Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

362results about How to "Avoid limitations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

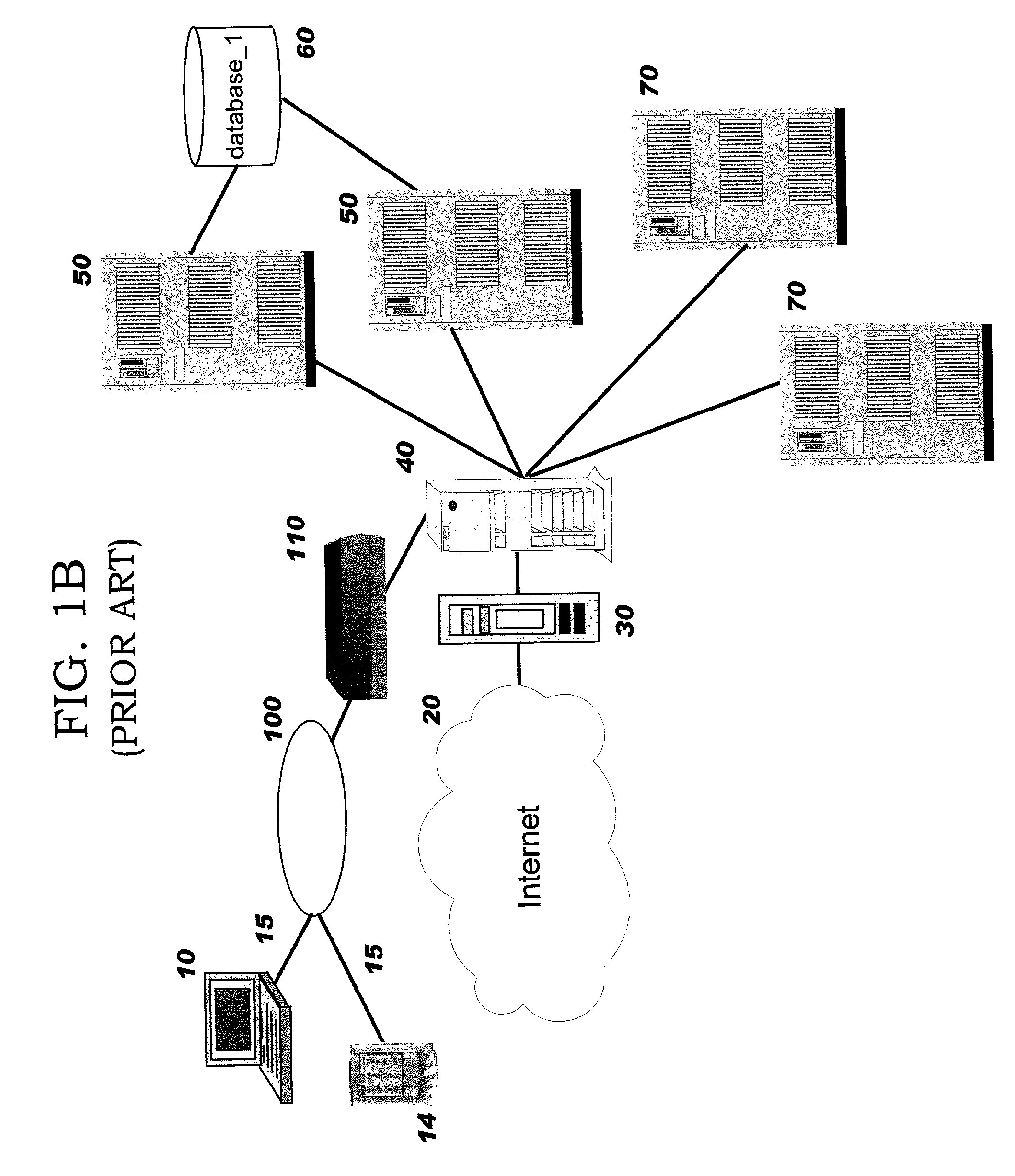

Technique for scheduling execution of jobs for or by network-connected devices

ActiveUS20020198923A1Limitations of prior art device management systems are avoidedAvoid restrictionsResource allocationMemory systemsCascading failureStart time

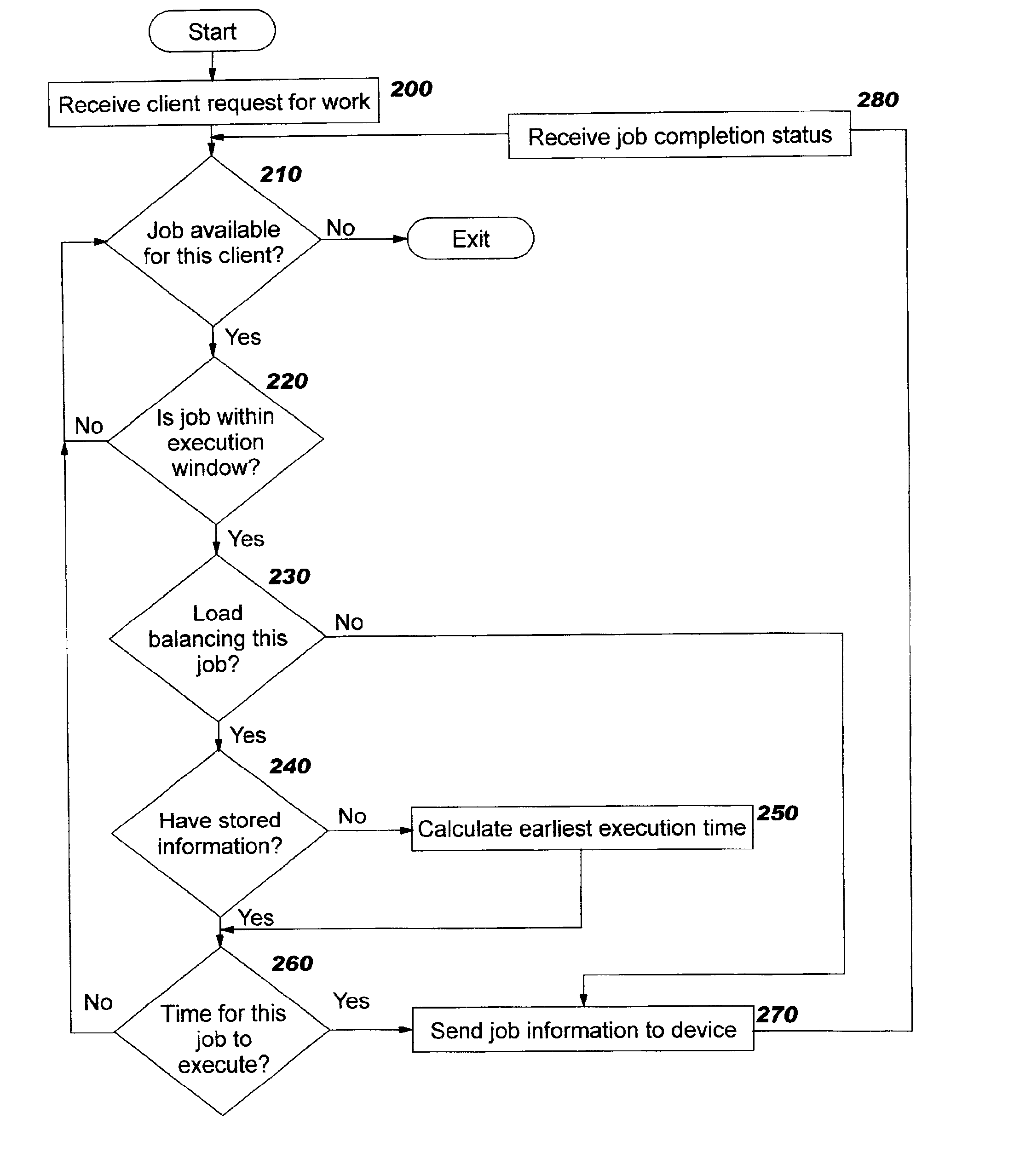

Methods, systems, computer program products, and methods of doing business by improving the scheduling of execution of jobs for or by network-connected devices, thereby enabling the job execution process to scale more easily, efficiently, and effectively to support large numbers of devices and / or users. Examples of jobs include, but are not limited to, distribution of resources (including software, configuration information, images, and other types of content) to a device, fetching a device's inventory information, backing up a device's contents, and so forth. Jobs are programmatically scheduled based upon a specified time internal, according to a class of the requester. Only if an earliest start time after which the job may be executed for this requester has been reached will the job be executed; otherwise, the job execution is delayed. The disclosed techniques lessen the need for additional servers to handle spikes in processing load, reduce the likelihood of reaching system overload, and reduce the likelihood of cascading failures that may occur when systems are overloaded.

Owner:TWITTER INC

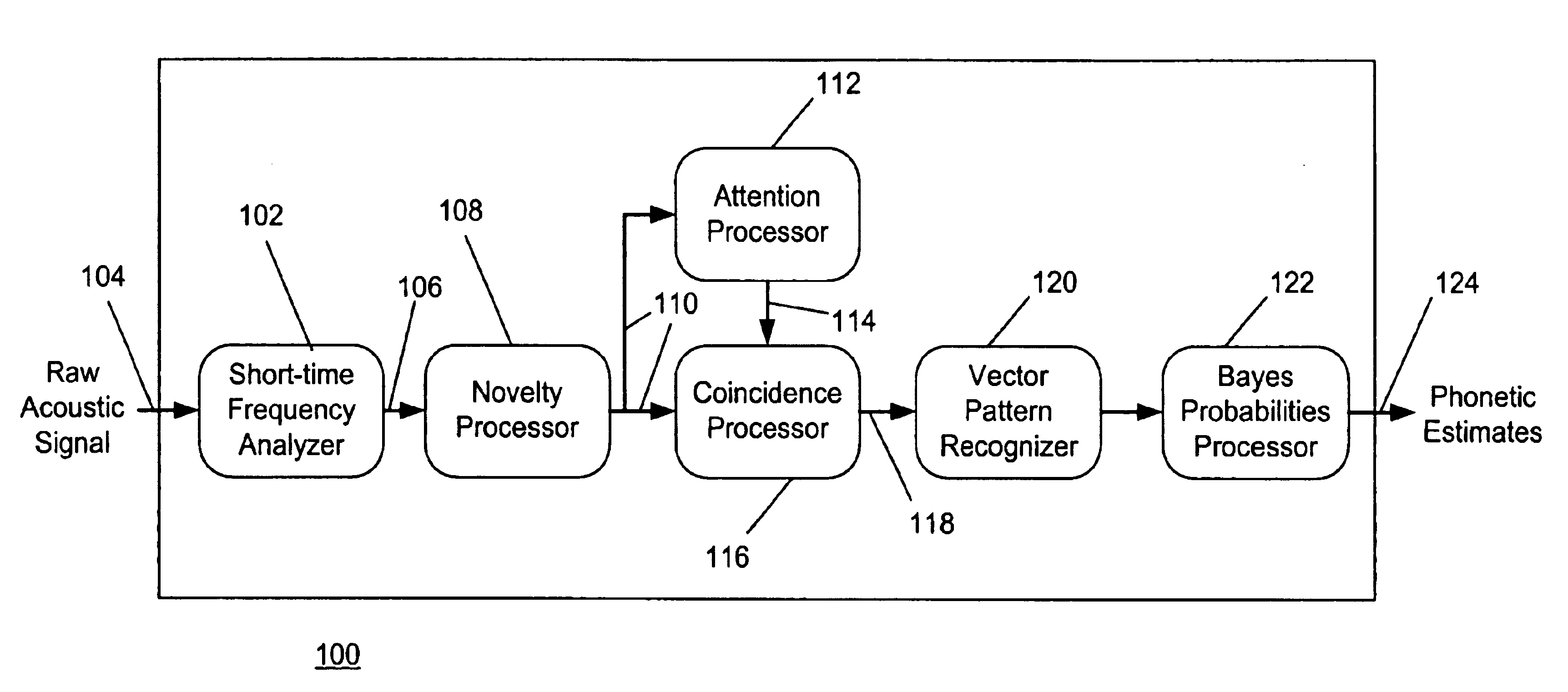

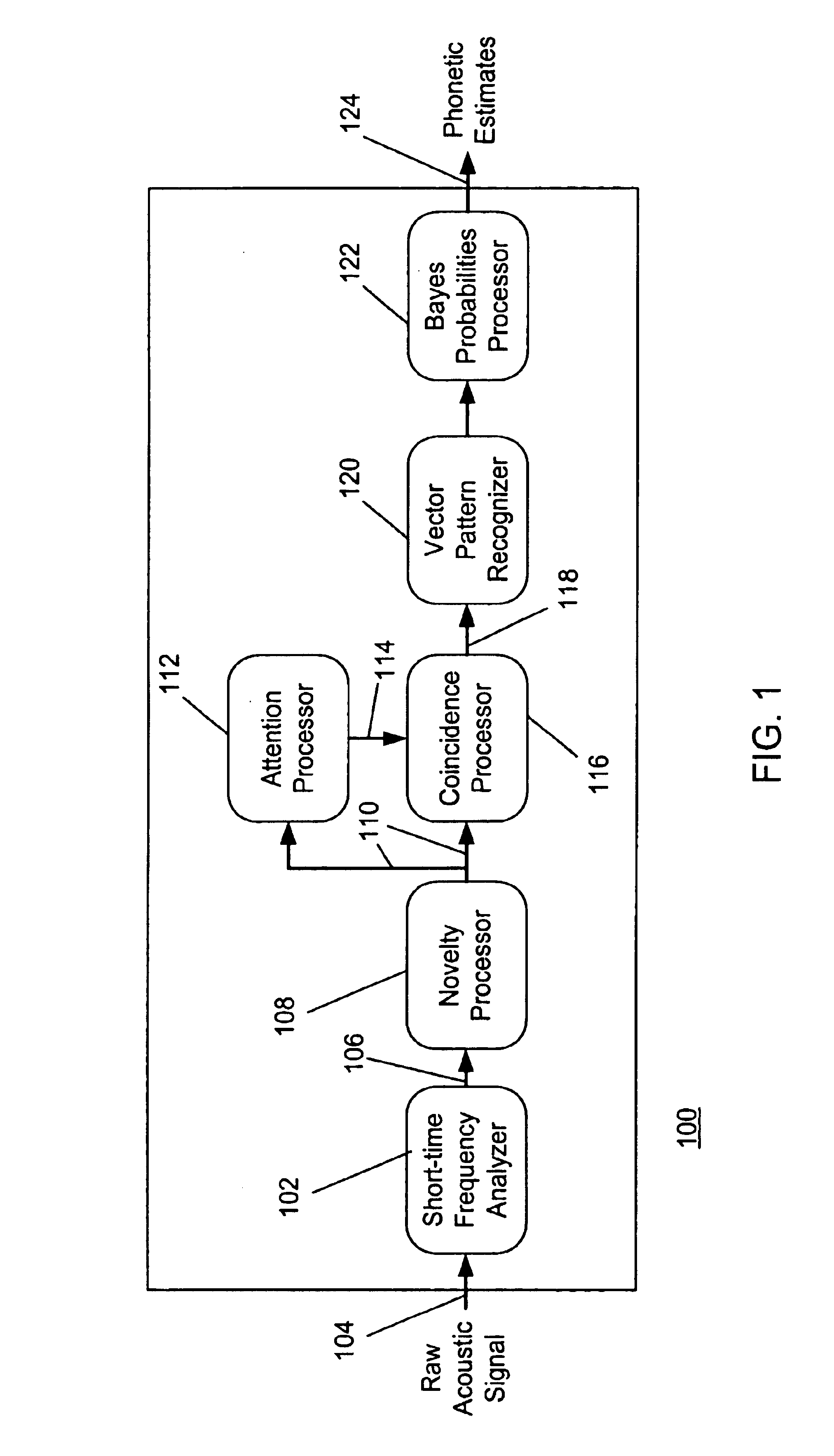

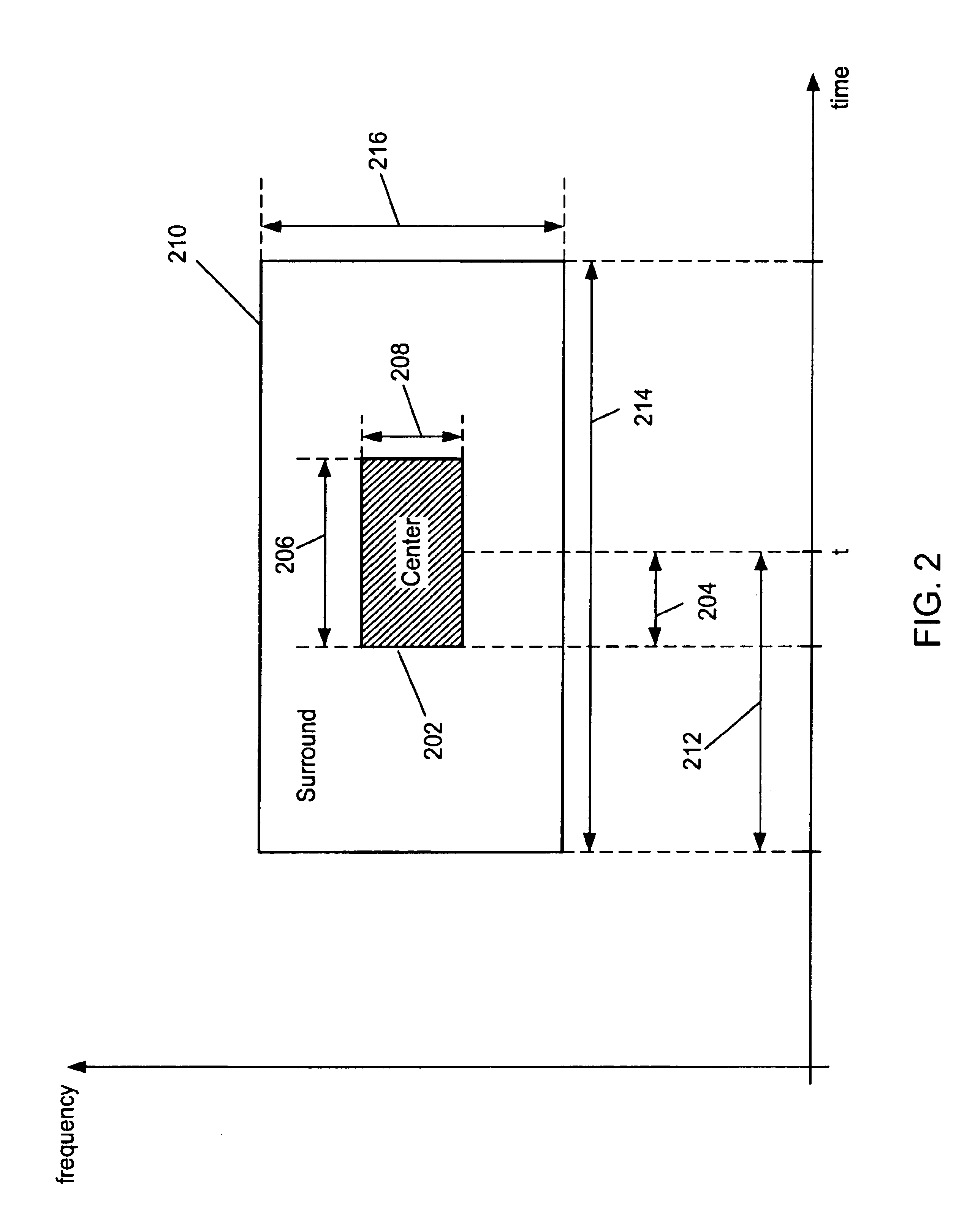

Speech recognition system and method for generating phonotic estimates

InactiveUS6868380B2Simplify subsequent processing stepsAvoid difficultySpeech recognitionMarketingCo-occurrenceSpeech identification

A speech recognition system for transforming an acoustic signal into a stream of phonetic estimates includes a frequency analyzer for generating a short-time frequency representation of the acoustic signal. A novelty processor separates background components of the representation from region of interest components of the representation. The output of the novelty processor includes the region of interest components of the representation according to the novelty parameters. An attention processor produces a gating signal as a function of the novelty output according to attention parameters. A coincidence processor produces information regarding co-occurrences between samples of the novelty output over time and frequency. The coincidence processor selectively gates the coincidence output as a function of the gating signal according to one or more coincidence parameters. A vector pattern recognizer and a probability processor receives the gated coincidence output and produces a phonetic estimate stream representative of acoustic signal.

Owner:ELIZA

Quantitative characterization method of low penetration double-medium sandstone oil reservoir microscopic aperture structure

ActiveCN103278436AIncrease reflectionAvoid one-sidednessPermeability/surface area analysisNMR - Nuclear magnetic resonanceRock core

The invention provides a quantitative characterization method of low penetration double-medium sandstone oil reservoir microscopic aperture structure, which comprises the following steps: selecting experiment samples, effectively combining various experiments, distributing samples, processing and analyzing experiment test data, combining macroscopic background and microscopic rock core, and combining static state analysis and dynamic production reality, thereby realizing quantitative characterization of ultra-low penetration double-medium sandstone oil reservoir microscopic aperture structure from qualitative analysis and semi-quantitative evaluation. The invention has the advantages that more comprehensive influence factors and micro crack, aperture throat parameter and nuclear magnetic resonance movable fluid parameter are considered, so the characterization result can better reflect change characteristics of ultra-low penetration double-medium sandstone oil reservoir microscopic aperture structure, which are consistent to the production exploitation real cases of the oil field, thereby effectively avoiding one-sidedness and limitation of single aspect evaluation result.

