Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Advantages of production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technique for producing germinating brown rice vinegar and products thereof

InactiveCN101215517AAdvantages of production processMerit productMicroorganism based processesVinegar preparationHorticultureProduct processing

The invention relates to a process technology of germinated brown rice vinegar and products, belonging to the technical filed of agricultural products processing, which is characterized in that the invention adopts germinated brown rice as the main raw material via saccharifying, alcoholic fermentation and acetic fermentation to obtain the germinated brown rice vinegar which contains abundant health care components such as gamma-aminobutyric acid (GABA) and the like. The method is high in industrialization degree, which reserves the functional components such as GABA and the like when obtaining the vinegar and the end product is clear and transparent, wherein the GABA content is 200-350mg / l, which is a novel health-care rice vinegar product.

Owner:NANJING AGRICULTURAL UNIVERSITY

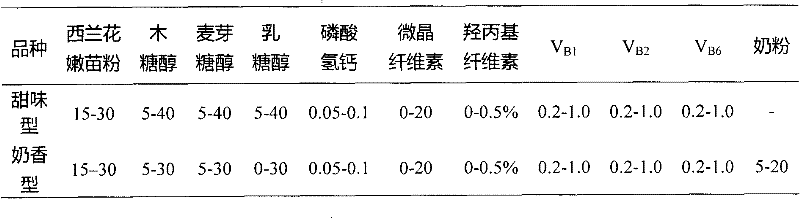

Process for preparing brassica vegetable seedling powder chewable tablets and brassica vegetable seedling powder chewable tablet product

InactiveCN102511753ASmooth appearanceEmerald green colorFood shapingFood preparationBrassica creticaBroccoli raab

The invention relates to a process for preparing brassica vegetable seedling powder chewable tablets and a brassica vegetable seedling powder chewable tablet product, belonging to the technical field of deep processing of agricultural products. The process is characterized by comprising the following steps of: with brassica vegetable seedling powder, such as broccoli and the like as a main basic stock, compounding, preparing a soft material, granulating, drying, tabletting, sterilizing and packing to prepare the brassica vegetable seedling powder chewable tablet with the advantages of clean appearance, green color and crispness. The process for preparing the brassica vegetable seedling powder chewable tablet, disclosed by the invention, is simple, has high industrial degree and can realize complete utilization on the brassica vegetable seedling, such as broccoli and the like, thereby increasing the additional value of the brassica vegetable seedling. The brassica vegetable seedling powder chewable tablets, including the broccoli and the like, prepared by the process disclosed by the invention have functions of resisting oxidation, slowing aging and resisting inflammation and cancer and the like of human bodies, and is a kind of casual healthcare food. According to the product of the process for preparing the brassica vegetable seedling powder chewable tablets, disclosed by the invention, the content of 4-methylsulfinylglucosinolate is up to 185.0-413.0mg / 100g, and the content of sulforaphane provided by each chewable tablet is equal to that provided by 30-75g of fresh brassica vegetable, such as broccoli and the like.

Owner:NANJING AGRICULTURAL UNIVERSITY

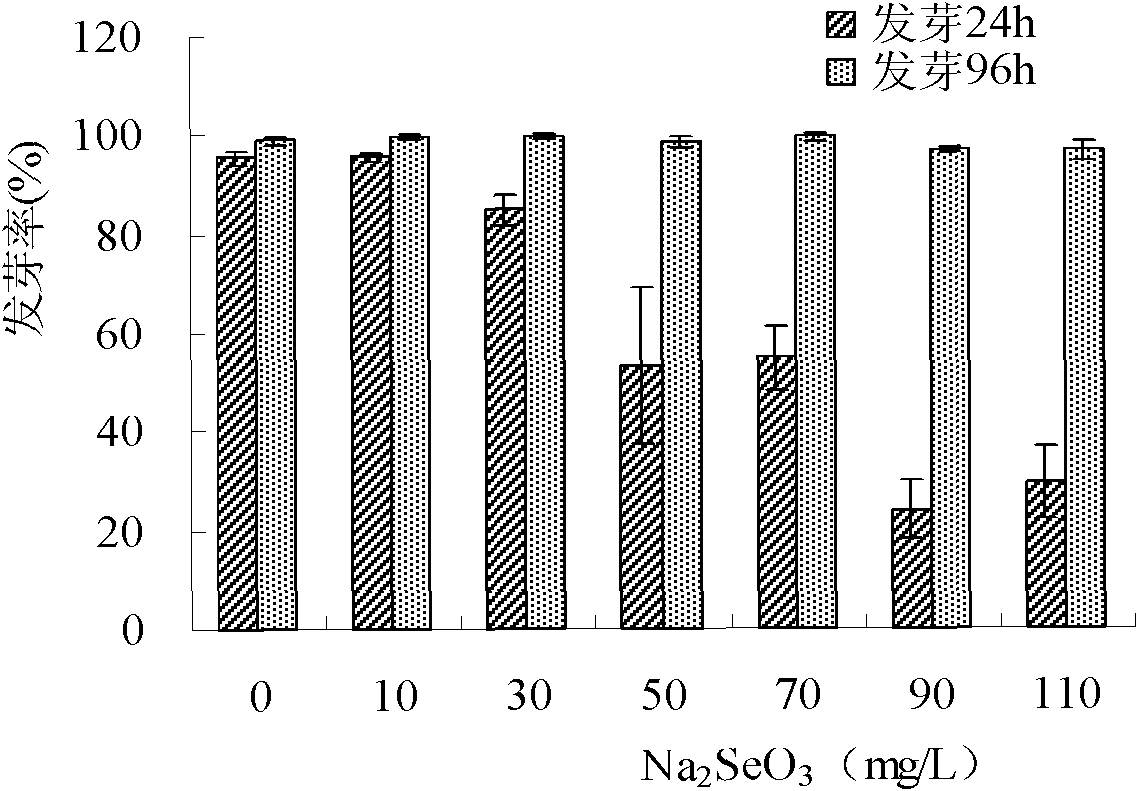

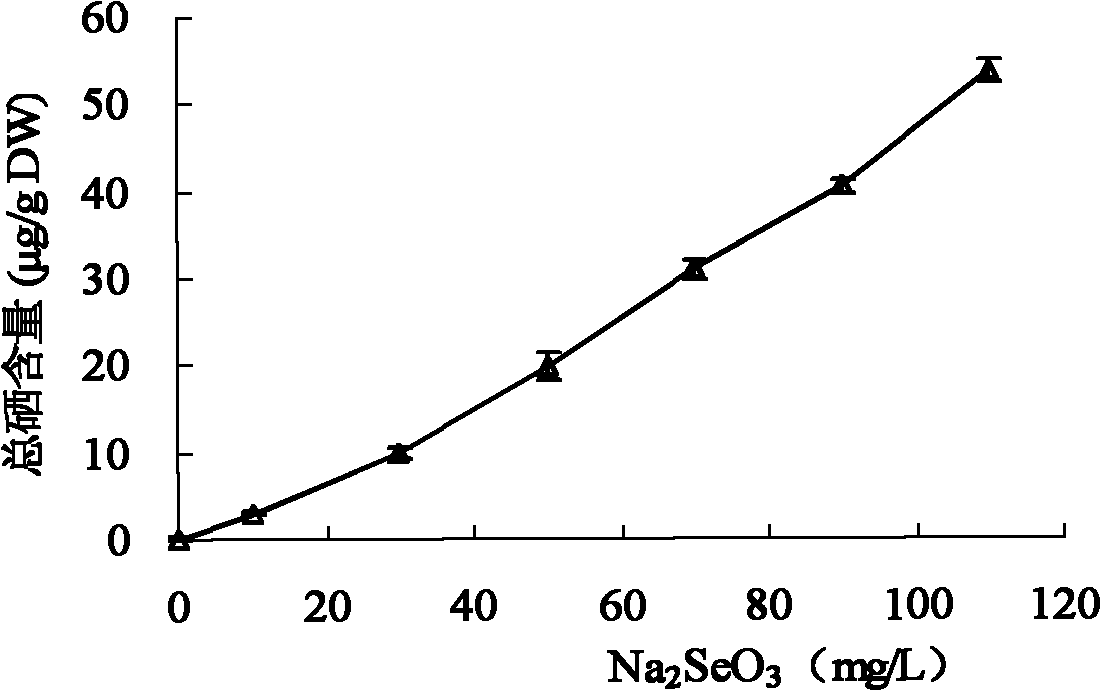

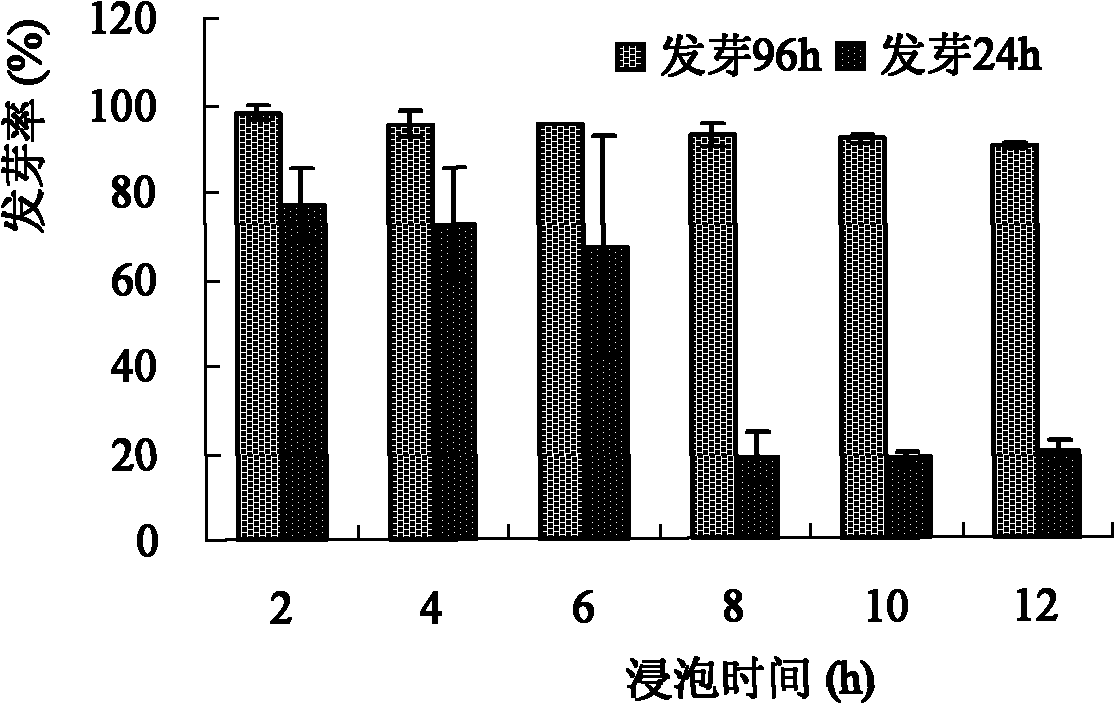

Method for cultivating selenium-rich bean sprouts

InactiveCN102090313AAdvantages of production processNo pollution in the processCultivating equipmentsSoilless cultivationSoybean sproutDrug biotransformation

The invention relates to selenium-rich bean sprouts and a production process thereof. The production process is to use sprouting of soybeans to perform the biotransformation of selenium to obtain a bean sprout product rich in organic selenium. The invention belongs to the field of deep processing of farm products, and also belongs to the field of the production of functional food. The production process comprises the following steps of: performing selection and impurity removal on the soybeans, then soaking in solution of sodium selenite, draining water, and then ensuring that the soybeans sprout in a mode of water spraying cultivation to obtain the selenium-rich bean sprouts.

Owner:常州五星禾绿蔬菜食品有限公司

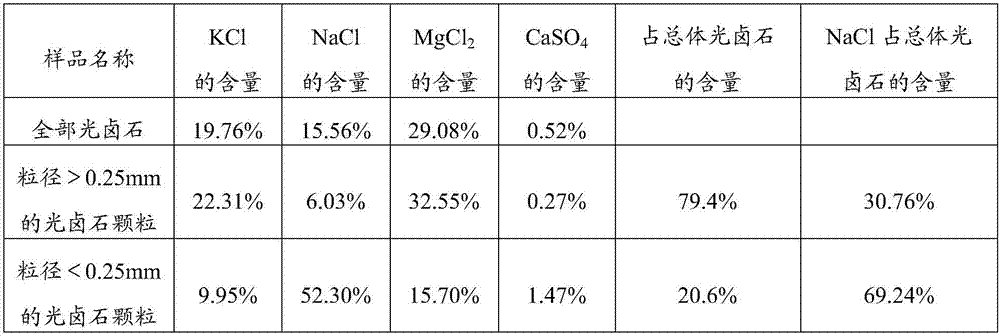

Technology for producing potassium chloride from carnallite

The invention discloses a technology for producing potassium chloride from carnallite. The technology comprises the following steps: determining a critical particle diameter of particles with the mostaverage content of the potassium chloride and selecting a standard screen mesh for sieving carnallite particles; sieving the carnallite particles into a primary oversize material and a primary undersize material by utilizing the standard screen mesh; adding a water amount for completely dissolving magnesium chloride into the primary oversize material to obtain a primary dissolving solution and primary mixed slurry; sieving the primary mixed slurry into a secondary oversize material and a secondary undersize material by utilizing the standard screen mesh; carrying out reverse flotation to obtain low-sodium carnallite and tail salt foam; adding the water amount for completely dissolving the magnesium chloride into the low-sodium carnallite to obtain a secondary dissolving solution and secondary mixed slurry; carrying out solid-liquid separation on the secondary undersize material and the secondary mixed slurry to obtain a crude potassium product; washing an obtained potassium chloride crude product to obtain a qualified potassium chloride finished product. The technology disclosed by the invention has the advantages of simplicity in operation, less investment, low energy consumptionand high yield and the quality of the prepared potassium chloride finished product is good.

