Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

98results about "Portal grinding machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

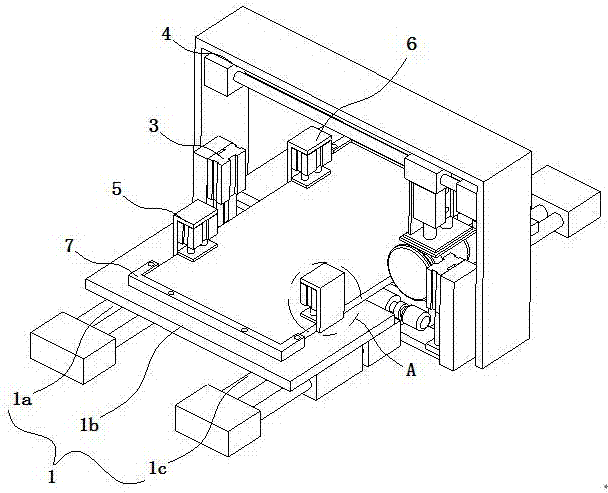

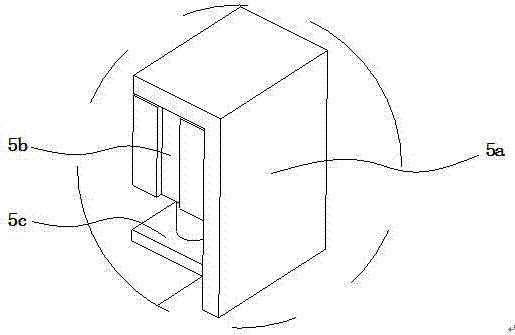

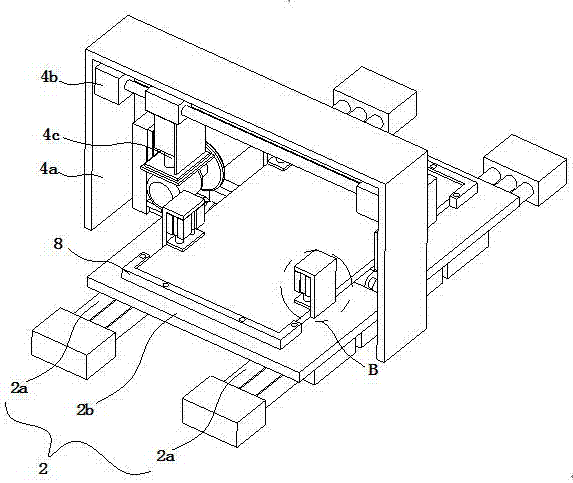

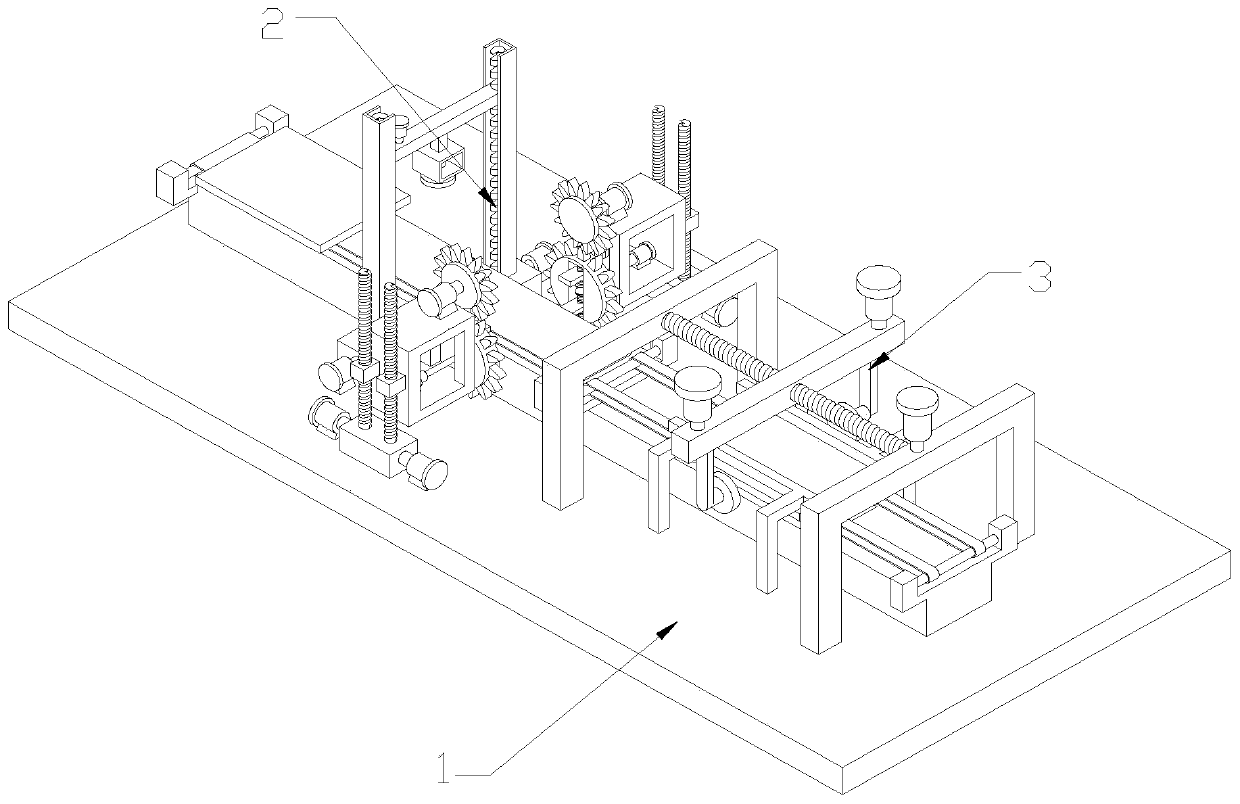

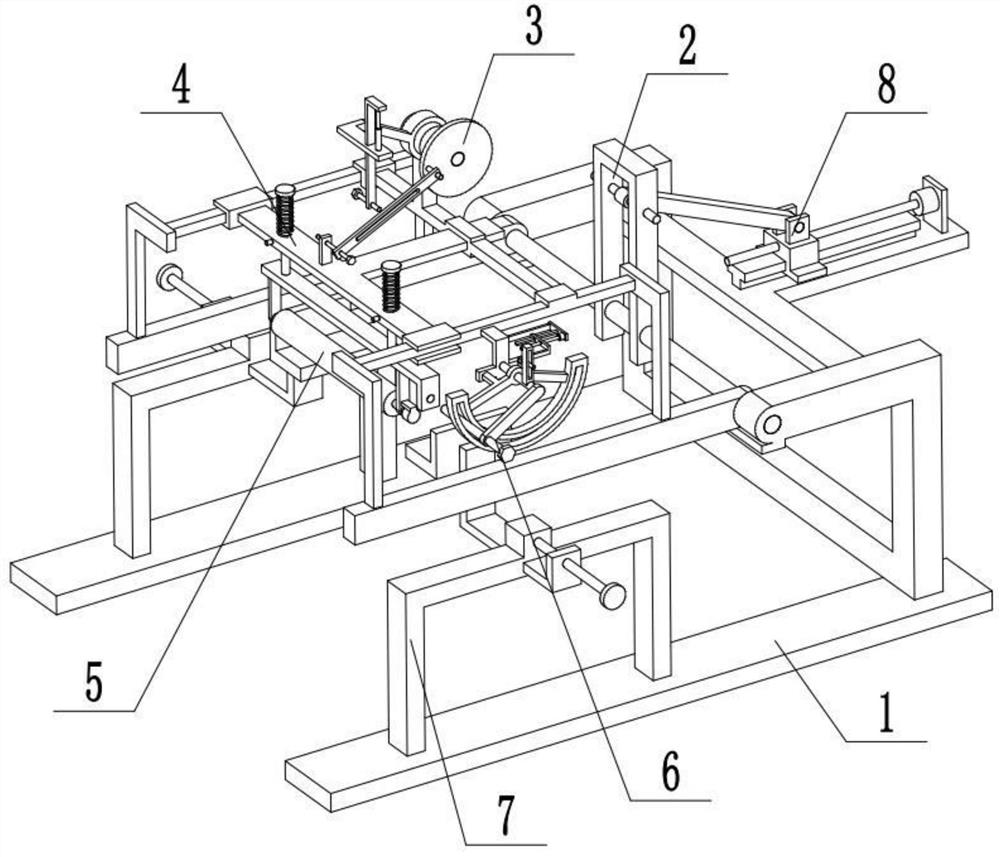

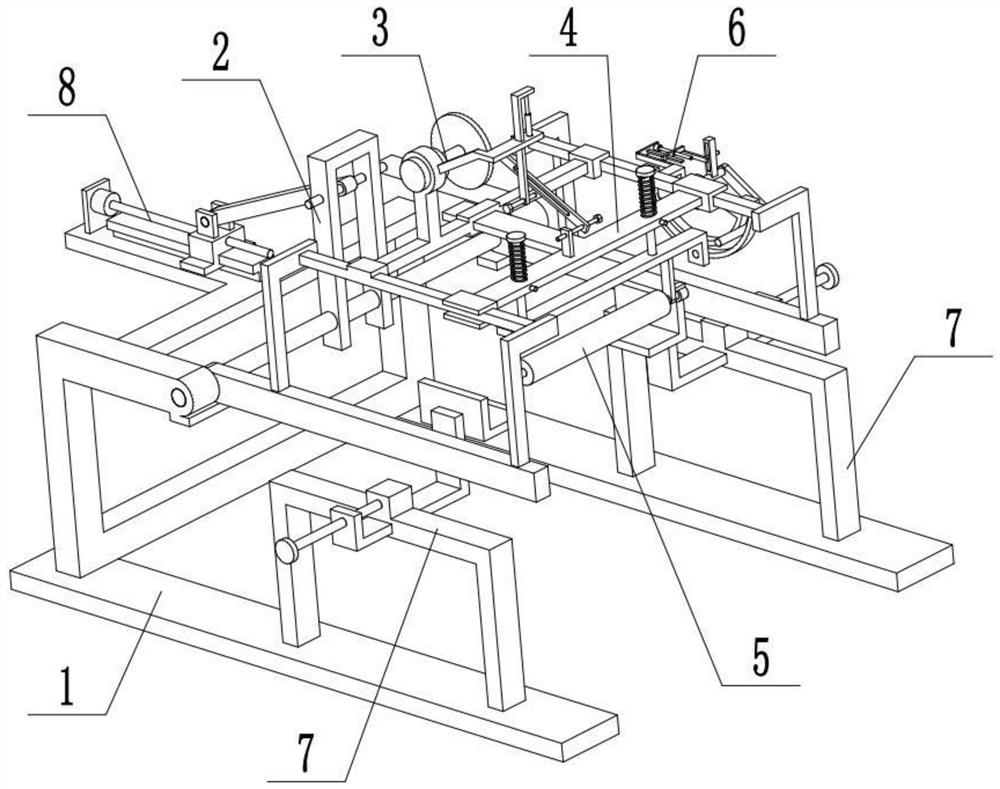

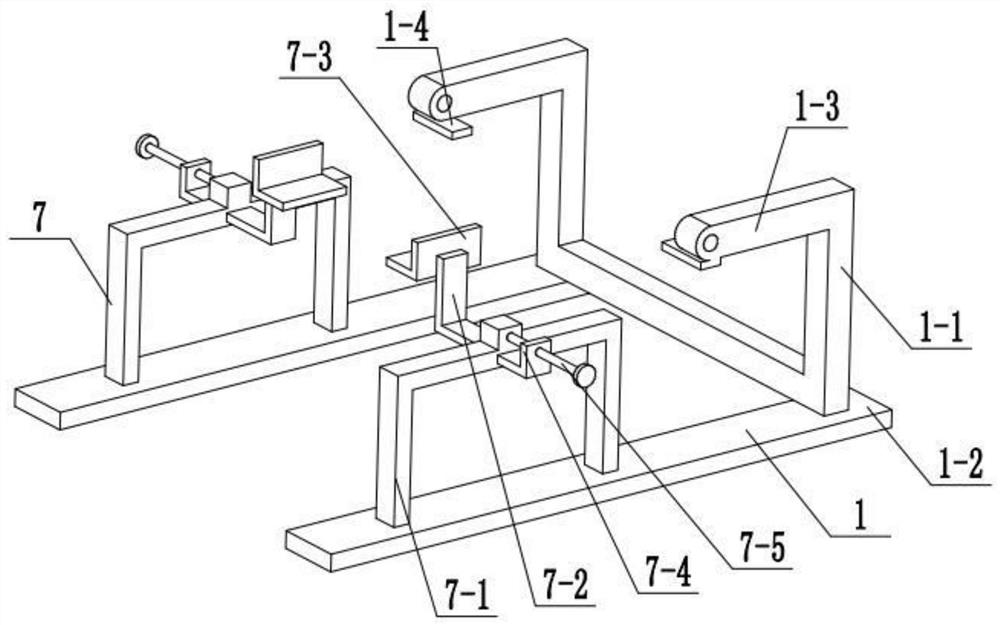

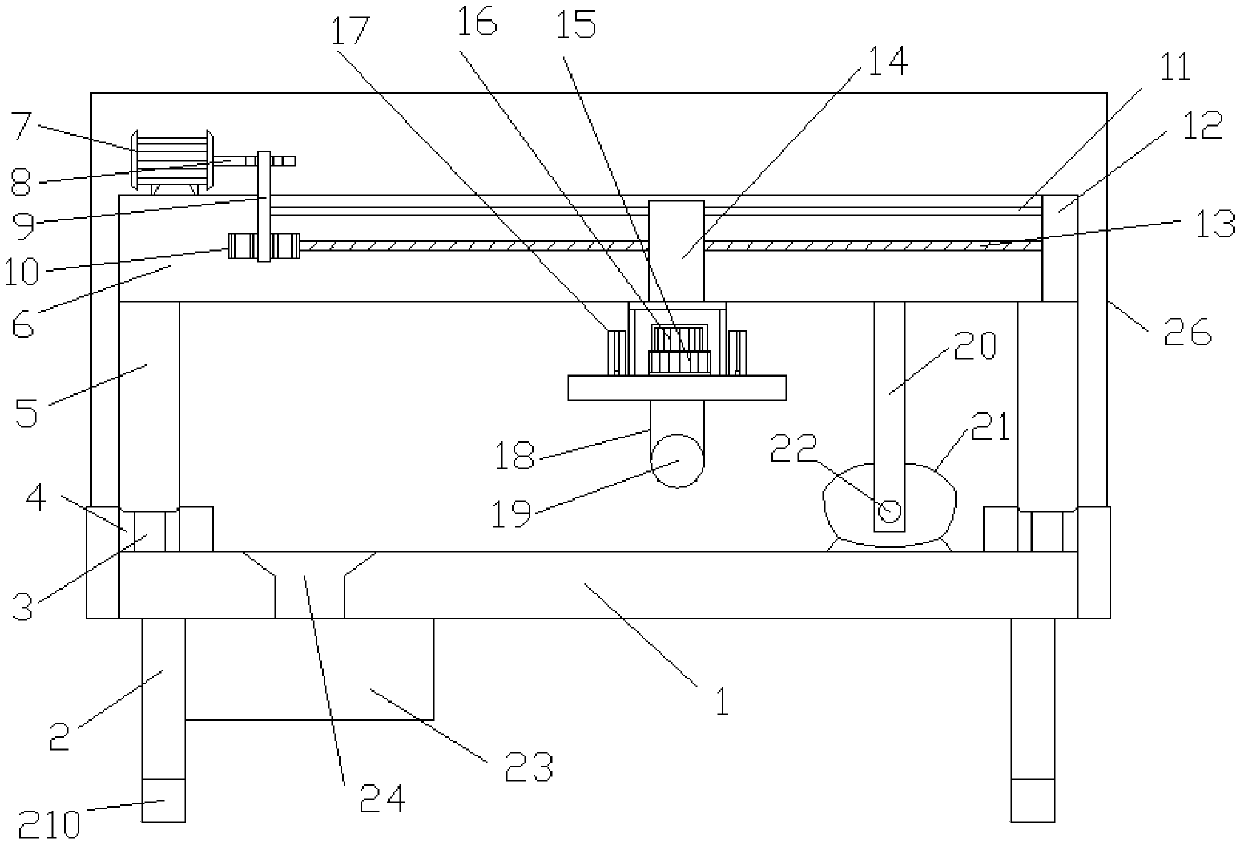

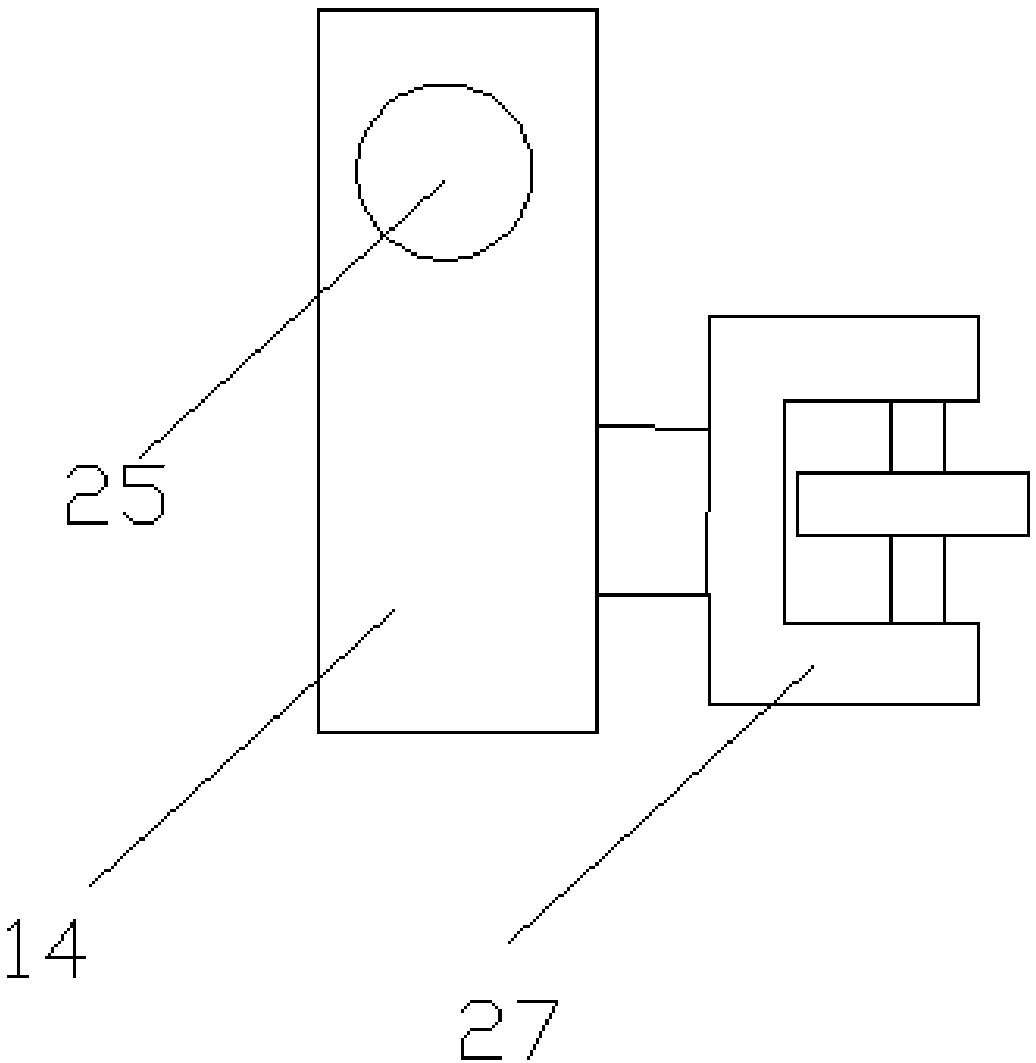

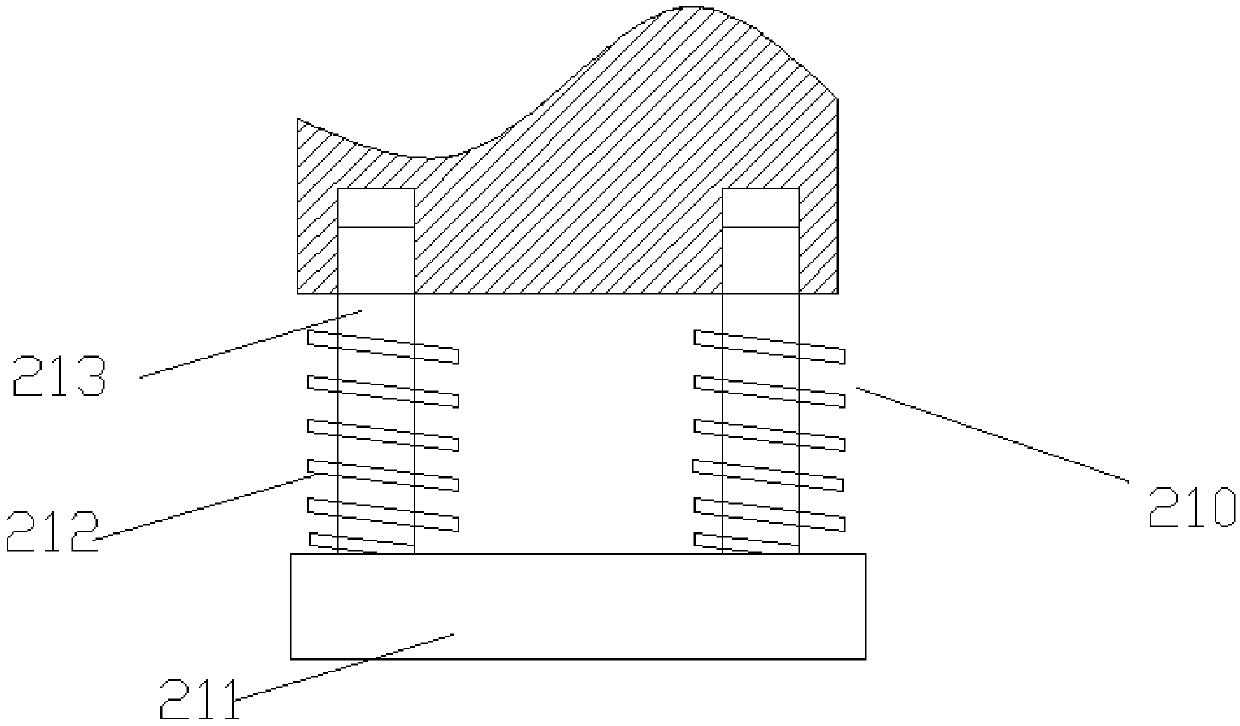

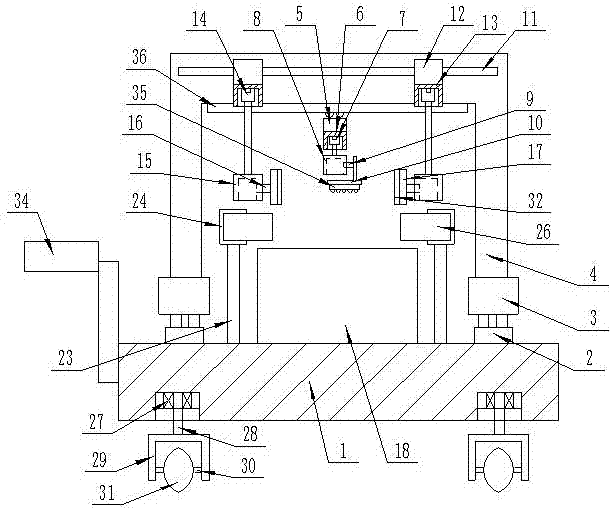

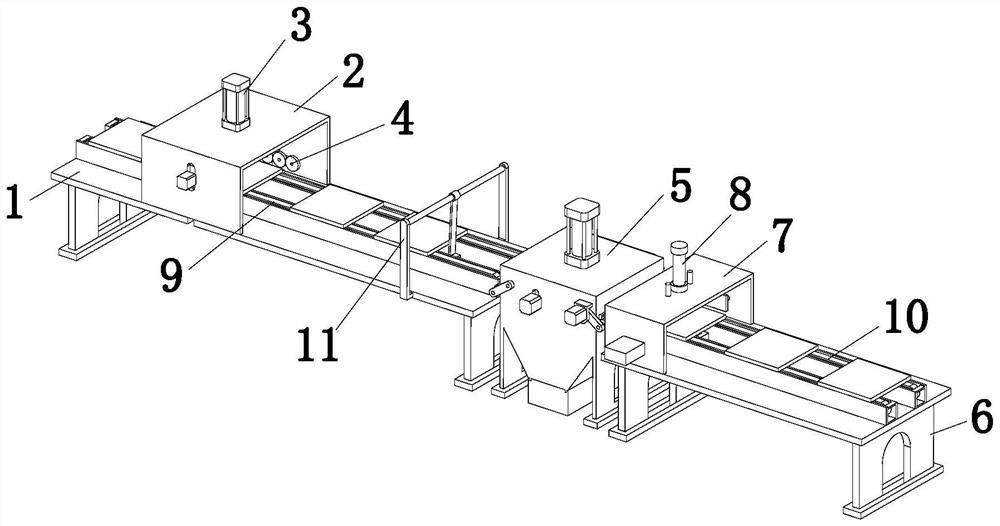

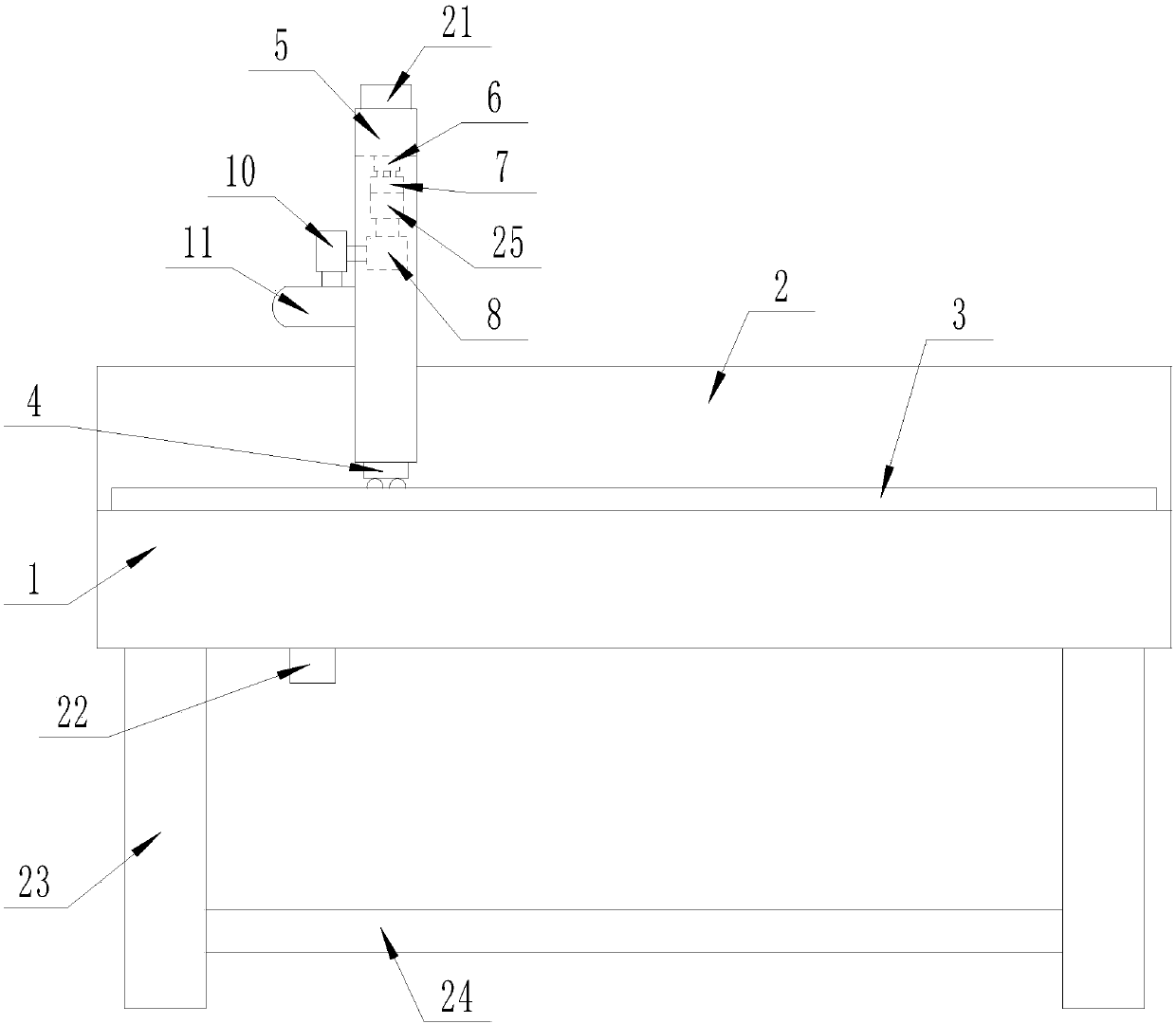

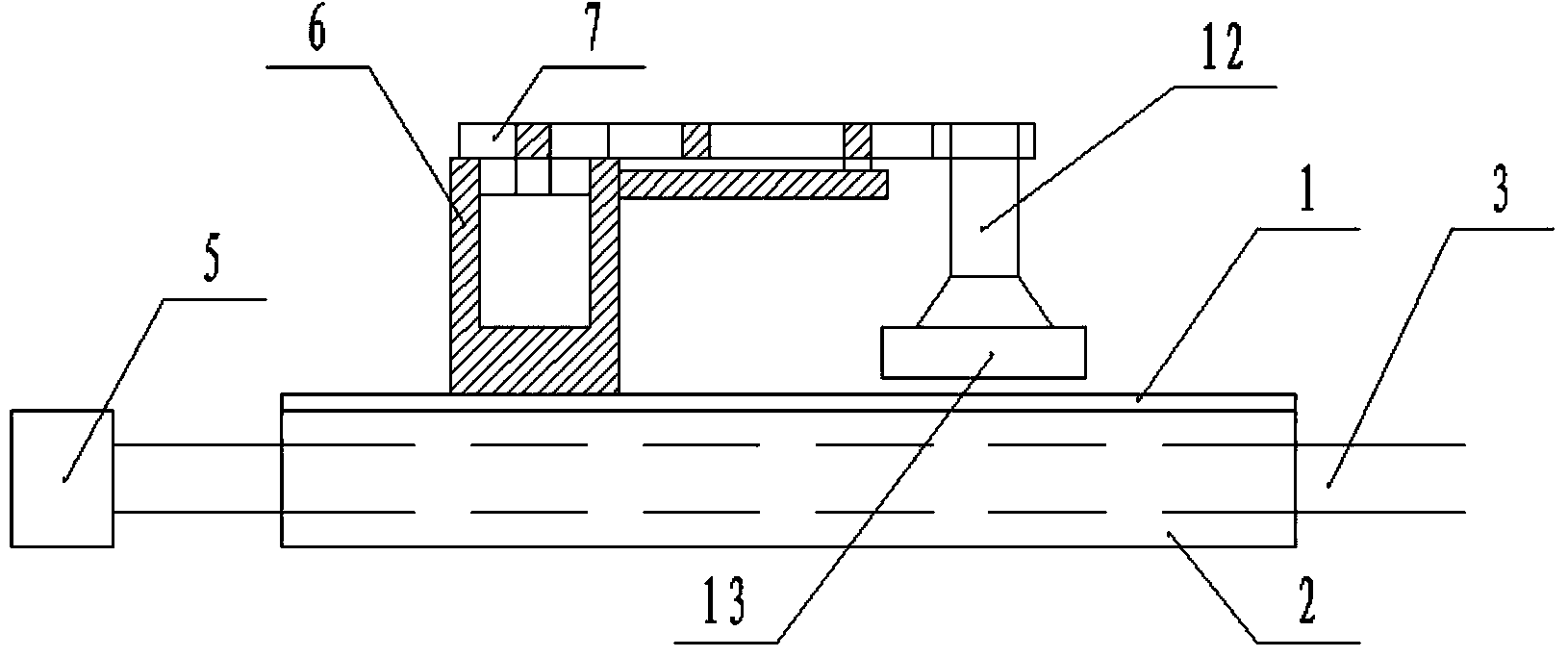

Cutting and grinding equipment for aluminum alloy plate material

InactiveCN107443185ALow costSimple structureOther manufacturing equipments/toolsGrinding work supportsEngineeringAluminium alloy

The invention relates to the technical field of cutting and grinding of plate-shaped workpieces, in particular to a cutting and grinding equipment for aluminum alloy plate-shaped materials, which includes a first support device and a second support device, and the first support device and the second support device are provided with There is a grinding device, a cutting device is provided on the side of the grinding device, and the cutting device includes a gantry frame and a first screw mandrel, a cutting assembly is arranged on the slider of the first screw mandrel, the first supporting device and the second screw mandrel The tops of the two