Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Accurate thickness measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

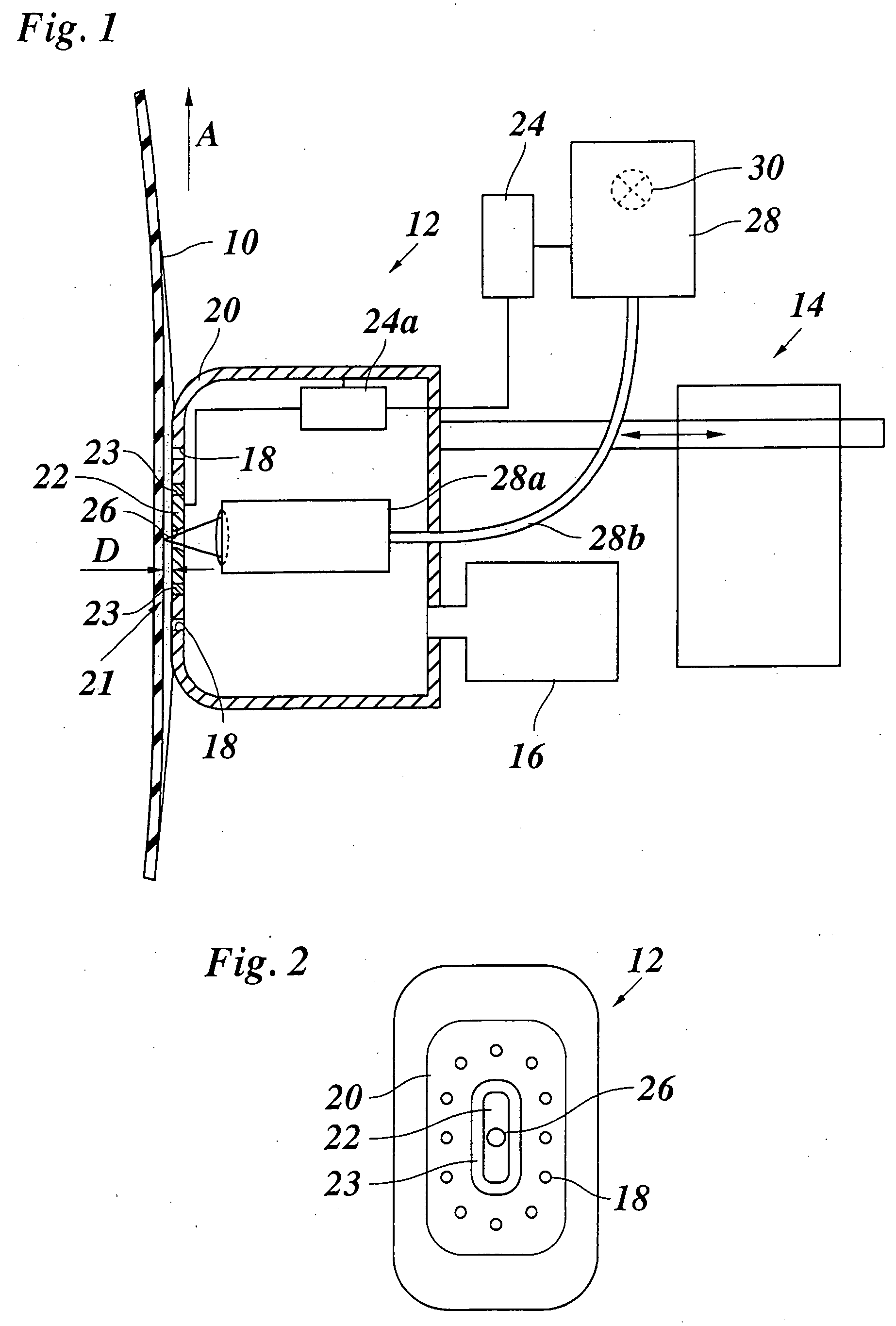

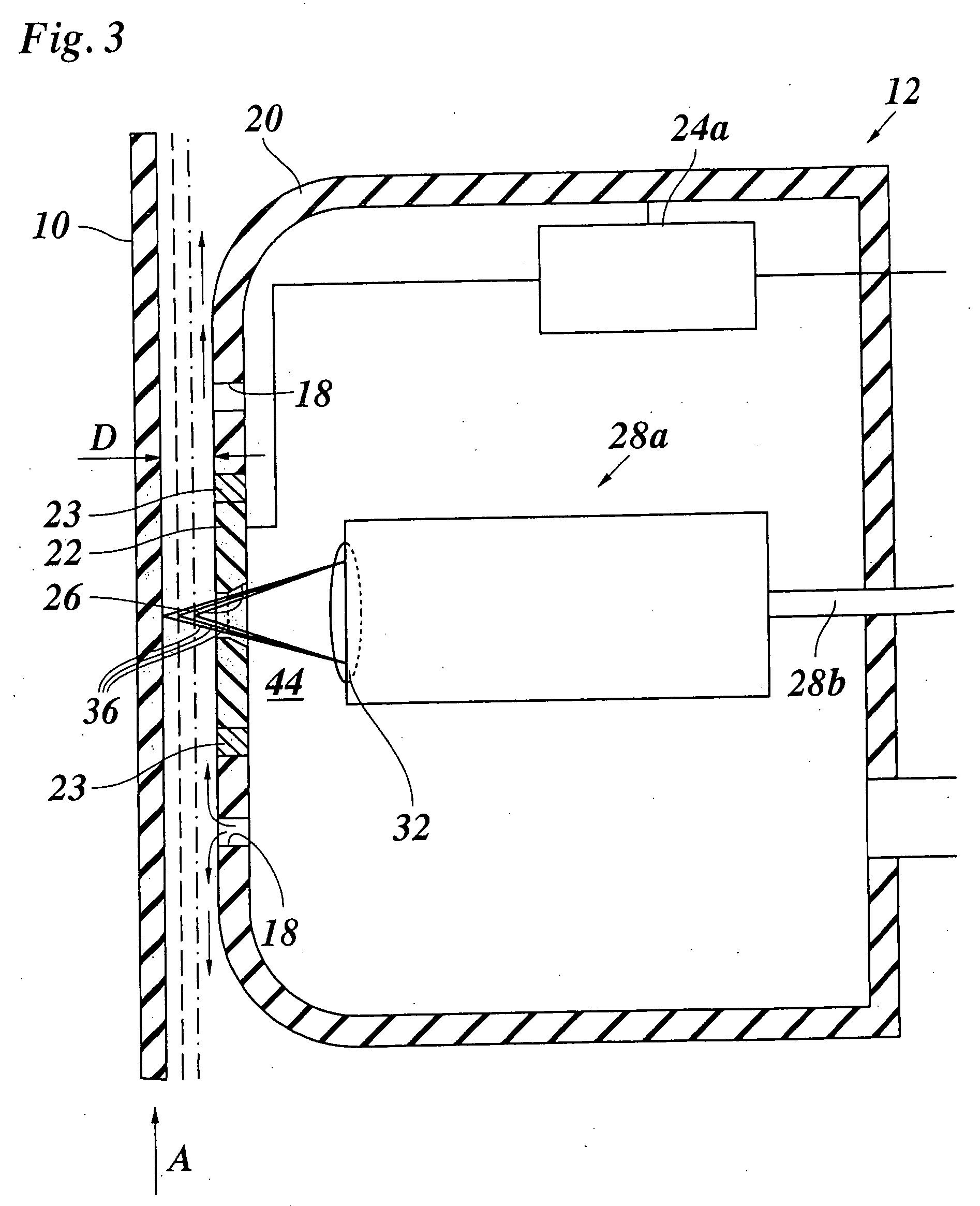

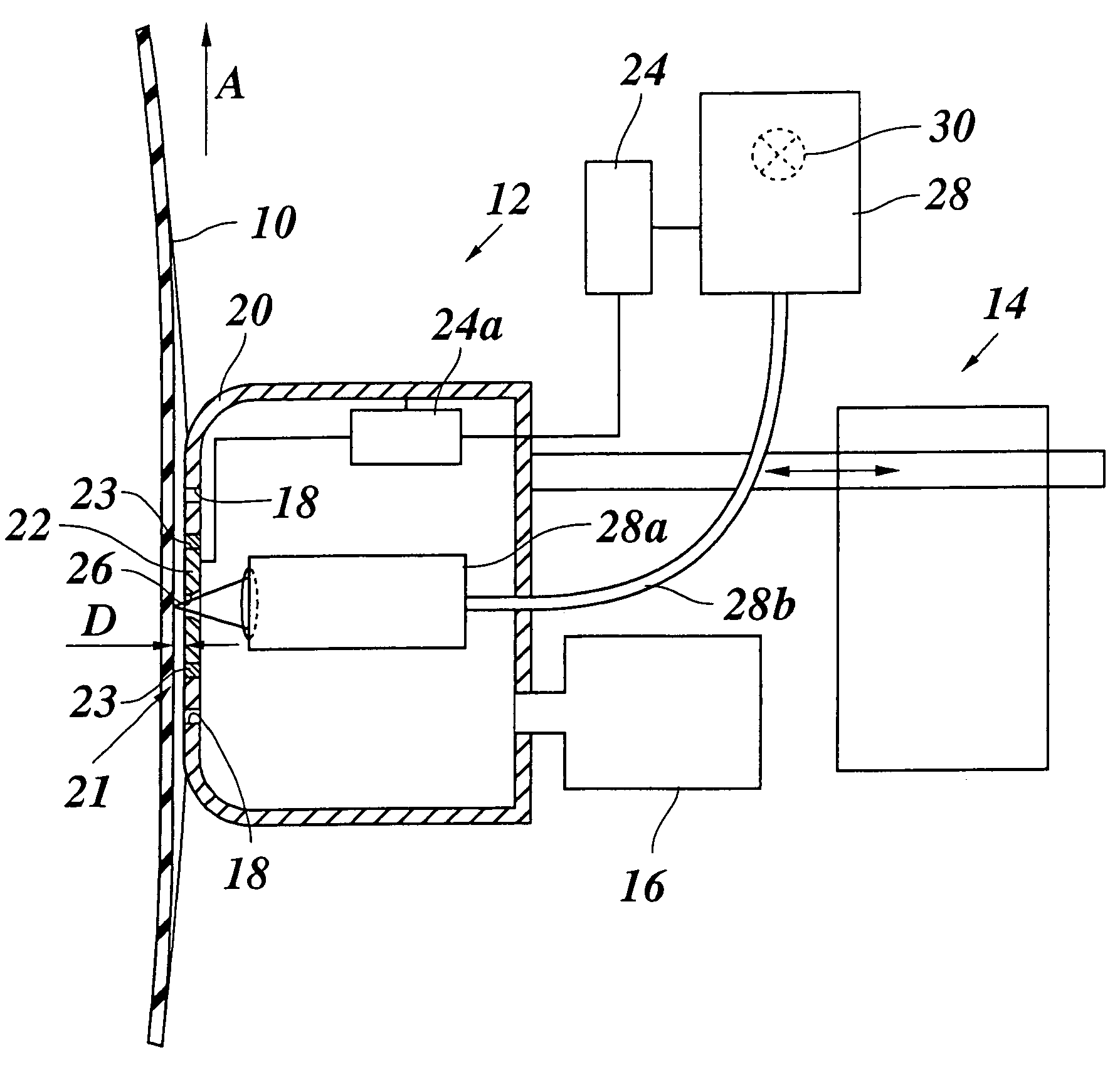

Apparatus and method for capacitive measurement of materials

InactiveUS20060152231A1Improve thickness measurement accuracyAccurate thickness measurementResistance/reactance/impedenceMaterial analysis by optical meansCapacitive measurementDistance measurement

Method for measuring thicknesses of a film, a foil or a material layer with a measuring head which is spaced away from the film and with which a capacitive thickness measurement is performed, in which an optical distance measurement is performed with a distance measuring device and a distance determined by the optical distance measurement is used in determining the film thickness in the capacitive thickness measurement.

Owner:PLAST CONTROL GMBH

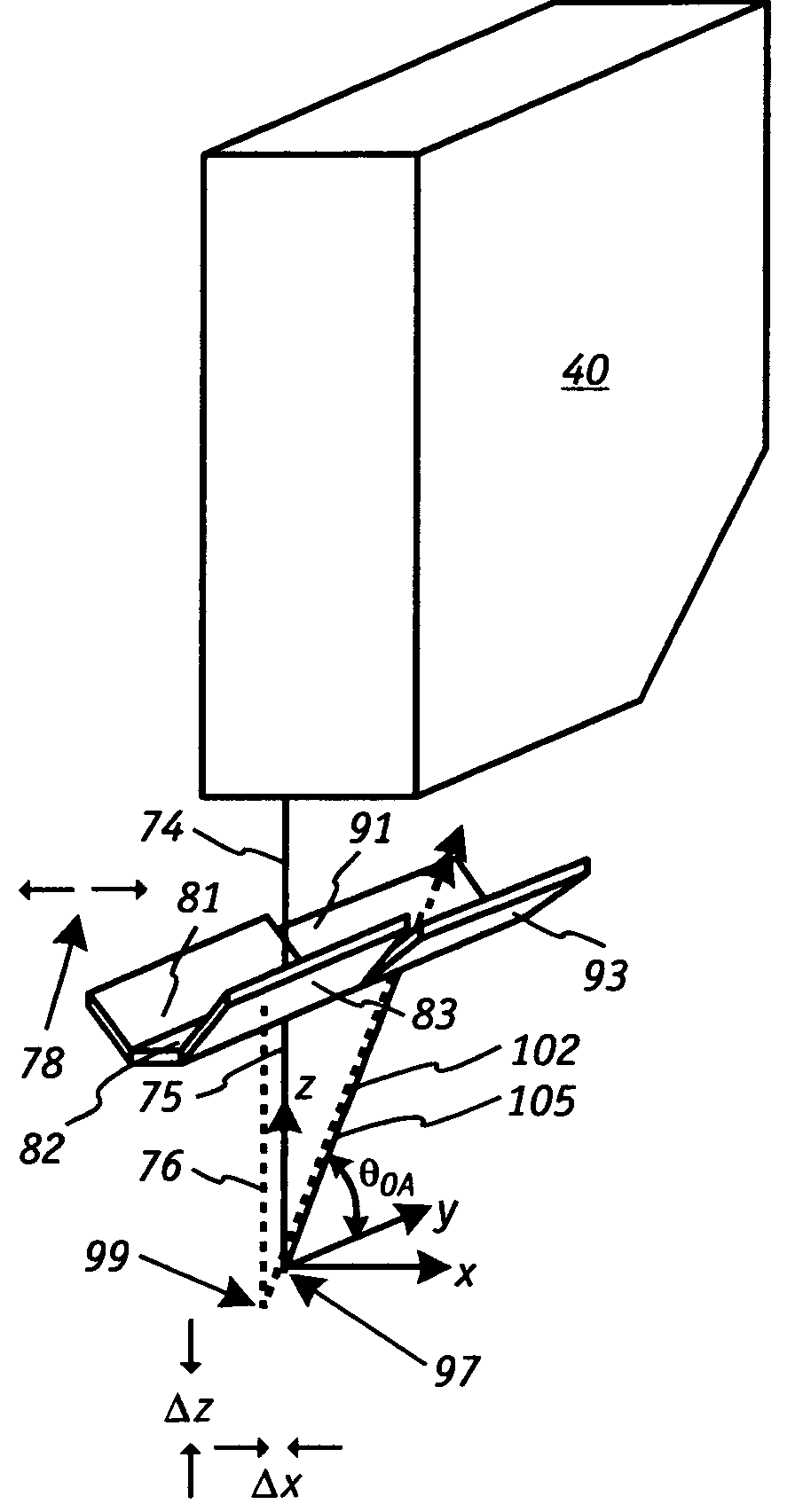

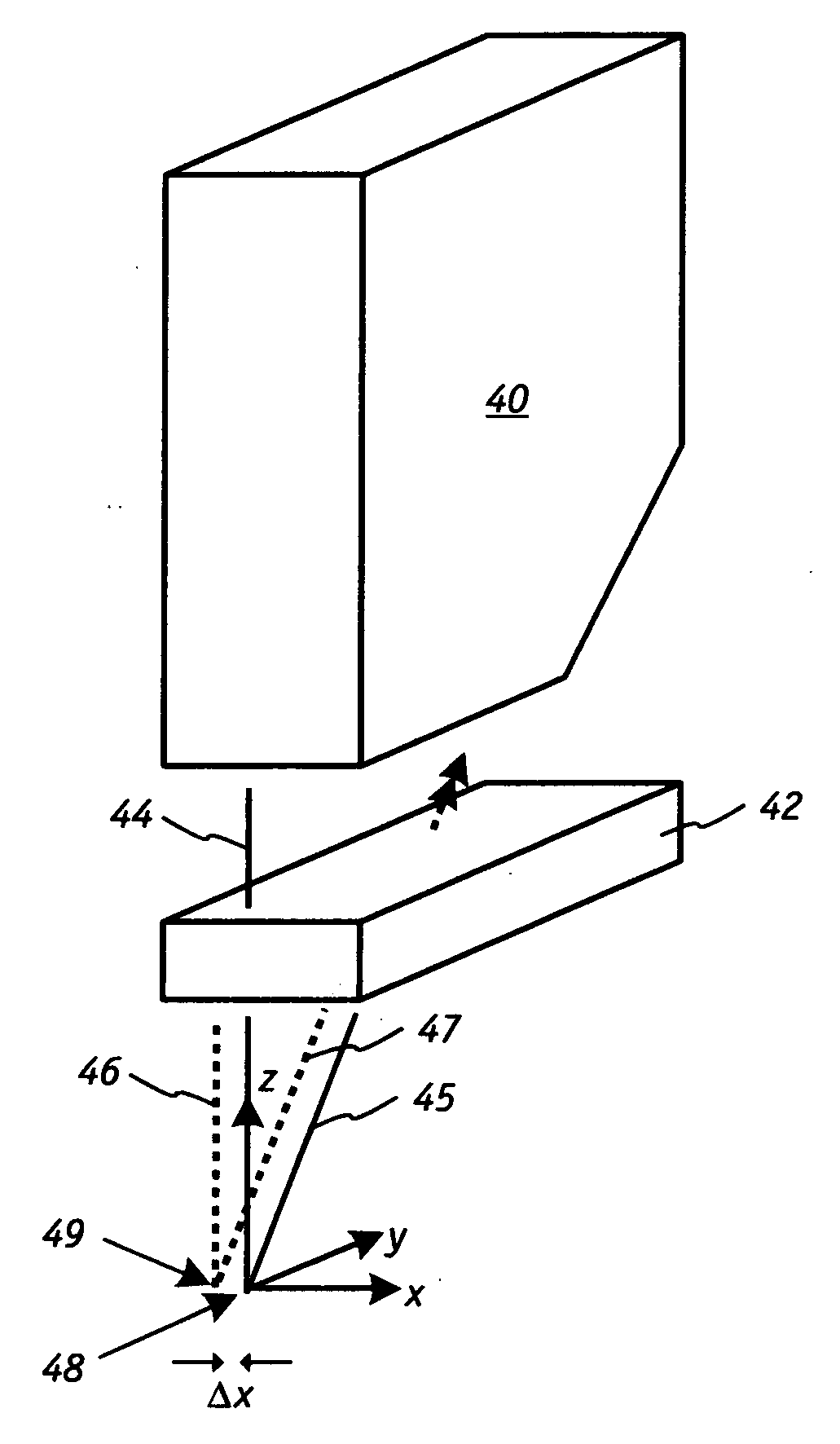

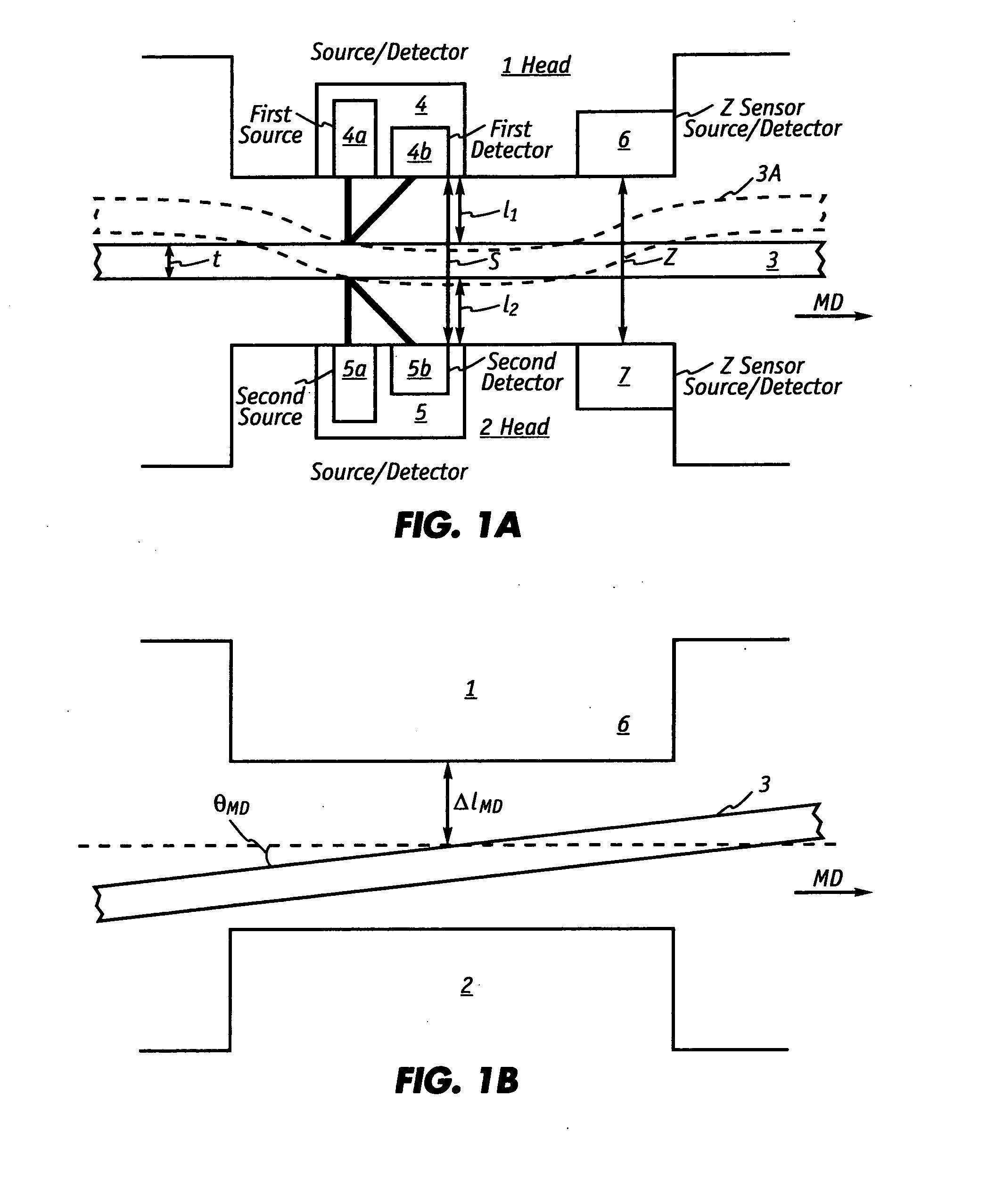

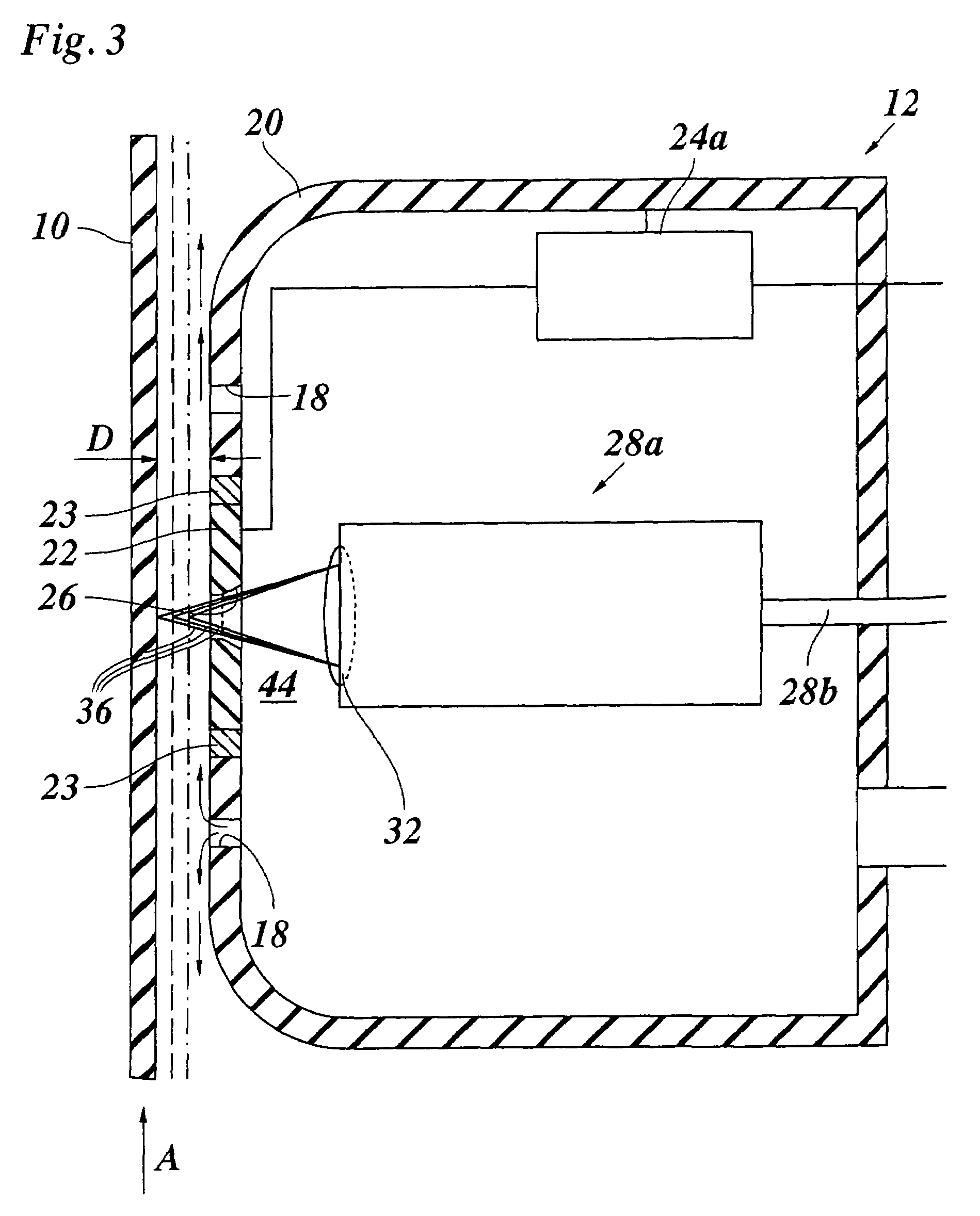

Optical translation of triangulation position measurement

InactiveUS7528400B2Accurate thickness measurementOptical rangefindersInvestigating moving sheetsTriangulationRefractive index

An optical translation technique for moving the interrogation spot at which a triangulation system measures the displacement of a target is disclosed. In normal operation of the laser triangulation sensor, an incident laser beam is projected from a sensor head onto a surface of a web that is facing the sensor head. Radiation is reflected from the surface and detected by the sensor. The distance from the sensor head to the web surface is calculated by triangulation. With optical translation, both the incident ray path and the captured ray path are translated with a plurality of high refractive index geometries such that the nominal functioning of the triangulation sensor remains undisturbed. The optimal position on the sheet wherein the interrogation spot will be located can be ascertained.