Owner:ЦИНХАЙ СОЛТ ЛЕЙК ИНДАСТРИ ГРУП КО ЛТД

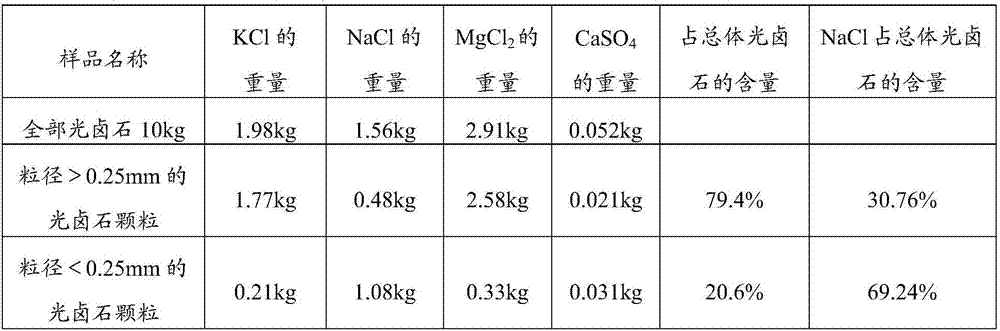

Peppermint essential oil and mixed cyclodextrin inclusion compound and preparation method thereof

InactiveCN103271991AHigh inclusion rateImprove solubility and stabilityCosmetic preparationsSenses disorderPeppermintsChemistry

The invention belongs to the technical field of medicines and in particular relates to a peppermint essential oil and mixed cyclodextrin inclusion compound and a preparation method thereof. According to the technical scheme, the mixture of alpha-cyclodextrin, beta-cyclodextrin and gamma-cyclodextrin and the peppermint essential oil are included in water, so that the inclusion rate is improved, the solubility and stability are improved, and an organic solvent is avoided in the production process.

Owner:江苏丰园生物技术有限公司

Preparation method of ethyl benzene by adopting alkylation exhaust gas generated in process of preparing styrene by adopting catalytic dry gas

ActiveCN103965009AAchieve self-sufficiencyLow costHydrocarbonsAbsorption purification/separationDehydrogenationEthylene

The invention belongs to the technical field of preparation of ethyl benzene through catalytic dry gas, and discloses a preparation method of ethyl benzene by adopting alkylation exhaust gas generated in the process of preparing styrene by adopting catalytic dry gas. The method comprises the following steps: separating ethane, demethanizing, deethanizing, performing oxidative dehydrogenation, dehydrating and depickling, performing hydrocarbylation reaction, and separating ethyl benzene. A preferred adsorbent and the cyclic utilization technology of ethane and the adsorbent can minimize the preparation cost of ethyl benzene, the technology is simple and the recyclability is high. Under appropriate technological conditions, the total conversion rate of ethane can reach above 88%, the overall selectivity of ethylene generating ethyl benzene can reach above 80%, the purity of ethyl benzene can reach above 83%, and the recovery rate of the adsorbent can reach above 99%.

Owner:陕西延长石油(集团)有限责任公司炼化公司

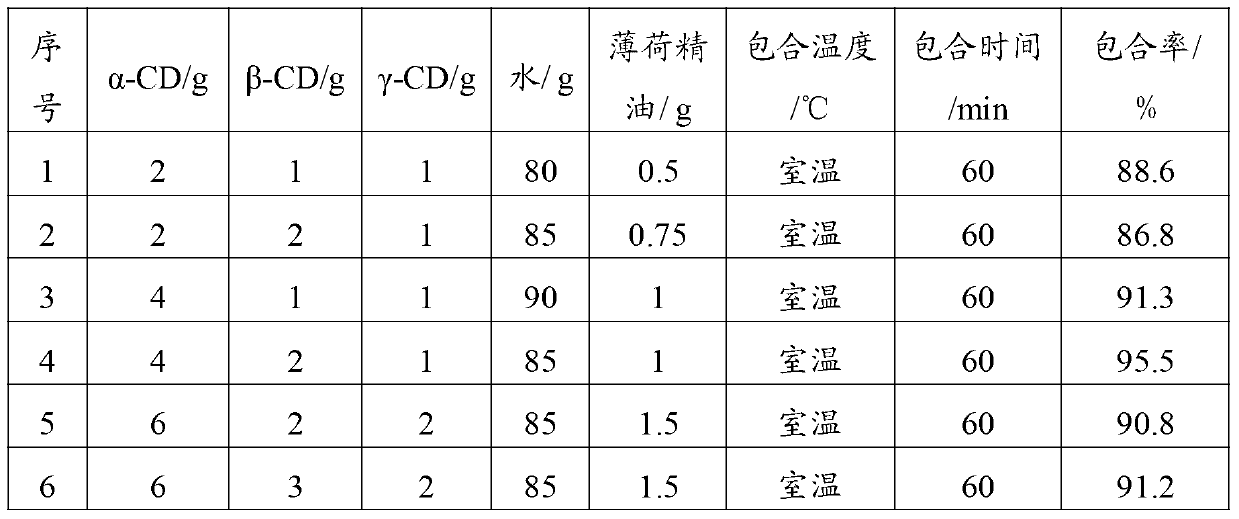

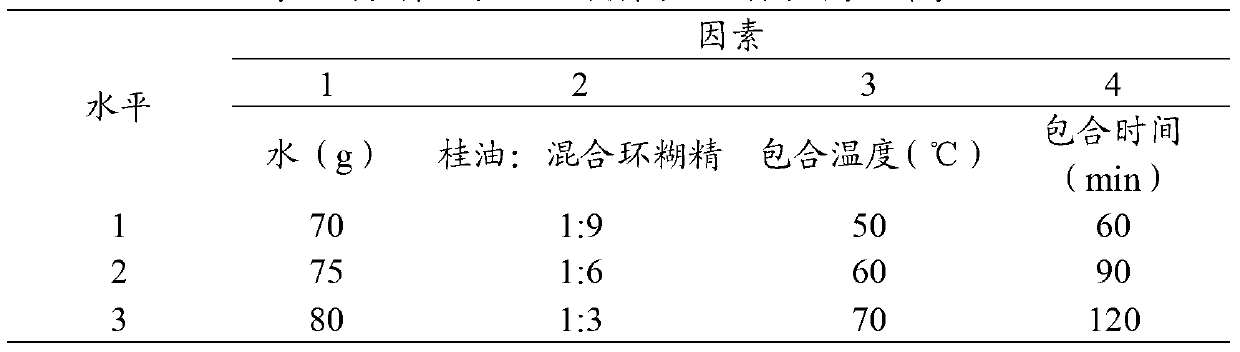

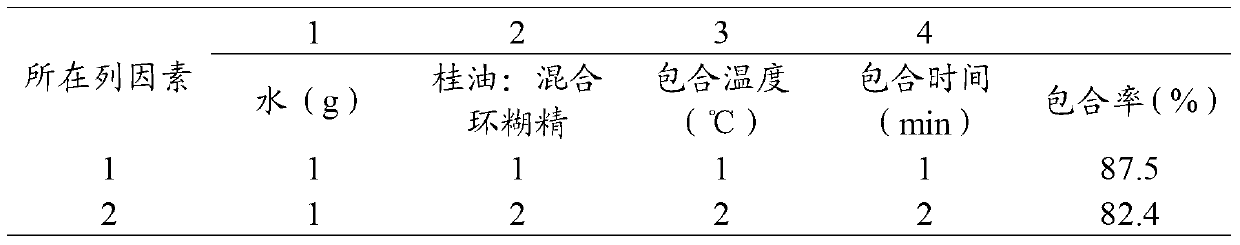

Cinnamon essential oil-cyclodextrin mixture inclusion compound and preparation method thereof

InactiveCN103271996AHigh inclusion rateImprove solubility and stabilityAntibacterial agentsAntimycoticsChemistrySolubility

The invention belongs to the technical field of medicine, and particularly relates to a cinnamon essential oil-cyclodextrin mixture inclusion compound and a preparation method thereof. The technical scheme, which is implemented by carrying out inclusion on an alpha-cyclodextrin / beta-cyclodextrin / gamma-cyclodextrin mixture and cinnamon essential oil in water, enhances the inclusion rate, increases the solubility and stability, and avoids using an organic solvent in the production process.

Owner:江苏丰园生物技术有限公司

A method for preparing ethylbenzene from alkylation tail gas after catalytic dry gas is used to prepare styrene

ActiveCN103965009BAchieve self-sufficiencyLow costHydrocarbonsAbsorption purification/separationDehydrogenationEthylene

The invention belongs to the technical field of preparation of ethyl benzene through catalytic dry gas, and discloses a preparation method of ethyl benzene by adopting alkylation exhaust gas generated in the process of preparing styrene by adopting catalytic dry gas. The method comprises the following steps: separating ethane, demethanizing, deethanizing, performing oxidative dehydrogenation, dehydrating and depickling, performing hydrocarbylation reaction, and separating ethyl benzene. A preferred adsorbent and the cyclic utilization technology of ethane and the adsorbent can minimize the preparation cost of ethyl benzene, the technology is simple and the recyclability is high. Under appropriate technological conditions, the total conversion rate of ethane can reach above 88%, the overall selectivity of ethylene generating ethyl benzene can reach above 80%, the purity of ethyl benzene can reach above 83%, and the recovery rate of the adsorbent can reach above 99%.

Owner:陕西延长石油(集团)有限责任公司炼化公司

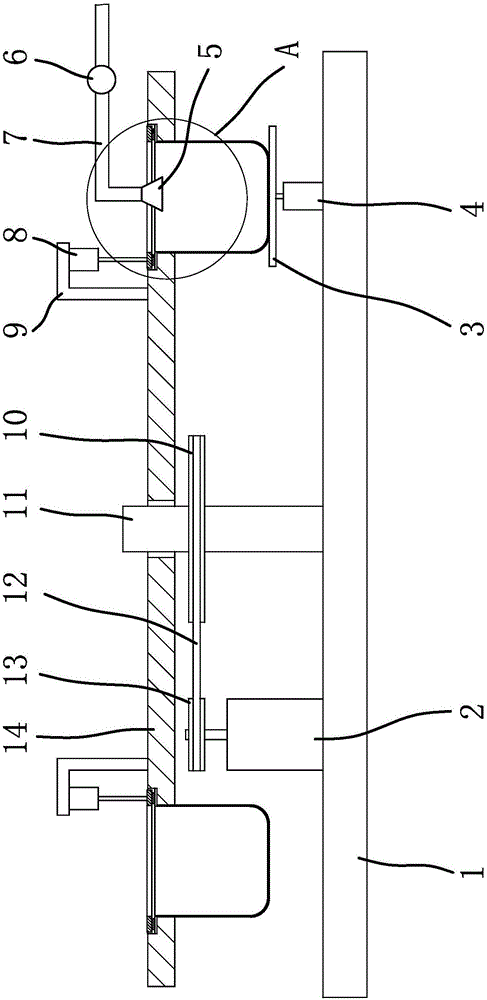

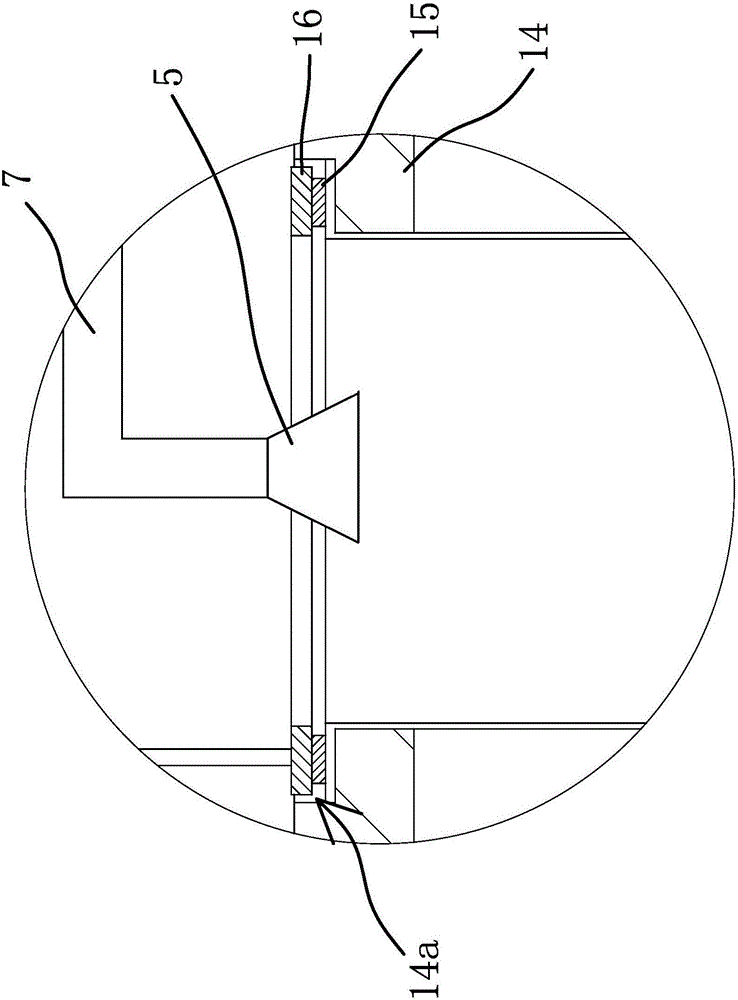

Production technology of aluminium-plastic panel

ActiveCN106379029ARapid positioningAdvantages of production processLamination ancillary operationsLaminationEngineeringComposite plate

The invention provides a production technology of an aluminium-plastic panel. The technical problem that an existing production method is too complex to operate, requires repeated manual operation and has slow production speed is solved. The production technology of the aluminium-plastic panel comprises the following steps: a, preheating by pouring a PE material into a preheating agitator through a feeding device with the ratio of polyethylene to color master batch being 1000:3, letting the PE material be sucked into a hopper of an extruder through a vacuum suction machine and enter the extruder to extrude a panel through a T-shaped die head; b, melting adhesive film through PE panel temperature of 220-230 DEG C, letting the PE panel and two layers of adhesive films and two layers of aluminum coil material enter two groups of thermal composite rolls and gluing the PE panel and the two layers of aluminum coil material together through the molten adhesive film; c, letting the panel enter a leveling setting machine to undergo setting and leveling; and d, letting the leveled composite panel enter an air-cooling box to be cooled. The technology of the invention has the advantage of high production efficiency.