supporting devices are respectively provided with a first pressing mechanism and a second pressing mechanism, and the tops of the first supporting device and the second supporting device are respectively provided with a first limiting plate and a second limiting plate. The invention performs cutting and grinding operations on the aluminum alloy plate through the cutting device and the grinding device, and has a simple structure, and can perform grinding operations on the aluminum alloy plate after the cutting operation is completed, and does not require a separate grinding machine for the aluminum alloy plate. The board is polished to reduce the cost of processing equipment.

Owner:卢长伟

Multifunctional glass polishing machine

InactiveCN105215805ASatisfied with polishingImprove processing efficiencyGrinding drivesGrinding feedersEngineeringSewage treatment

The invention discloses a multifunctional glass polishing machine which comprises a feeding frame and a polishing device. The polishing device comprises moving control boxes, a cantilever, a bottom operating table and a water tank. A cleaning trough, a horizontal slide rail, vertical slide rails and upper polishing mechanisms are arranged in the cantilever. The upper polishing mechanisms are connected to a cantilever rod through supporting frames. The feeding frame horizontally penetrates through the moving control boxes. The bottom operating table is located below the feeding frame, and a lifting table, a supporting plate, a sewage disposal pool and a lower polishing mechanism are arranged in the bottom operating table. The lower polishing mechanism is arranged on the top face of the lifting table. Pressing mechanisms are arranged on the two sides of the cantilever. The water tank is located on one side of the feeding frame and connected with the cantilever through a conveying pipe. The multifunctional glass polishing machine is simple in structure and high in practicability, can be used for polishing both plain glass and curved glass, and improves the efficiency and quality of polishing.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

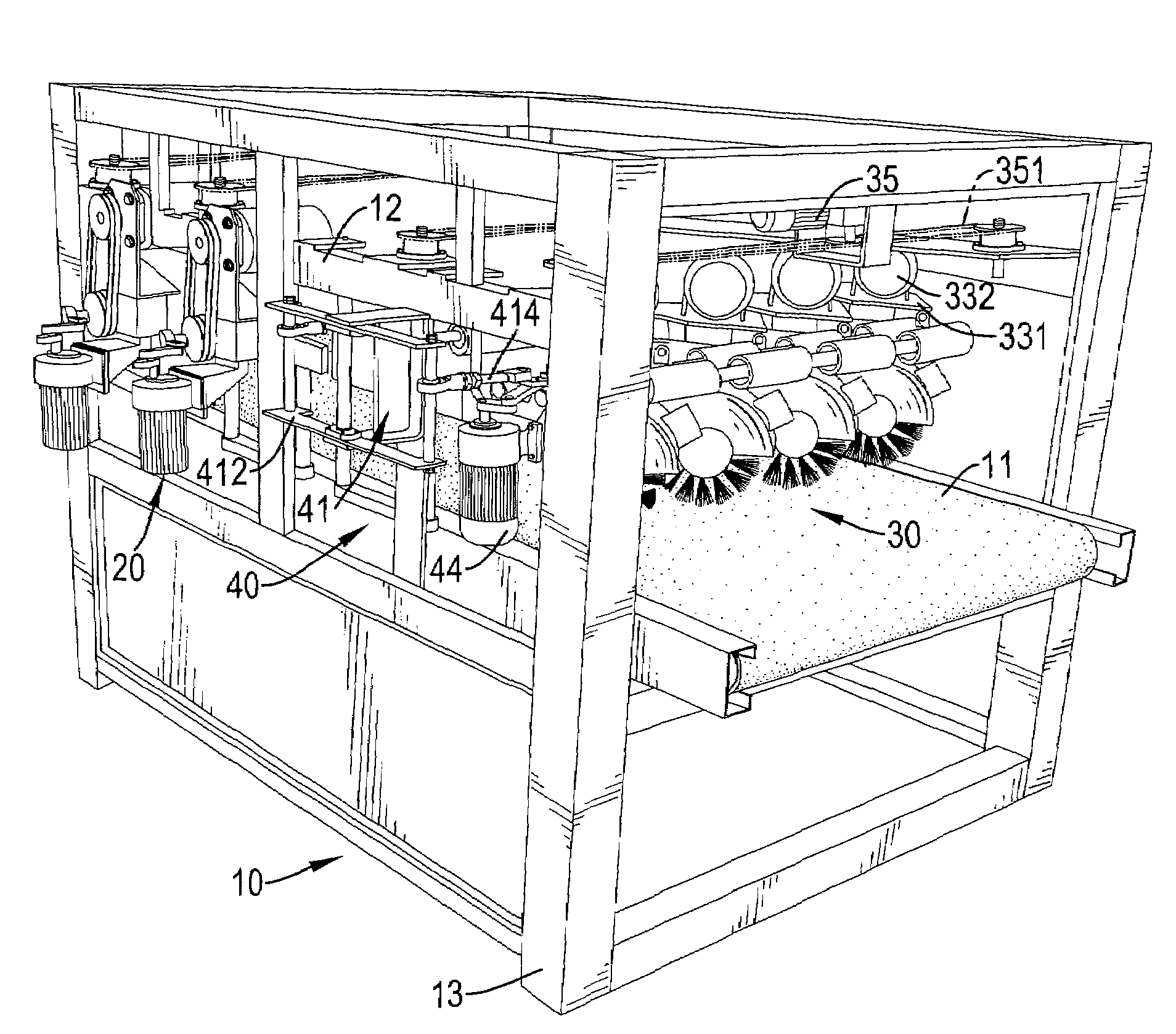

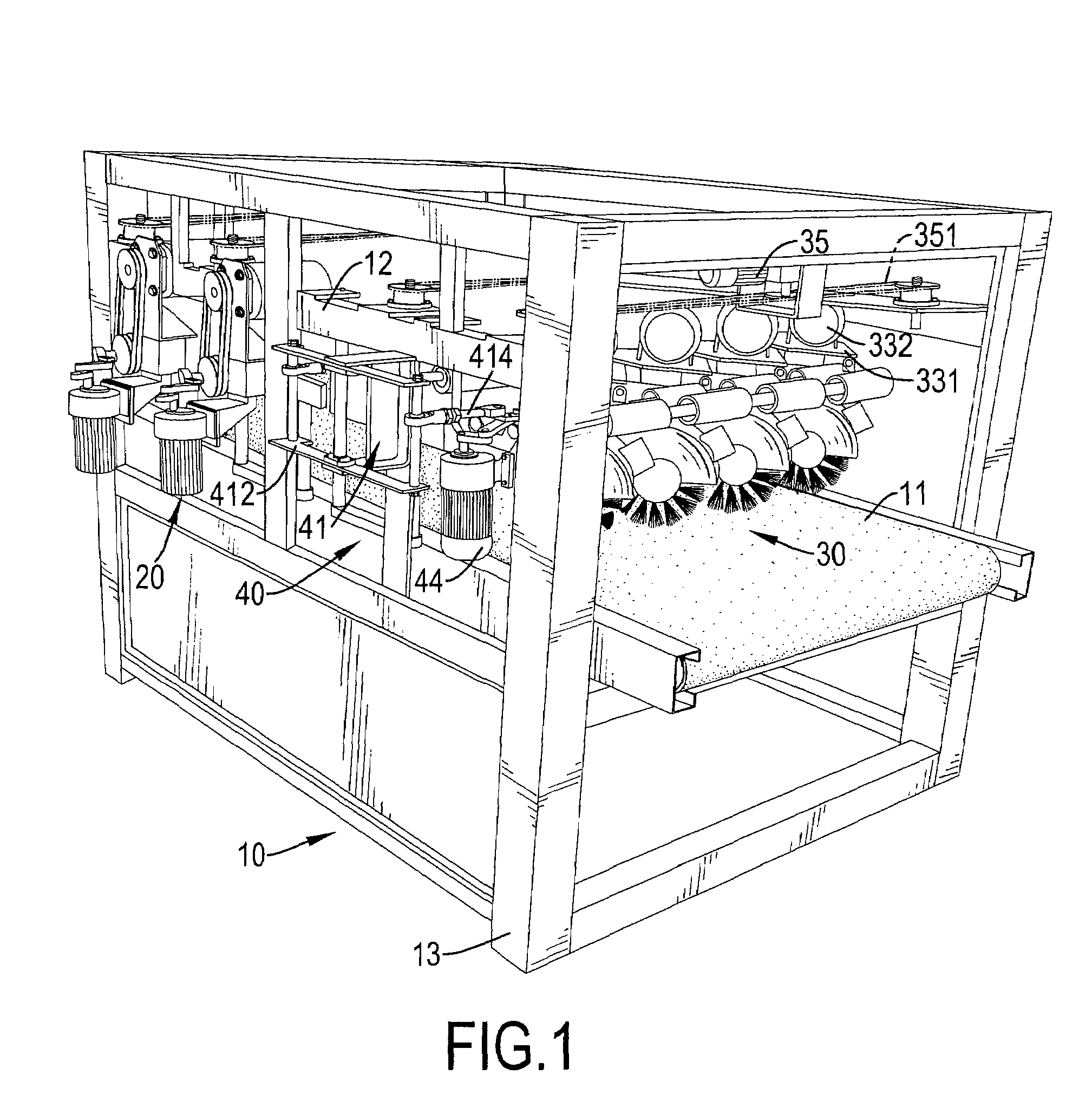

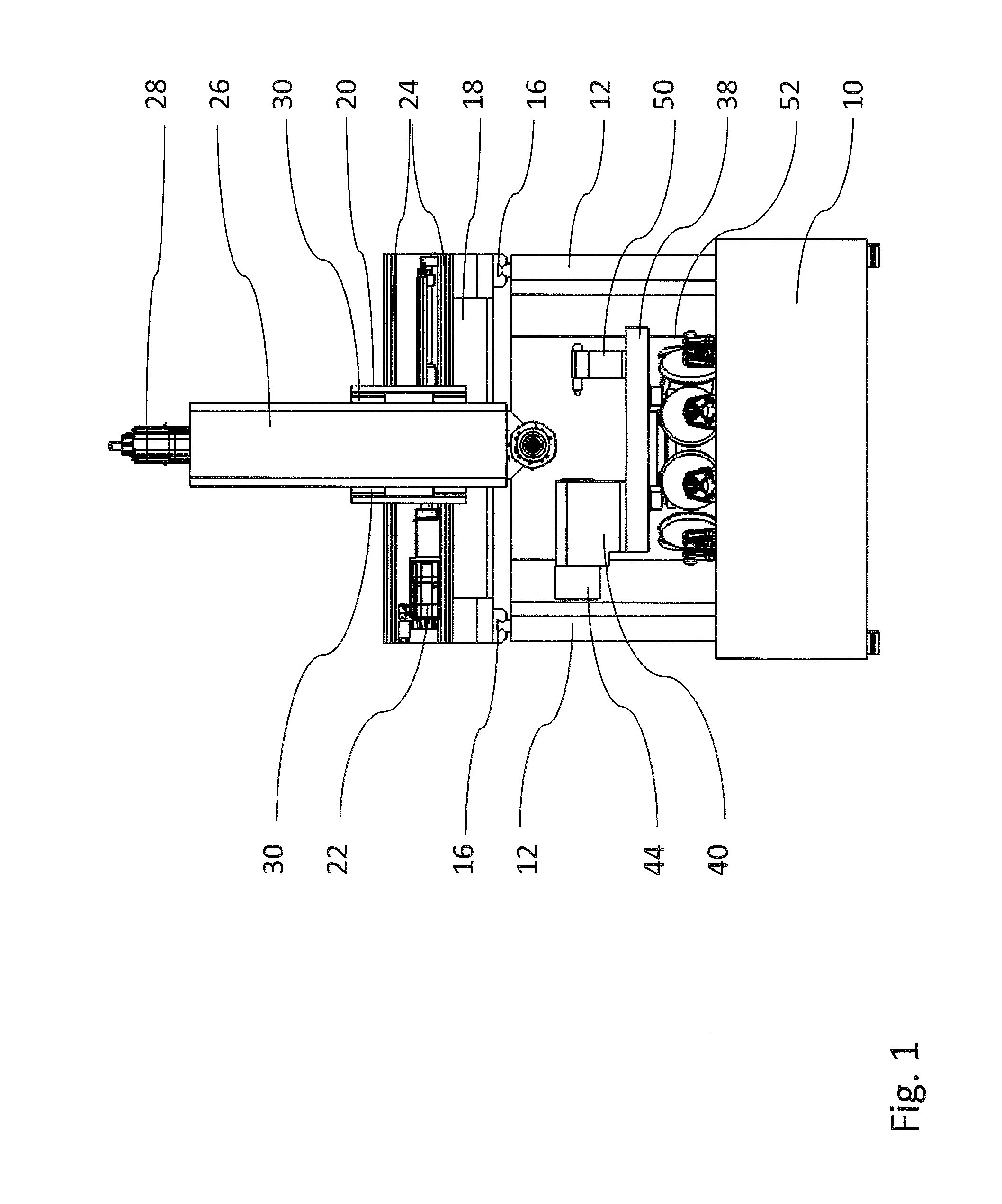

Linear sander

InactiveUS7503832B1Preferred polishingPreferred polishing effectEdge grinding machinesPolishing machinesRotational axisSander

A linear sander has a base, at least one rough abrasive assembly, at least one fine abrasive assembly and a reciprocating device. The base has two sides and a belt. Each rough abrasive assembly is mounted on the base above the belt and has a rotating axle and an abrasive brush mounted around the rotating axle. Each fine abrasive assembly is rotatable mounted on the base is aligned obliquely to the mounting shafts and has two mounting brackets, two mounting shafts and multiple abrasive rollers. The reciprocating device is connected to the abrasive assembly and has a pivot bracket mounted securely on one of the mounting brackets, two drive bars mounted on move the abrasive rollers linearly along the mounting shafts and a linear driver connected to the drive bar.