Owner:HONEYWELL ASCA INC

Optical translation of triangulation position measurement

InactiveUS20070145307A1Accurate thickness measurementInvestigating moving sheetsUsing optical meansTriangulationRefractive index

An optical translation technique for moving the interrogation spot at which a triangulation system measures the displacement of a target is disclosed. In normal operation of the laser triangulation sensor, an incident laser beam is projected from a sensor head onto a surface of a web that is facing the sensor head. Radiation is reflected from the surface and detected by the sensor. The distance from the sensor head to the web surface is calculated by triangulation. With optical translation, both the incident ray path and the captured ray path are translated with a plurality of high refractive index geometries such that the nominal functioning of the triangulation sensor remains undisturbed. The optimal position on the sheet wherein the interrogation spot will be located can be ascertained.

Owner:HONEYWELL ASCA INC

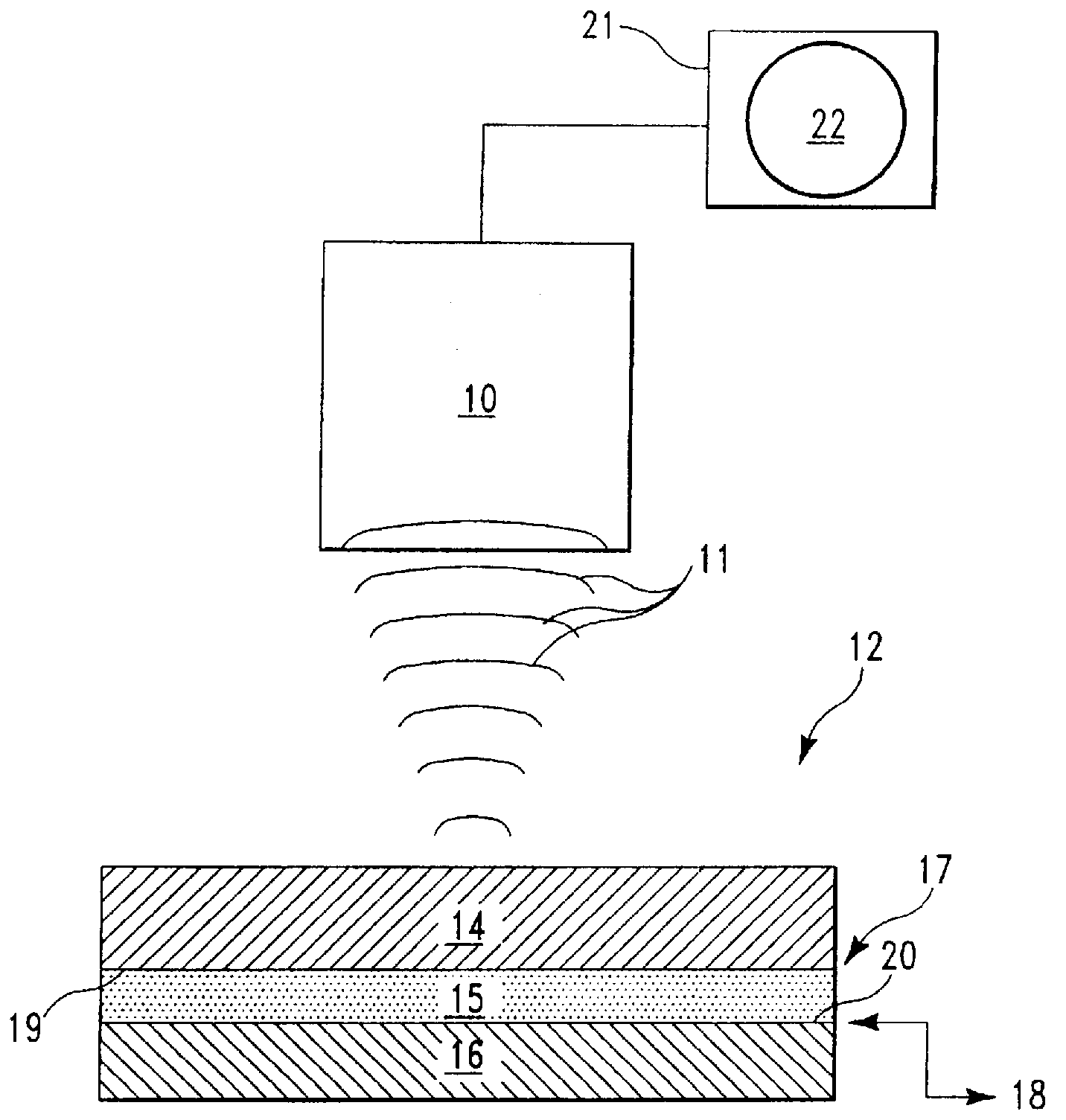

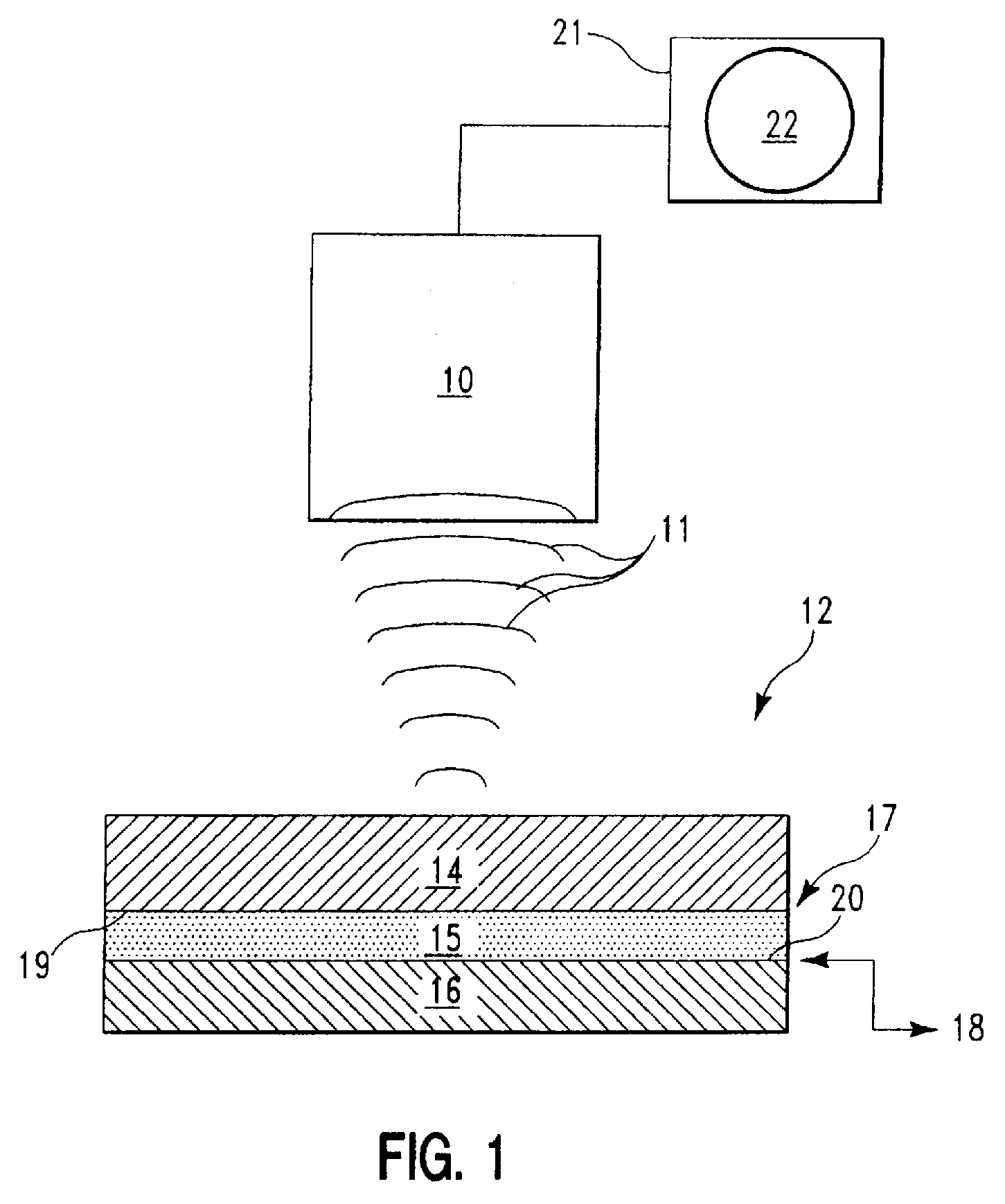

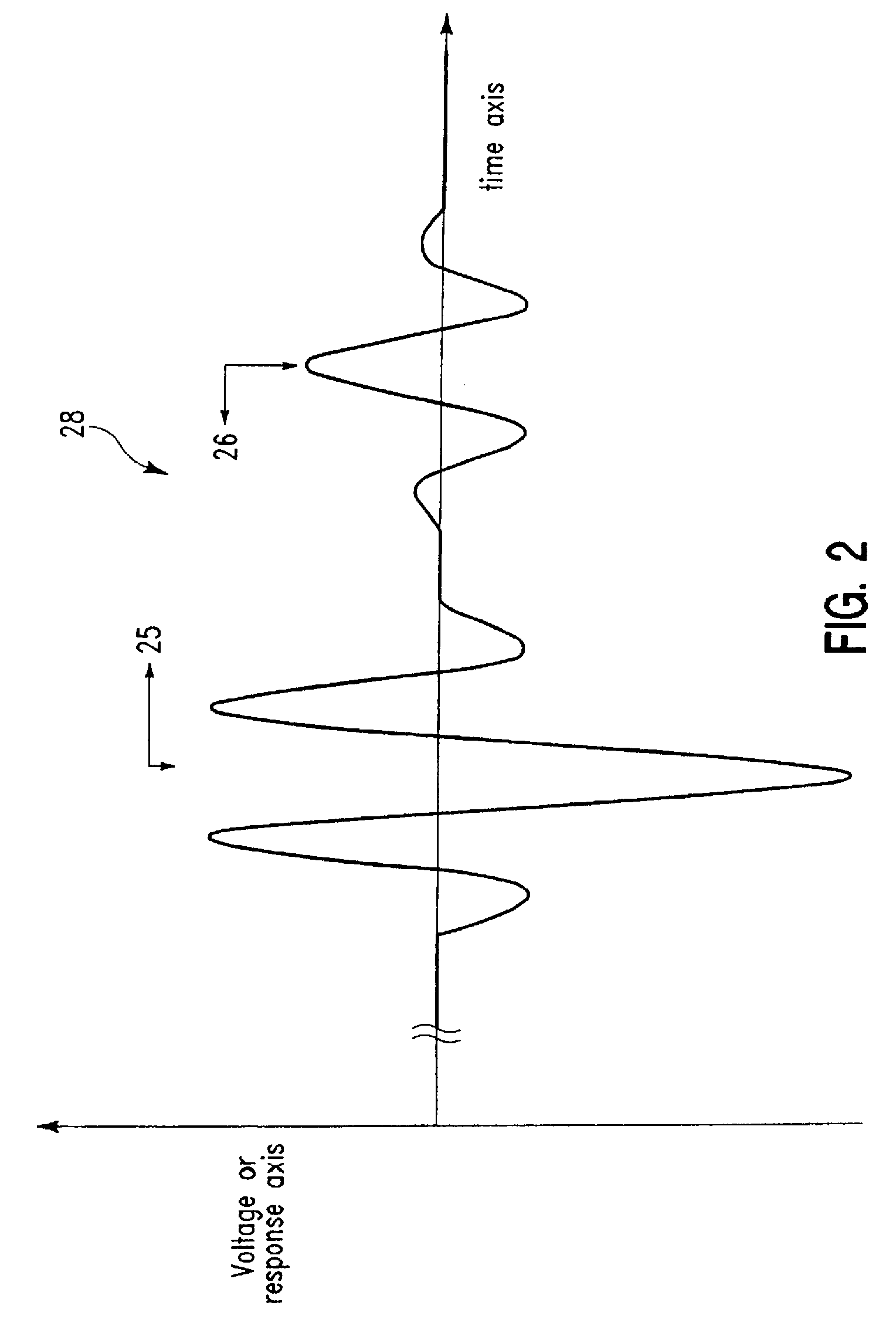

Method for measuring thin layers in solid state devices

InactiveUS20080021673A1Accurate thickness measurementUsing subsonic/sonic/ultrasonic vibration meansDigital computer detailsNon destructiveThin layer

A method of using acoustic signals in the form of waves or pulses to non-destructively measure the thickness of a bonding layer sandwiched between and bonding together overlying and underlying materials different from the bonding layer especially when the thickness of the bonding layer is so small that the features (maxima, minima, time position) of the echo from the interface of the bonding layer and the overlying material is indistinguishable, i.e., not independently observable from the features (maxima, minima, time position) of the echo from the interface of the bonding layer and the underlying material.