Owner:ZHEJIANG BAOYE BUILDING MATERIAL TECH

High-temperature heat insulation pipeline production technology

InactiveCN103753824AAdvantages of production processGood insulation performanceThermal insulationPerlite

The invention provides a high-temperature heat insulation pipeline production technology. The technology is characterized in that a plurality of aerogel felts are axially installed along the outer wall of a work tube before an outer protection tube is jointed to make the aerogel felts combined with a polyurethane thermal insulation layer formed through foaming in order to form a heat insulation system of a heat insulation pipeline, and the heat insulation system combines the respective excellent performances of the aerogel felts and the foamed polyurethane thermal insulation layer, can substitute traditional heat insulation materials having an unfavorable heat insulation effect, like cement perlite tiles and glass wool, has an improved temperature tolerance, and also has the characteristics of energy saving, environmental protection, safety, reliability and the like; and additionally two ends of the aerogel felts are abutted surrounding the outer wall of the work tube, abutment lines are formed between the two ends, and the abutment lines of the plurality of aerogel felts are assigned along the axial outer wall of the work tube in an interlace manner, so a defect of the heat insulation performance decrease caused by the rapid loss of heat along the abutment lines distributed along a straight line because one abutment line cracking of the aerogel felts when the abutment lines are positioned in a same straight line is avoided, thereby the pipeline heat insulation performance is guaranteed.

Owner:BEIJING HTN PIPELINE EQUIP

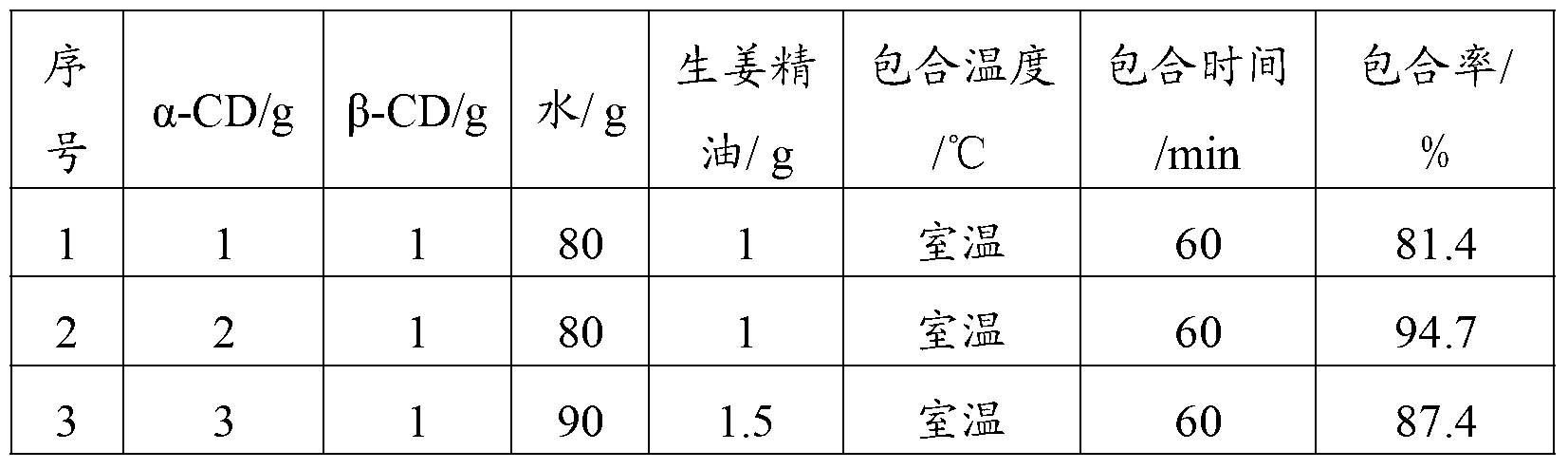

Fresh ginger essential oil and mixed cyclodextrin inclusion compound and preparation method thereof

InactiveCN103263651AHigh inclusion rateImprove solubility and stabilityAntipyreticDigestive systemChemistrySolubility

The invention belongs to the field of a medical technology and particularly relates to a fresh ginger essential oil and mixed cyclodextrin inclusion compound and a preparation method of the fresh ginger essential oil and mixed cyclodextrin inclusion compound. The invention provides a technical scheme of carrying out inclusion on a mixture of alpha-cyclodextrin and beta-cyclodextrin and fresh ginger essential oil in water, so that the inclusion rate is improved, the solubility and the stability are increased and an organic solvent used in a production process is avoided.

Owner:江苏丰园生物技术有限公司

Heap-leaching dressing process for clay type gold mine

InactiveCN1970802AMeet high demand requirementsImprove permeabilityProcess efficiency improvementHeap leachingGold deposit

The invention discloses an ore selecting technique through piling method, which comprises the following steps: 1) grinding ore with grain size less than 5cm; 2) making particle; 3) constructing pile; paving a layer of straw to mask; cutting straw with length at 18-22cm; 4) sprinkling with strength at 20-40l / cm2 / h; setting the interval sprinkling time not less than 1.5h; blending clay gold and loose permeatible sawdust in the graining machine evenly with 1-5kg per ton; adding enough water.

Owner:钟志林

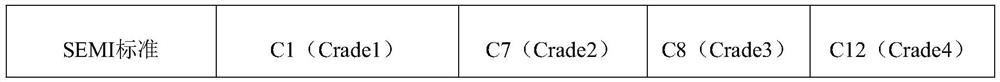

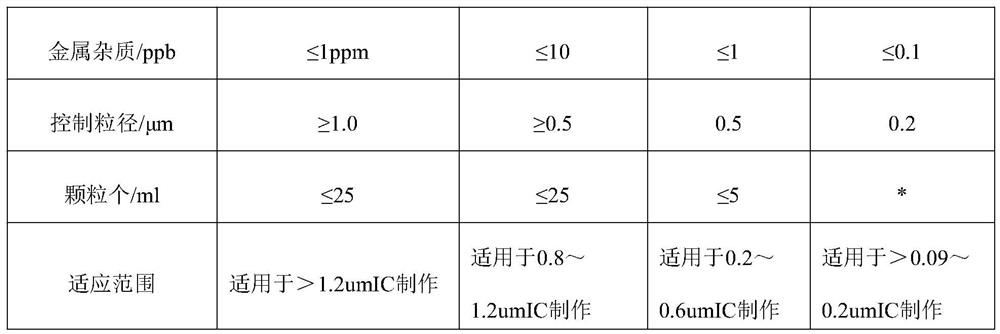

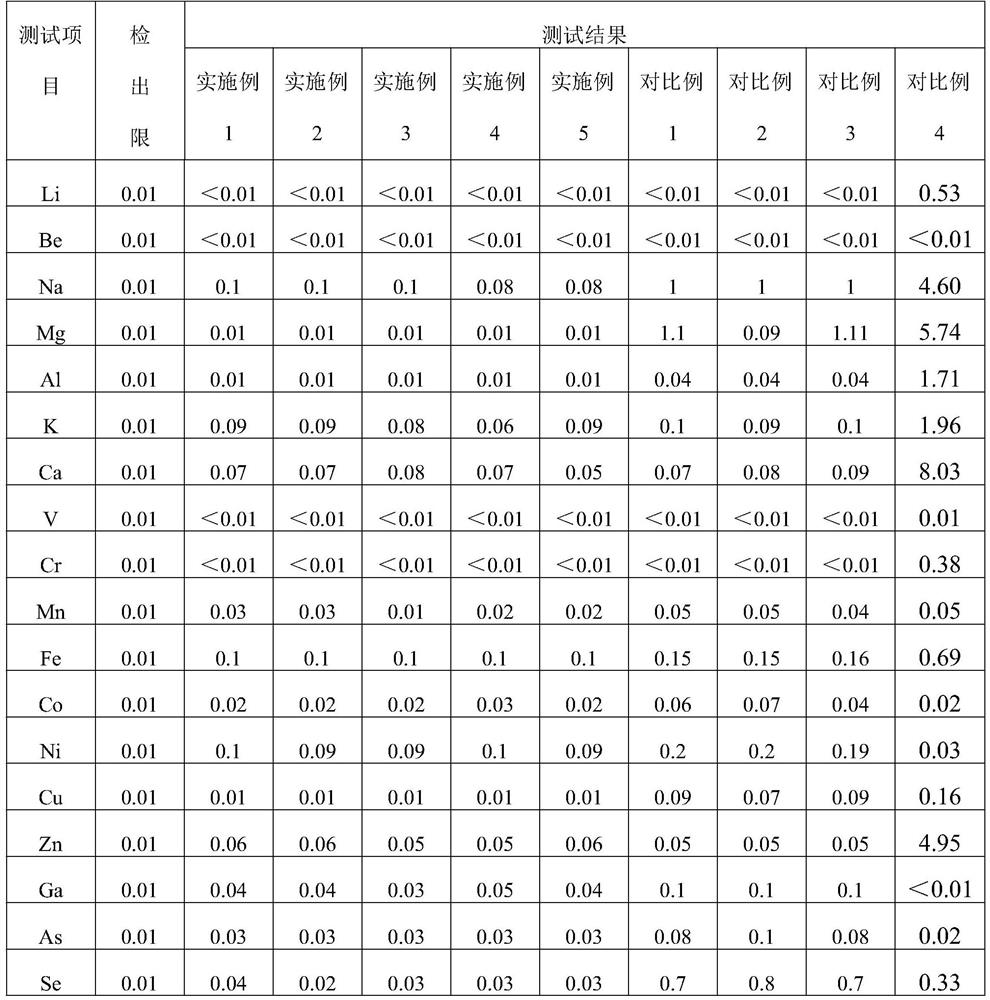

N-methyl pyrrolidone for liquid crystal display panel and production process thereof

InactiveCN111892525AHigh throughput low pressure dropAvoid accumulationOrganic chemistryFiberLiquid-crystal display

The invention discloses a production process of N-methyl pyrrolidone for a liquid crystal display panel. The process comprises a reaction section, an intermittent purification section, a gas strippingpurification section and a secondary rectification purification section, compared with the prior art, the method has the advantages that the N-methyl pyrrolidone product can reach the SEMI C8 standard completely by innovating reaction raw materials, a reaction process and a purification process and strictly controlling process parameters without traditional fiber filtration, and the quality of the product can basically reach the SEMI C12 standard after pressurized adsorption filtration.

Owner:MAIQI CHEM CO LTD

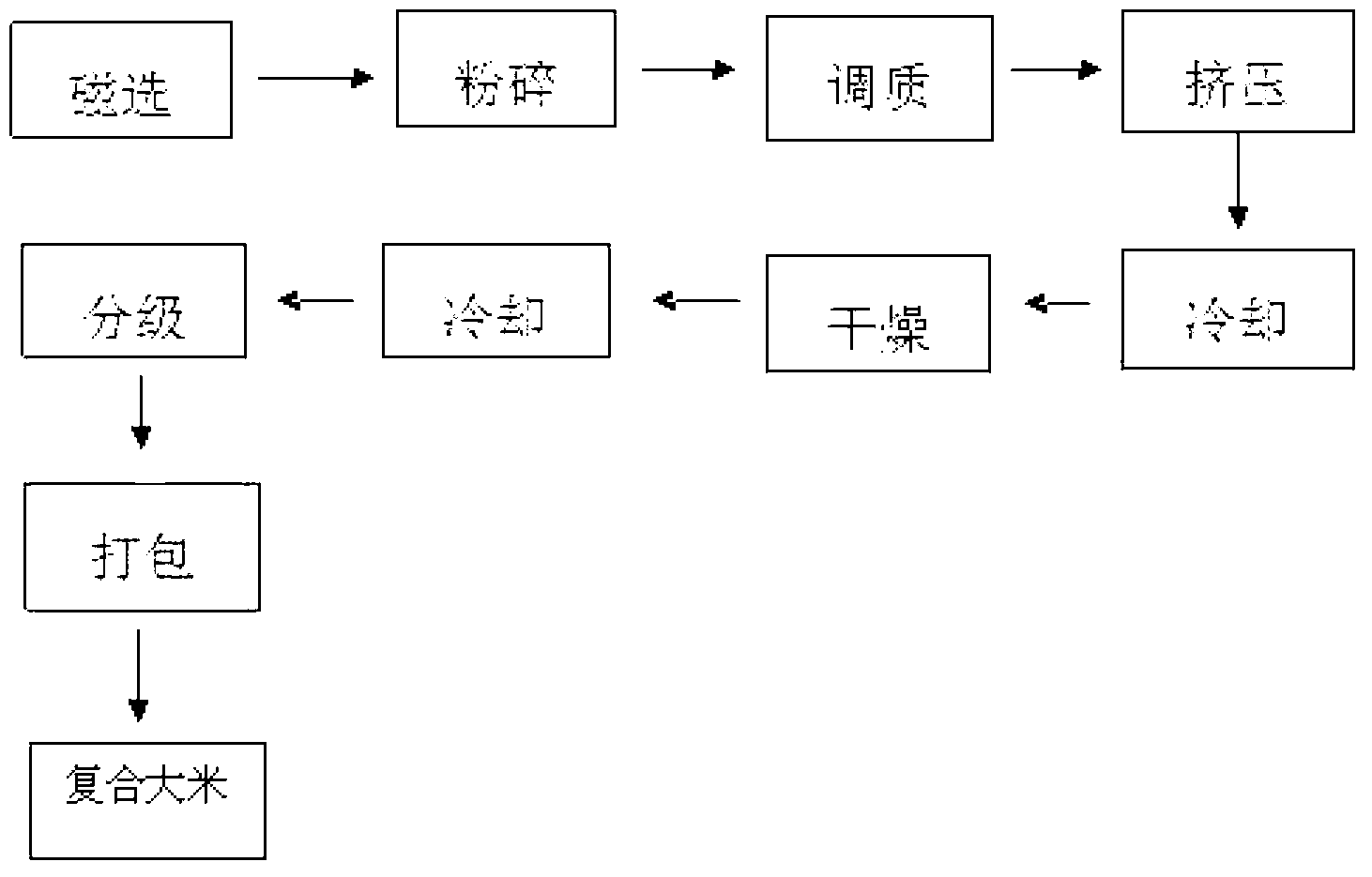

Bean tissue protein composite nutritive rice and production method thereof

The invention provides bean tissue protein composite nutritive rice and a production method thereof. The bean tissue protein composite nutritive rice is obtained by mixing 30wt% of soybeans, 20wt% of mung beans, 20wt% of black beans, 20wt% of red beans and 10wt% of rice flour. The invention also provides a production method of the bean tissue protein composite nutritive rice. Through the production method, broken rice grains and fallen rice germs produced by rice milling are repaired or processed into rice grains the same as common whole polished rice grains. The bean tissue protein composite nutritive rice is all natural and environmentally friendly and has no pollution, a high nutritive value and a good taste. Through the production method, a product having peculiar characteristics and satisfying market demands can be developed. The production method can be operated flexibly, has high efficiency, saves energy, is environmentally friendly and can realize production of different products satisfying consumer demands according to people having different body constitutions. The production method realizes production of a product having credible quality, saves energy and improves production efficiency of enterprises. The production method guarantees quality of each rice grain so that consumer health is protected.