Owner:XI'AN PETROLEUM UNIVERSITY

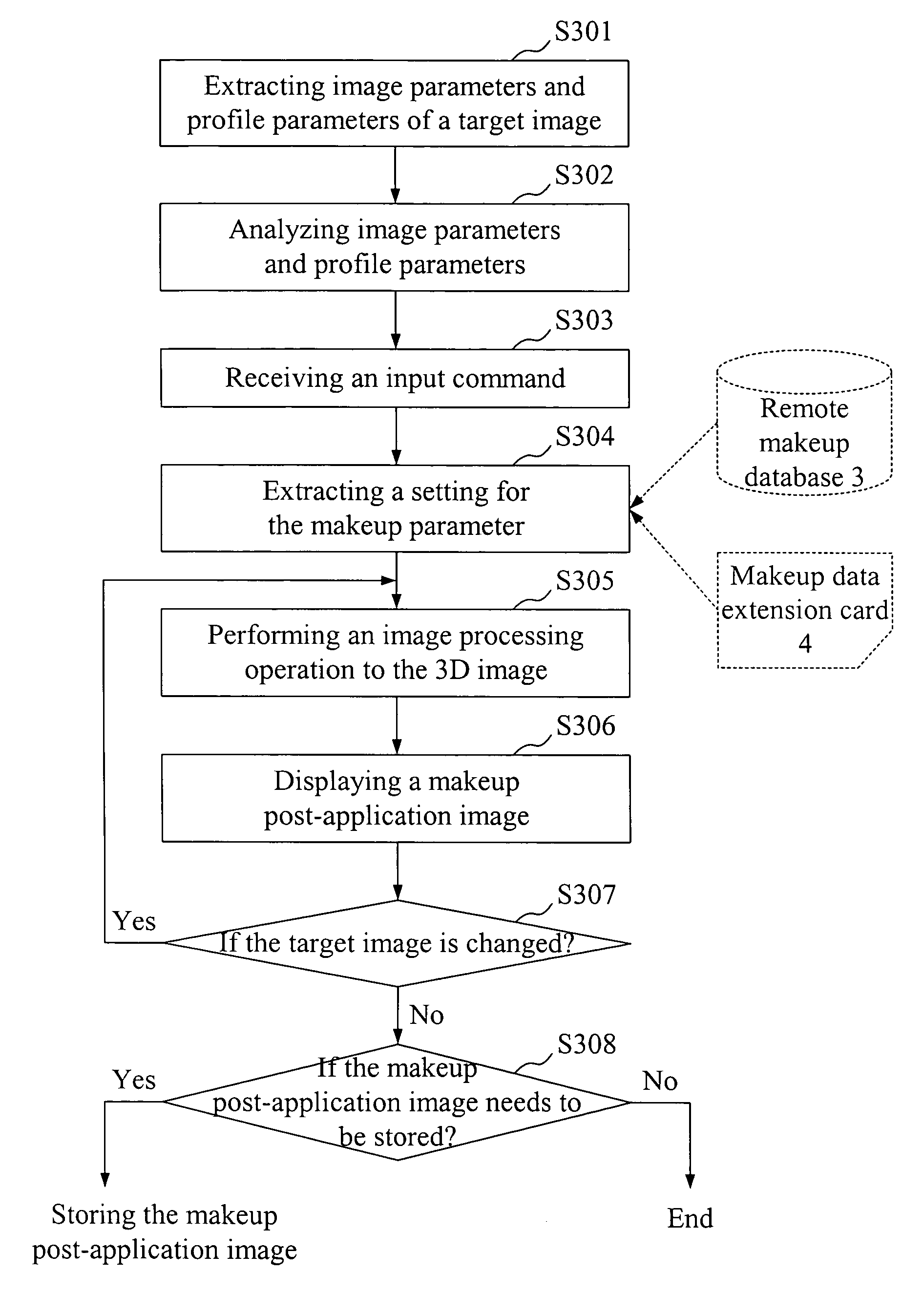

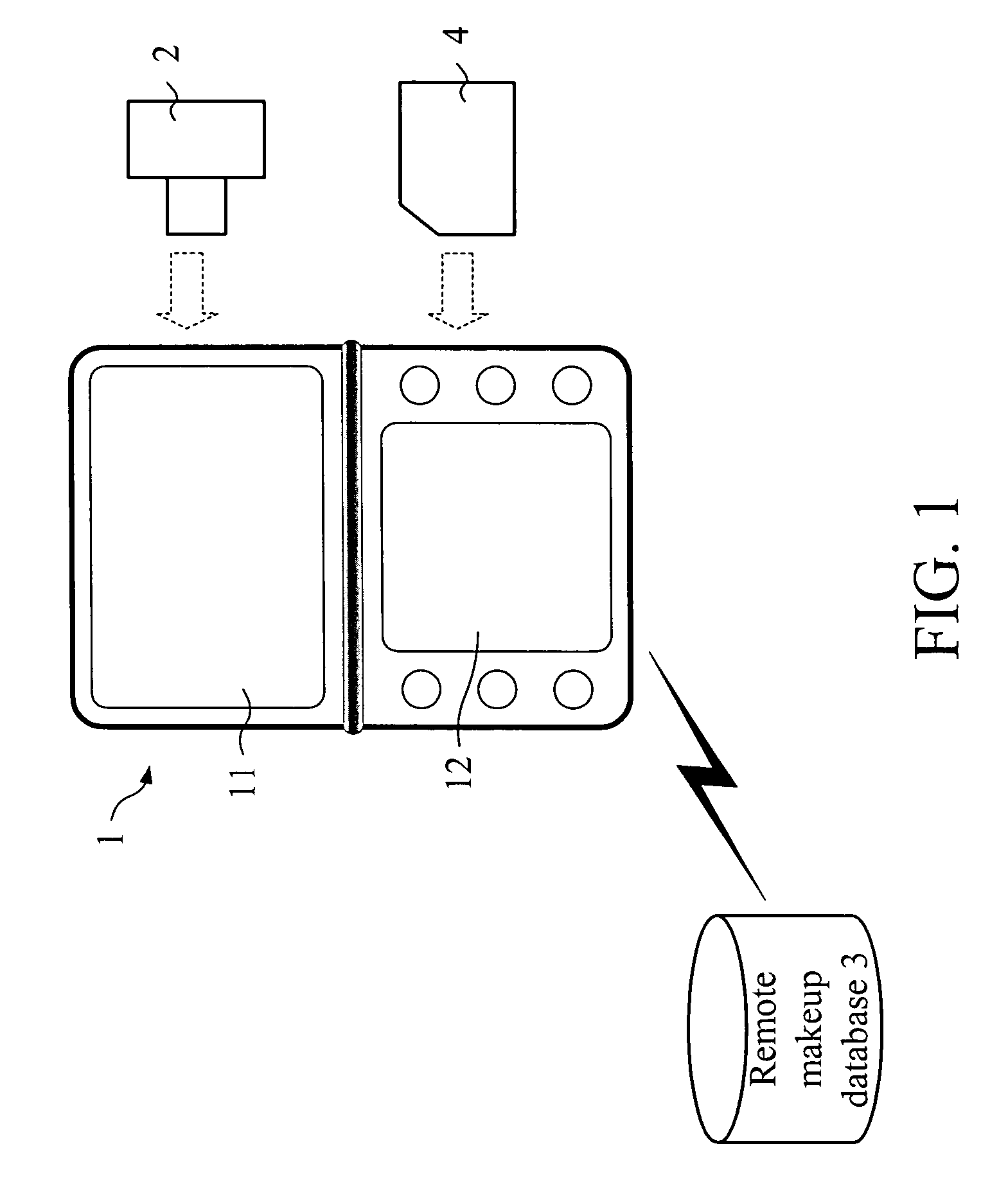

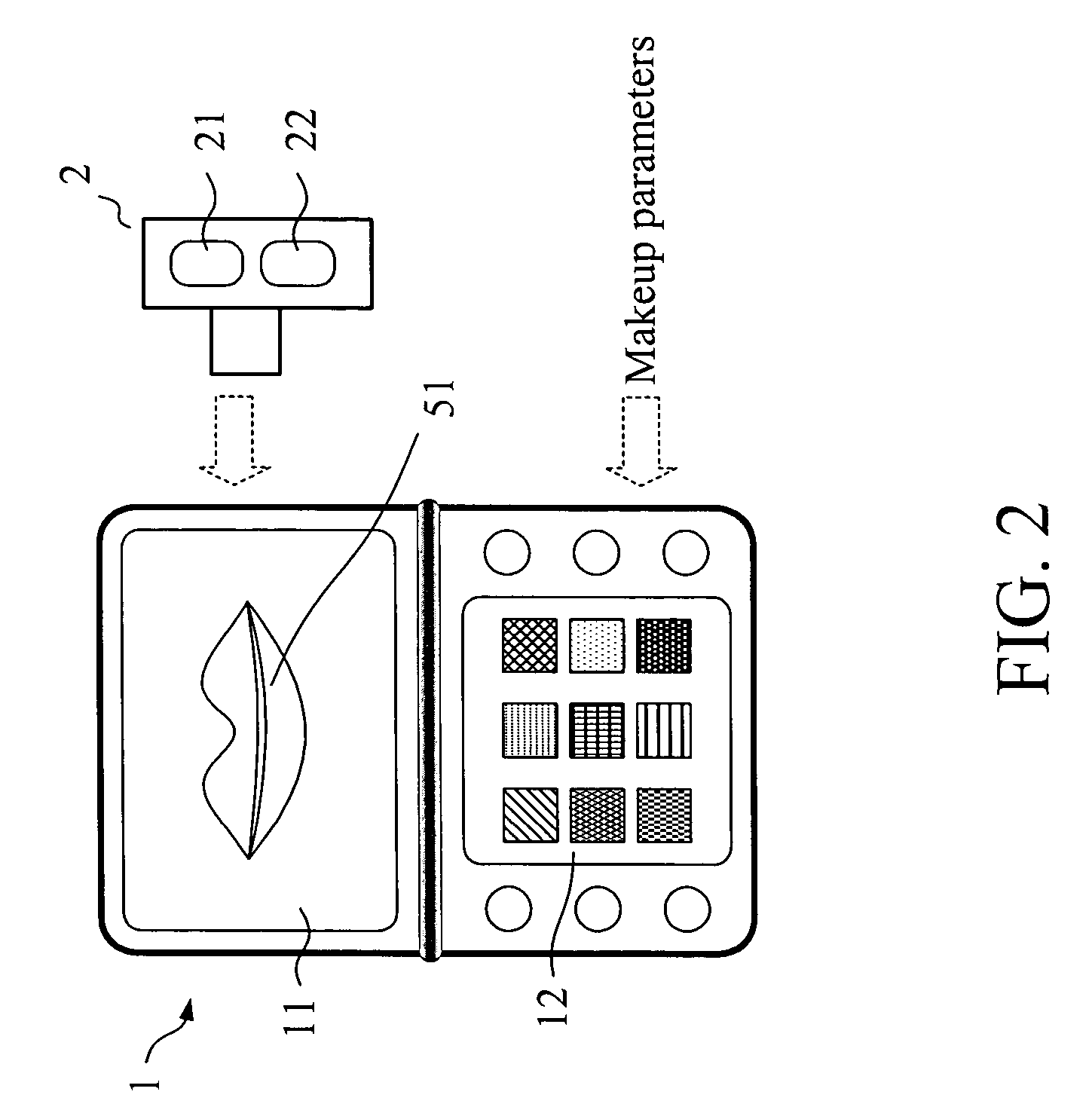

Simulation method for makeup trial and the device thereof

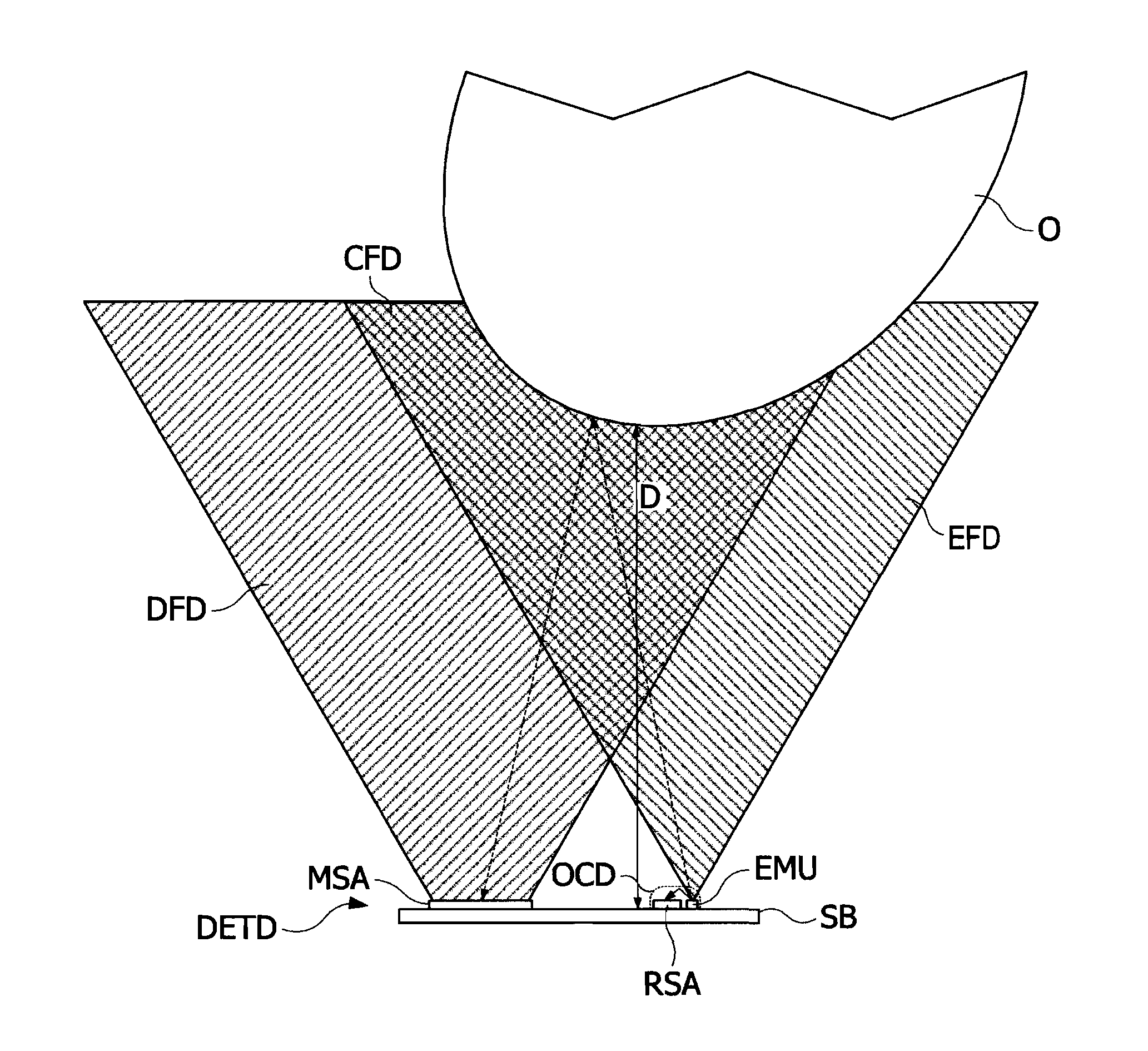

InactiveUS20050135675A1Reduce sampling costsPrevent invasion2D-image generationCharacter and pattern recognition3d imageEntire face

A simulation method for makeup trial and the device thereof are disclosed, which utilize an image sensor and a deep sensor to establish a 3D image according to a target image of a user and a profile signal, such as the lips, eyes or the entire face, and provide makeup data for the makeup product. A user can select a corresponding makeup product using a touch panel. The simulation device for makeup trial reads makeup material data and application skill information via a network or a makeup data extension card, and displays a makeup post-application image on a display module. The present invention is capable of immediately calculating makeup effects when the user turns his or her head.

Owner:INSTITUTE FOR INFORMATION INDUSTRY

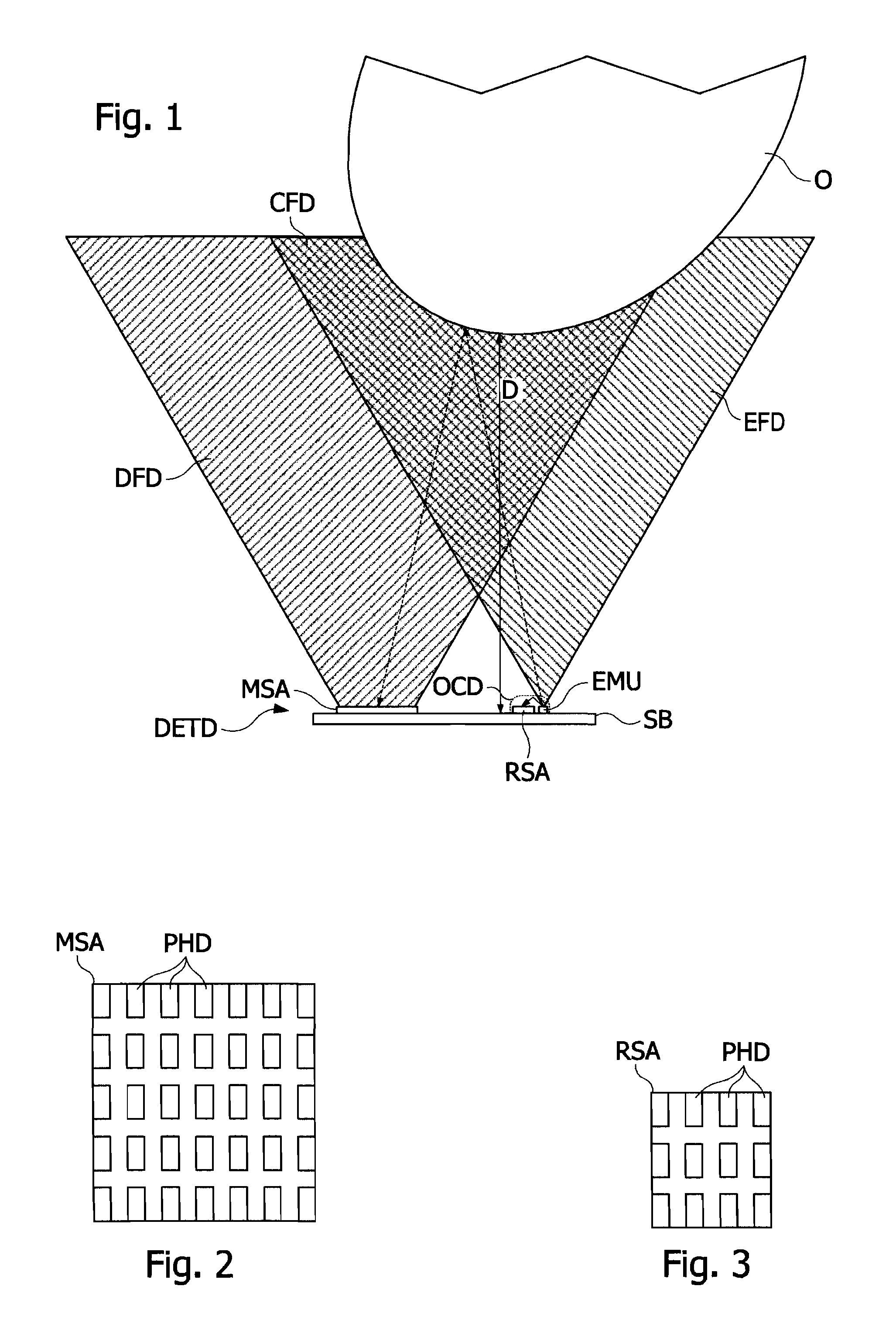

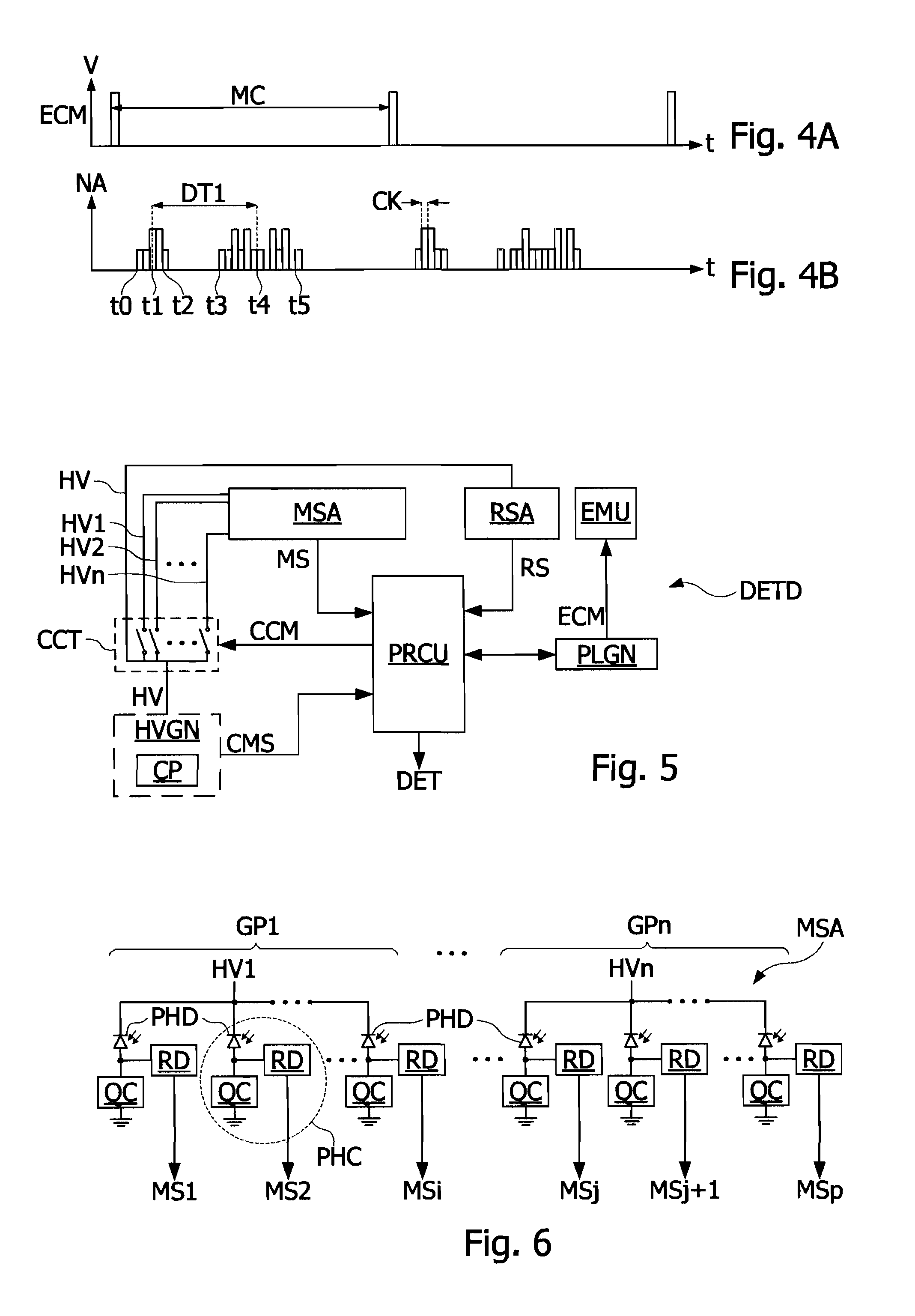

Device having spad photodiodes for detecting an object

ActiveUS20130153754A1High voltage is generatedAvoid limitationsMaterial analysis by optical meansPhotometry using electric radiation detectorsPhoton beamLight beam

The disclosure relates to a method for detecting the presence of an object near a detection device, comprising: reverse biasing single photon avalanche photodiodes, at a bias voltage greater than a breakdown voltage of a PN junction of each photodiode, emitting pulses of an incident photon beam, detecting photodiodes which avalanche trigger after the reception by the photodiode of at least one photon of a reflected photon beam produced by a reflection of the incident beam on an object near the detection device, determining the object presence as a function of the existence of at least one avalanche triggering in one of the photodiodes, and selecting a number of photodiodes to be reverse biased in relation to the detection device, as a function of a load of a circuit for generating the bias voltage.

Owner:STMICROELECTRONICS (GRENOBLE 2) SAS

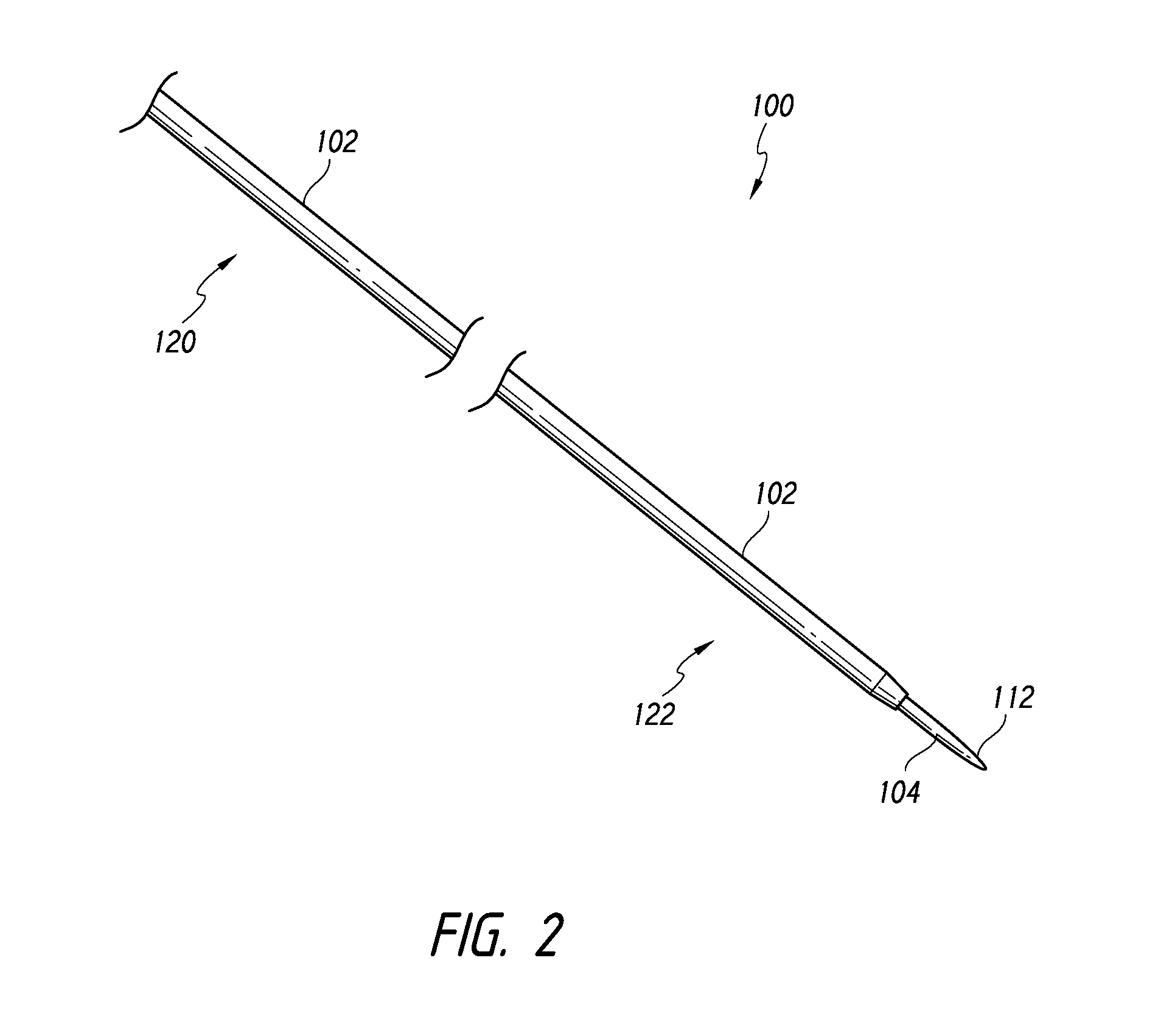

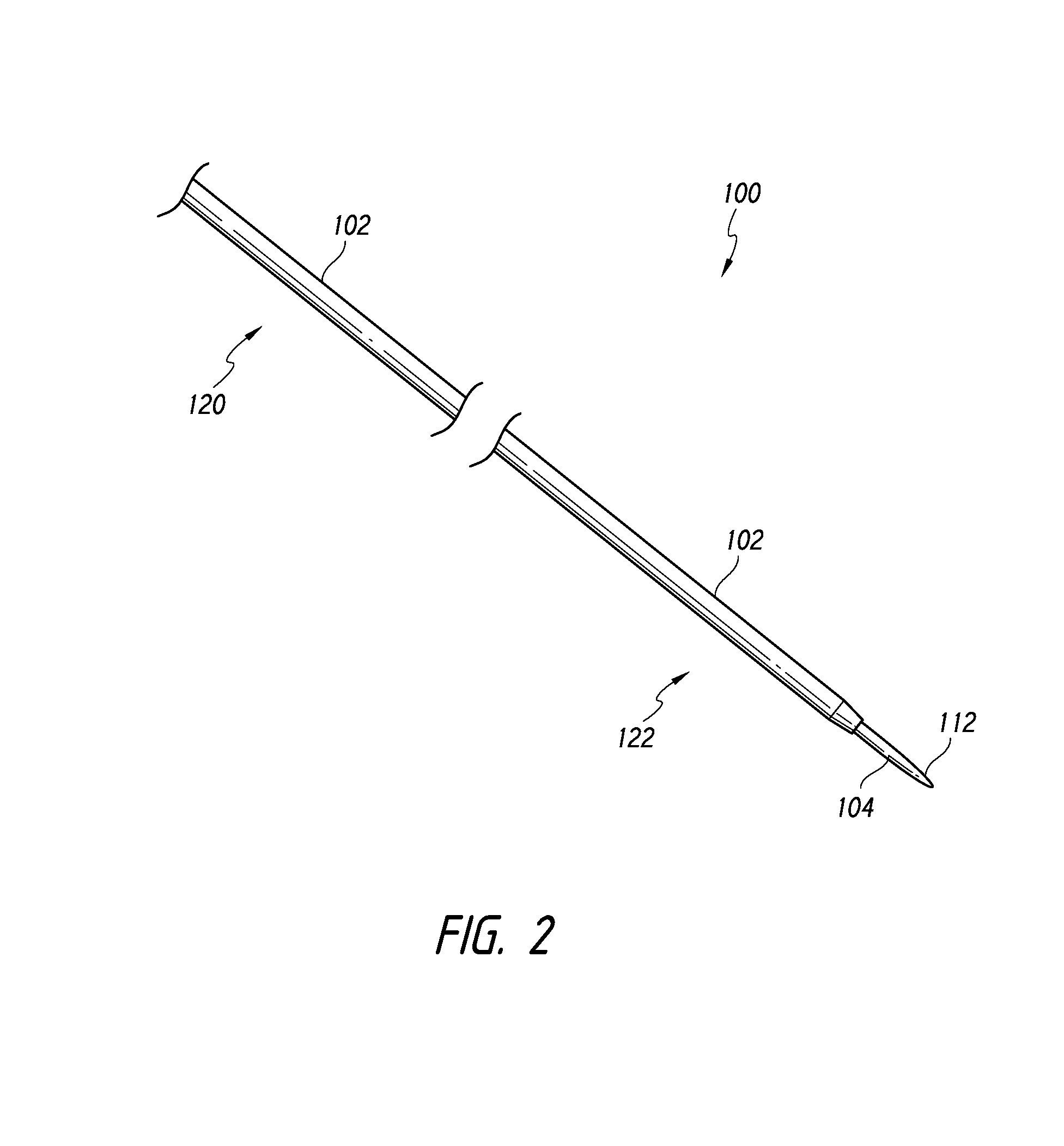

Needleless hypodermic jet injector apparatus and method

InactiveUS7347851B1Less painful experienceLess discomfortJet injection syringesAutomatic syringesLiquid jetJet flow

In the present invention, the impedance between patient's body and the jet injection drug delivery device is measured through the liquid jet during the drug delivery process. The liquid jet completes the electrical circuit formed by impedance monitor, drug delivery device, and the patient's body. When the jet pierces stratum corneum, the impedance in the circuit immediately decreases, thus an indicating the successful drug delivery. The impedance monitor then provides a signal, visible, audible, or electronic, indicating that the process of the drug delivery through skin was successful.

