Carbon fiber multifilament compression strength sample preparation and test method

A compressive strength, carbon fiber technology, applied in the field of carbon fiber multifilament compressive strength sample preparation and testing, can solve the problems of instability and failure, large dispersion, etc., to achieve the effect of easy operation, small dispersion value, and improved compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

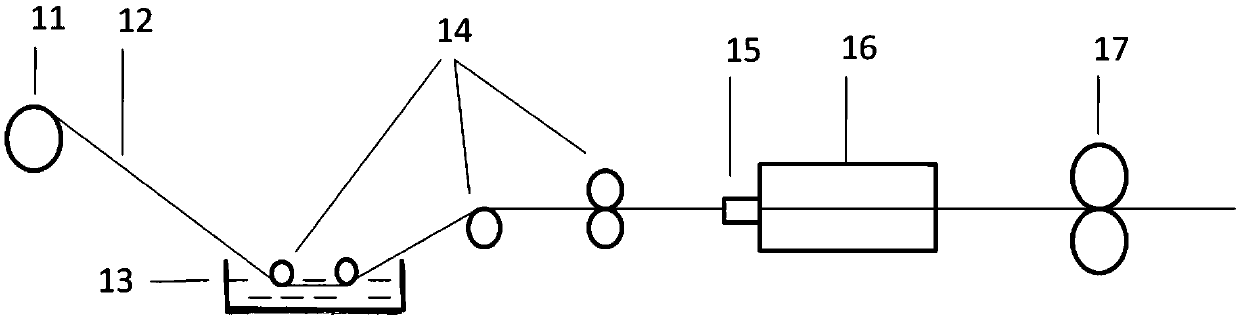

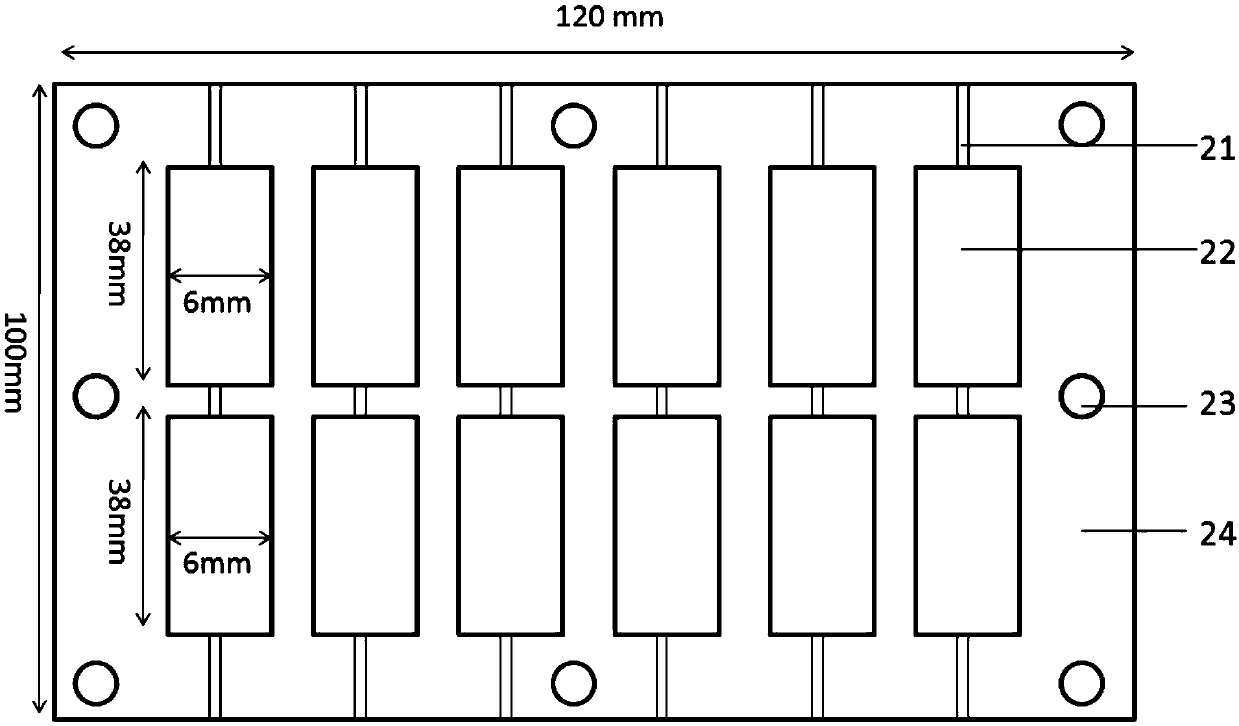

[0099] Place the Toray T300-3K carbon fiber multifilament on the unwinding creel of the automatic sample preparation device of carbon fiber multifilament rod, and perform dipping, shaping, and heating curing at a certain traction tension and speed. The glue composition is 100 parts by mass. Diglycidyl phthalate, 60 parts by mass of tetrahydrophthalic anhydride, 1 part by mass of N,N-dimethylbenzylamine and 100 parts of acetone, curing temperature is 140°C, curing time 4h, and cutting to obtain the diameter after cooling It is a 0.7mm multifilament rod; the multifilament rod is placed in the compressed sample resin reinforcement sheet sample preparation device, glued, cured, demolded, and trimmed to obtain a 1mm test section of carbon fiber multifilament compression specimen. The resin reinforcement sheet is J -22 resin, curing temperature is 40℃, curing time is 2h; the compressed sample is installed in the compression test fixture, and the compression test is carried out at a lo...

Embodiment 2

[0101] The domestic T300-3K carbon fiber multifilament is placed on the unwinding creel of the automatic sample preparation device of carbon fiber multifilament rod, and the glue is dipped, shaped, and heated and cured at a certain traction tension and speed. The glue composition is 100 parts by mass of phthalate Diglycidyl formate, 60 parts by mass of tetrahydrophthalic anhydride, 1 part by mass of N,N-dimethylbenzylamine and 100 parts of acetone, curing temperature is 140°C, curing time is 4h, and the diameter is 0.7 after cooling. mm multifilament rod; the multifilament rod is placed in the compressed sample resin reinforcement sheet sample preparation device, glued, cured, demolded, and trimmed to obtain a 1mm test section of carbon fiber multifilament compression specimen. The resin reinforcement sheet is J-22 Resin, curing temperature is 40℃, curing time is 2h; the compressed sample is installed in the compression test fixture, and the compression test is performed at a lo...

Embodiment 3

[0103] Place the Toray T700-12K carbon fiber multifilament on the unwinding creel of the automatic sample preparation device for carbon fiber multifilament rods, and perform dipping, shaping, and heating curing at a certain traction tension and speed. The glue composition is 100 parts by mass 3 ,4-epoxycyclohexanecarboxylic acid methyl ester, 40 parts by mass methylhexahydrophthalic anhydride, 2 parts by mass 2,4,6-tris(dimethylaminomethyl)phenol and 80 parts toluene, curing temperature The temperature is 160℃, the curing time is 2h, and the multifilament rod is cut after cooling to obtain a 1.2mm diameter multifilament rod; the multifilament rod is placed in the compressive strength sample preparation device, and the carbon fiber multifilament of 2mm test section is obtained by injecting, curing, demolding and trimming Compress the sample, the resin reinforcement sheet is 914 resin, the curing temperature is 50℃, and the curing time is 2h; the compressed sample is installed in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com