Owner:天津北融米业有限公司

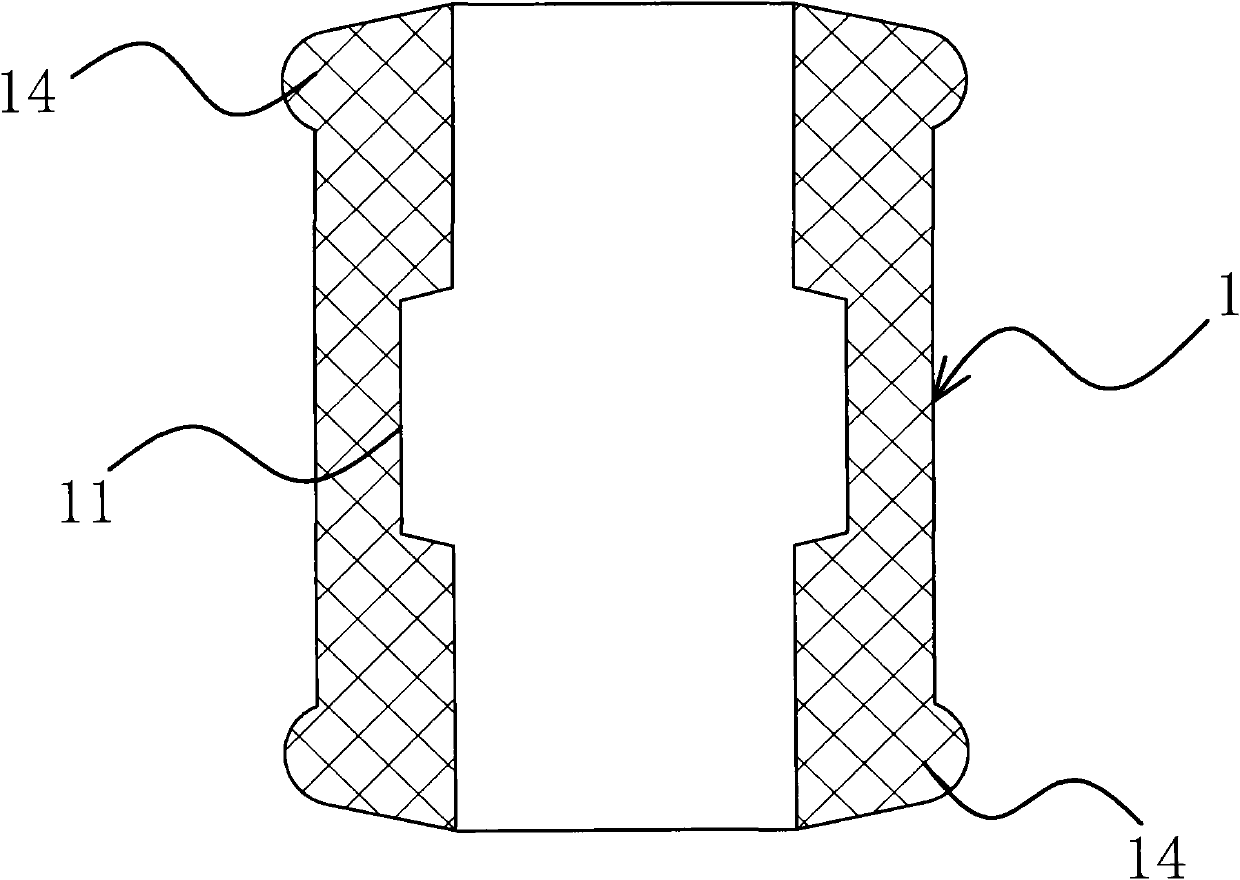

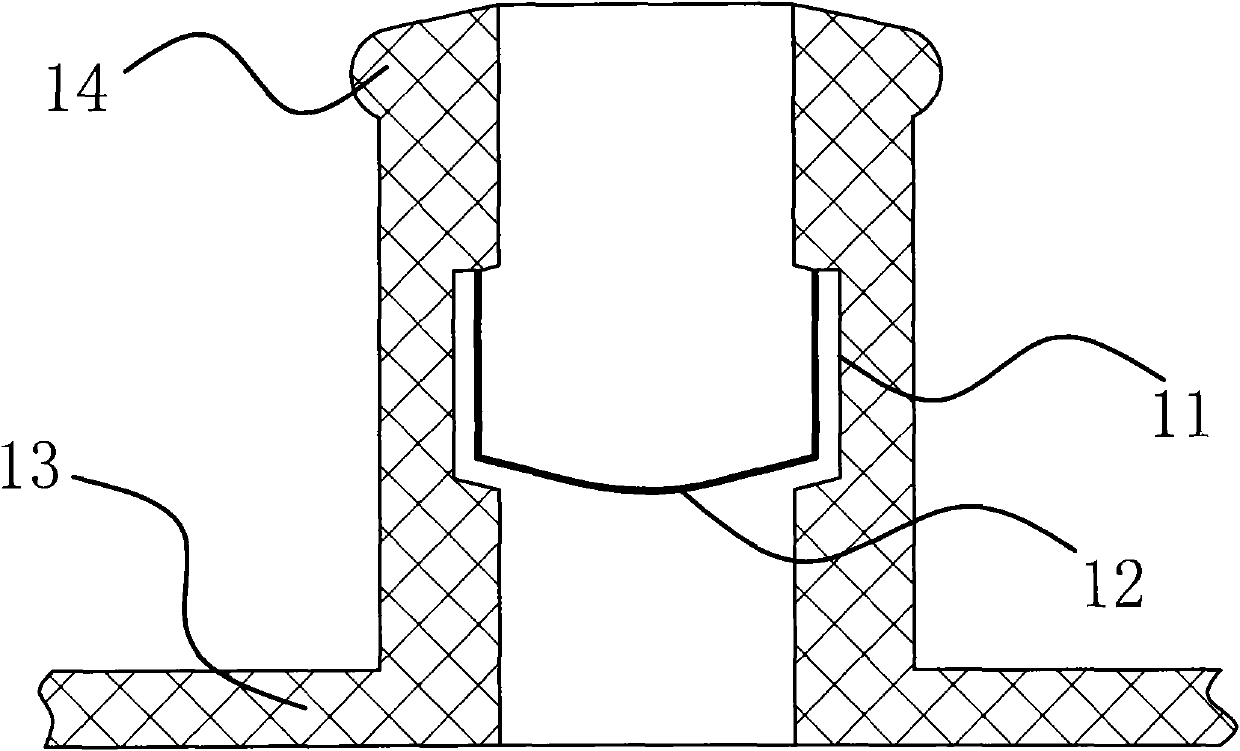

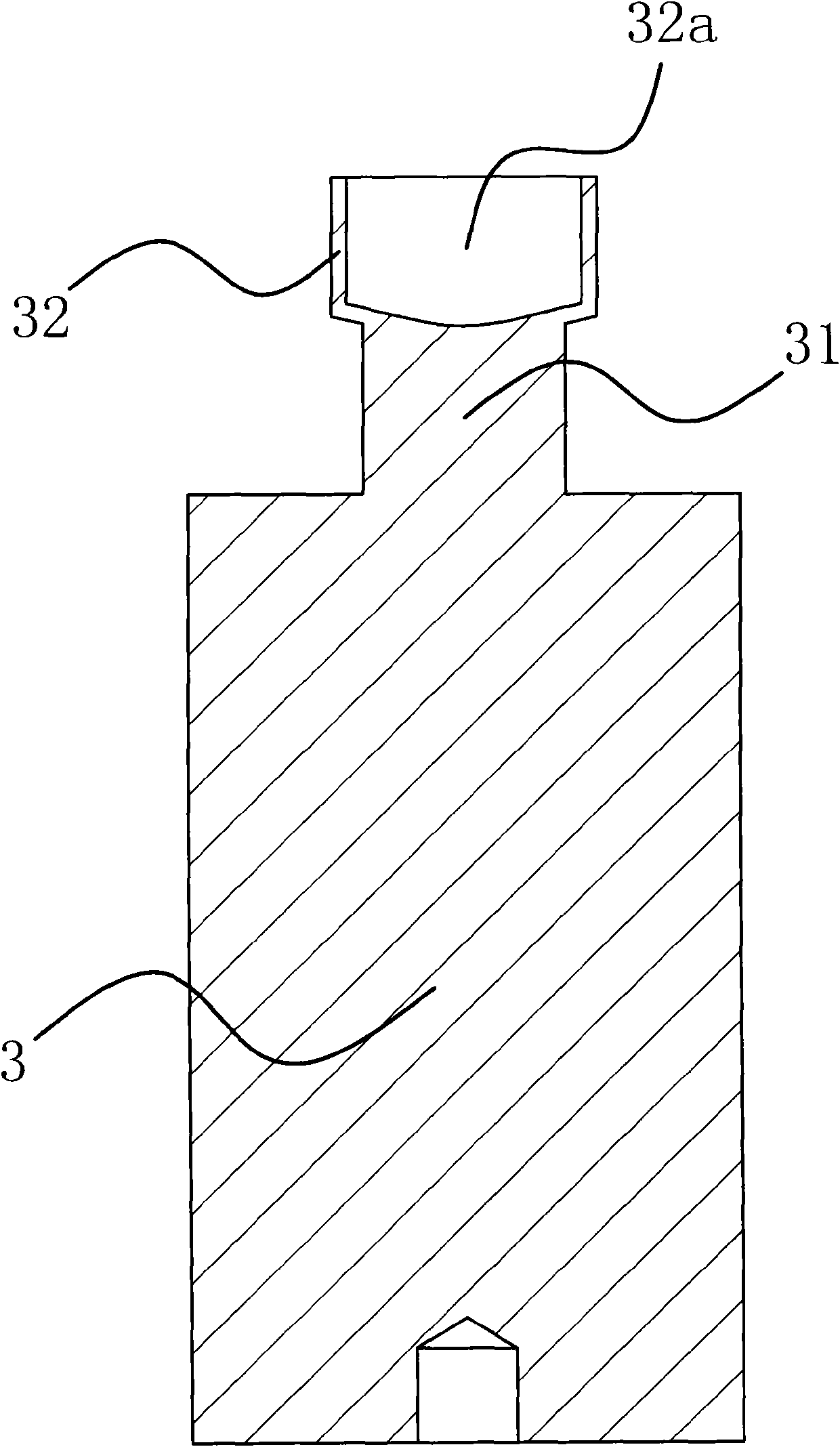

Producing technique and producing die of syringe rubber stopper

ActiveCN101767470AAdvantages of production processAdvantages ProductivityDomestic articlesMetal working apparatusEngineeringSyringe

The present invention provides a producing technique and a producing die of a syringe rubber stopper, belonging to the technical field of medical apparatuses. The present invention solves the problems that the existing producing technique of a syringe rubber stopper is complicated and the existing producing die of a syringe rubber stopper is complicated in structure. The rubber stopper produced by the producing technique of a syringe rubber stopper is cylindrical. The producing technique comprises the following steps of loading materials, molding and obtaining finished products. The die of a syringe rubber stopper comprises a concave die and a convex die which can be mutually buckled. The concave die is provided with a cylindrical cavity, the center of the bottom of the cylindrical cavityis provided with an inner rod axially projected, and the center of the convex die is provided with an inserting rod axially projected. When the concave die and the convex die are buckled, the inserting rod is inserted in the cylindrical cavity, and the inserting rod is coaxially arranged with the inner rod. The present invention has the advantages of simple processing procedure, easy operation, high work efficiency, capability of effectively removing flashes, convenient processing, reasonable structure design, etc.