Owner:KRIKSUNOV LEO B

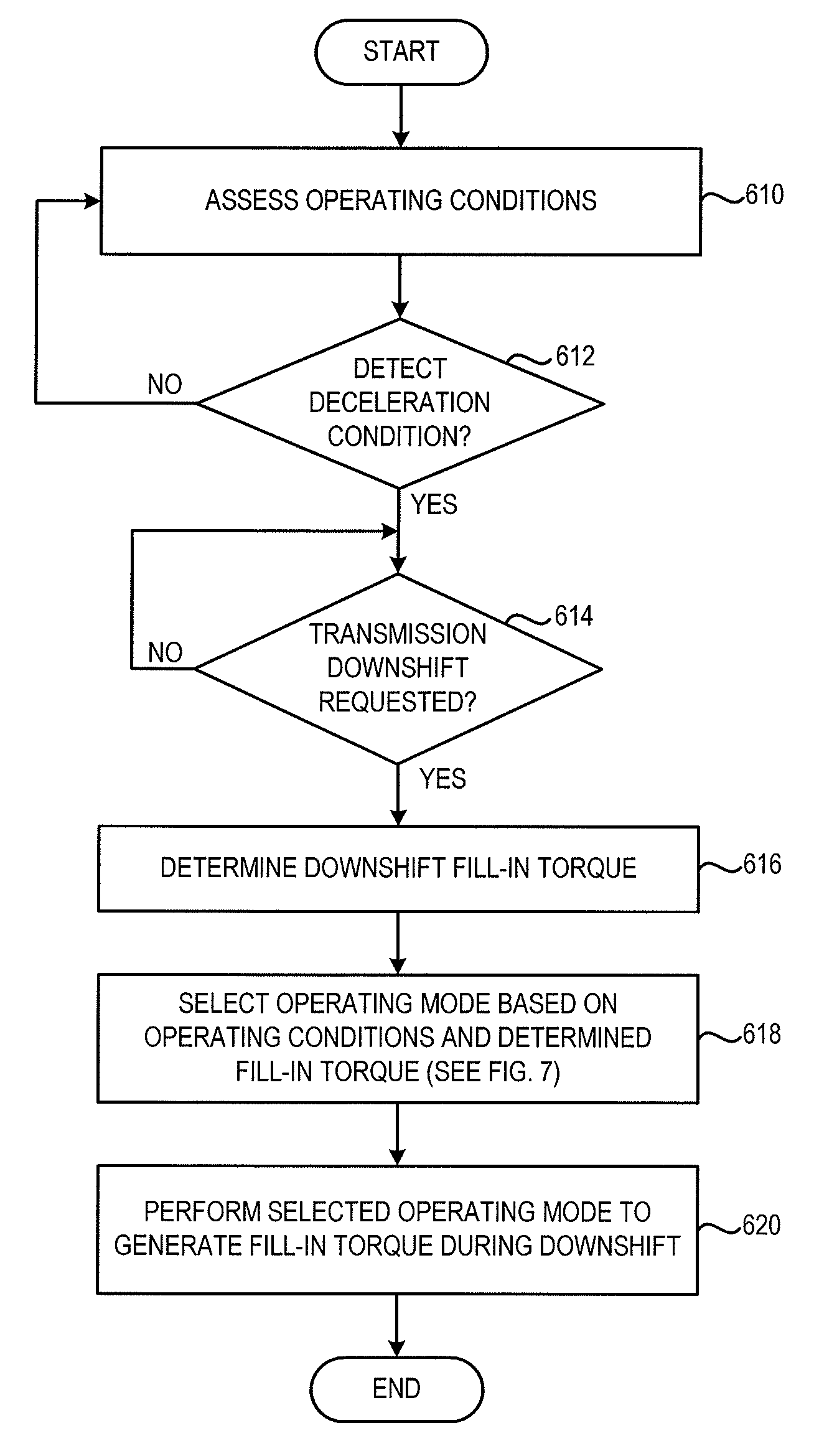

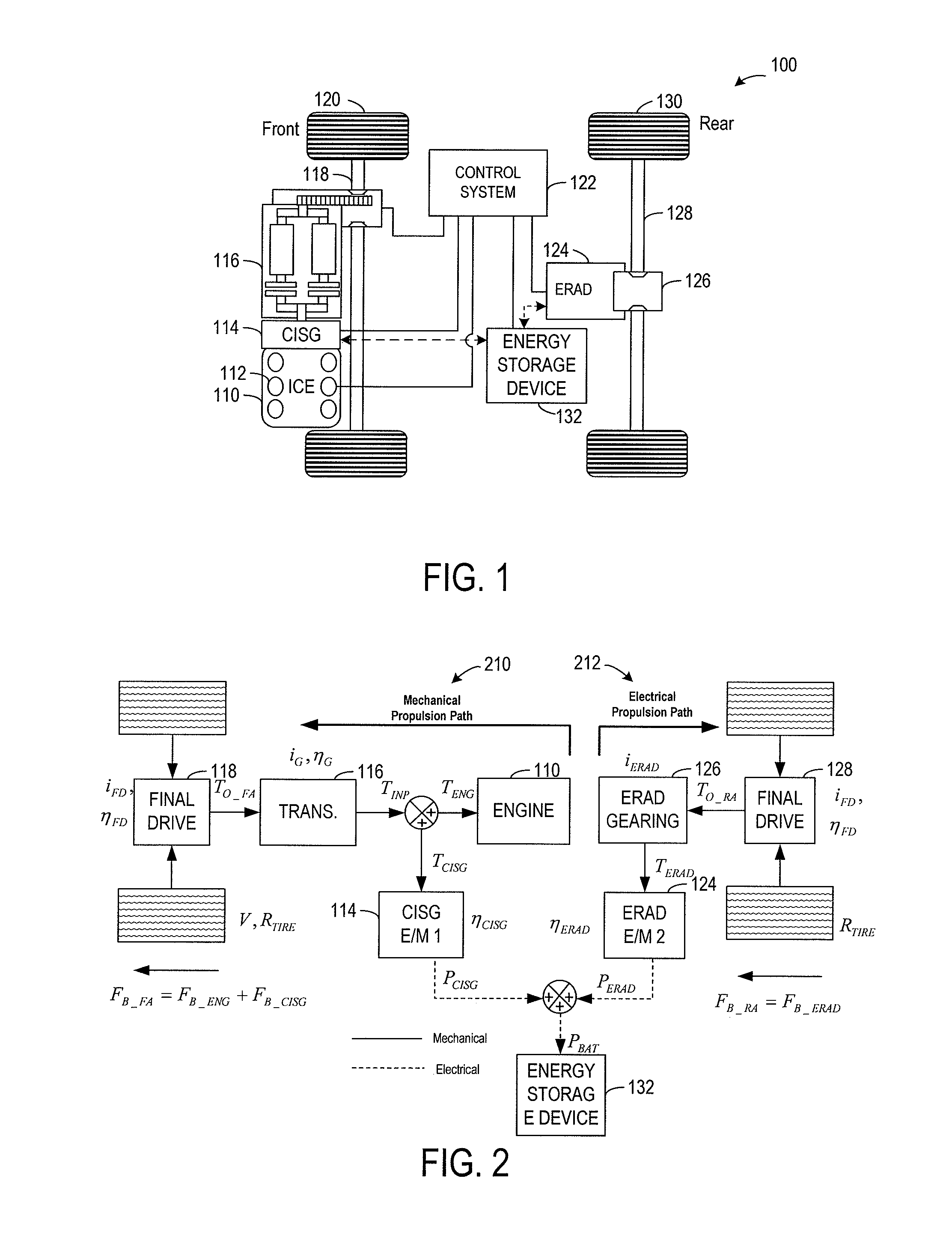

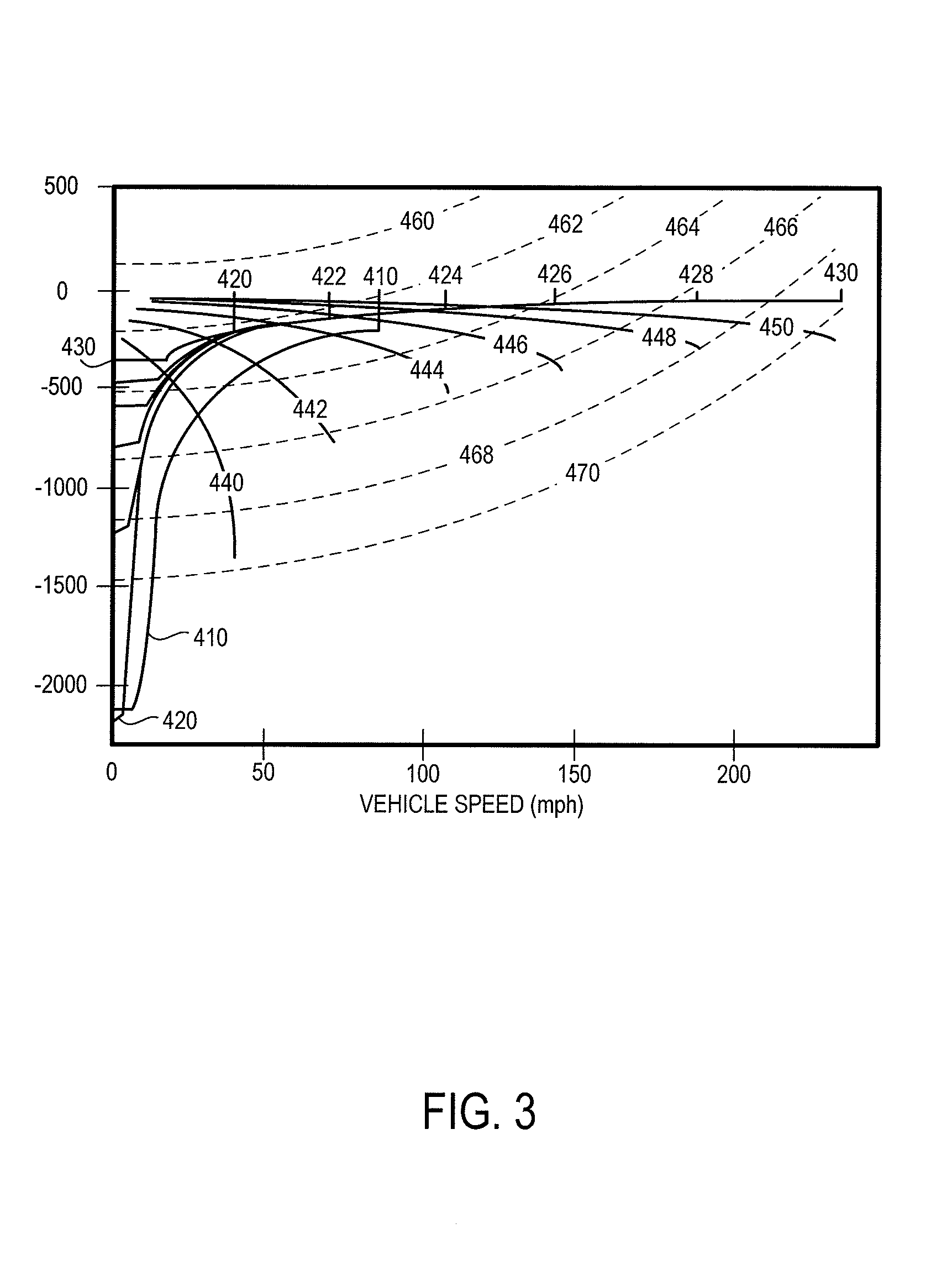

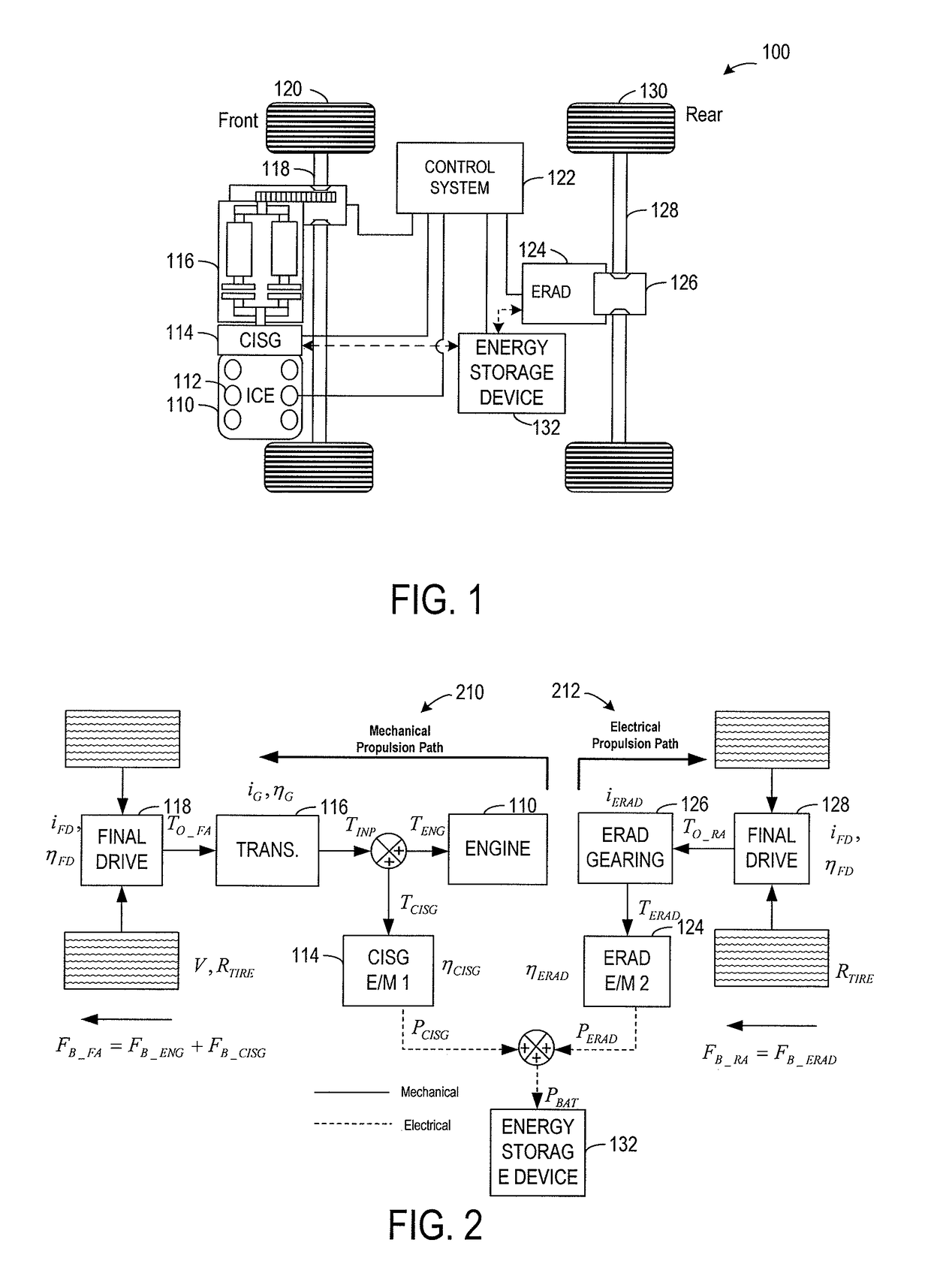

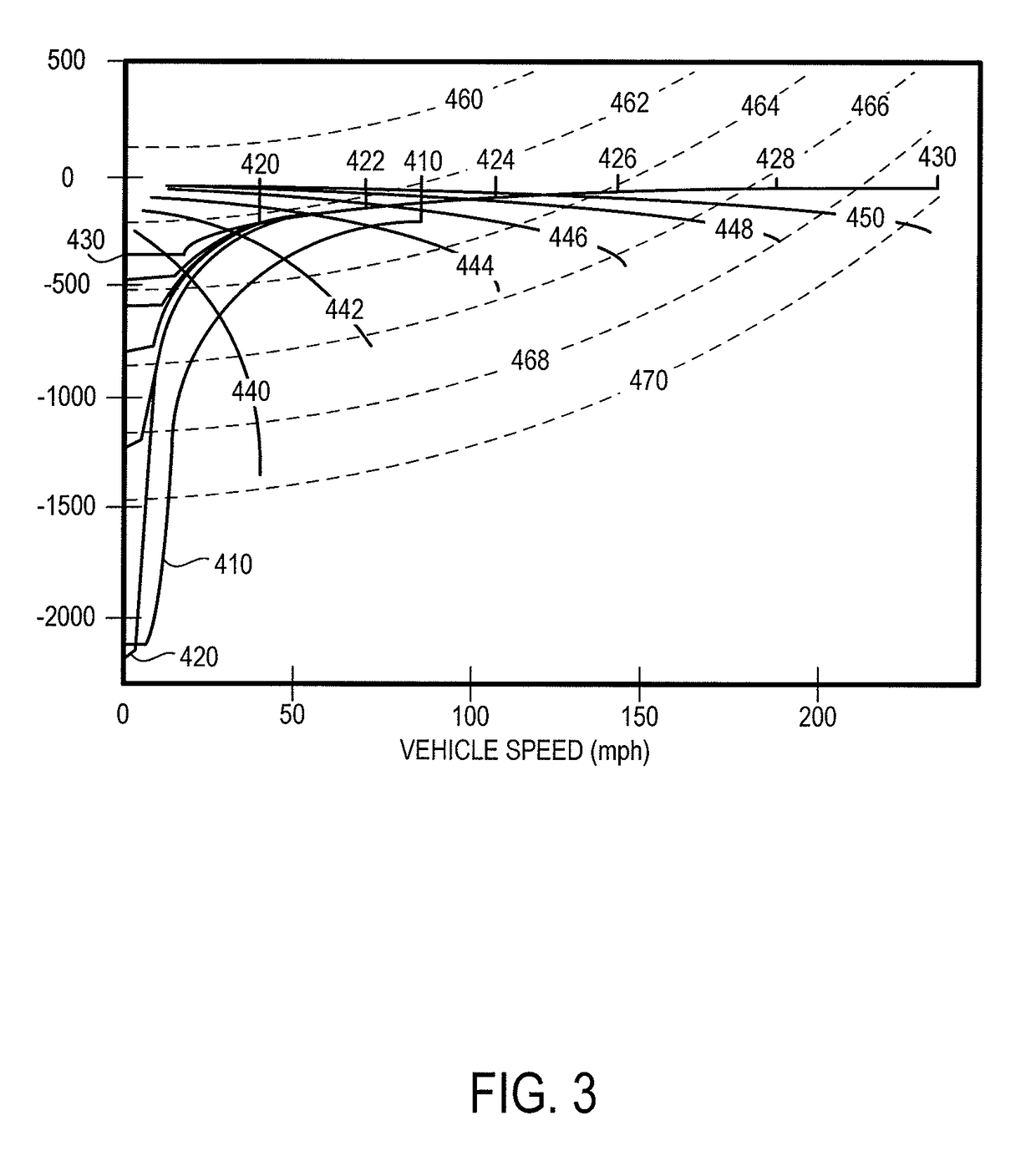

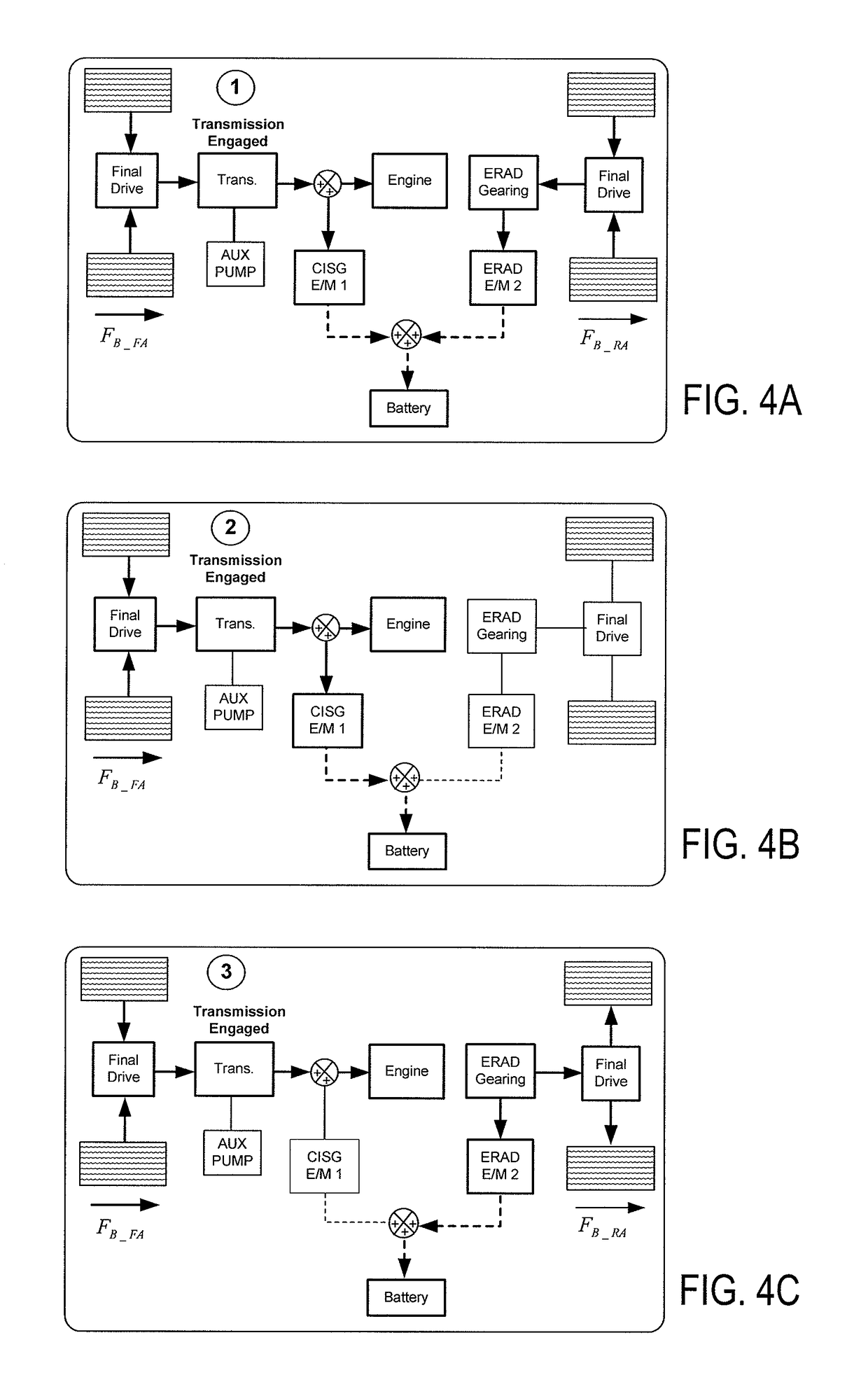

Hybrid Electric Vehicle Braking Downshift Control

ActiveUS20090150035A1Stable torque deliveryIncreased torque outputDigital data processing detailsElectric propulsion mountingBrake torqueDrive wheel

A hybrid propulsion system for a vehicle. The hybrid propulsion system including a multiple step fixed-gear transmission device for transmitting torque to a first at least one drive wheel, a first electric energy conversion device coupled to an input of the multiple step fixed-gear transmission device, and a control system, during a deceleration condition, the control system increasing negative torque output of the first electric energy conversion device to meet a desired wheel braking torque in response to the multiple step fixed-ratio transmission transitioning from a first gear ratio to a second gear that is higher than the first gear ratio.