Owner:IBM CORP

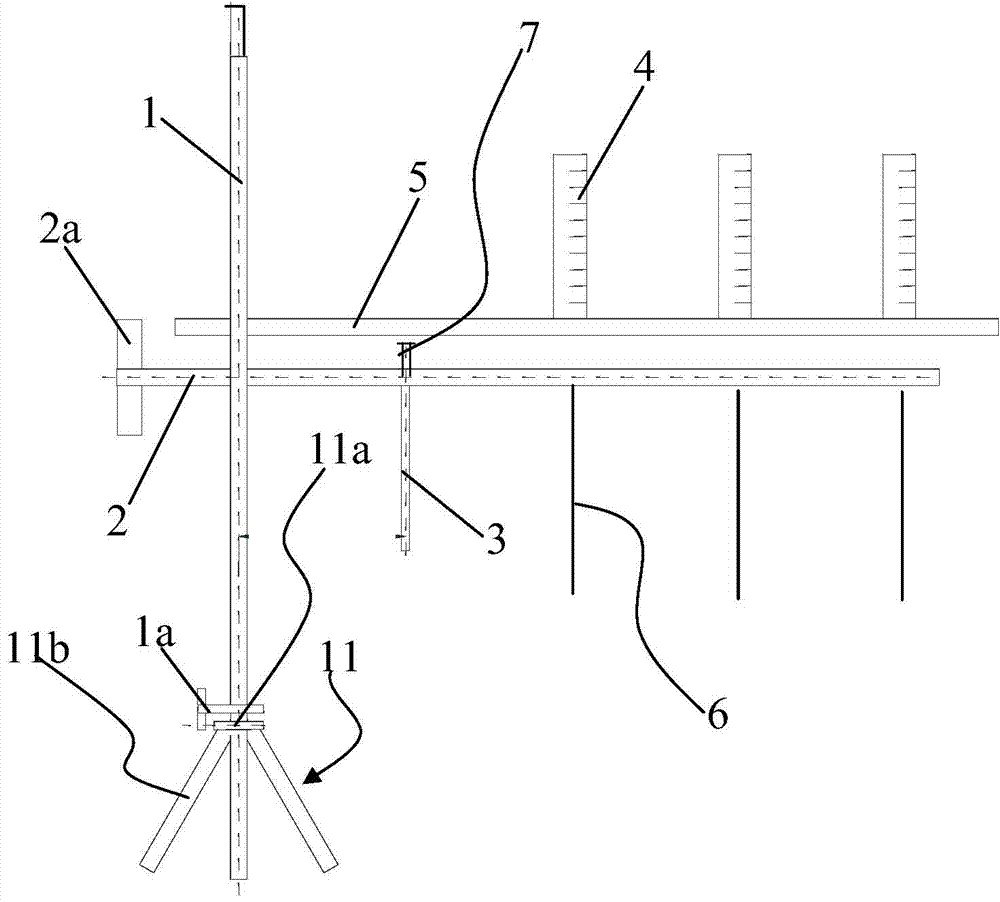

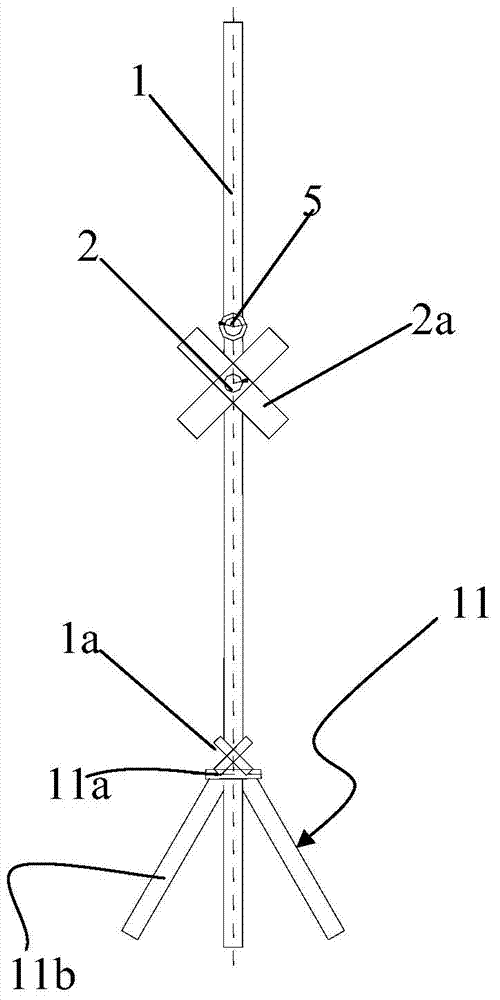

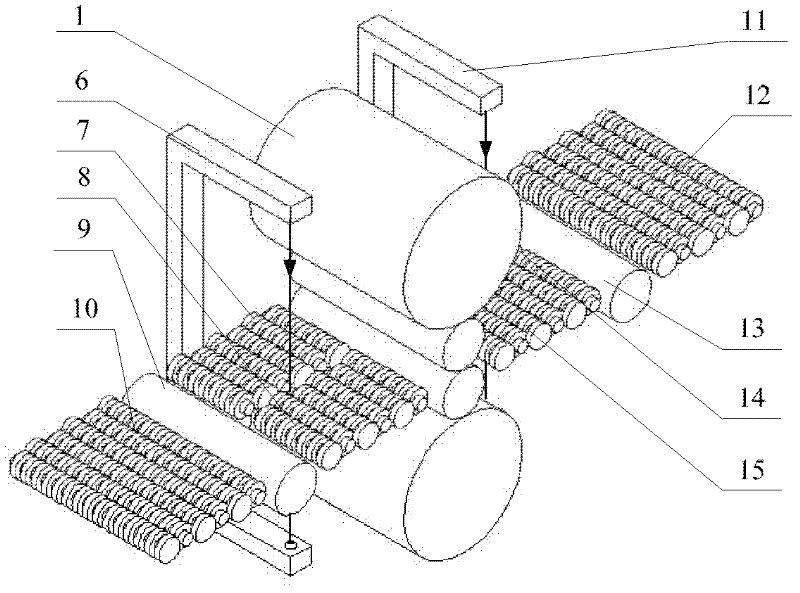

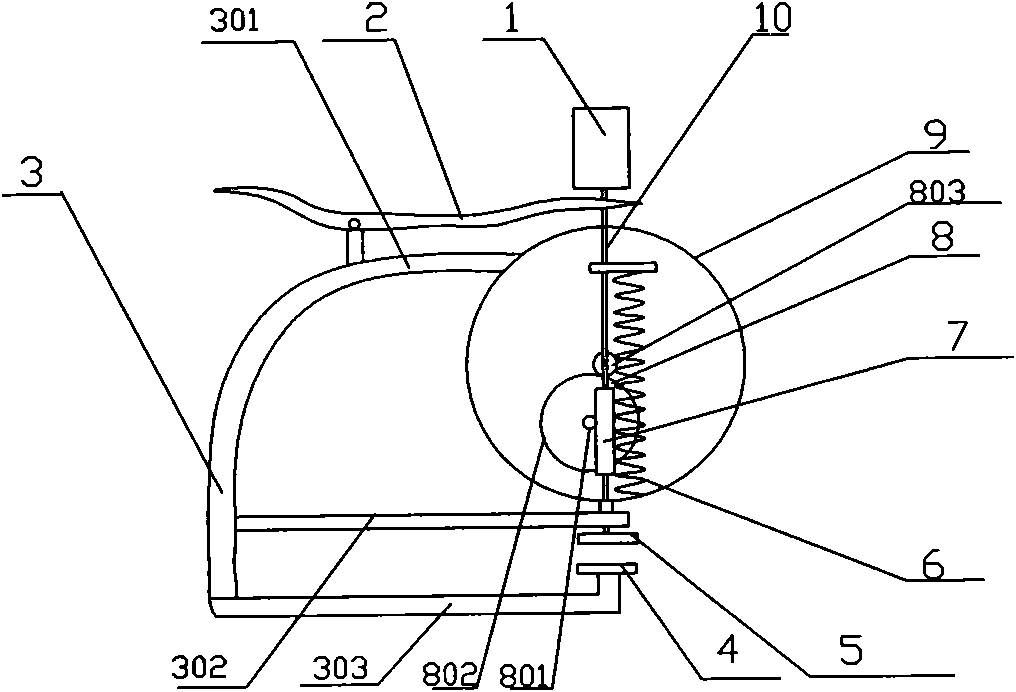

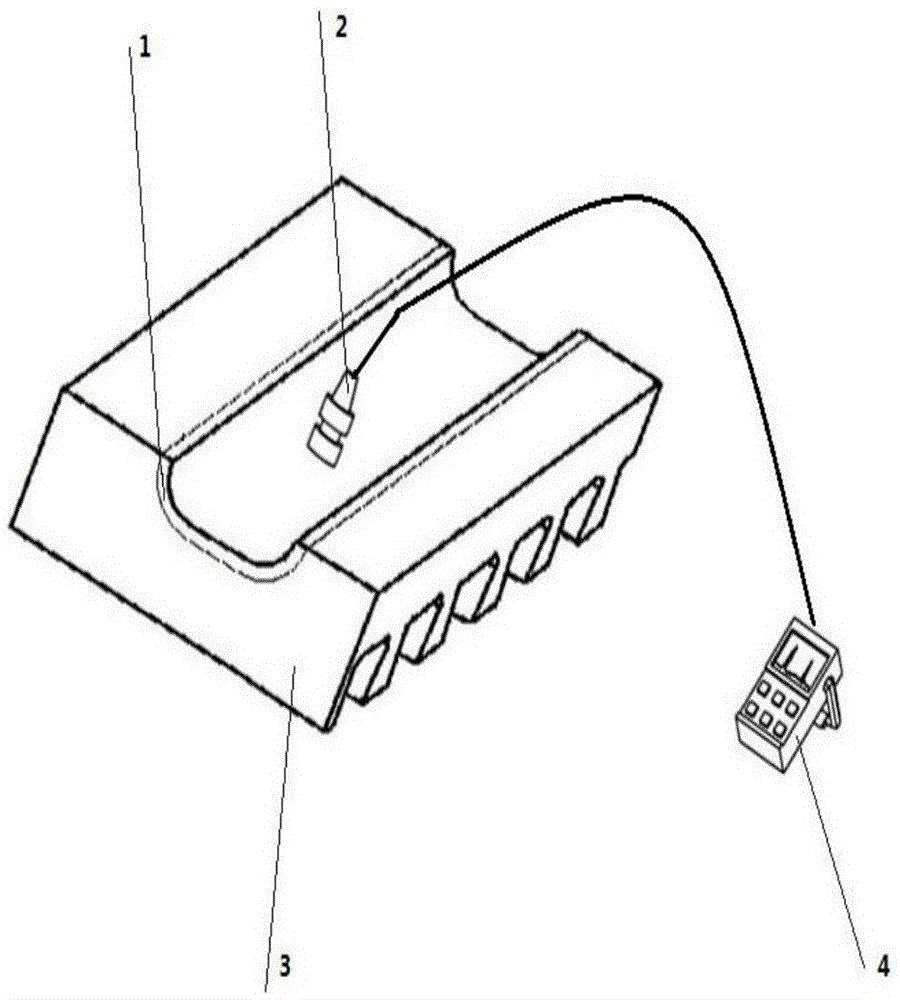

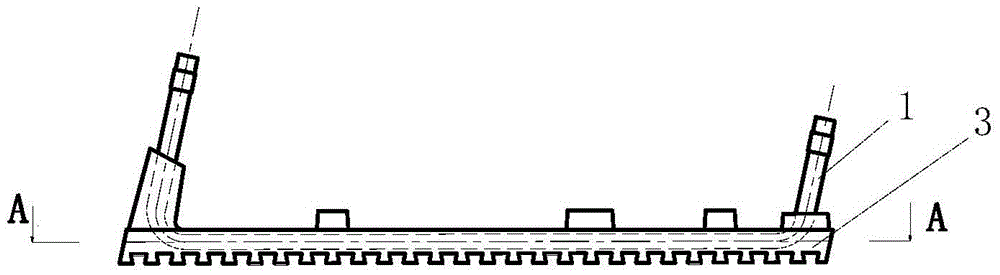

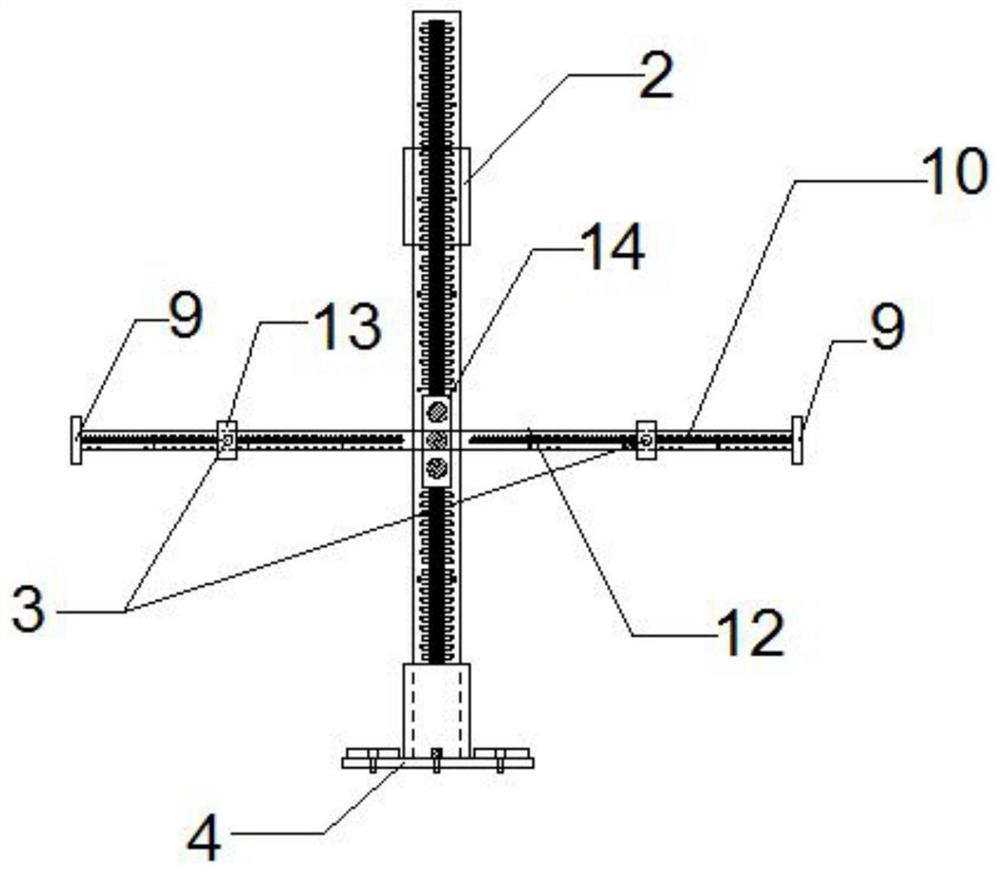

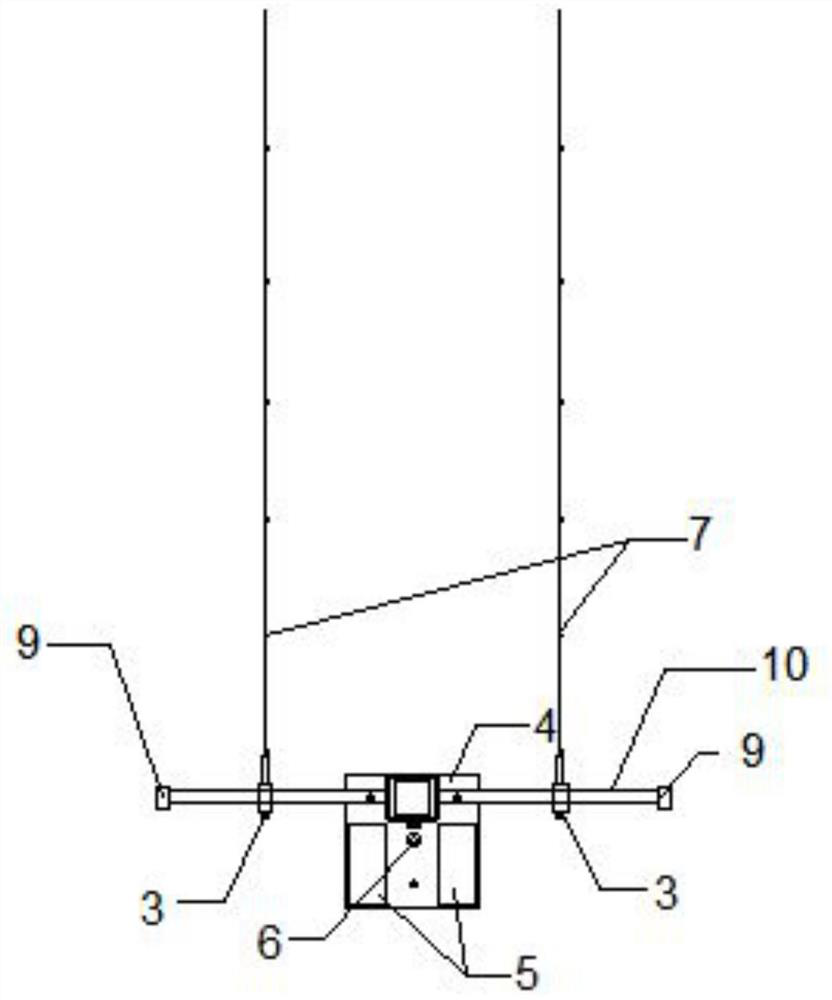

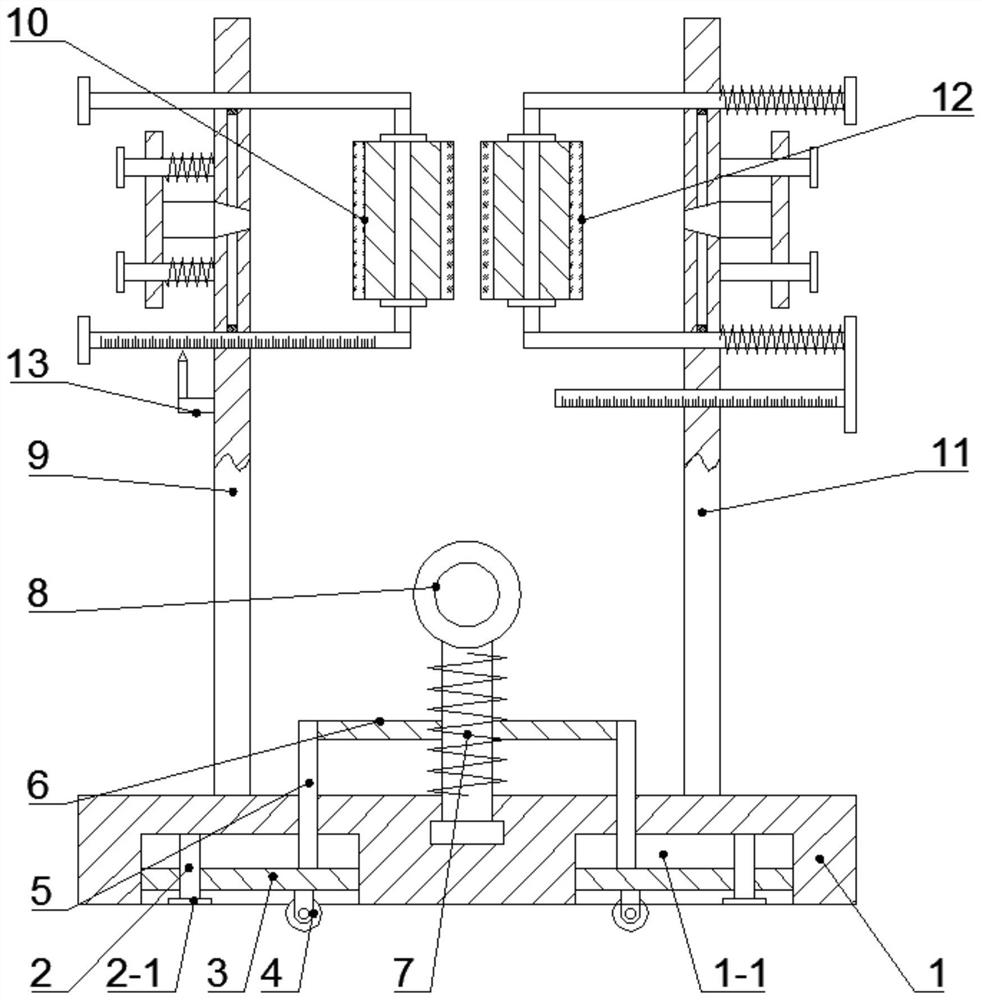

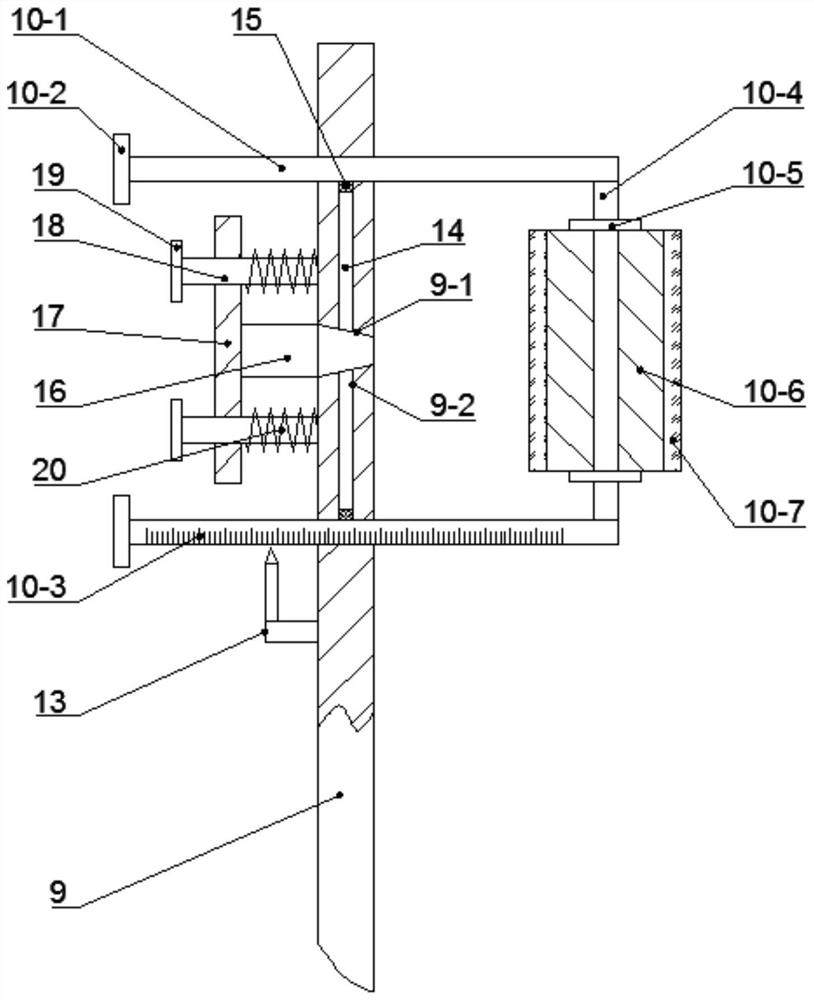

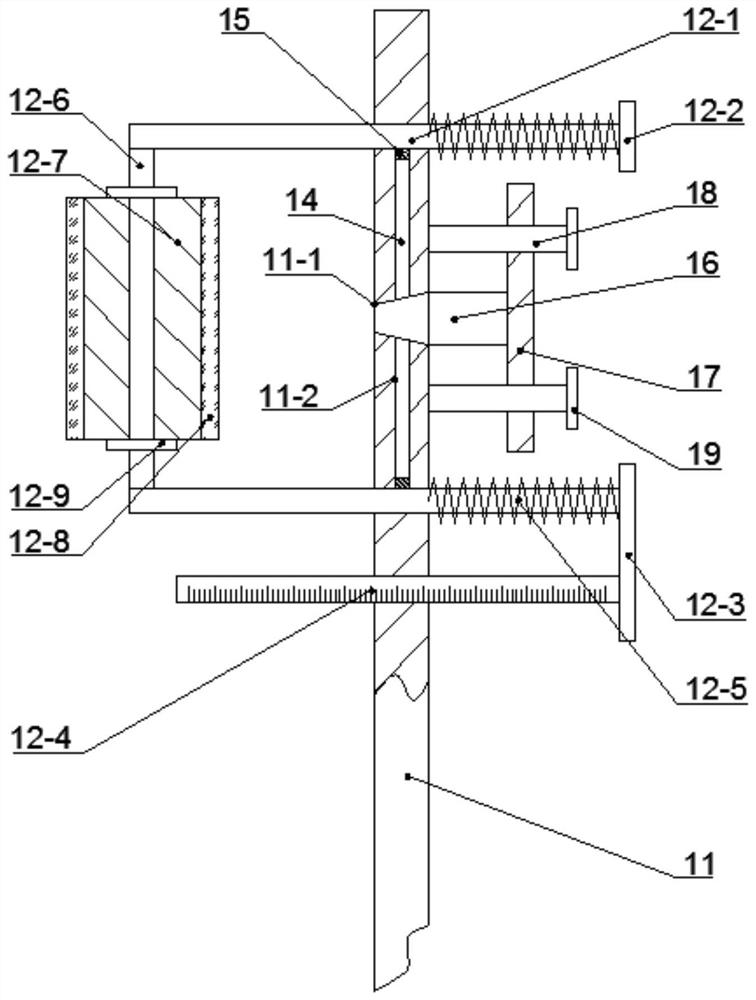

Measuring method and measuring apparatus for the thickness of molten layer of mold powder and fluctuation of liquid level of molten steel

ActiveCN104841897AAccurate thickness measurementReflect thickness distributionMechanical thickness measurementsCasting parameters measurement/indication devicesMolten steelScrew thread

The invention provides a measuring method and measuring apparatus for the thickness of a molten layer of mold powder and fluctuation of liquid level of molten steel. The measuring device comprises a tripod assembly, a metal rod, a plurality of metal wires, a tripod fixing device, a horizontal locator and a rotatable metal screw. The horizontal locator comprises a horizontal locating sheet metal and at least one scale. The tripod assembly comprises a tripod and a tripod fixing plate, a tripod fixing device comprises a vertically lifting adjusting screw and a rotatable head, and the vertically lifting adjusting screw is threaded to the tripod fixing plate. The rotatable metal screw is horizontally fixed to the vertically lifting adjusting screw, and the plurality of metal wires are arranged in the direction of rotatable metal screw and threaded to the rotatable metal screw at intervals. The horizontal locating sheet metal is fixed to the rotatable metal screw, and the scale is perpendicularly welded to the metal rod at intervals. By adopting the measuring method and the measuring apparatus, the thickness of a molten layer can be accurately measured, and the fluctuation of the liquid level of the molten steel can be reflected.

Owner:BAOSHAN IRON & STEEL CO LTD

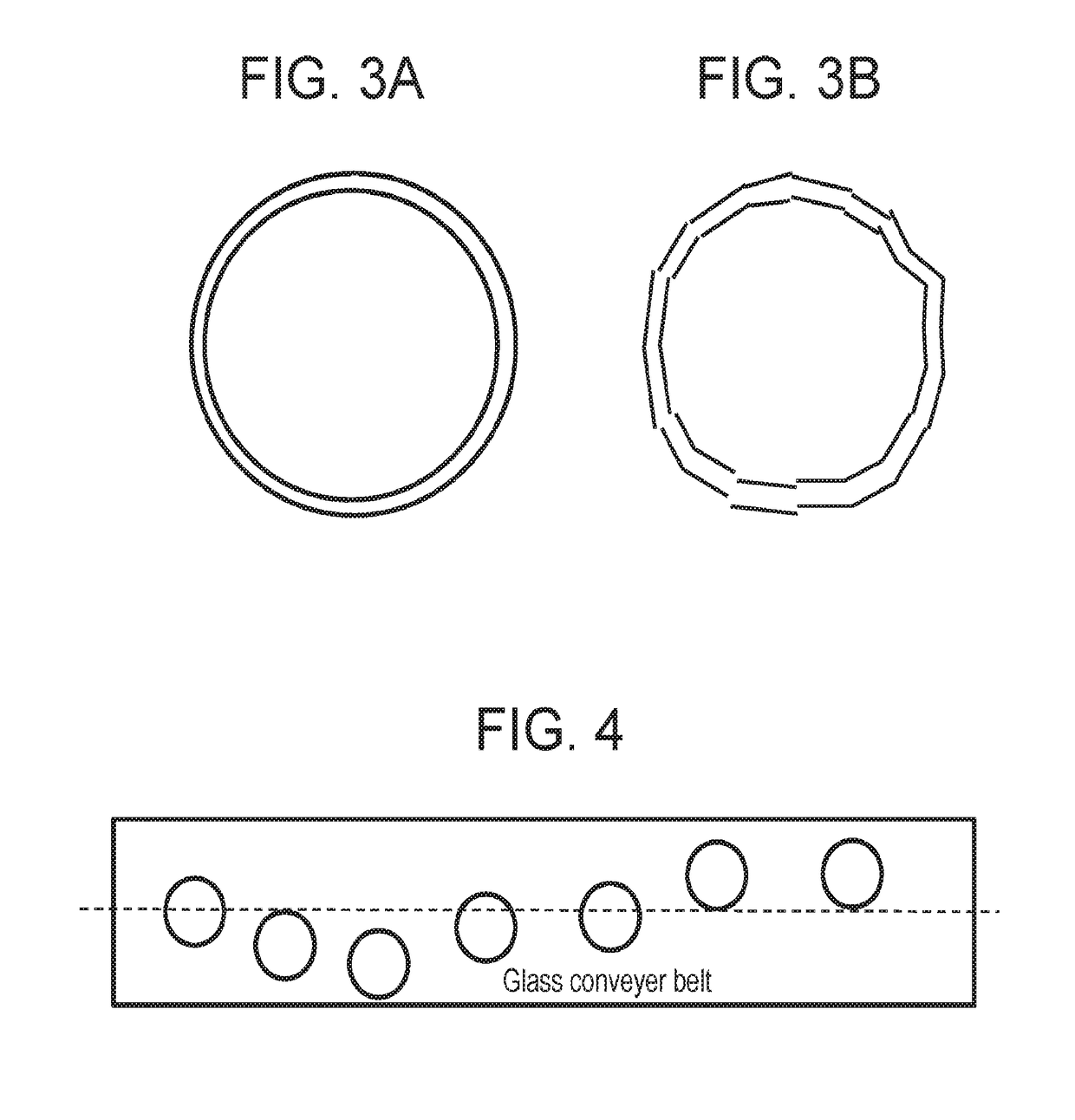

Object position independent method to measure the thickness of coatings deposited on curved objects moving at high rates

ActiveUS20190011251A1Accurate measurementAccurately identifying small change in coating thicknessColor/spectral properties measurementsUsing optical meansChannel geometryHigh rate

Methods and apparatus for measuring a thickness of a coating on an moving object are provided. Light is directed toward the object at a predetermined location on the object such that a portion of the light interacts with the object. A I D and / or 2D maximum intensities for at least one wavelength channel is captured that is produced by the portion of the light interacting with the object. A measured average intensity of the wavelength channel and / or intensities and their arithmetic derivatives of multi wavelength channel geometries is converted into I D (averaged) and / or 2D thickness values. Based on these values an acceptability of the coating is evaluated and thickness calculated.

Owner:ARKEMA INC

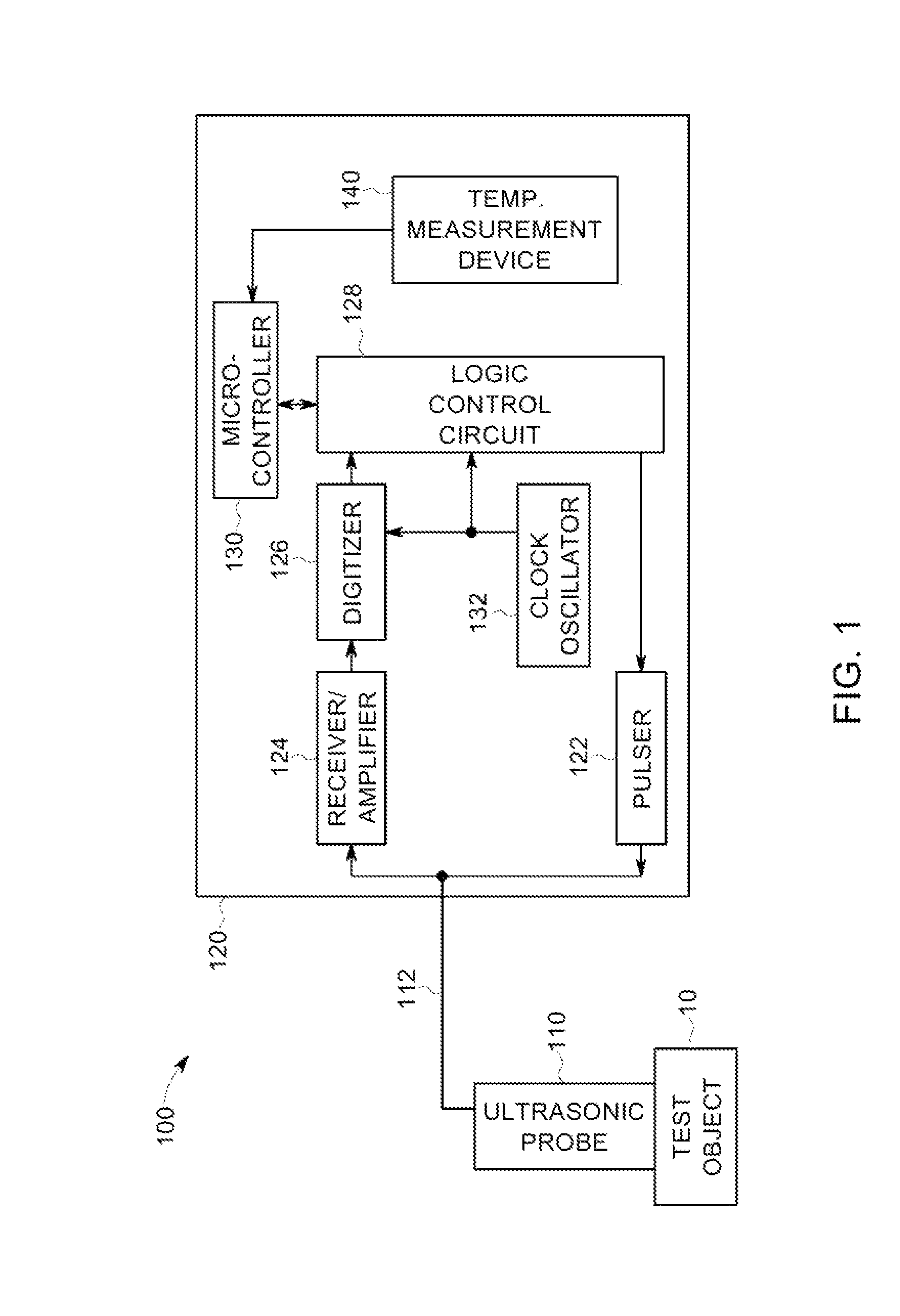

Method and system for correcting for temperature variations in ultrasonic testing systems

InactiveUS20130333441A1Accurate time of flightAccurate thickness measurementAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationEngineering

A method and system for correcting for temperature variation in ultrasonic testing systems is disclosed. In one embodiment, an offset is determined for correcting a time of flight measurement, wherein the offset is based on the pulse delays at first and second calibration temperatures. In another embodiment, a factor is determined for correcting a time of flight measurement, wherein the factor is based on clock signal errors at first and second calibration temperatures.

Owner:GENERAL ELECTRIC CO

Apparatus and method for capacitive measurement of materials

InactiveUS7369255B2Accurate thickness measurementEasy constructionResistance/reactance/impedenceMaterial analysis by optical meansCapacitive measurementDistance measurement

Method for measuring thicknesses of a film, a foil or a material layer with a measuring head which is spaced away from the film and with which a capacitive thickness measurement is performed, in which an optical distance measurement is performed with a distance measuring device and a distance determined by the optical distance measurement is used in determining the film thickness in the capacitive thickness measurement.

