A new type of end high temperature protection structure and the structure of the end of the traction rope

A protective structure and high temperature technology, applied in the direction of elevators, transportation and packaging, etc., can solve problems such as rope body falling off, affecting the locking function of the end, and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

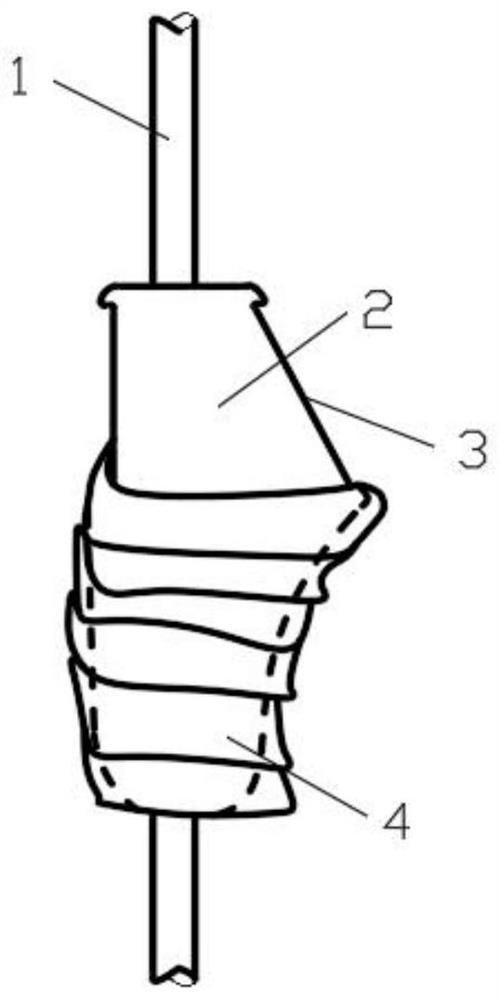

[0029] A high-temperature protection structure for a terminal, comprising a heat-shrinkable sleeve that can be installed on the terminal, and modified glass fiber coated on the outer surface of the heat-shrinkable sleeve. The end is a wedge-shaped metal socket end, and the heat-shrinkable sleeve is composed of trans-1,4-polyisoprene, which is made into a heat-shrinkable sleeve through irradiation and cross-linking. Put it in the wedge-shaped metal socket device at the end, heat it with an open flame, and the sleeve shrinks and forms and fits closely to the wedge-shaped metal socket at the end. Then, the modified glass fiber with flame-retardant and heat-insulating properties is wound or bonded on the outer surface of the heat-shrinkable sleeve.

[0030] The modified glass fiber is: the mass ratio is 30%Na 2 SiO 3 , 35% B 2 o 3 , 10% Sb 2 o 3 , 10%TiO 2 , 5% Al 2 o 3 , 5% MgO, 5% Fe 2 o 3 The nano-inorganic substances are added to the glass fiber, and then fused at 3...

Embodiment 2

[0032] A high-temperature protection structure for a terminal, comprising a heat-shrinkable sleeve that can be installed on the terminal, and modified glass fiber coated on the outer surface of the heat-shrinkable sleeve. The end is a wedge-shaped metal socket end, and the heat-shrinkable sleeve is composed of trans-1,4-polyisoprene, which is made into a heat-shrinkable sleeve through irradiation and cross-linking. Put it in the wedge-shaped metal socket device at the end, heat it with an open flame, and the sleeve shrinks and forms and fits closely to the wedge-shaped metal socket at the end. Then, the modified glass fiber with flame-retardant and heat-insulating properties is wound or bonded on the outer surface of the heat-shrinkable sleeve.

[0033] Different from Example 1, the mass ratio is 20% SiO 2 , 35% B 2 o 3 , 10% Sb 2 o 3 , 10%TiO 2 , 10% CaO, 5% Al 2 o 3 , 5% MgO, 5% K 2 O nano-inorganic substances are added to glass fibers, and then fused at 300°C to 36...

Embodiment 3

[0035]A high-temperature protection structure for a terminal, comprising a heat-shrinkable sleeve that can be installed on the terminal, and modified glass fiber coated on the outer surface of the heat-shrinkable sleeve. The end is a wedge-shaped metal socket end, and the heat-shrinkable sleeve is composed of trans-1,4-polyisoprene, which is made into a heat-shrinkable sleeve through irradiation and cross-linking. Put it in the wedge-shaped metal socket device at the end, heat it with an open flame, and the sleeve shrinks and forms and fits closely to the wedge-shaped metal socket at the end. Then, the modified glass fiber with flame-retardant and heat-insulating properties is wound or bonded on the outer surface of the heat-shrinkable sleeve.

[0036] The mass ratio is 30% Na 2 SiO 3 , 35% B 2 o 3 , 10% Sb 2 o 3 , 10%TiO 2 , 5% Fe 2 o 3 , 5% MgO, 5% K 2 O nano-inorganic substances are added to glass fibers, and then fused at 300°C to 360°C to make a special shieldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com