Edge-lit liquid crystal module, direct-lit liquid crystal module and TV

A liquid crystal module, edge-lit technology, applied in the field of televisions, can solve the problems of the decline of LED luminosity and lifespan, the softening and deformation of the light guide plate, and the shortening of the lifespan of LED lamps, so as to improve the luminosity and service life and ensure the picture quality. , to avoid the effect of softening and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

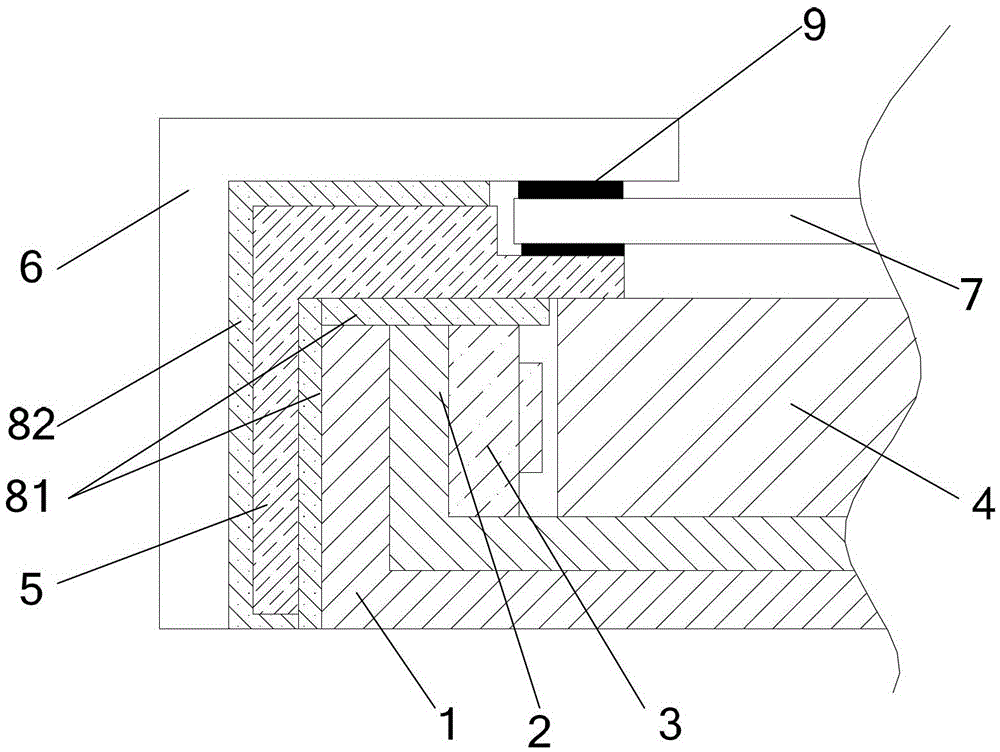

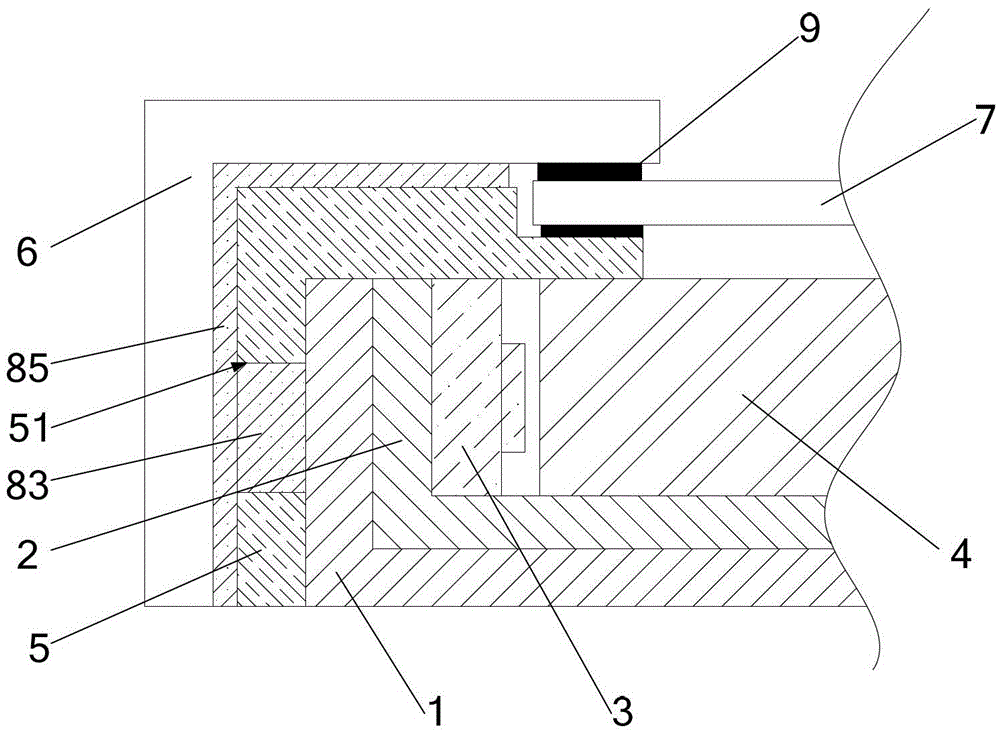

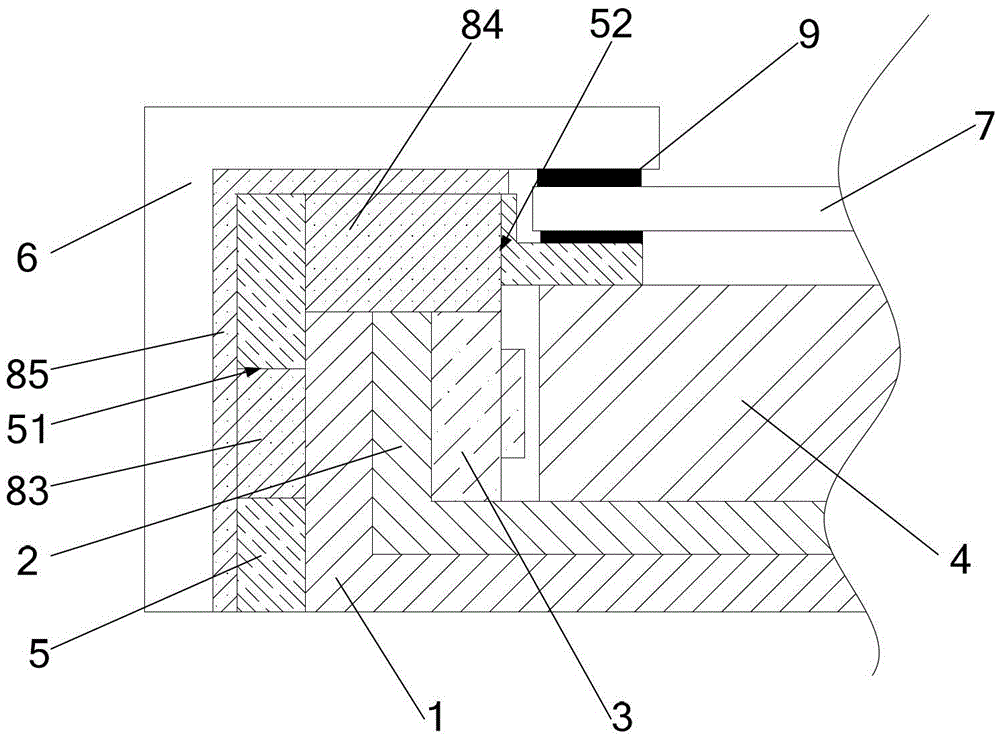

[0023] Such as figure 1 or Figure 2(a) or Figure 2(b) or Figure 4 or Figure 5 As shown, the present invention provides a side-lit liquid crystal module, including: a backplane 1, a heat sink 2, a light bar 3, an optical film set 4, a plastic frame 5, a surface frame 6, and a liquid crystal panel 7. The heat dissipation plate 2 is installed on the backplane 1, the light bar 3 is installed on the heat dissipation plate 2, and the optical film group 4 is installed between the backplane 1 and the liquid crystal panel 7, so The light bar 3 is located on the side of the optical film set 4, the plastic frame 5 is wrapped around the periphery of the optical film set 4 and fixedly connected with the back plate 1, and the surface frame 6 is wrapped around the The periphery of the liquid crystal panel 7 is fixedly connected with the plastic frame 5, and also includes a heat conduction sheet 8, and the heat conduction sheet 8 can transfer the heat generated by the light bar 3 to the p...

Embodiment 2