Owner:PLAST CONTROL GMBH

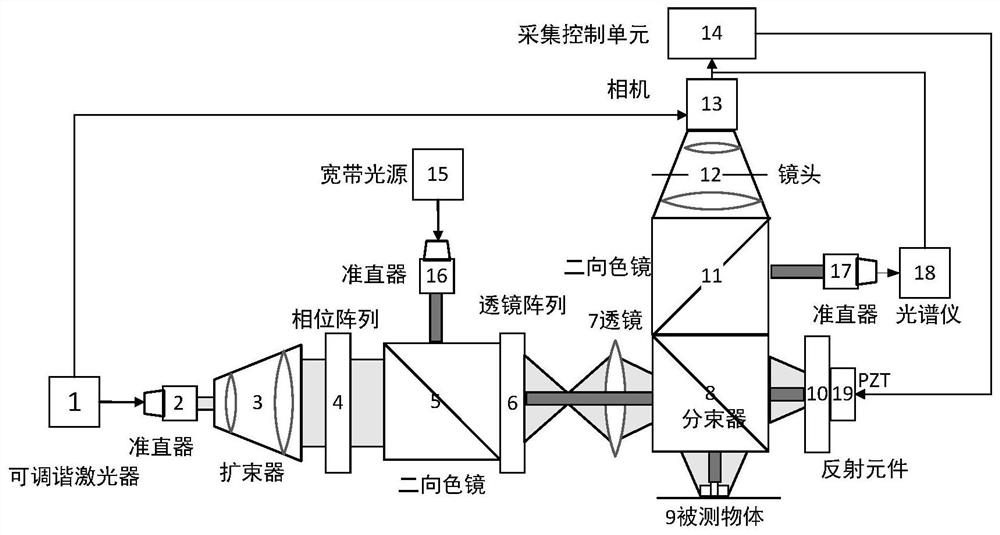

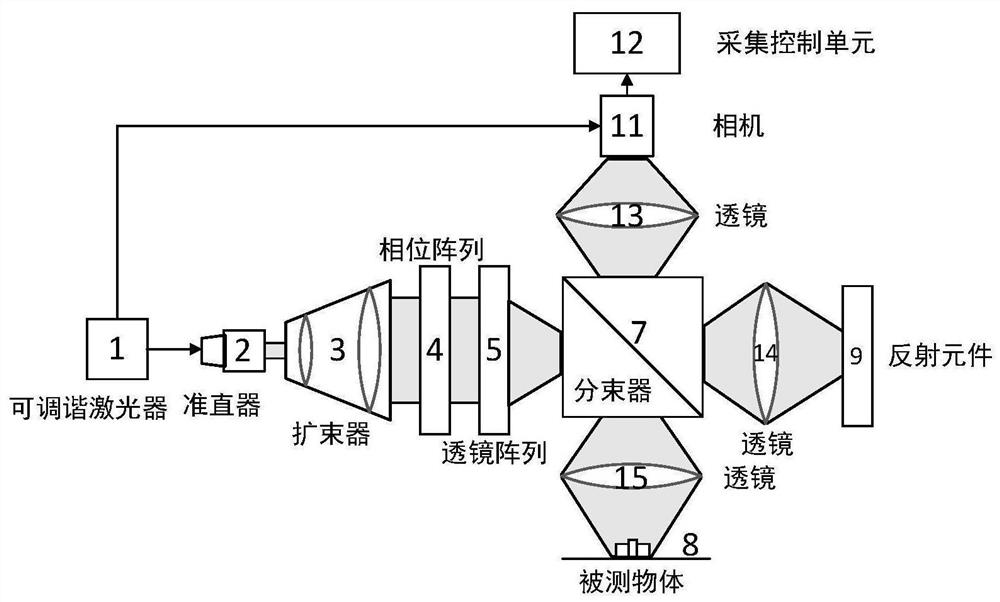

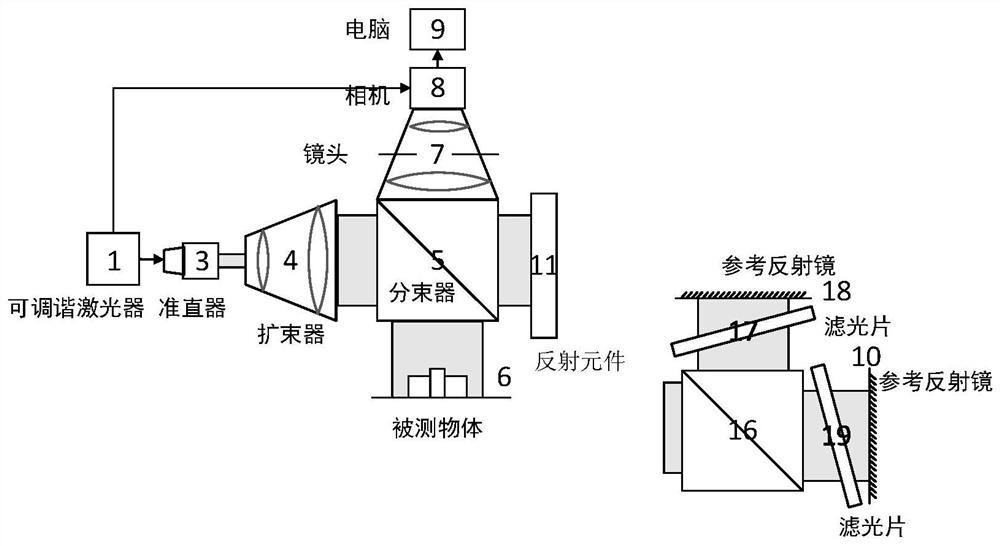

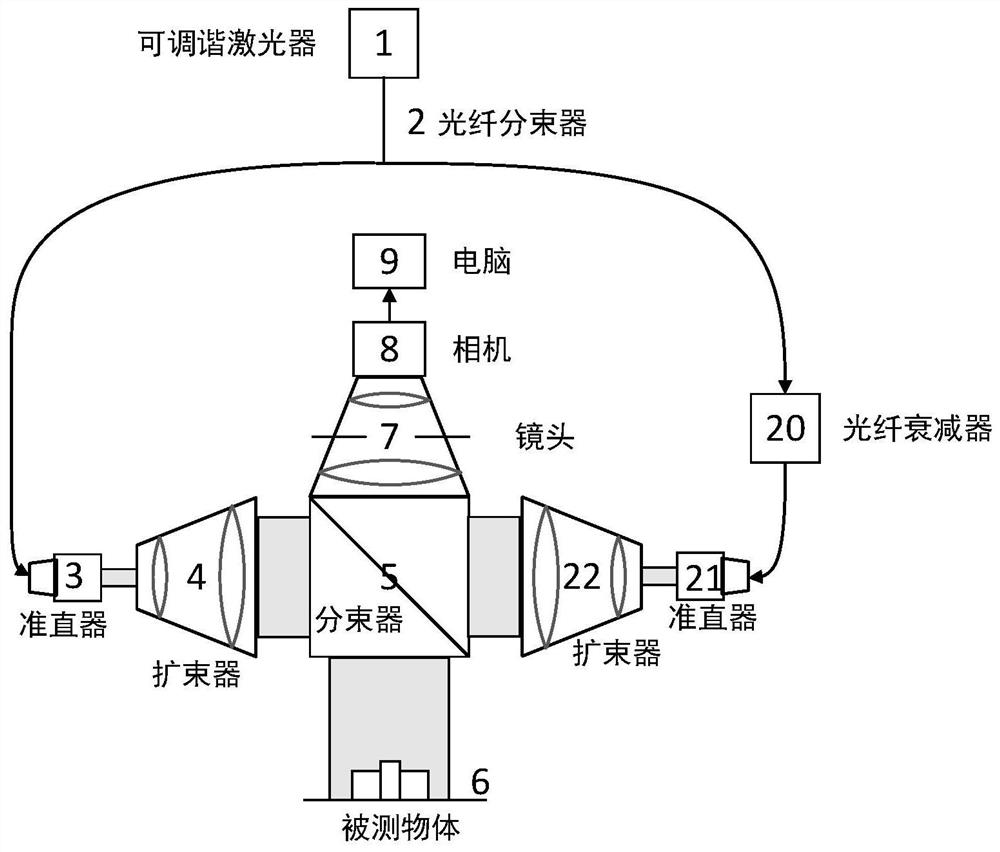

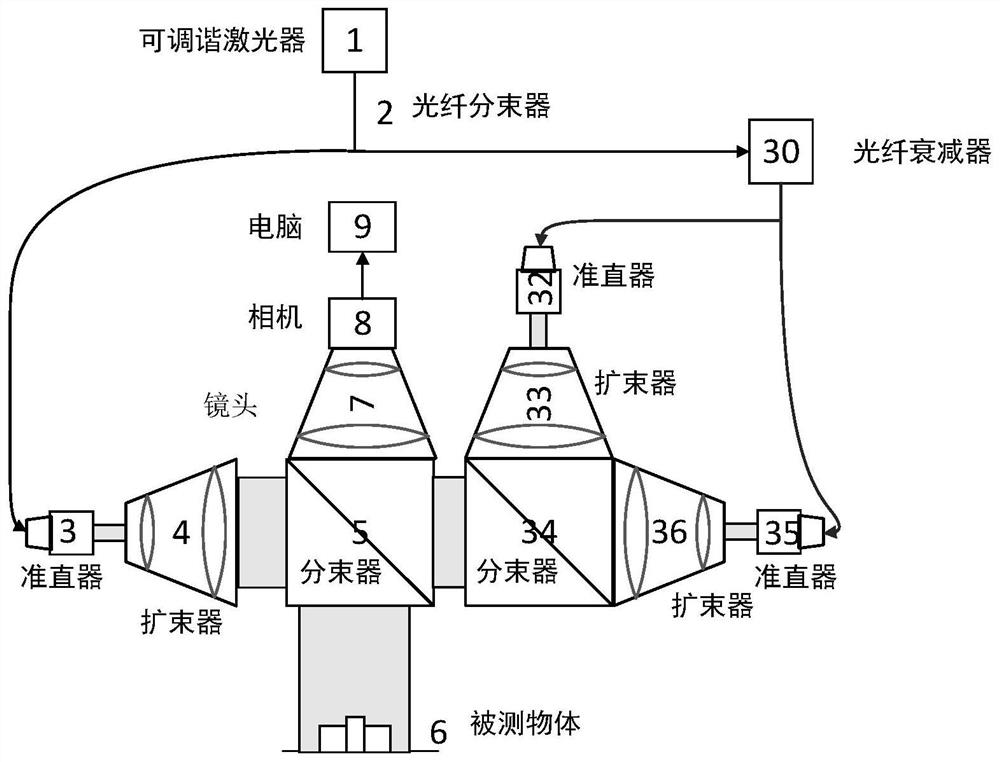

Area array sweep frequency measurement device and method

PendingCN112684463AVibration compensationImprove accuracyUsing optical meansElectromagnetic wave reradiationBeam splitterSpectrograph

The invention provides an area array sweep frequency measurement device and method, and belongs to the technical field of laser ranging. A beam splitter decomposes a converged light beam into reflected light and transmitted light; during use, a measured object reflects the reflected light to form signal light; a reflecting element is used for reflecting the transmitted light; a second dichroscope is used for decomposing the reflected transmitted light into reference light and wide-spectrum light; a spectrograph is used for acquiring spectral information through the decomposed wide-spectrum light; a camera is used for collecting an interference image formed by interference of the signal light and the reference light; an acquisition control unit can analyze the surface topography of the measured object according to the interference image and the compensation information; vibration information is obtained according to the spectral information and used for controlling a piezoelectric ceramic displacement table to move, and compensation information is obtained. Through superposition of a plurality of independent speckles, the effect of reducing the speckle contrast is achieved; meanwhile, an optical anti-shake function is achieved, and the laser ranging accuracy is improved.

Owner:武汉光目科技有限公司

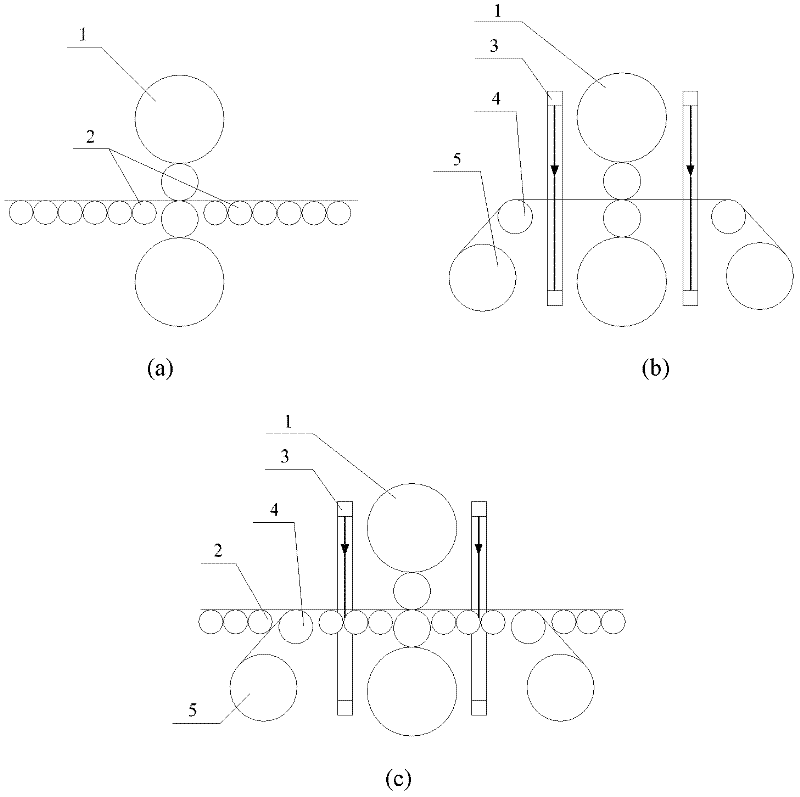

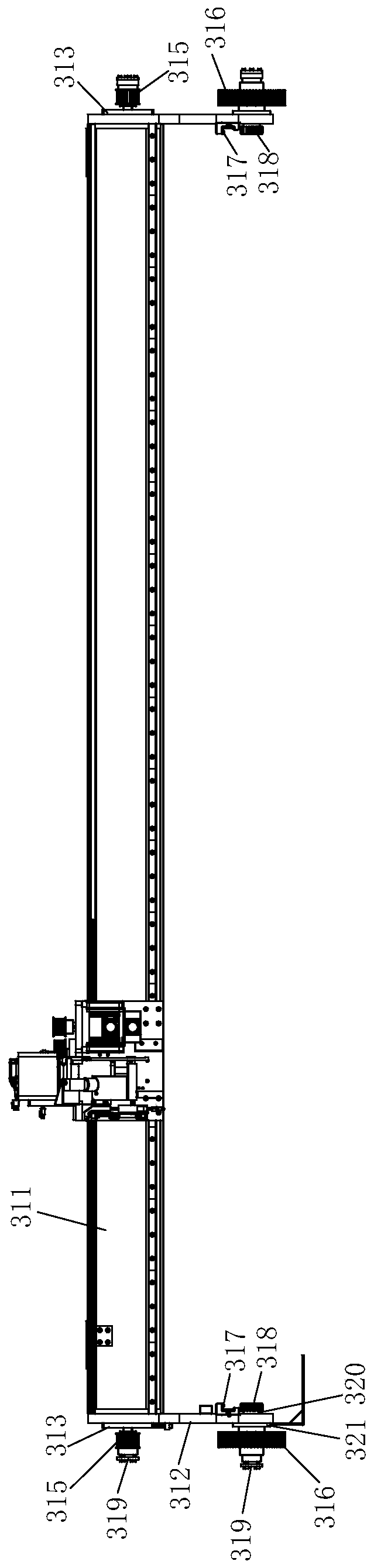

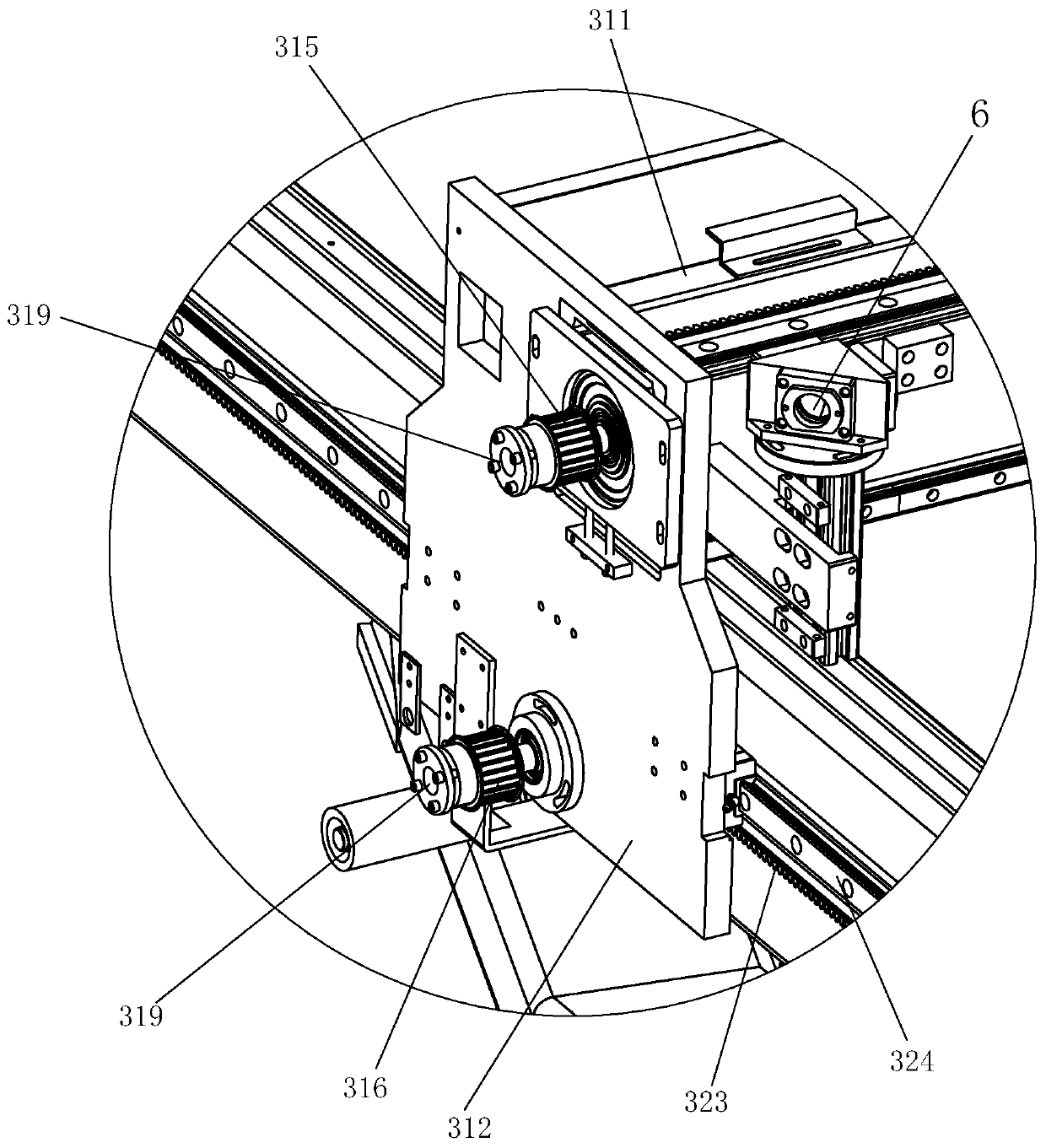

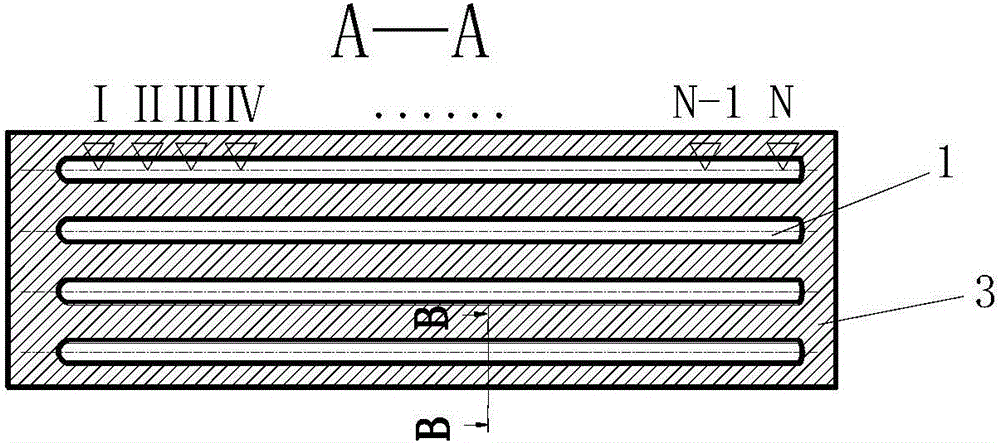

Device for measuring precision cold rolling thickness of single plate

InactiveCN102343368AAccurate thickness measurementInsert will notMeasuring devicesMetal rolling arrangementsMeasurement deviceMeasuring instrument

The invention belongs to the technical field of mechanical equipment and relates to a device for measuring the precision cold rolling thickness of a single plate. In the invention, a special roller way system is designed specific to a plate-coil dual-purpose rolling mill, i.e., an inner machine front roller way and an inner machine back roller way which are adjacent to the rolling mill are partitioned into two-section roller ways, and a gap is formed between every two sections of roller ways. The inner machine front roller way is partitioned into an operation side inner machine front roller way and a transmission side inner machine roller way, and the inner machine back roller way is partitioned into an operation side inner machine back roller way and a transmission side inner machine back roller way, so that rays of thickness measuring instruments in front of and behind the rolling mill pass through the center of the single plate in the rolling process, and accurate thickness measurement is realized. In the cold rolling process of a single plate, the head part of the single plate is inserted into a roller way when downward buckling occurs. In the invention, each section of roller way is designed with a patterned roller structure, so that the single plate is prevented from being inserted into roller way gaps.