Owner:浙江胜利医疗器械有限公司

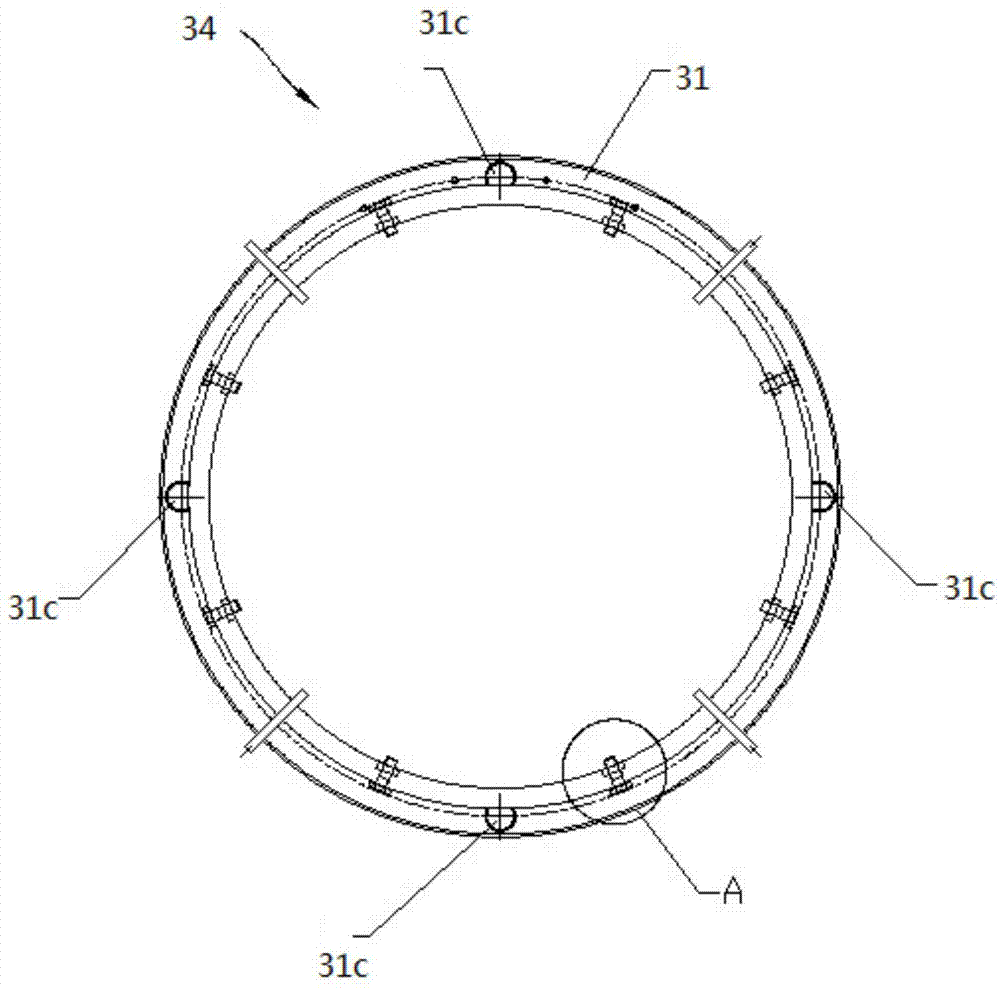

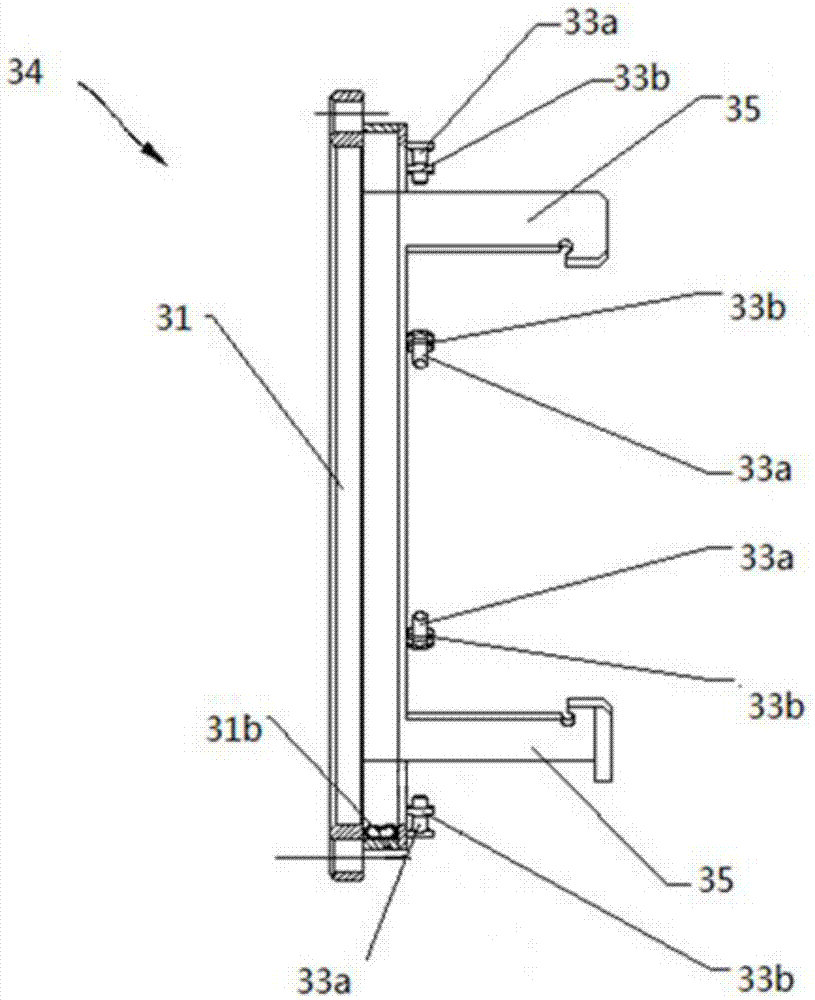

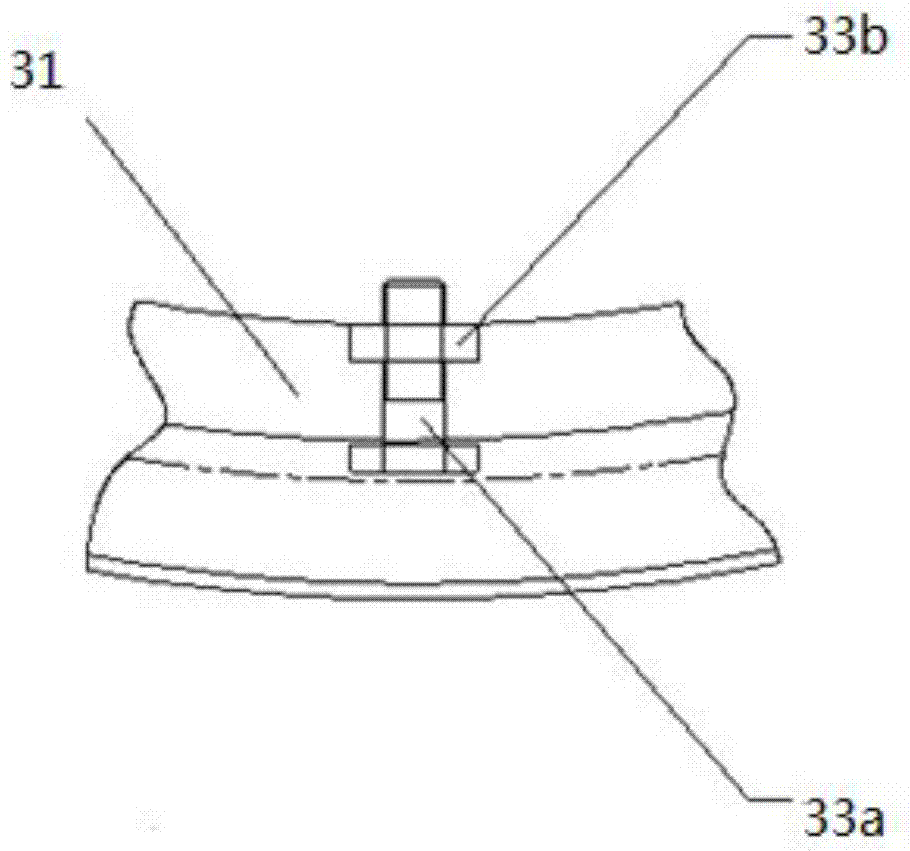

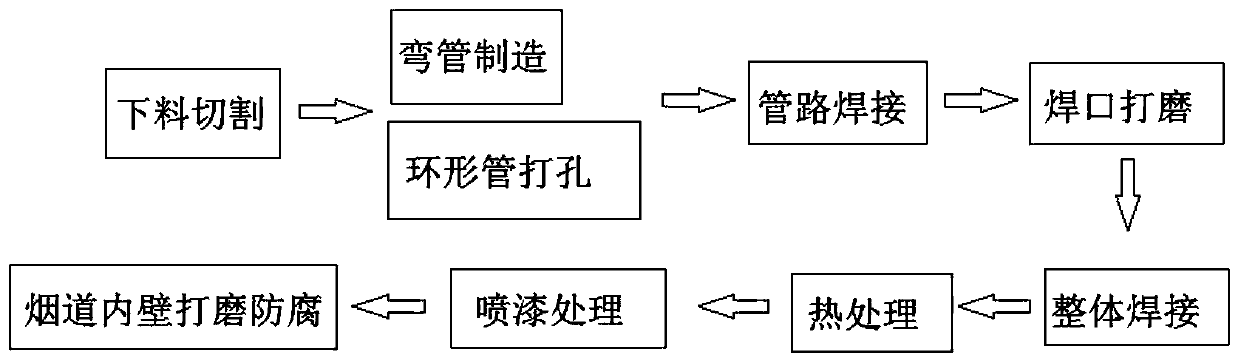

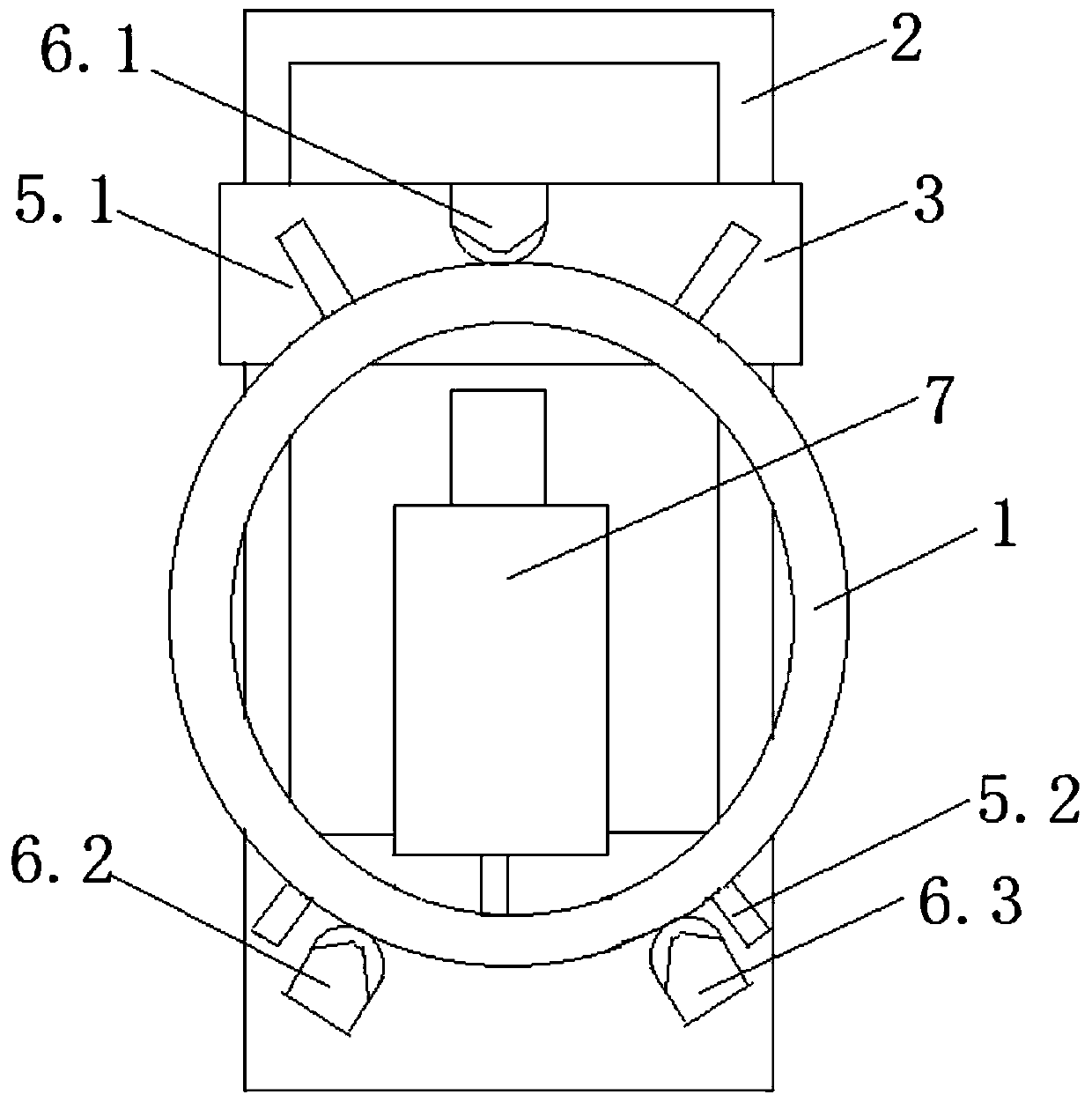

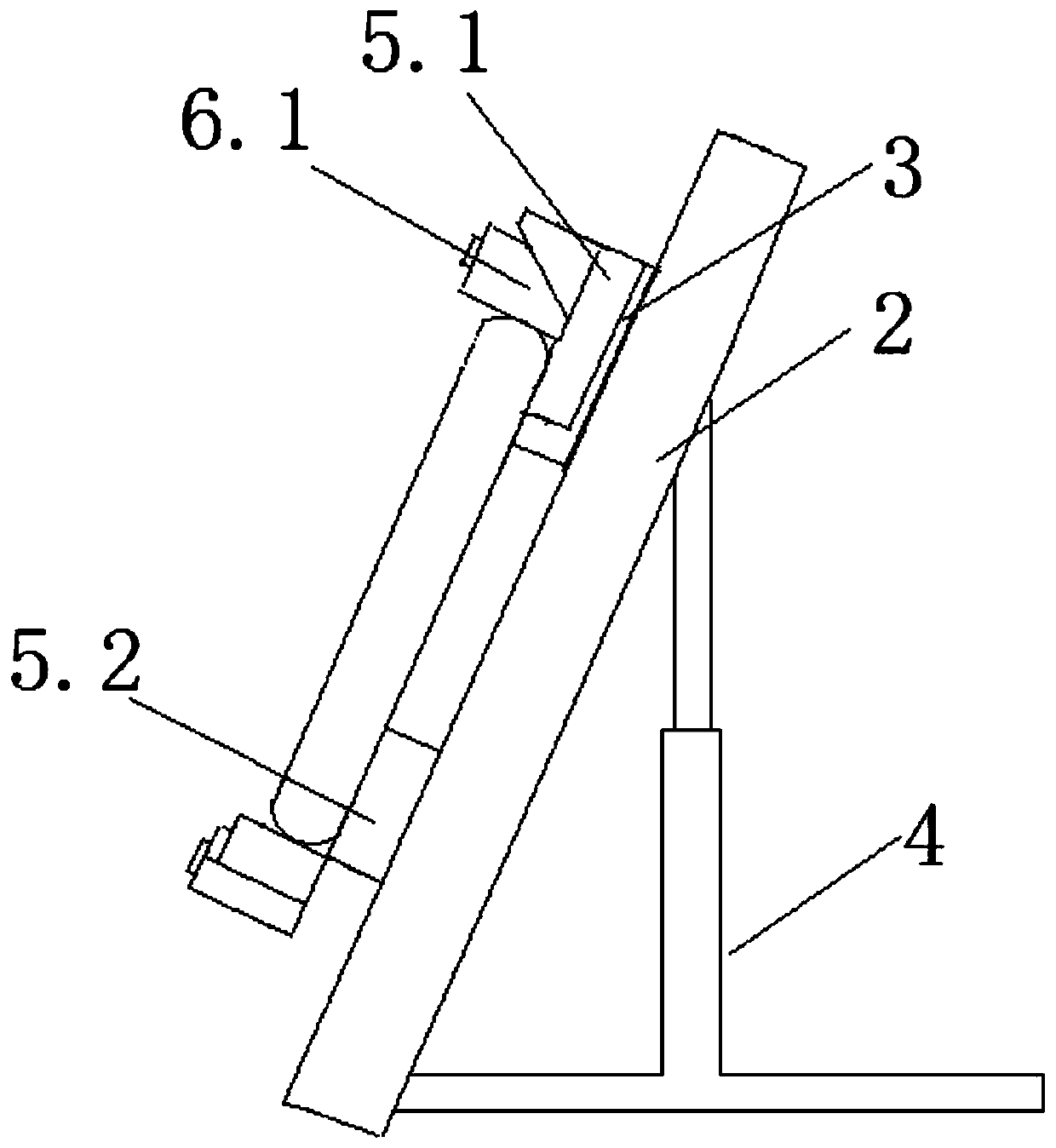

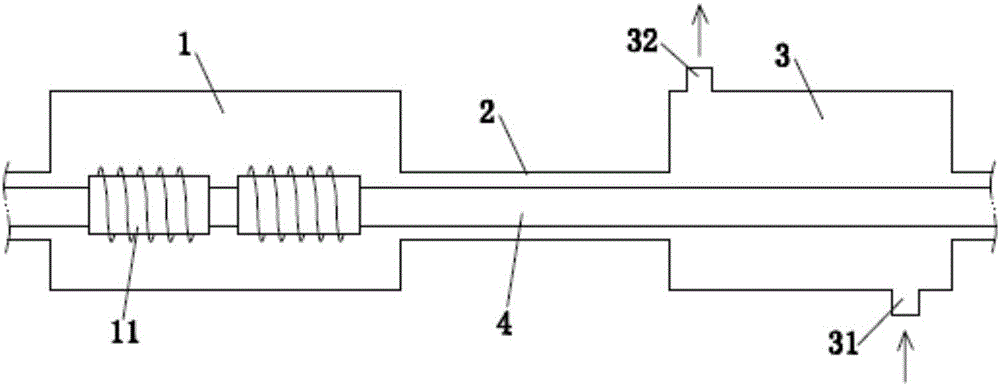

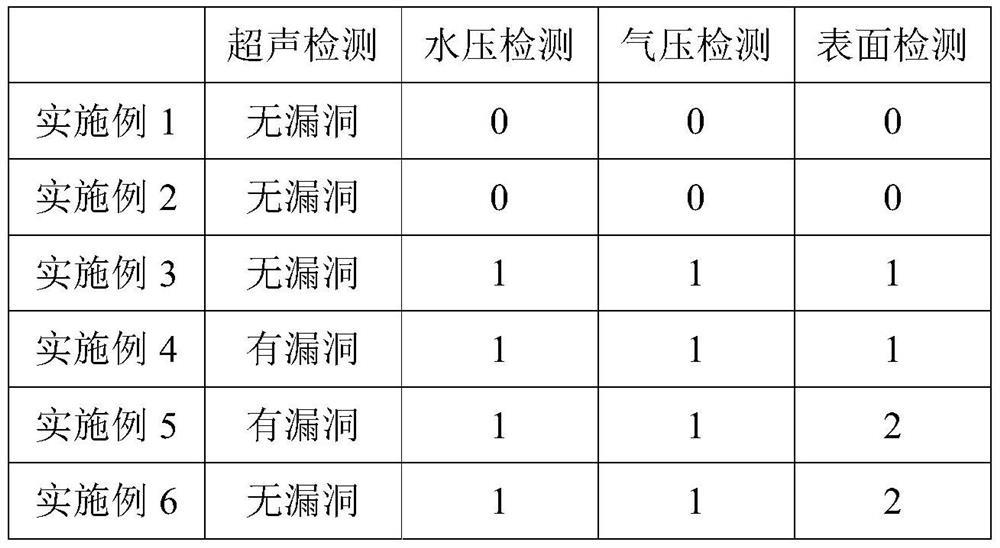

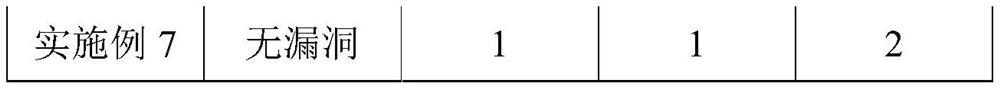

Production equipment and production process of steelmaking converter flue

InactiveCN110293369AAdvantages equipment processAdvantages of production processOther manufacturing equipments/toolsFlueThermal treatment

The invention relates to production equipment and production process of a steelmaking converter flue. The production process comprises the following steps: at first, blanking and cutting a flue; then,using a flue annular pipe perforating device to perforate an annular pipe, and using pipe bending equipment to bend the end part of a steel pipe to form an elbow pipe; welding straight pipes, weldinga straight pipe and the elbow pipe, and welding the annular pipe at the external part of a pipeline in the mode that a through hole in the inner wall of the annular pipe communicates with the interior of the pipeline; after welding, polishing a weld bore; after hoisting the flue in place, integrally welding the flue; after welding, carrying out thermal treatment on the flue; after the thermal treatment, spraying paint on the flue; and finally, after the flue is mounted, carrying out polishing and anticorrosion treatment on the inner wall of the flue. The invention relates to the production equipment and the production process of the steelmaking converter flue to form an integrated technological process, and all working procedures are cooperated tightly to ensure the production efficiencyand the working quality.

Owner:WUXI XIANGLONG GLOBAL TECH CO LTD

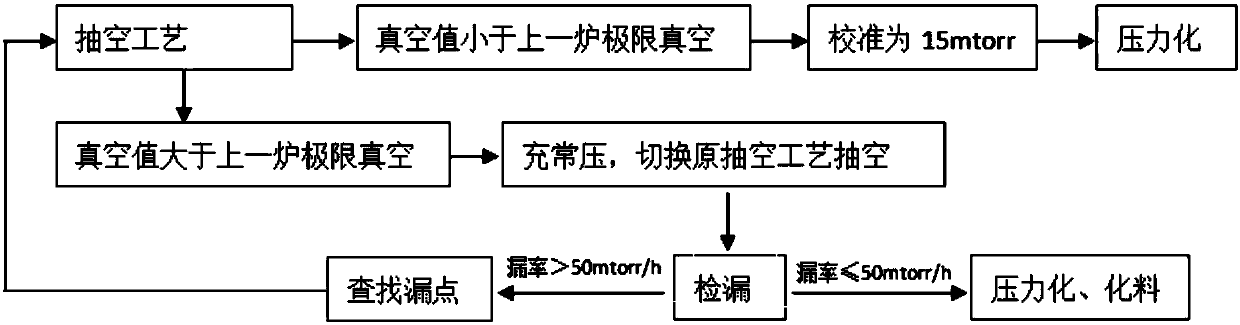

Crystal pulling production process of single crystal furnace, and method for obtaining limited vacuum value of single crystal furnace

ActiveCN107761164AAdvantages of crystal pulling production processAdvantages of production processPolycrystalline material growthBy pulling from meltMetallurgyEconomic benefits

The invention provides a crystal pulling production process of a single crystal furnace. The crystal pulling production process of the single crystal furnace comprises the following steps: 1) measuring the limit vacuum value when the single crystal furnace is vacuumized for m minutes (m is less than n, and n is the conventional single crystal furnace crystal pulling production vacuumizing time); and 2) after the single crystal furnace is charged and closed, vacuumizing for m minutes, detecting the vacuum value in the furnace, judging that sealing of the furnace body is qualified if the detection value is less than or equal to the limit vacuum value and continuing production, and judging that sealing of the furnace body is unqualified if the detection value is more than the limit vacuum value, performing leakage measurement and maintenance on the furnace body until the sealing of the furnace body is qualified and performing subsequent production. According to the crystal pulling production process of the single crystal furnace, the vacuum degree value is compared with the limit vacuum value after the furnace is closed, so that the sealing property of the furnace body is judged, operation is facilitated, the process route is optimized, the crystal pulling time is saved, the production efficiency is improved and great economic benefit is brought to production.

Owner:INNER MONGOLIA ZHONGHUAN SOLAR MATERIAL

Production technology of water-soluble capsaicin

InactiveCN108484429AReduce dosageShorten the timeCarboxylic acid amide separation/purificationFlavorSolubility

