An environmentally friendly and degradable thermal insulation food packaging bag

A packaging bag and food technology, which is applied in the field of new materials, can solve the problems of heat-insulating coating peeling off and weakening heat-insulating effect of packaging bags, and achieve the effects of avoiding softening and deformation, excellent heat-insulating effect, and easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

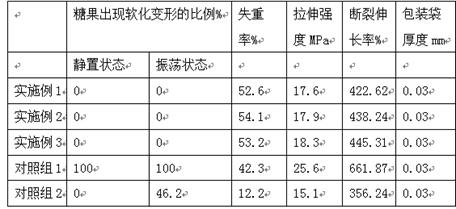

Examples

Embodiment 1

[0023] An environmentally friendly and degradable heat-insulating food packaging bag, the specific preparation method is as follows:

[0024] 1) Mix ethyl orthosilicate, absolute ethanol, deionized water and concentrated hydrochloric acid according to a certain ratio of substances, stir at a high speed of 800r / min for 2h, then add trimethylchlorosilane and February Dibutyltin silicate, under the condition of 30°C, stirred and reacted at a speed of 150r / min for 3h, and then stood still for 40h to obtain a modified silica sol;

[0025] 2) Mix butyl titanate, triethanolamine and absolute ethanol according to a certain ratio of substances and stir evenly, then add the mixed solution composed of absolute ethanol and deionized water dropwise, and stir at 700r / min for 2h, Then add it to the modified silica sol, stir for 3 hours at a rotating speed of 150r / min, and let it stand for 40 hours to obtain a composite sol;

[0026]3) Pour the composite sol into a high-pressure spray gun, s...

Embodiment 2

[0036] An environmentally friendly and degradable heat-insulating food packaging bag, the specific preparation method is as follows:

[0037] 1) Mix ethyl orthosilicate, absolute ethanol, deionized water and concentrated hydrochloric acid according to a certain ratio of substances, stir at a high speed of 900r / min for 1.5h, then add trimethylchlorosilane and dichlorosilane Dibutyltin lauricate was stirred and reacted at a speed of 180r / min for 2.5h at 35°C, and then left to stand for 45h to obtain a modified silica sol;

[0038] 2) Mix butyl titanate, triethanolamine and absolute ethanol according to a certain ratio of substances and stir evenly, then add the mixed solution composed of absolute ethanol and deionized water dropwise, and stir at 800r / min for 1.5h , then added to the modified silica sol, stirred for 2.5 hours at a rotational speed of 200r / min, and left to stand for 42 hours to obtain a composite sol;

[0039] 3) Pour the composite sol into a high-pressure spray ...

Embodiment 3

[0049] An environmentally friendly and degradable heat-insulating food packaging bag, the specific preparation method is as follows:

[0050] 1) Mix ethyl orthosilicate, absolute ethanol, deionized water and concentrated hydrochloric acid according to a certain ratio of substances, stir at a high speed of 1100r / min for 1h, then add trimethylchlorosilane and February Dibutyltin silicate, under the condition of 40°C, stirred and reacted at a speed of 200r / min for 2h, and then stood still for 50h to obtain a modified silica sol;

[0051] 2) Mix and stir butyl titanate, triethanolamine and absolute ethanol according to a certain ratio of substances evenly, then add the mixed solution composed of absolute ethanol and deionized water dropwise, and stir at 1000r / min for 1h, Then add it to the modified silica sol, stir for 2 hours at a rotating speed of 250r / min, and let it stand for 45 hours to obtain a composite sol;

[0052] 3) Pour the composite sol into a high-pressure spray gun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com