Owner:UNIV OF SCI & TECH BEIJING

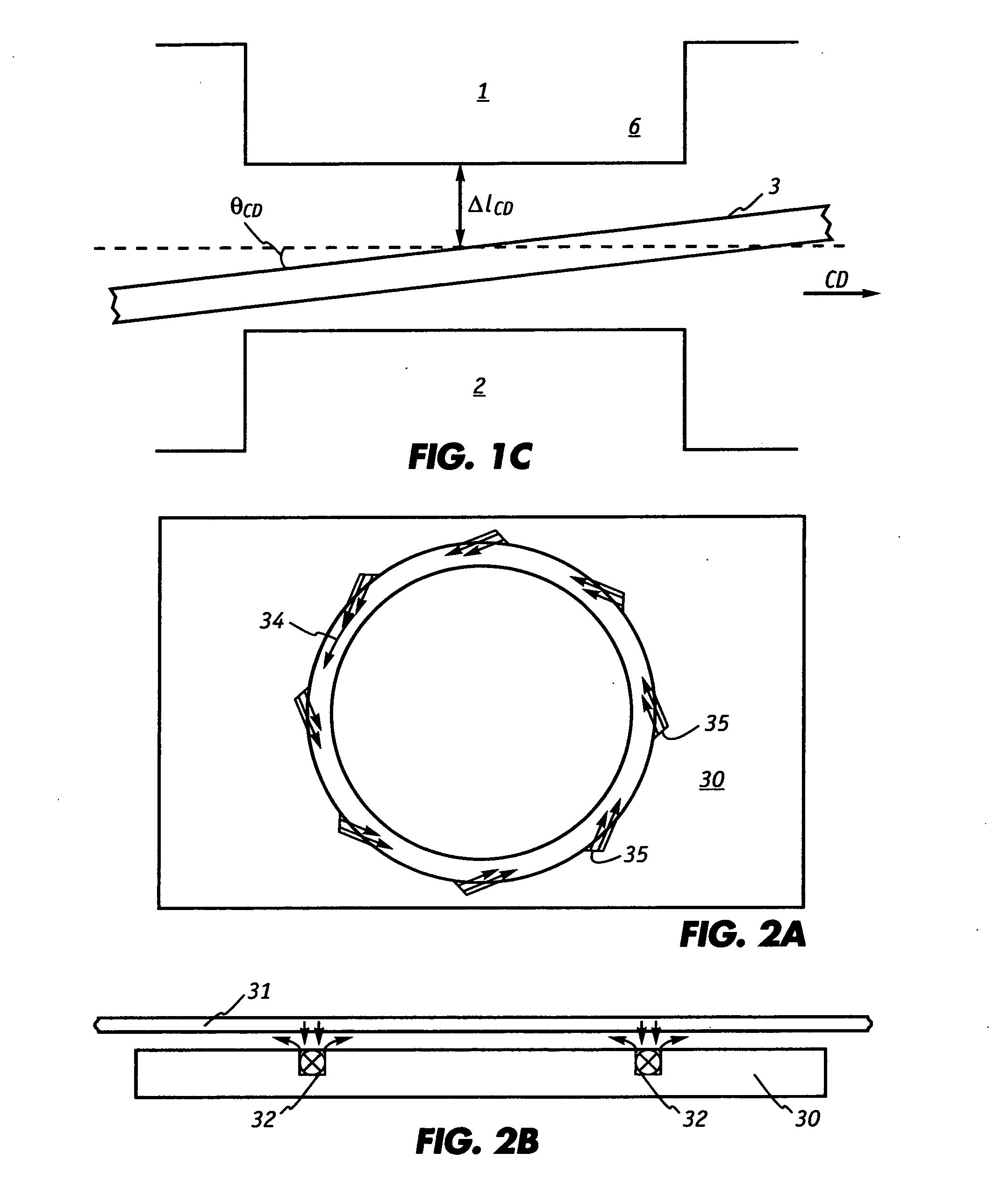

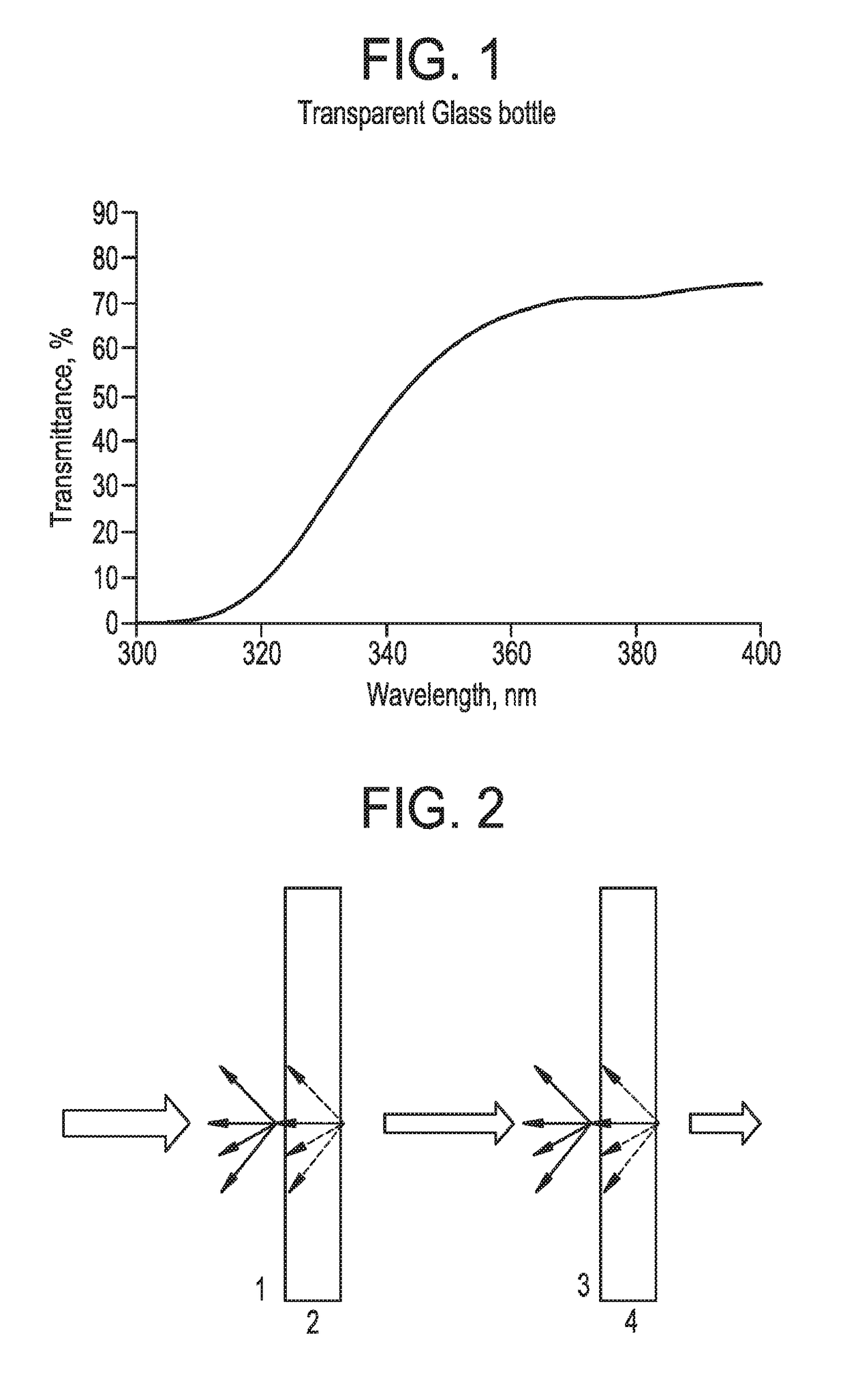

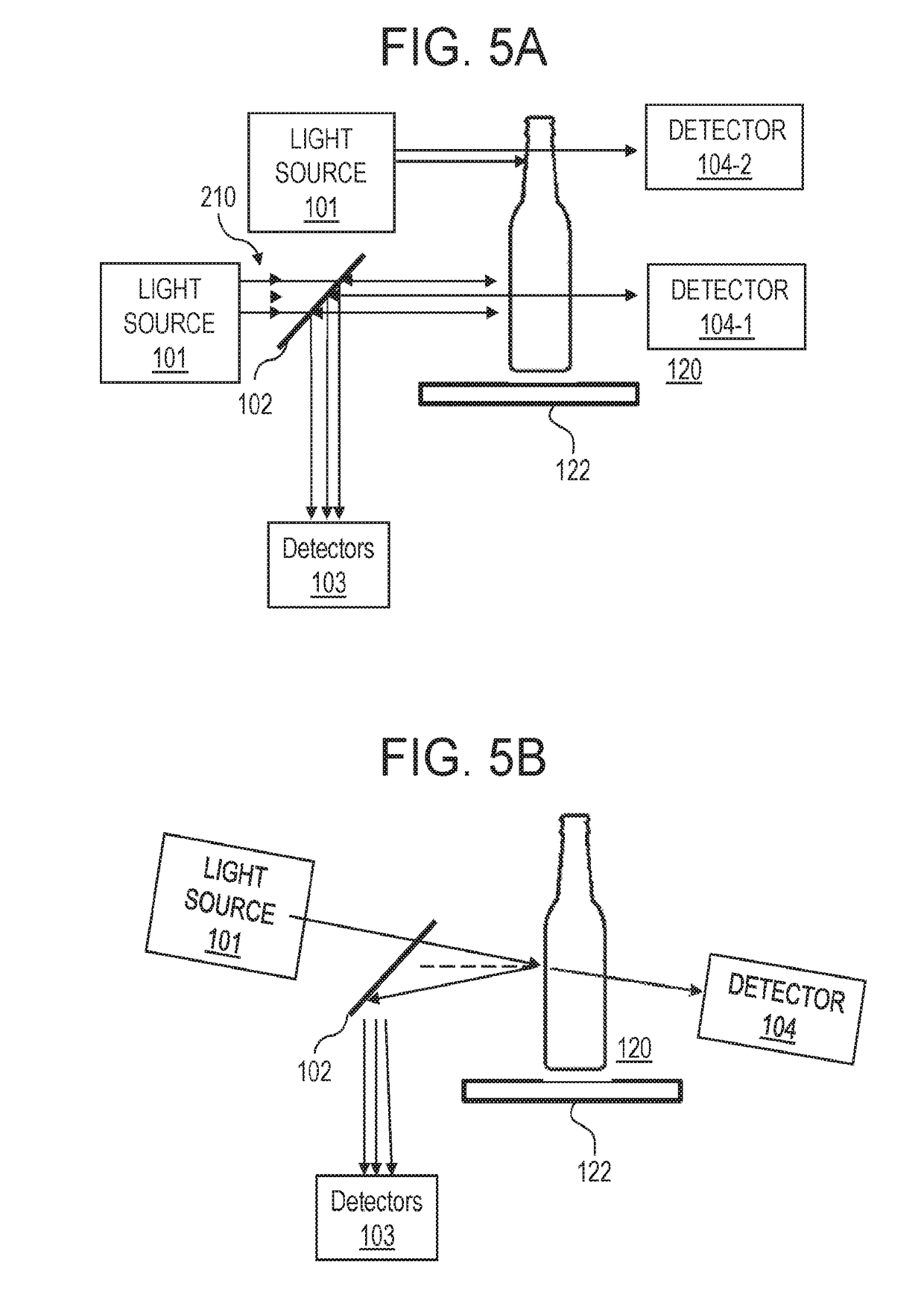

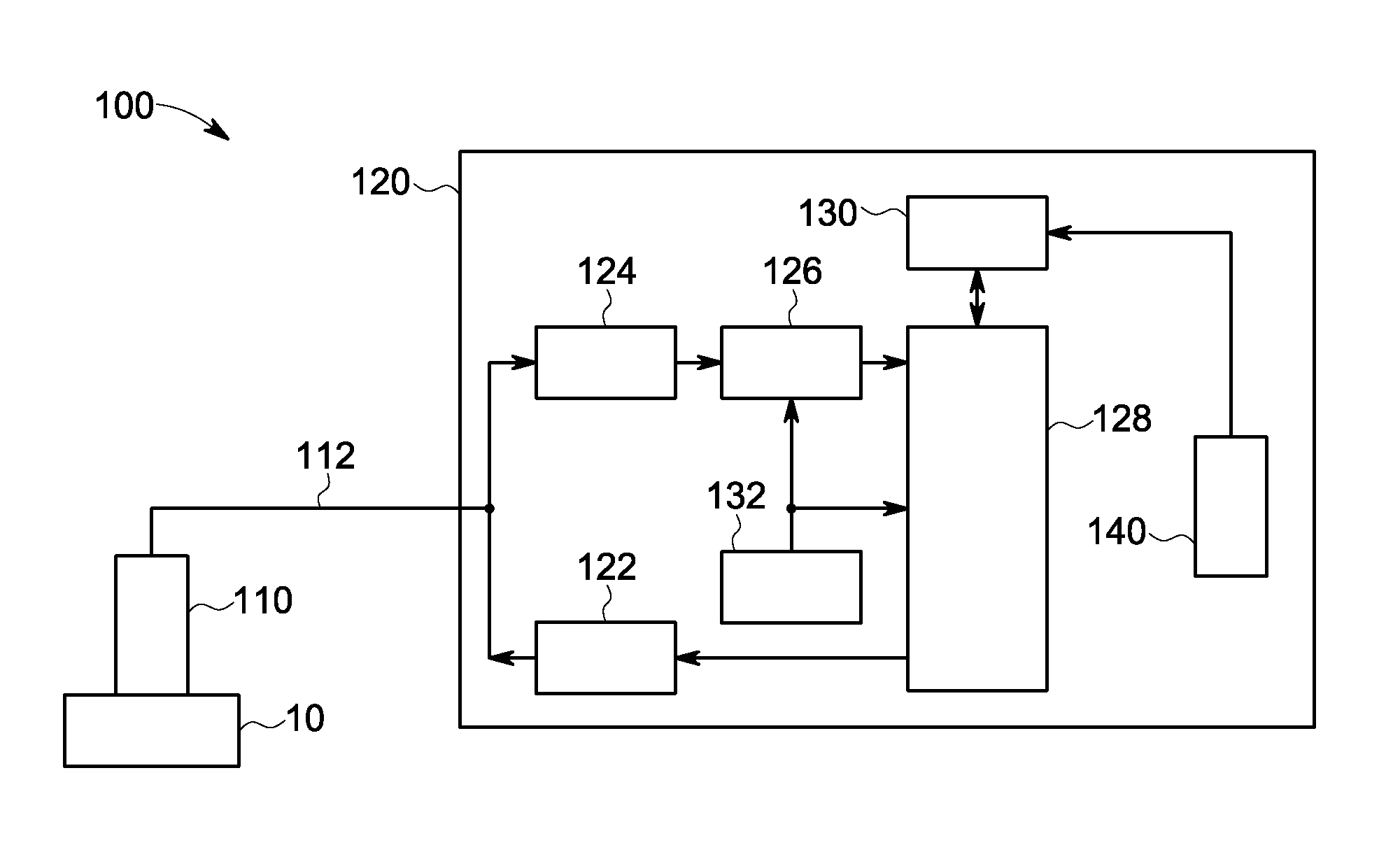

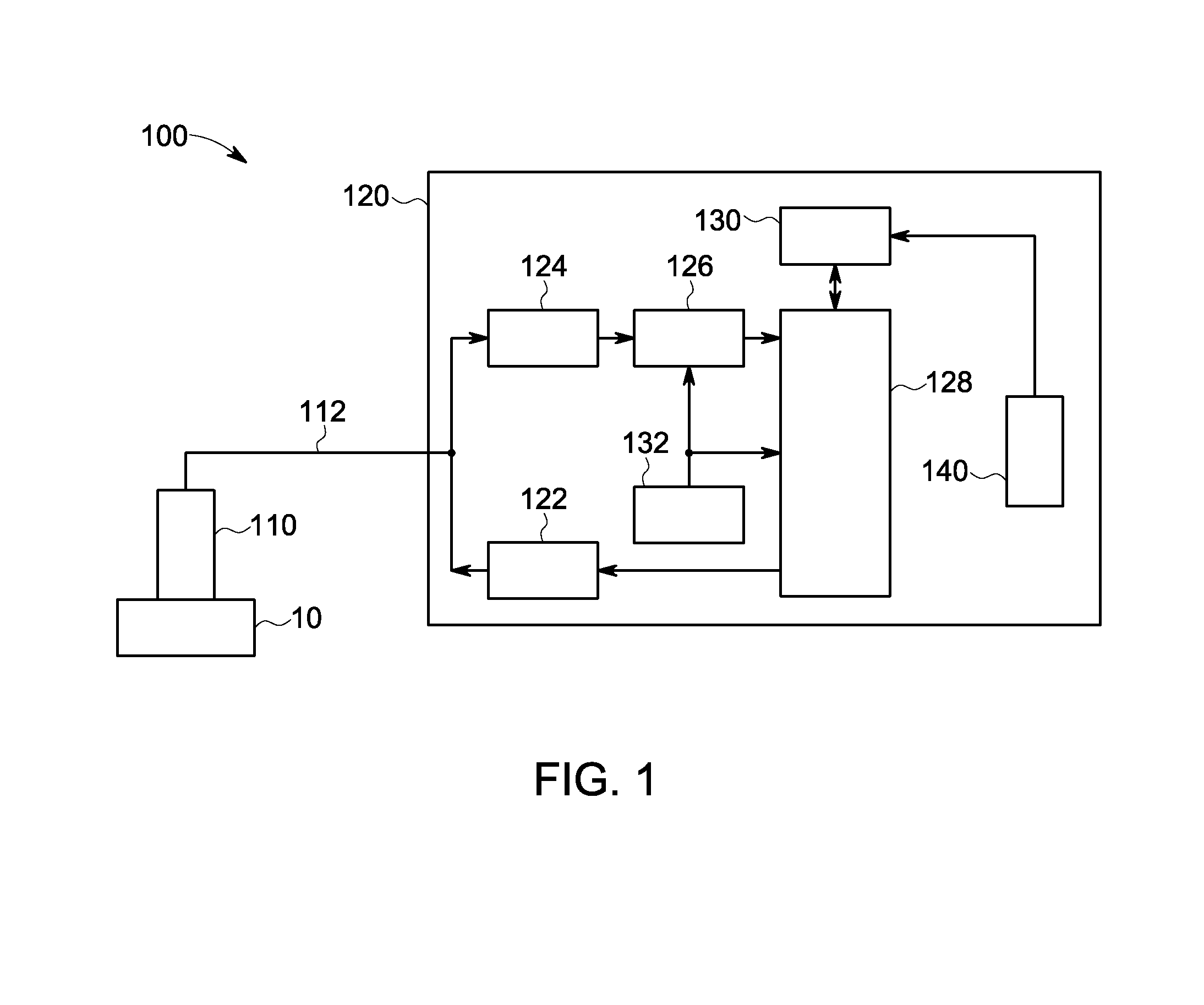

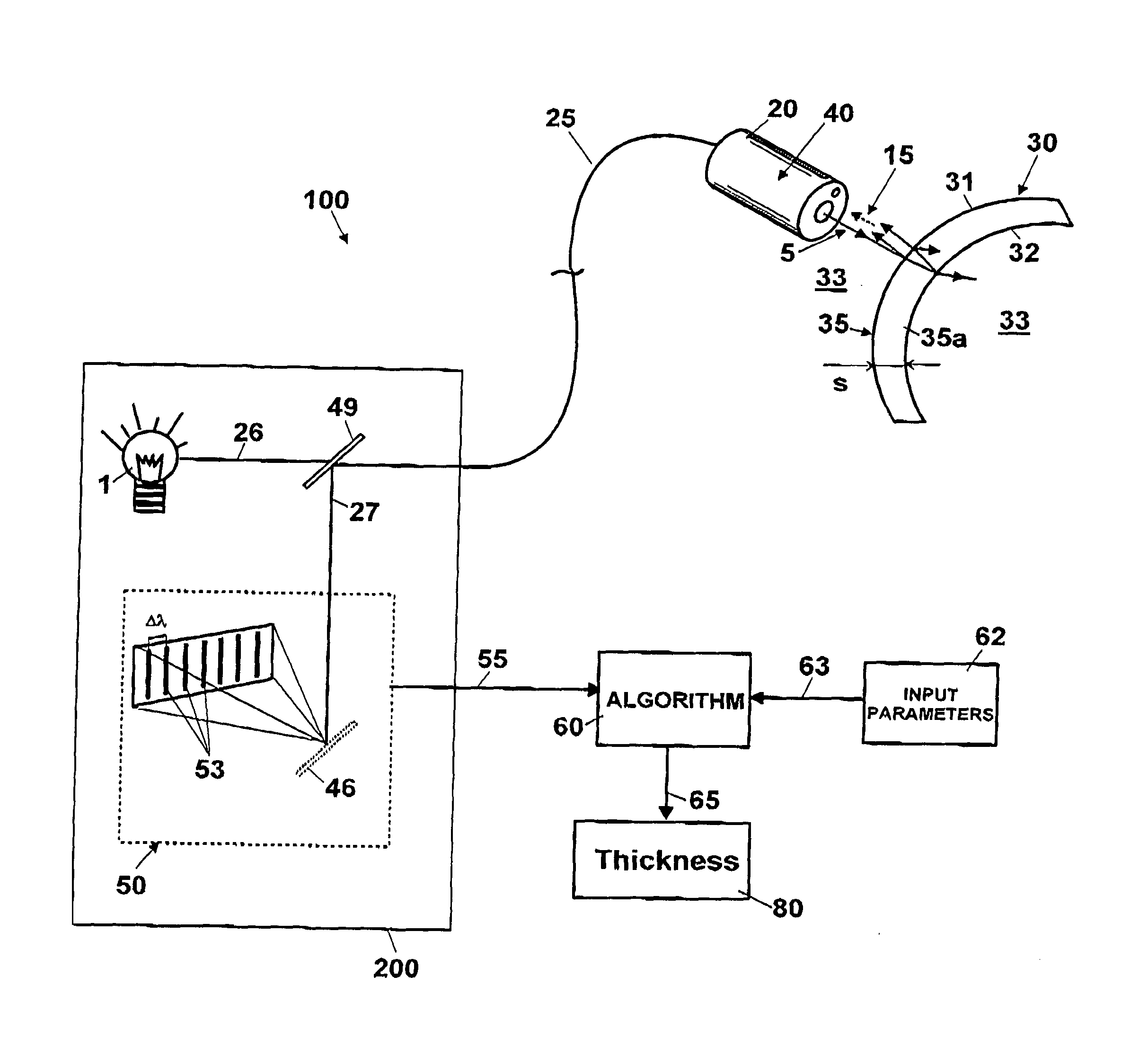

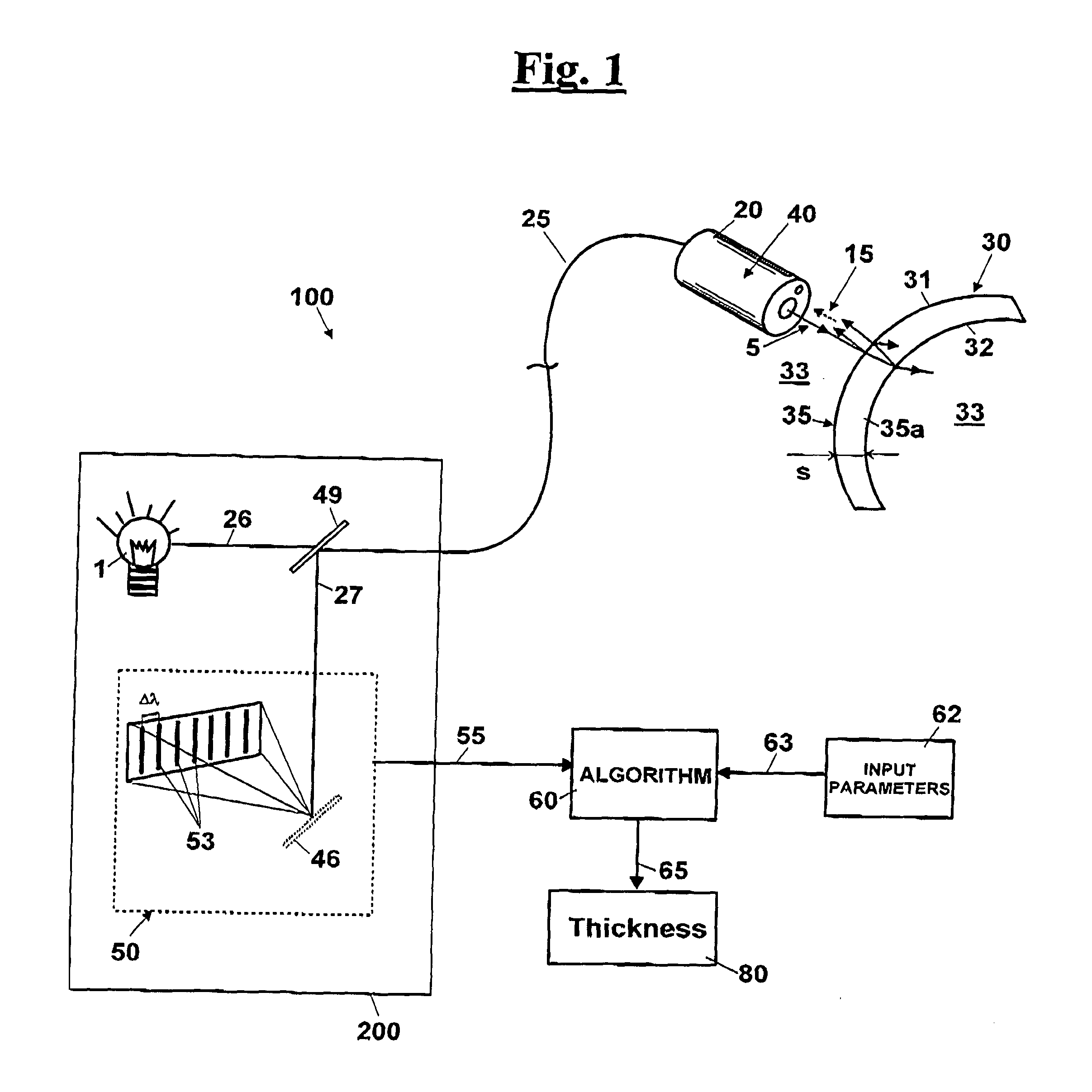

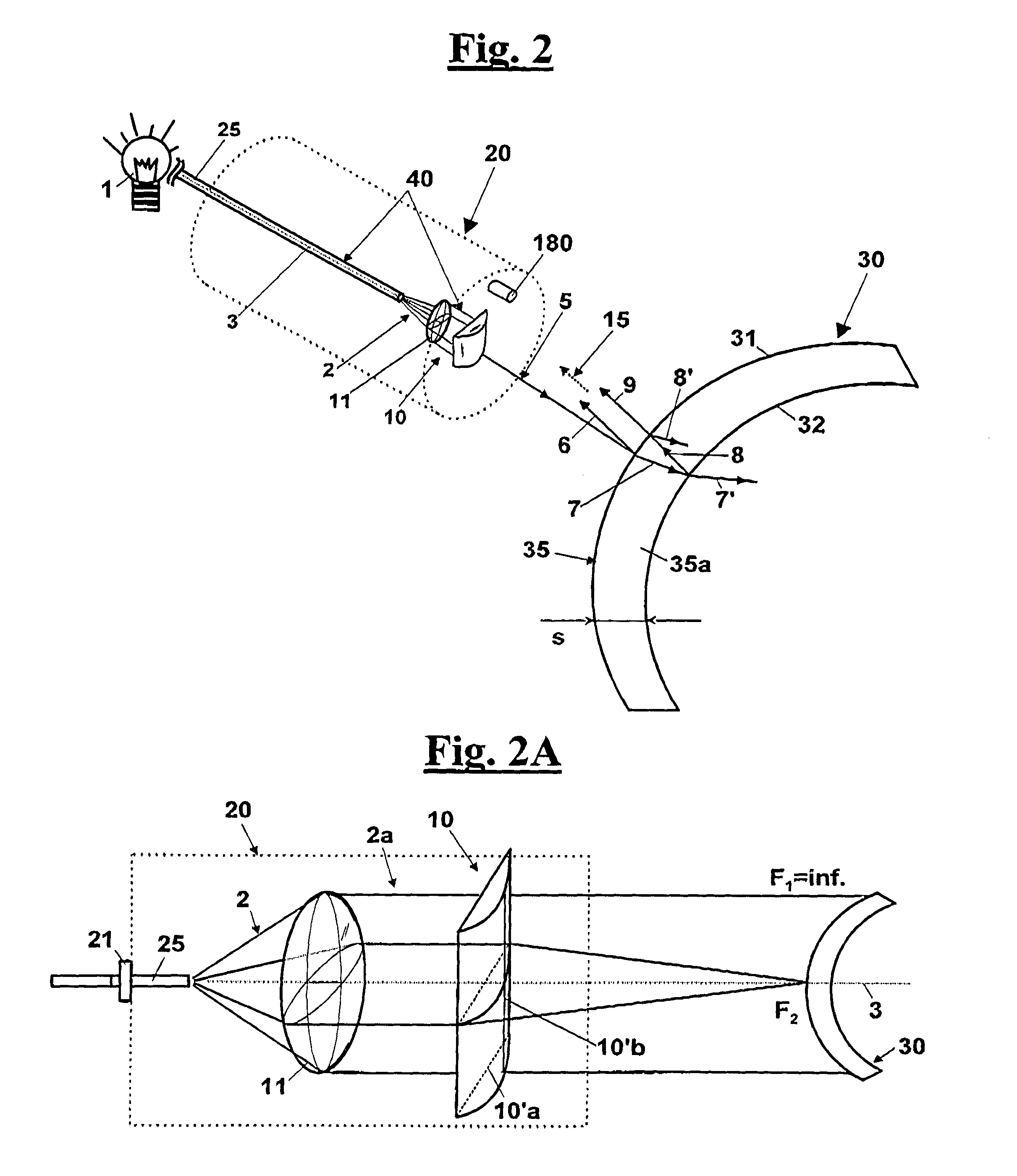

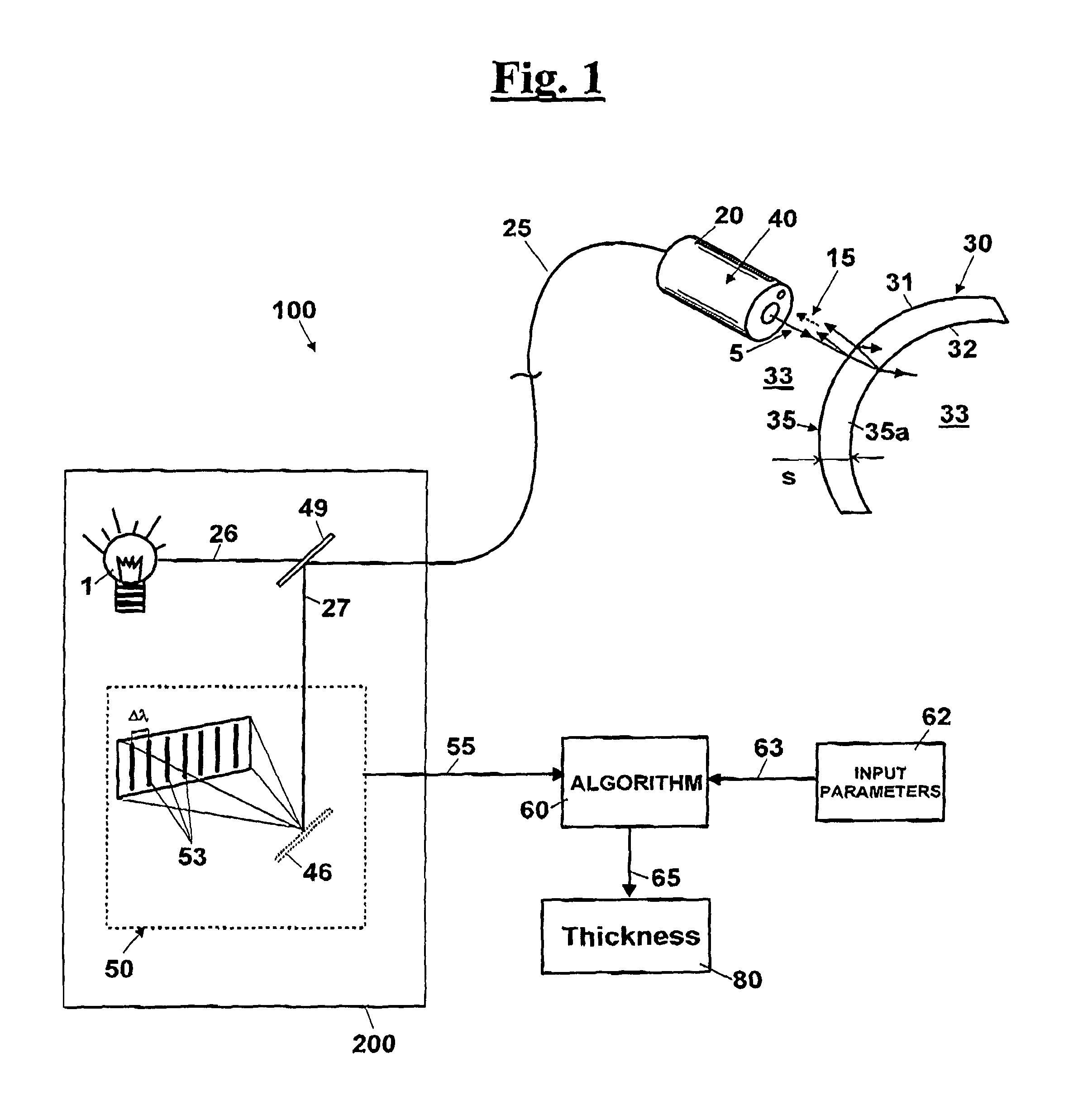

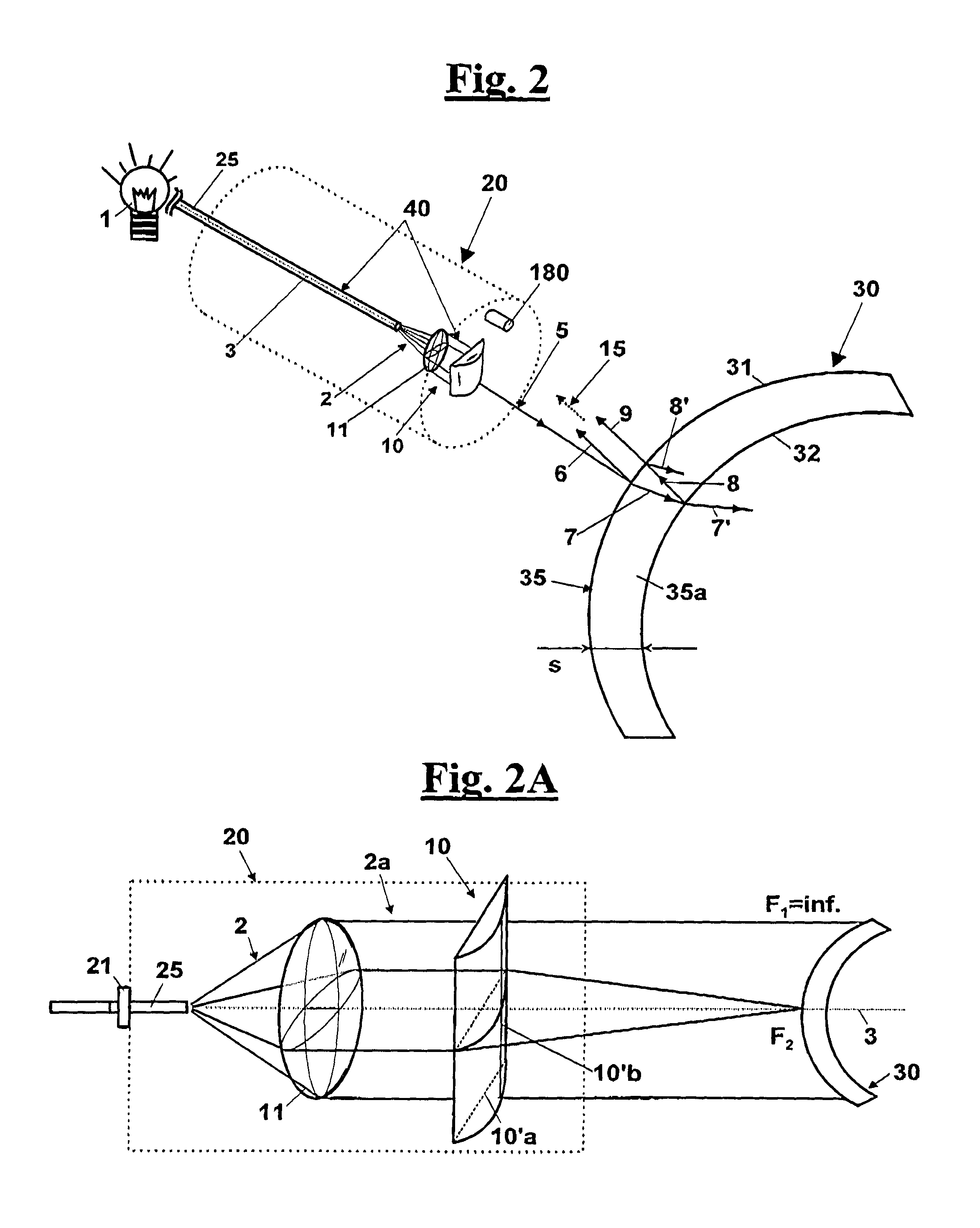

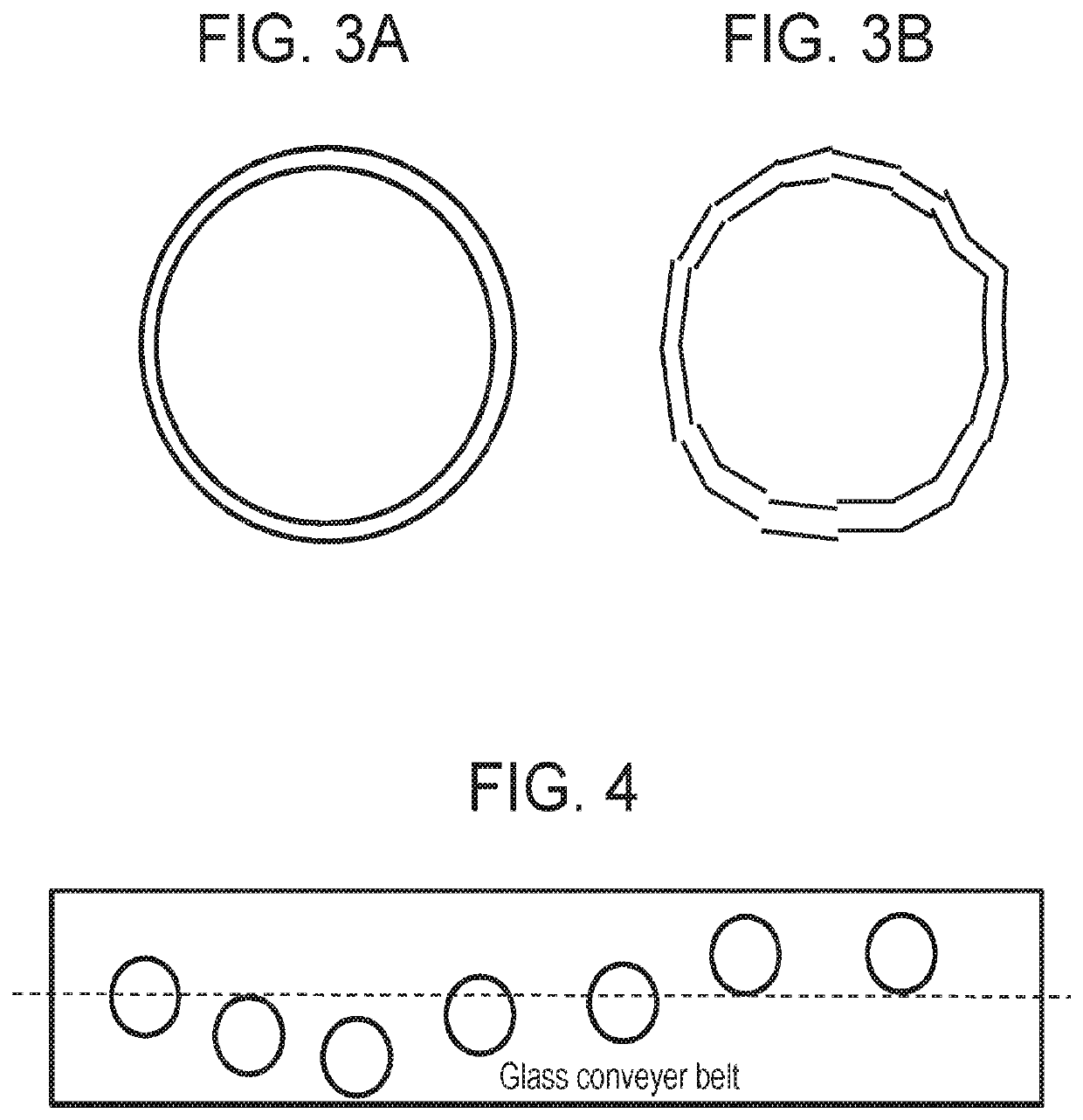

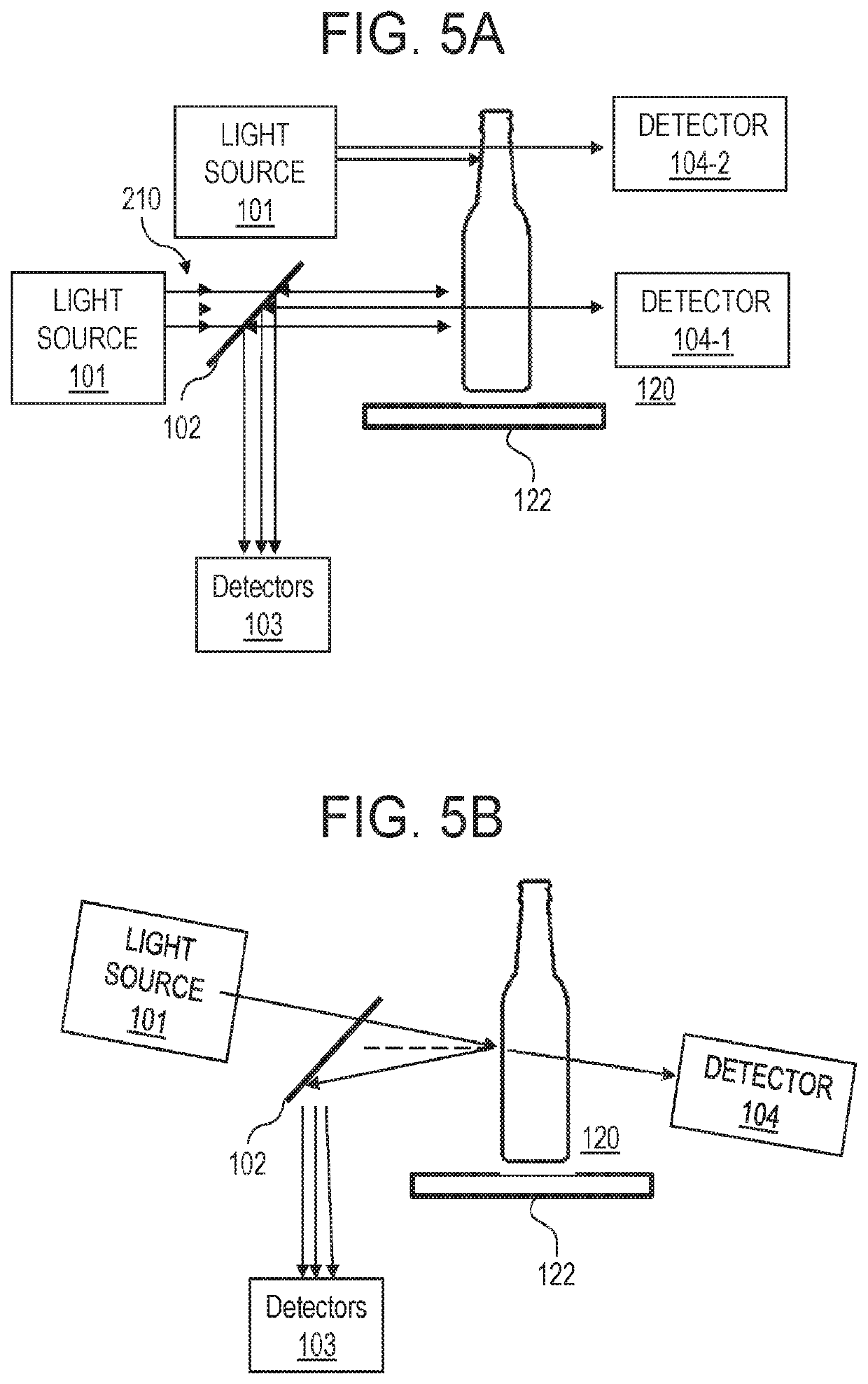

Method and apparatus for measuring the thickness of a transparent object in an automatic production line

ActiveUS20150204654A1Precise thickness measurementAccurate thickness measurementUsing optical meansEngineeringMeridian plane

An apparatus (100) and a method for measuring the thickness (s) for a wall (35) of a transparent object (30); the wall (35) comprises a transparent material (35a) arranged between a proximal interface (31), set between an environment (33) and the transparent material (35a), and a distal interface (32), set between said transparent material (35a) and the environment (33). The apparatus (100) comprises a source (1) of a starting light radiation (2) and a means for focusing it (10), in order to obtain an entering light radiation (5) directed towards the wall (35) that hits the proximal interface (31) of the wall (35) of the object and is in part reflected, in order to generate a first reflected radiation (6). A part of the entering light radiation (5) that is transmitted (7), through the transparent material (35a), hitting upon the distal interface (32), is in turn reflected (8) and crosses in an opposite direction the transparent material (35a) through the proximal interface (31), in order to generate a second reflected radiation (9). A collected radiation (15) given by overlapping the first (6) and second (9) reflected radiations have a difference of intensity that is configured to obtain an interference, which allows determining the thickness (s) of the wall (35). In particular, the means for focusing comprises a lens means (10) that have two main meridians (10a, 10b) orthogonal to each other, such that the entering light radiation (5) is focused on a first virtual focus (F1) in the first meridian plane (10a), and on a second virtual focus (F2) in the second meridian plane (10b). This way, it is obtained that the collected radiation (15) is substantially independent from possible movements of the transparent object (30), and this allows a remarkable reliability and robustness of the measurement with respect to fluctuations and vibrations of the object (30).

Owner:GERRESHEIMER PISA

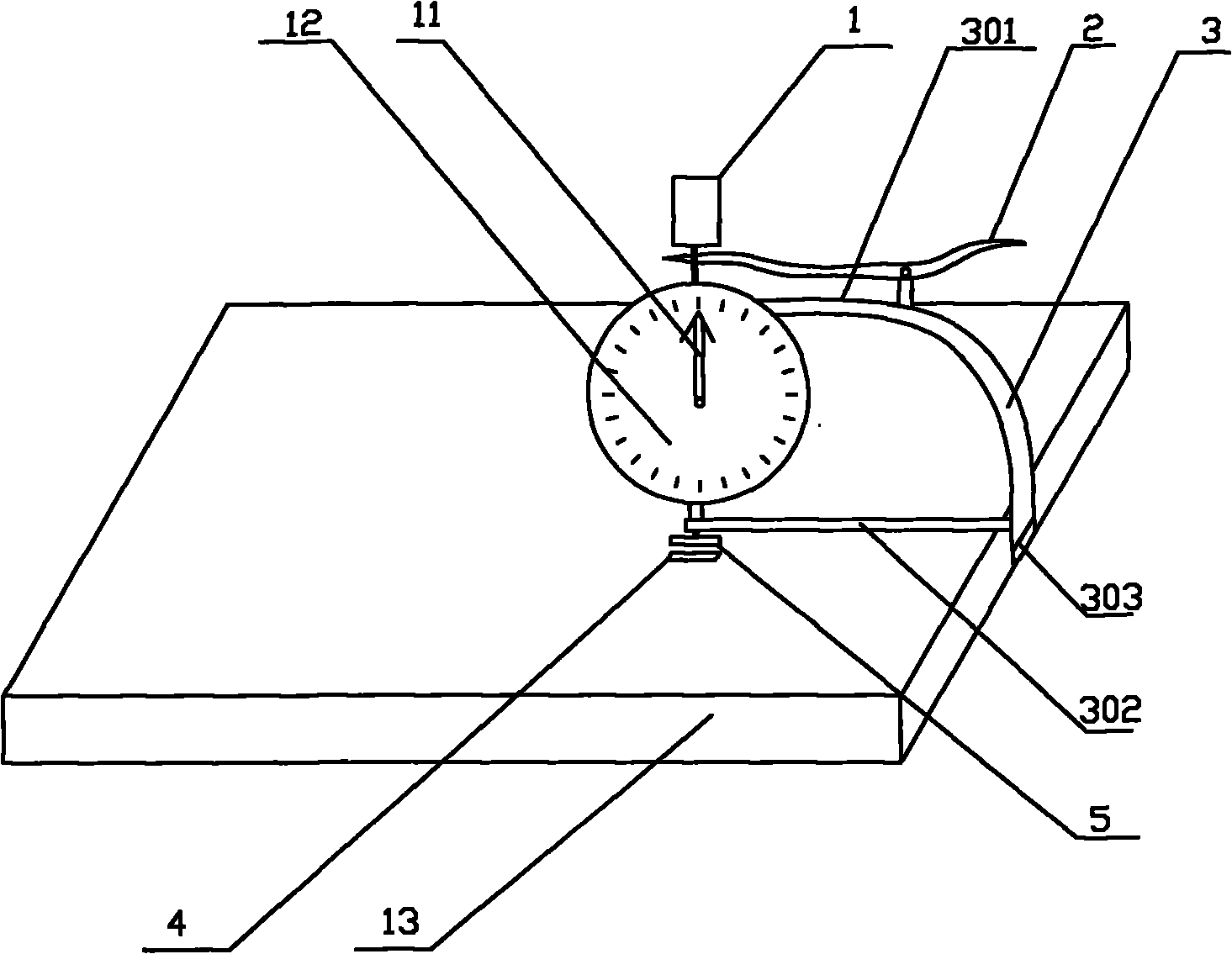

Device for measuring thickness of rubber-coated steel cord

InactiveCN102213579ANo creepAccurate importMechanical thickness measurementsMeasuring instrumentEngineering

The invention relates to a device for measuring thickness of a rubber-coated steel cord. The device comprises a dial gauge thickness measuring instrument consisting of a gauge frame, a counter weight, a measuring rod, a shifting fork, upper and lower measuring heads, a return spring, a gauge body, a pointer and a dial, wherein the gauge body is arranged on a supporting guide part of the gauge frame; the measuring rod passes through the gauge body and the supporting guide part; the top and bottom ends of the measuring rod are connected with the counter weight and the upper measuring head; the lower measuring head is arranged on a base of the gauge frame; two ends of the return spring in the gauge body are connected to the measuring rod and the gauge body; the shifting fork hinged on a hinge part of the gauge frame is connected to the measuring rod; and the measuring rod changes linear displacement into angular displacement of the pointer through a transmission piece so as to indicate the thickness value on the dial. The device is characterized by also comprising a measuring platform, wherein the base of the gauge frame is embedded in the platform; and an upper surface of the lower measuring head and an upper surface of the measuring platform are positioned on the same plane. The samples to be tested can be flatly put on the measuring platform and are accurately introduced between the upper and lower measuring heads, sample rubber cannot generate creep deformation, and the device is accurate in measurement and easy and convenient to operate.

Owner:CHENGSHAN GROUP

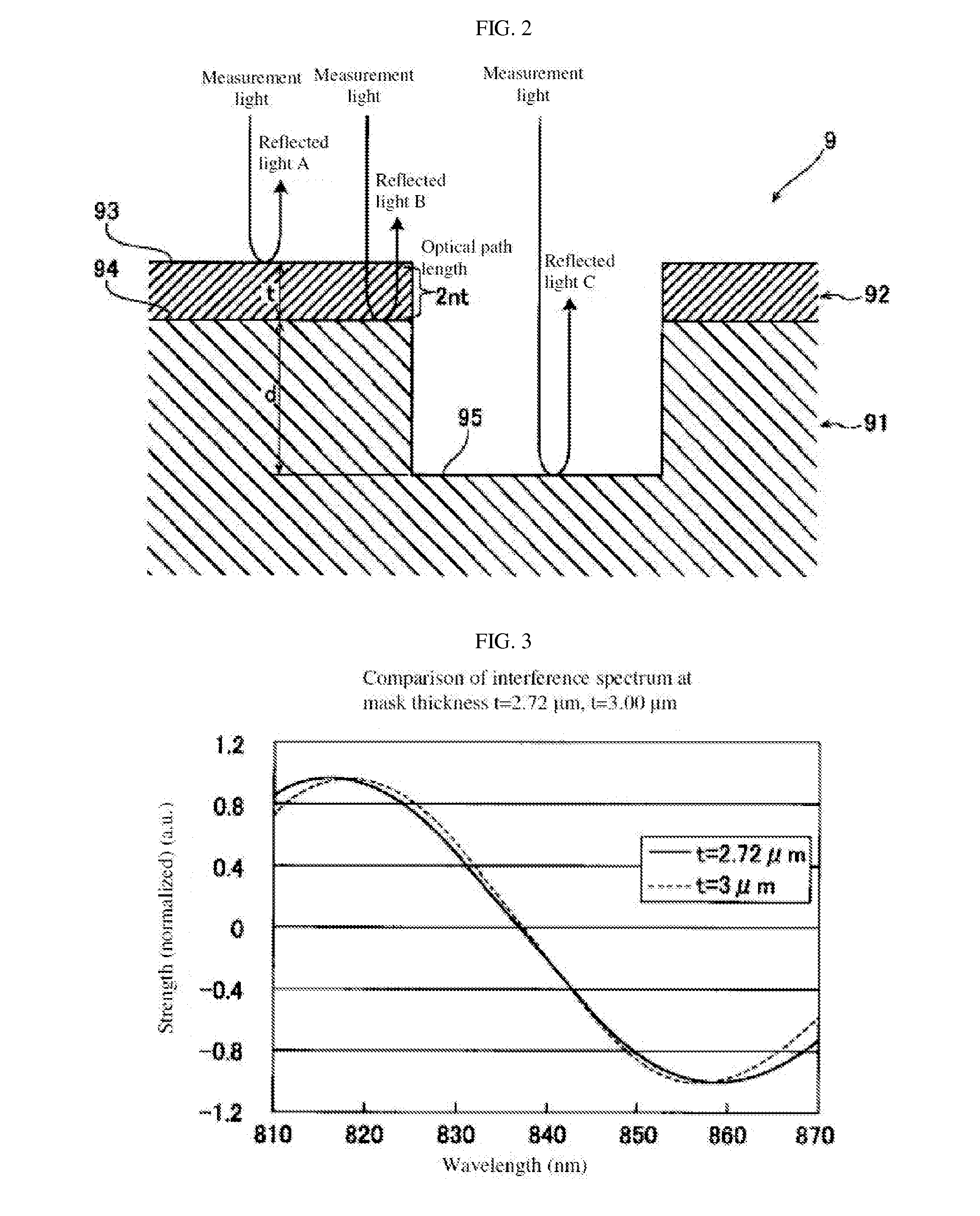

Thickness monitoring device, etching depth monitoring device and thickness monitoring method

InactiveUS20130334422A1Good precisionRemove distortionRadiation pyrometryMaterial analysis by optical meansOptoelectronicsLength wave

A thickness monitoring device capable of performing thickness measurement of an object of measurement in real time even when using a relatively narrow band light source. This etching monitoring device (thickness monitoring device) includes a light source which produces measurement light having a predetermined wavelength bandwidth; an array detector which detects, for each wavelength, interference light of measurement light reflected from mask, whereof the thickness changes over time; and data processing unit which computes the thickness of the mask based on change over time of a plurality of single-wavelength components of the interference light detected by the array detector.

