Full-automatic glass laser melting marking equipment and working method thereof

A glass laser and marking equipment technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of heavy load of three-axis motion mechanism, easy damage of laser generator, poor traceability of glass products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074]The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0075] Example.

[0076] see Figure 1 to Figure 17 .

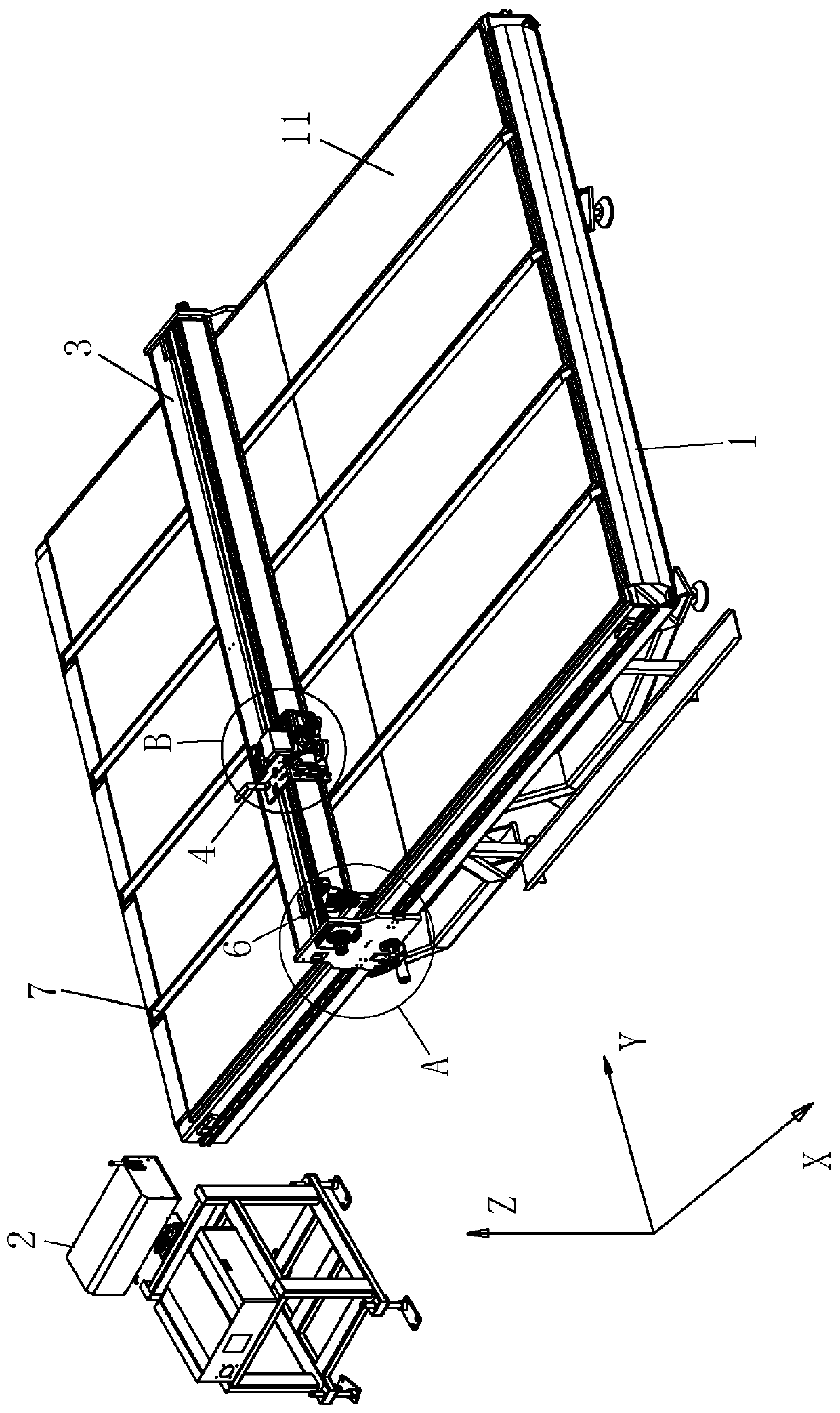

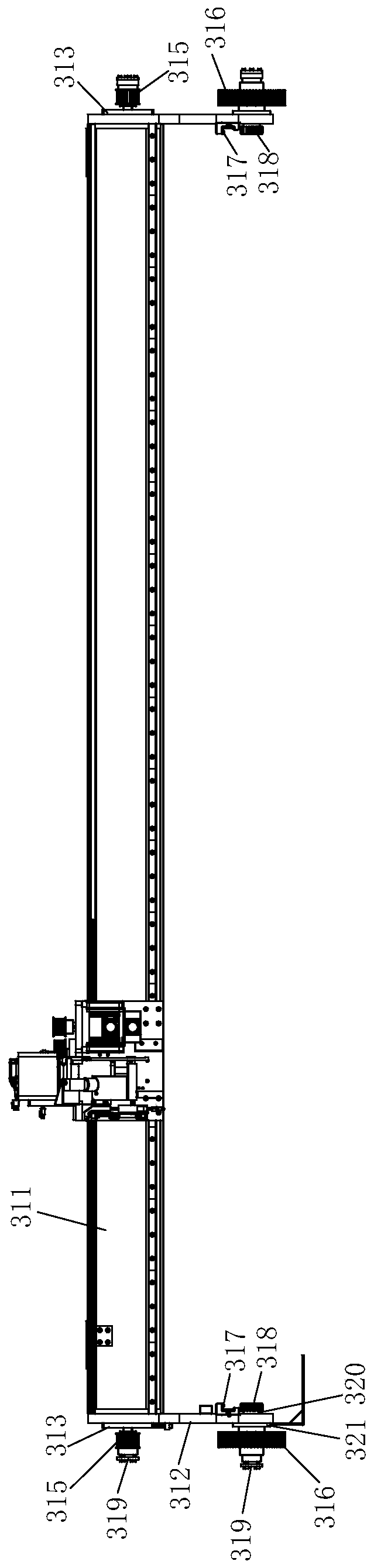

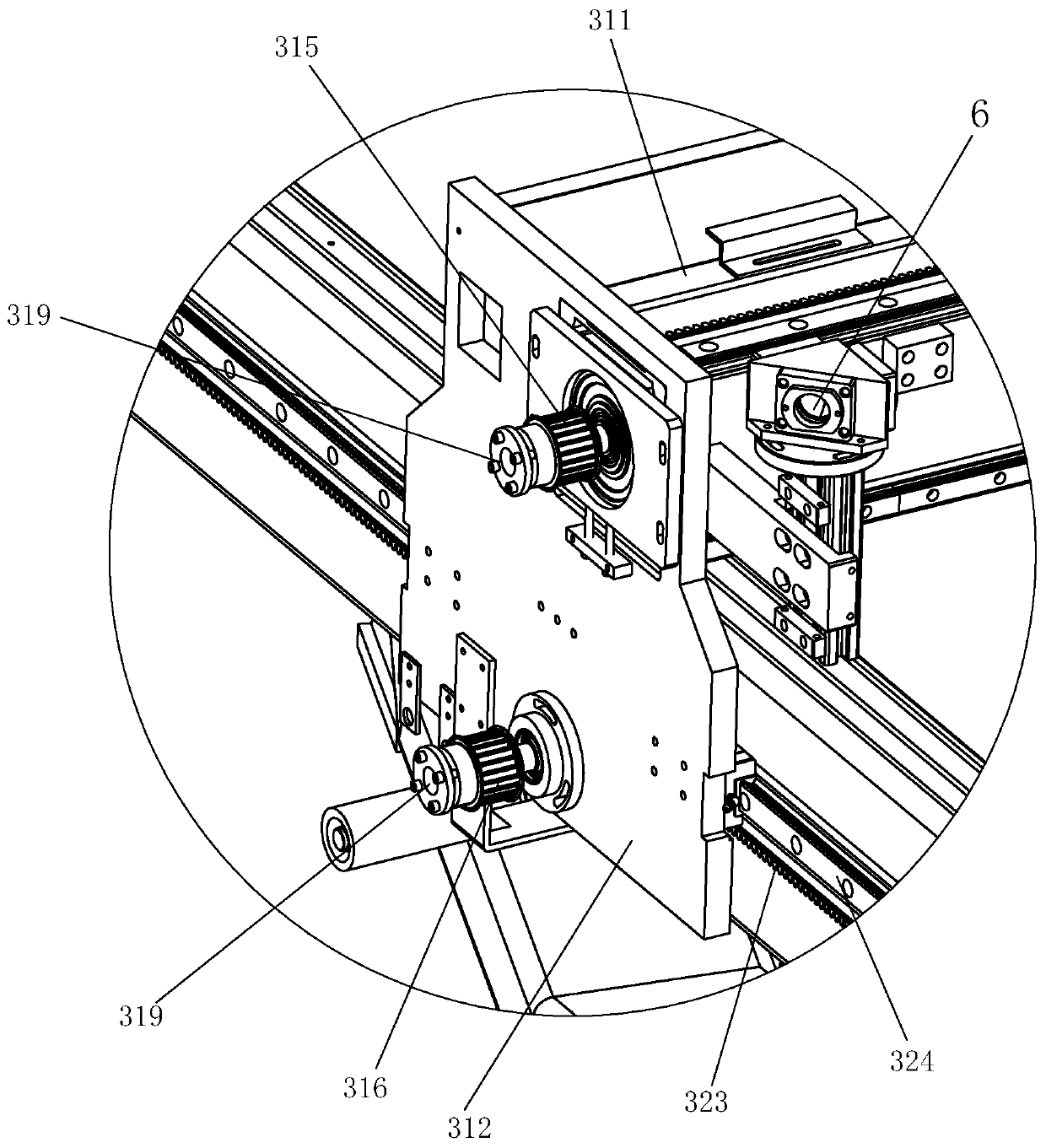

[0077] This embodiment discloses a fully automatic glass laser melting marking equipment, including a frame 1, a laser generator device 2, an X-axis moving beam assembly 3, a Y-axis moving mechanism 4, a vibrating mirror 422, a field mirror 521, an optical fiber Edge-finding probe 525, optical path setting mechanism 6, glass lifting and conveying mechanism 7 and central controller. The spatial Cartesian coordinate system where the device is located refers to figure 1 The coordinate system shown in .

[0078] In this embodiment, the frame 1 is equipped with a glass carrier platform 11 for carrying the glass to be processed; the laser generator device 2 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com