Owner:CHANG WEN CHI

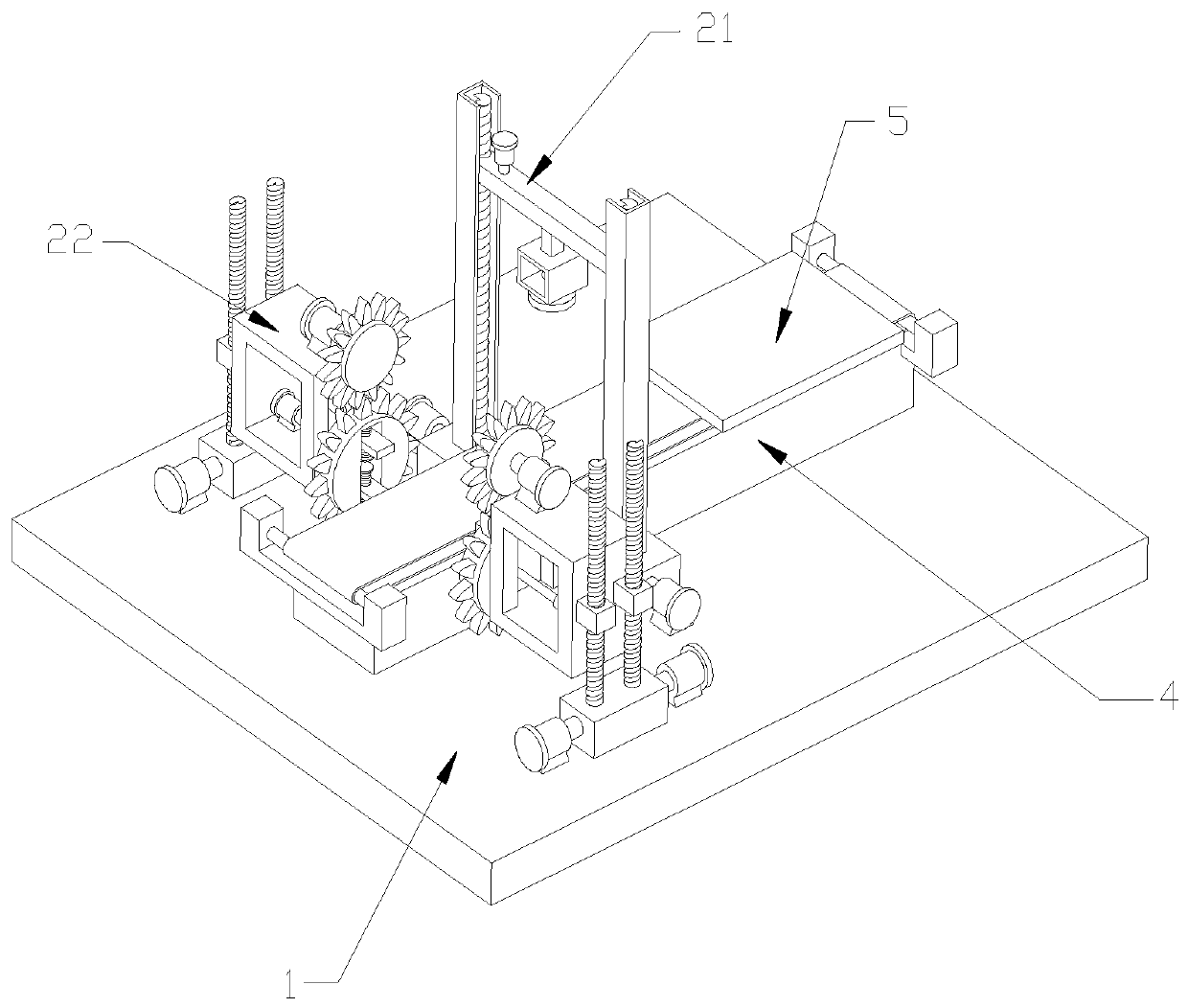

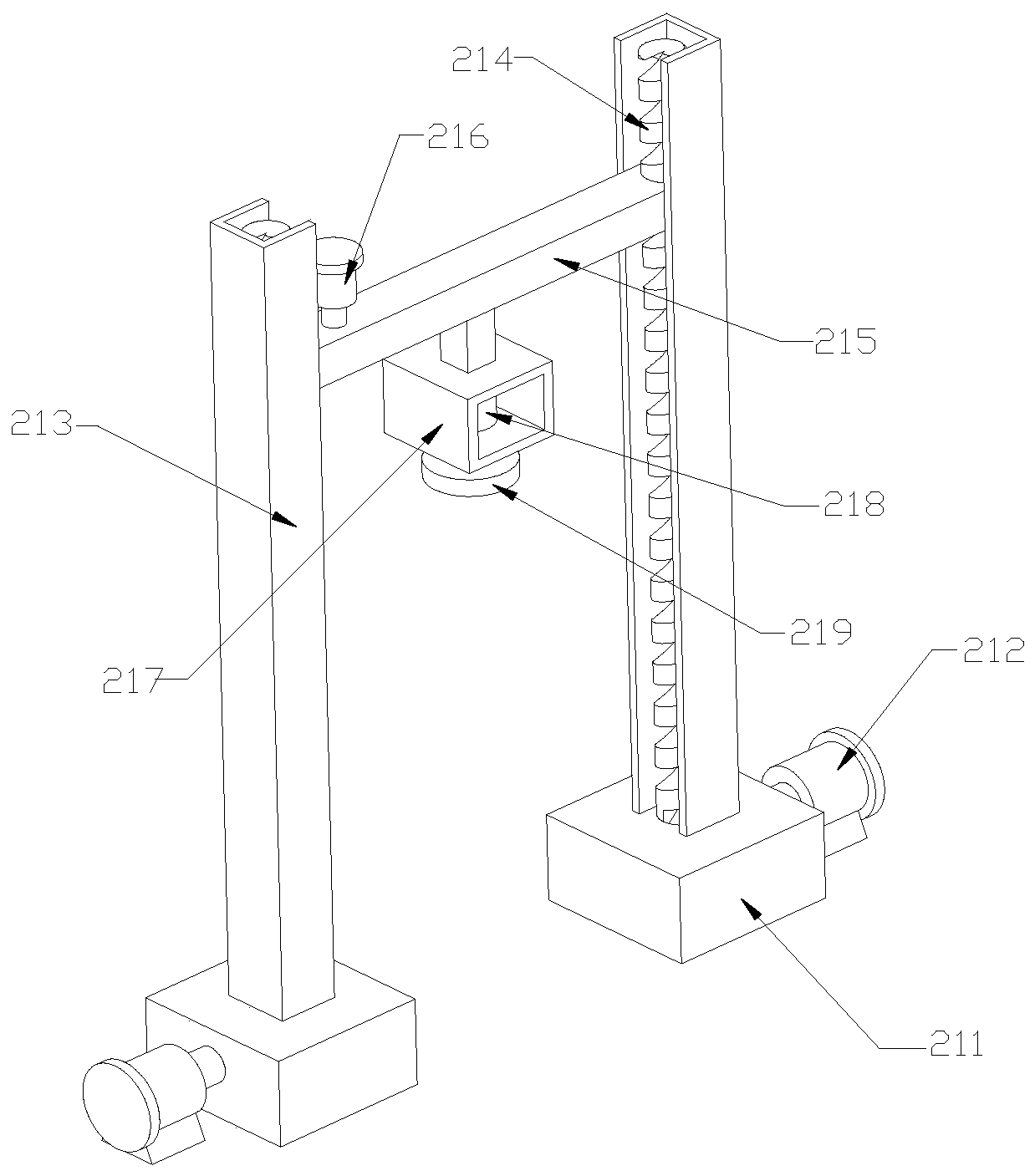

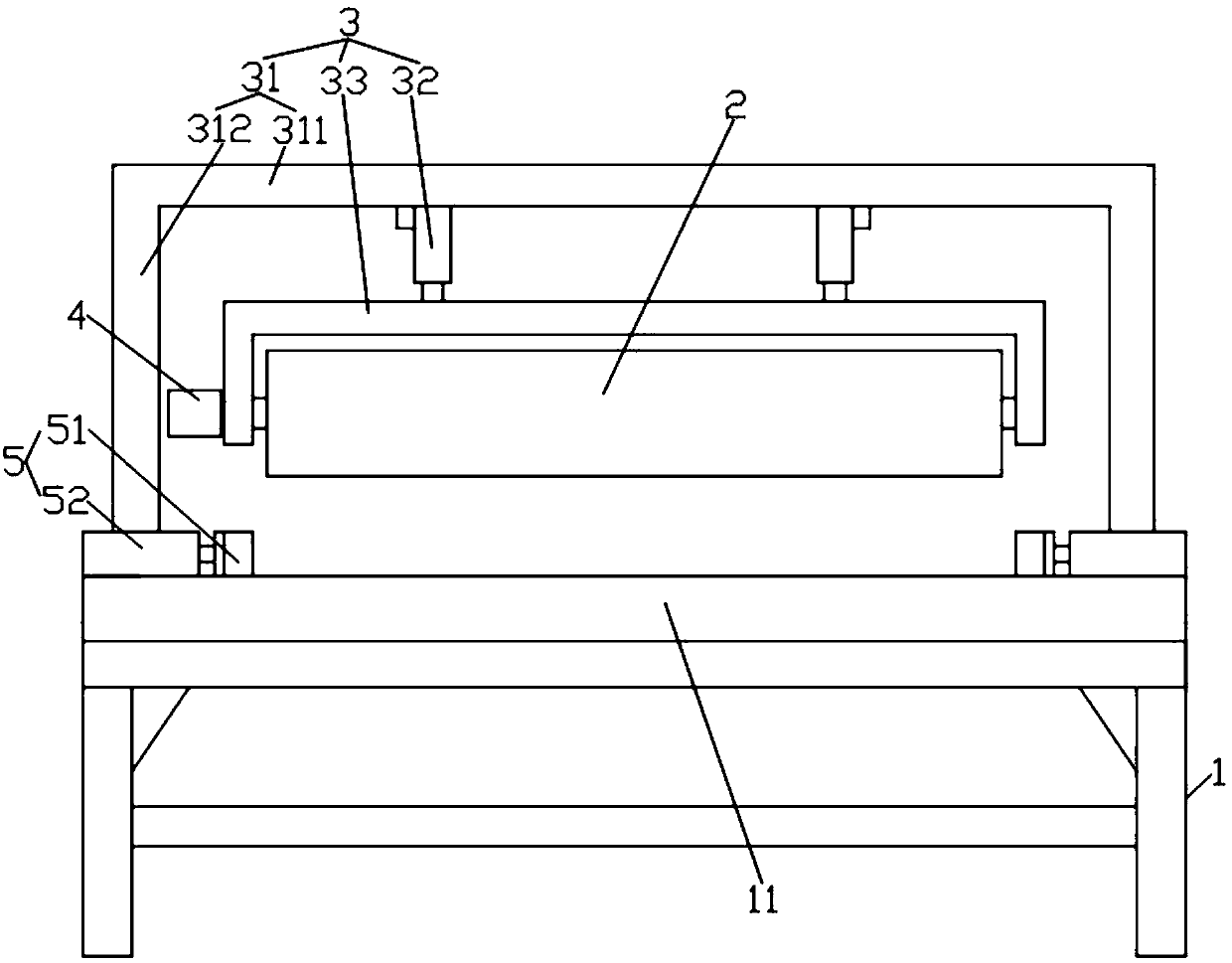

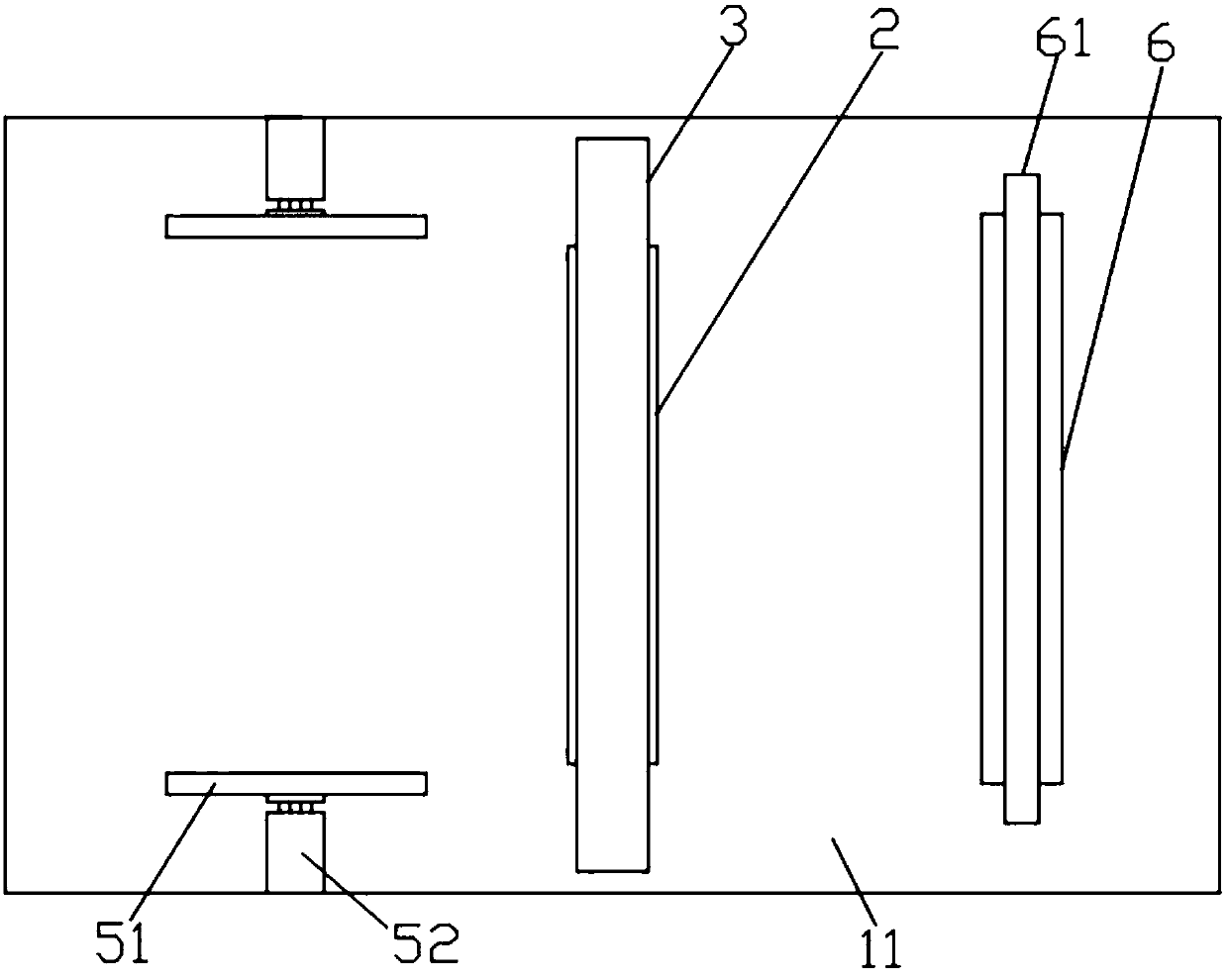

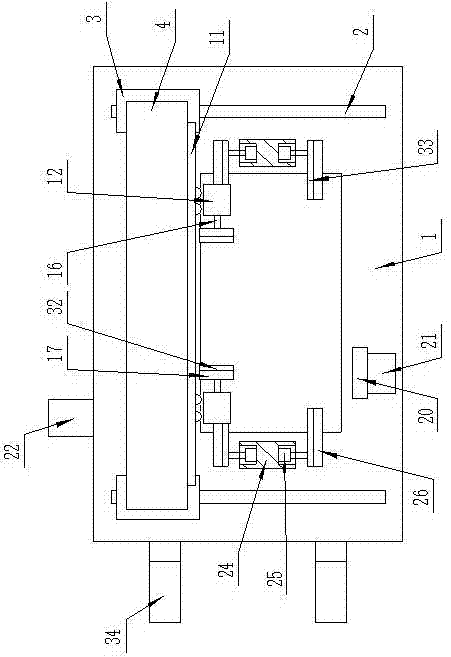

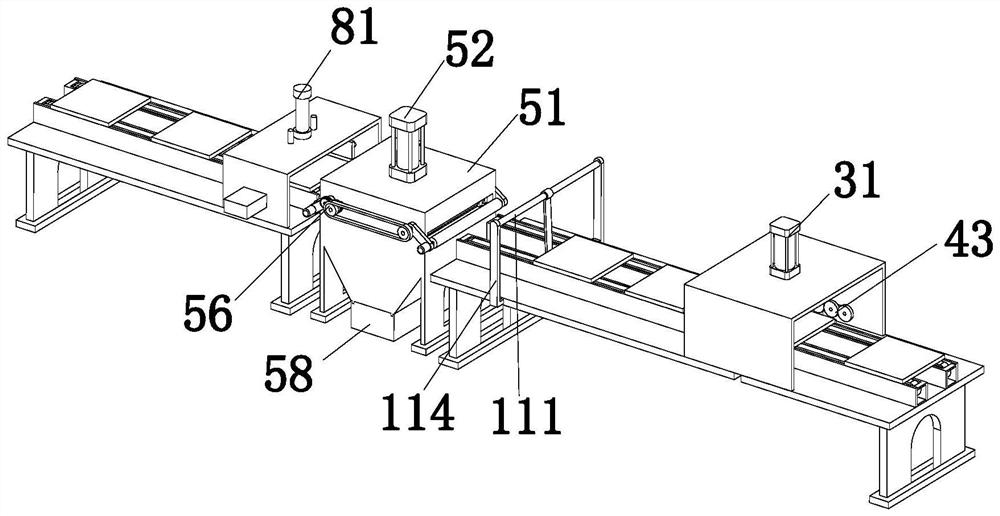

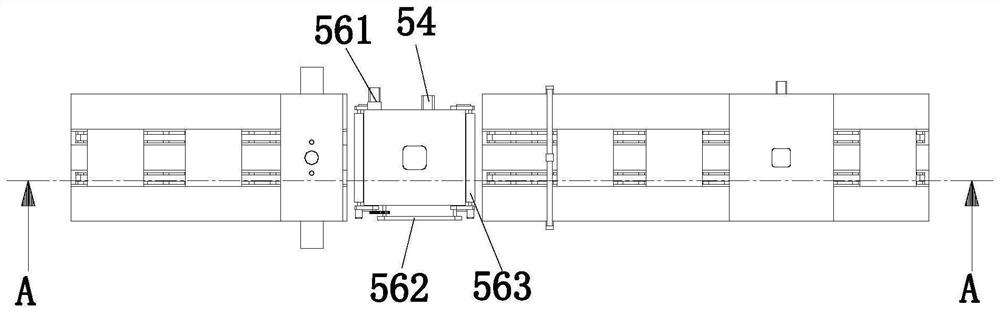

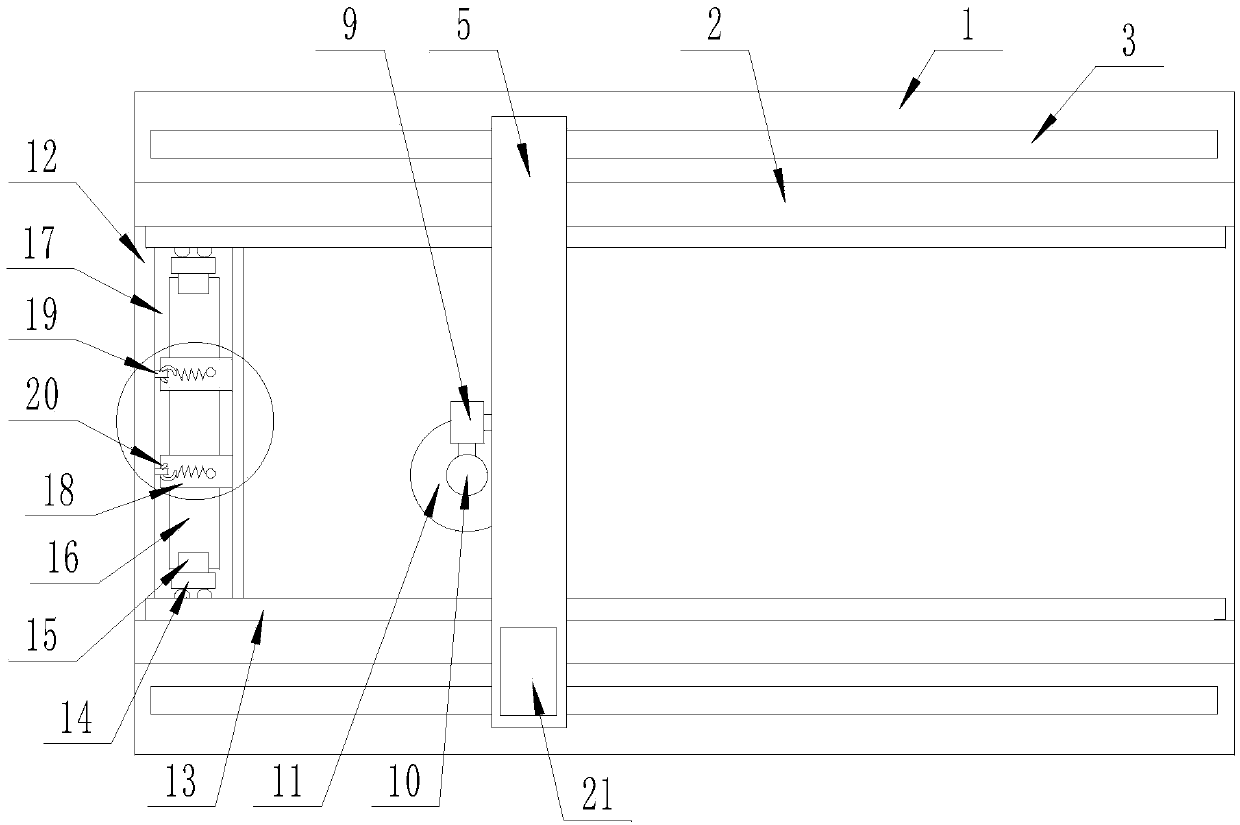

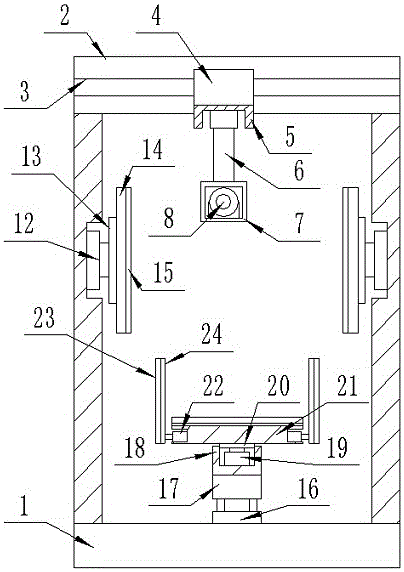

Sheet material grinding mechanism and grinding method thereof

InactiveCN110977640AAchieve grindingSimple structureGrinding drivesGrinding work supportsElectric machineEngineering

The invention discloses a sheet material grinding mechanism and a grinding method thereof. The sheet material grinding mechanism comprises an upper and lower surface grinding and turning module and asheet material side end grinding device; the upper and lower surface grinding and turning module comprises a sheet material upper and lower surface grinding device and a sheet material turning device;the sheet material upper and lower surface grinding device comprises a first lead-screw, a first motor, a second motor, a third motor, a second lead-screw and a first grinding table; the sheet material turning device comprises a third lead-screw, a fourth motor, a fifth motor, a sixth motor, a first rotating block, a second rotating block, a fourth lead-screw and a rotating rod; and the sheet material side end grinding device comprises a fifth lead-screw, a seventh motor, an eighth motor, a second grinding table and a sixth lead-screw. The sheet material grinding mechanism is provided with the sheet material turning device, which can automatically lift a sheet material and rotate 180 degrees without manual turning after the upper surface of the sheet material is polished, thus the lower surface faces upward, and thereby polishing of the lower surface is realized; and the structure is simple, the practicability is high, and the sheet material grinding mechanism can be applied to a widevariety of fields such as the field of a variety of sheet material processing.

