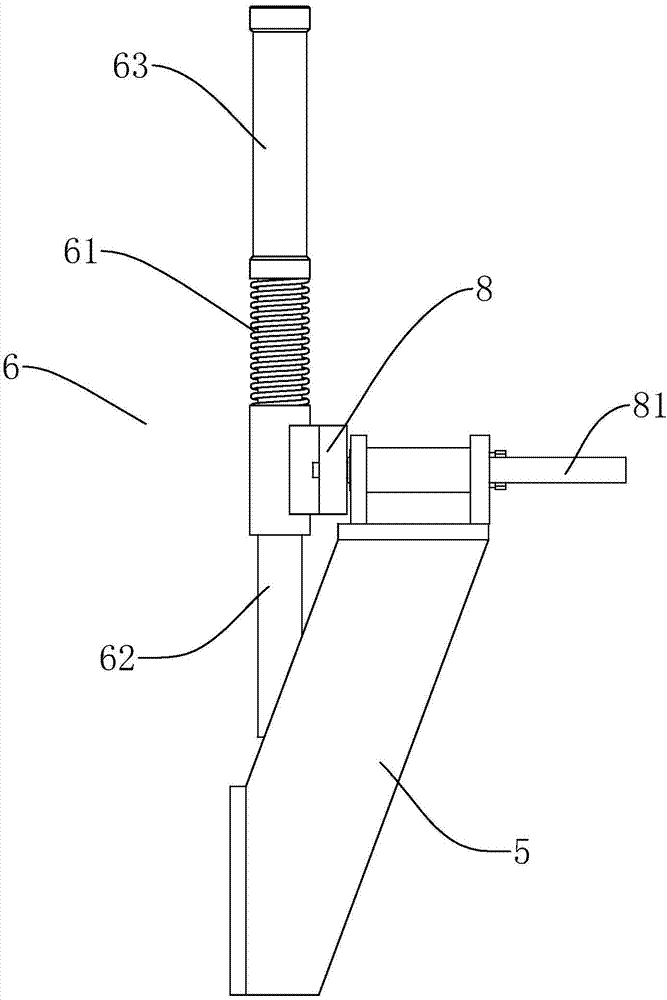

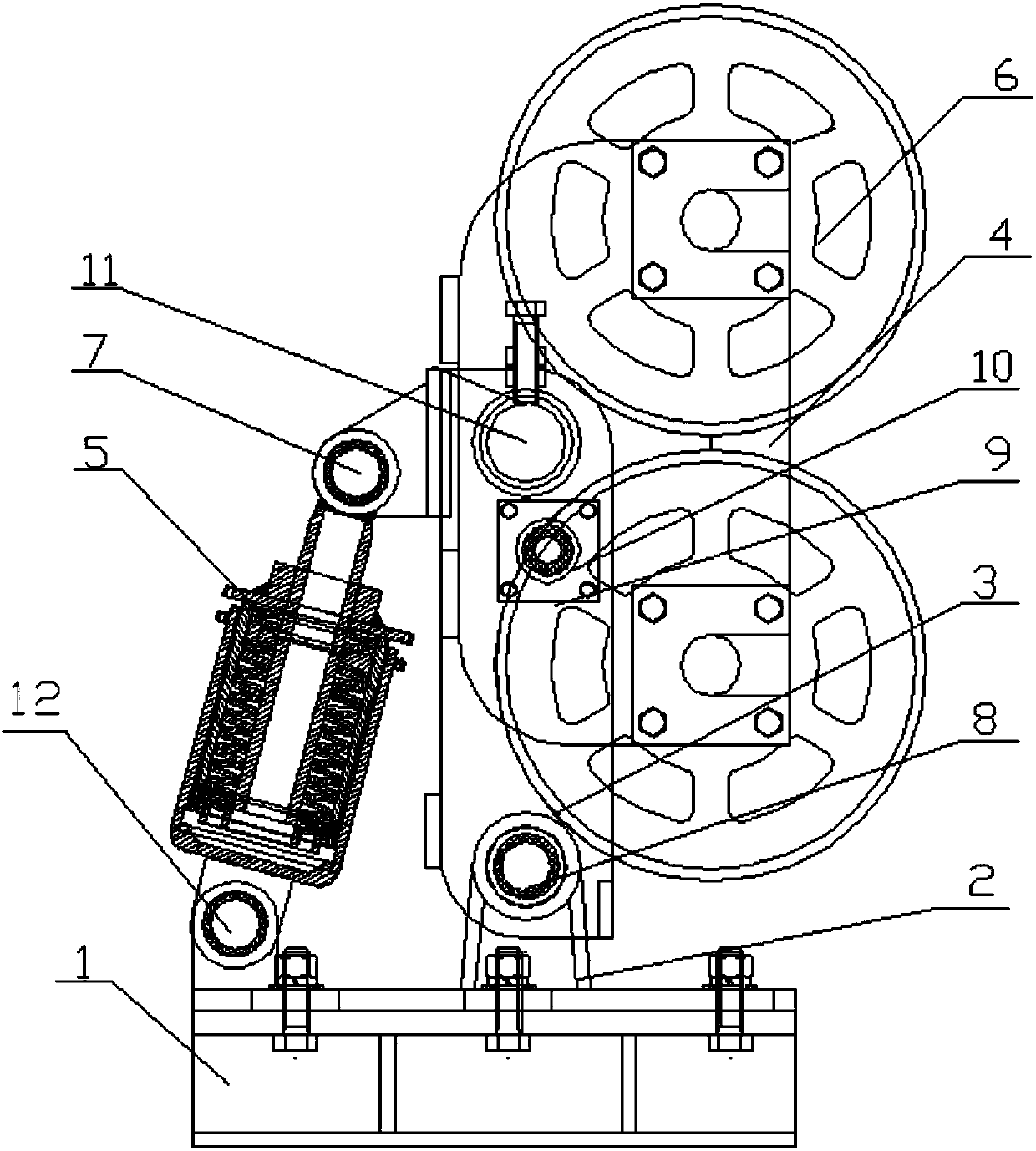

Efficient and safe oil press with preheating function

InactiveCN104841748AImprove work efficiencyImprove securityShaping toolsMetal-working feeding devicesSupporting systemPunching

The invention discloses an efficient and safe oil press with a preheating function. The efficient and safe oil press comprises a rack, a hydraulic system, uprights, an upper pressing plate, a lower pressing plate, a safe supporting system and a preheating system. The safe supporting system comprises a support, a moving device and supporting rods, and the preheating system comprises a transverse moving device, an up-down moving device and a heating device. During working, a workpiece is placed on the heating device for preheating, the heating device is moved to space above a lower die through the transverse moving device, and the workpiece is accurately placed on the lower die through the up-down moving device, so that the workpiece is effectively avoided softening and deforming after being heated, punching quality is improved, and working efficiency of the oil press is improved; when punching is completed, the upper pressing plate is moved to set height, the moving device disposes the supporting rod between the upper pressing plate and the lower pressing plate so as to play a role in supporting the upper pressing plate and the lower pressing plate, so that the circumstance that working personnel is pressed and injured due to the fact that the upper pressing plate accidentally falls down is prevented, and safety and reliability of the oil press are improved.