Owner:FORD GLOBAL TECH LLC

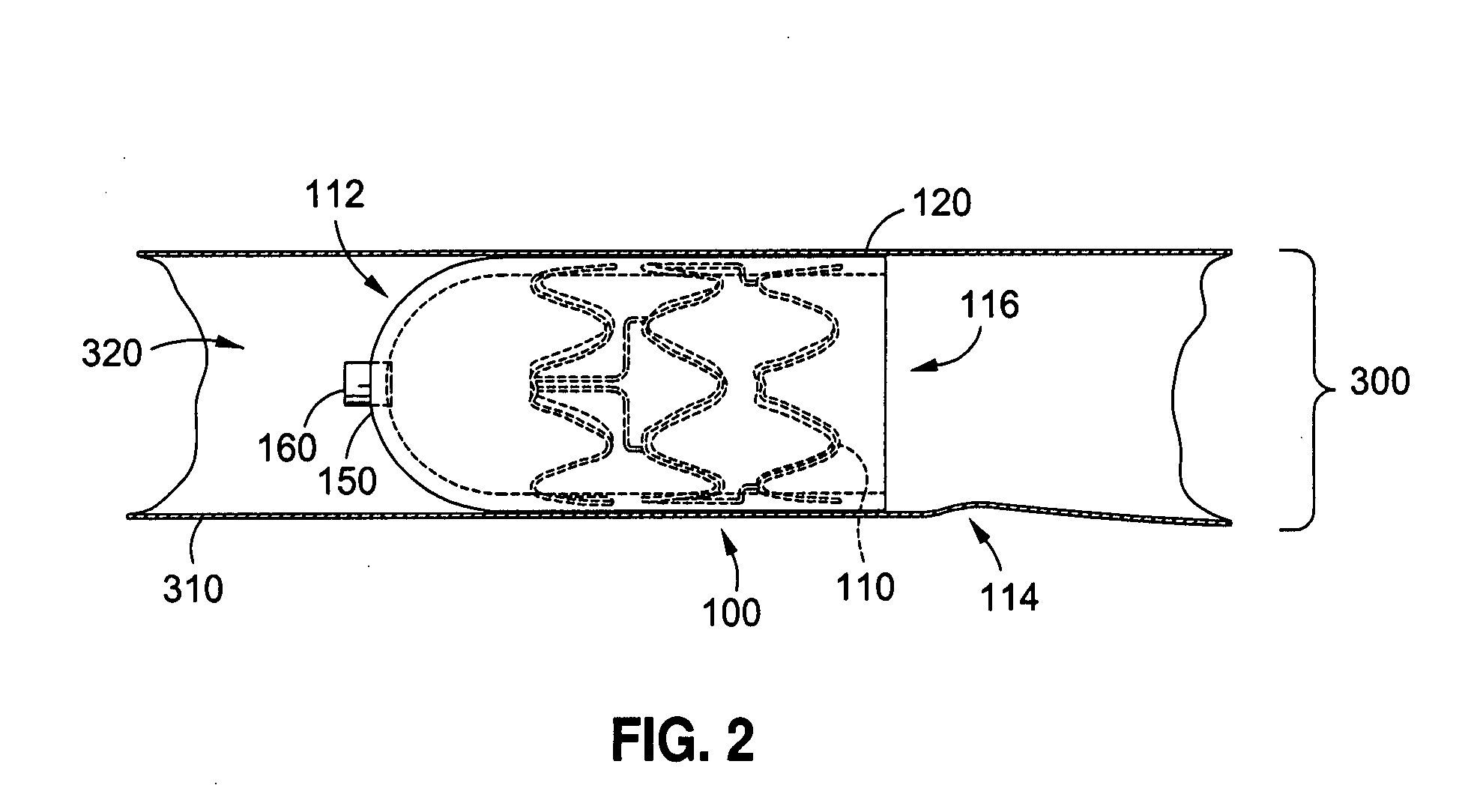

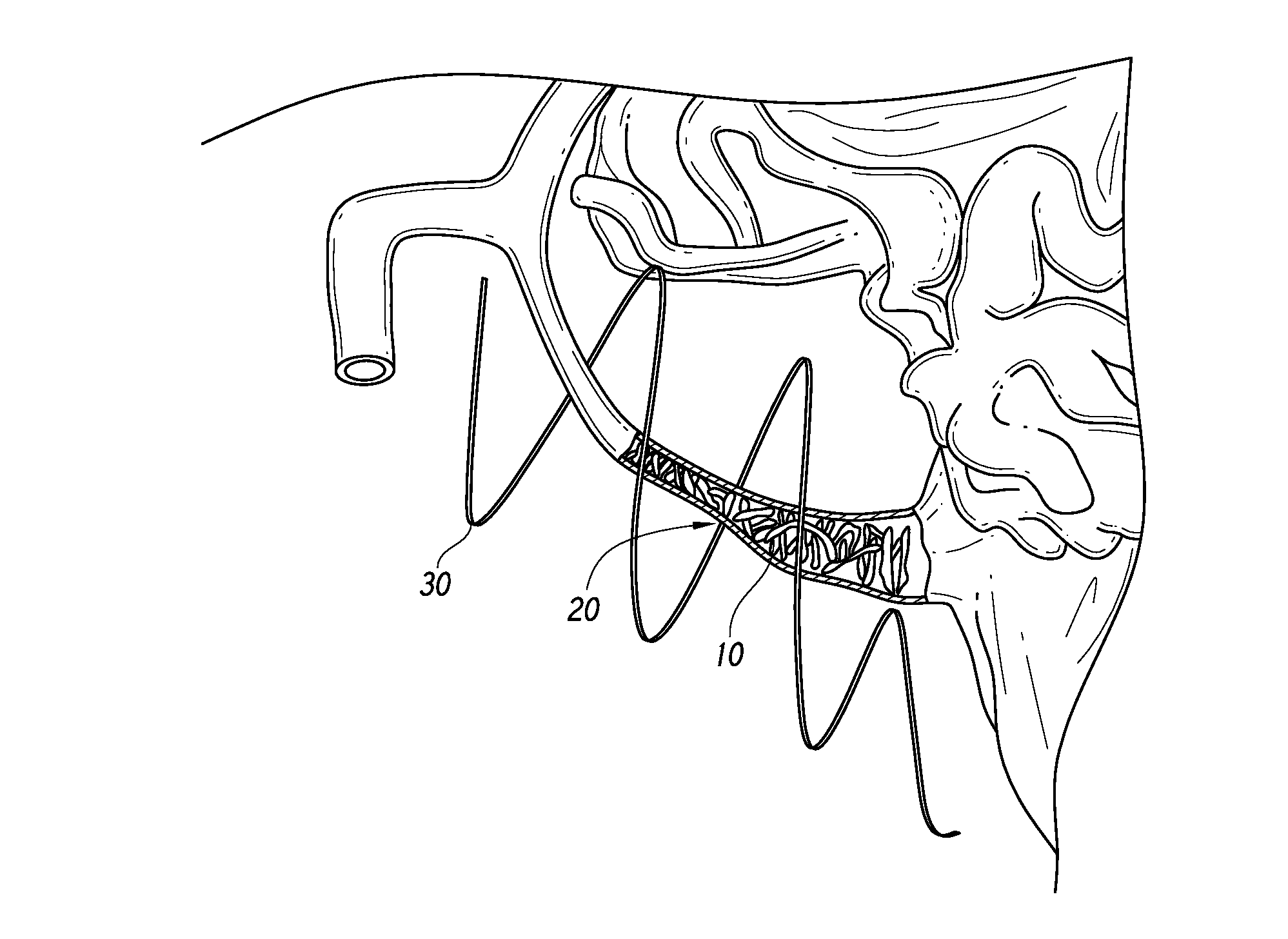

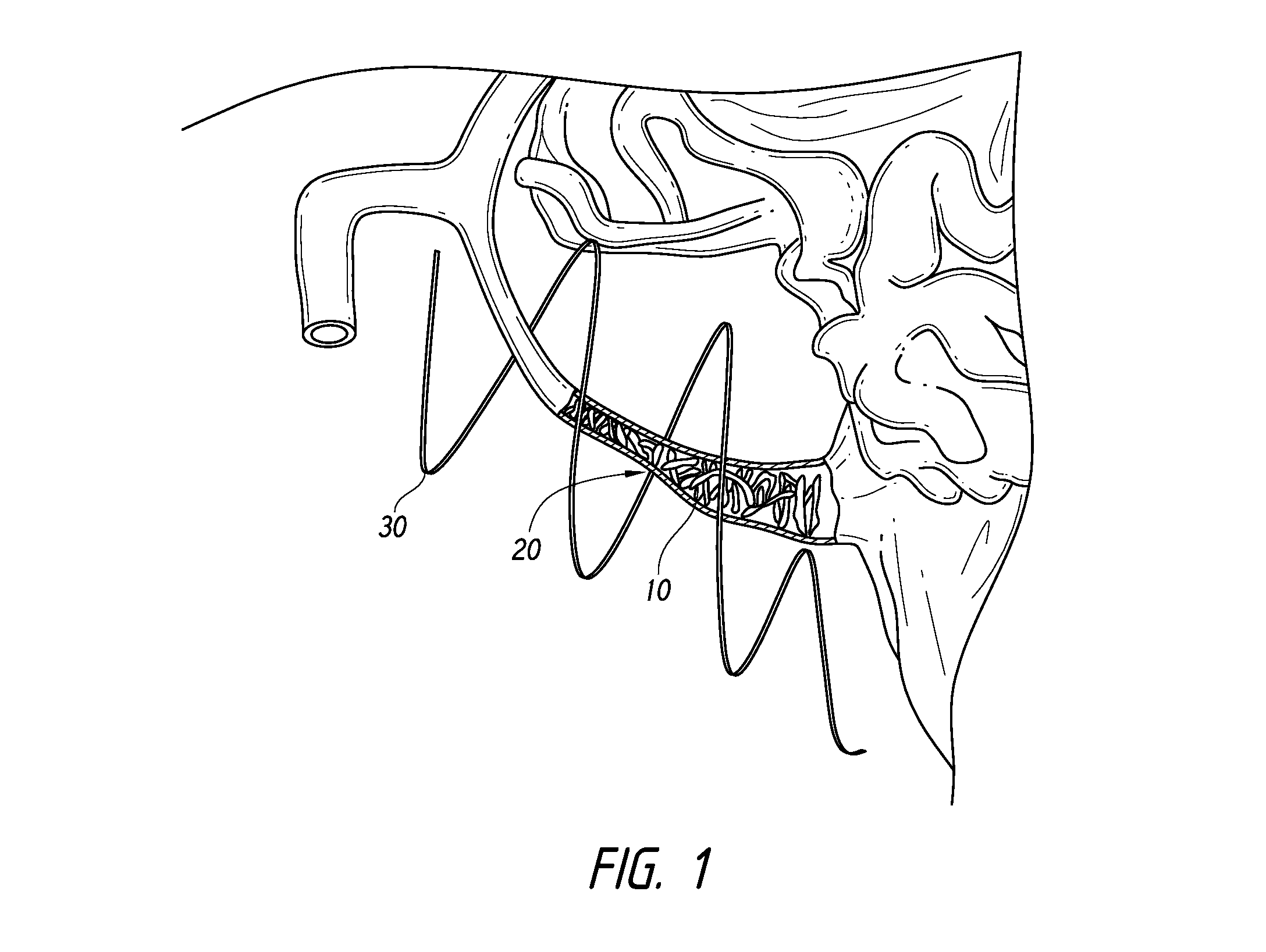

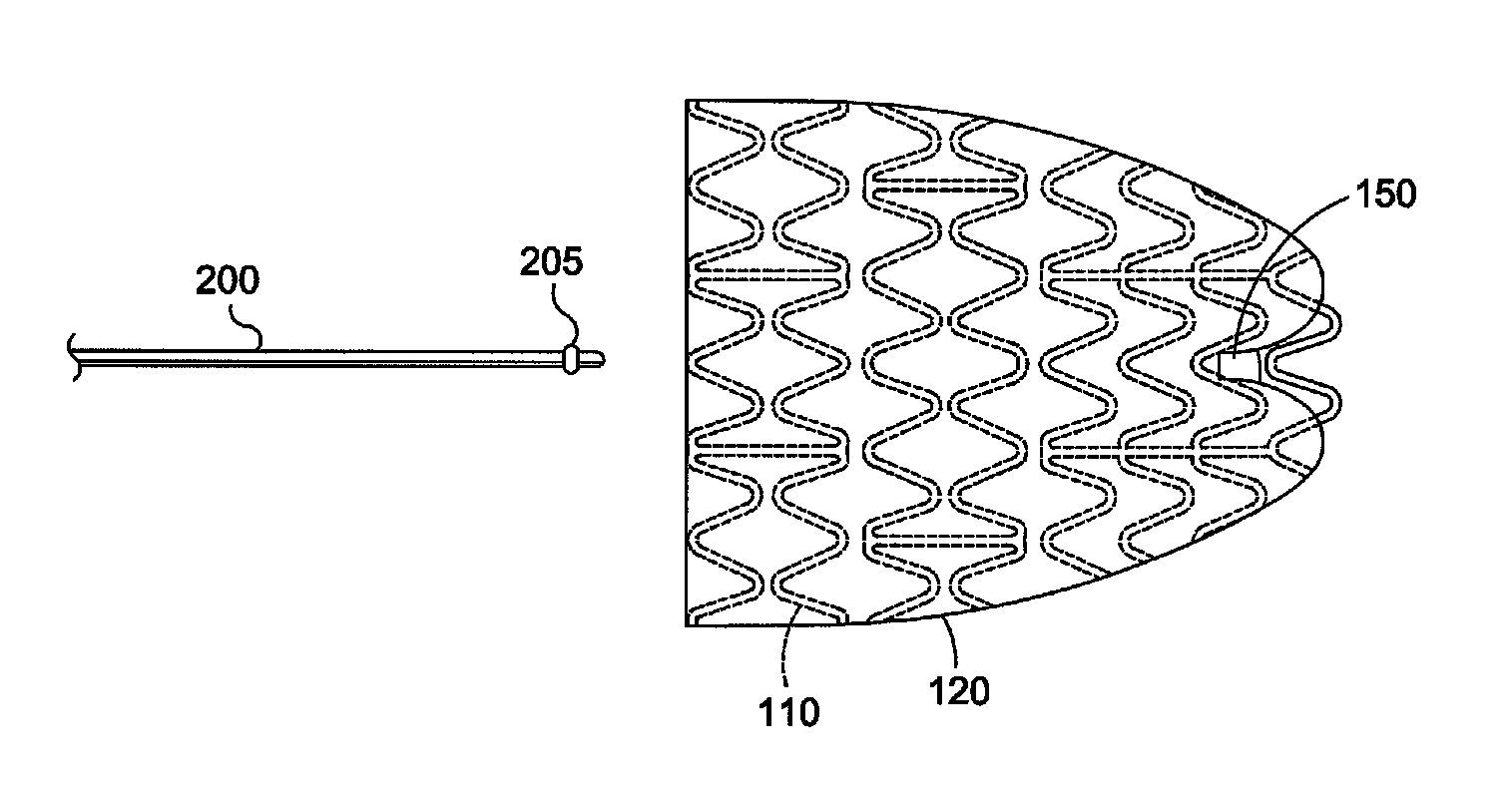

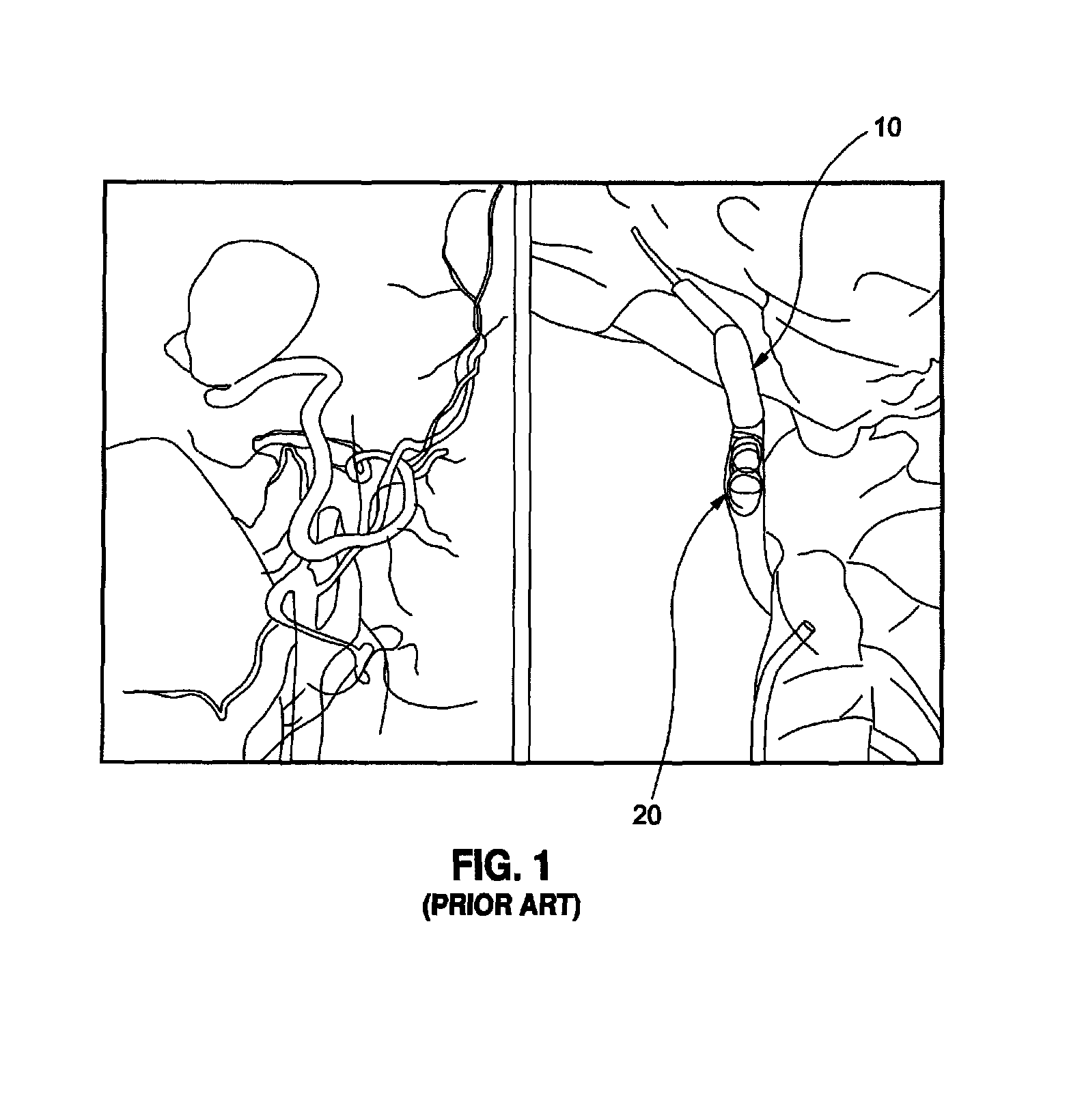

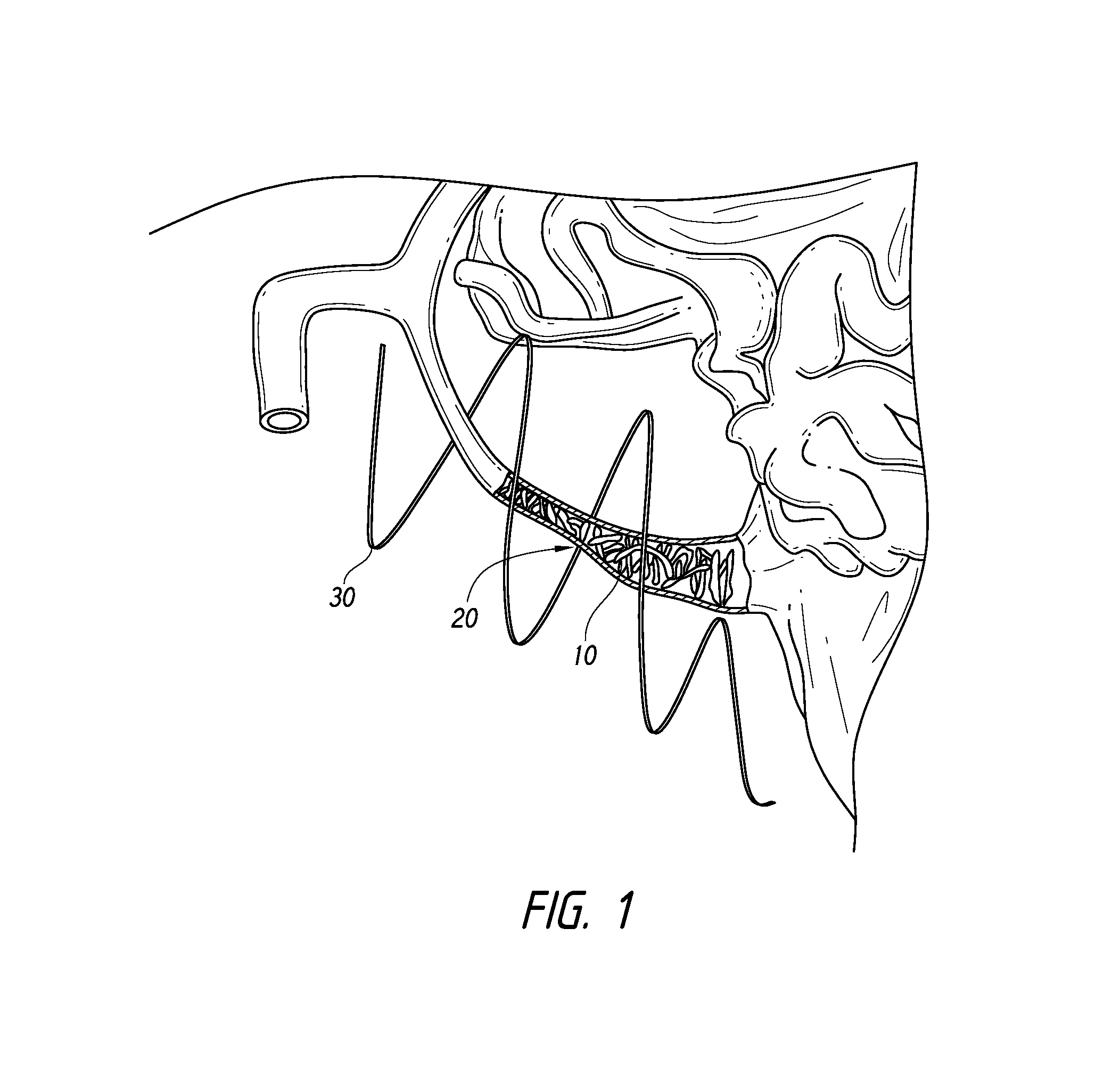

Methods and apparatus for rapid endovascular vessel occlusion and blood flow interruption

ActiveUS20090018636A1Promote thrombosisEffective limitBalloon catheterDiagnosticsInsertion stentGuide wires

An occluding device including expandable scaffold and a flow-limiting member is described. In some embodiments the scaffold is an expandable or self-expanding stent deliverable over a guide wire. The flow-limiting member can include a valve that can be closed following deployment. On deployment the stent and flow-limiting member can engage an inner surface of a body cavity lumen, blocking flow of material. In some embodiments the body cavity is a blood vessel, and the device can be used to block blood flow. In some embodiments the device includes bioactive agents.

Owner:ARTVENTIVE MEDICAL GROUP

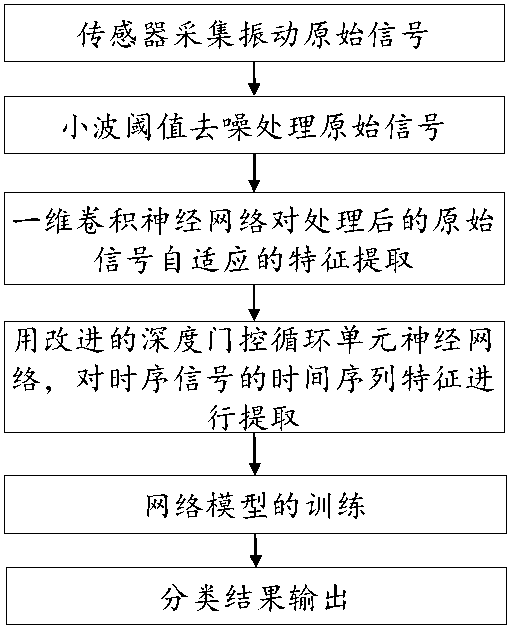

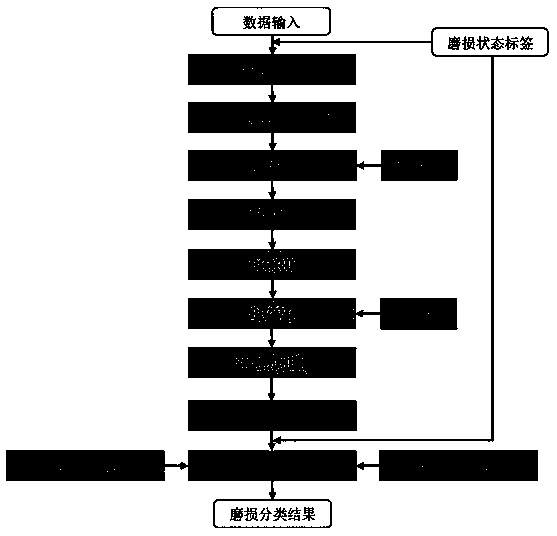

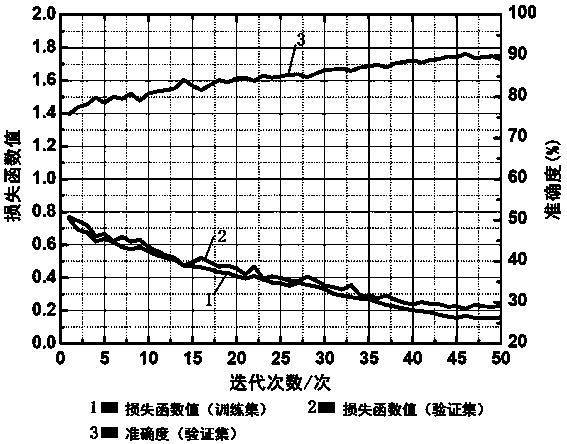

Cutter wear state monitoring method based on deep gated cycle unit neural network

ActiveCN111325112AReal-time monitoring of wear statusImprove accuracyCharacter and pattern recognitionNeural architecturesAlgorithmWavelet thresholding

The invention discloses a cutter wear state monitoring method based on a deep gated cycle unit neural network. The method comprises the steps that vibration signals generated in the tool machining process are collected in real time through a sensor, after wavelet threshold denoising, the signals are input into a one-dimensional convolutional neural network for single time step time sequence signallocal feature extraction; then, inputting the time series signal into an improved deep gated recurrent unit neural network CABGRUs to carry out time series signal time series feature extraction; an Attention mechanism is introduced to calculate network weights and reasonably distribute the network weights, and finally, signal feature information with different weights is put into a Softmax classifier to classify tool wear states, so that complexity and limitation caused by manual feature extraction are avoided; meanwhile, the problem that a single convolutional neural network ignores correlation before and after a time sequence signal is effectively solved, and the accuracy of the model is improved by introducing an Attention mechanism. Therefore, the method has the characteristic of improving the real-time performance and accuracy of cutter wear state monitoring.

Owner:GUIZHOU UNIV

Technique for scheduling execution of jobs for or by network-connected devices

InactiveUS6993763B2Avoid limitationsImprove schedulingResource allocationMemory systemsCascading failureStart time

Methods, systems, computer program products, and methods of doing business by improving the scheduling of execution of jobs for or by network-connected devices, thereby enabling the job execution process to scale more easily, efficiently, and effectively to support large numbers of devices and / or users. Examples of jobs include, but are not limited to, distribution of resources (including software, configuration information, images, and other types of content) to a device, fetching a device's inventory information, backing up a device's contents, and so forth. Jobs are programmatically scheduled based upon a specified time internal, according to a class of the requester. Only if an earliest start time after which the job may be executed for this requester has been reached will the job be executed, otherwise, the job execution is delayed. The disclosed techniques lessen the need for additional servers to handle spikes in processing load, reduce the likelihood of reaching system overload, and reduce the likelihood of cascading failures that may occur when systems are overloaded.