Owner:江苏国振家昌家居有限公司

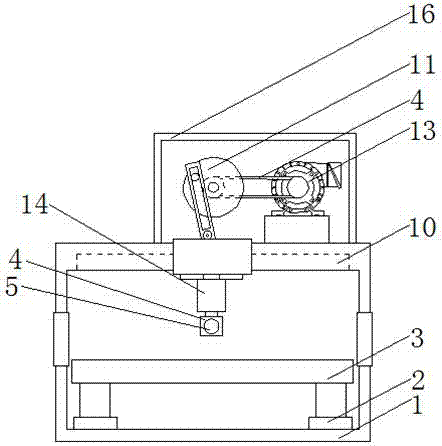

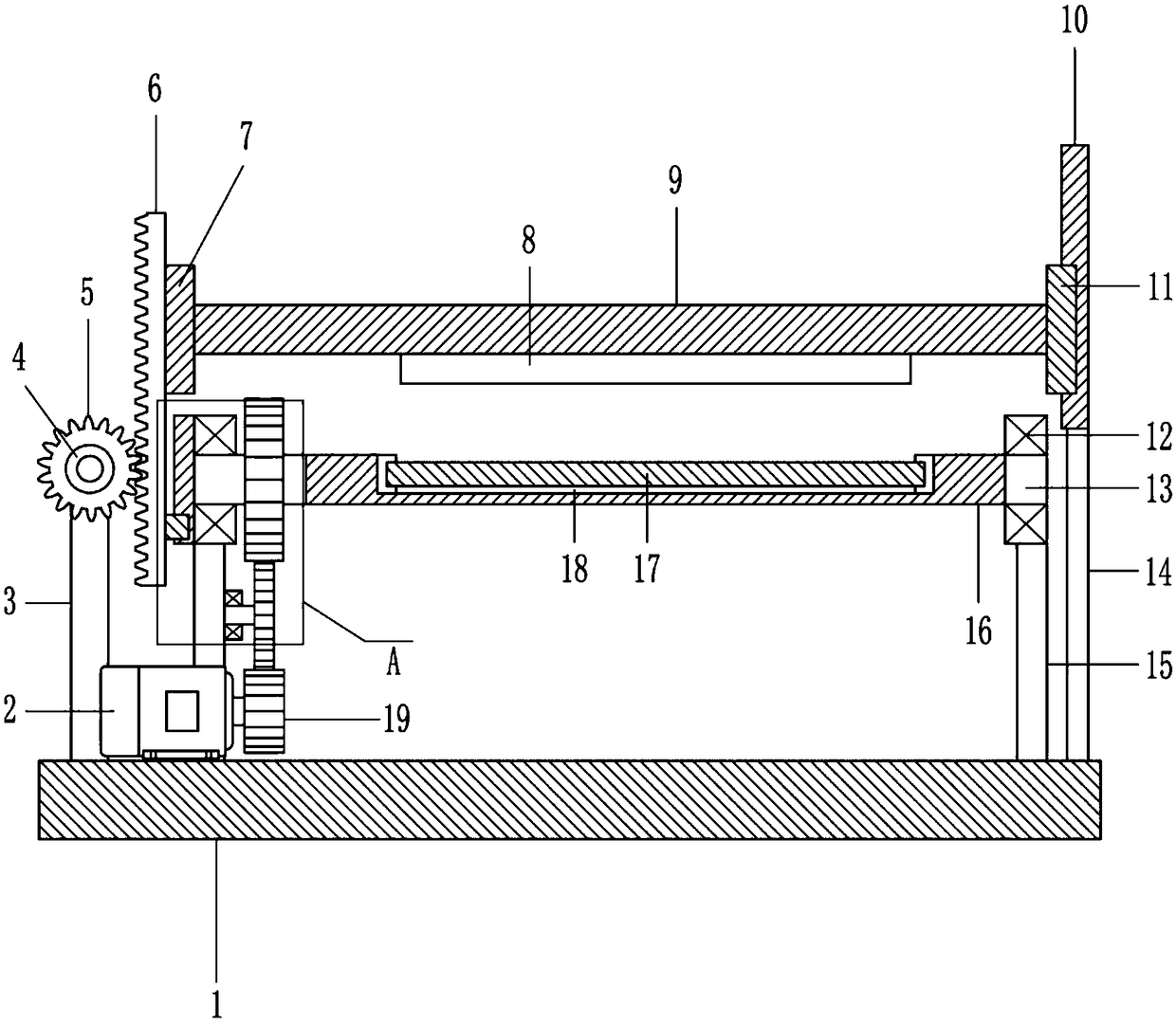

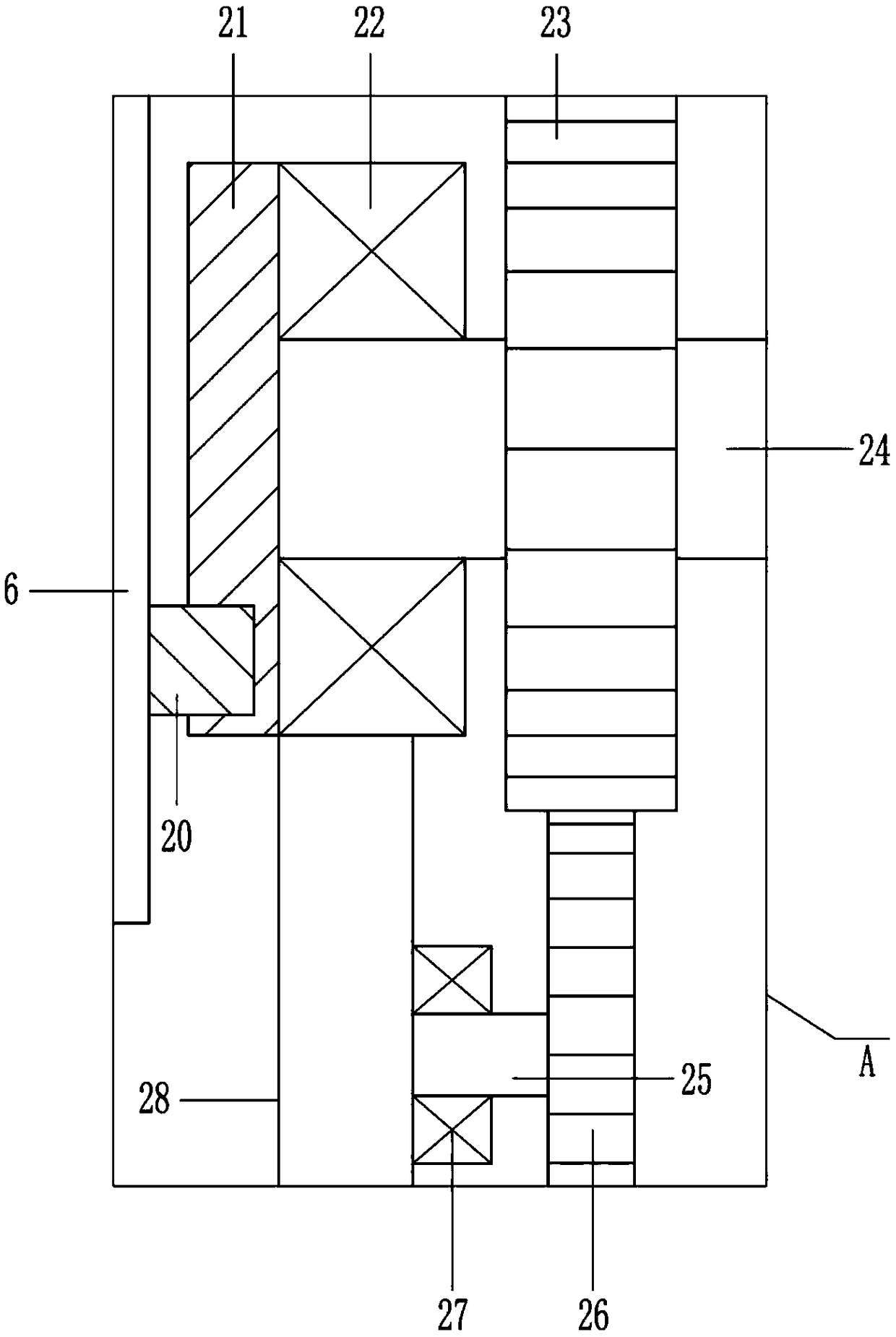

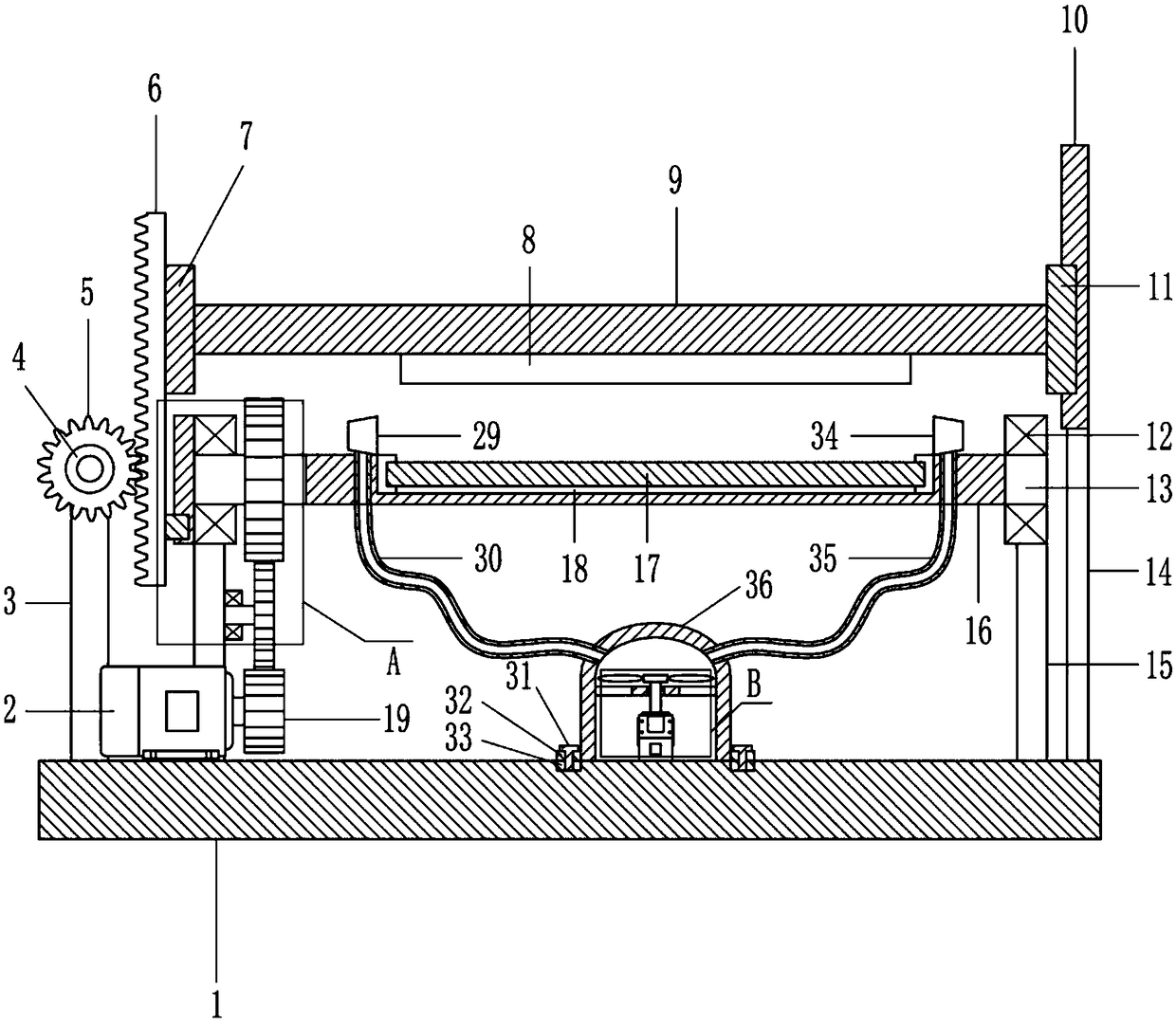

Gantry grinder

ActiveCN110666605AEasy to useEasy clamping of discsGrinding carriagesGrinding drivesElectric machineGear wheel

The invention relates to a gantry grinder. The gantry grinder comprises a base, wherein a worktable capable of sliding along a length direction of the base is arranged on the upper side of the base; two sides of the base are rotatably connected with swinging arms; a support arm is arranged on sides close to each other of two ends of the two swinging arms; a movable frame is arranged on the lower side of the support arm; a telescopic frame is vertically arranged on the movable frame; the lower end of the telescopic frame is fixedly connected to a driving motor; an output shaft of the driving motor faces down and is detachably connected with a grinding head; sides close to each other of the base are fixedly connected with arc-shaped racks by taking articulation centers between the swinging arms and the base; sides close to each other of the swinging arms are rotatably connected with reversing gears which are engaged with the racks and are capable of swinging along the swinging arms and rolling along the racks; and servo motors III capable of driving the reversing gears to rotate are also fixedly connected in the swinging arms. The gantry grinder has the effect of machining oblique surfaces of workpieces.

Owner:深圳市雄兴实业有限公司

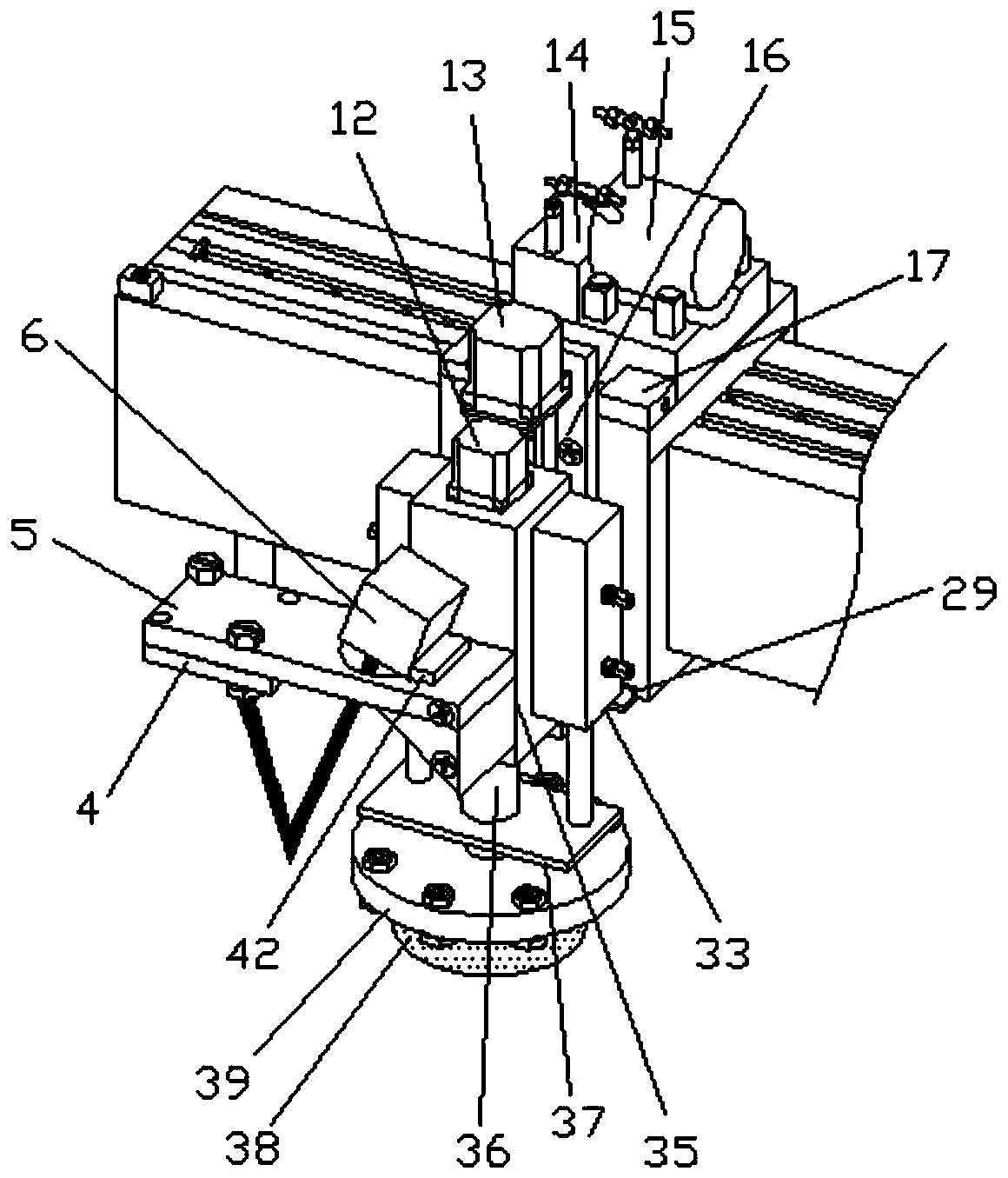

Processing technology and processing system of LED ceramic substrates

A processing technology and processing system of LED ceramic substrates have the beneficial technical effects that the ceramic substrate on the horizontal plane can be polished, and the ceramic substrate on the arc-shaped end face can also be polished. The method comprises the following steps that 1, an angle control mechanism drives a polishing mechanism to rotate upwards by a rotary adjusting seat assembly; 2, the ceramic substrate is fixedly connected between two clamping fixing pieces; 3, the angle control mechanism drives the polishing mechanism to return to a horizontal state; 4, a reciprocating driving mechanism starts to drive the polishing mechanism to horizontally and reciprocally move to polish the horizontal plane of the ceramic substrate through the reciprocating moving mechanism; and 5, after the reciprocating driving mechanism is separated from the reciprocating moving mechanism, a radian adjusting mechanism is adjusted to be connected with the reciprocating moving mechanism, and the radian adjusting mechanism drives the polishing mechanism to slide along an arc-shaped track through the reciprocating moving mechanism to polish the ceramic substrate on the arc-shapedend face.