Owner:中山市八达机器制造有限公司

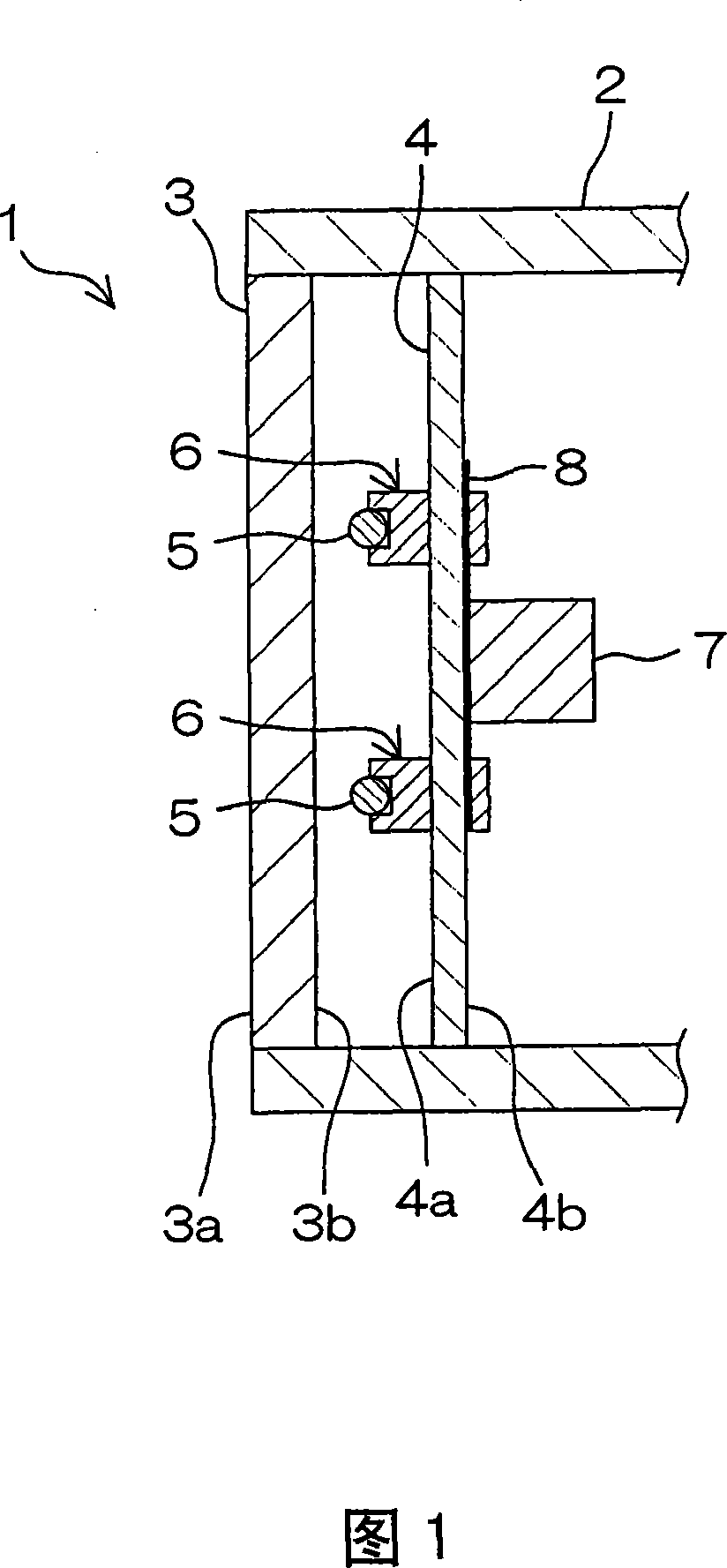

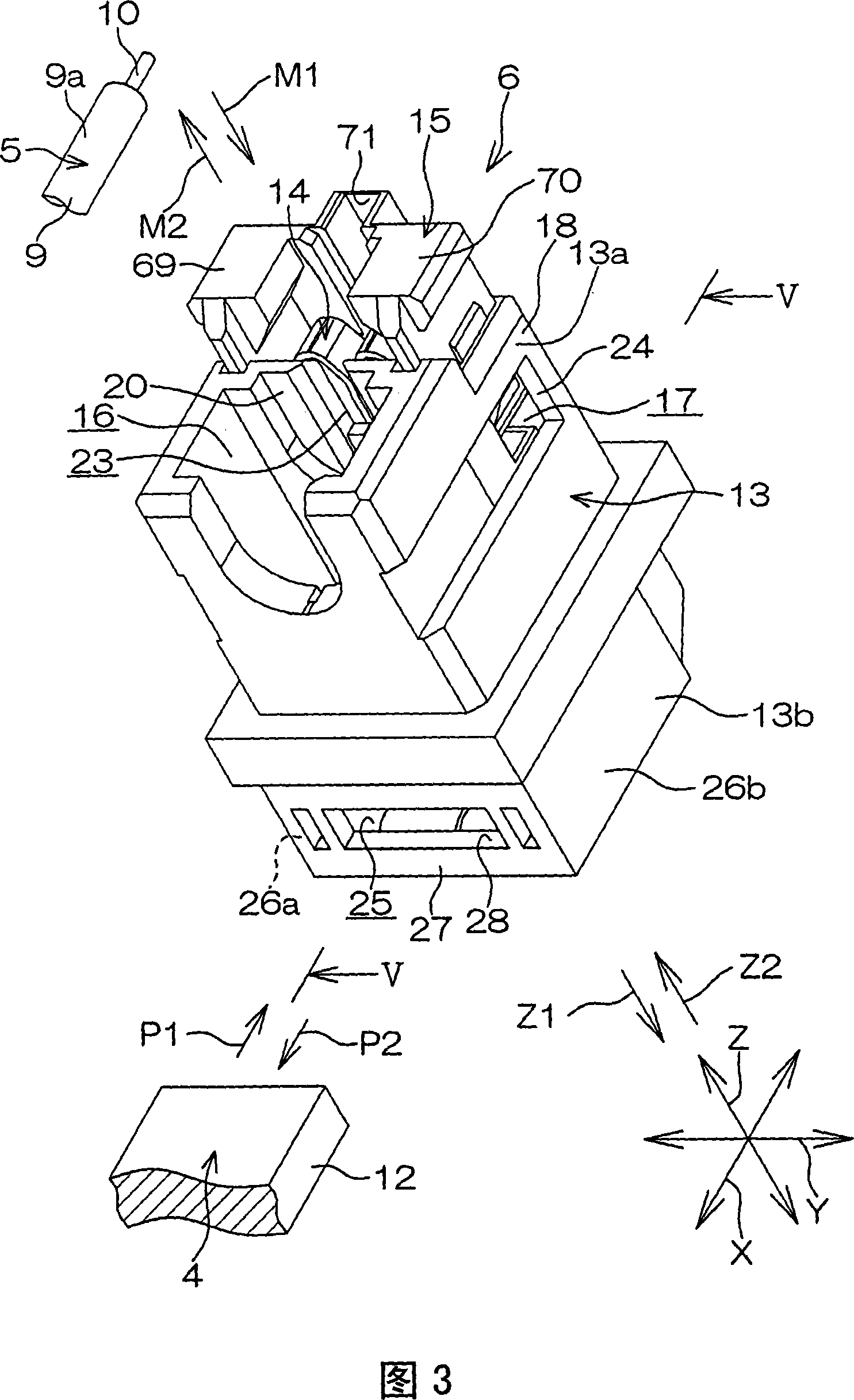

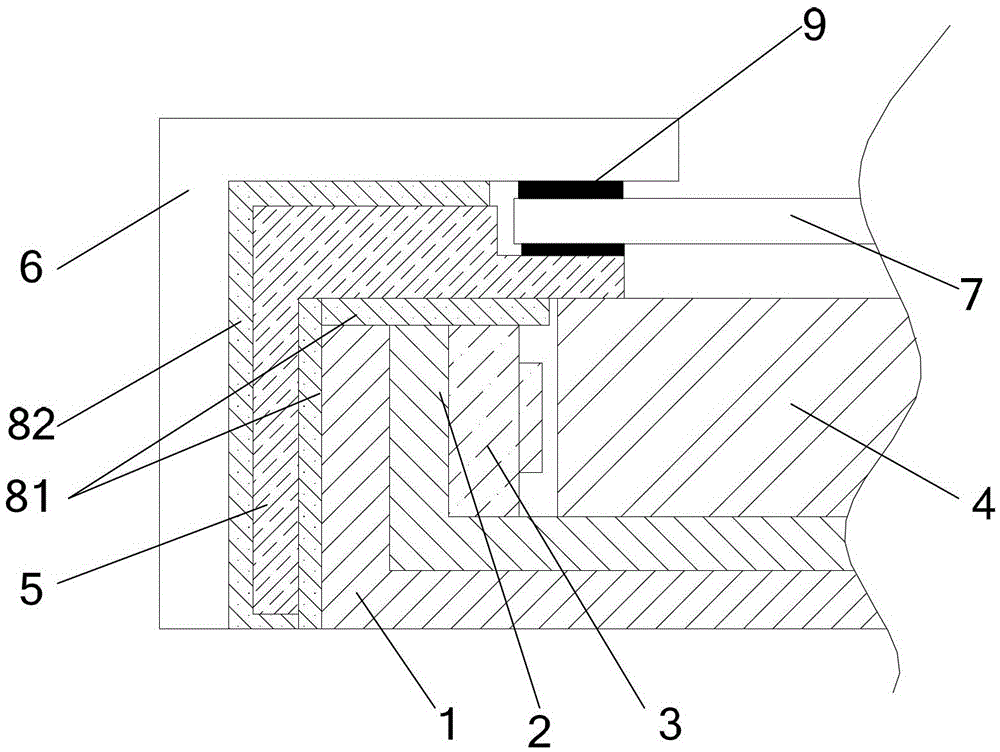

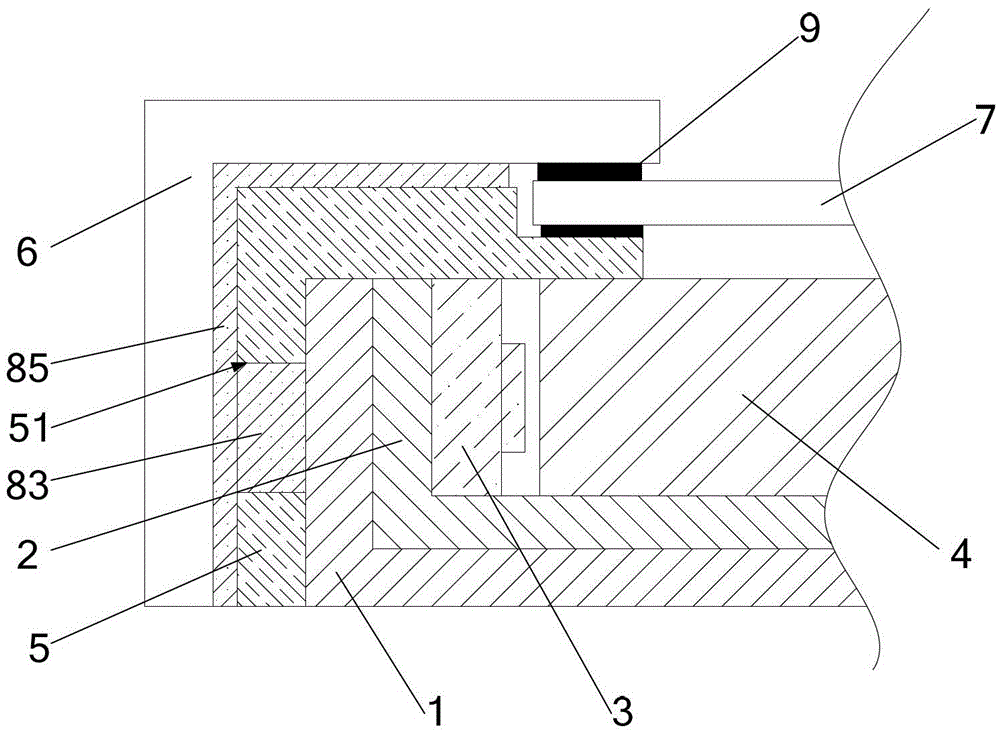

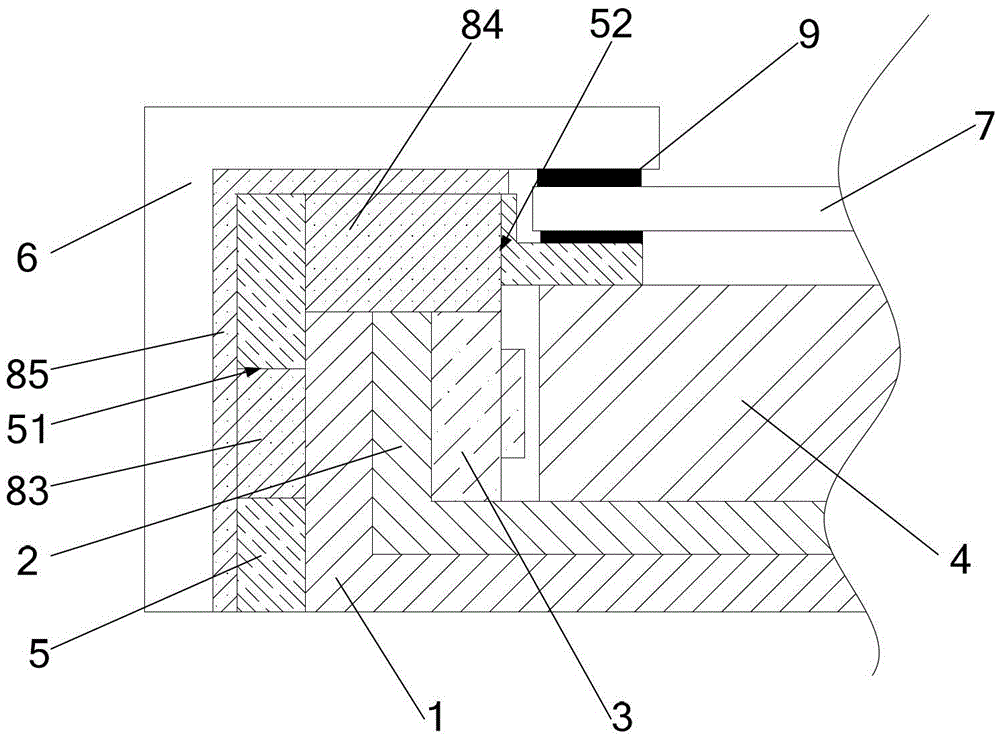

Electric connector and connection structure for electric connector

InactiveCN101098058AAvoid softening and deformationContact pressure is maintained stablyElectrical apparatusMechanical engineeringEngineering

An electric connector (6) to be attached to a plate-like connection member (4; 100) having an edge portion (402; 102), a plurality of insertion convex portions (12; 103) formed sideways at the edge portion (402; 102), and a conductive portion (8; 8B; 103a, 103b) formed on at least one of the front surface (4a; 103a). The back surface (4b; 103b) of each insertion convex portion (12; 103) includes an insulating housing (13) and a contact forming member (14; 14A; 14B; 14B'; 14C; 14C'; 14D; 14E; 14F; 14G; 14H; 14J) made of a metal and held in the housing (13). The contact forming member (14; 14A; 14B; 14B'; 14C; 14C'; 14D; 14E; 14F; 14G; 14H; 14J) includes a box-like portion (33; 33D) having four.walls (41, 42, 43, 44; 41D, 42D, 43D, 44D) and a connection member connecting contact (34; 34B) extended from at least one of the walls of the box-like portion (33; 33D). The four walls (41, 42, 43, 44; 41D, 42D, 43D, 44D) define an insertion concave portion (45) into which the insertion convex portion (12; 103) corresponding thereto is inserted along a predetermined insertion direction (P1). The connection member connecting contact (34; 34B) includes a contact portion (475; 475A; 475B; 475C; 475D; 475E; 475F; 475G; 475J) that makes contact with the conductive portion (8; 8B; 103a, 103b) of the corresponding insertion convex portion (12; 103) inserted into the insertion concave portion (45).

Owner:JST MFG CO LTD

Electric connector for interconnecting at least one fluorescent lamp and a circuit board and connection structure for same

InactiveUS7591695B2Avoid softening and deformationMaintain relatively stableCoupling contact membersTwo-part coupling devicesContact formationEngineering

An electric connector to be attached to a plate-like connection member having an edge portion, a plurality of insertion convex portions formed sideways at the edge portion, and a conductive portion formed on at least one of the front surface and the back surface of each insertion convex portion includes an insulating housing and a contact forming member made of a metal and held in the housing. The contact forming member includes a box-like portion having four walls and a connection member connecting contact extended from at least one of the walls of the box-like portion. The four walls define an insertion concave portion into which the insertion convex portion corresponding thereto is inserted along a predetermined insertion direction. The connection member connecting contact includes a contact portion that makes contact with the conductive portion of the corresponding insertion convex portion inserted into the insertion concave portion.

Owner:JST MFG CO LTD

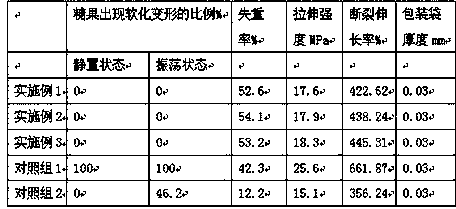

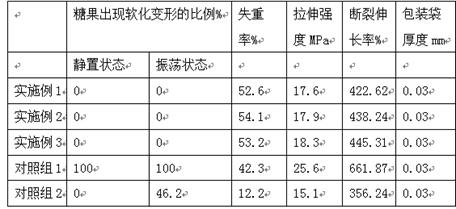

Environment-friendly and degradable thermal insulation food packaging bag

ActiveCN110791004AGood heat insulationAvoid softening and deformationFlexible coversWrappersFood packagingPolyvinyl alcohol

The invention discloses an environment-friendly and degradable thermal insulation food packaging bag. A preparation method comprises the following steps that (1) a modified silica sol is prepared; (2)a prepared titanium dioxide sol is added to the modified silica sol to obtain a composite sol; (3) the composite sol is sprayed on the surface of a substrate, after drying, cyclic heat treatment is performed, and a coating is removed after cooling and pulverized and ground to obtain composite powder; (4) sodium periodate is added into a sodium alginate solution, and a light avoiding reaction is performed to obtain modified sodium alginate; and (5) polyvinyl alcohol is dissolved and then added with the modified sodium alginate for reaction, an obtained product and the composite powder are added into molten polyethylene, then citric acid, calcium stearate and talc are added, and processing is performed to obtain the required packaging bag. The food packaging bag has an excellent thermal insulation effect, can effectively avoid softening and deformation of candy, has good biodegradability, can achieve complete degradation, meets the environmental protection requirements and is easy to popularize and apply.