The invention provides a production technology of water-soluble capsaicin. The production technology comprises the following steps: performing countercurrent leaching on hot pepper peel by using a leaching solution, adsorbing capsaicin from a solution obtained in the upper layer by using macroporous resin, circulating the adsorbed solution back to countercurrent leaching of the hot pepper peel, then adsorbing, circulating in such a manner, eluting capsaicin adsorbed in the macroporous resin by using ethanol, and concentrating by evaporation to obtain a water-soluble capsaicin solution; dryingin a vacuum, crushing and sieving to obtain a water-soluble capsaicin powder product; by a dry granulating technology, producing a water-soluble capsaicin granule product, wherein the leaching solution is a food-grade alkaline solution and is a monovalent alkali solution and the pH of the leaching solution is 9-14. By a dynamic countercurrent leaching, adsorbing and separating continuous cyclic integrated technology, the prepared water-soluble capsaicin product is light yellow in color, good in water solubility, rich and pure in pepper fragrance, unique in flavor, spicy and refreshing in mouthfeel, free of organic solvent residue, safe and reliable, and can be safely applied to the field of food.

Owner:天津市天联调味制品有限公司

Functional Ariophyllum squarrosum composite soybean milk and production process thereof

InactiveCN107836526AAdvantages of production processReduce anti-nutritional factorsMilk substitutesFood scienceNutrientFlavor

The invention relates to a functional Ariophyllum squarrosum composite soybean milk and a production process thereof, belonging to the technical field of deep processing of food. The production process is characterized by comprising the following steps: with germinated soybean pulp rich in active substances like gamma-aminobutyric acid (GABA) and polypeptides and Ariophyllum squarrosum as main rawmaterials, subjecting Ariophyllum squarrosum to roasting and pulping, compounding the soybean pulp with Ariophyllum squarrosum pulp in proportion, adding a sweetener, a thickening agent and an emulsifier, and then successively carrying out homogenization, degassing, sterilization and aseptic filling so as to prepare the functional Ariophyllum squarrosum composite soybean milk. The functional Ariophyllum squarrosum composite soybean milk provided by the invention enables the varieties of soybean milk to be increased, broadens the application scope of Ariophyllum squarrosum, taste refreshing and fine, has pure flavor, rich nutrients, no sugar and abundant GABA, and is capable of improving immunity, lowering blood pressure, reducing fat, decreasing blood sugar and enhancing sleep; and the content of GABA in the produced functional Ariophyllum squarrosum composite soybean milk is 8 to 15 mg / 100 ml.

Owner:NANJING AGRICULTURAL UNIVERSITY

Production process for low-point horizontally-poured polyurethane for heat insulation pipeline

InactiveCN112521569AAdvantages of production processEnsure the efficiency and quality of production reactionsTemperature controlEngineering

The invention provides a production process for a low-point horizontally-poured polyurethane for a heat-insulating pipeline. The production process comprises the following steps: cleaning a gun head needle valve of a foaming machine and a black material filter screen and a white material filter screen of a premixing box of the foaming machine; injecting black materials into a black material tank,and injecting white materials into a white material tank; enabling the periphery of a to-be-filled inner container to be connected to an inner ring of a to-be-filled outer shell through an outer shellsupporting mold in a sleeving mode. preheating the relevant device through a temperature control cabinet; premixing the black material and the white material according to a specific ratio through thepremixing box of the foaming machine; injecting a mixture of a black material and a white material into the gap between the shell and the inner container through an injection gun head of the foamingmachine; carrying out pressure maintaining curing; and cooling the foaming machine and the shell supporting mold through the temperature control cabinet. According to the production process , the problems that when the temperature of a foaming material in summer is too high, the foaming material is easy to react for a short time, the foaming speed is high, and the foaming density is not uniform are solved.

