Efficient and safe oil press with preheating function

A hydraulic press and preheating technology, applied in the field of hydraulic presses, can solve the problems of easily causing industrial accidents, difficulty in alignment, danger to workers, etc., and achieve the effects of improving safety and reliability, improving work efficiency, and avoiding softening and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

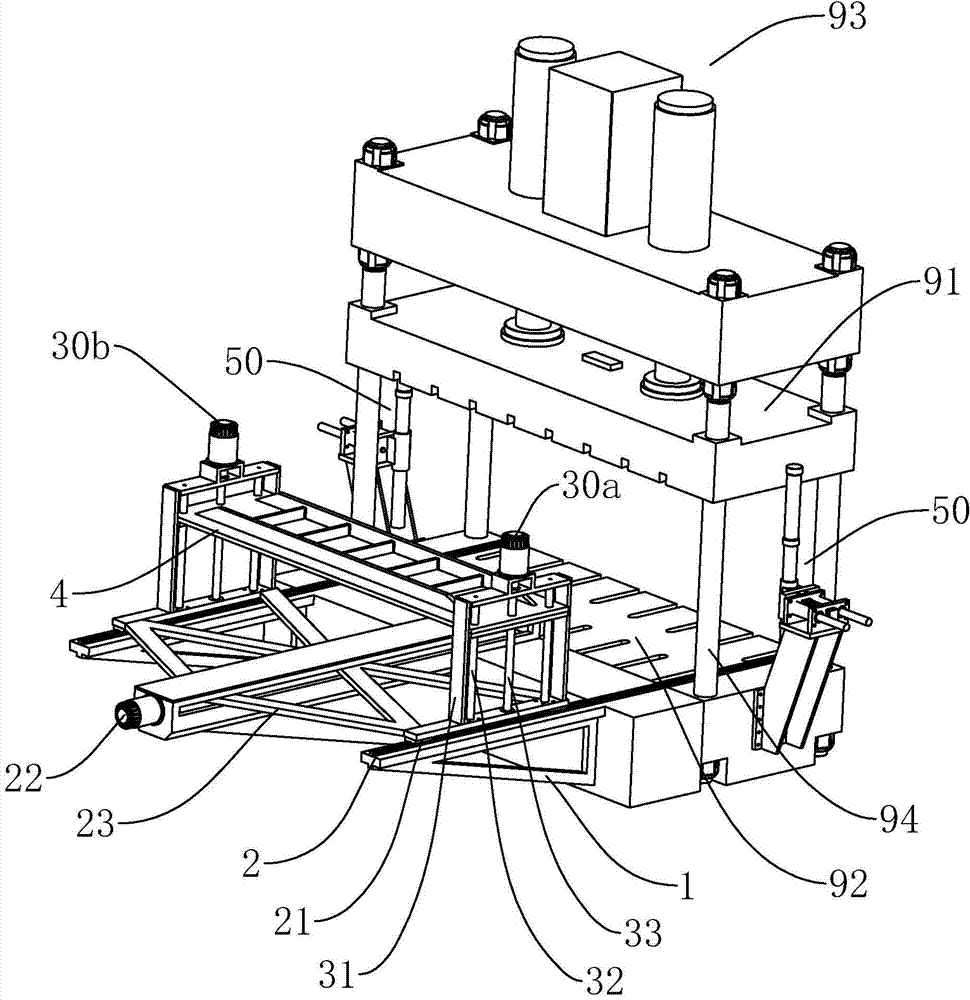

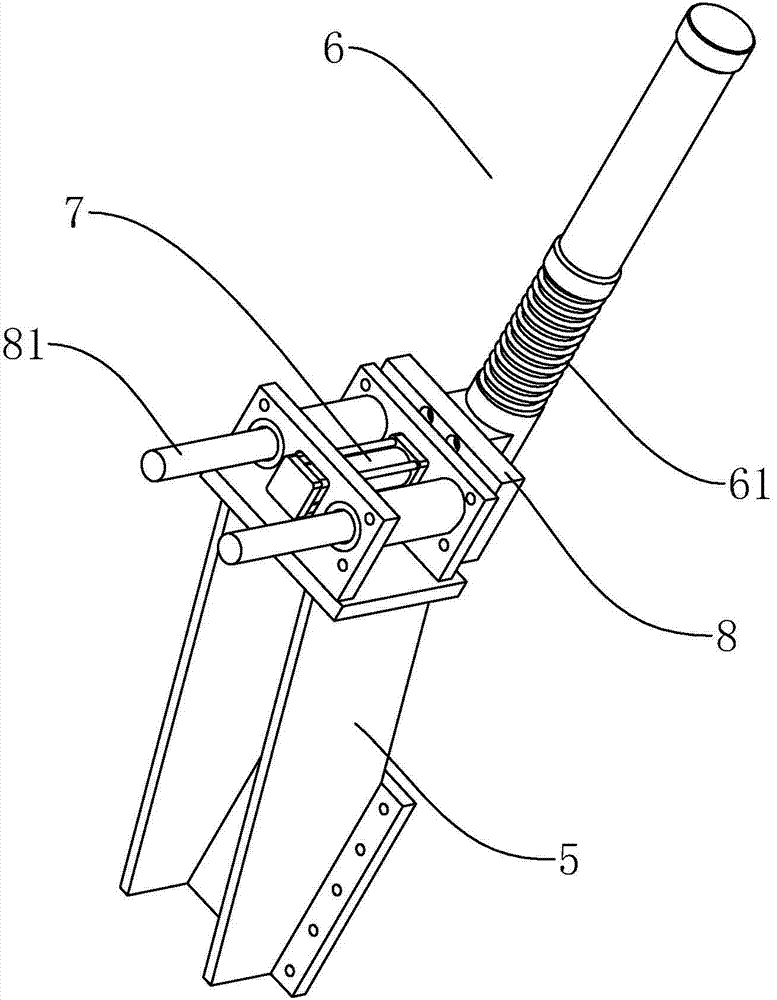

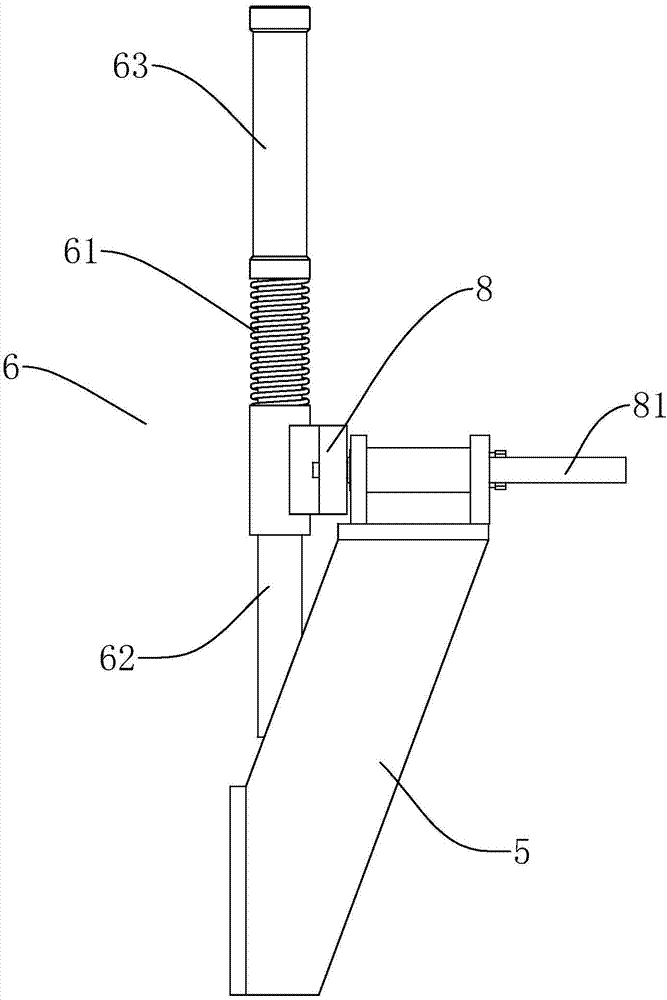

[0022] refer to Figure 1 to Figure 3 , Figure 1 to Figure 3 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, a high-efficiency and safe hydraulic press with preheating function includes a hydraulic press body, and the hydraulic press body includes a frame, a hydraulic system 93, a column 94, and an upper platen 91 , the lower pressing plate 92, a beam is arranged above the column 94, the hydraulic system 93 is arranged on the beam and connected with the upper pressing plate 91, the upper pressing plate 91 is slidably arranged on the column 94, and the lower pressing plate 92 is located below the column 94, The upper mold and the lower mold of the stamping die are fixed on the upper pressing plate 91 and the lower pressing plate 92 respectively.

[0023] Such as figure 1 As shown, the hydraulic press body also includes a preheating system. The preheating system includes a lateral movement device, an up and down ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com