Owner:安徽天路新材料股份有限公司

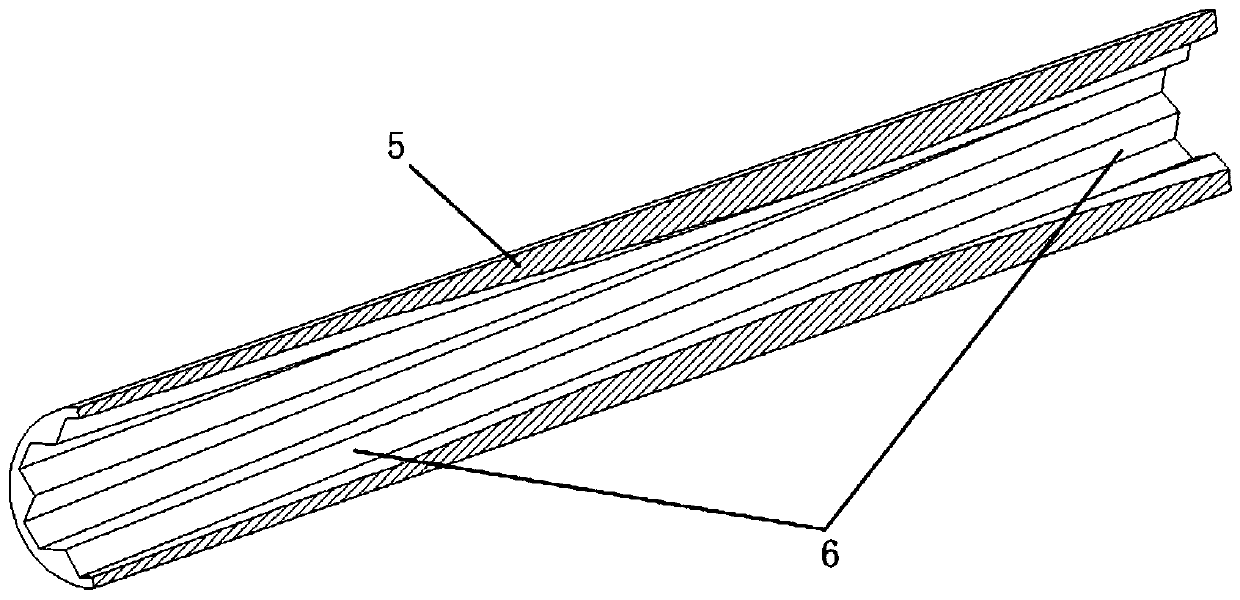

Welding method of composite copper bar conducting layer, and composite copper bar

ActiveCN104319010AReduce hardnessReduce intensitySingle bars/rods/wires/strips conductorsSoldering apparatusBar productHardness

The invention relates to a welding method of a composite copper bar conducting layer. A welding part of a lead workpiece is positioned on a mounting part of a copper bar substrate by a positioning structure, so that next welding is facilitated. After positioning, a resistance soldering technology instead of chamfering is adopted, so that the mounting part can be arranged in any position of the copper bar substrate, the lead workpiece can be welded on the mounting part, a complicated composite copper bar product comprising a small forming part structure is obtained, and the welding strength and the connection reliability are improved. A non-welding part of the lead workpiece is placed in a heat-dissipation mold, so that heat of the non-welding part of the lead workpiece conducted by welding can be dissipated by the heat-dissipation mold, the non-welding part of the lead workpiece can avoid softening deformation and hardness and strength reduction due to overheating, the hardness and the strength of the non-welding part are ensured, and torsion resistance of riveting a nut in a non-welding area is ensured. In addition, the invention further relates to a composite copper bar.