Owner:TWITTER INC

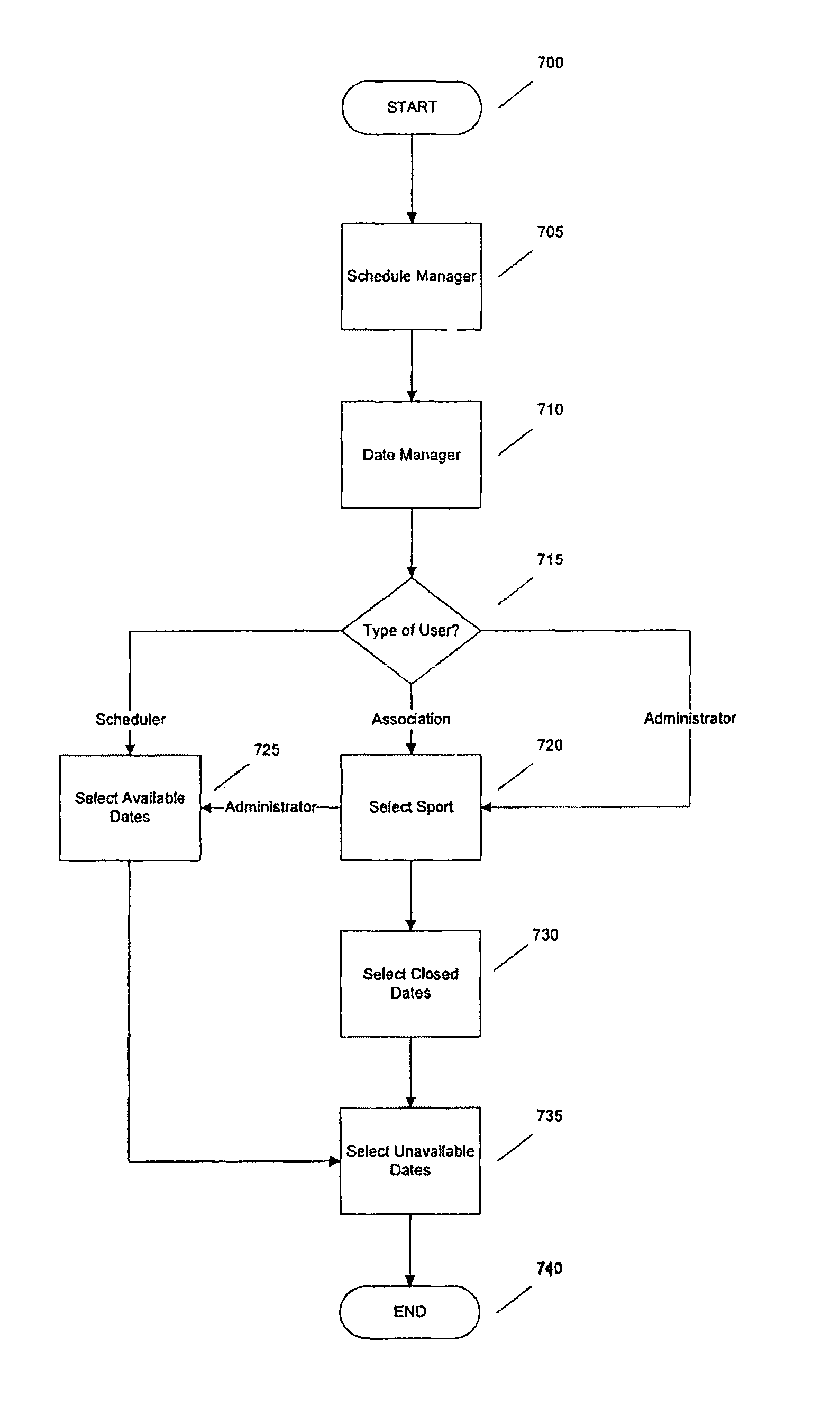

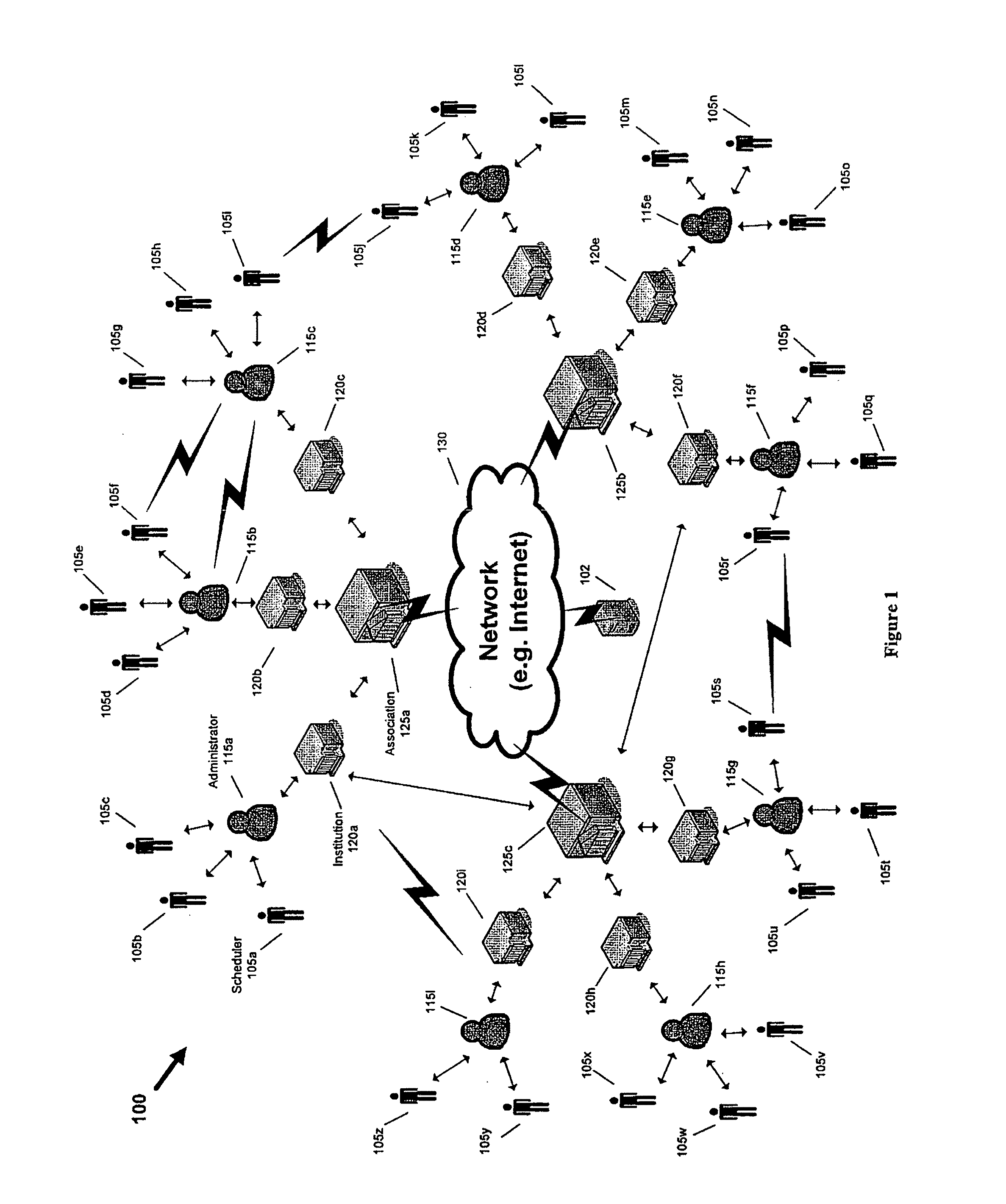

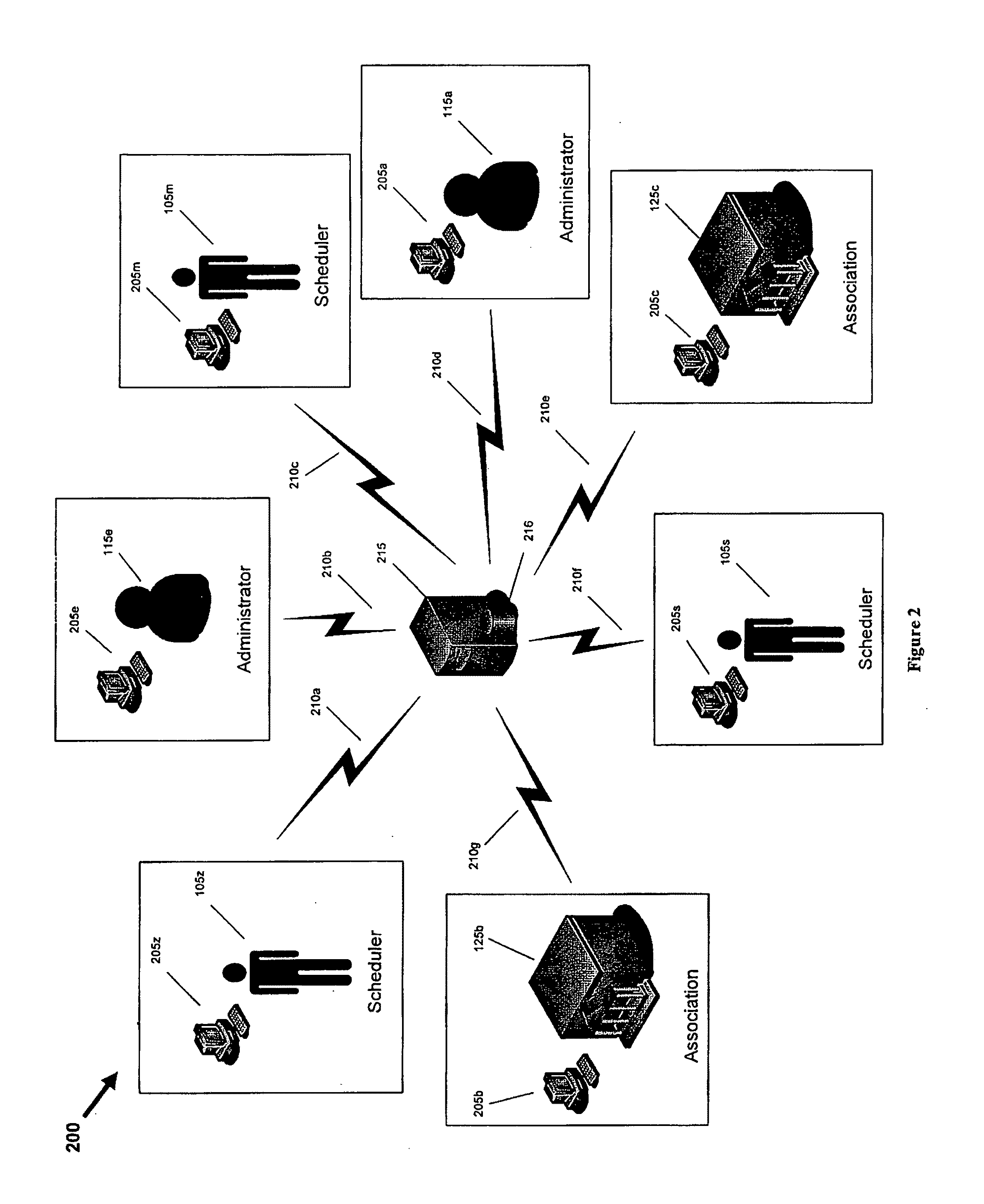

System and method for web-based sports event scheduling

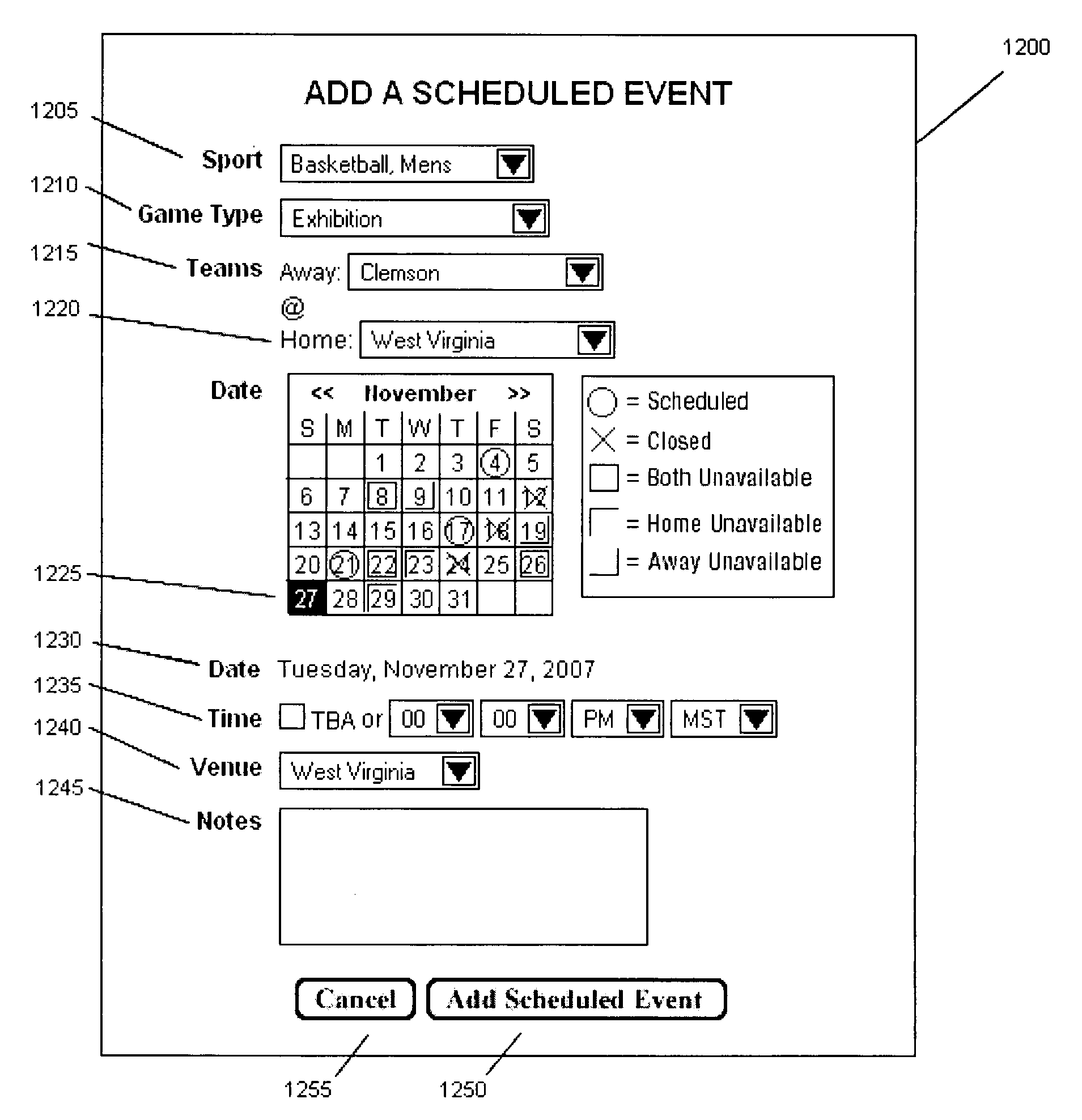

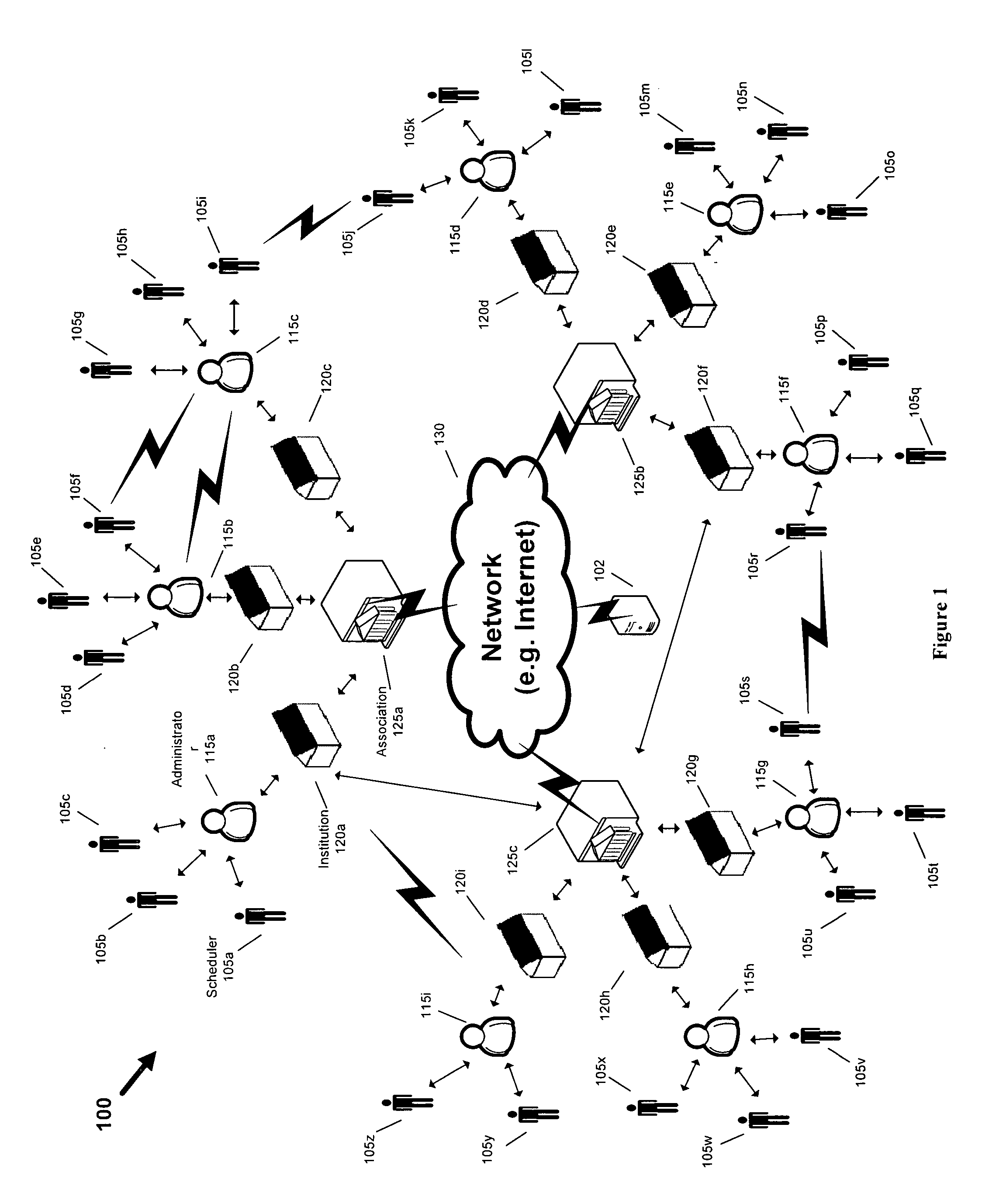

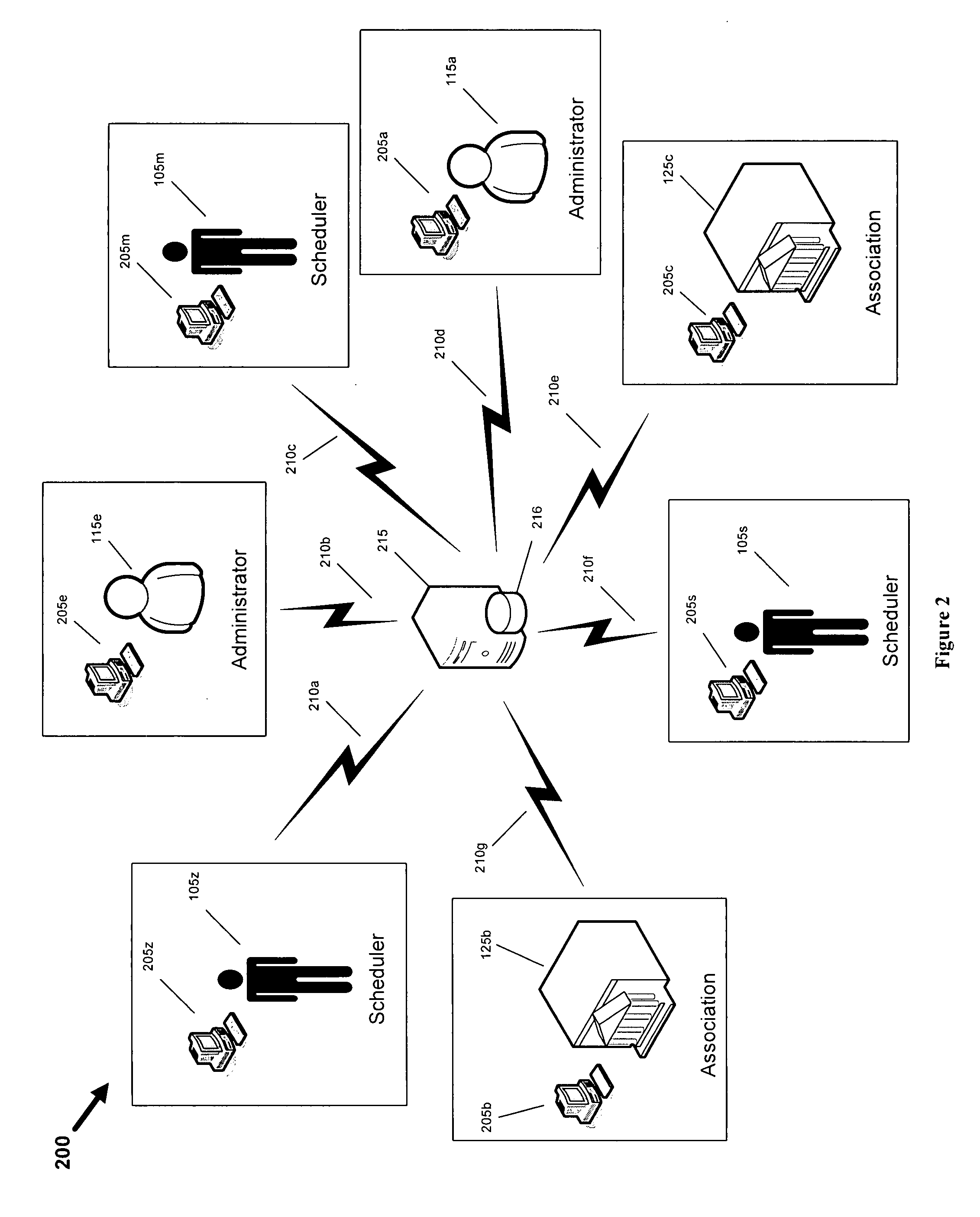

ActiveUS20080010106A1Good and more timely and effective process of communicationAvoid frustrationMultiprogramming arrangementsOffice automationCentralized databaseEvent scheduling

A system and methods are provided for communication between entities that need to coordinate on scheduling events. Communication between schedulers, such as coaches, athletic administrators or organization administrators who may be in charge of a multiplicity of sports or activities at institutions, such as colleges or universities, who need to connect and communicate on a particular task. These tasks may include scheduling of events such as sports competitions or other events or activities in which there may be shared or common interests or a shared network of users, players or participants. Search by criteria to find matching potential opponents for scheduling events is also provided. Automatic schedule updates are maintained, typically in a logically centralized database, facilitated by a messaging system to facilitate ease of scheduling.

Owner:BOURNE MARY L

Hybrid electric vehicle braking downshift control

ActiveUS7908067B2Improve vehicle efficiencyLess complexDigital data processing detailsElectric propulsion mountingElectric vehicleHybrid propulsion

Owner:FORD GLOBAL TECH LLC

Projective texture mapping-based oblique projection distortion correction method

InactiveCN102014259AAvoid disadvantagesAvoid limitationsTelevision system detailsProjectorsTransformation parameterProjection screen

The invention discloses a projective texture mapping-based oblique projection distortion correction method. The projective texture mapping-based oblique projection distortion correction method comprises the following steps of: 1, establishing models of a projector, a projection screen and an observer; 2, mapping a texture image to the projection screen through projective texture mapping, wherein the observer is regarded as a virtual projector; 3, applying colors to the projection screen after the projective texture mapping and acquiring a deformed image that a virtual observer observes, wherein the projector is regarded as the virtual observer and the deformed image is a pre-deformed image that a projection system needs during image correction; and 4, applying the pre-deformed image in the step 3 serving as a projected image to the actual projection system to realize geometric distortion correction of the projected image. By the projective texture mapping-based oblique projection distortion correction method, defects and limitation of estimating projection transformation parameters are overcome and cost is reduced.

Owner:杭州华泰医疗科技有限公司

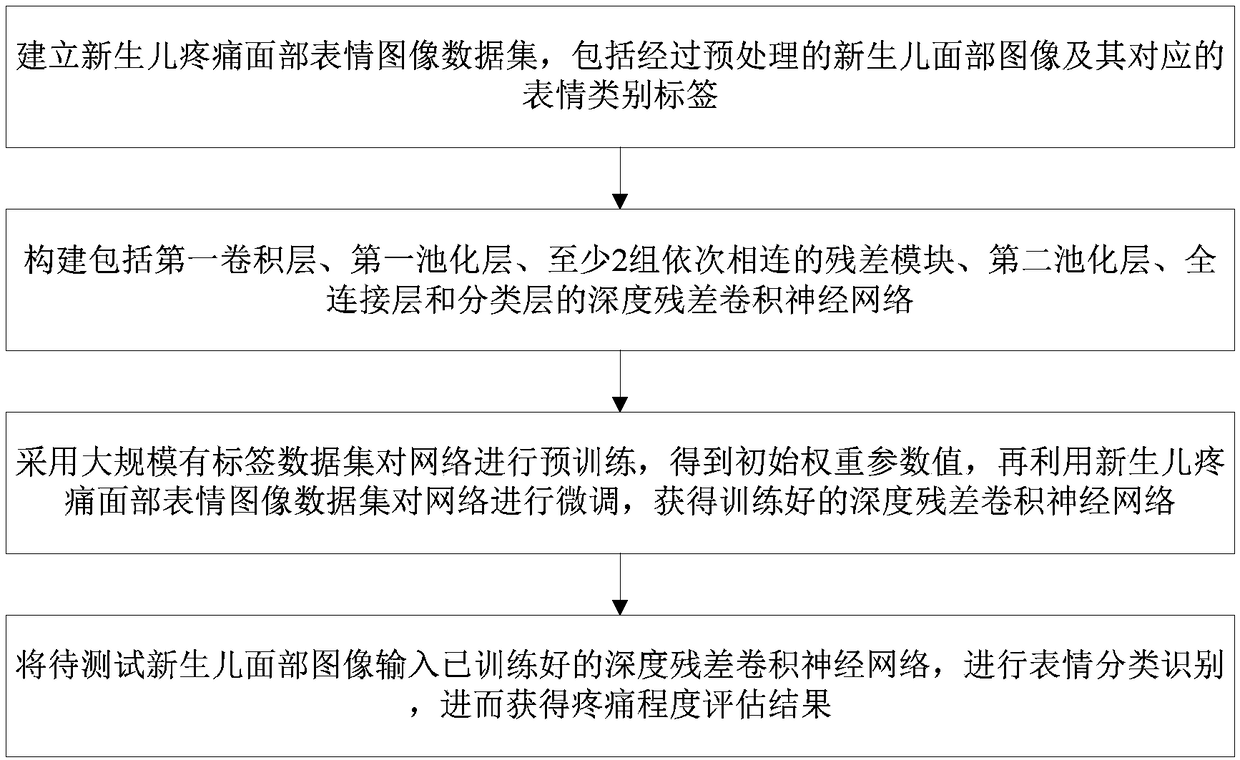

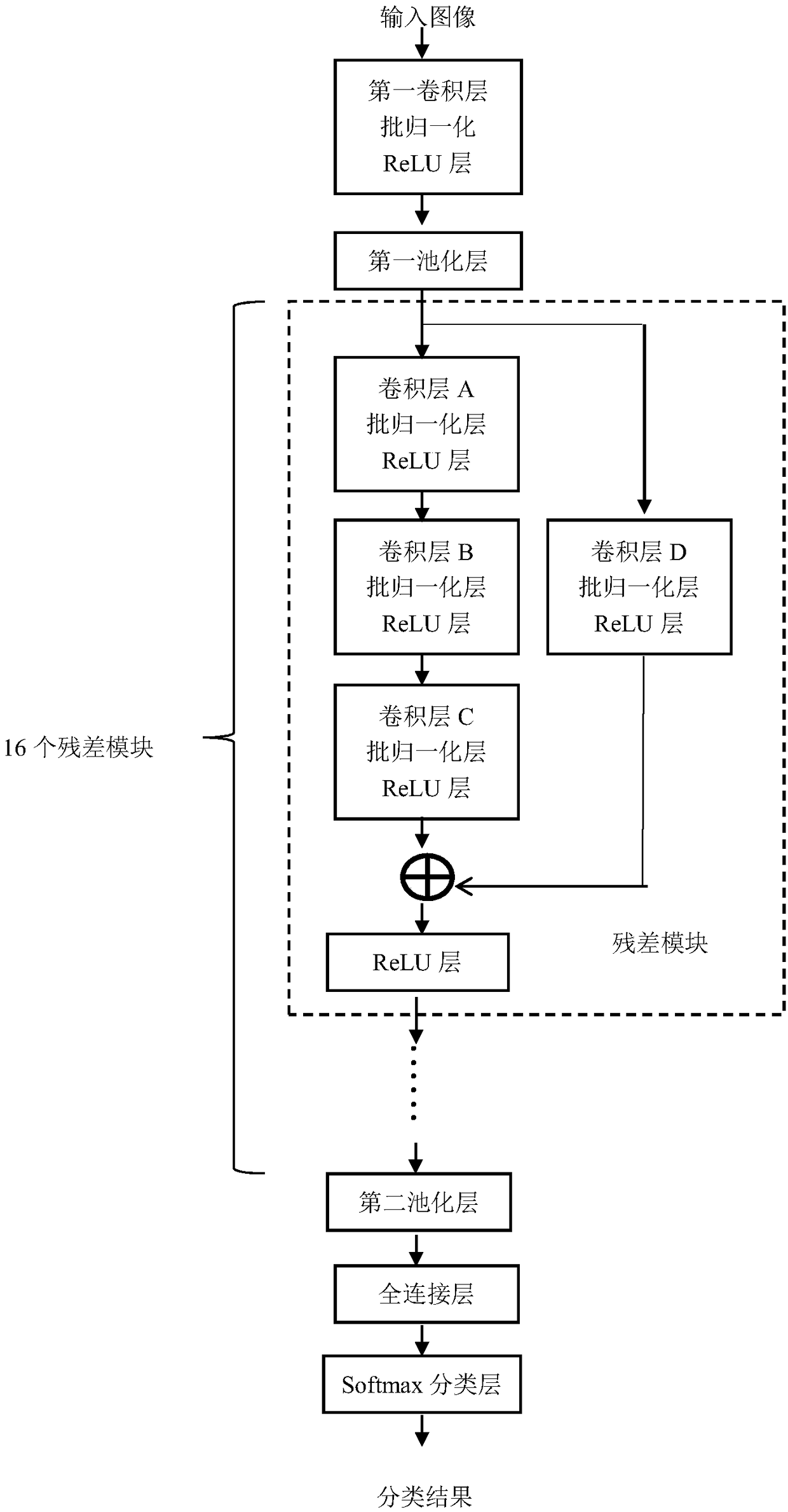

Newborn pain degree assessment method and system based on facial expression recognition

InactiveCN108388890AStrong representation ability and generalization abilityAvoid limitations and subjectivityCharacter and pattern recognitionAssessment methodsNetwork model

The invention discloses a newborn pain degree assessment method and system based on facial expression recognition, and the method comprises the steps: building a newborn pain facial expression image data set which comprises a preprocessed newborn facial expression image and a corresponding expression class label; constructing a DCNN (deep convolutional neural network) for estimating the pain degree of a newborn, employing a disclosed large-size data set with a label for the pre-training of a network, obtaining an initial weight parameter value, carrying out the fine tuning of the network through the facial expression image data set, and obtaining a trained network model; inputting a to-be-tested newborn facial image into the trained network for facial expression classification and recognition, and obtaining a pain degree assessment result. The method can make the most of the features extracted through the DCNN, can obtain a better pain degree assessment result through a small-size newborn pain degree facial expression image data set, and is a new method for the development of a system for automatic assessment of the pain degree of the newborn based on the facial expression recognition.