Owner:中投(天津)智能管道股份有限公司

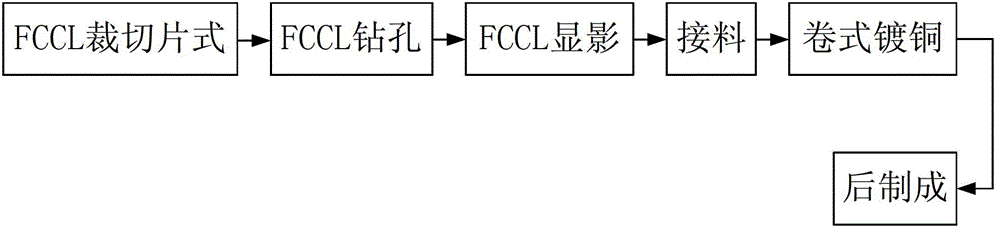

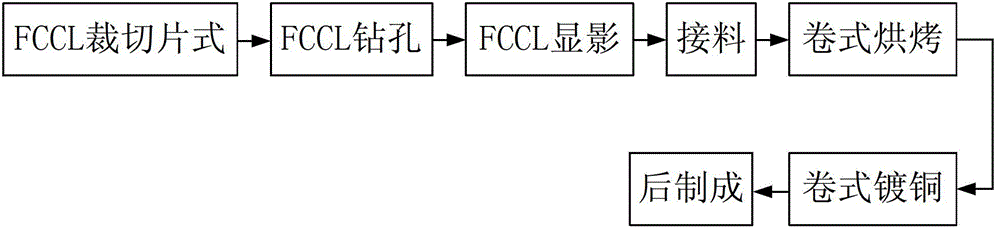

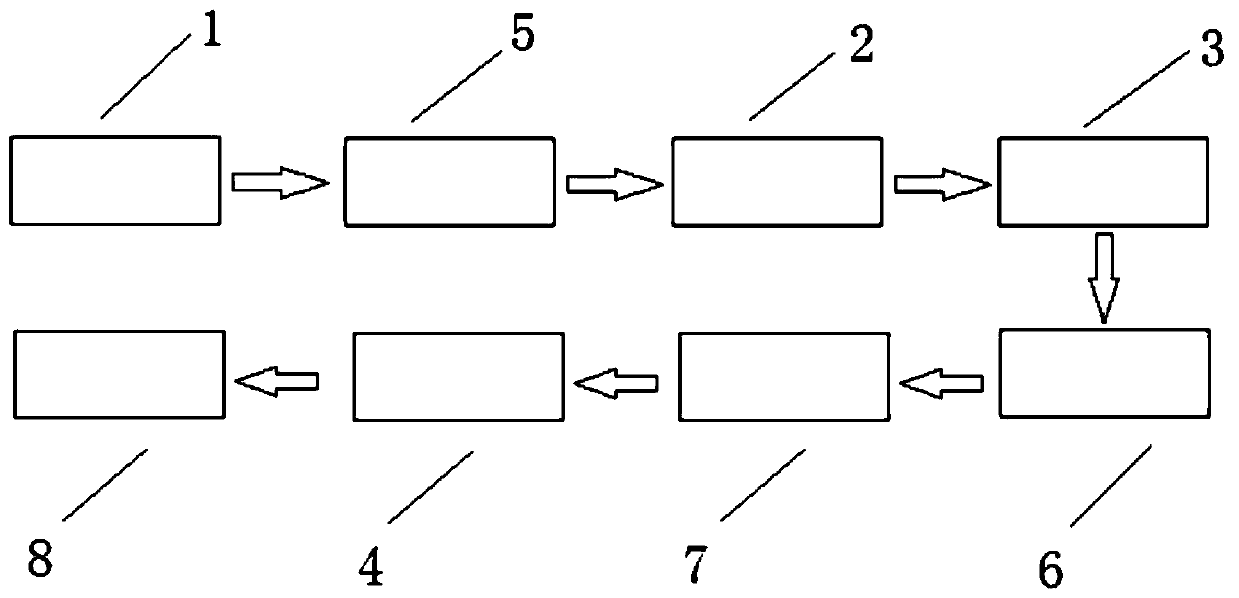

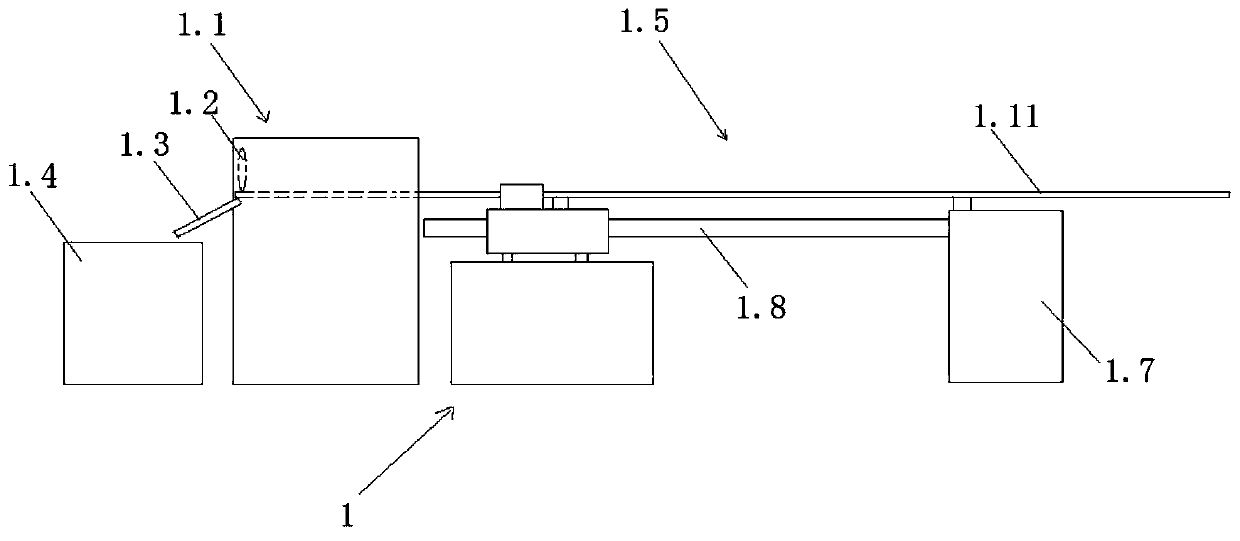

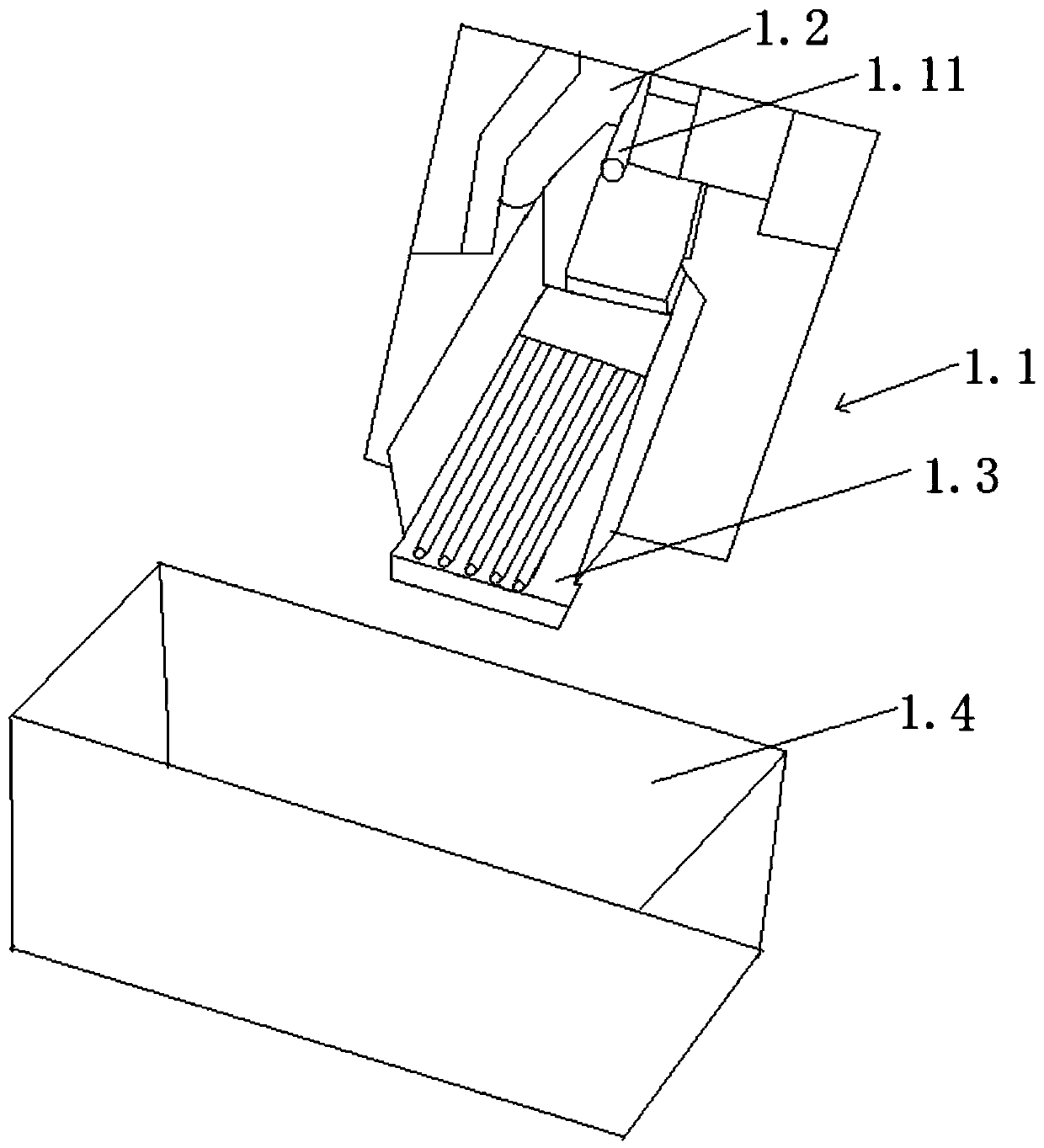

Two-sided flexible printed circuit (FPC) roll-type material-receiving production process

InactiveCN102984886AAdvantages of production processLow pricePrinted circuit manufactureState of artCooking & baking

The invention relates to a two-sided flexible printed circuit (FPC) roll-type material-receiving production process. The two-sided FPC roll-type material-receiving production process comprises the following steps: flexible copper clad laminate (FCCI) piece cutting; FCCI drilling; FCCI developing; receiving materials, wherein the material of the receving material is an epoxy glue series covering membrane; roll-type baking; roll-type copper plating and later making. According to the two-sided FPC roll-type material-receiving production process, an epoxy glue series covering membrane is adopted to replace an acrylic adhesive series covering membrane which is adopted by the prior art, and the two-sided FPC roll-type material-receiving production process has the advantage that the price is relatively low. According to the two-sided FPC roll-type material-receiving production process, not only pollution to environment can be avoided through avoiding using halogen, but also good electroplating performance and chemical liquid-resisting performance are achieved. Further, due to the fact that the step of roll-type baking is added correspondingly, the binding force is much good, and tensile property of products becomes much good too.

Owner:欣兴同泰科技(昆山)有限公司

Production technology of Gentiana scabra Bunge tablet film coating

InactiveCN103520322AAdvantages of production processUse less excipientsPharmaceutical delivery mechanismRespiratory disorderMaterial consumptionMoisture resistance

The invention relates to a production technology of a Gentiana scabra Bunge tablet film coating. The production technology of the Gentiana scabra Bunge tablet film coating mainly comprises the following steps: 1, dissolving a coating material in 95% ethanol, and uniformly stirring to obtain a coating material solution for later use, wherein the coating material is a healthcare Chinese herbal medicine, and has a weight only accounting for 0.8% of the weight of a Gentiana scabra Bunge tablet; 2, placing a pre-pressed Gentiana scabra Bunge tablet in a coating machine, and gradually heating the tablet to 39-40DEG C; and 3, well adjusting a spray gun, uniformly spraying the rolling tablet with the uniformly-stirred coating material solution until the color is uniform, and drying to obtain the Gentiana scabra Bunge tablet film coating. The production technology of the Gentiana scabra Bunge tablet film coating has the protruding advantages of less coating material consumption, cost reduction, substantially shortened production time, improvement of the appearance form of the tablet, good moisture resistance and the like.

Owner:LUOYANG SHUNSHI PHARMA

Production process of automobile hub fastening component

ActiveCN110576294AAdvantages of production processQuality improvementEngineeringMechanical engineering

The invention relates to a production process of an automobile hub fastening component. According to the production process of the automobile hub fastening component, the production flow and the process are improved, the quality of the finished fastening component is improved, and the production efficiency is improved. A sawing device in production equipment is used for sawing a cylindrical blankto cut the blank into studs with the same length; a cold heading device carries out upsetting and forging on the studs to form nuts at the end parts of the studs; a thread rolling device carries out thread rolling on the studs to make the studs be bolts; and the combination assembly mechanism automatically assemble the bolts and bushings and washers together in a sleeve mode. According to the production process of the automobile hub fastening component, the lengths of the bolt sawed materials are consistent, an upsetting and forging mechanism can be accurately lubricated, normal operation of the upsetting and forging mechanism is not influenced, lubricating oil can be recycled, the bolt rolled thread quality and efficiency are improved, the bolts can be orderly collected after thread rolling is finished, manual material taking is facilitated, the labor is saved, and the working efficiency and the finished product quality are improved.

Owner:江阴市乐天紧固件有限公司

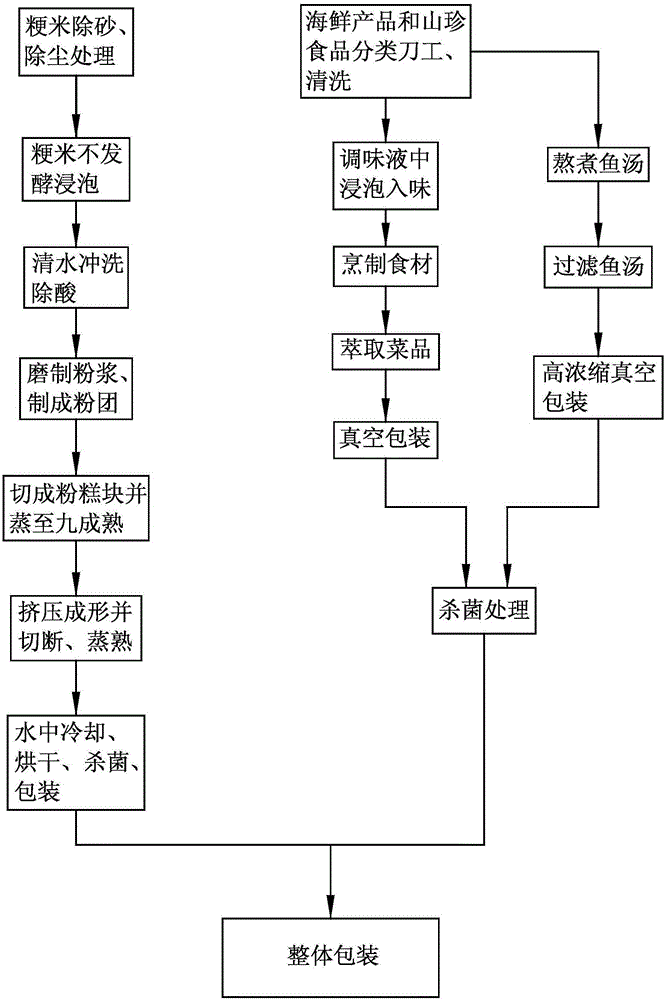

Production process of dietary therapy delicacy seafood thin noodles

InactiveCN105211742AImprove securityImprove food valueFood ingredient functionsFood preparationInstant noodleConvenience food

The invention provides a production process of dietary therapy delicacy seafood thin noodles and belongs to the technical field of processing of instant foods, aiming at solving the problems that existing instant noodles have few nutrients and are not healthy and unsafe to eat. The production process of the dietary therapy delicacy seafood thin noodles comprises the following steps: A, preparing materials; B, cooking seafood and delicacies; C, boiling fish soup; D, preparing thin noodles; E, packaging in vacuum; and F, wholly packaging. The production process of the dietary therapy delicacy seafood thin noodles has the advantages of abundant nutrients, convenience for eating and high eating safety.