Owner:浙江冠华电气有限公司

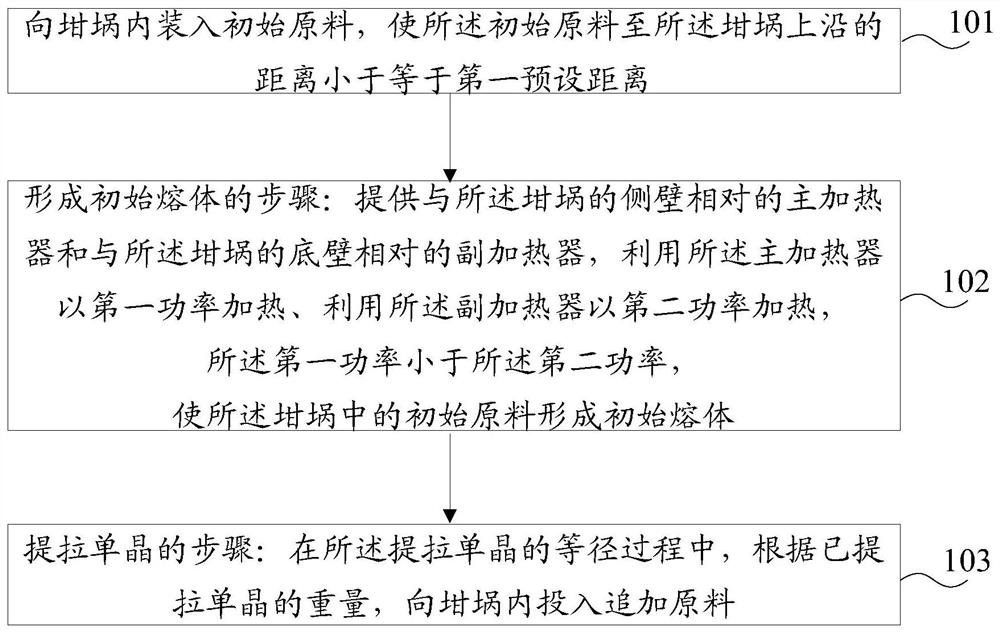

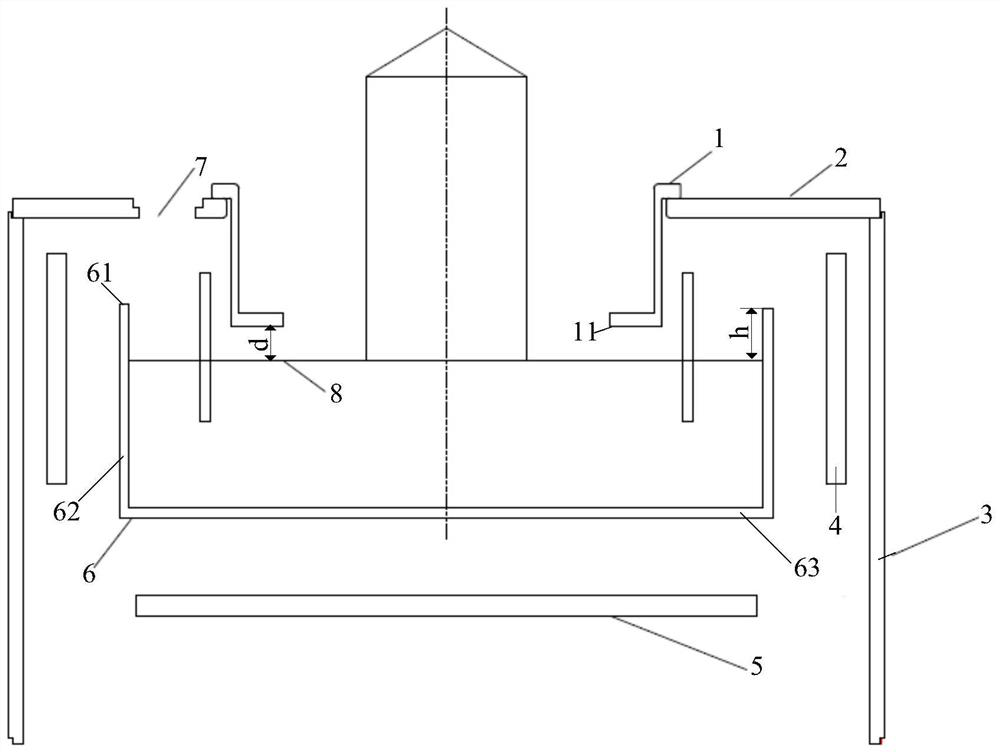

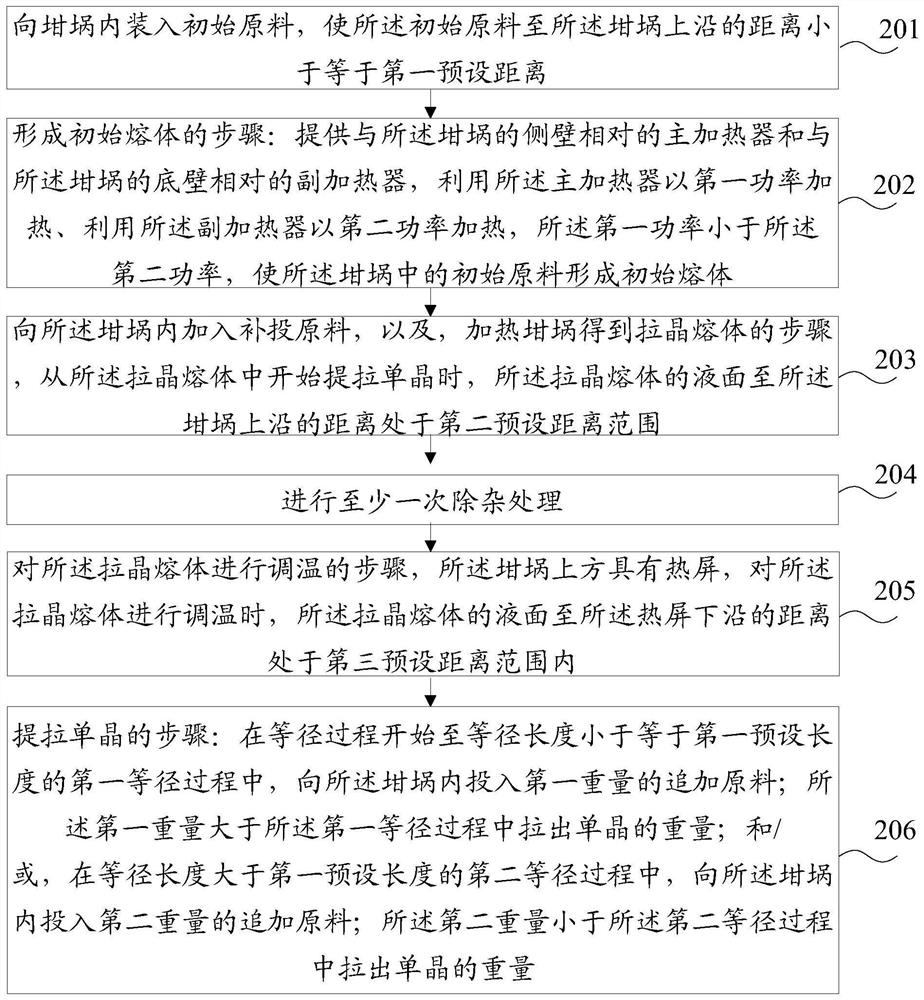

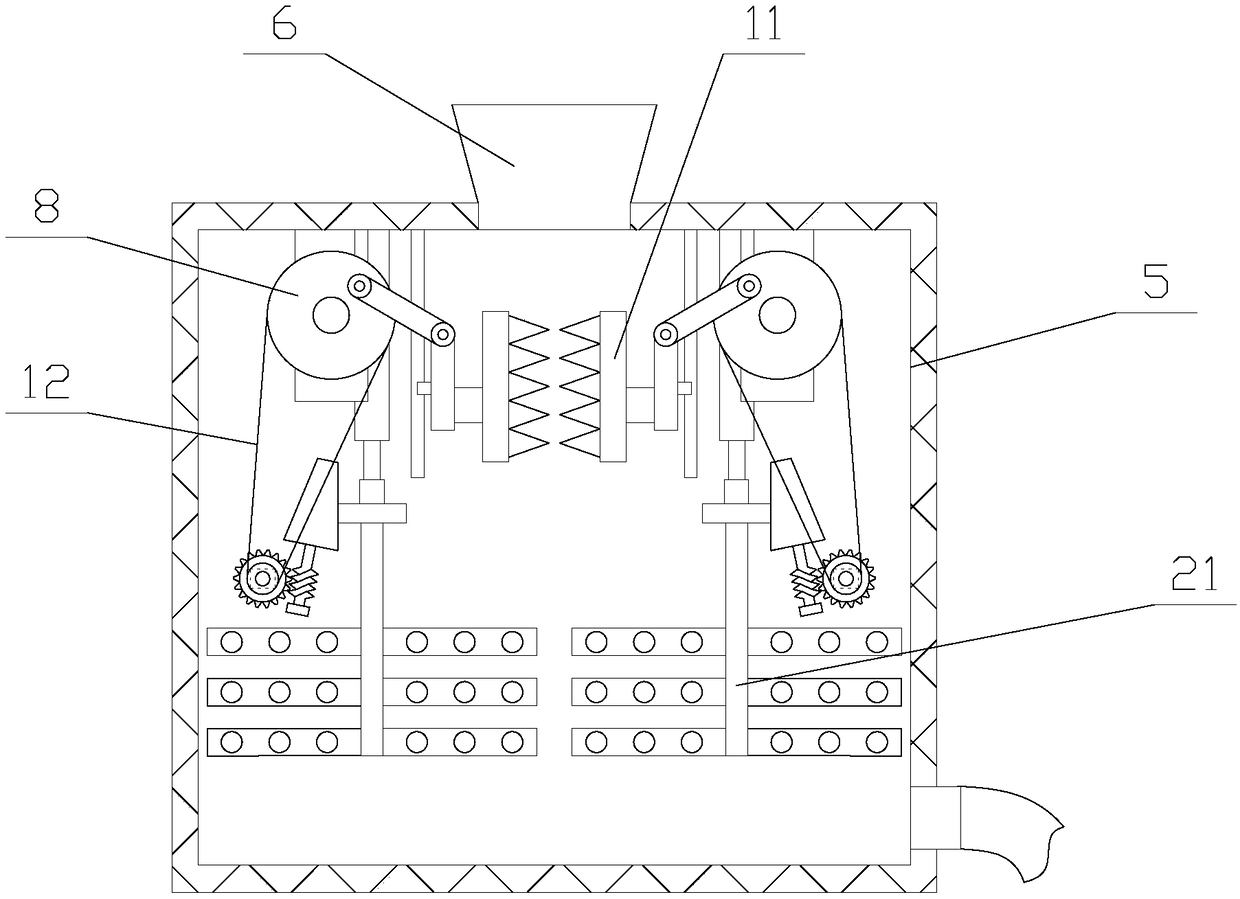

Crystal pulling method, single crystal furnace and computer readable storage medium

ActiveCN112095141AAvoid softening and deformationSmall temperature fluctuationsPolycrystalline material growthBy pulling from meltThermodynamicsCrucible

The invention provides a crystal pulling method, a single crystal furnace and a computer readable storage medium, and relates to the technical field of solar photovoltaics. The method comprises the steps that loading an initial raw material into a crucible, wherein the distance between the initial raw material and the upper edge of the crucible is made to be smaller than or equal to a first presetdistance; forming an initial melt: providing a main heater opposite to the side wall of the crucible and an auxiliary heater opposite to the bottom wall of the crucible, heating at a first power by using the main heater, heating at a second power by using the auxiliary heater, the first power being smaller than the second power, and enabling the initial raw material in the crucible to form an initial melt; and pulling the single crystal: in the isodiametric process of pulling the single crystal, adding an additional raw material into the crucible according to the weight of the pulled single crystal. The side wall of the crucible which does not contain the initial raw materials is prevented from being deformed by dry baking, the deformation of the side wall of the crucible caused by overhigh heating power of the main heater is avoided, the temperature fluctuation is small, and crystal pulling is facilitated.

Owner:NINGXIA LONGI SILICON MATERIALS

3D printer for chocolate shaping based on Internet of things

The invention relates to a 3D printer for chocolate shaping based on Internet of things. The 3D printer comprises a main body, a platform, a moving arm and a spray nozzle, and also comprises a processing mechanism and a temperature lowering mechanism, wherein the processing mechanism comprises a heating chamber and two processing assemblies; each processing assembly comprises a crushing assembly and a stirring assembly; the temperature lowering mechanism also comprises an ascending and descending assembly and an air blowing assembly. The 3D printer for chocolate shaping based on Internet of things has the advantages that through the processing mechanism, the solid chocolate can be crushed and stirred, so that the chocolate pulp fusion and mixing effect is better; the mouthfeel is the chocolate is improved; in addition, the 3D printer is applicable to solid and liquid state chocolate; the stirring effect is better; through the temperature lowering mechanism, the uniform heat radiation is realized on different height of a printed article, so that the chocolate pulp is shaped after being cooled; the collapse and fracture of the printed articles due to substrate softening deformation are avoided; the printing time is saved; the printing work effect is improved; the practicability and the reliability of the 3D printing equipment are greatly improved.

Owner:深圳市中科智诚科技有限公司

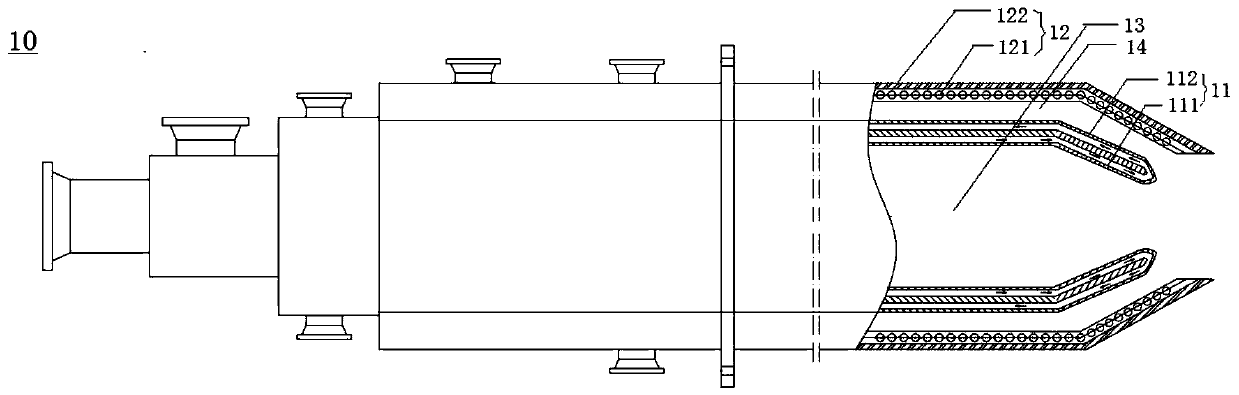

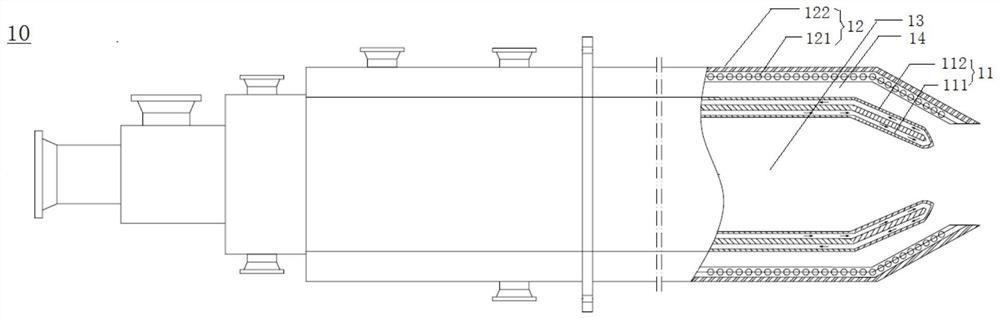

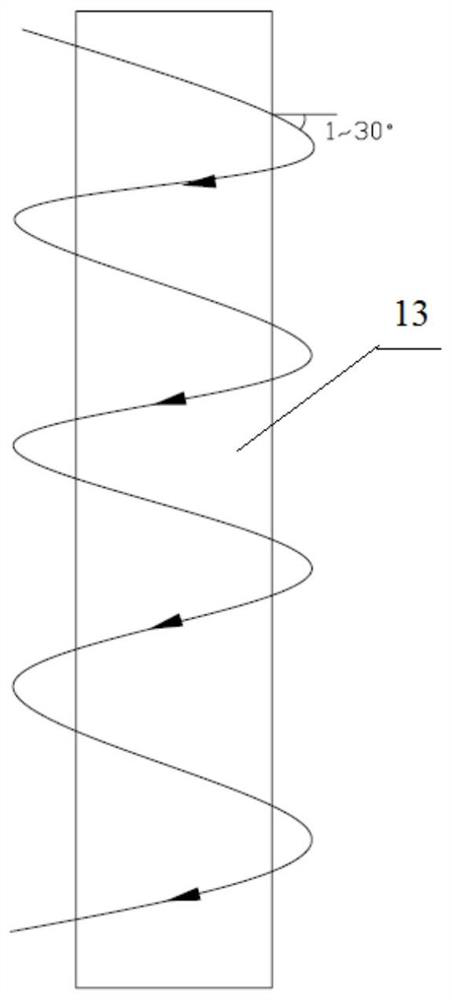

Combustion system and burner

ActiveCN110577846AAvoid softening and deformationSolve the burning problemCombustible gas productionCombustion systemCombustion

The invention belongs to the field of coal gasification combustion, and relates to a combustion system and a burner. The combustion system comprises a control system, the burner and a gasification furnace which are connected in sequence, wherein the burner comprises a cooling water jacket and an outer sleeve; the cooling water jacket is of an annular cavity structure and is arranged in the outer sleeve; the first outer wall of the cooling water jacket forms a central channel of the burner; and the second outer wall of the cooling water jacket and the inner wall of the outer sleeve form a nitrogen channel. According to the invention, the burner with a special structure and the wall of the gasification furnace are oppositely arranged at an angle of 17-20 degrees, and the rotational flow angle of the air supply outlet of the burner is controlled to be 1-30 degrees, so the problems of deviated combustion, channeling and the like of the gasification furnace can be effectively avoided.

Owner:杨建平

Waste plastic regenerated environment-friendly particles and production process thereof

InactiveCN111825997AStrong weather resistanceHighly corrosivePolishing machinesGrinding drivesPhysical chemistryLimiting oxygen index

The invention discloses waste plastic regenerated environment-friendly particles and a production process thereof. According to the process, poly-3, 5- diamino-1H-pyrazole-4-carboxylic acid allyl ester and 2, 3, 5, 6-tetrafluoroterephthalic acid amide are added, and the fluorobenzene structures are introduced, the weather resistance and the corrosion resistance of the material are higher; with introduction of pyrazole structures, the ultraviolet aging resistance and the flame retardance of the material are further improved; the tensile strength of the prepared waste plastic regenerated environment-friendly particles is 54.7-55.2 MPa according to GB / T1040-2006 measurement, the limit oxygen index is 38.239% according to GB5454-85 measurement, and the technical problems in the prior art thatwaste plastic is not high in strength and prone to combustion are solved.