Owner:SHIMADZU CORP

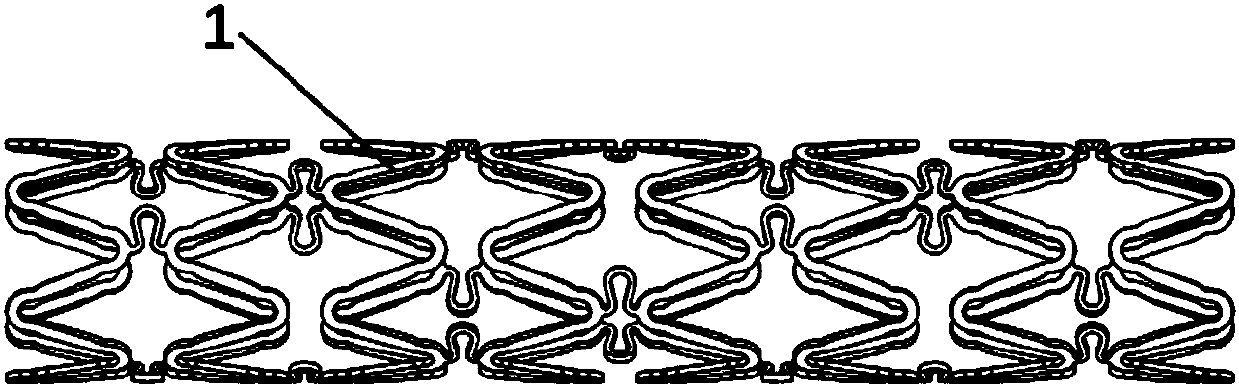

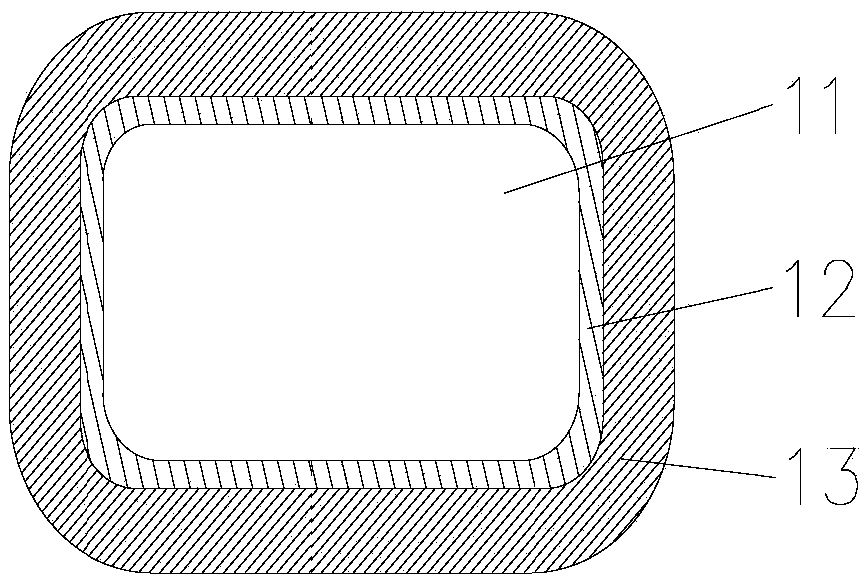

Method for measuring thickness of coating layer of degradable drug eluting stent

ActiveCN107607071AAvoid breakingIntegrity guaranteedScanning probe techniquesCoated surfaceMetal coating

The invention discloses a method for measuring the thickness of a coating layer of a degradable drug eluting stent. Through the coating of a precious metal protection layer on the surface of a stent polymer coating, the contact of the polymer coating with solution for curing is prevented during the subsequent cold inset curing processing of a sample, thereby preventing the direct contact and mutual dissolving of the polymer coating and the solution from damaging the polymer coating and causing a problem that the subsequent measurement cannot be carried out. The method provided by the inventioncan maintain the integrity of the polymer coating after the cold inset curing processing, and achieves the accurate measurement of the thickness of the polymer coating and the metal coating under a scanning electron microscope.

Owner:深圳市领先医疗服务有限公司

Method and system for correcting for temperature variations in ultrasonic testing systems

InactiveUS8997550B2Accurate timingAccurate thickness measurementAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationUltrasonic testing

A method and system for correcting for temperature variation in ultrasonic testing systems is disclosed. In one embodiment, an offset is determined for correcting a time of flight measurement, wherein the offset is based on the pulse delays at first and second calibration temperatures. In another embodiment, a factor is determined for correcting a time of flight measurement, wherein the factor is based on clock signal errors at first and second calibration temperatures.

Owner:GENERAL ELECTRIC CO

Ultrasonic thickness measurement method for metal composite material and application of interlayer interface in ultrasonic thickness measurement

ActiveCN110006996ACalculate thicknessSolve difficult problems that cannot be effectively utilizedAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansUltrasonic thickness measurementPropagation time

The invention aims to solve the problems that the thickness of each layer of metal of the metal composite material cannot be measured and the overall thickness of the metal composite material cannot be accurately measured in the prior art. The invention provides an ultrasonic thickness measurement method for a metal composite material. According to the method, using interlaminar interface substances mixed between adjacent materials of the composite material as interlaminar interfaces of two metal materials; recording the propagation time of the ultrasonic waves by taking the reflected waves ofthe interlayer interface as interface reflected waves during measurement; and calculating the thickness of each layer of material according to the echo time of the interlayer interface, summing the thicknesses of the layers of materials to obtain the total thickness of the metal composite material, and obtaining the thickness of each layer of material and the total thickness of the metal composite material by adopting the method.

Owner:葫芦岛探克科技有限公司

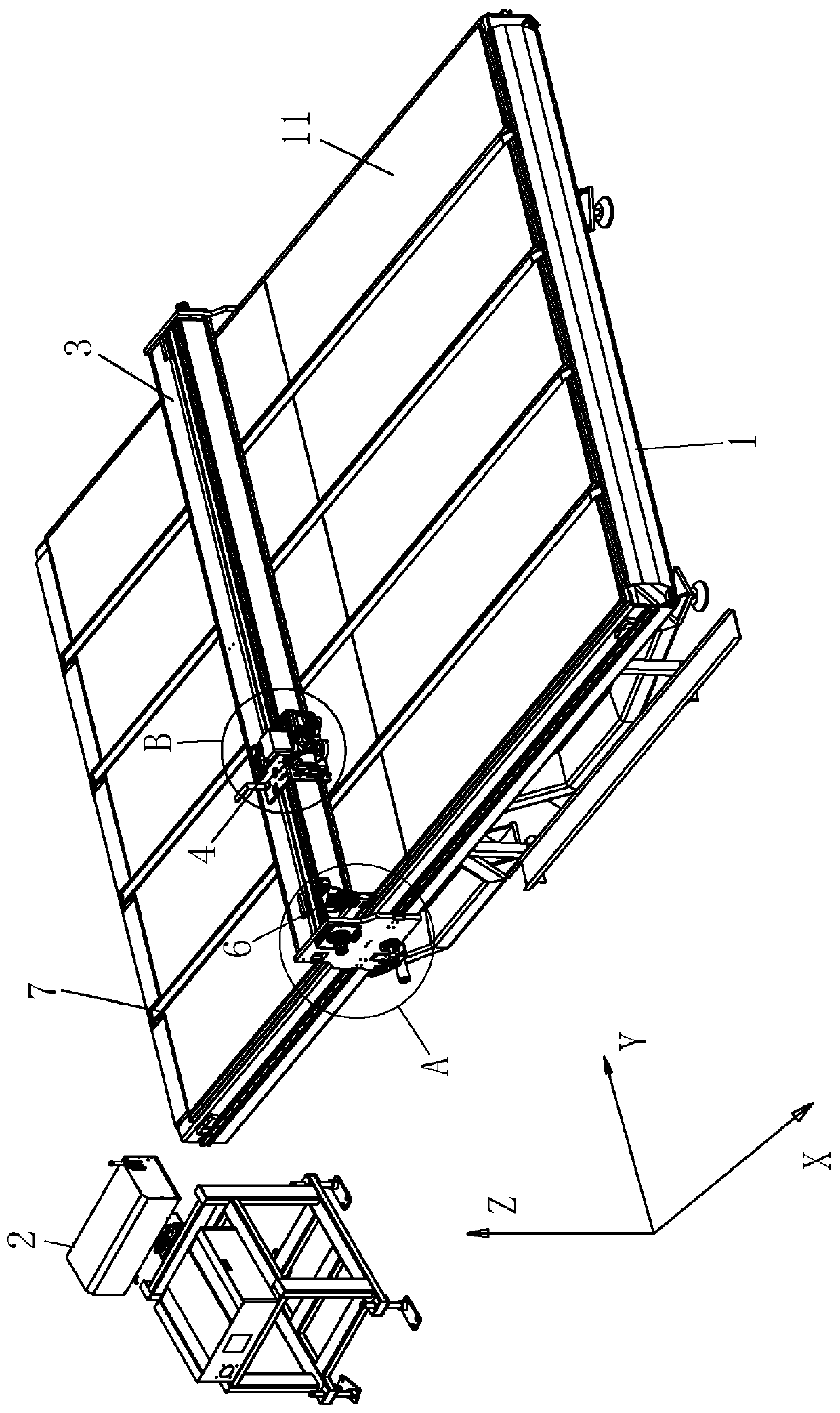

Full-automatic glass laser melting marking equipment and working method thereof

PendingCN110842370ASimple structureAchieve traceabilityWelding/soldering/cutting articlesLaser beam welding apparatusProduction lineGalvanometer

The invention relates to full-automatic glass laser melting marking equipment and a working method thereof. The full-automatic glass laser melting marking equipment is characterized in that a glass bearing platform is mounted on a rack, a laser generator device is arranged beside the rack for generating a laser beam, an X-axis moving beam assembly is located above the glass bearing platform and can move in the X-axis direction, a Y-axis moving mechanism is mounted on the X-axis moving beam assembly, an optical path setting mechanism is mounted at one end of the X-axis moving beam assembly andis used for receiving the laser beam generated by the laser generator device and sequentially refracting the laser beam onto a galvanometer and a field lens, an optical fiber edge finding probe, the galvanometer and the field lens are all mounted on the Y-axis moving mechanism, and the field lens can do lifting motion in the Z-axis direction. The marking equipment is perfect in system, simple andreasonable in structure, and capable of performing machining of identifications such as surface bar codes and two-dimensional codes on glass of different specifications, so that the unique identity which cannot be washed and eliminated is endowed to a glass product, and the traceability of machining the product in the subsequent working process of a production line connected with the marking equipment is greatly improved.