Owner:谢兆琪 +1

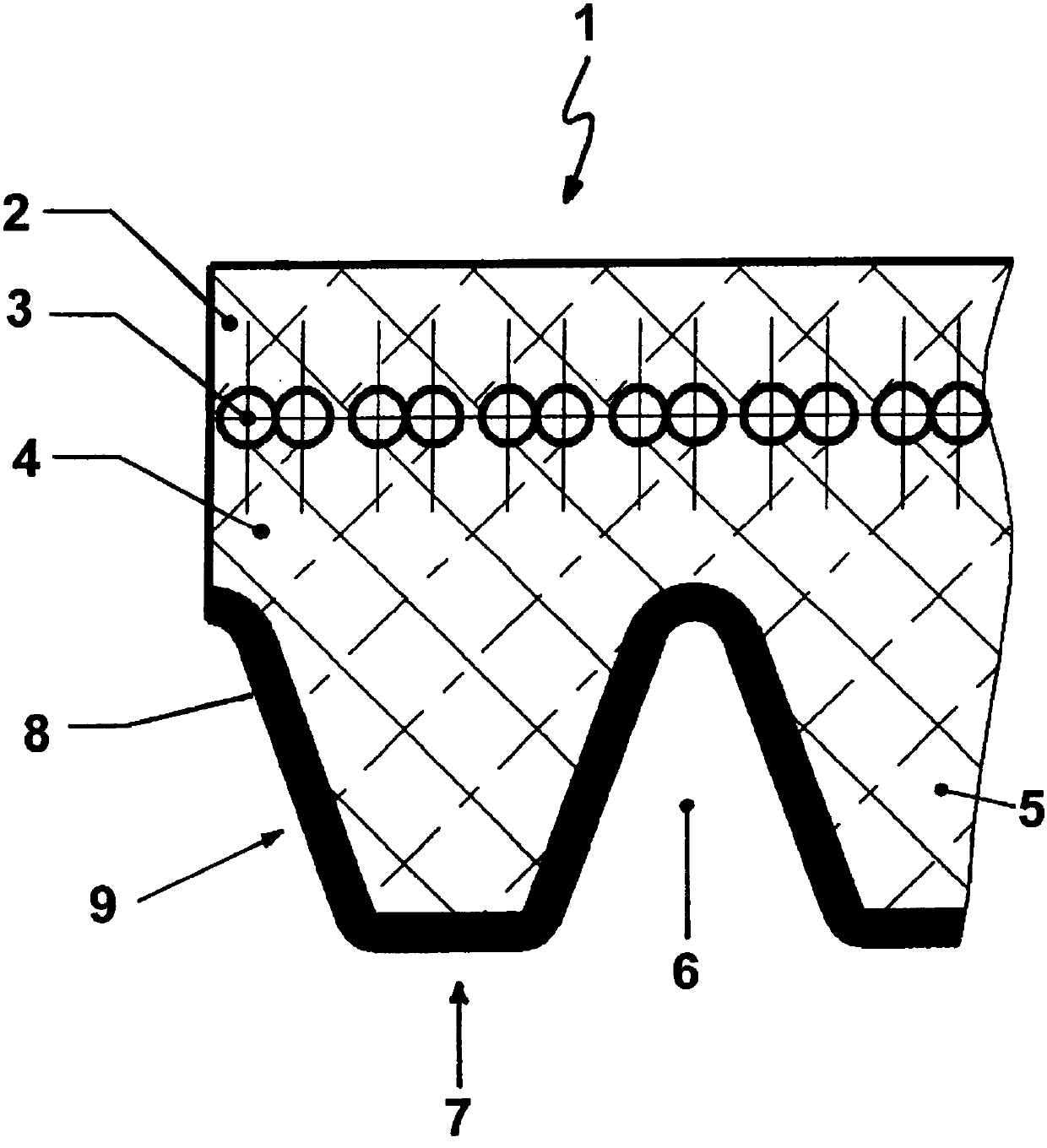

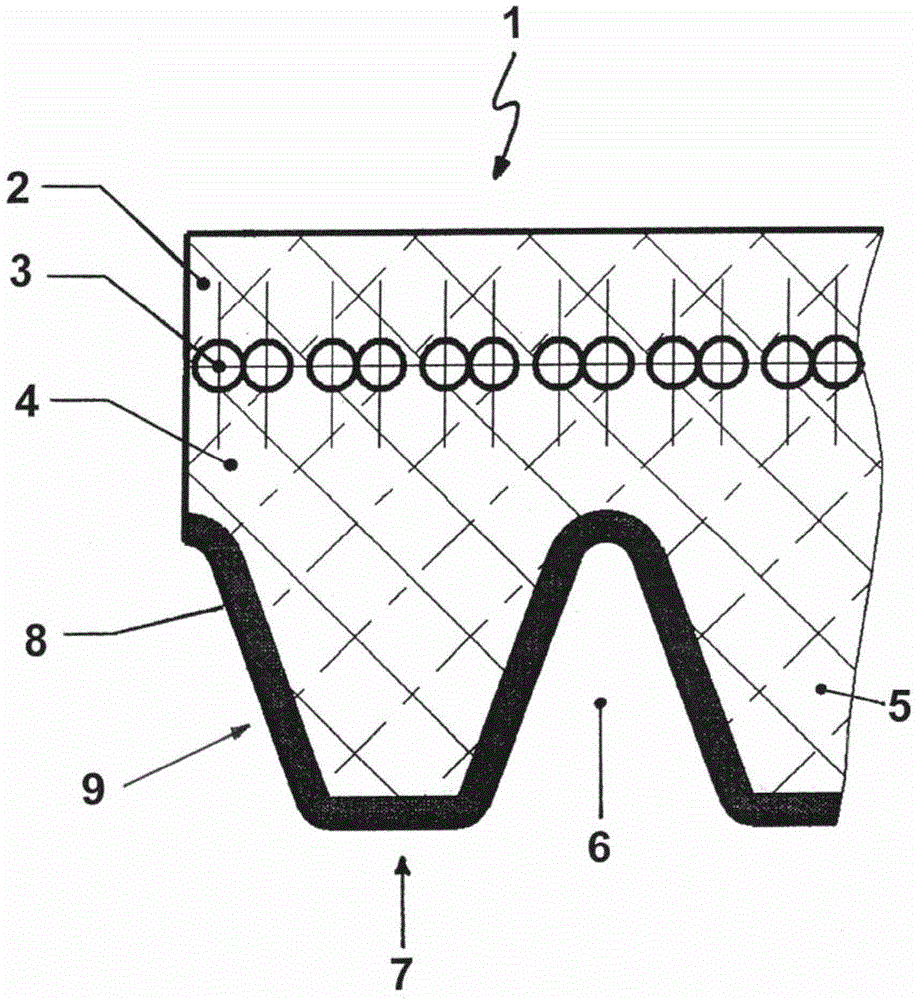

Elastic articles with coverings, especially drive belts

ActiveCN104619756BSuppresses running noiseIncrease coefficient of frictionV-beltsDriving beltsLinear low-density polyethyleneVulcanization

The invention relates to an article with an elastic matrix based on vulcanized rubber. The article is in particular a drive belt (1) in the form of a ribbed V-belt having a cover layer (2) as the back of the belt and a substructure (4) with a force transmission zone (9) , wherein at least the force transmission area is provided with a covering (8), wherein the covering of the force transmission area in turn consists of at least one film, wherein the film contains at least 50% by weight of a linear polyethylene with a low density ( LLDPE) and wherein the film is produced such that the film melts during vulcanization and simultaneously forms a firm adhesive composite of the substrate and the covering.

Owner:CONTITECH ANTRIEBSSYST GMBH

Ore dressing process of clay type gold ore leaching method

InactiveCN1220784CGood seepage performanceImprove leaching rateProcess efficiency improvementGranularityWorking environment

The dump leaching process for clay type gold ore consists of the following steps: crushing ore; making pellet; stacking; and showering. The dump leaching process features the pellet making step, in which husk as loose material in the amount of 0.2-0.5 wt% of ore and water in the amount of 15-25 wt% of dry matter are added; and the stacking step including spreading wet pellet and spreading rice straw cut into 18-22 cm length. The present invention has the features of high permeability, high gold leaching out rate, low production cost and improved work environment.

Owner:钟志林

Resilient item, more particularly drive belt, with a coating

ActiveCN104619756AGood for wear protectionIncrease coefficient of frictionV-beltsDriving beltsLinear low-density polyethyleneVulcanization

Article comprises an elastic base body based on a vulcanizate with a wear-prone article surface, which is provided with a coating (8). At least one surface coating of the article is made of at least one film. The film comprises at least 50 wt.% linear low density polyethylene (LLDPE). The film melts during vulcanization and forms a solid adhesive bond of the base body and coating. The article is a drive belt (1) comprising a belt back (2), a top layer mixture and a base (4) with a force transmission zone (9). At least one force transmission zone is provided with the coating. An independent claim is also included for producing the article, comprising applying the film containing at least 50 wt.% LLDPE to the mixture of the base, before packaging the article.

Owner:CONTITECH ANTRIEBSSYST

Technique for producing shining stainless steel pipe

InactiveCN106435124ASave production time and shipping costsAvoid gray-black scale and scalingIncreasing energy efficiencyFurnace typesProduct gasBlack oxide

The invention discloses a technique for producing a shining stainless steel pipe. The technique comprises the steps of unreeling, forming, welding and cutting. Between the welding step and the cutting step, the technique further comprises the following steps that the stainless steel pipe is firstly placed into a heat treatment box filled with protective gas, air pressure in the heat treatment box is 0.4MPa-0.65MPa, the temperature of the stainless steel pipe is made to reach 1000 DEG C-1100 DEG C, and the time of heat treatment is 300-420 seconds; and then the stainless steel pipe is moved to a cooling pipe filled with protective gas to be cooled naturally, the time of cooling treatment is 300-420 seconds, and the pressure in the cooling pipe is 0.4MPa-0.65MPa. According to the technique for producing the shining stainless steel pipe, an original step that the stainless steel pipe is conveyed to a heat treatment station after being cut is omitted; and when the surface of the stainless steel pipe is subjected to heat treatment, grey black oxide skin is not generated, subsequent acid pickling and polishing are not needed, the working process is simpler, and pollution is avoided in the production process.

Owner:广州永大不锈钢有限公司

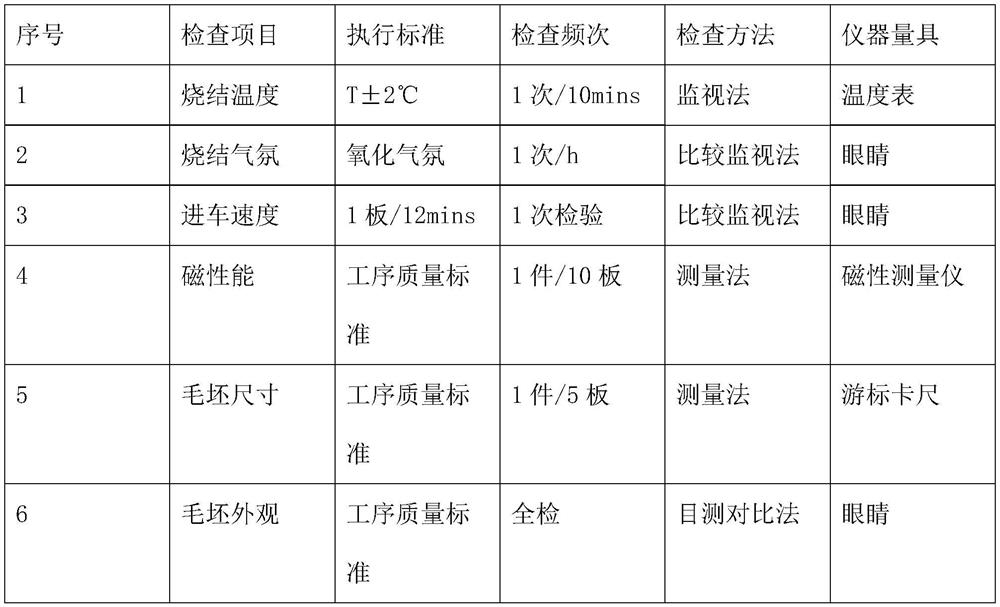

Production process of motor arc-shaped magnetic shoe

PendingCN113210610AAdvantages of production processReduce manufacturing costInductances/transformers/magnets manufactureLanthanumStrontium sulfate

The invention relates to the technical field of motor equipment processing, in particular to a production process of a motor arc-shaped magnetic shoe. The production process of the motor arc-shaped magnetic shoe comprises the following steps of S1, carrying out ball-milling processing operation on production raw materials of the motor arc-shaped magnetic shoe; S2, forming a motor arc-shaped magnetic shoe blank from the ball-milled raw materials by adopting a wet pressing molding process; S3, sintering the molded motor arc-shaped magnetic shoe blank; and S4, performing grinding machining operation and quality inspection of the sintered motor arc-shaped magnetic shoe. According to the production technology of the motor arc-shaped magnetic shoe, in the production process of the motor arc-shaped magnetic shoe, rare earth materials such as cobalt and lanthanum are replaced with additive raw materials such as silicon dioxide and strontium sulfate, so that on one hand, the production cost is reduced, and on the other hand, the performance deviation of the product can be kept stable.

Owner:安徽群兴磁材科技有限公司

Production process and application of stainless steel seamless tube

PendingCN112808791AAdvantages of production processSimple processFurnace typesProcess efficiency improvementMetallurgySS - Stainless steel

The invention relates to the field of stainless steel, in particular to a production process and application of a stainless steel seamless tube. The production process of the stainless steel seamless tube is characterized by comprising the following specific steps that S1, outer circle polishing is carried out; S2, cold rolling is carried out; S3, degreasing is carried out; S4, vacuum bright annealing is carried out; S5, straightening and pipe cutting are carried out; S6, inner circle polishing is carried out; and S7, packaging and warehousing are carried out. The production process of the stainless steel seamless tube has the following advantages that (1), the process is simple and easy to implement and high in practicability; (2), the produced stainless steel seamless tube is smooth and attractive, and is not prone to bulging and cracking; and (3), the produced stainless steel seamless tube is resistant to high temperature, humidity and heat and high in stability.

Owner:上海久砾不锈钢管有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com