Device for measuring thickness of rubber-coated steel cord

A measuring device and steel wire coating technology, which is applied in the direction of mechanical thickness measurement, etc., can solve the problems of rubber creep measurement data, instability, and difficulty in accurately importing the measurement product, and achieves the effect of simple operation, accurate thickness and accurate measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

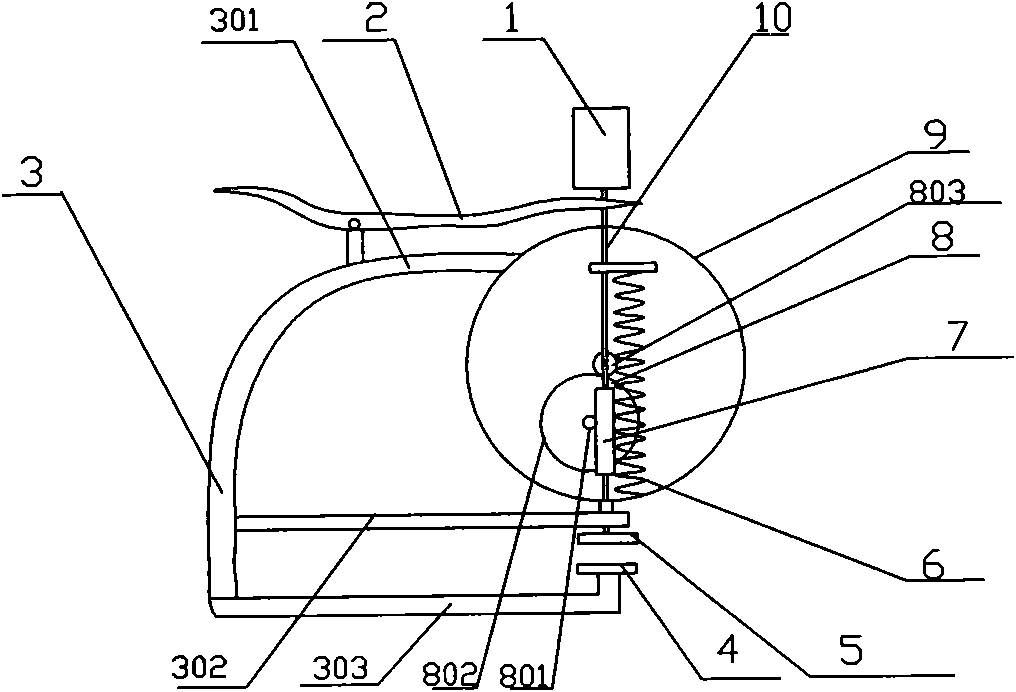

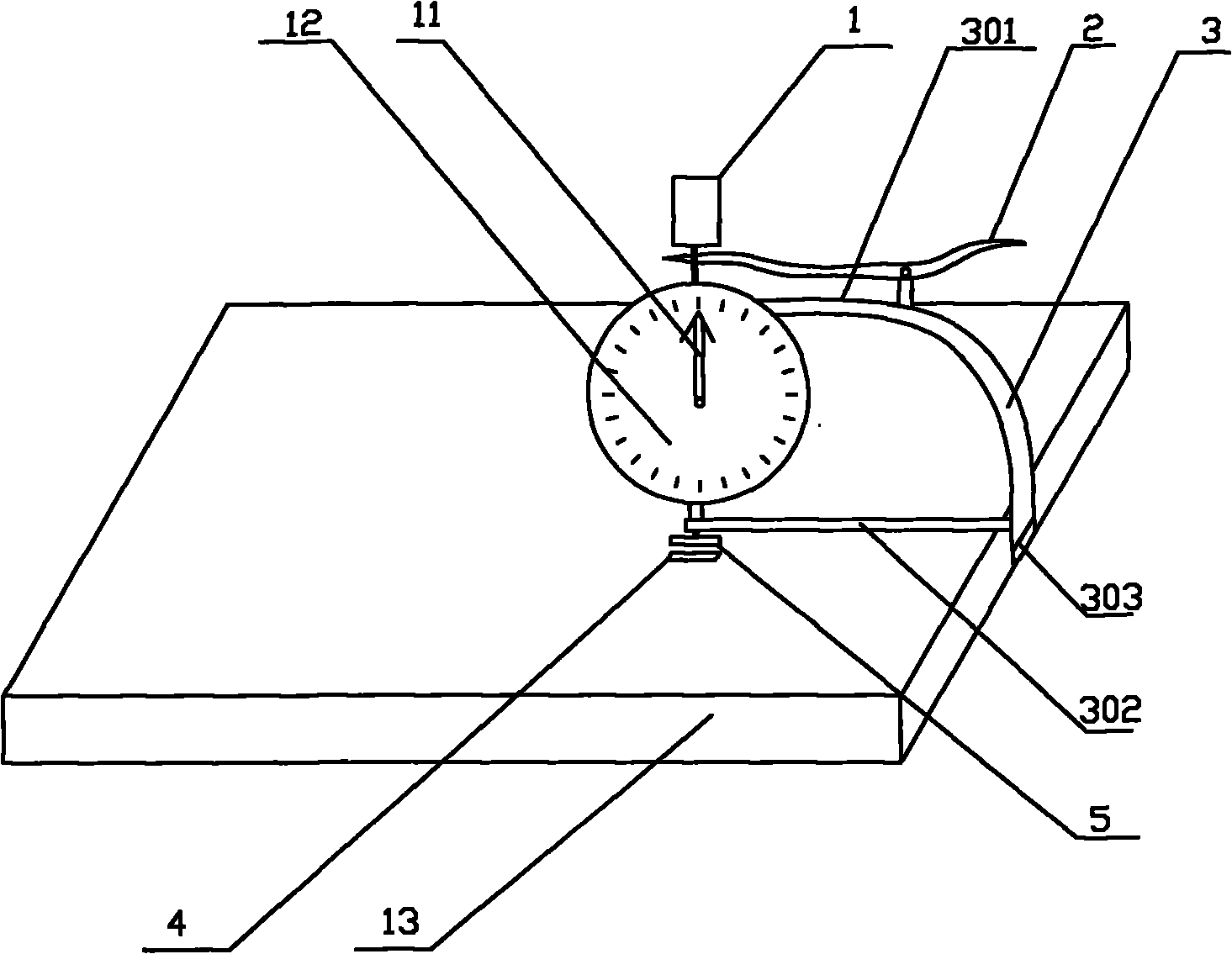

[0011] The utility model relates to a measuring device for the thickness of a rubber-coated steel cord, which includes a dial gauge thickness gauge. Such as figure 1 , figure 2 As shown, the dial gauge thickness gauge is composed of a weight 1, a shift fork 2, a table frame 3, a lower probe 4, an upper probe 5, a return spring 6, a dial indicator body 9, a measuring rod 10, a pointer 11, The dial is composed of 12.

[0012] exist figure 1 Among them, the watch frame 3 is composed of a hinged part 301 , a supporting guide part 302 and a base 303 .

[0013] Such as figure 1 As shown, the dial indicator body 9 is installed on the supporting guide part 302 of the meter frame 3 .

[0014] The measuring rod 10 corresponds to the guide hole passing through the inside of the dial indicator body 9 and the supporting guide part 302. Connect, and its bottom end is threaded with upper measuring head 5.

[0015] The lower probe 4 is assembled on the base 303 of the watch frame 3 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com