Humic acid compound fertilizer spraying, granulating and drying process and granulating and drying equipment

A technology of shotcrete granulation and drying equipment, which is applied in the directions of drying solid materials, drying goods processing, drying gas arrangement, etc., can solve the problem of different medium characteristics, moisture content, concentration and viscosity, and cannot be directly granulated with humic acid compound fertilizer. Drying and other problems to achieve the effect of improving drying efficiency, preventing excessive temperature and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Such as Figure 1-5 As shown, the present invention provides a technical solution: humic acid compound fertilizer spray granulation drying process and granulation drying equipment, including the following steps:

[0032] S1, pulverizing lignite into granules of 60 mesh to 80 mesh, then adding water and dilute lye with a concentration of 2%, adding coal, alkali and water to the mixing and dissolving tank, and the ratio of coal, alkali and water is 100: 6:400, pass in steam so that when the temperature reaches 80°C, control the temperature at 80°C for 1 hour;

[0033] S2. After the heating is over, pump the slurry into the settling tank for settlement. The settling time is not less than 24 hours, so that the insoluble impurities can be fully settled. Filtration and pressure filtration treatment, using filtration and pressure filtration to remove impurities and insolubles in the humic acid aqueous solution;

[0034] S3. Use a pump to pump the obtained humic acid solution...

Embodiment 2

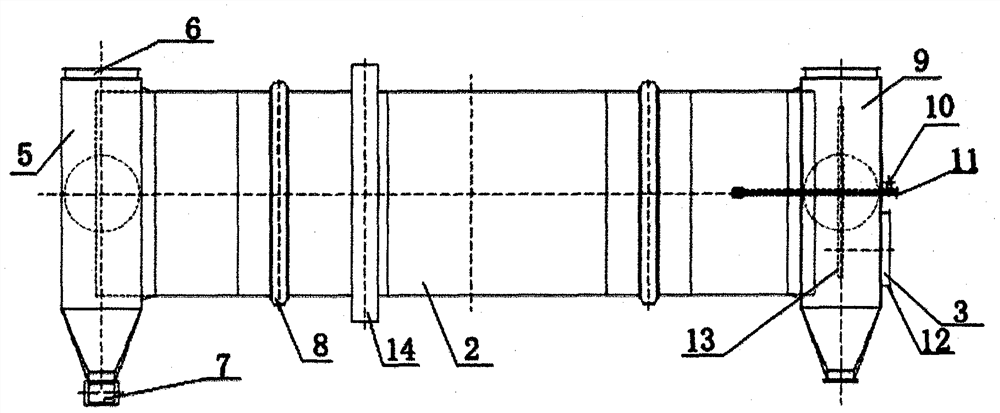

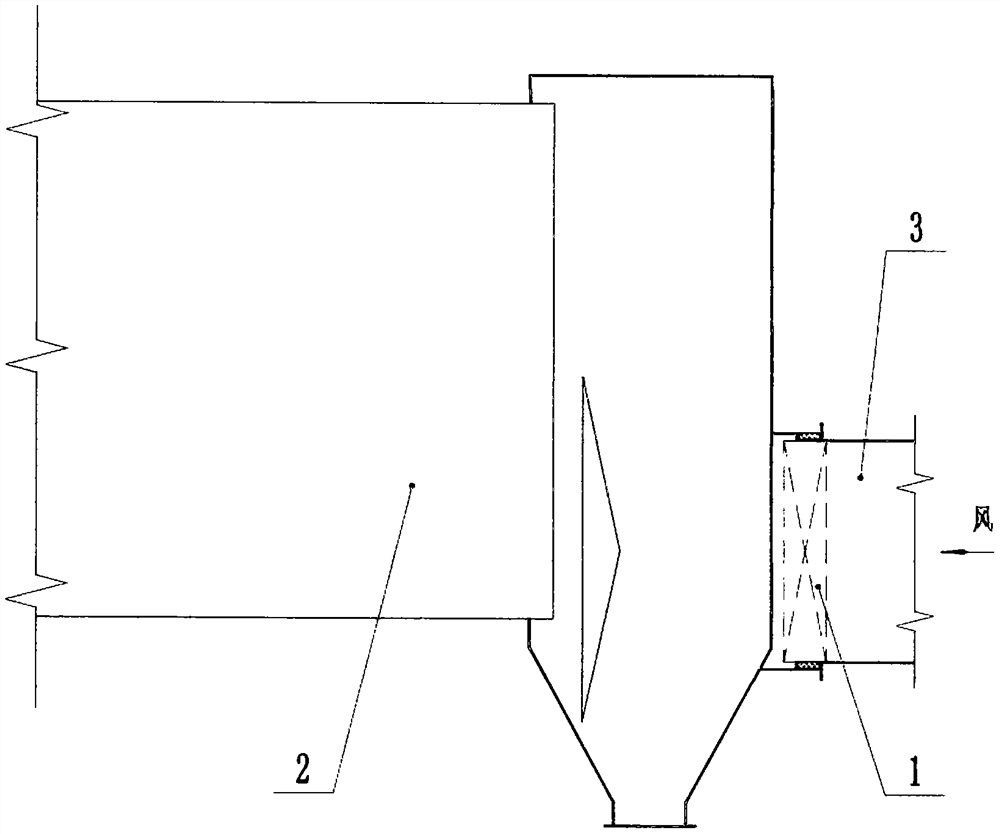

[0042] Such as Figure 1-5 As shown, the present invention provides a technical solution: granulation drying equipment for humic acid compound fertilizer spray granulation drying process, the granulation drying equipment includes a drum 2, and one end of the drum 2 is provided with a feed chamber 9. The other end of the drum 2 is provided with a discharge chamber 5, and one side of the feed chamber 9 is provided with a flue gas inlet pipe 3, and the flue gas inlet pipe 3 is provided with a regulating plate 4, the There are multiple sets of adjustment plates 4, and the adjustment plates 4 are arranged around. The flue gas inlet pipe 3 is provided with a cold air port 12, and a cold air blade valve 1 is installed in the cold air port 12. The feed chamber 9 is located at The flue gas inlet is provided with a swirling smoke barrier 13, and the feed chamber 9 is located above the flue gas inlet pipe 3 and is provided with a grouting inlet 11, and the grouting inlet 11 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com