Owner:亳州丰色信息科技有限公司

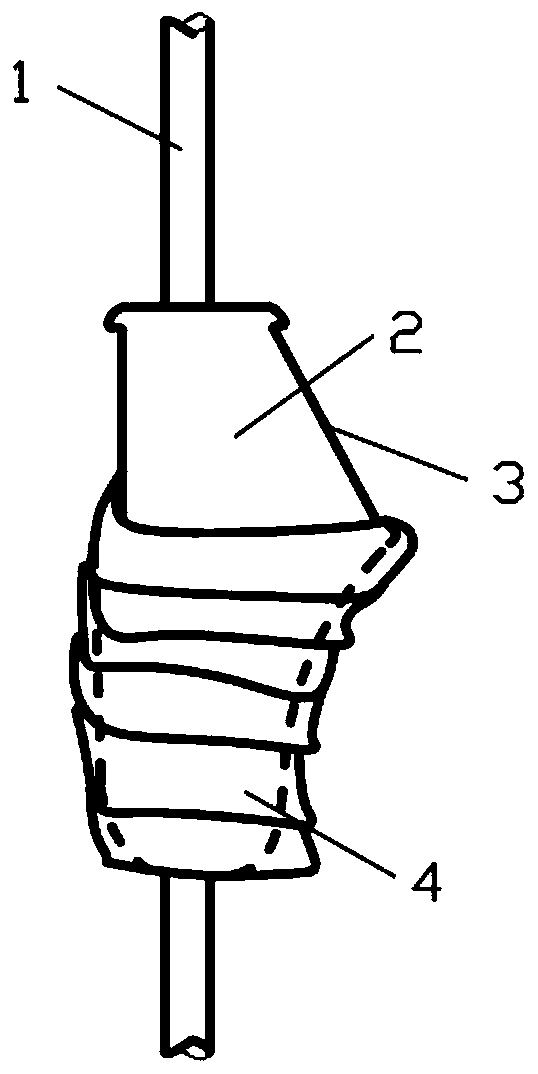

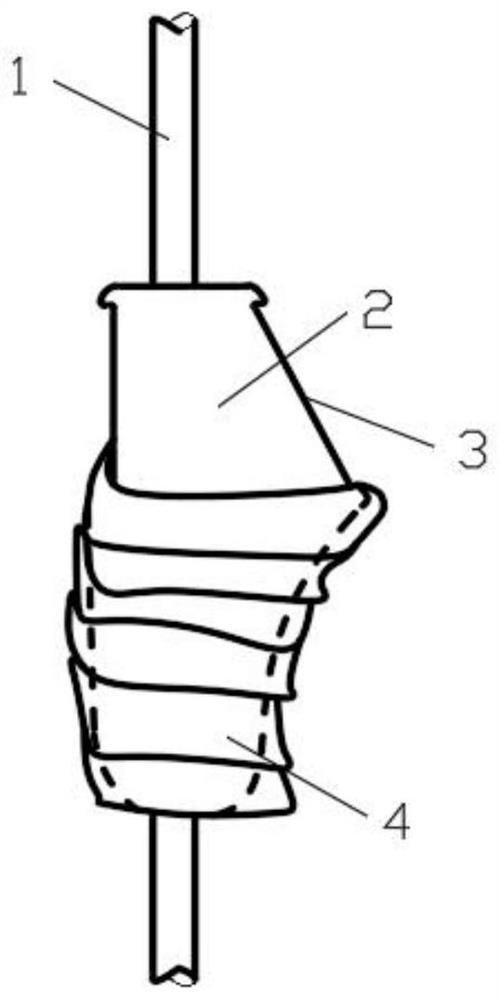

Novel end head high-temperature protection structure and traction rope end head structure

The invention relates to a novel end head high-temperature protection structure and novel traction rope end head structure. The end head high-temperature protection structure comprises a heat-shrinkable sleeve which can be mounted on an end head as well as a modified glass fiber which coats the heat-shrinkable sleeve and has flame-retardant and heat-insulation performance; and the end head high-temperature protection structure is characterized in that the heat-shrinkable sleeve is made of a heat-shrinkable shape memory material. The traction rope end head structure comprises an end head for fixing a rope body, a modified glass fiber arranged on the surface of the end head and a modified glass fiber coating the surface of the heat-shrinkable sleeve; and the traction rope end head structureis characterized in that the heat-shrinkable sleeve is made of a shape memory material. The novel end head high-temperature protection structure and traction rope end head structure have the beneficial effects that the situation that a locking function is influenced due to the fact that the temperature of the end head is too high under extreme high-temperature conditions can be avoided, so that the rope body of the end head of an elevator rope does not melt, deform, loosen and slide off when being subjected to heating, and thus accidents can be completely avoided.

Owner:ARITEC WUHAN NEW MATERIALS CO LTD

An environmentally friendly and degradable thermal insulation food packaging bag

ActiveCN110791004BGood heat insulationAvoid softening and deformationFlexible coversWrappersPolyvinyl alcoholThermal insulation

The invention discloses an environmentally friendly and degradable heat-insulating food packaging bag. The preparation method is as follows: 1) preparing a modified silica sol; 2) adding the prepared titanium dioxide sol to the modified silica sol to obtain a composite sol ; 3) Spray the composite sol on the surface of the substrate, dry it and carry out cyclic heat treatment, remove the coating after cooling, and obtain a composite powder after crushing and grinding; 4) Add sodium periodate to the sodium alginate solution, and obtain it through light-shielding reaction Modified sodium alginate; 5) Dissolve polyvinyl alcohol and add modified sodium alginate for reaction, the obtained product is added to molten polyethylene together with composite powder, and then citric acid, calcium stearate and talc are added The powder can be processed to obtain the required packaging bag. The food packaging bag has an excellent heat insulation effect, can effectively avoid the softening and deformation of the candy, has good biodegradability, can achieve complete degradation, meets environmental protection requirements, and is easy to popularize and apply.

