An eddy current detection method for continuous casting billet shell thickness

A detection method, eddy current technology, applied in the direction of electric/magnetic thickness measurement, electromagnetic measurement device, etc., can solve the problems that have not fundamentally solved the field application of industrial production, and achieve the effect of accurate thickness measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

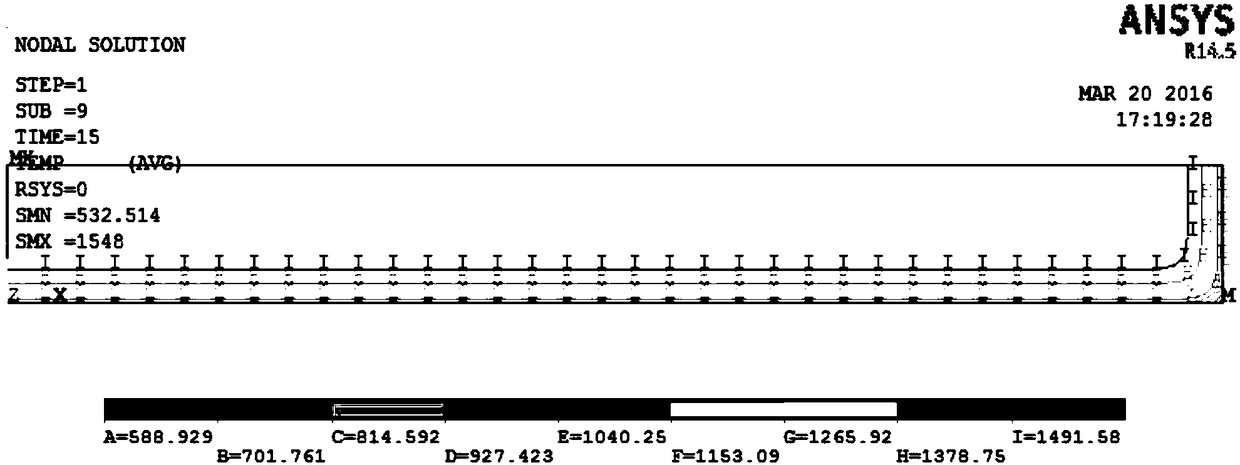

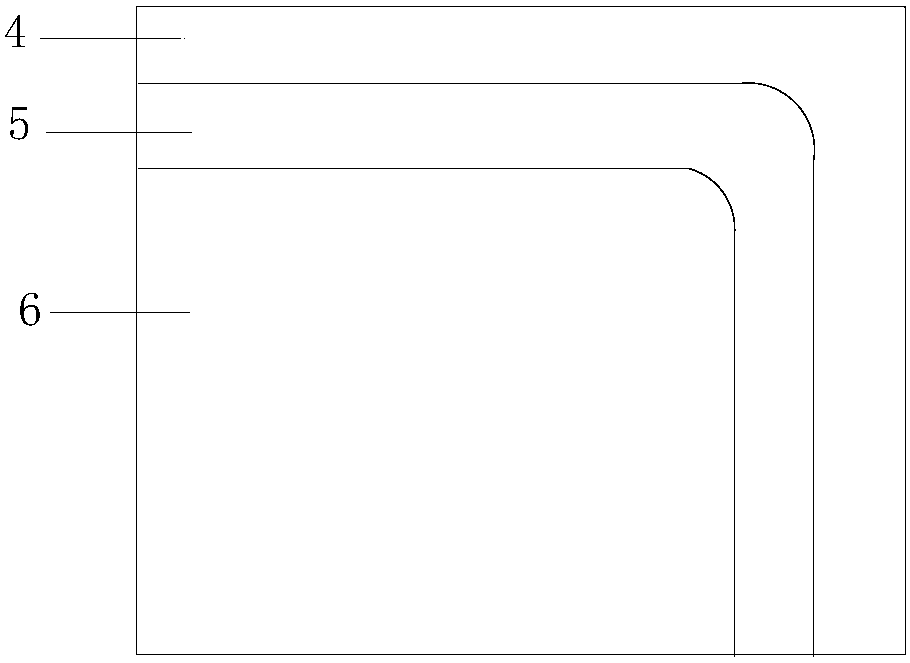

[0041] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

[0042] The invention measures the thickness of the solidified slab shell at the exit of the continuous casting mold online. The eddy current coil of the invention measures the thickness of the solidified slab at the exit of the continuous casting mold. Due to the particularity of the object, the eddy current coil is independently designed. When the slab just leaves the continuous casting mold, the interior of the slab is a solid region, a solid-liquid two-phase region, and a liquid phase region, and the thickness of these regions is difficult to measure. First of all, it is necessary to know the thickness range of the billet shell, and design the probe and measurement system according to the measurement range.

[0043] Through the finite element simulation software ANSYS, the temperature field of the slab at the outlet of the crystallizer is simulated and calc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com