Owner:NANJING UNIV OF POSTS & TELECOMM

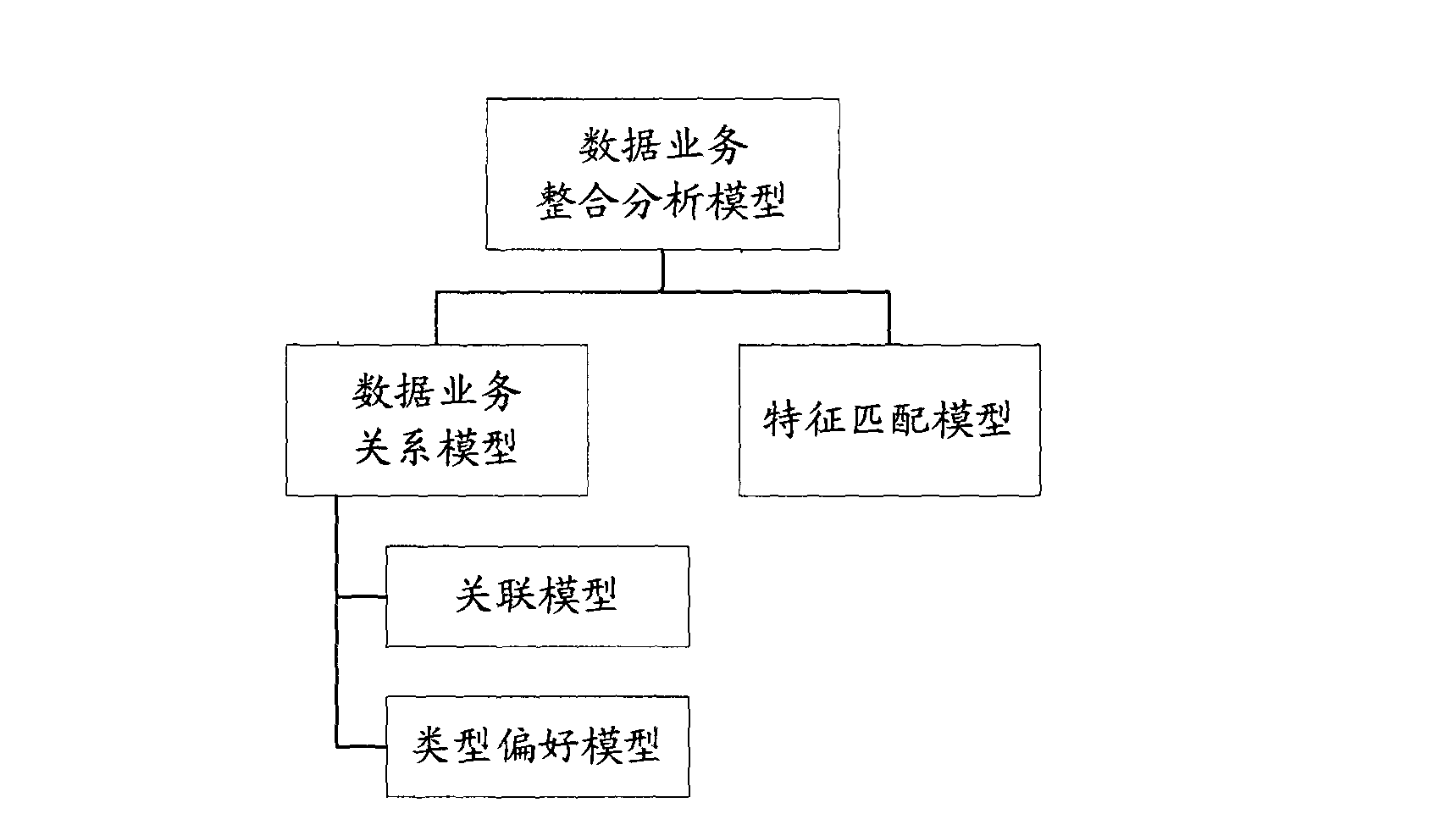

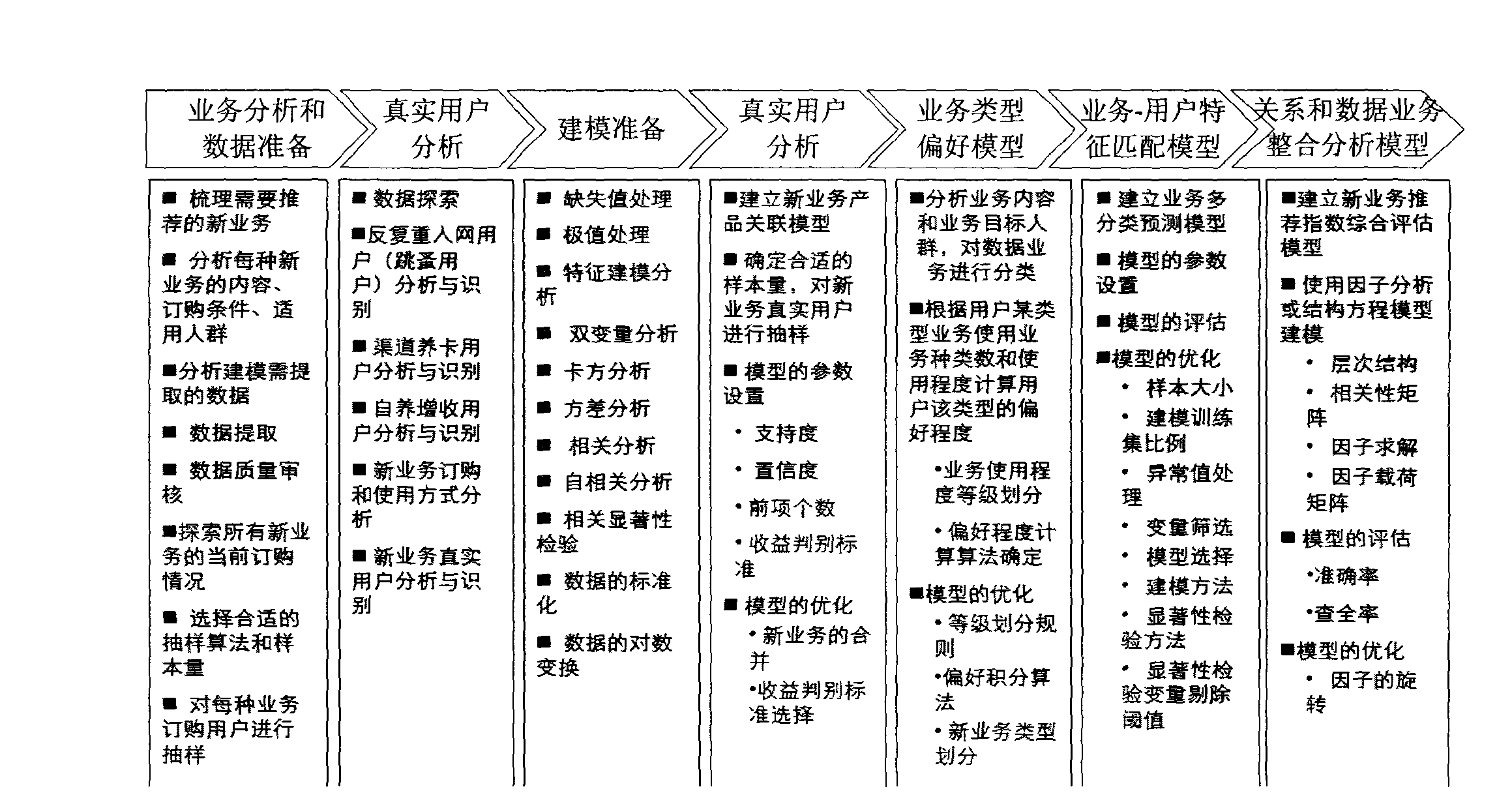

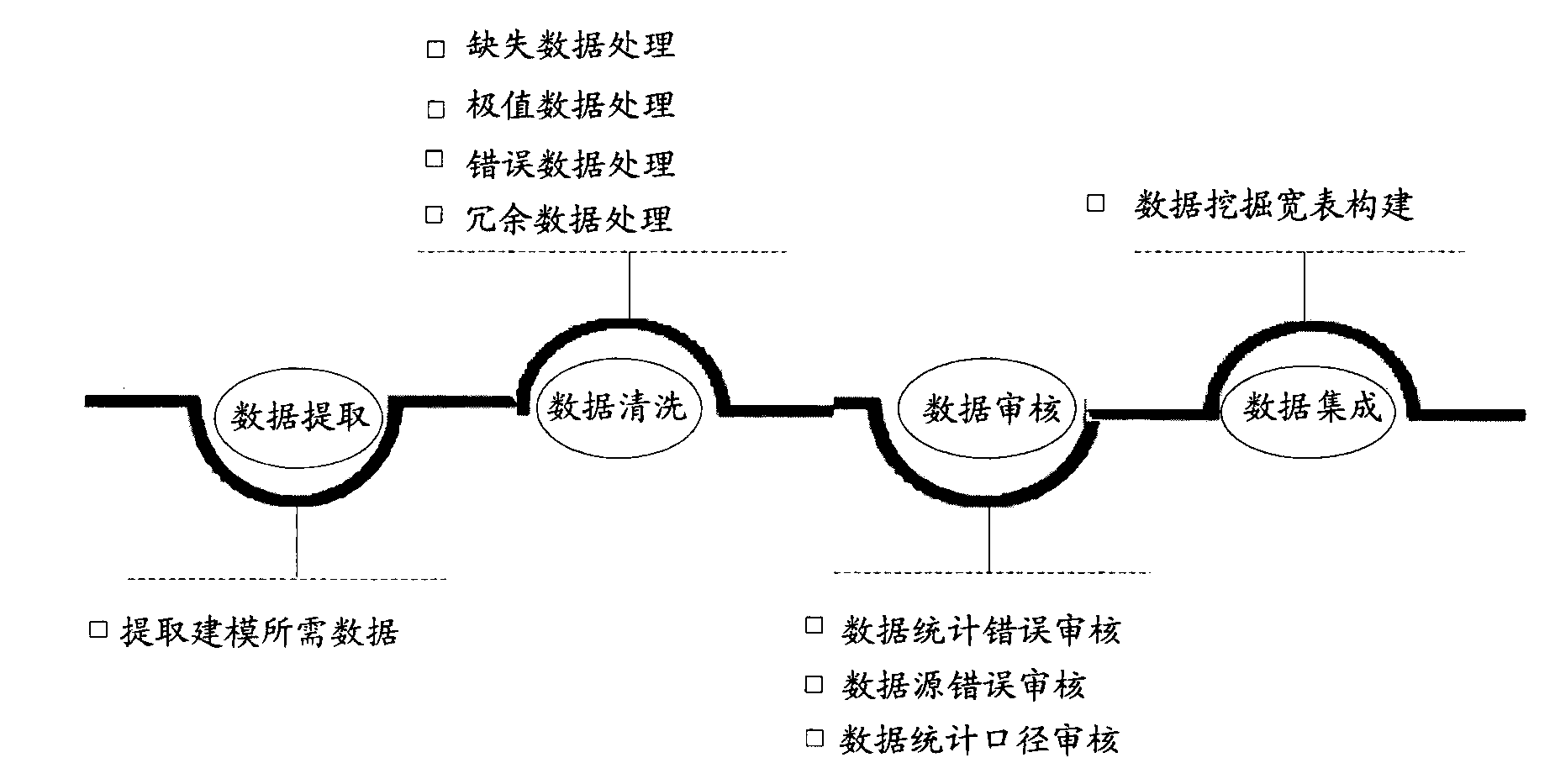

Method for analyzing data service

ActiveCN103164474ASystem science is completeAvoid limitationsSpecial data processing applicationsData as a serviceFeature matching

The invention provides a method for analyzing a data service. The method for analyzing the data service includes the following steps: building a correlation model and a type preference model based on using conditions of a user to the data service, and building a feature matching model; then building a data service relation model by making use of the correlation model and the type preference model, and building a data service integrated analysis model by using the data service relation model and the feature matching model; and finally analyzing the data service by means of the data service integrated analysis model and using the analysis result in data service recommendation. By means of the method for analyzing the data service, the accuracy of the analysis result is improved, the analysis result is used in the data service recommendation, and thus the precision of data service recommendation can be improved.

Owner:ZUNYI BRANCH OF CHINA MOBILE GRP GUIZHOU COMPANY

Establishing method of regional CORS coordinate time series noise model

InactiveCN104392414AExtract comprehensiveReliable extractionImage enhancementImage analysisTime domainPattern recognition

The invention relates to an establishing method of a regional CORS coordinate time series noise model. The establishing method is characterized by comprising the following steps that: step 1, observation data of a regional CORS station are obtained; step 2, GNSS data pre-processing software TEQC is adopted; step 3, GAMIT / GLOBK baselines are adopted to solve adjustment; step 4, a high-precision coordinate time series is established; step 5, singular spectrum analysis-based spatial filtering is performed; step 6, MLE estimation-based noise model selection is performed; and step 7, regional CORS velocity filed estimation is performed in view of colored noise models. According to the establishing method of the invention, time-domain frequency domain characteristic analysis is adopted to perform spatial filtering on the regional CORS time series; and maximum likelihood values are selected for different noise models of the regional CORS time series, so that judgment can be performed, and therefore, optimal noise models in the N (North), E (East) and U (altitude) are determined, and the regional CORS velocity filed can be estimated in view of the optimal noise models.

Owner:HOHAI UNIV

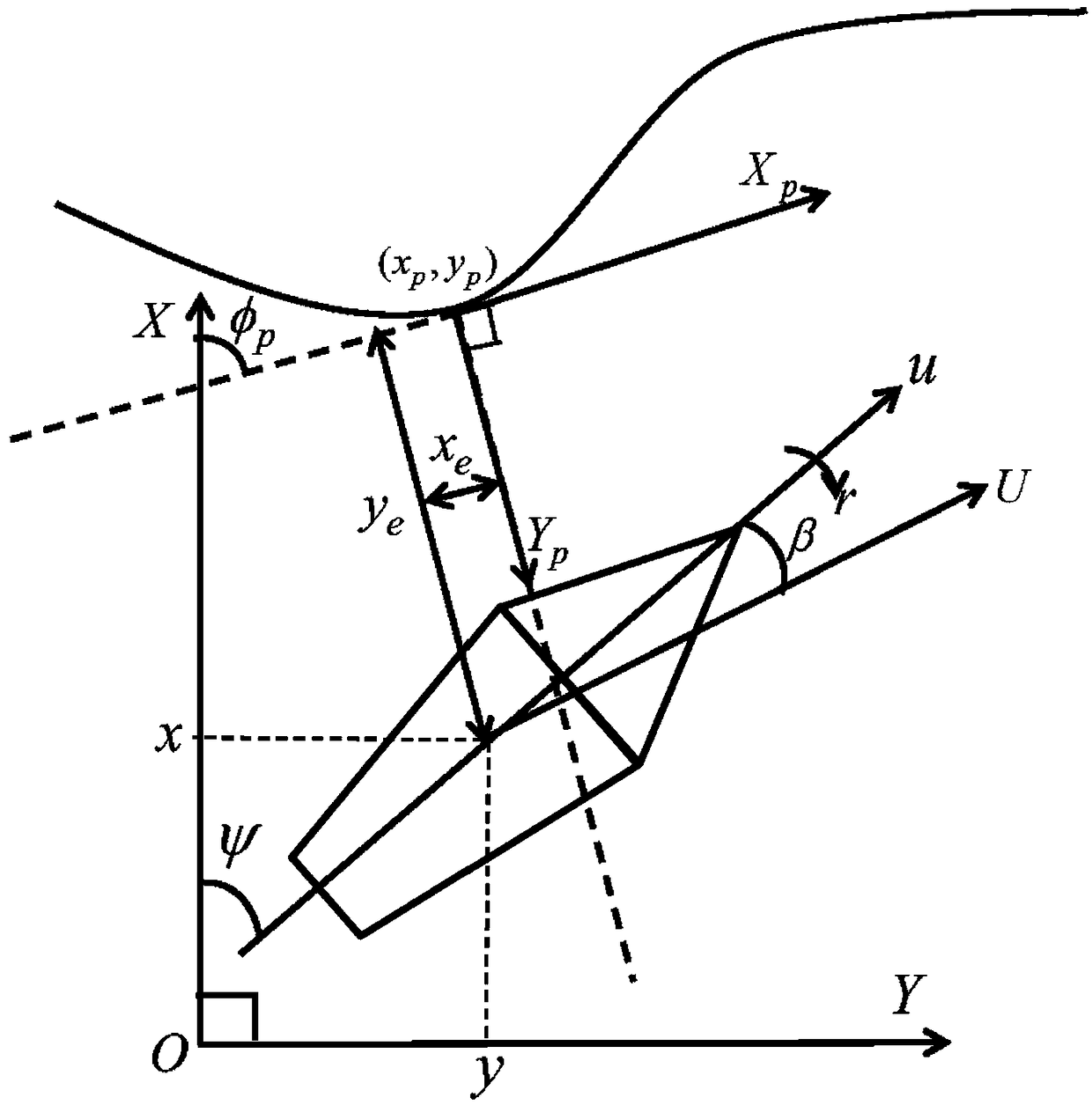

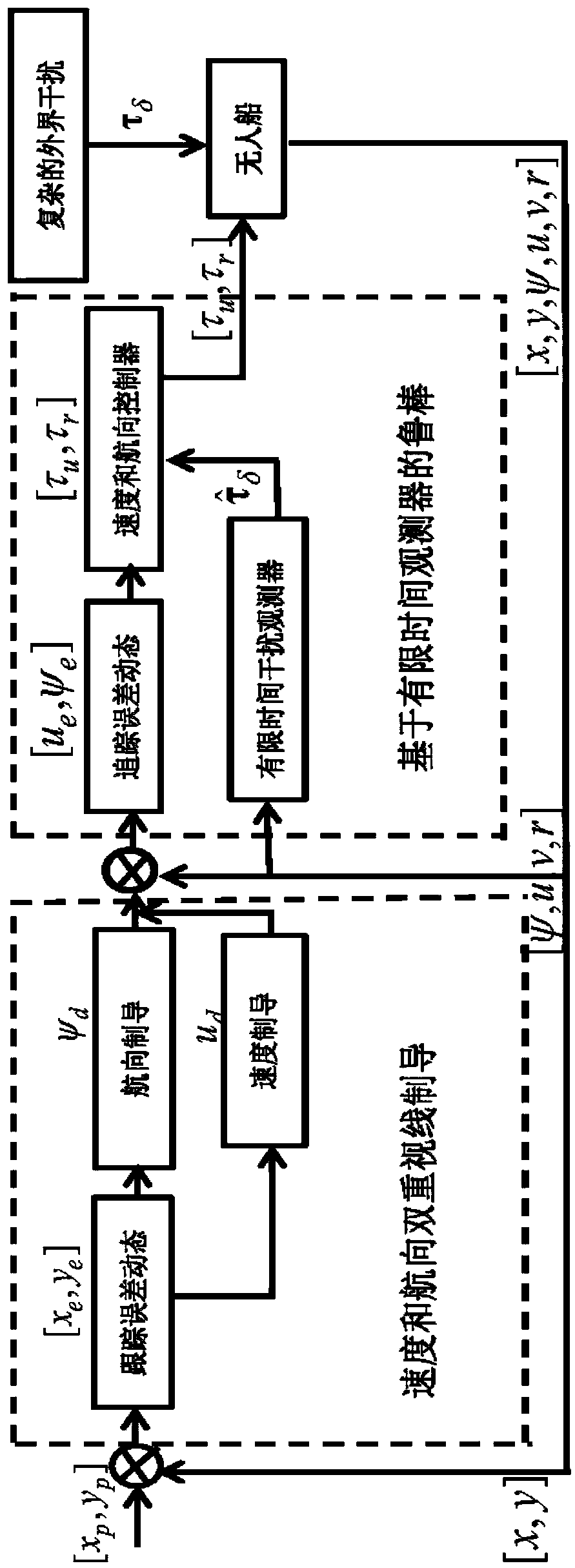

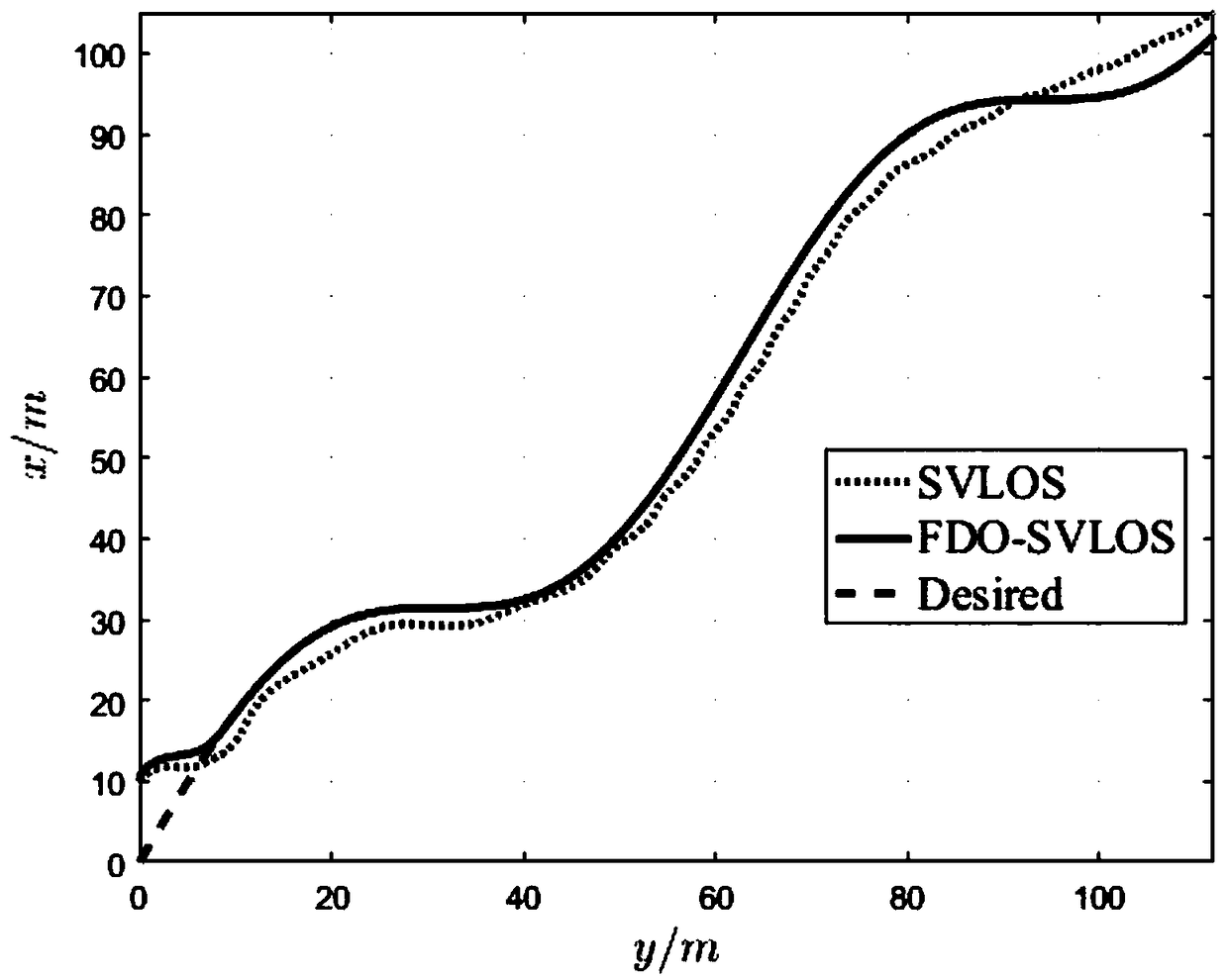

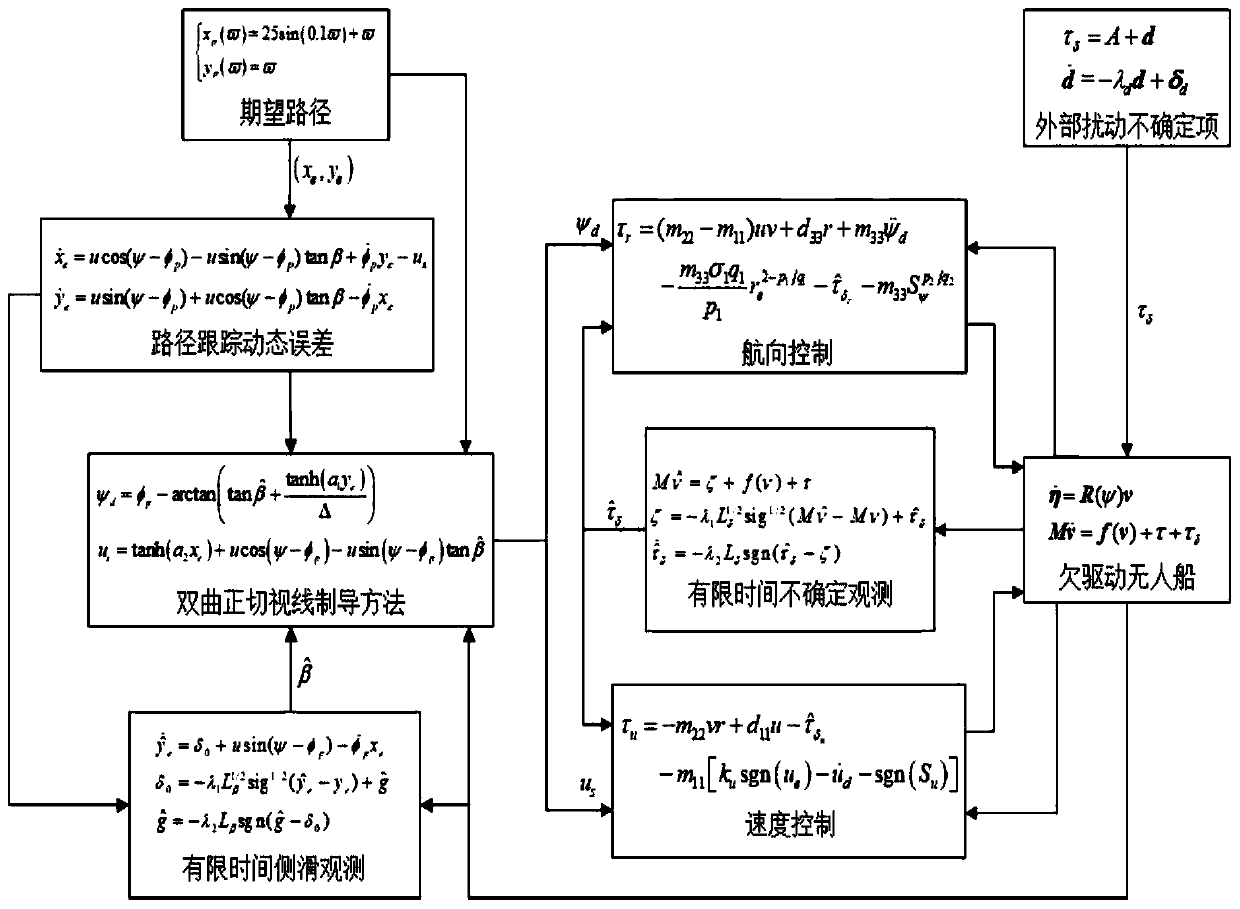

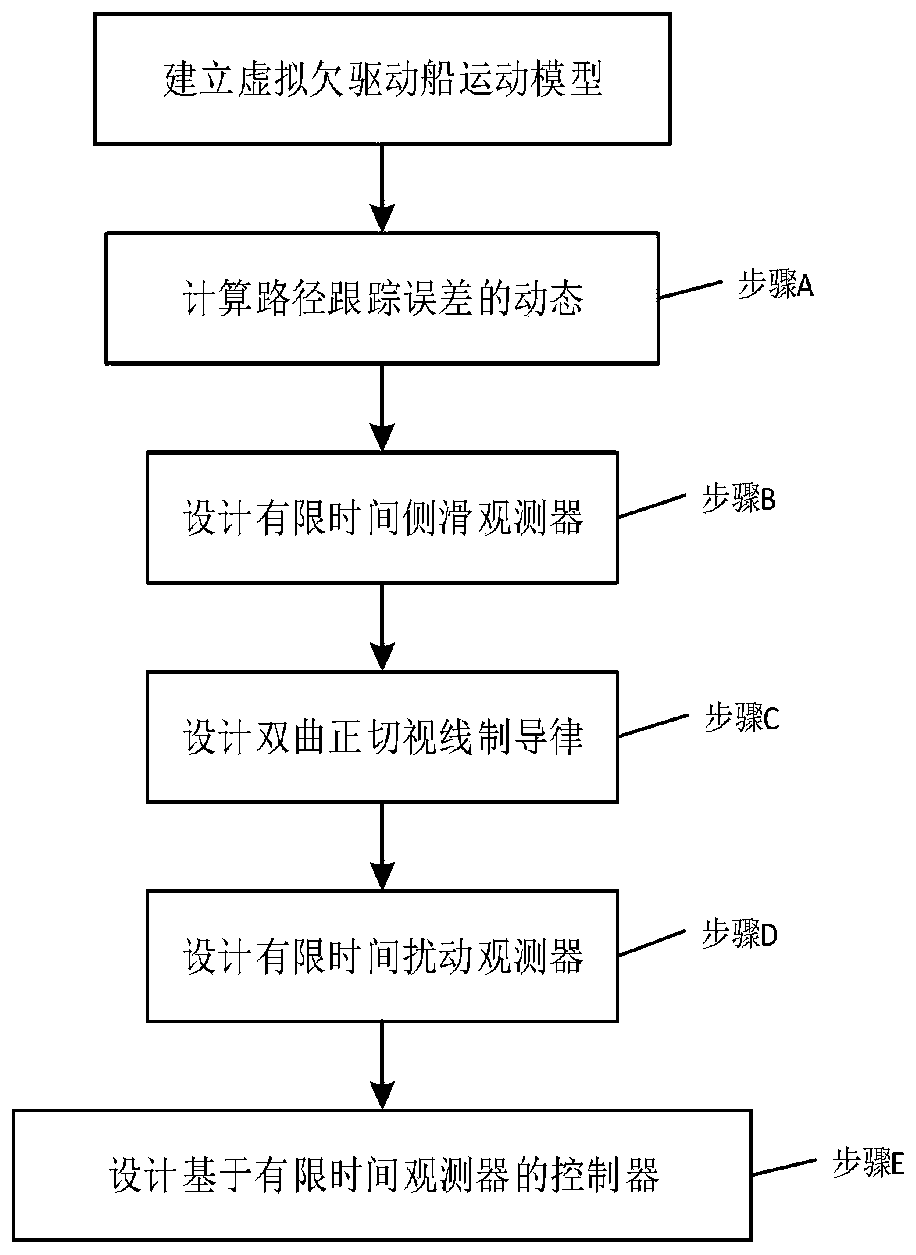

Accurate control method for path tracking of unmanned ship based on dual guidance of speed and heading

The invention discloses an accurate control method for a path tracking of an unmanned ship based on a dual guidance of the speed and the heading. The method comprises the following steps of: establishing a kinematics model and a dynamics model of the unmanned ship; constructing an error dynamics of the path tracking; designing a dual guidance law of the speed and the heading; and designing a finite-time interference observer. According to the accurate control method for the path tracking of the unmanned ship based on the dual guidance of the speed and the heading, the dual guidance law of thespeed and the heading provided by the control method can simultaneously guide the speed and the heading angle according to the path tracking errors, and improves the stability and flexibility of the path tracking control system. The finite-time interference observer constructed by the control method can accurately observe the complex external disturbances; ensures that the observation error is zero for a finite time; and can avoid the limitations of bounded observations and asymptotic observations. The control method designs a speed and heading tracking controller combining the design of a finite time observer and the back stepping control technology, so that the guidance signal can be accurately tracked in the presence of a complex interference, thereby achieving the accurate control forthe path tracking of the unmanned ship.