Owner:安徽天路新材料股份有限公司

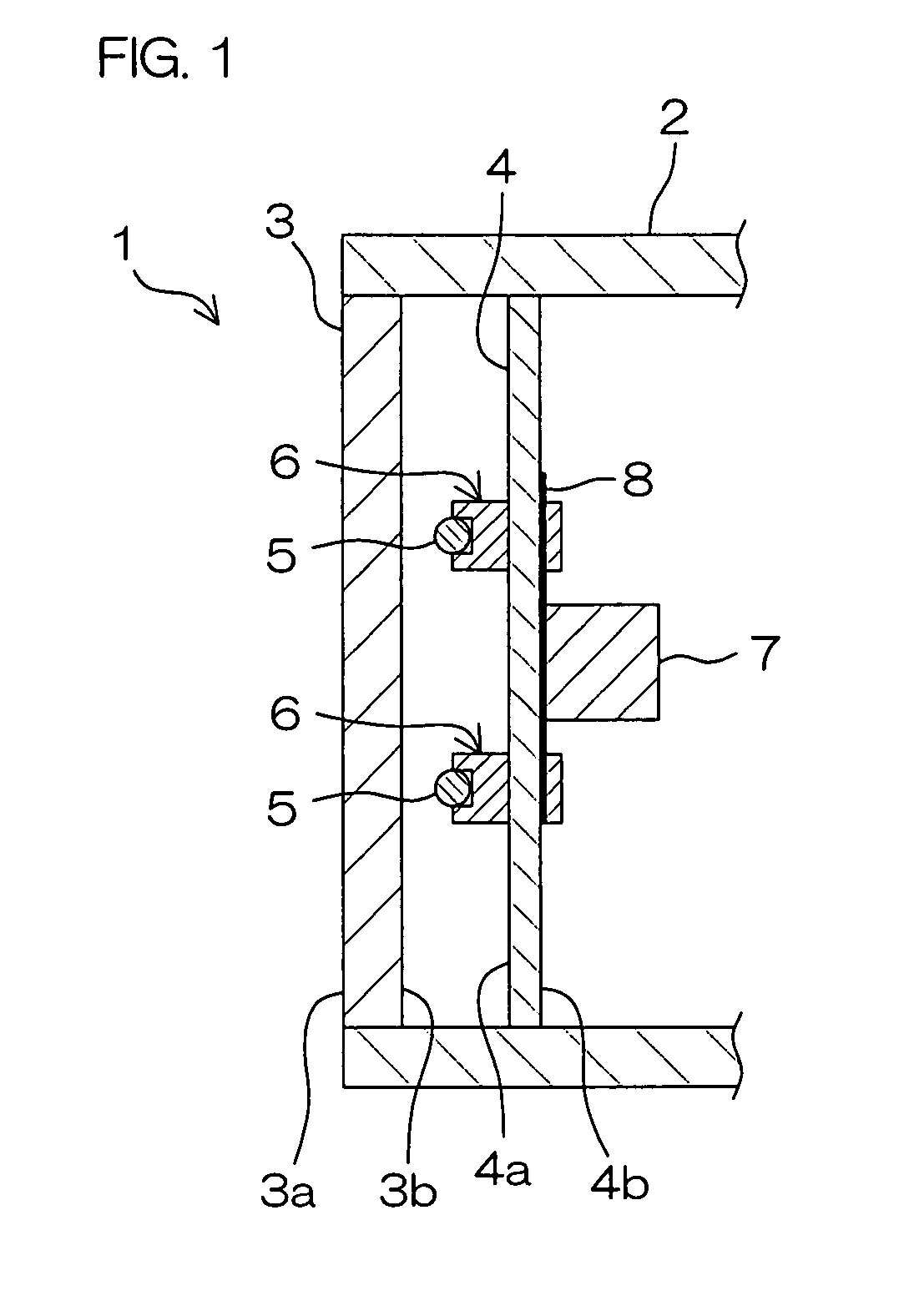

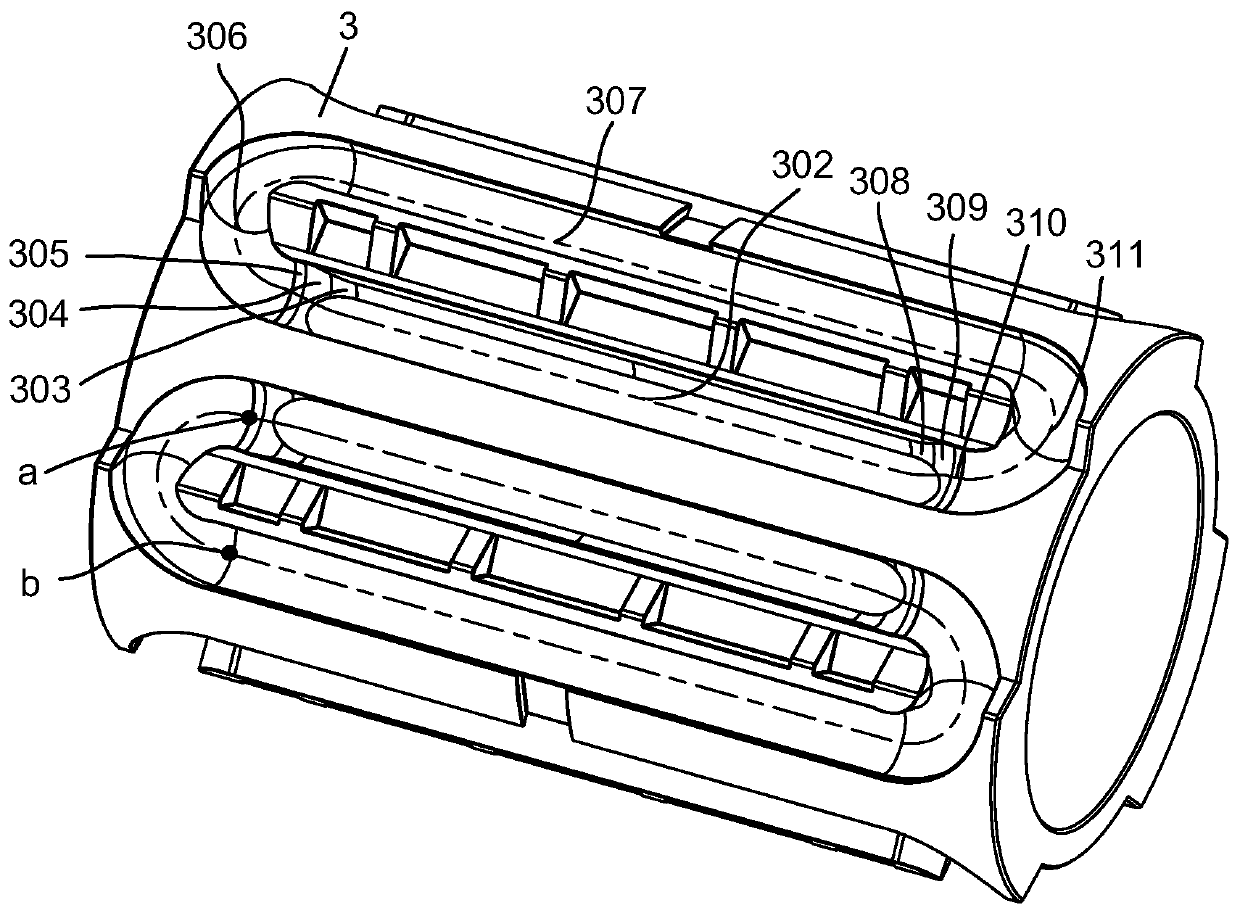

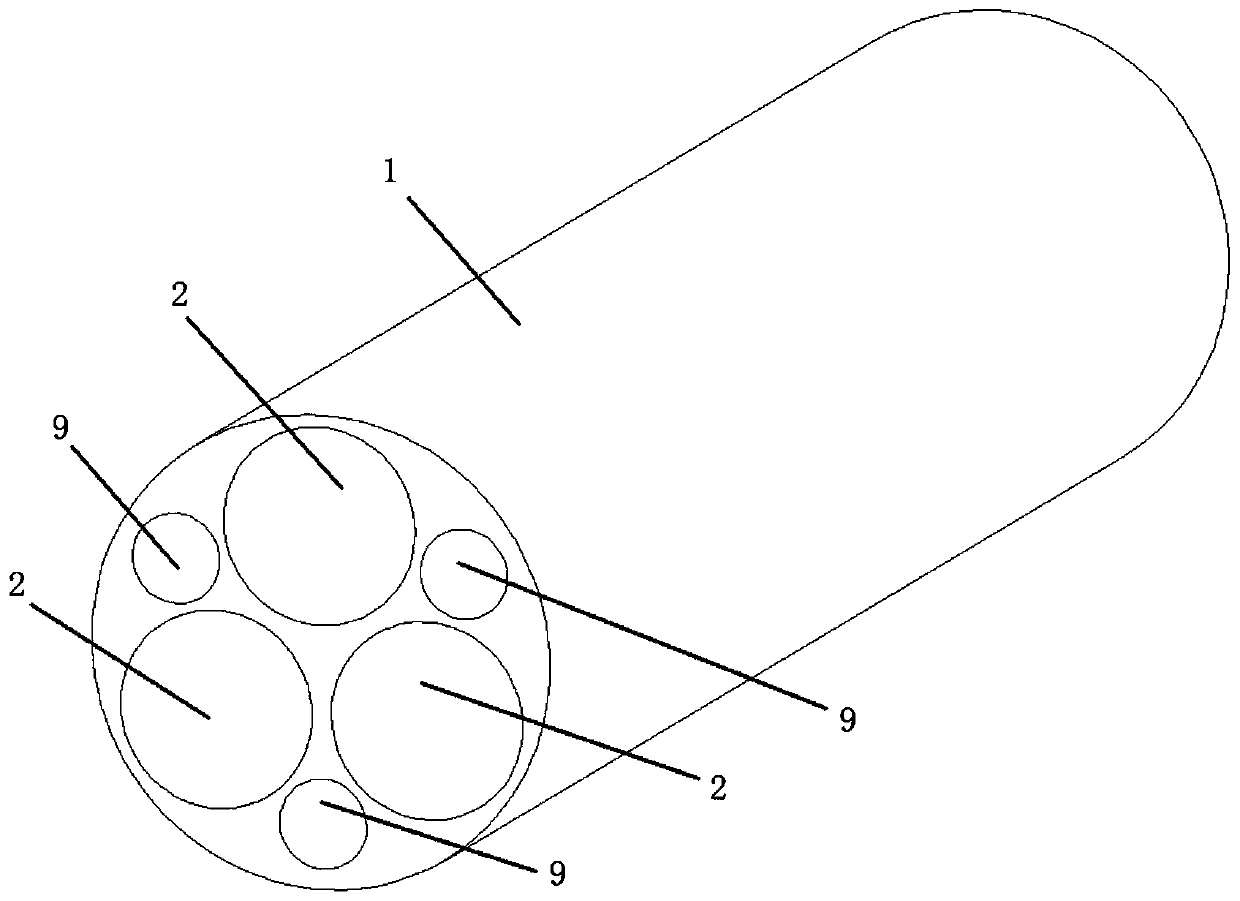

Linear retainer and ball spline device

PendingCN111486174AAvoid softening and deformationCycle evenlyLinear bearingsGearingStructural engineeringMechanical engineering

The invention provides a linear retainer and a ball spline device. The linear retainer comprises a main tubular body, and the outer wall of the main tubular body comprises a plurality of ball circulation tracks. Each ball circulation track comprises a linear channel segment, a linear passage segment, two climbing step stages and two arc-shaped turning segments. At least one climbing step stages comprises a first transition segment connected with the second end of the arc-shaped turning segments, a second transition segment connected with the linear channel segment and an inclined segment positioned between the first transition segment and the second transition segment. The impact of a ball in movement between the inclined segment and the arc-shaped turning segments is reduced through the first transition segment, and the impact of the ball in movement between the inclined segment and the linear channel segment is reduced through the second transition segment. The linear retainer can smooth the cycle running process of the ball, thus improving the smoothness of the ball running in the ball circulation tracks.

Owner:上海莱恩精密机床附件有限公司

Lost foam casting method for heavy casting

ActiveCN102825215BAvoid deformationAvoid softening and deformationFoundry mouldsFoundry coresVibration amplitudeVacuum pumping

The invention discloses a lost foam casting method for a heavy casting. The method comprises the following steps of: a. manufacturing a foam model; b. mounting a counter-deformation bracket: manufacturing the steel-structured counter-deformation bracket according to the size and the length of a workpiece and placing the counter-deformation bracket on the bottom of the foam model; c. painting: the thickness of the paint is not less than 4mm; d. drying: placing the painted foam model in a drying room for drying at the constant temperature of 50 DEG C; e. fixing core: placing the steel-structured bracket in an inner cavity of the foam model so as to fix the model, and putting the whole foam model into a sandbox together; f. boxing: enabling the sandbox containing the foam model to drop sand evenly, vibrating the sandbox during sand dropping, gradually enhancing the vibration amplitude with the increasing of added sand quantity, mounting a main runner and a branch runner of a ceramic tube, and placing a pouring cup; g. pouring: opening a vacuum pump for vacuum pumping before pouring; h. releasing negative pressure: after pouring, keeping the negative pressure for 8 to 15 minutes until solidification of an iron liquid, and then releasing the negative pressure; and i. cleaning.

Owner:广东巨高智能设备有限公司

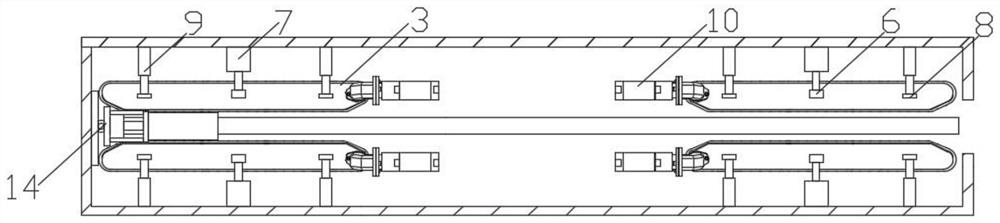

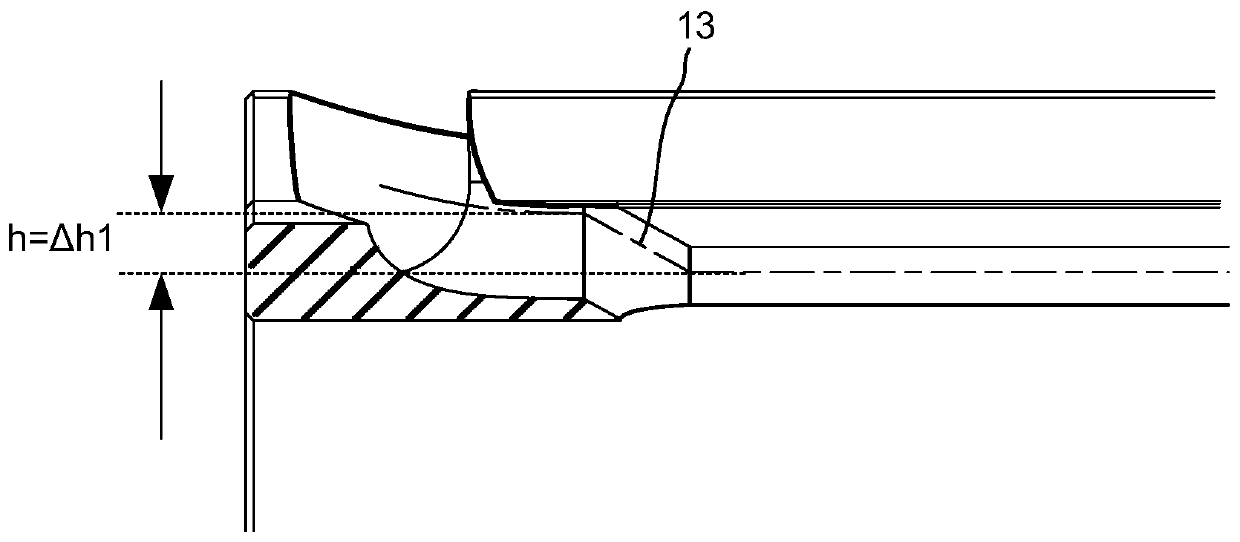

Heating mechanism of bottle preform with handle

PendingCN111283986AAvoid softening and deformationTemperature controlDomestic articlesThermodynamicsLight tube

The invention discloses a heating mechanism of a bottle preform with a handle. According to the heating mechanism, a heating area is divided into a low-temperature heating area and a common heating area through a first handle protection plate and a second handle protection plate, by adjusting the power of heating lamp tubes in low-temperature heating area and the power of heating lamp tubes in common heating area, radiation energy and temperature of the heating lamp tubes in respective areas on a plastic bottle preform can be controlled, meanwhile, due to the fact that the first handle protection plate and the second handle protection plate are arranged, mutual direct heat radiation light of the heating lamp tubes in the low-temperature heating area and the common heating area can be blocked, and the mutual oblique radiation light of the heating lamp tubes in the low-temperature heating area and the common heating area can be partially blocked, so that the low-temperature heating of ahandle part of the plastic bottle perform and the common heating of the perform body of the part below the handle are realized. Due to the fact that low-temperature heating of the handle part can be achieved, the problem that a handle of the plastic bottle perform which is provided with the handle and made of PET materials becomes soft and deforms due to heating is avoided, and bottle blowing quality is guaranteed.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

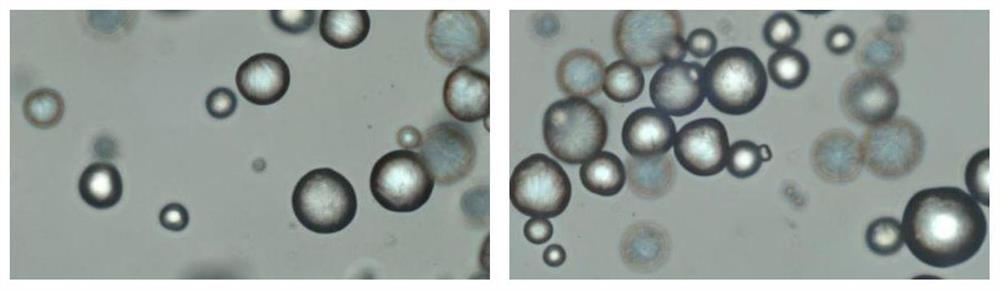

Preparation process of solid floating ball for marine product culture

PendingCN111923461AReduce resource and environmental wasteAvoid softening and deformationHollow articlesProcess engineeringMechanical engineering

The invention discloses a preparation process of a solid floating ball for marine product culture. The preparation process of the solid floating ball for marine product culture comprises the followingsteps of floating ball shell forming, jacket mounting, foaming material casting and jacket dismounting. An inner cavity matched with the size of a shell is arranged in a jacket, and a heat exchange mechanism is arranged in the jacket. Through the above manner, the solid floating ball high in external strength and even in internal foaming can be obtained, the service life of the floating ball forculture can be effectively prolonged, and the problem that water enters a hollow floating ball due to shell damage, and consequently the floating ball fails is avoided; and the floating ball can be recycled and then utilized after the floating ball reaches the service life period, and resource and environment waste is further reduced.

Owner:江苏聚强电子科技有限公司

A new type of end high temperature protection structure and the structure of the end of the traction rope

The invention relates to an end high temperature protection structure and a traction rope end structure. The end high temperature protection structure includes a heat shrinkable sleeve that can be installed on the end, and a modified heat-resistant heat-insulating sleeve coated on the heat shrinkable sleeve. It is characterized in that: the heat shrinkable sleeve is made of heat shrinkable shape memory material. The traction rope end structure includes. The end for fixing the rope body, the heat shrinkable sleeve arranged on the surface of the end, and the modified glass fiber coated on the surface of the heat shrinkable sleeve, are characterized in that: the heat shrinkable sleeve is made of shape memory material. The present invention is beneficial in that under extreme high temperature conditions, the end temperature is prevented from being too high to affect the locking function, so that the rope body of the elevator rope end does not melt, deform, loosen or slip when heated, thereby completely avoiding accidents.