Owner:浙江愚工智能设备有限公司

Detection method for melting effect between cast copper cooling wall body for blast furnace and cast-in cooling water pipe for blast furnace

ActiveCN105588880AHigh feasibilityEasy to detectAnalysing solids using sonic/ultrasonic/infrasonic wavesCopperHot blast

Owner:武钢集团襄阳重型装备材料有限公司 +1

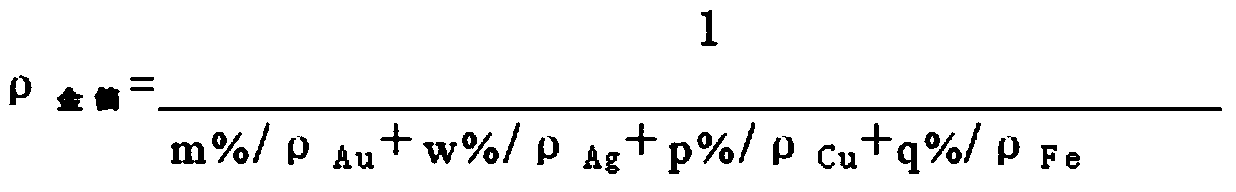

Method for measuring thickness of gold foil product

PendingCN111089556AAccurate thickness measurementMeets requirementsMeasurement devicesOptical spectrometerMaterials science

The present invention discloses a method for measuring the thickness of a gold foil product. The gold foil product is subjected to component measurement according to a measurement method of QB / T1734 and GB / T 21198.6 by adopting an inductive coupling plasma emission spectrometer, and according to the percentage content and density of constituent elements, the comprehensive density of gold foil is calculated out. A vernier caliper is used for accurately measuring the length and width of the gold foil at the same time, a precision balance is used for weighing the mass of the gold foil, and finally the exact thickness of the gold foil product is calculated out according to the mass, length, width and comprehensive density of the gold foil.

Owner:NANJING INST OF PROD QUALITY INSPECTION

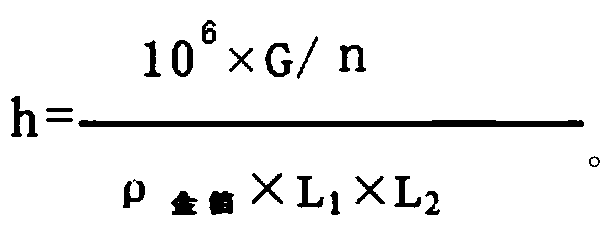

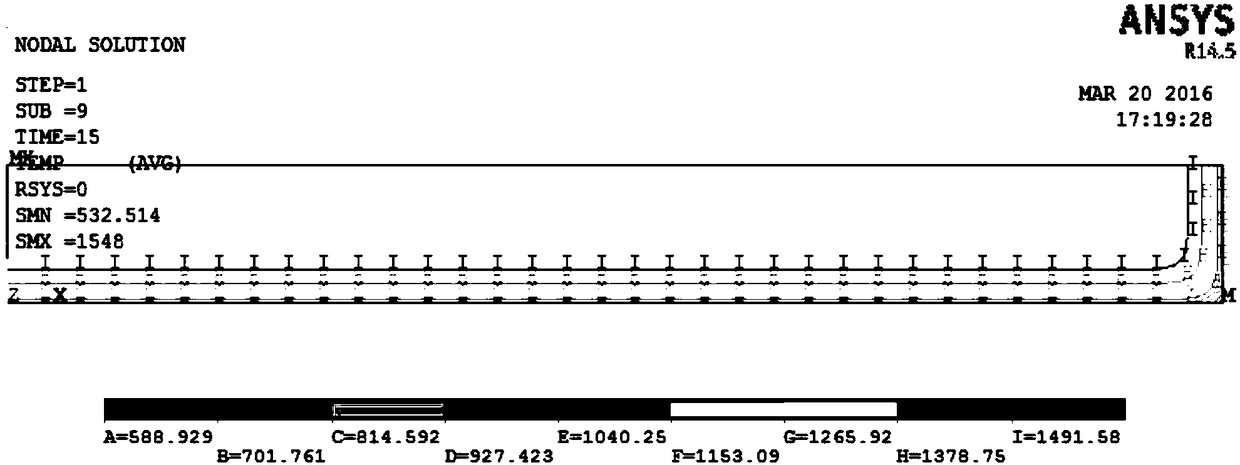

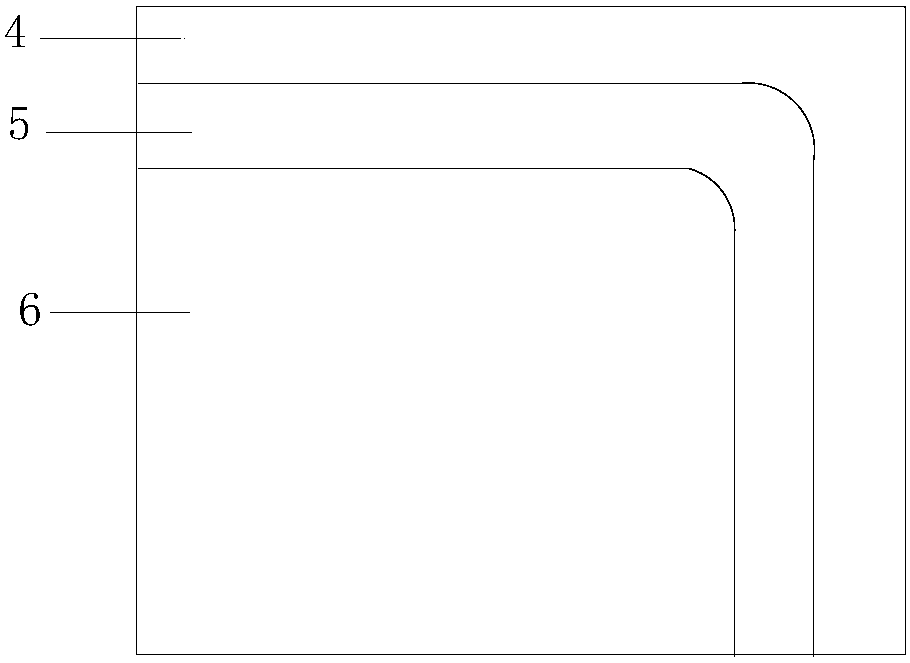

Laser height pole device capable of controlling flatness of masonry

InactiveCN111636695AAccurate length measurementAccurate width measurementBuilding material handlingStructural engineeringControl theory

The invention discloses a laser height pole device capable of controlling the flatness of masonry. The laser height pole device capable of controlling the flatness of the masonry comprises a levelingbase, a vertical rod is fixedly connected to the leveling base, the vertical rod is perpendicular to the leveling base, and a cross rod is fixedly connected to the vertical rod. The cross rod and thevertical rod are perpendicular to each other; the vertical rod is movably connected with a sleeve, the sleeve is located above the cross rod, the sleeve is fixedly connected with a longitudinal measuring rod, the longitudinal measuring rod is perpendicular to the vertical rod, and a vertical rod limiting block is arranged at the top end of the vertical rod; the vertical rod, the cross rod and thelongitudinal measuring rod are all height poles, the vertical rod, the cross rod and the longitudinal measuring rod are all telescopic rods, and the leveling base is in bolted connection with a vertical rod inserting cylinder; and the vertical rod is fixedly connected with a leveling base plate through an inserting groove, the leveling base is in bolted connection with a counterweight, and the leveling base is in bolted connection with a horizontal air bubble meter. The laser height pole device capable of controlling the flatness of the masonry has the advantages of high precision, rich functions, simple operation, convenient carrying and use and the like. The laser height pole device capable of controlling the flatness of the masonry has the function of controlling the flatness of the masonry wall.

Owner:CHINA MCC17 GRP

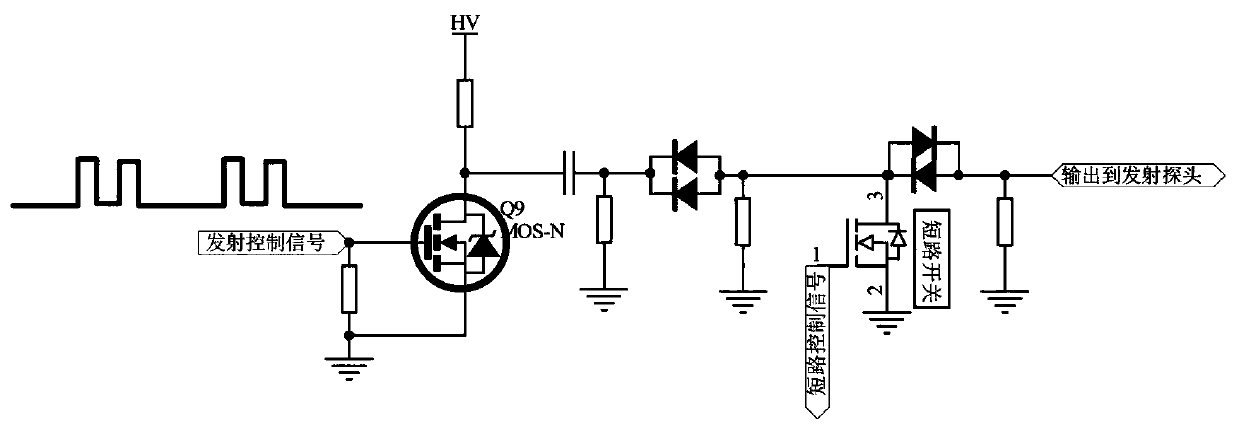

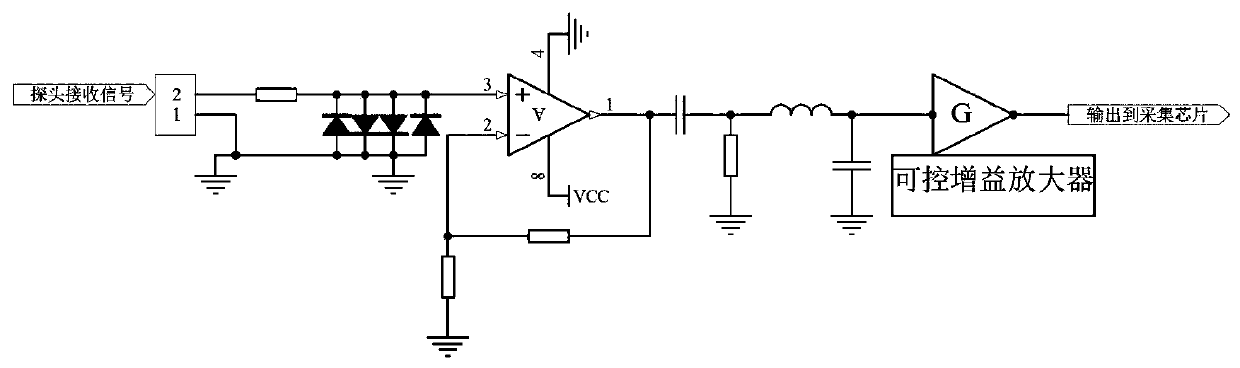

An eddy current detection method for continuous casting billet shell thickness

ActiveCN106289037BWork reliablyAccurate thickness measurementElectrical/magnetic thickness measurementsElectricitySignal conditioning circuits

The invention discloses a continuous casting billet shell thickness eddy current detection method, and belongs to the technical field of continuous casting billet detection. The object is to overcome the defect of measurement of the thickness of a continuous casting solidification shell in the prior art and provide a method for measuring the thickness of the continuous casting billet shell by employing a multifrequency eddy current measuring method and dividing the inner part of billet into layers according to the conductivity corresponding to the temperature. The method specifically includes steps: an eddy current sensor is arranged on the surface of a casting blank at an outlet of a continuous casting mold, the sensor is a mutual induction differential type sensor, the eddy current sensor performs frequency mixing excitation through a digital frequency synthesizer, frequency mixing of a plurality of excited different frequency signals is performed through an adder, measuring signals are amplified and filtered through a signal conditioning circuit, cross-correlation operation is performed with reference signals of different frequencies in a correlator, the signals are separated, amplitude-phase separation of eddy current impedance signals is performed, the separated signals are transmitted to a computer for data processing through acquisition and conversion, and the thickness of the continuous casting billet shell is obtained.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

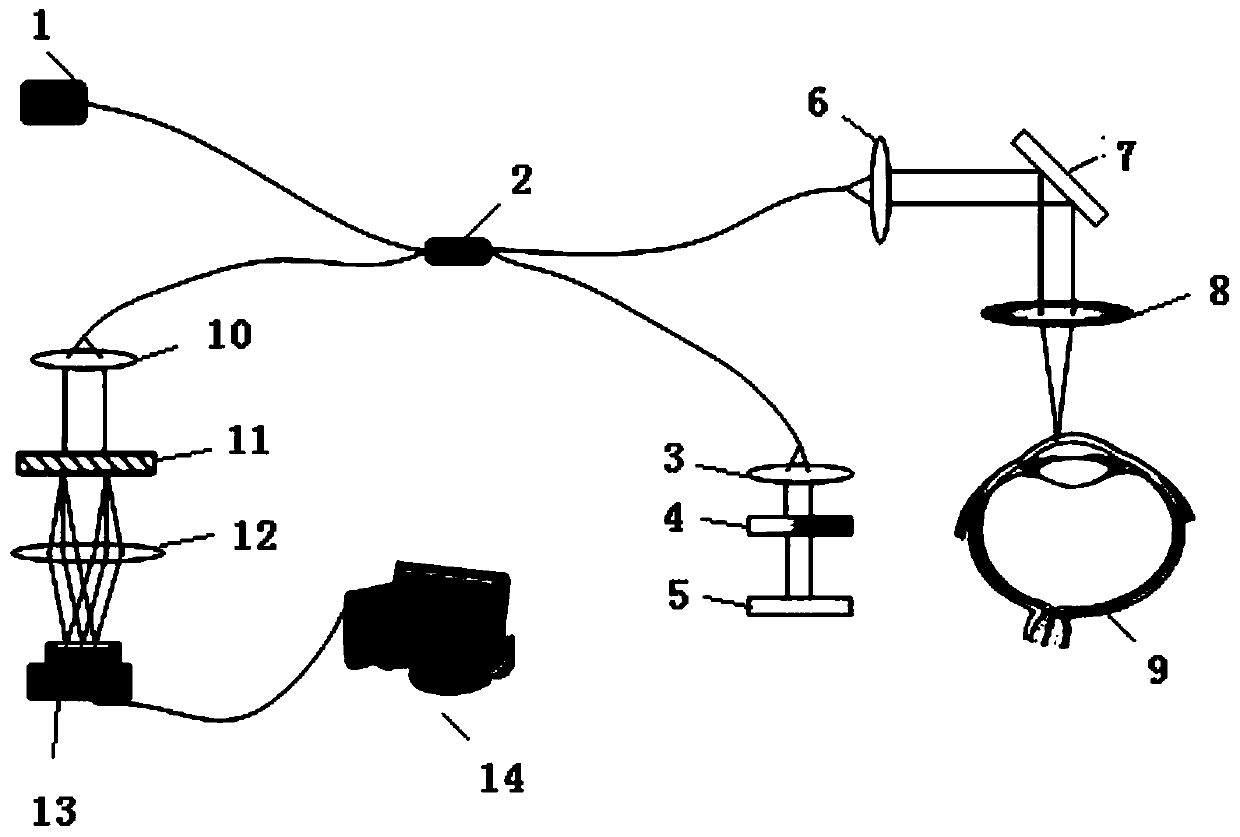

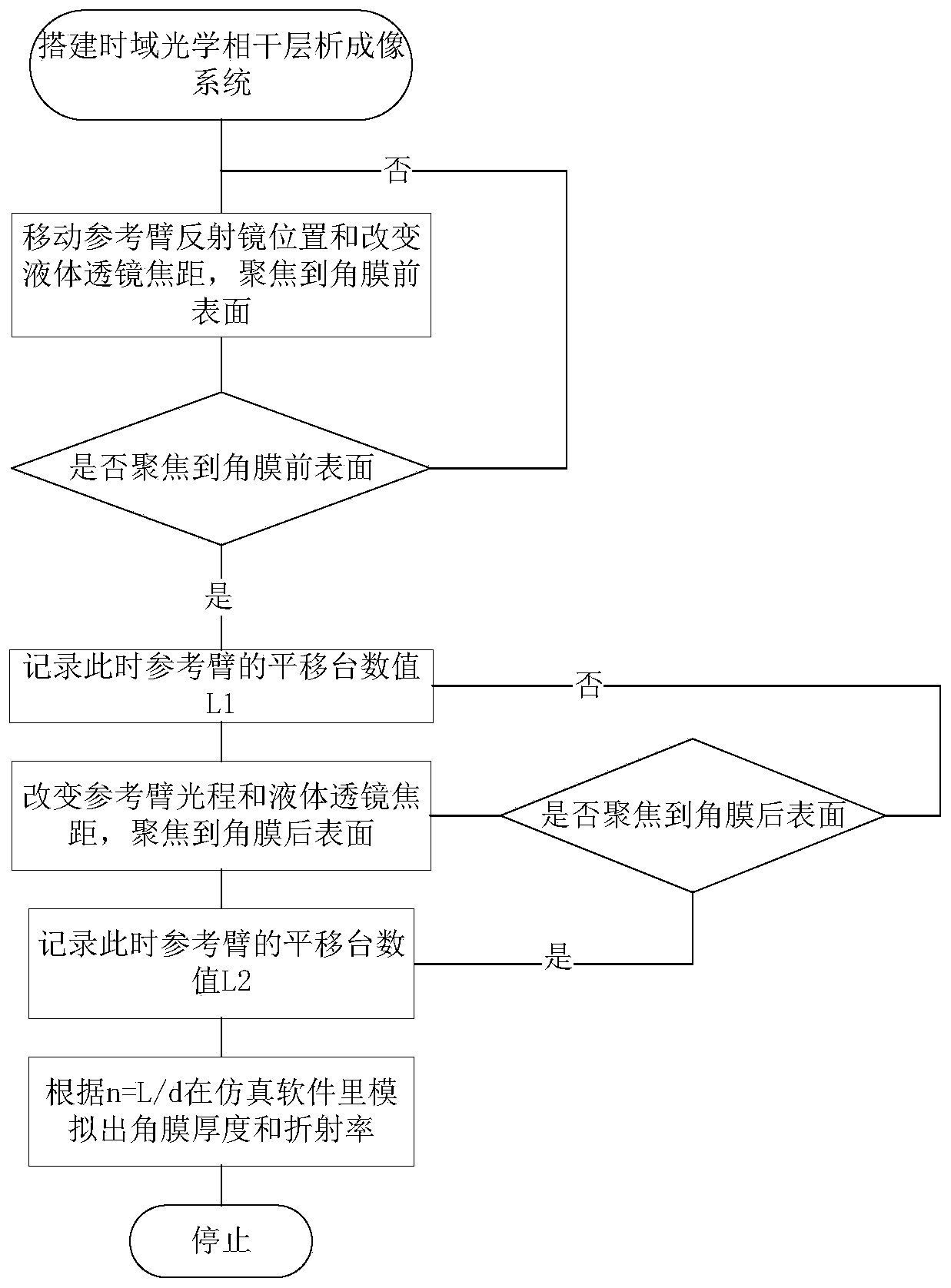

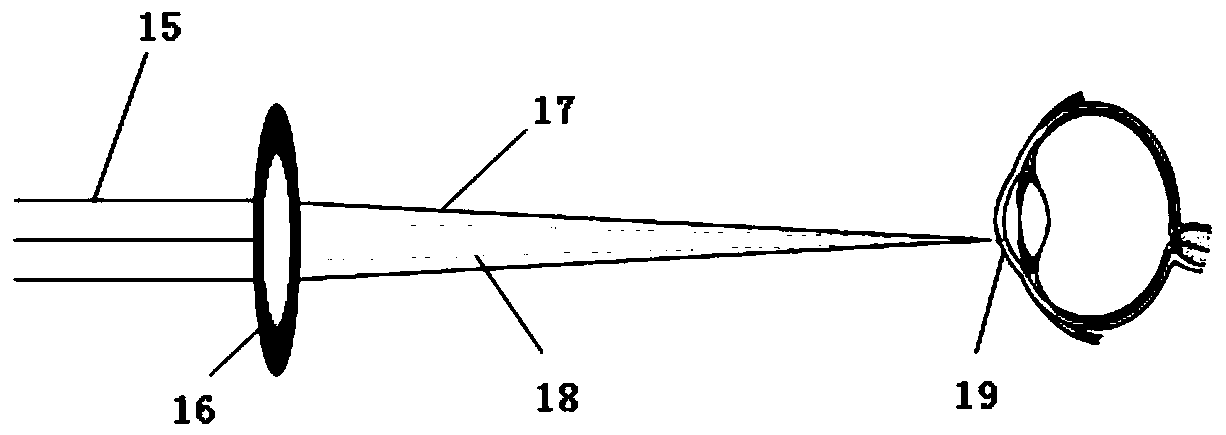

Cornea surface optical path difference measuring device and method of measuring cornea thickness and refractivity

PendingCN109691972AAccurate thickness measurementHigh precisionEye diagnosticsKeratorefractive surgeryHigh resolution imaging

A time domain-optical coherence tomography (TD-OCT) technology is adopted to carry out high resolution imaging on a human cornea; the thickness of the human cornea can be accurately measured by usinga quick zoom lens; through the moving distance of a reference arm, the optical path difference between the front surface and the rear surface of a cornea can be calculated, thus the refractivity of the cornea can be calculated by ZEMAX optical simulation software; and the method is noncontact and is used to measure the thickness and refractivity of a cornea. The method can measure the thickness and refractivity of a cornea in a human body, the measurement is noncontact, high precision, and nondestructive; moreover, after a corneal surgery, the thickness and refractivity of corneas can be tracked, and at the same time, a preoperative detection device and method are provided for a refractive surgery.

