Waste plastic regenerated environment-friendly particles and production process thereof

A technology of waste plastics and production technology, which is applied in the direction of manufacturing tools, grinding workpiece supports, metal processing equipment, etc., and can solve the problems of easy burning, easy splashing of plastic shavings, and low strength of waste plastics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

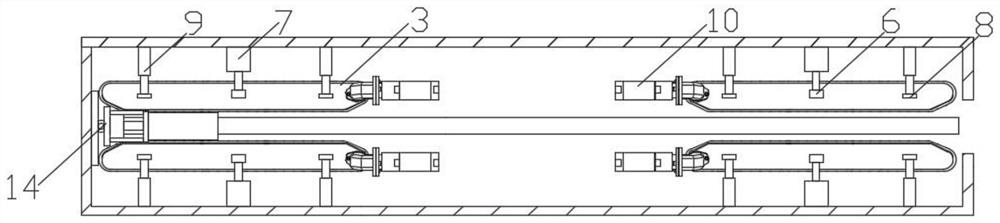

Image

Examples

Embodiment 1

[0030] A recycled environmental protection particle of waste plastic, prepared from the following raw materials in parts by weight: 500 parts of waste plastic, 5 parts of sodium dodecylbenzenesulfonate, 10 parts of lecithin, 5 parts of sorbitan fatty acid, and 30 parts of water;

[0031] Wherein, the recycled environmental protection particles of waste plastics are prepared through the following steps:

[0032] Step 1: Put the waste plastic into a crusher to crush to obtain plastic fragments, add the plastic fragments to boiling water to boil, take out the plastic fragments after cooling, and mix sodium dodecylbenzenesulfonate, lecithin, and fatty acid sorbitan , mixed with water evenly to obtain a cleaning agent, mixed the plastic powder with the cleaning agent, put it into a ball mill for ball milling, added water 30 times the weight of the mixture to the mixture after ball milling, and stirred evenly, then ultrasonically cleaned, centrifuged after cleaning, and took the sedi...

Embodiment 2

[0039] A recycled environmental protection particle of waste plastics, which is prepared from the following raw materials in parts by weight: 600 parts of waste plastics, 10 parts of sodium dodecylbenzenesulfonate, 15 parts of lecithin, 10 parts of sorbitan fatty acid, and 40 parts of water;

[0040] Wherein, the recycled environmental protection particles of waste plastics are prepared through the following steps:

[0041] Step 1: Put the waste plastic into a crusher to crush to obtain plastic fragments, add the plastic fragments to boiling water to boil, take out the plastic fragments after cooling, and mix sodium dodecylbenzenesulfonate, lecithin, and fatty acid sorbitan , mixed with water evenly to obtain a cleaning agent, mix the plastic powder with the cleaning agent, put it into a ball mill for ball milling, add water 50 times the weight of the mixture to the mixture after ball milling, and stir evenly, then ultrasonically clean, centrifuge after cleaning, and take the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com