Owner:国网浙江省电力有限公司龙游县供电公司

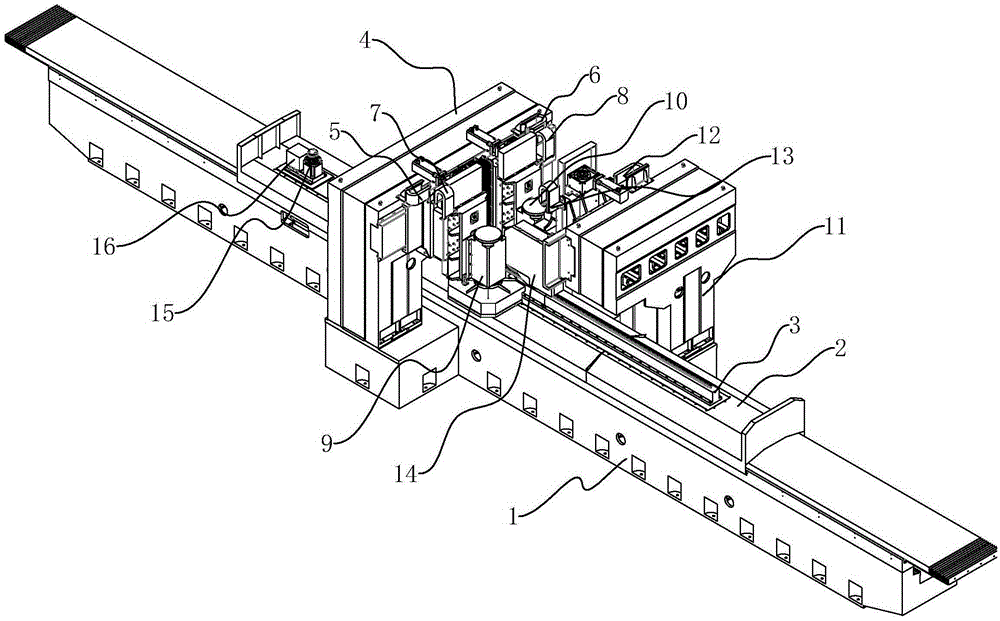

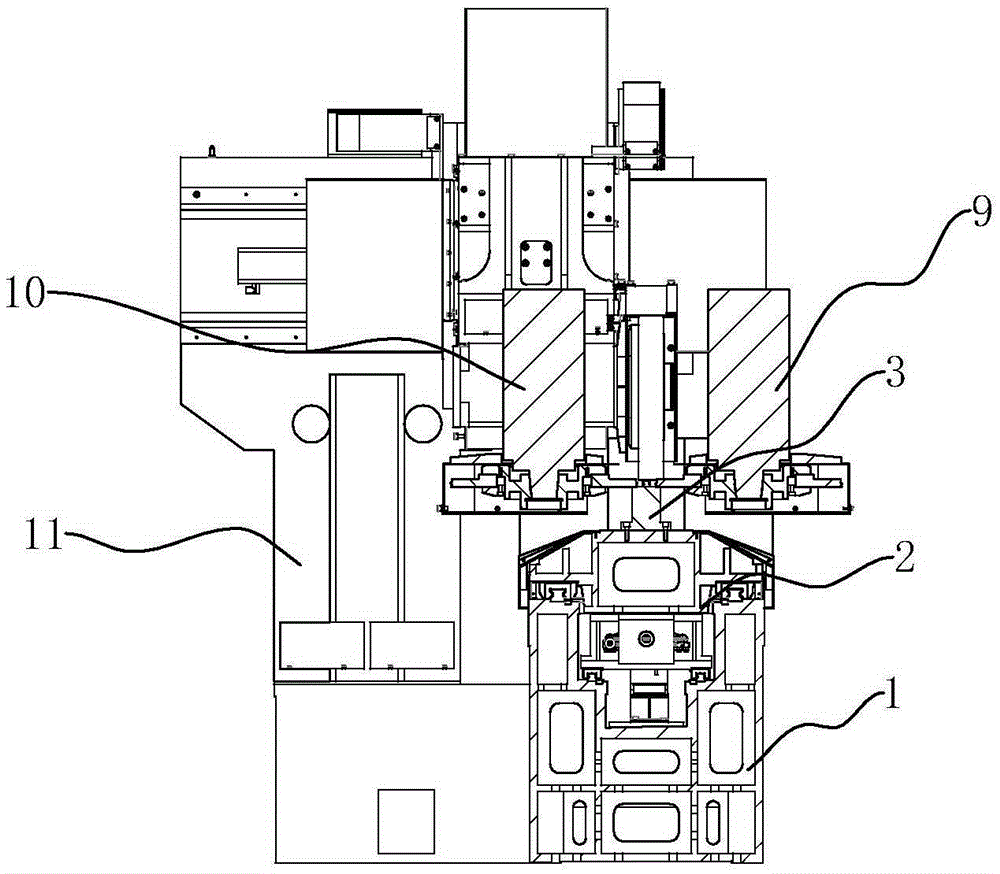

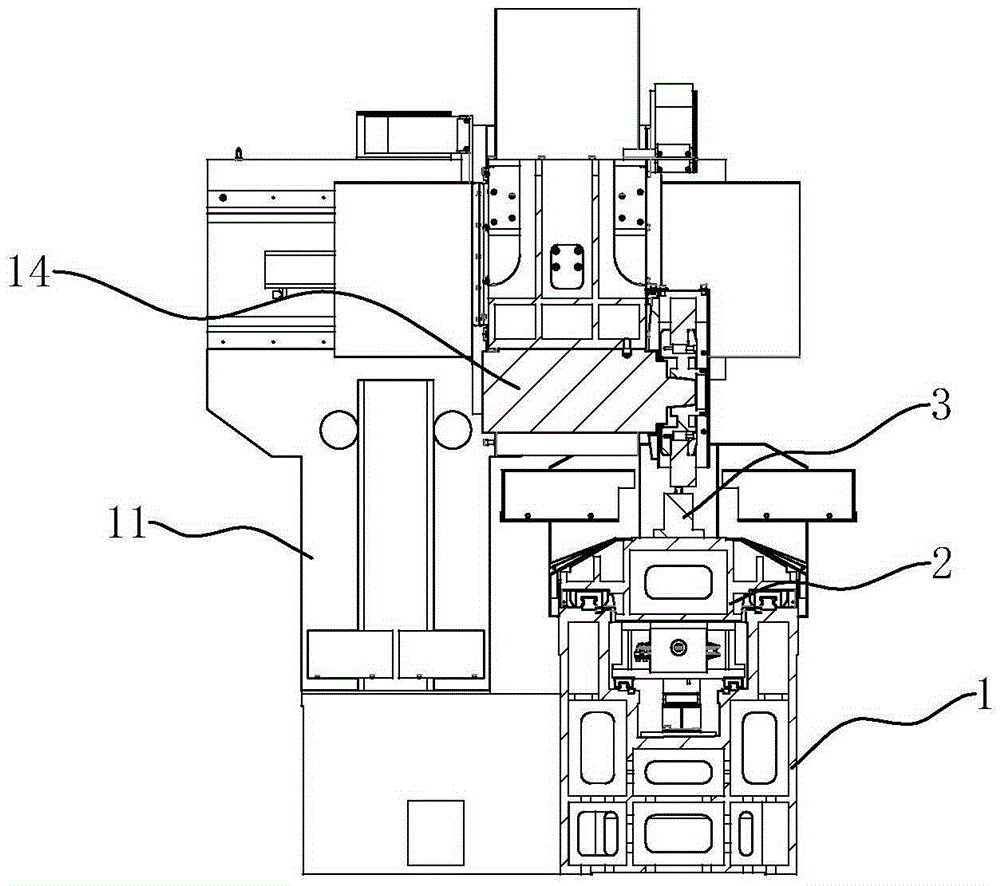

Monocrystalline silicon rod cutting and grinding all-in-one machine

PendingCN111376393AAvoid interferenceImprove general performanceGrinding carriagesGrinding drivesPolishingElectric machinery

The invention relates to the technical field of hard and brittle material cutting, in particular to a monocrystalline silicon rod cutting and grinding all-in-one machine, which comprises a clamping tool, a cutting operation mechanism and a grinding and polishing mechanism, wherein the clamping tool is used for clamping a crystalline silicon rod to be cut and grinded; the cutting operation mechanism comprises a rack, an annular wire sawing unit and a lifting unit, wherein the annular wire sawing unit is slidably fixed to the rack and is arranged above the clamping tool, and the lifting unit isused for driving the annular wire sawing unit to ascend or descend in order to extract a monocrystalline silicon rod; the grinding and polishing mechanism is slidably arranged on the side wall of therack and comprises a grinding and polishing assembly and a horizontal sliding component, wherein the grinding and polishing component comprises a grinding and polishing motor, a transmission part anda grinding head, the grinding and polishing motor is connected to the grinding head through the transmission part, the grinding and polishing component is arranged on the horizontal sliding component,and the horizontal sliding component is used for driving the grinding head to abut against or keep away from a crystalline silicon square stock after extraction. The equipment in the scheme is high in universality, high in processing efficiency and low in use cost.

Owner:福州天瑞线锯科技有限公司

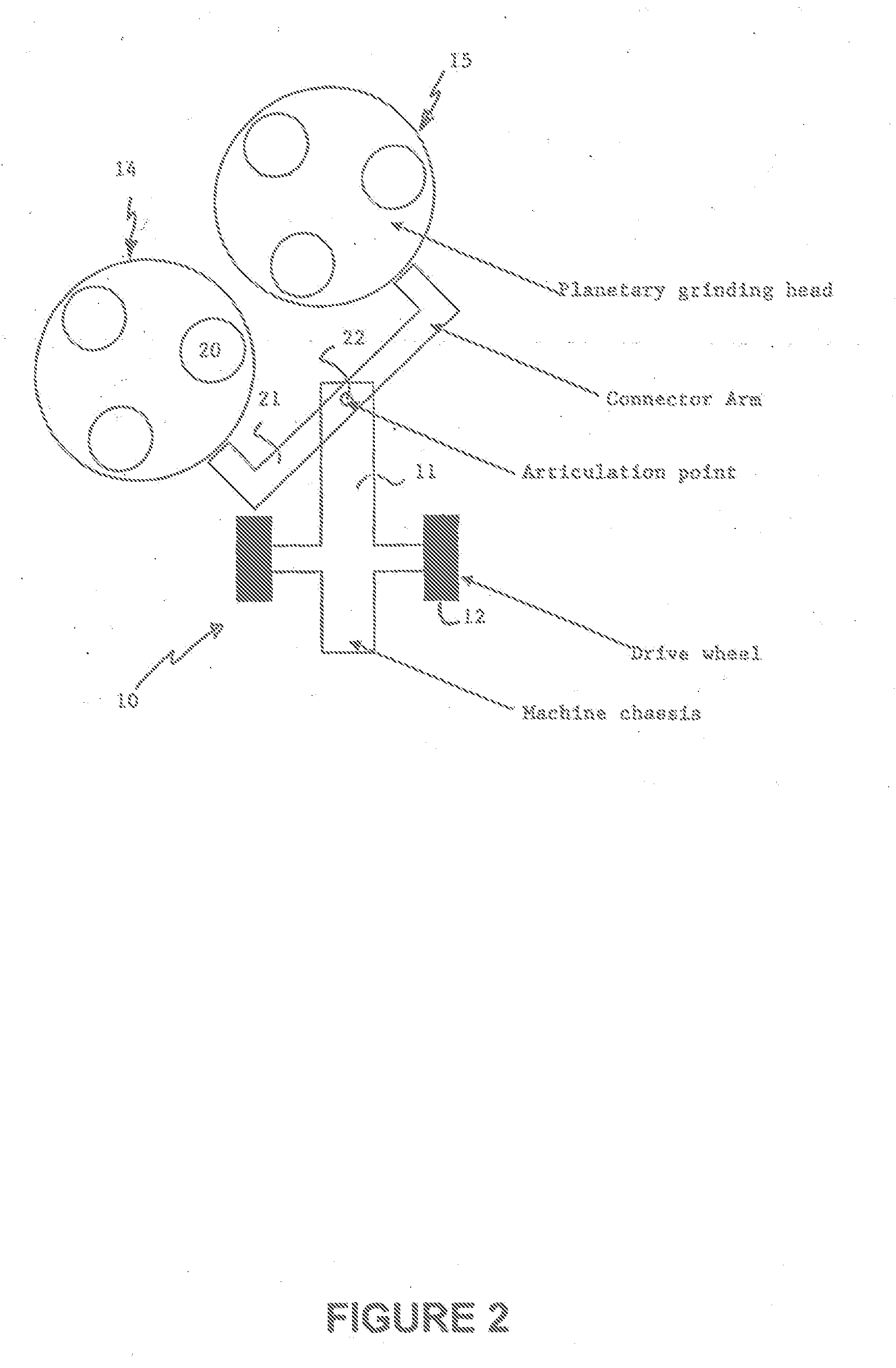

Robotic Surface Treatment Device

InactiveUS20140127975A1Increase rotation speedEdge grinding machinesAutomatic obstacle detectionRechargeable cellEngineering

A robotic surface treatment device includes at least two wheels, at least two electric motors, wherein one electric motor is connected to one corresponding wheel via a motor shaft, at least two treatment pads, wherein at least one treatment pad is attached to a bottom surface of a corresponding wheel, a main controller positioned on top of and in connection with drive controllers positioned on top of each electric motor, a plurality of sensors integrated in the main controller, and a rechargeable battery connected to the main controller. At least one treatment fluid tank may be positioned on the robotic surface treatment device, and at least one treatment fluid tube may extend from a bottom surface of the treatment fluid tank to a bottom surface of the robotic surface treatment device. The sensors may be laser or acoustic sensors configured to create a boundary line for a treatment area.

