United detection method for determinming freshness of prepared aquatic product at low temperature shelf life

A joint detection and aquatic product technology, which is applied in the direction of testing food, material inspection products, and using nuclear magnetic resonance to analyze, etc., can solve the problems that the freshness model system error cannot be ignored, achieve fast and accurate prediction of simulation effects, and meet fast and accurate requirements Detection requirements, the effect of high prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: A joint freshness detection method for determining the low-temperature shelf life of conditioned surimi products.

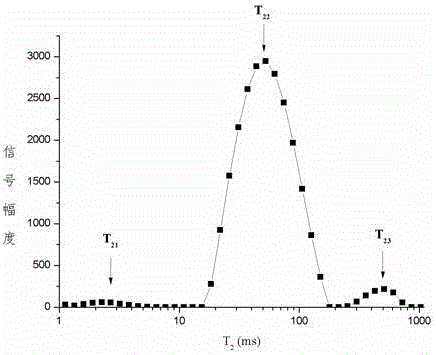

[0036] First, add 0.5% salt to thawed 10% frozen surimi and grind for 15 minutes, then add 6% soybean oil, 6% egg white, 7% soybean protein, 5% potato starch and ice water to continue mixing for 5 minutes, and finally put Put it into a steamer (steam at 100°C for 15 minutes) to get the conditioned surimi product, and put it in an environment of 0-4°C for storage. The detection steps are as follows: firstly detect the TVB-N value change of the conditioned surimi products after different storage time, and carry out low-field nuclear magnetic technology and electronic nose flavor measurement, and calculate T 2 The weighted value of the peak of the curve and the electronic nose S1 value. Finally, with TVB-N value, T 2 The peak weighted value of the curve and the S1 value of the electronic nose are the input layer, and the RBF neural network shelf ...

Embodiment 2

[0037] Example 2: A combined freshness detection method for determining the low-temperature shelf life of conditioned grass carp pieces.

[0038] First, wash and cut fresh grass carp into pieces, then cut into standard pieces and drain the raw fish pieces into the seasoning liquid for dipping. The cooked fish pieces are packaged in plastic bags and placed in a refrigerated environment (0-4°C). The change of TVB-N value after different storage time of the conditioned grass carp pieces was carried out by low-field nuclear magnetic technology and electronic nose flavor determination, and the calculation of T 2 The weighted value of the peak of the curve and the electronic nose S1 value. Finally, with TVB-N value, T 2 The peak weighted value of the curve and the electronic nose S1 value are the input layer, and the RBF neural network shelf-life prediction model is output after repeated calculations through the Matlab programming software. Finally, the TVB-N value, low-field nuc...

Embodiment 3

[0039] Example 3: A combined freshness detection method for determining the low-temperature shelf life of conditioned prawns.

[0040] First, wash the Penaeus vannamei to remove the sediment impurities, and then boil it in water. The number of shrimps is limited to submerge the Penaeus vannamei in the boiling liquid; after boiling, boil for 2 to 4 minutes, then pick up the vannamei shrimp, cool and drain the water , and finally weighed and bagged and then vacuum-packed to obtain the conditioned prawn product, which was then refrigerated at 0-4°C. The TVB-N value changes of the conditioned prawns after different storage time were measured by low-field nuclear magnetic technology and electronic nose flavor, and the T 2 The weighted value of the peak of the curve and the electronic nose S1 value. Finally, with TVB-N value, T 2 The peak weighted value of the curve and the S1 value of the electronic nose are the input layer, and the RBF neural network shelf life prediction model ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com