Owner:FOSHAN UNIVERSITY

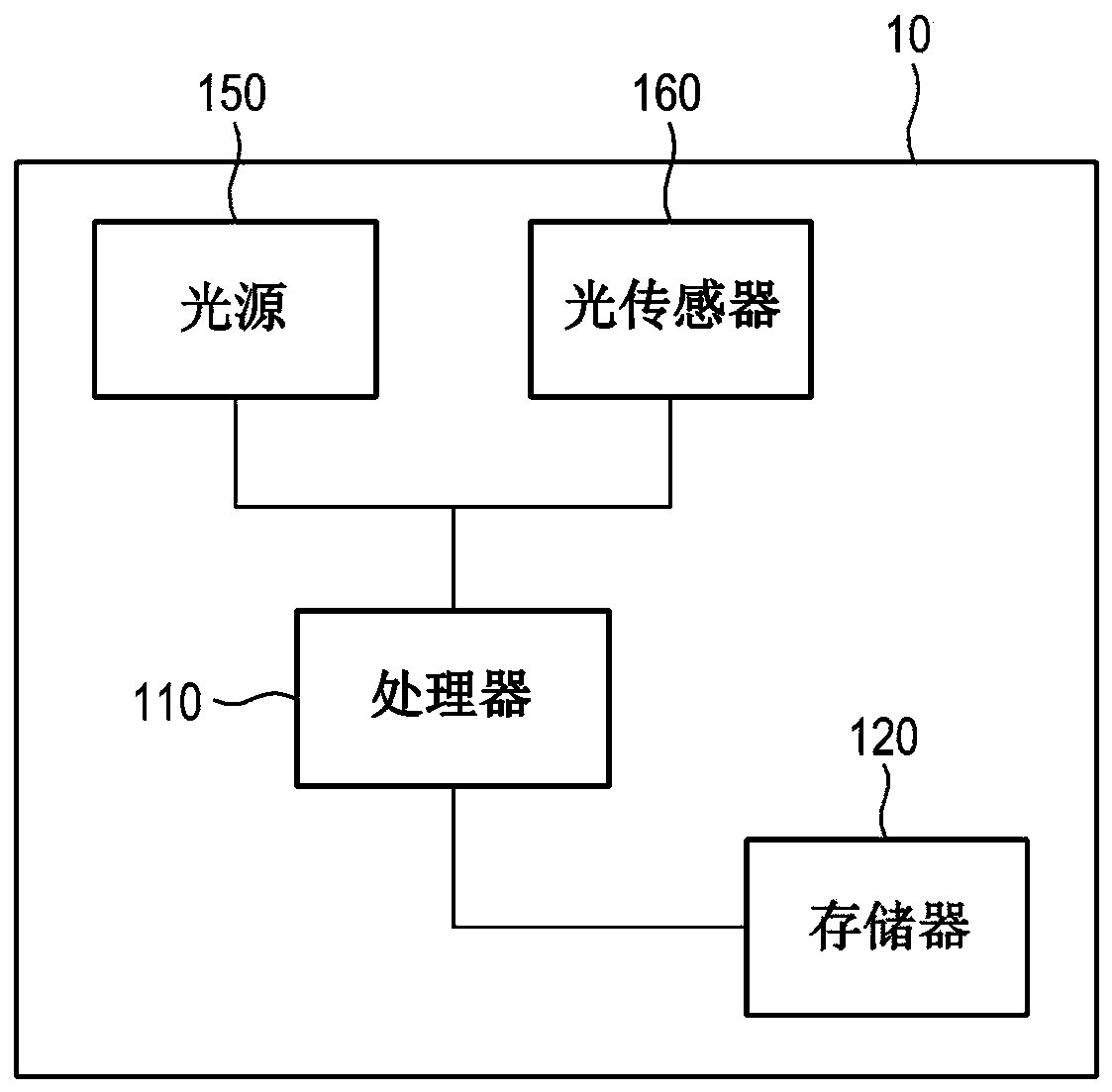

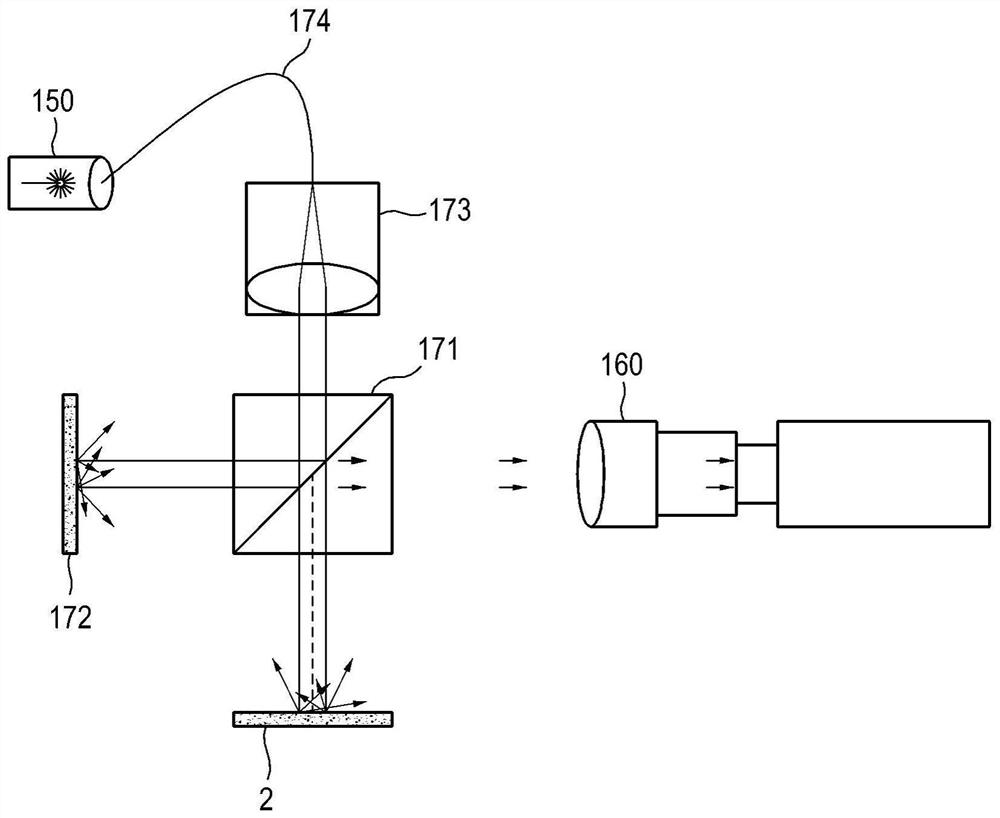

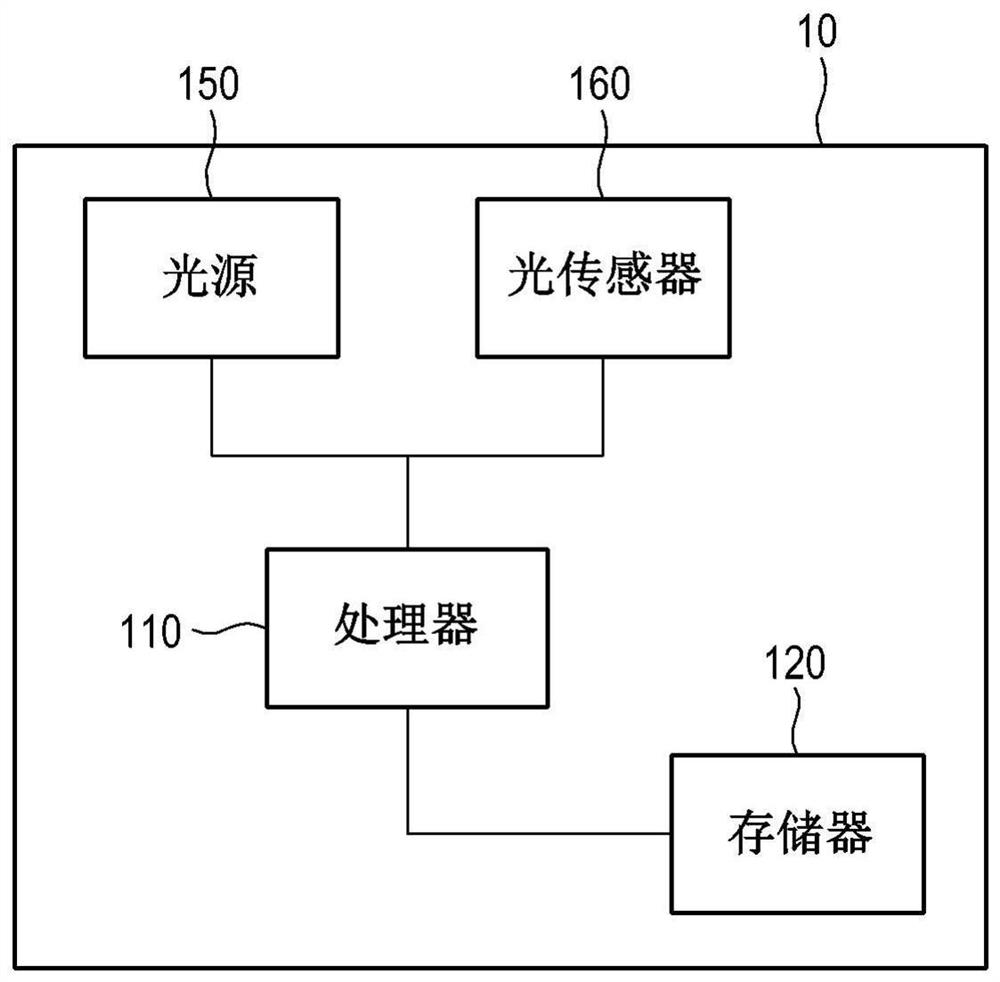

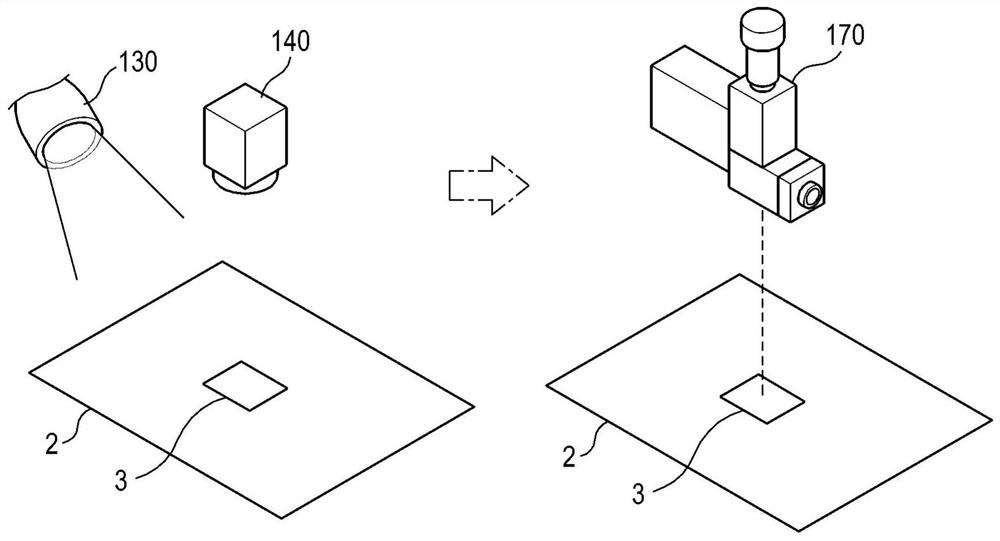

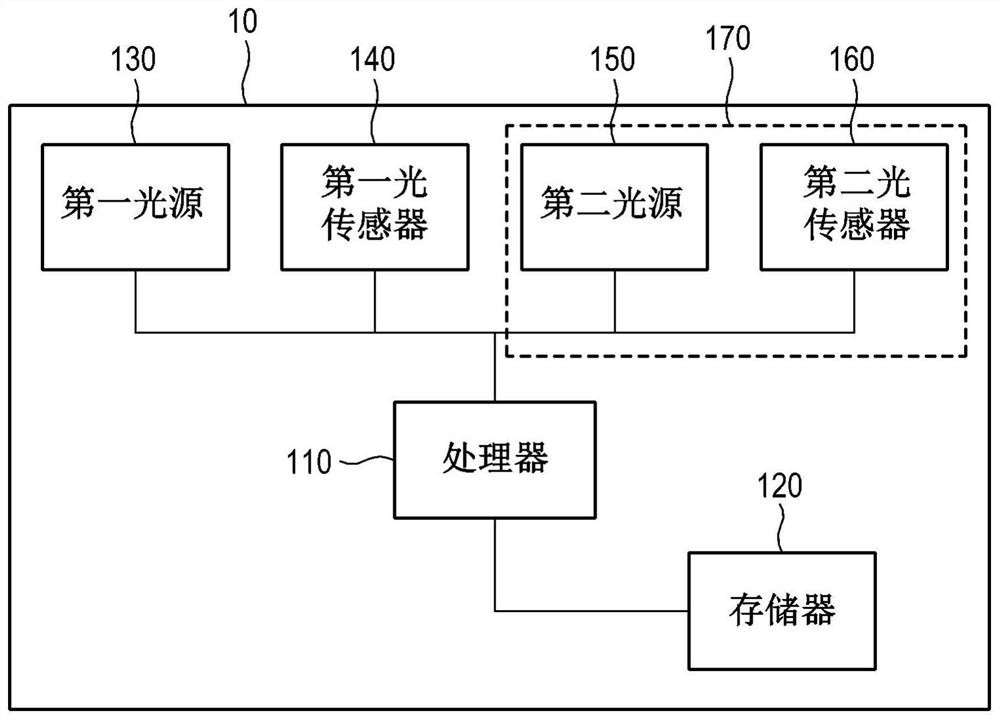

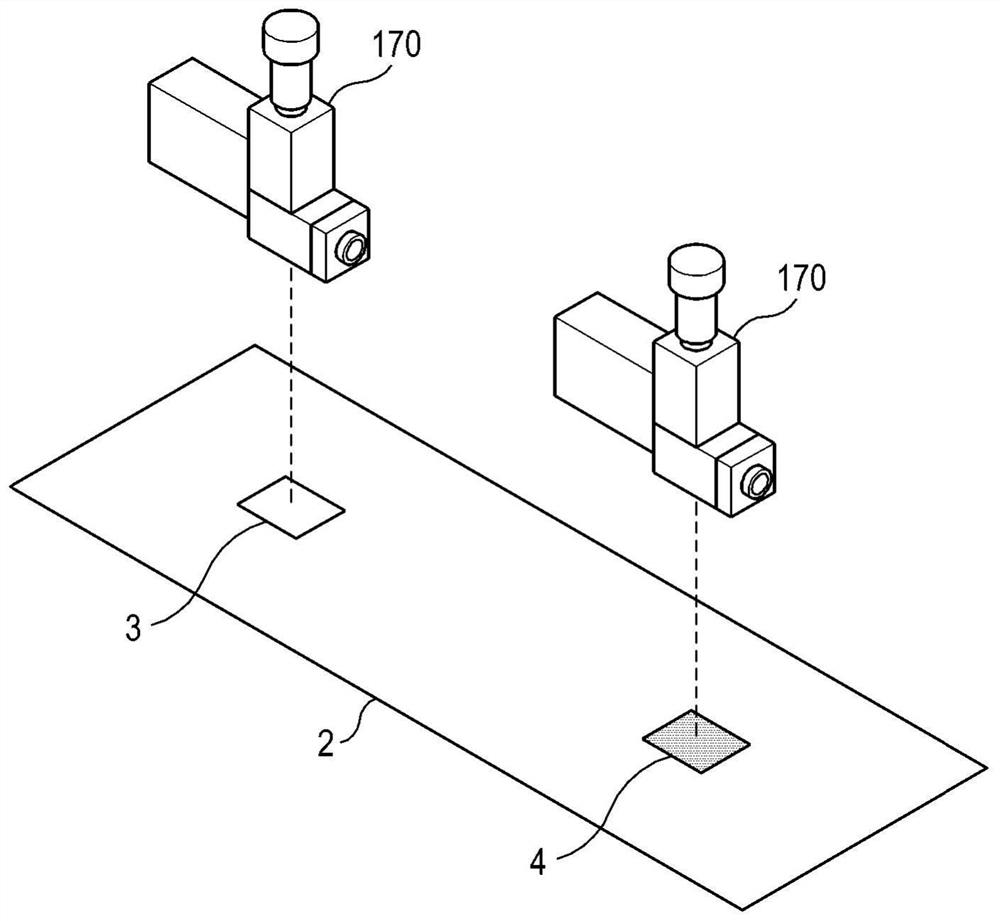

Apparatus for inspecting substrate and method thereof

ActiveCN109974599AAccurate thickness measurementReduce measurement errorsUsing optical meansLaser lightOptoelectronics

The disclosure provides a substrate inspection apparatus. The substrate inspection apparatus according to the present disclosure may include: a light source configured to radiate laser light onto a coated film that is spread on a region of a substrate; a light detector configured to obtain optical interference data caused by an interference between reference light, that is generated by the laser light being reflected from a surface of the coated film, and measurement light, that is generated by the laser light penetrating the coated film and being scattered; and a processor configured to derive a thickness of the coated film corresponding to the region, based on the optical interference data.

Owner:株式会社高迎科技

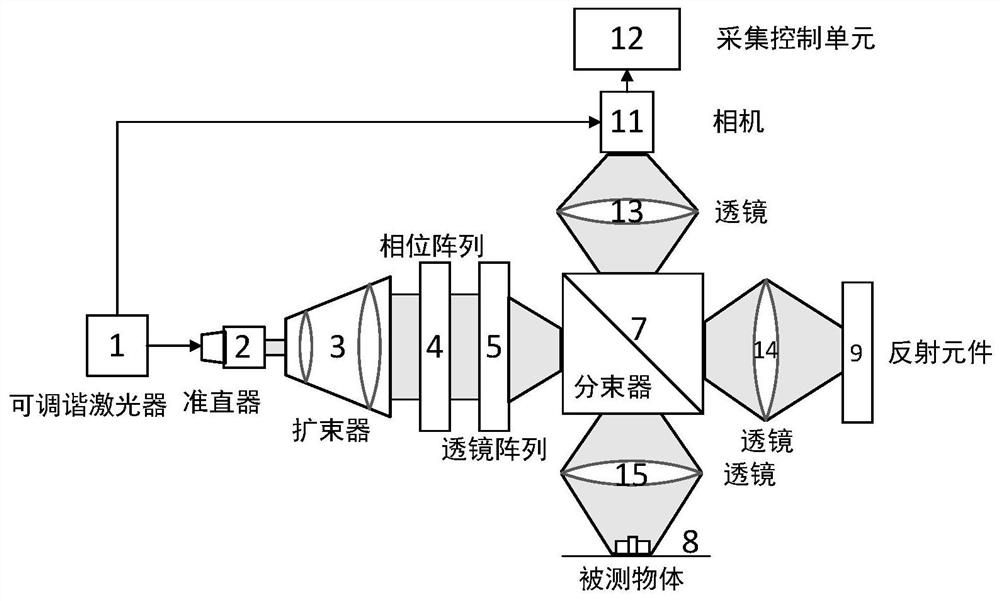

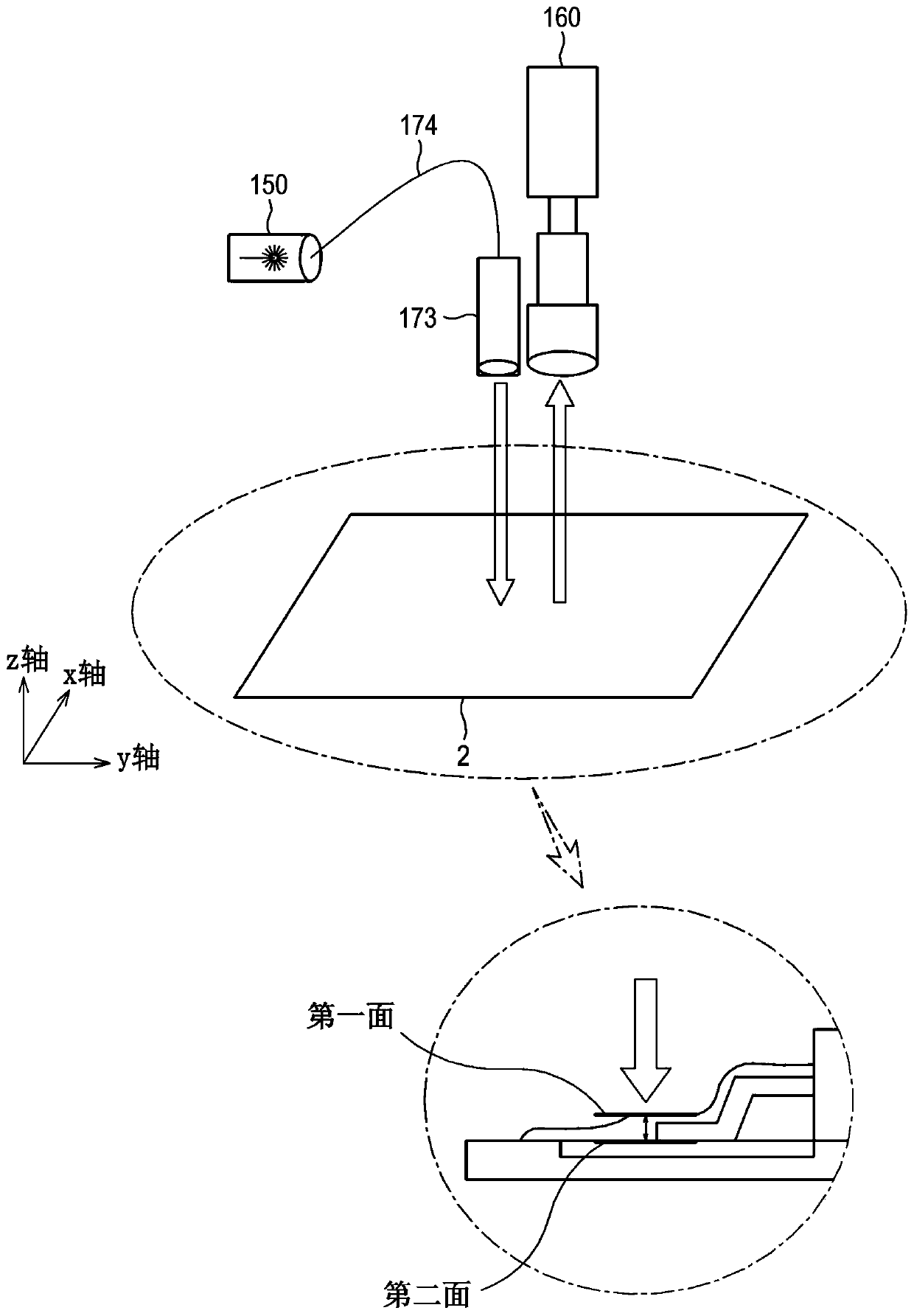

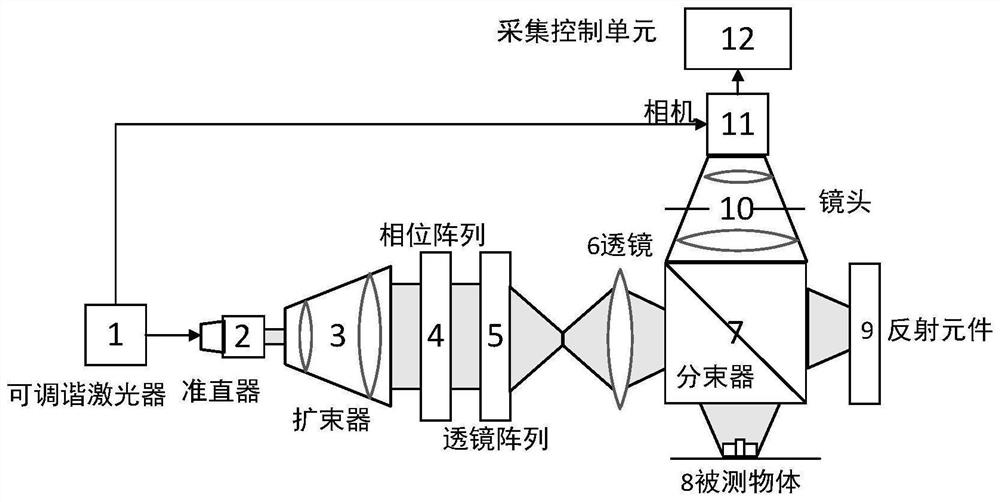

Area array sweep frequency measurement device and method

PendingCN112684460AReduce Speckle ContrastInfluence 3D Position AnalysisUsing optical meansElectromagnetic wave reradiationBeam splitterControl cell

The invention provides an area array sweep frequency measurement device and method, and belongs to the technical field of laser ranging. The device comprises a tunable laser, a collimator, a beam expander, a phase array, a lens array, a first lens, a beam splitter, a lens, a camera, an acquisition control unit, and a reflection element. The tunable laser is used for providing a laser beam; the phase array is used for carrying out phase modulation on the expanded parallel light; the lens array is used for focusing the light beams output by each phase array; the beam splitter is used for splitting the light beam output by the first lens into reflection light and transmission light; the reflection element is used for reflecting the transmission light to form reference light; during working, a measured object reflects reflection light to form signal light; the signal light and the reference light interfere to form an interference pattern; the camera is used for collecting the interference image; and the acquisition control unit is used for analyzing the surface topography of the measured object according to the interference image. Through superposition of a plurality of independent speckles, the effect of reducing the speckle contrast is achieved.

Owner:武汉光目科技有限公司

Method and apparatus for measuring the thickness of a transparent object in an automatic production line

ActiveUS9127932B2Accurate thickness measurementMaterial analysis by optical meansUsing optical meansProduction lineEngineering

An apparatus (100) and a method for measuring the thickness (s) for a wall (35) of a transparent object (30); the wall (35) comprises a transparent material (35a) arranged between a proximal interface (31), set between an environment (33) and the transparent material (35a), and a distal interface (32), set between said transparent material (35a) and the environment (33). The apparatus (100) comprises a source (1) of a starting light radiation (2) and a means for focusing it (10), in order to obtain an entering light radiation (5) directed towards the wall (35) that hits the proximal interface (31) of the wall (35) of the object and is in part reflected, in order to generate a first reflected radiation (6). A part of the entering light radiation (5) that is transmitted (7), through the transparent material (35a), hitting upon the distal interface (32), is in turn reflected (8) and crosses in an opposite direction the transparent material (35a) through the proximal interface (31), in order to generate a second reflected radiation (9). A collected radiation (15) given by overlapping the first (6) and second (9) reflected radiations have a difference of intensity that is configured to obtain an interference, which allows determining the thickness (s) of the wall (35). In particular, the means for focusing comprises a lens means (10) that have two main meridians (10a, 10b) orthogonal to each other, such that the entering light radiation (5) is focused on a first virtual focus (F1) in the first meridian plane (10a), and on a second virtual focus (F2) in the second meridian plane (10b). This way, it is obtained that the collected radiation (15) is substantially independent from possible movements of the transparent object (30), and this allows a remarkable reliability and robustness of the measurement with respect to fluctuations and vibrations of the object (30).

Owner:GERRESHEIMER PISA

Substrate inspection device and substrate inspection method

ActiveCN109974599BAccurate thickness measurementReduce measurement errorsUsing optical meansEngineeringLaser light

The present disclosure proposes a substrate inspection device. The substrate inspection apparatus of the present disclosure may include: a light source that irradiates laser light toward a coating film coated on an area on a substrate; an optical sensor that obtains a reference generated by the laser light being reflected by the surface of the coating film light interference data caused by interference between light and measurement light scattered by the laser light through the coating film; and a processor that derives the coating corresponding to the one region based on the light interference data. The thickness of the film.

Owner:株式会社高迎科技

Area array sweep frequency measurement device and method

PendingCN112711029AAvoid mechanical scanning errorsImprove accuracyElectromagnetic wave reradiationBeam splitterControl cell

The invention provides an area array sweep frequency measurement device and method, and belongs to the technical field of laser ranging, and the device comprises a tunable laser, a first collimator, a first beam expander, a first beam splitter, a lens, a reflection element, a camera, and an acquisition control unit. The tunable laser is used for controlling the camera to acquire an interference image by sending a trigger signal and providing an original light beam; the first beam splitter is used for splitting the collimated and expanded light beam into a first light beam and a second light beam, and the first light beam irradiates a to-be-measured object and then is reflected; the reflection element is used for reflecting the second light beam to form reference light; and the camera is used for collecting an interference image formed by interference of the first reflected light and the reference light. According to the invention, a traditional point detection acquisition mode is replaced to acquire the surface topography, mechanical scanning errors introduced during point detection are avoided, and the measurement accuracy in a general field of view is improved.

Owner:武汉光目科技有限公司

Object position independent method to measure the thickness of coatings deposited on curved objects moving at high rates

ActiveUS10788314B2Accurate measurementLittle changeOptically investigating flaws/contaminationUsing optical meansHigh rateLayer thickness

Methods and apparatus for measuring a thickness of a coating on an moving object are provided. Light is directed toward the object at a predetermined location on the object such that a portion of the light interacts with the object. A I D and / or 2D maximum intensities for at least one wavelength channel is captured that is produced by the portion of the light interacting with the object. A measured average intensity of the wavelength channel and / or intensities and their arithmetic derivatives of multi wavelength channel geometries is converted into I D (averaged) and / or 2D thickness values. Based on these values an acceptability of the coating is evaluated and thickness calculated.

Owner:ARKEMA INC

Substrate inspection device and substrate inspection method

ActiveCN109974598BAccurate thickness measurementShorten the timeUsing optical meansFirst lightEngineering

The substrate inspection apparatus of the present disclosure may include: a first light source that irradiates ultraviolet rays toward a coating film of a substrate mixed with a fluorescent dye; a first photosensor that captures fluorescence generated from the coating film irradiated from the ultraviolet rays and obtaining a two-dimensional image of the substrate; a processor that derives one of a plurality of regions of the substrate based on the two-dimensional image; a second light source that irradiates laser light toward the one region; and a second light a sensor that obtains light interference data occurring from the one area by means of the laser light; the processor can derive a thickness of the coating film with respect to the one area based on the light interference data.

Owner:GAOYING TECH CO LTD

A kind of maintenance and testing equipment for coating machine

ActiveCN108716882BCladding effectAccurate thickness measurementMechanical thickness measurementsStructural engineeringMachine

The invention discloses a maintenance and testing device for a cladding machine, which comprises a base, two wheel grooves are arranged at the lower end of the base, a first guide rod is fixed on the upper end of the wheel groove, and the lower end of the first guide rod The first block is fixed, the first guide rod is provided with a wheel plate slidingly connected with it, the lower end of the wheel plate is fixed with a universal wheel, the upper end of the wheel plate is fixed with a vertical rod, and the vertical rod Pass through the base and be fixed on the lower end of the horizontal plate. In the present invention, by setting the wheels that can be hidden, when it is installed at the feeding end and the discharging end of the coating machine, the universal wheel at the bottom of the device is retracted to make the device more stable, and the first anti-static layer is set to prevent static electricity from affecting the material For cladding, by setting a roller whose size is determined according to the actual situation and a roller whose length can be changed at any time, the thickness of the cladding material can be accurately measured during the cladding, and whether there is a fault in the structure of the device can be obtained according to the thickness.

Owner:蒋祥初

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com