Owner:DALIAN MARITIME UNIVERSITY

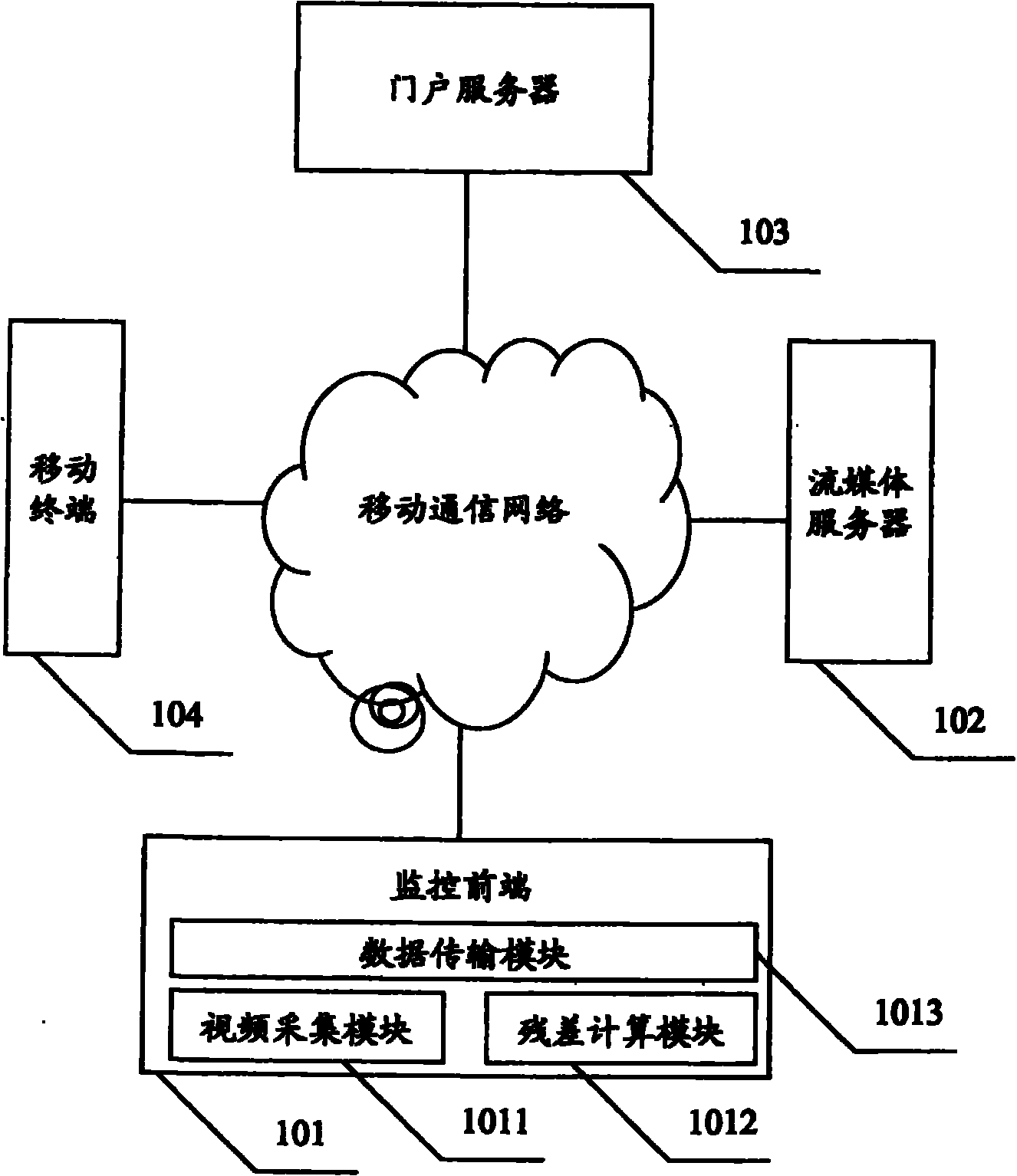

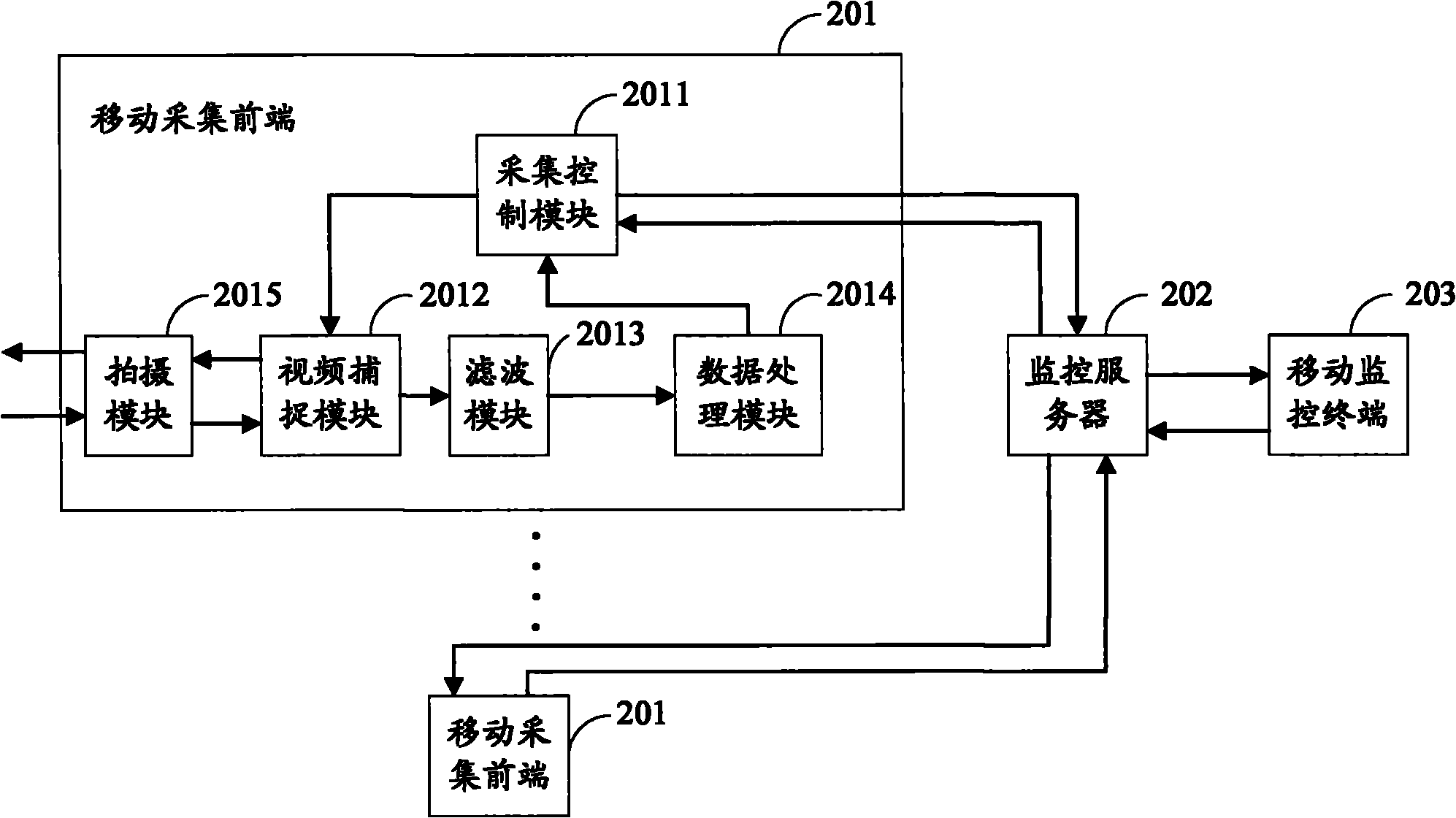

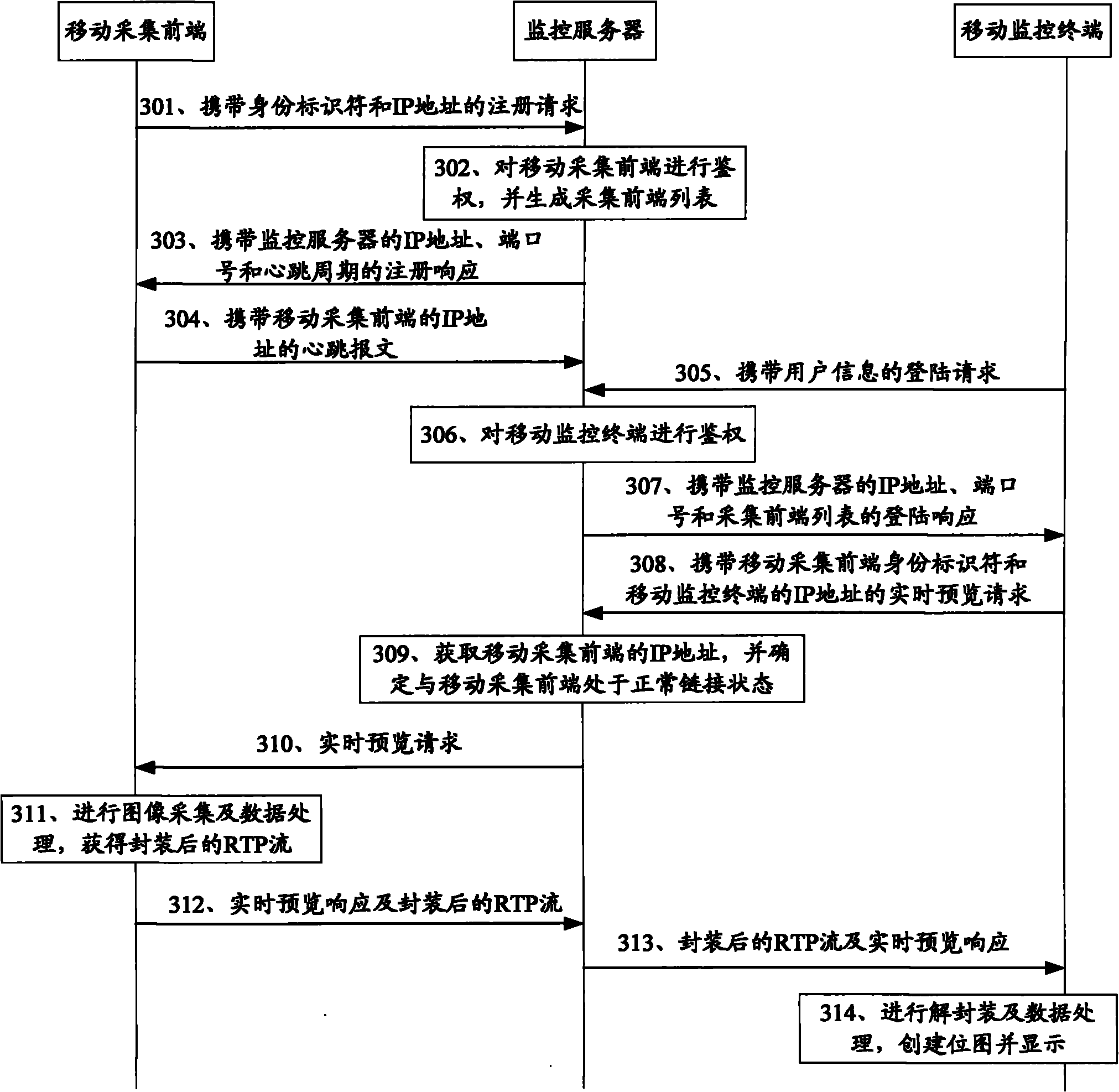

Mobile video monitoring system and method

ActiveCN102196248AExpand the scope ofAvoid limitationsClosed circuit television systemsTransmissionIp addressReal-time Transport Protocol

The invention provides a mobile video monitoring system. A monitoring server of the system generates an acquisition front-end list according to identifiers and Internet protocol (IP) addresses of mobile acquisition front-ends passing authentication, stores the acquisition front-end list, obtains the IP address of the mobile acquisition front-end passing the authentication according to a real-timepreviewing request, transmits the real-time previewing request, and transmits a packaged real-time transport protocol (RTP) stream and a real-time previewing response to a mobile monitoring terminal passing the authentication according to the IP address of the mobile acquisition front-end; the mobile acquisition front-end passing the authentication acquires an image of a place with the mobile acquisition front-end in real time according to the real-time previewing request, obtains the packaged RTP stream and transmits the RTP stream to the monitoring server; and the mobile monitoring terminalpassing the authentication processes the packaged RTP stream according to the real-time previewing response, and outputs and displays the processed RTP stream. The invention also provides a mobile video monitoring method. By the system and the method, limitations to video image acquisition can be broken through, and the flexibility can be improved.

Owner:HANGZHOU HIKVISION SYST TECH

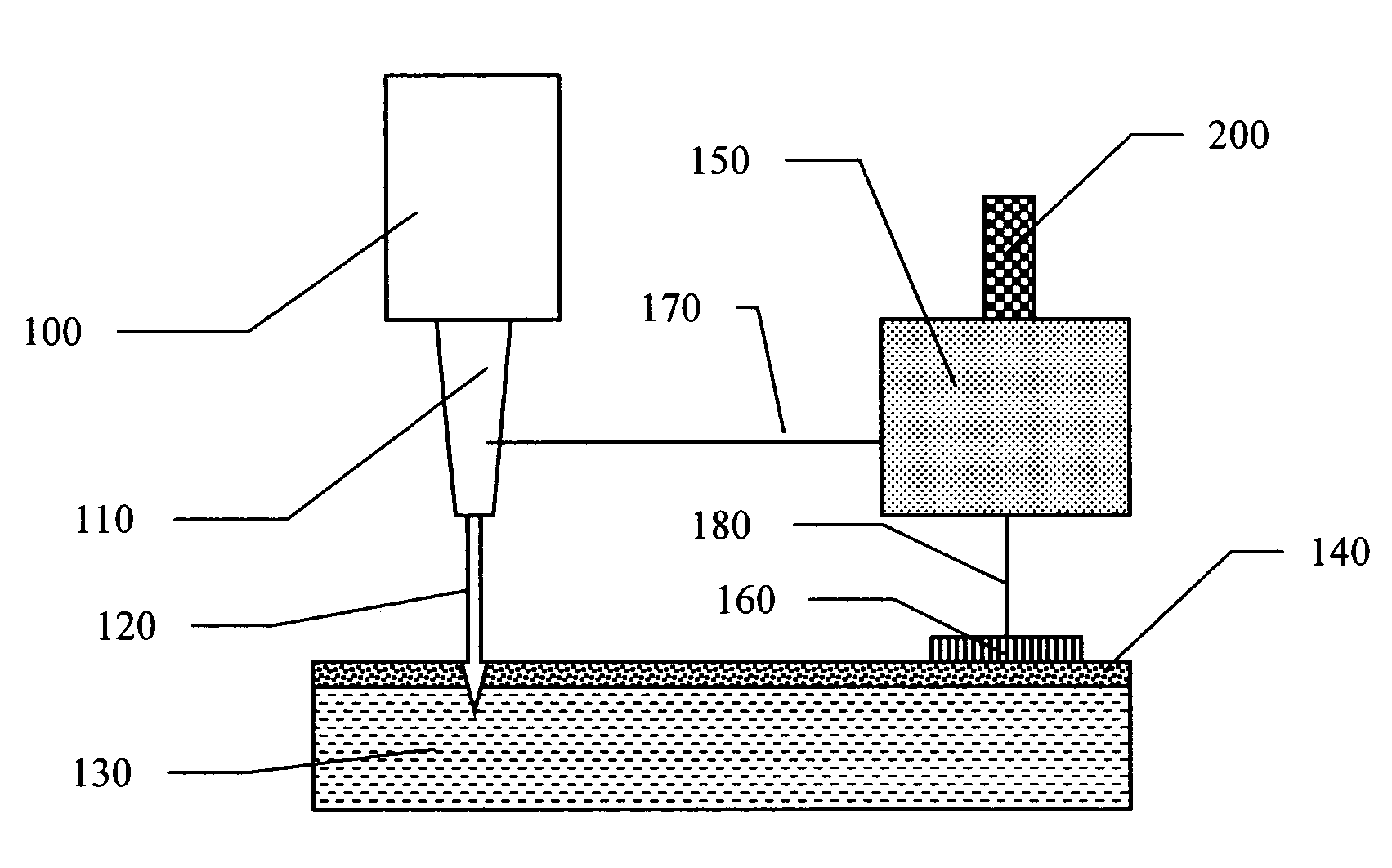

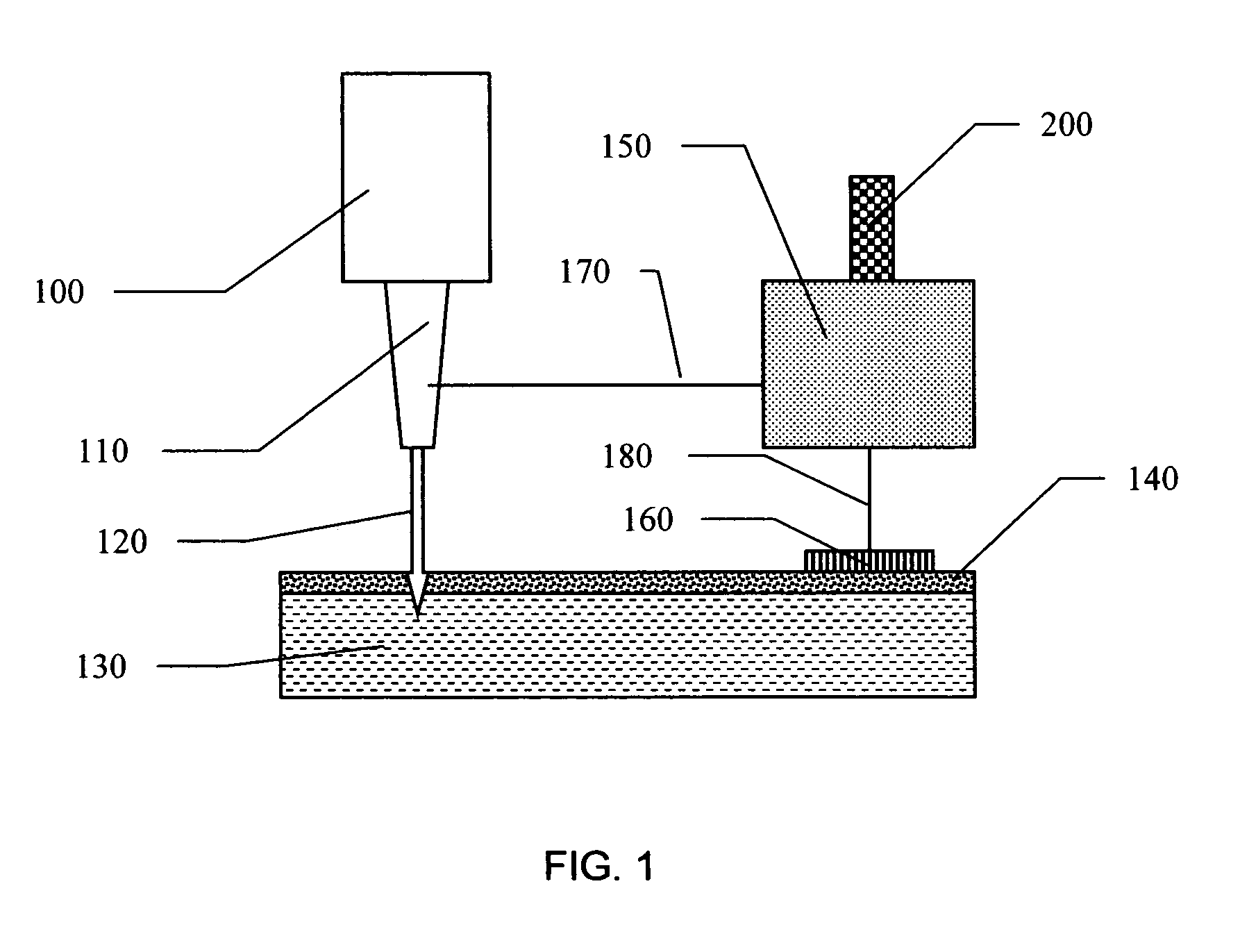

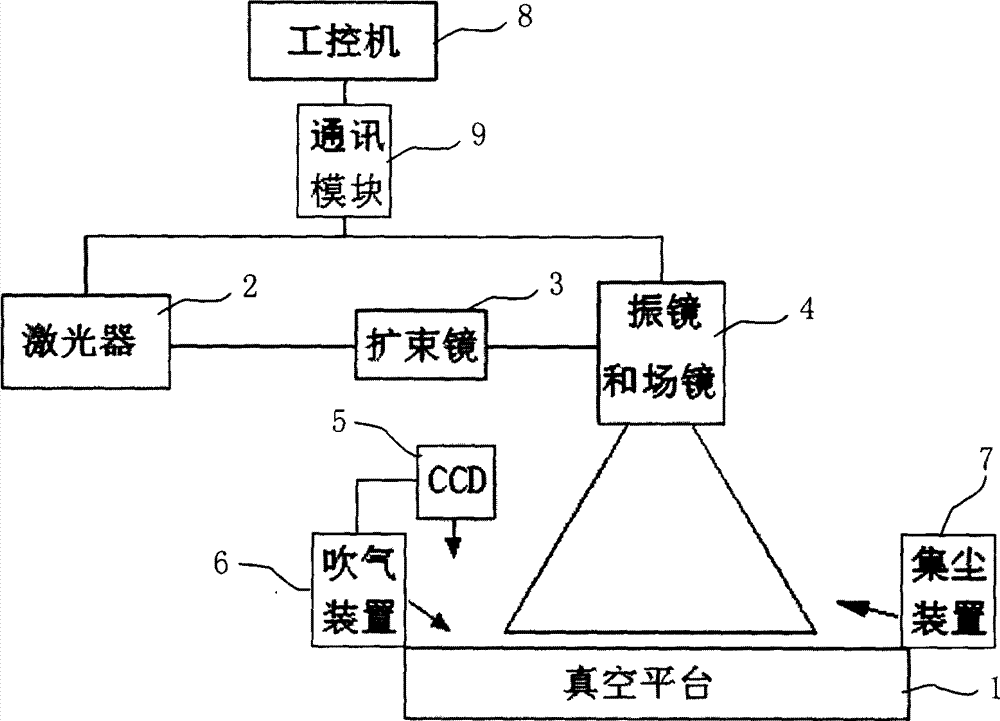

Pulse laser etching device used for transparent electroconductive thin film and control method of pulse laser etching device

InactiveCN103586586AThe equipment is easy to operateReduce labor costsConductorsMetal working apparatusPhysicsGalvanometer

The invention discloses a pulse laser etching device used for a transparent electroconductive thin film and a control method of the pulse laser etching device. The pulse laer etching device comprises a vacuum platform used for adsorbing a film material, a laser and a galvanometer, a beam expander is arranged between the laser and the galvanometer, a CCD image sensor is arranged above the vacuum platform, an air blowing device is arranged on one side of the vacuum platform, and a dust collecting device is arranged on the other side of the vacuum platform. The high-frequency short-pulse laser is adopted as a laser source for laser etching, film material etching is completed through the small-breadth galvanometer, and generated dust is collected through an air blowing system and a dust collecting system, so that the defects of high cost, low efficiency, large processing limitation, serious pollution and the like in the prior art can be overcome, etching process can be simplified, and accuracy can be improved.