[0075] Such as Figure 6 As shown, this implementation provides a direct type liquid crystal module, including: a backplane 1, a light strip 3, a plastic frame 5 and a surface frame 6, the light strip 3 is installed on the inner wall of the backplane 1, The plastic frame 5 is fixedly connected to the backboard 1, the surface frame 6 is fixedly connected to the plastic frame 5, and further includes a heat conduction sheet 8, one side of the heat conduction sheet 8 is connected to the backboard 1 , and the other side is connected to the surface frame 6 , which can transfer the heat generated by the light bar 3 to the surface frame 6 .

[0076] By setting the heat conduction sheet in the direct-type liquid crystal module, part of the heat generated by the light bar is transferred to the front frame through the heat conduction sheet, and dissipated through the front frame, while the other part of the heat generated by the light bar is directly dissipated through the back plate, so...

Embodiment 3

[0088] This embodiment provides a TV, including the edge-lit liquid crystal module or the direct-lit liquid crystal module provided in any one of the above embodiments.

[0089] The structure of the TV set provided by this embodiment is not shown in the accompanying drawings, and it has good heat dissipation performance. A heat conduction sheet is arranged in the side-light liquid crystal module, and the heat conduction sheet is combined with the aluminum material used on the current back plate. The combined use of the heat sink can effectively conduct all the heat generated by the LED light bar through the back plate, plastic frame and surface frame, which enhances the heat dissipation effect, thereby ensuring the luminosity and service life of the light bar, and avoiding the surrounding area of the light bar. The phenomenon of heat softening and deformation of the light guide plate, etc. prolongs the service life of the TV, and ensures the picture quality of the TV without ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com