Owner:ARITEC WUHAN NEW MATERIALS CO LTD

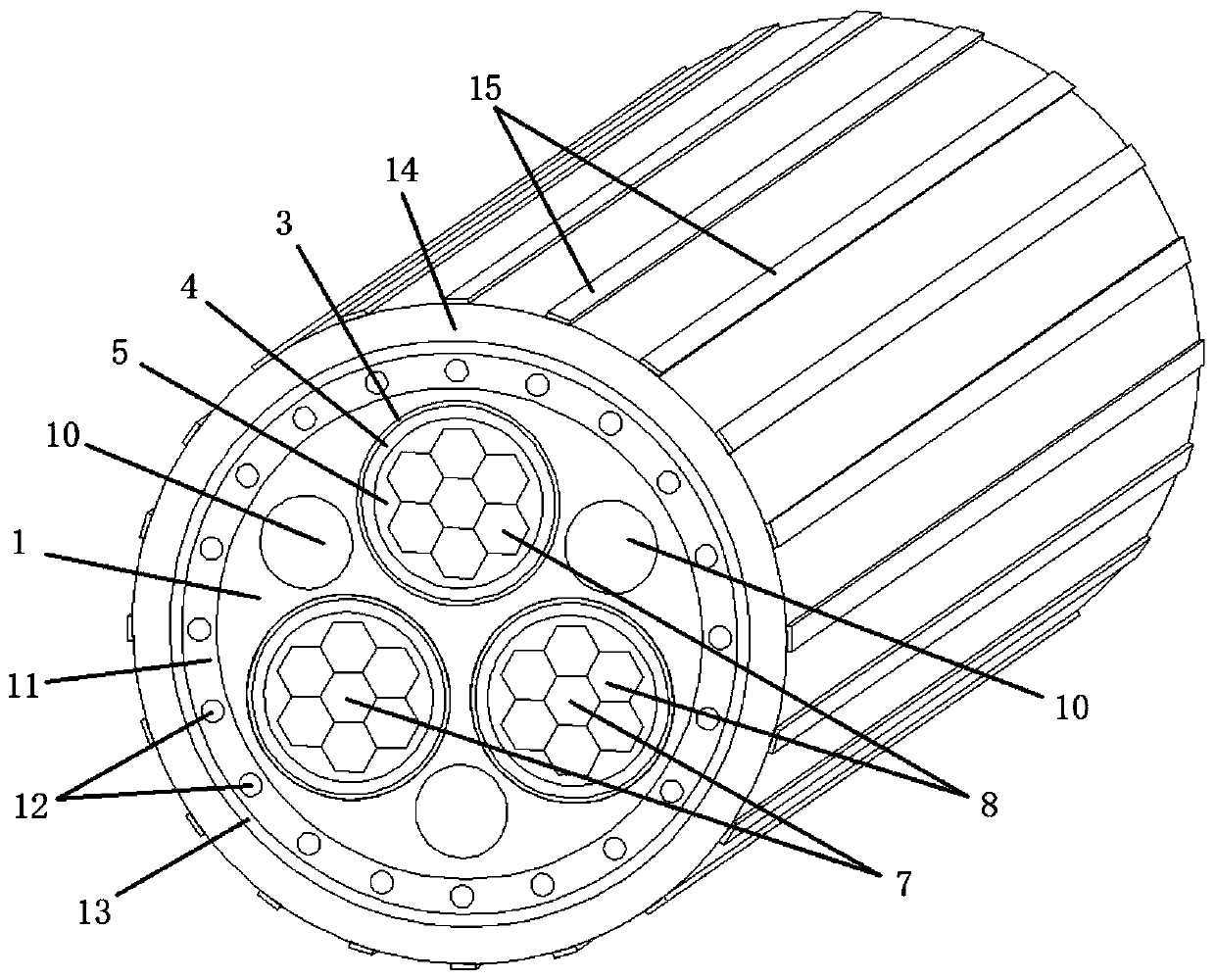

Power cable with cross-linked polyethylene insulated polyvinyl chloride sheath

InactiveCN111584126ADistribute quicklyAvoid accumulationPlastic/resin/waxes insulatorsPower cables with screens/conductive layersPower cablePolyvinyl chloride

The invention relates to the technical field of power cables, and especially relates to a power cable with a cross-linked polyethylene insulated polyvinyl chloride sheath. The power cable comprises aheat conduction filling core; an anti-interference layer is fixedly connected to the inner side of each of a plurality of uniformly distributed mounting holes formed in the heat conduction filling core; the inner side of each anti-interference layer is fixedly connected with a high-temperature-resistant layer; the inner side of each high-temperature-resistant layer is fixedly connected with an insulating layer; each insulating layer is internally provided with a spiral hole; the inner side of each spiral hole is provided with an inner wire core; the outer side of each inner wire core is fixedly connected with a plurality of uniformly distributed outer wire cores; and each outer wire core is fixedly connected to the inner side of the spiral hole. By arranging the heat conduction filling core, the high-temperature-resistant layer, the anti-interference layer, the tensile layer, a high-elasticity springback rope, a waterproof and damp-proof layer, a protective sheath and wear-resistant strips, the cable has high high-temperature resistance, heat conduction, tensile strength, wear resistance and the like, and has anti-interference, anti-breaking and springback functions and the like.

Owner:哈尔滨交联电力电缆制造有限公司

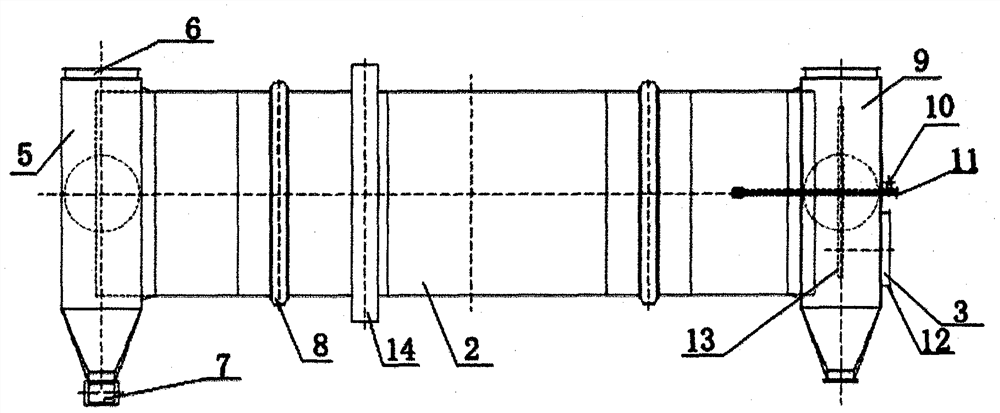

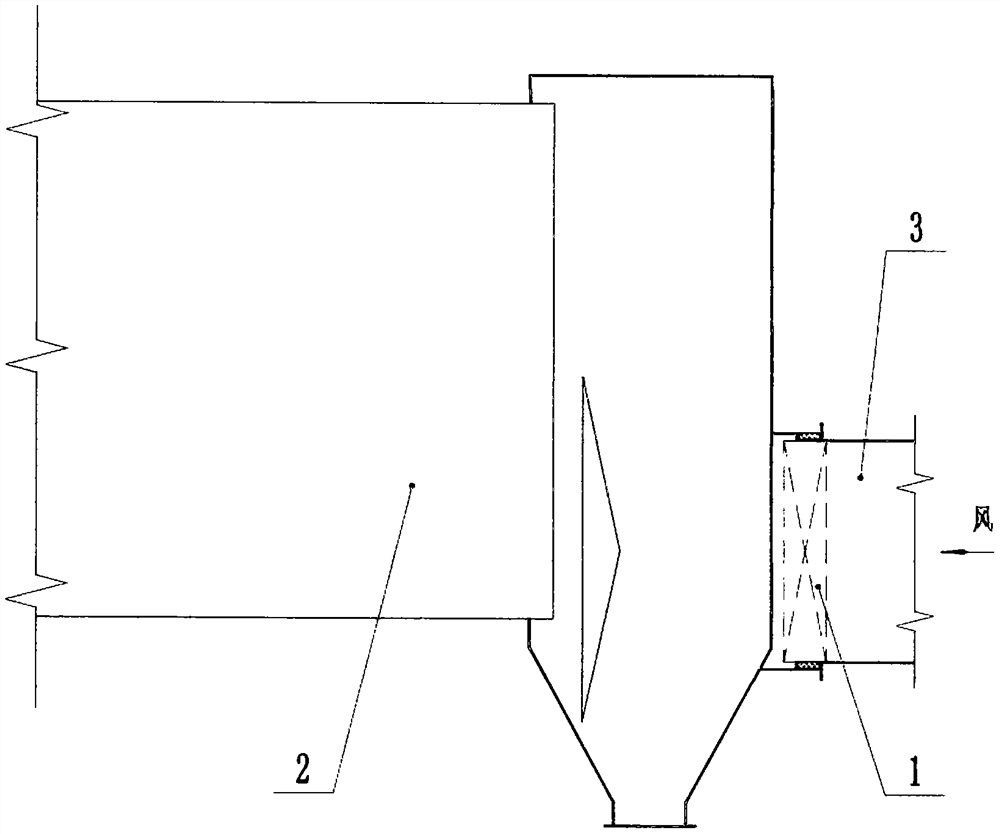

Humic acid compound fertilizer spraying, granulating and drying process and granulating and drying equipment

PendingCN113932580AAvoid breakingAvoid softening and deformationDrying gas arrangementsDrying machines with non-progressive movementsBrown coalPhosphate

The invention discloses a humic acid compound fertilizer spraying, granulating and drying process and granulating and drying equipment. The humic acid compound fertilizer spraying, granulating and drying process comprises the steps that lignite is crushed into 60-80 mesh particles, then water and dilute alkali liquor with the concentration of 2% are added, coal, alkali and the water are added into a mixing dissolving tank, the ratio of the coal to the alkali to the water is 100: 6: 400, steam is introduced, when the temperature reaches 80 DEG C, the temperature is controlled to be 80 DEG C, and heat preservation is performed for 1 hour; S2, slurry is pumped into a settling tank for settling for not less than 24 hours so as to fully settle insoluble impurities, after settling is finished, liquid containing humic acid on the upper layer is pumped, the liquid is pumped into a filter tank for filtering and filter pressing treatment, and impurities and insoluble substances in a humic acid aqueous solution are removed by utilizing a filtering and filter pressing method. According to the humic acid compound fertilizer spraying, granulating and drying process and the granulating and drying equipment, the problems that traditional monoammonium phosphate spraying, granulating and drying equipment is not suitable for humic acid compound fertilizer, and continuous production is difficult are solved, particle breaking and softening deformation caused by high temperature are avoided, and a good effect is achieved.

Owner:红河锦东化工股份有限公司

Manufacturing method of heat-resistant plastic bottle

InactiveCN112552593AImprove heat resistanceEasy to produceHollow articlesProcess engineeringMold removal

The invention relates to a manufacturing method of a heat-resistant plastic bottle. The manufacturing method comprises the steps of 1 material preparing, 2 feeding, 3 embryo preparing, 4 molding, 5 demoulding, 6 disinfection, and 7 packaging. According to the invention, a high-temperature-resistant additive is added when the plastic bottle is prepared, so that the prepared plastic bottle is good in heat resistance, softening deformation caused by temperature rise is avoided, the application range is expanded, the manufacturing method is simple, and the production is convenient.

Owner:TIANJIN CHENGYUAN PACKAGING PROD

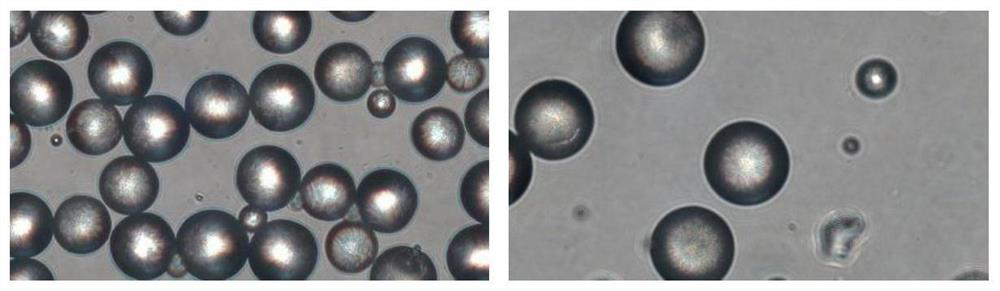

an injection filler

ActiveCN110559489BImprove protectionLong degradation cycleMicrocapsulesProsthesisAbsorbable polymersCellulose

The present invention combines PCL (polycaprolactone), PGA (polyglycolide), PVA (polyvinyl alcohol), PLA (polylactic acid), PDO (polydioxanone), P-TMC (polytrimethylene Homopolymers or copolymers of absorbable synthetic polymer materials such as carbonate) are prepared into absorbable synthetic polymer microspheres less than 200 microns, and then dispersed in cross-linked sodium hyaluronate gel to obtain degradation time Long-lasting, controlled injectable fillers. In addition, when surfactants such as CMC (carboxymethyl cellulose) and MC (methyl cellulose) are added to the mixed system of sodium hyaluronate gel and absorbable polymer microspheres at a very low ratio, it can It has a very good protective effect on the shape maintenance of the microspheres in the wet heat sterilization. In the present invention, absorbable synthetic polymer microspheres are used to prolong the degradation cycle of injection fillings. In addition, surfactants are added to the injection fillings to protect the surface of absorbable synthetic polymer microspheres and prevent them from softening under high temperature. out of shape.