Owner:苏州镭明激光科技有限公司

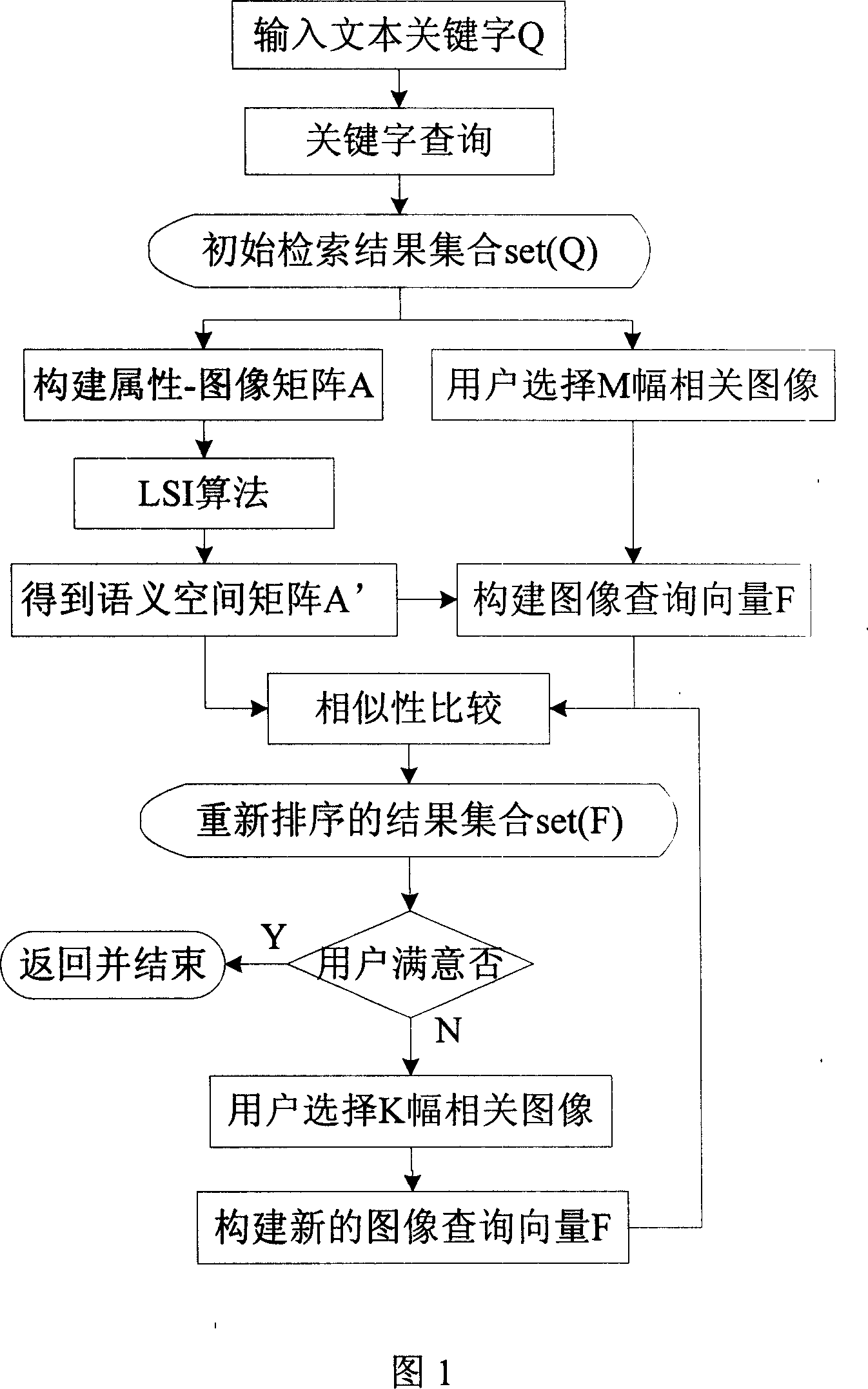

Region based multiple features Integration and multiple-stage feedback latent semantic image retrieval method

InactiveCN1967536AImprove retrieval accuracyImplement Semantic Similarity MatchingSpecial data processing applicationsImage querySemantic feature

The invention discloses a latent semantic image retrieval method of region-oriented multi-feature integration and multi-level feedback. It uses result list returned by the initial keyword search, extracting a variety of region-oriented images characteristics, constructing attribute-image matrix, using latent semantic indexing algorithm to get the semantic space of image sets and semantic features of each image, and then using similar images by users feedback to construct or update image query vector, searching again the semantic space, calculating image semantics features and images inquiries vector similarity, getting outcome sets by descending order, and repeatable retrieval. The invention takes full advantage of image content information, making up for the deficiencies of the keyword search, and through the region-oriented multi-feature integration, enhances image content information from the bottom physical layer to the object layer, then further enhances to the semantic layer by HCI feedback, thereby reducing the gap between the image bottom features and high-level semantic, and allowing Web image retrieval to get higher retrieval accuracy.

Owner:HUAZHONG UNIV OF SCI & TECH

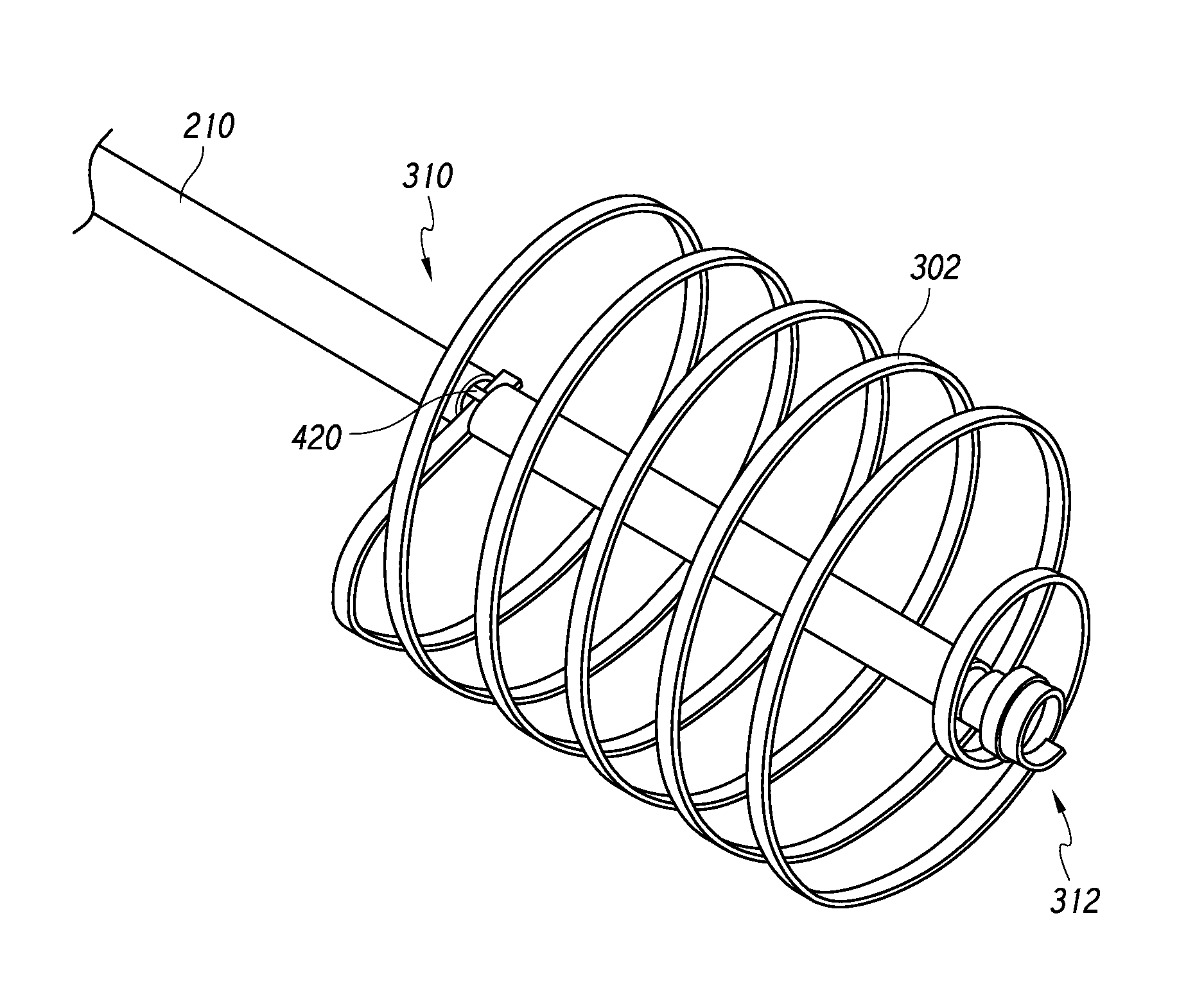

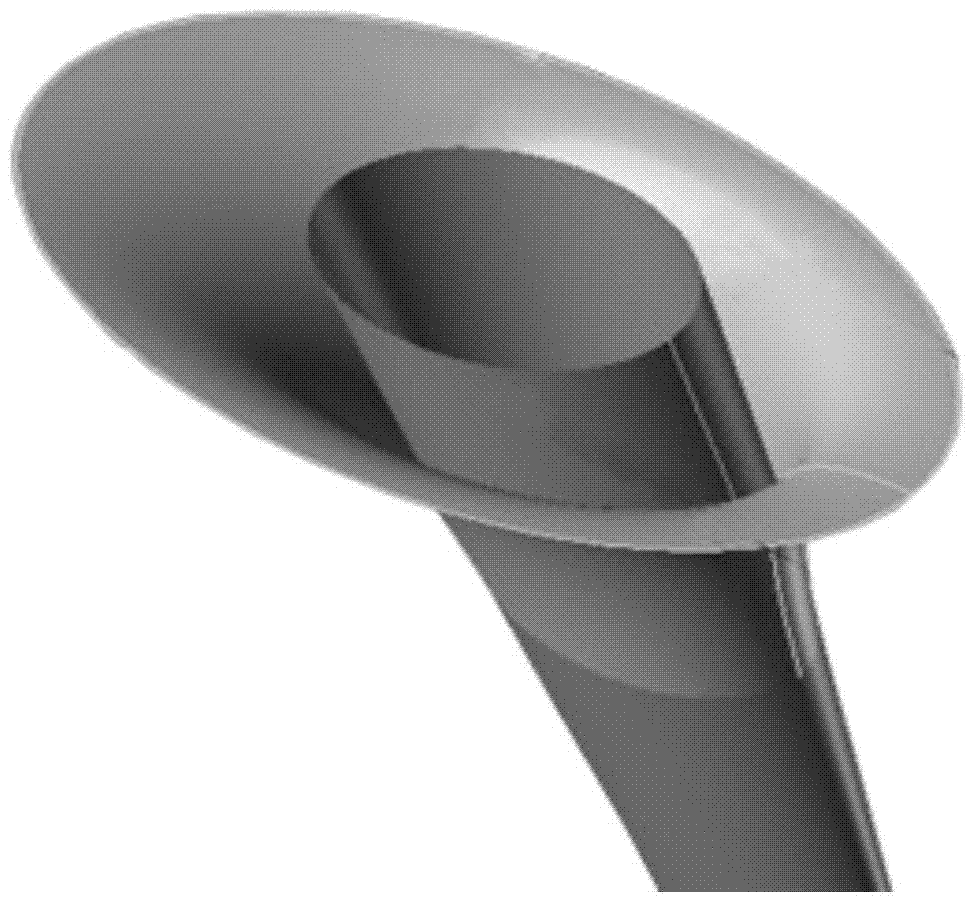

Methods and apparatuses for blood vessel occlusion

ActiveUS20140222059A1Prevent movementEasy to placeDilatorsOcculdersBlood vessel occlusionDistal portion

An occlusion device delivery system and methods are provided in which an expandable coiled implant can be delivered using the delivery system. The system can comprise a catheter having a lumen extending between distal and proximal portions. The distal portion can have proximal and distal apertures extending through a wall of the catheter. The expandable coiled implant, which can be wound about the distal portion, can have a proximal section that extends within the proximal aperture and a distal section that can extend radially within the distal aperture. Further, the system can comprise an elongate member that extends through the lumen and engages and radially restrains the at least one of the proximal and distal sections within its respective aperture while engaged with the member.

Owner:ARTVENTIVE MEDICAL GROUP

Unmanned ship path tracking control method based on finite time guidance and control

ActiveCN110032197AImprove stabilityIncrease flexibilityPosition/course control in two dimensionsGuidance systemDrift angle

The invention discloses an unmanned ship path tracking control method based on finite time guidance and control. The unmanned ship path tracking control method based on the finite time guidance and control comprises the following steps that dynamic states of path tracking errors are calculated; a finite time sideslip observer is designed; a hyperbolic tangent sight line guidance law is designed; afinite time disturbance observer is designed; and a controller based on the finite time observers is designed. According to the unmanned ship path tracking control method based on the finite time guidance and control, the speed and course angle are simultaneously guided through the provided hyperbolic tangent sight line guidance law according to the tracking errors and the designed finite time sideslip observer, and the stability and the flexibility of a guidance system are improved; the time-varying large drift angle can be accurately observed by the designed finite time sideslip observer, the observation error is ensured to be zero within finite time, the error convergence speed is increased, the robustness is improved, and the boundedness of bounded and asymptotic observation can be avoided; and complicated external disturbance can be accurately observed, the observation error is ensured to be zero within the finite time, and the boundedness of the bounded and asymptotic observation can be avoided.

Owner:DALIAN MARITIME UNIVERSITY

Methods and apparatus for rapid endovascular vessel occlusion and blood flow interruption

An occluding device including expandable scaffold and a flow-limiting member is described. In some embodiments the scaffold is an expandable or self-expanding stent deliverable over a guide wire. The flow-limiting member can include a valve that can be closed following deployment. On deployment the stent and flow-limiting member can engage an inner surface of a body cavity lumen, blocking flow of material. In some embodiments the body cavity is a blood vessel, and the device can be used to block blood flow. In some embodiments the device includes bioactive agents.

Owner:ARTVENTIVE MEDICAL GROUP

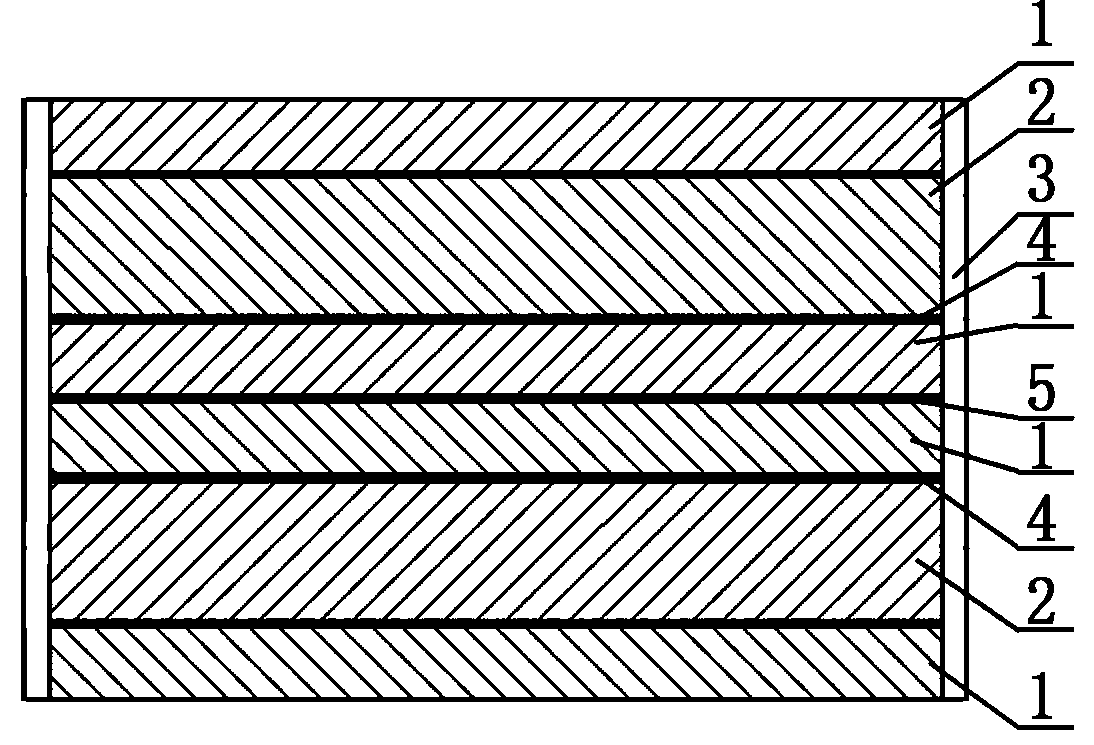

Production method for titanium steel titanium composite board diffusion welding

InactiveCN103817426AOvercoming environmental pollutionAvoid limitationsNon-electric welding apparatusWeld beadDiffusion welding

The invention discloses a production method for titanium steel titanium composite board diffusion welding. The technical key point is that the method comprises the following steps that 1, a steel plate, a titanium plat and a pure iron thin plate or a pure copper thin plate are cut, the combination surfaces are polished for standby use; 2, the above materials form two groups of composite board blanks, a parting compound is smeared between the two groups of composite board blanks, the composite board blanks are placed in a cover made of low-carbon steel, the contact surfaces between the upper and lower titanium plates and the cover are smeared with the parting compound, a degassing hole is formed in the side face of the cover, a guide pipe is welded in the degassing hole, and the gas tightness is detected; 3, the cover is vacuumized to the vacuum degree less than 0.001 Pa; 4, an oil press is used for pressing the composite board blank and the cover, the vacuum is kept during pressing, the composite board blank is heated to 880-950 DEG C for the diffusion welding of the composite board blank, and the composite board blank is cooled in the air to room temperature; 5, the cover is removed, the spot welding beads at the periphery are removed, and two titanium steel titanium composite boards are obtained. The method is free of the influence of seasons and environmental pollution, the production scale and the product specification are controllable, and the boundedness that only a thin plate can be manufactured by a continuous hot rolling manufacturing method is avoided.

Owner:沈阳和世泰通用钛业有限公司

Blood vessel occlusion

ActiveUS20140257369A1Easy to placeEasy to deployDilatorsOcculdersBlood vessel occlusionDistal portion

An occlusion device delivery system can deliver an expandable coiled implant using a catheter. A distal portion of the catheter has proximal and distal apertures extending through a wall of the catheter. The expandable coiled implant is wound about the distal portion and has a proximal section that extends within the proximal aperture and a distal section that can extend radially within the distal aperture. Further, the system has an elongate member that extends through the lumen and engages and radially restrains the at least one of the proximal and distal sections within its respective aperture while engaged with the member.

Owner:ARTVENTIVE MEDICAL GROUP

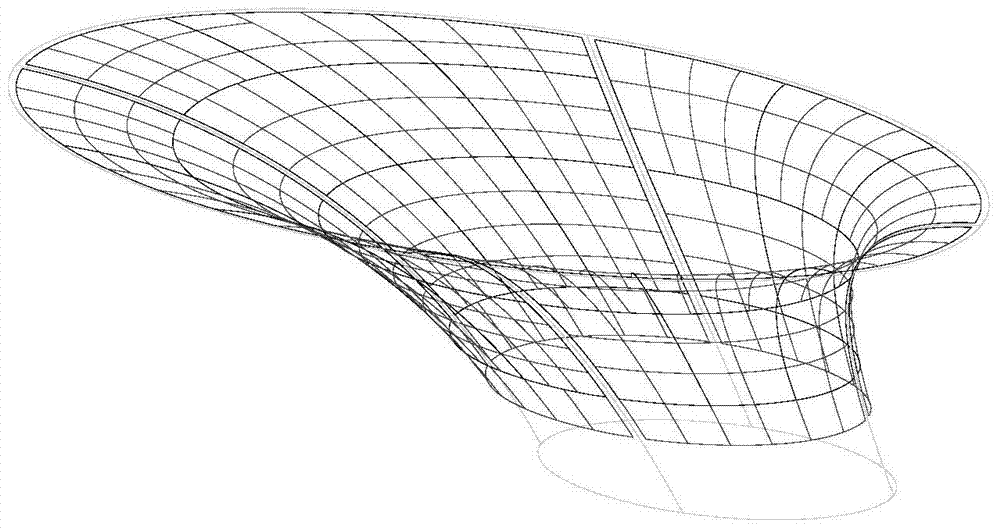

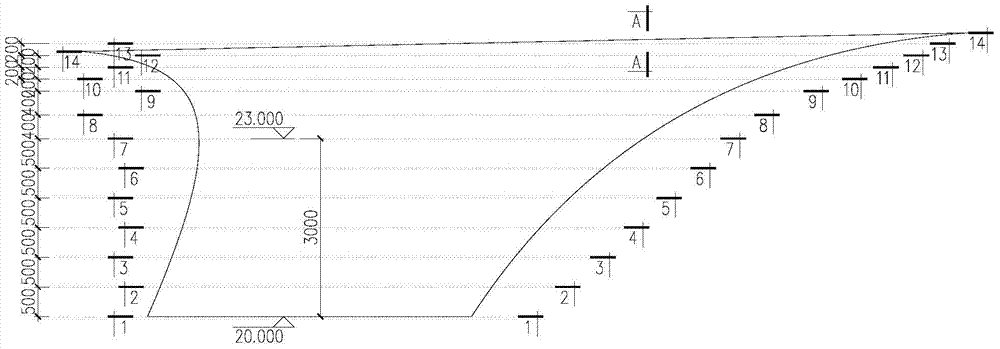

Construction method for using layering method to construct double-curved-surface stainless steel curtain wall

ActiveCN103541474AFast Construction CompletedSafe construction completedWallsBuilding material handlingSurface layerKeel

The invention discloses a construction method for using a layering method to construct a double-curved-surface stainless steel curtain wall. The method includes: building a double-curved-surface stainless steel curtain wall three-dimensional model and deepen drawing; decomposing the double-curved-surface curtain wall structure according to the model and deepen drawing into a surface layer and a keel layer; deepening construction drawings of the surface layer and the keel layer; machining and constructing the surface layer of the double-curved-surface stainless steel curtain wall; cutting and transporting the surface layer; constructing the keel layer of the double-curved-surface stainless steel curtain wall; mounting and seam welding the surface layer; processing the facing of the double-curved-surface stainless steel curtain wall. The construction method has the advantages that the layering method is used to construct the double-curved-surface stainless steel curtain wall, the surface layer with large welding and splicing work load is constructed in a factory, the keel layer is welded on site, filed structural features are combined to adjust and eliminate construction errors reasonably, coordinating and unifying of the curtain wall structure and a main body structure are guaranteed, and accurate curved surfaces and radian smoothness of the curtain wall are guaranteed.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

System and method for web-based sports event scheduling

ActiveUS7716078B2Avoid frustrationAvoid limitationsMultiprogramming arrangementsOffice automationCentralized databaseEvent scheduling

Owner:BOURNE MARY L

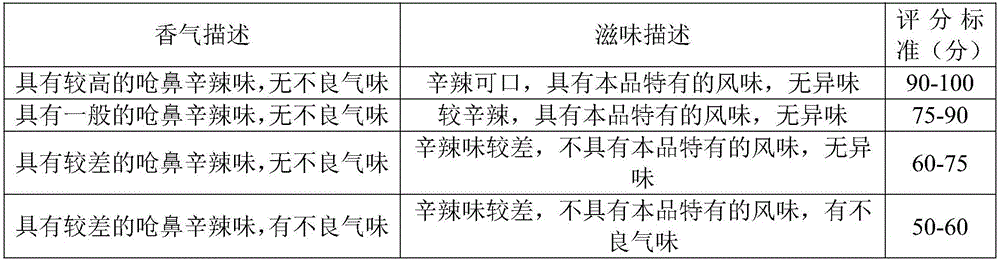

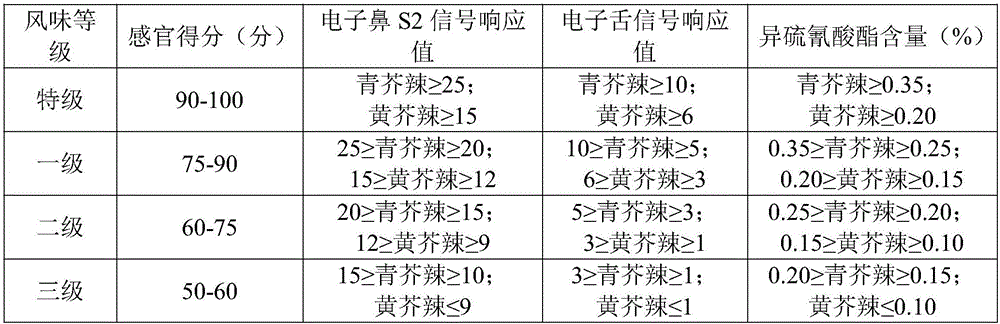

Method for evaluating mustard sauce flavor grades by taste system and electronic nose

ActiveCN106501470AMeet the requirements of fast and accurate detectionAnalysis results are objectiveChemical analysis using titrationChemical machine learningGustatory systemOrganoleptic evaluation

The invention discloses a method for evaluating mustard sauce flavor grades by a taste system and an electronic nose, and belongs to the technical field of condiment analysis and identification methods. The method includes the steps of acquiring intelligent sensory data of mustard sauce by an electronic tongue taste system and an electronic nose olfactory system; performing digital processing for traditional sensory evaluation indexes; analyzing relations among the acquired sensory evaluation indexes, stoichiometric indexes and the intelligent sensory data by the aid of a random forest model; evaluating sensory grades of mustard sauce flavor. According to the method, objectivity and accuracy of sensory evaluation of the mustard sauce can be effectively improved, and the method is simple to operate, low in sample consumption and cost and short in consumed time and has high popularization and application values.

Owner:GUANGDONG JIAHAO FOOD +1

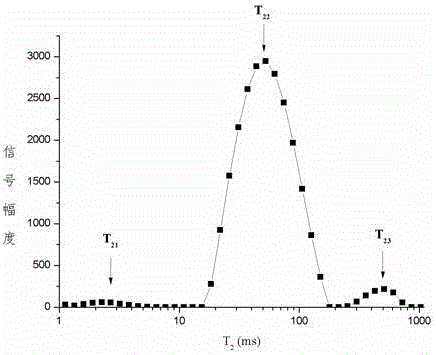

United detection method for determinming freshness of prepared aquatic product at low temperature shelf life

ActiveCN106324011AImprove forecast accuracyReduce forecast errorAnalysis using nuclear magnetic resonanceTesting foodSmall sampleLow field nuclear magnetic resonance

A united detection method for determinming freshness of prepared aquatic product at low temperature shelf life belongs to the technical field of food preservation. This invention is based on low field nuclear magnetic resonance (NMR) combined with the electronic nose as the main measurement tools, on the basis of regulating RBF neural network model which is eatablished among the relaxation time data, flavor changing data and volatile base nitrogen (TVB- N) data of aquatic products and based on regulating nuclear magnetic resonance (NMR) and electronic nose signal in the process of low temperature storage of aquatic products as the main target of observation, through the analysis of relaxation time data and the flavor changing data of aquatic products in the process of low temperature storage, and makes the judgement to regulate shelf life limits of aquatic products. This invention has the advantages of simple analysis process, small sample usage quantity, and high accuracy, short time-consuming, low cost and easy popularization. By adopting the similar method of the invention, the corresponding database and the prediction model can be established for other meat products, and the accurate prediction for the limit value of the shelf life during the storage process can be realized.

Owner:JIANGNAN UNIV +1

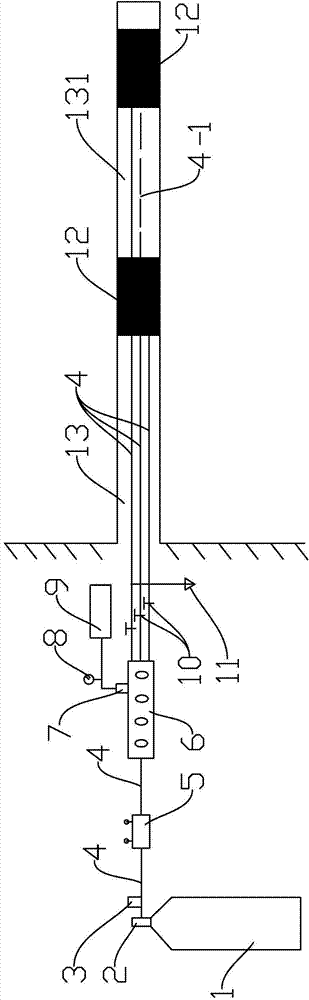

Surrounding rock stress disturbing degree test device

ActiveCN104729969AAvoid uneven geological conditionsAvoid errorsPermeability/surface area analysisElectricityCheck valve

The invention relates to a surrounding rock stress disturbing degree test device. The invention aims at providing a surrounding rock stress disturbing degree test device which can simply, rapidly and directly evaluate the stress disturbing degree of surrounding rock and does not affect the state of the surrounding rock. According to the technical scheme, the surrounding rock stress disturbing degree test device comprises a packer device which is arranged in a surrounding rock borehole and a gas supply device which is arranged outside the surrounding rock, the packer device comprises two packers for packing the surrounding rock borehole, a pressure-bearing section cavity is formed between the two packers, the gas supply device comprises a nitrogen tank, the nitrogen tank is communicated with a multichannel conversion switch by virtue of a gas conveying pump, a gas conveying pipe, a flow sensor and a check valve, the nitrogen tank is divided into three branches by virtue of the multichannel conversion switch, one branch is communicated with the pressure-bearing section cavity by virtue of the gas conveying pipe, the other two branches are respectively communicated with the two packers by virtue of the gas conveying pipe, and the gas conveying pipe of each branch is provided with a check valve and a pressure release valve; and the multichannel conversion switch is provided with a pressure sensor for detecting the air pressure in each gas conveying pipe, and each pressure sensor is electrically connected with a pressure gauge and a recorder.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com