Power cable with cross-linked polyethylene insulated polyvinyl chloride sheath

A PVC sheathed, cross-linked polyethylene technology, used in power cables, insulated cables, power cables with shielding/conductive layers, etc. It can achieve the effect of strong tensile performance, improved anti-break performance, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

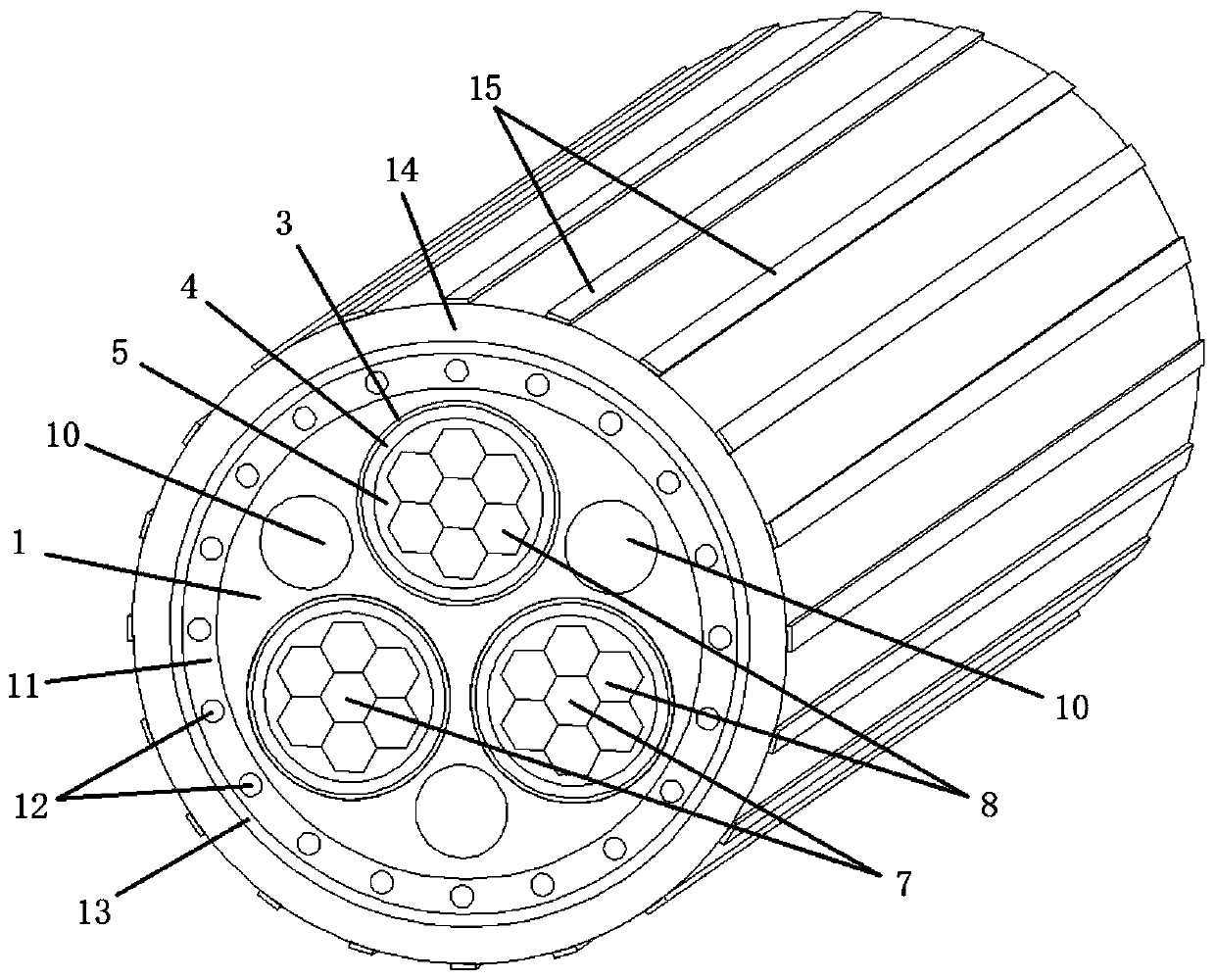

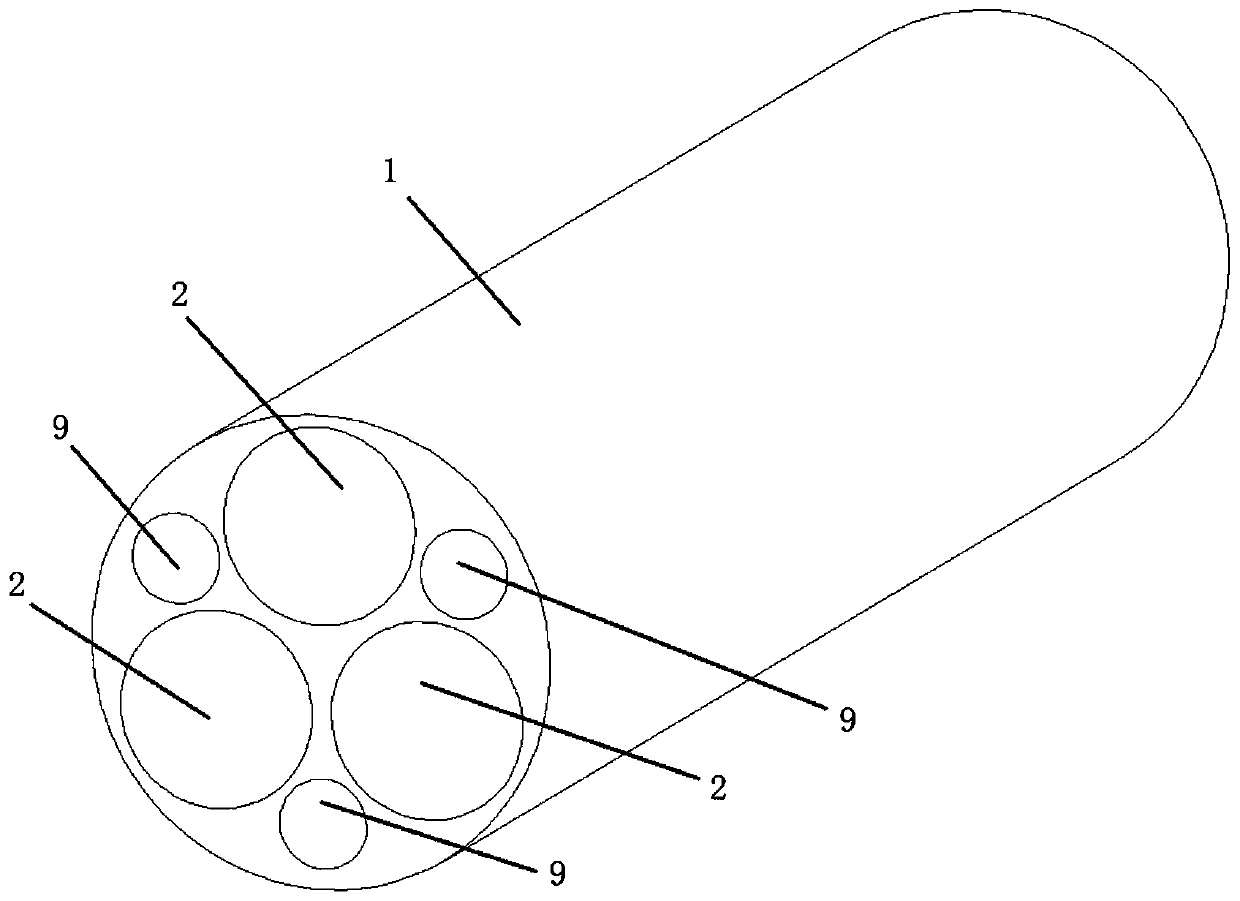

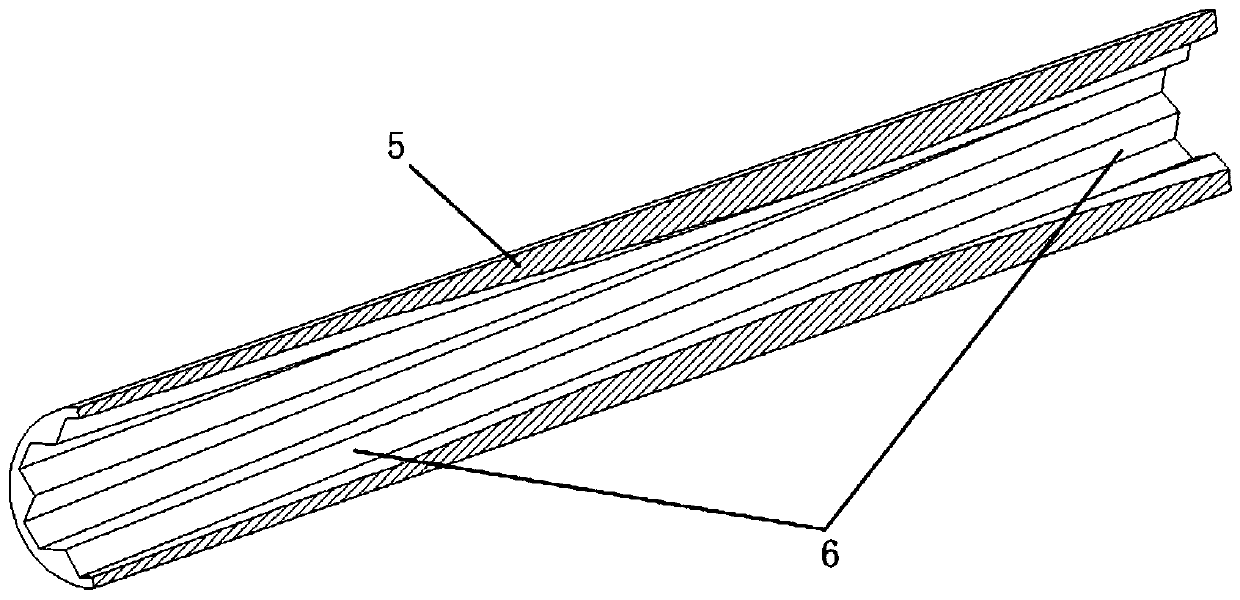

[0024] refer to Figure 1-6 , XLPE insulated PVC sheathed power cable, including heat conduction filling core 1, so that it has good heat conduction and heat dissipation performance, can quickly dissipate heat and avoid heat accumulation, and heat conduction fill core 1 is equipped with a number of evenly distributed The inside of the installation hole 2 is fixedly connected with an anti-jamming layer 3, which is made of tin-plated copper, and the anti-jamming layer 3 is a braided mesh structure, which makes it have an anti-jamming function and greatly improves its transmission stability. And it still has anti-jamming function inside. The inside of the anti-jamming l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com