Owner:GUANGZHOU YICHENG BIOTECH CO LTD

Carbon, graphite/steel composite lifting tooling used for high-temperature furnaces

ActiveCN101638206BFully meet the requirements of useMeet the use requirementsTravelling cranesCarbon compositesGraphite

The invention discloses carbon, graphite / steel composite lifting tooling used for high-temperature furnaces, comprising a base, a heat-resistant steel cap frame, a graphite sheet frame, a graphite beam and a plurality of heat-resistant steel hooks, wherein, the base is composed of a heat-resistant steel bottom sheet and a low-density carbon / carbon composite sheet which is spread and fixed on the upper surface of the heat-resistant steel bottom sheet; the heat-resistant steel cap frame is fixed right above the base by being supported by a plurality of heat-resistant steel columns; the graphitesheet frame is arranged beneath the heat-resistant steel cap frame like a cushion; the graphite beam is positioned on the heat-resistant steel cap frame and is used for hanging the treated heater products in the high-temperature furnaces; the heat-resistant steel hooks are positioned above the graphite beam; the heat-resistant steel columns are fixed on the base; graphite tubes are sleeved outside the heat-resistant steel columns, and a plurality of graphite hanging structures are correspondingly arranged on the graphite beam. The tooling is simple in structure, convenient in assembly, low inmanufacturing cost, easy in use and operation and wide in application temperature range, and can effectively solve the practical problem that the existing carbon / carbon composite lifting tooling is inconvenient in operation, poor in performance, high in manufacturing cost and the like.

Owner:XIAN CHAOMA SCI TECH

Electric connector and connection structure for electric connector

InactiveCN100521381CAvoid softening and deformationContact pressure is maintained stablyElectrical apparatusMechanical engineeringEngineering

An electric connector (6) to be attached to a plate-like connection member (4; 100) having an edge portion (402; 102), a plurality of insertion convex portions (12; 103) formed sideways at the edge portion (402; 102), and a conductive portion (8; 8B; 103a, 103b) formed on at least one of the front surface (4a; 103a). The back surface (4b; 103b) of each insertion convex portion (12; 103) includes an insulating housing (13) and a contact forming member (14; 14A; 14B; 14B'; 14C; 14C'; 14D; 14E; 14F; 14G; 14H; 14J) made of a metal and held in the housing (13). The contact forming member (14; 14A; 14B; 14B'; 14C; 14C'; 14D; 14E; 14F; 14G; 14H; 14J) includes a box-like portion (33; 33D) having four.walls (41, 42, 43, 44; 41D, 42D, 43D, 44D) and a connection member connecting contact (34; 34B) extended from at least one of the walls of the box-like portion (33; 33D). The four walls (41, 42, 43, 44; 41D, 42D, 43D, 44D) define an insertion concave portion (45) into which the insertion convex portion (12; 103) corresponding thereto is inserted along a predetermined insertion direction (P1). The connection member connecting contact (34; 34B) includes a contact portion (475; 475A; 475B; 475C; 475D; 475E; 475F; 475G; 475J) that makes contact with the conductive portion (8; 8B; 103a, 103b) of the corresponding insertion convex portion (12; 103) inserted into the insertion concave portion (45).

Owner:JST MFG CO LTD

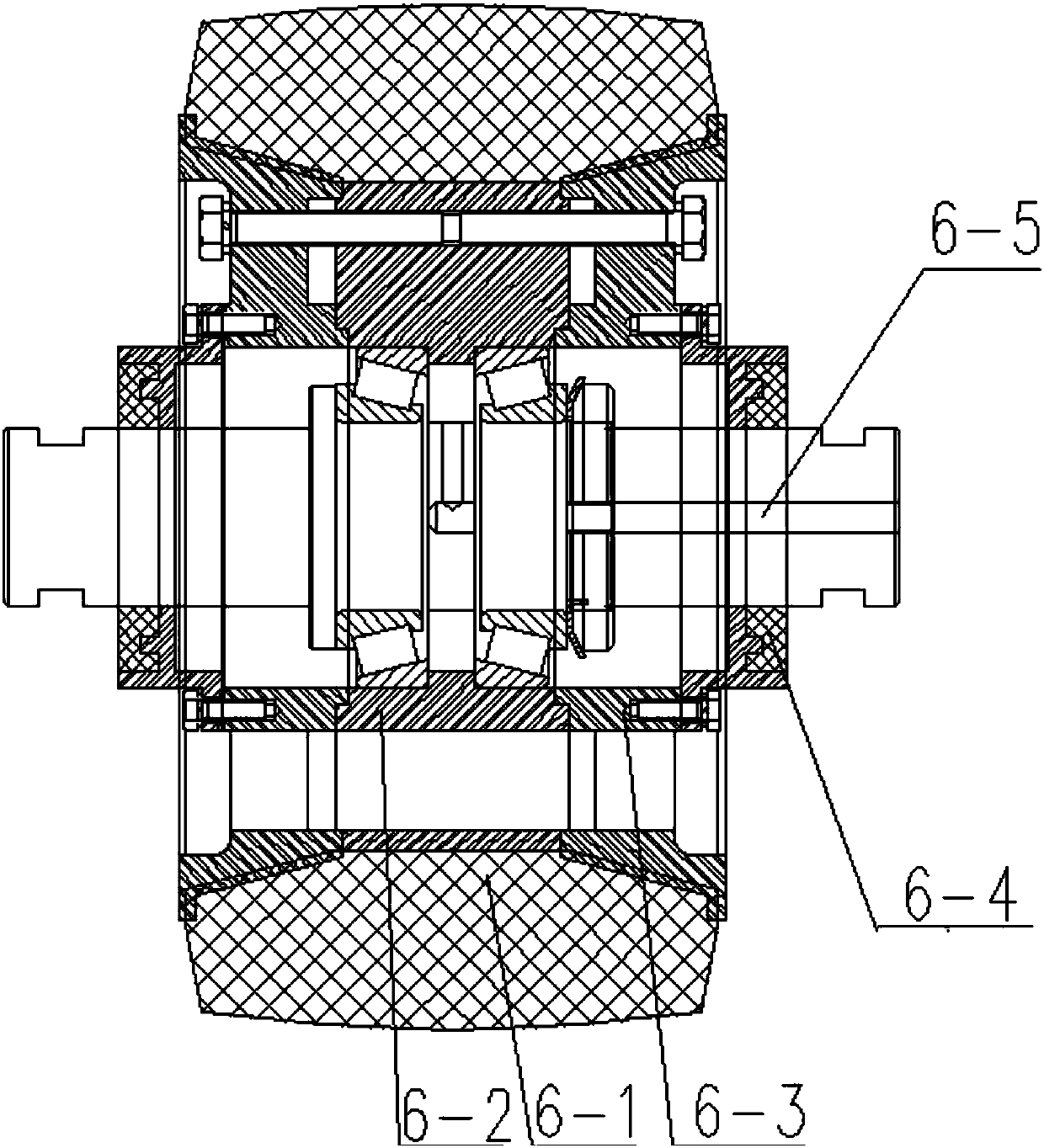

A kind of self-swinging double-wheel roller tank ear

ActiveCN106006296BExtended service lifeReduce weightElevatorsMine liftsDirect deviceMechanical engineering

Owner:SHANDONG NUOTAI ELECTRICAL EQUIP CO LTD

Anti-fouling protective film for lacquer of rail traffic vehicle

InactiveCN110746896AEasy to cleanReduce heatAntifouling/underwater paintsFilm/foil adhesivesChemistryLacquer

The invention discloses an anti-fouling protective film for lacquer of a rail traffic vehicle. The protective film comprises a base material layer, an anti-fouling layer is arranged on one side of thebase material layer, the water contact angle of the anti-fouling layer is larger than 70 degrees, the other side of the base material layer is provided with a bonding glue layer bonded with the lacquer of the rail traffic vehicle, and release force of bonding glue is larger than 15 N / 25 mm and smaller than 30 N / 25 mm. The protective film adopts a hydrophobic coating and has a hydrophobic effect similar to surface layers of lotus leaves, thus ordinary fouling has difficulty in adhering to the surface layer of the protective layer, and cleaning is convenient; the anti-fouling protective film further has the function of naturally repairing slight scratches in the surface of the protective film, and the lacquer can be protected to the utmost extent; and the anti-fouling layer of the protective film is dried and cured through a UV-LED photocuring process, the drying temperature can be decreased, using of a solvent in the coating process is reduced, and economical efficiency and environmental protection are achieved.

Owner:武汉羿阳科技有限公司

Preparation method for glass fiber reinforced plastic water collector

The invention provides a preparation method for a glass fiber reinforced plastic water collector. The preparation method comprises the following steps that S1, a water collector sheet mold and corrosion-resistant resin are prepared; S2, the water collector sheet mold is coated with a release agent; S3, a gel coat layer is coated after the release agent is dried; S4, lamination coating is carried out, and specifically, the resin and fibers are circularly coated once until the required thickness is reached; S5, curing stripping is carried out, specifically, a product obtained after lamination coating in the step S4 and the mold are placed in a normal-temperature environment together to be cured, and stripping is carried out after lamination curing to prepare a water collector sheet; and S6, assembling is carried out, specifically, multiple water collector sheets are assembled into the water collector, and the adjacent water collector sheets are connected through a support. According to the glass fiber reinforced plastic water collector provided by the technical scheme, glass fiber reinforced plastic is formed by the resin and the fibers to serve as a water collector sheet material, the supports made of ABS materials are used for connection, high temperature resistance can be achieved so as to prevent softening deformation, and the strength, corrosion resistance and durability are far higher than those of a common water collector.

Owner:ANHUI HANGDA ENVIRONMENTAL PROTECTION TECH

Combustion system and burner

ActiveCN110577846BAvoid softening and deformationSolve the burning problemCombustible gas productionCombustion systemThermodynamics

The invention belongs to the field of coal gasification combustion, and relates to a combustion system and a burner. The combustion system includes a control system, a burner and a gasifier connected in sequence, the burner includes a cooling water jacket and an outer casing, the cooling water jacket is an annular cavity structure and is arranged inside the outer casing ; The first outer wall of the cooling water jacket forms the central channel of the burner, and the second outer wall of the cooling water jacket and the inner wall of the outer casing form a nitrogen channel. The invention can effectively avoid gasification by controlling the installation angle between the opposed burner with a special structure and the wall of the gasification furnace at 17°-20°, and controlling the swirl angle of the air outlet of the burner at 1°-30° Partial burning of the furnace, channeling and other problems.

Owner:杨建平

Edge-lit liquid crystal module, direct-lit liquid crystal module and TV

InactiveCN103439831BSimple structureImprove cooling effectTelevision system detailsLighting heating/cooling arrangementsLuminosityEngineering

The invention provides a sidelight type liquid crystal module, a direct type liquid crystal module and a television. The sidelight type liquid crystal module comprises a back plate, a heat radiation plate, a lamp strip, a rubber frame and a surface frame, wherein the heat radiation plate is mounted on the back plate; the lamp strip is mounted on the side face of the heat radiation plate; the rubber frame and the back plate are fixedly connected; the surface frame and the rubber frame are fixedly connected; the sidelight type liquid crystal module further comprises a heat-conduction sheet; one side of the heat-conduction sheet is connected with the lamp strip, the heat radiation plate and / or the back plate and the other side of the heat-conduction sheet is connected with the rubber frame and / or the surface frame; the heat generated by the lamp strip can be transmitted to the surface frame. The liquid crystal module provided by the invention is simple in structure; the liquid crystal module is internally provided with the heat-conduction sheet so that the heat generated by the lamp strip can be simultaneously dissipated from the back plate and the surface frame; the heat radiation effect is effectively enhanced, the luminosity of the lamp strip is improved and the service life of the lamp strip is prolonged; the quality of a picture displayed by the liquid crystal module is ensured; and furthermore, the picture quality of the television is ensured.

Owner:HISENSE VISUAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com