Owner:DEMING SYST

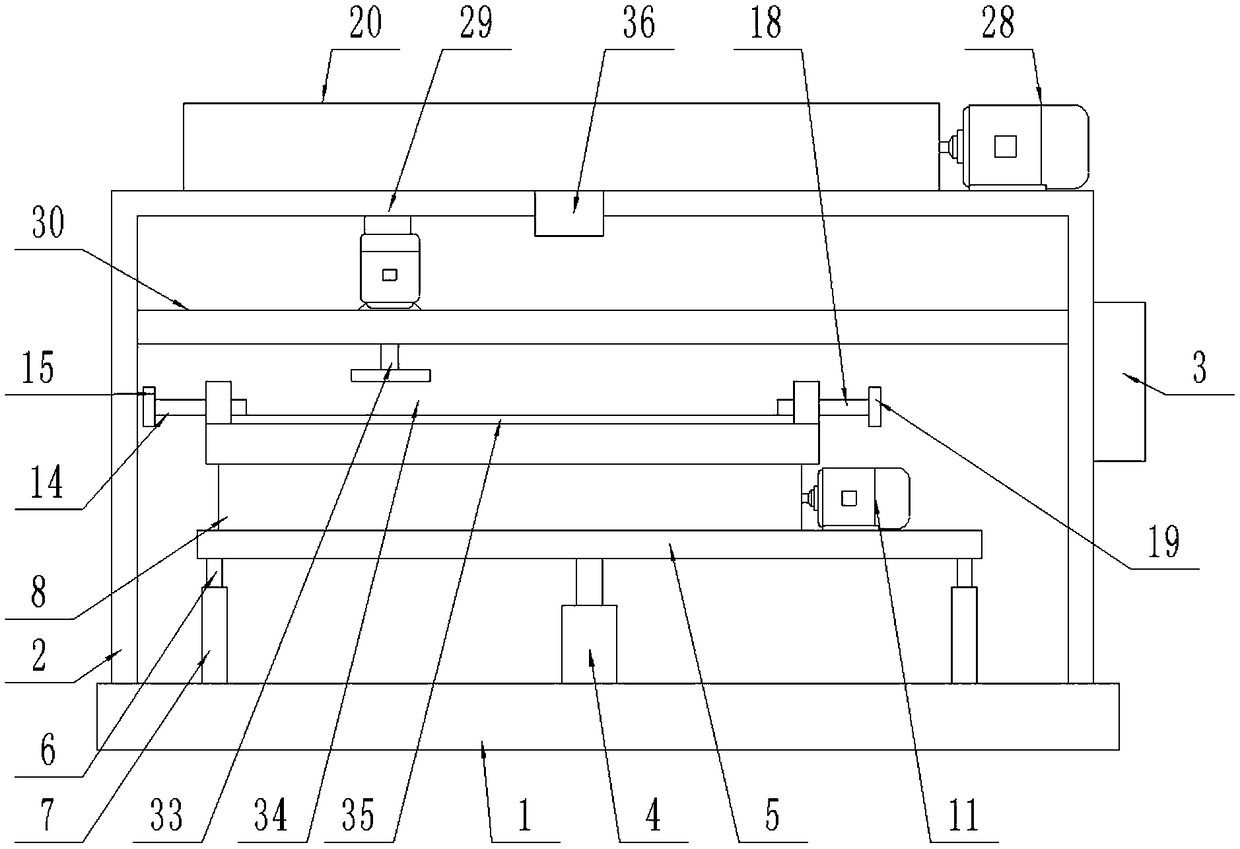

Wood plate polishing machine

PendingCN107855856AReal-time cleaningSimple structureGrinding carriagesGrinding bedsDust controlMachining process

The invention relates to a wood plate polishing machine which comprises a support, a frosting roller, a lifting mechanism, a drive mechanism, a limiting guide mechanism and a dust removal mechanism. Amachining table face is arranged at the upper end of the support. The frosting roller is transversely arranged above the middle portion of the machining table face, the two ends of the frosting roller are rotationally connected with the lifting mechanism, and the lifting mechanism can drive the frosting roller to move up and down. The drive mechanism is in transmission connection with the frosting roller. The limiting guide mechanism comprises two rectangular limiting plates, and the two limiting plates are symmetrically arranged on the two sides of the upper end of the machining table face in the length direction of the machining table face and are located on one side of the frosting roller. The sides, deviating from each other, of the two limiting plates are each provided with a pushingmechanism, and the two pushing mechanisms can push the two limiting plates correspondingly to move oppositely to be close to or away from each other. The dust removal mechanism is arranged above themachining table face and located on the other side of the frosting roller. The wood plate polishing machine has the beneficial effects that operation is flexible and convenient, it can be ensured thata wood plate is pushed in the correct direction in the machining process, and chippings on the surface of the wood plate can be cleared away in real time.

Owner:湖北金成光电科技股份有限公司

Ceramic tile polishing machine

InactiveCN107855855ASimple structural designEasy to useGrinding carriagesGrinding drivesElectric machinerySlide plate

The invention discloses a ceramic tile polishing machine which comprises a base, supporting legs and a mounting plate; the supporting legs are fixedly and symmetrically installed at the upper end of the base; the base is horizontally provided with the mounting plate and the supporting legs; the lower end of each supporting leg is provided with a longitudinal pulley and a longitudinal pulley groove; a longitudinal sliding plate, a longitudinal screw rod and a longitudinal motor are arranged on the lower right side of the mounting plate; a horizontal motor and a horizontal threaded rod are installed above the mounting plate; a sliding plate is connected to the horizontal threaded rod; a supporting plate is fixedly connected to the lower side of the sliding plate and is provided with a lifting table, a lifting motor and lifting cylinders; a connection device is arranged below the supporting plate; a polishing machine is connected to the lower end of the connection device; the horizontal motor, the longitudinal motor, the lifting motor and the polishing machine are connected with one another through a control panel; the base is provided with a transparent sealing cover; and a collection cavity is arranged below the base. The ceramic tile polishing machine provided by the invention is simple in structure and reasonable in design, can use the polishing machine to perform omnidirectional polishing on a product, is smoother in transmission and is beneficial to improving the quality of the product.

Owner:WUXI HUIOU CERAMIC CO LTD

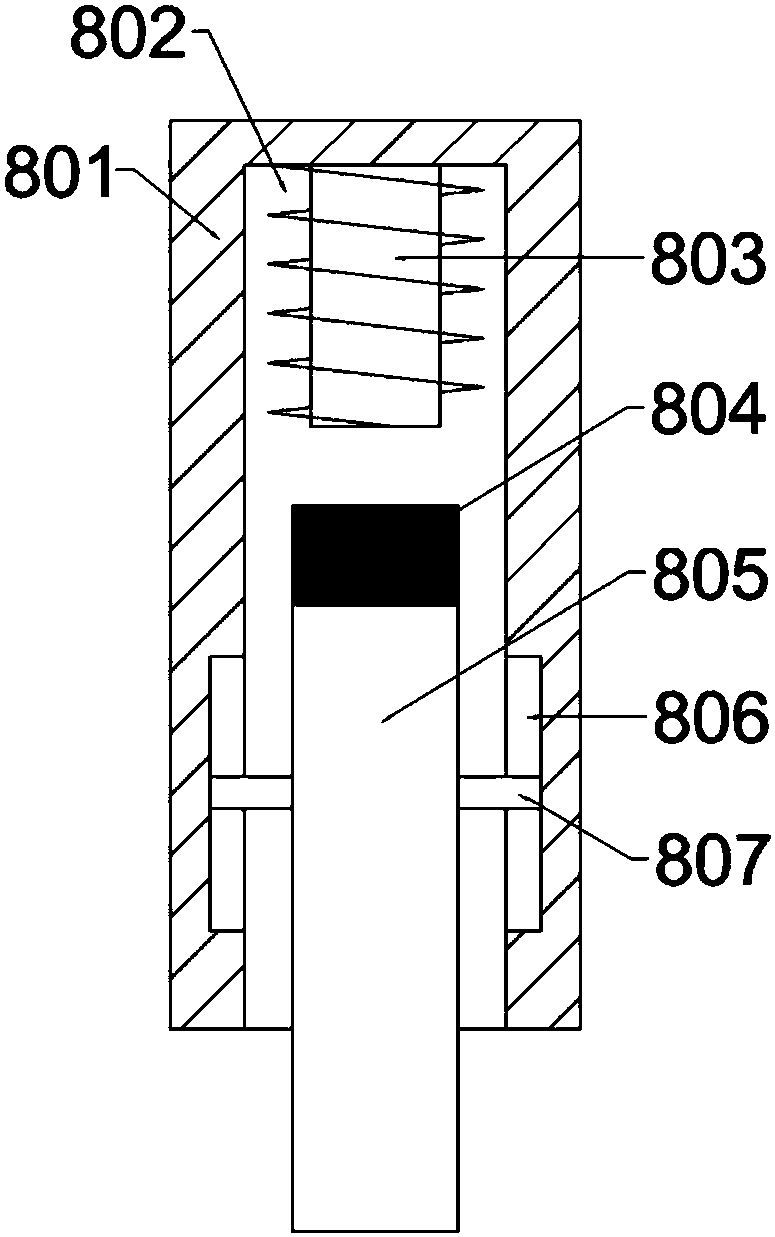

Method and device for detecting and dressing quality of end face grinding wheel in real time

ActiveCN110587402AWear monitoringImprove work efficiency and processing qualityGrinding drivesGrinding feed controlWheel wearLimit value

The invention discloses a method and device for detecting and dressing quality of an end face grinding wheel in real time. The device comprises a laser, a receiver, a grinding wheel dresser, the grinding wheel, a grinding wheel seat, a displacement sensor and a three-dimensional driving mechanism. According to the device, a laser beam emitted by the laser is obliquely emitted to the ground surfaceof a workpiece, the receiver continuously receives the reflected laser beam reflected by the ground surface, and the abrasion degree of the grinding wheel is detected in real time by detecting the energy of the reflected laser beam; when the energy of the laser beam reflected by the receiver reaches the corresponding grinding wheel wear limit value, the grinding wheel is triggered to stop grinding, the current grinding position of the grinding wheel is recorded through the displacement sensor, and the grinding wheel is moved to the position of the grinding wheel dresser by a grinding wheel driving mechanism and is dressed in real time; and the dressed grinding wheel returns to the current grinding position, and the grinding stroke of the surface of the workpiece continues. The on-line detection and dressing of the grinding wheel can be quickly and efficiently realized, and the processing quality and the grinding efficiency of end face grinding are improved.

Owner:NANTONG UNIVERSITY

Timber bulge processing device

InactiveCN107030554AAvoid indirect contactProtect personal safetyGrinding carriagesGrinding drivesElectricityHydraulic cylinder

The invention discloses a wood protrusion processing device, which comprises a bearing plate, a grinding mechanism is arranged on the upper surface of the bearing plate, a placing platform is arranged on the upper surface of the bearing plate and between a group of slide rails, the bearing plate A vertical pole is provided on the upper surface of the board and in front of the placing table, a vertical mounting plate is provided on the upper surface of the vertical mounting plate, a controller is provided on the front surface of the vertical mounting plate, and a mains interface is provided on the rear surface of the bearing plate. The power terminal of the controller is connected to the mains interface through wires, and the output end of the controller is respectively connected to the No. 1 electric trolley, the No. 2 electric trolley, the No. 1 hydraulic cylinder, the No. The trolley, the No. 2 hydraulic cylinder and the rotary motor are connected. The beneficial effects of the present invention are that the semi-automatic fixed rotary grinding has fast grinding speed, liberates manpower, improves work efficiency, is moderate in size, convenient to move, easy to use, and strong in novelty.

Owner:丽水市知科科技有限公司

Building artificial stone machining equipment with local reciprocating grinding function

InactiveCN107900819ALess attractiveAchieve reductionGrinding carriagesGrinding drivesMotor drivePower flow

The invention discloses building artificial stone machining equipment with the local reciprocating grinding function. The building artificial stone machining equipment comprises a base. Two support plates are fixedly connected to the upper side of the base in a symmetrical manner. The top ends of the two support plates are jointly and fixedly connected with a mounting plate. A moving groove is formed in the mounting plate, wherein an opening of the moving groove faces downwards. The moving groove is internally provided with a moving block. A horizontal threaded through hole is formed in the moving block. A horizontal threaded rod is connected into the horizontal threaded through hole in a threaded manner. The two ends of the horizontal threaded rod are arranged at the two ends of the mounting plate in an erected manner. The right end of the horizontal threaded rod is fixedly connected with an output shaft of a first motor. The building artificial stone machining equipment has the beneficial effects that when grinding is needed, the magnitude of an introduced current is reduced, the suction force on a magnetic pole is reduced, descending of grinding teeth is achieved, and grinding treatment is conducted on stone; and the two motors drive a rotating shaft to rotate, the rotating shaft drives a gear to rotate, a rack engaged with the gear moves toward the left side, a moving plateis driven to move toward the left side, and thus leftward movement of the grinding teeth is achieved.

Owner:徐继传

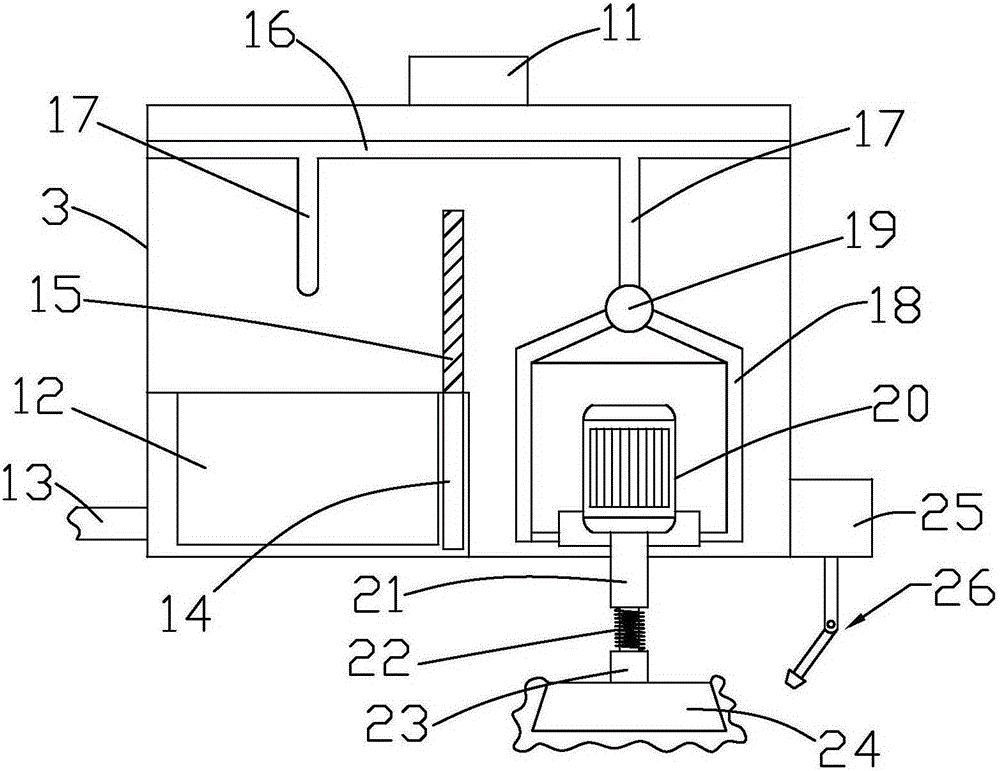

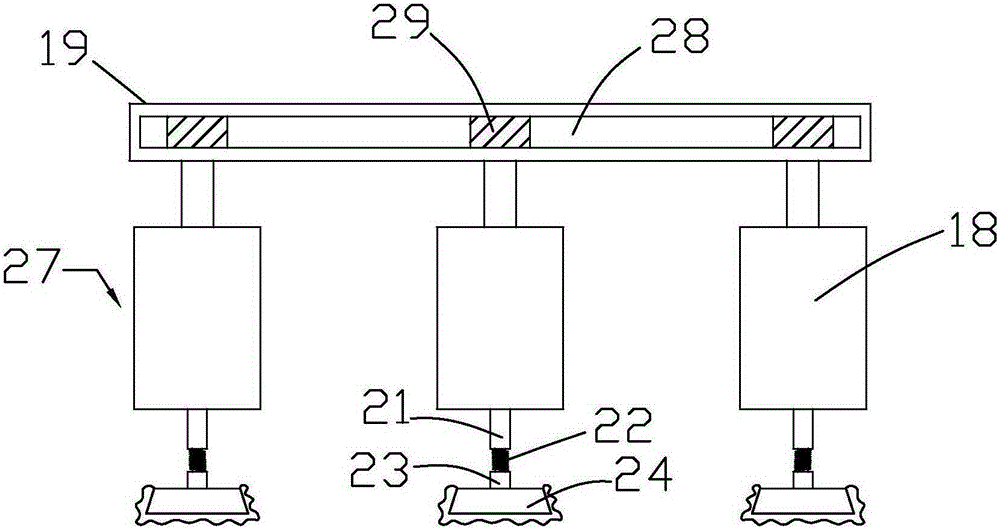

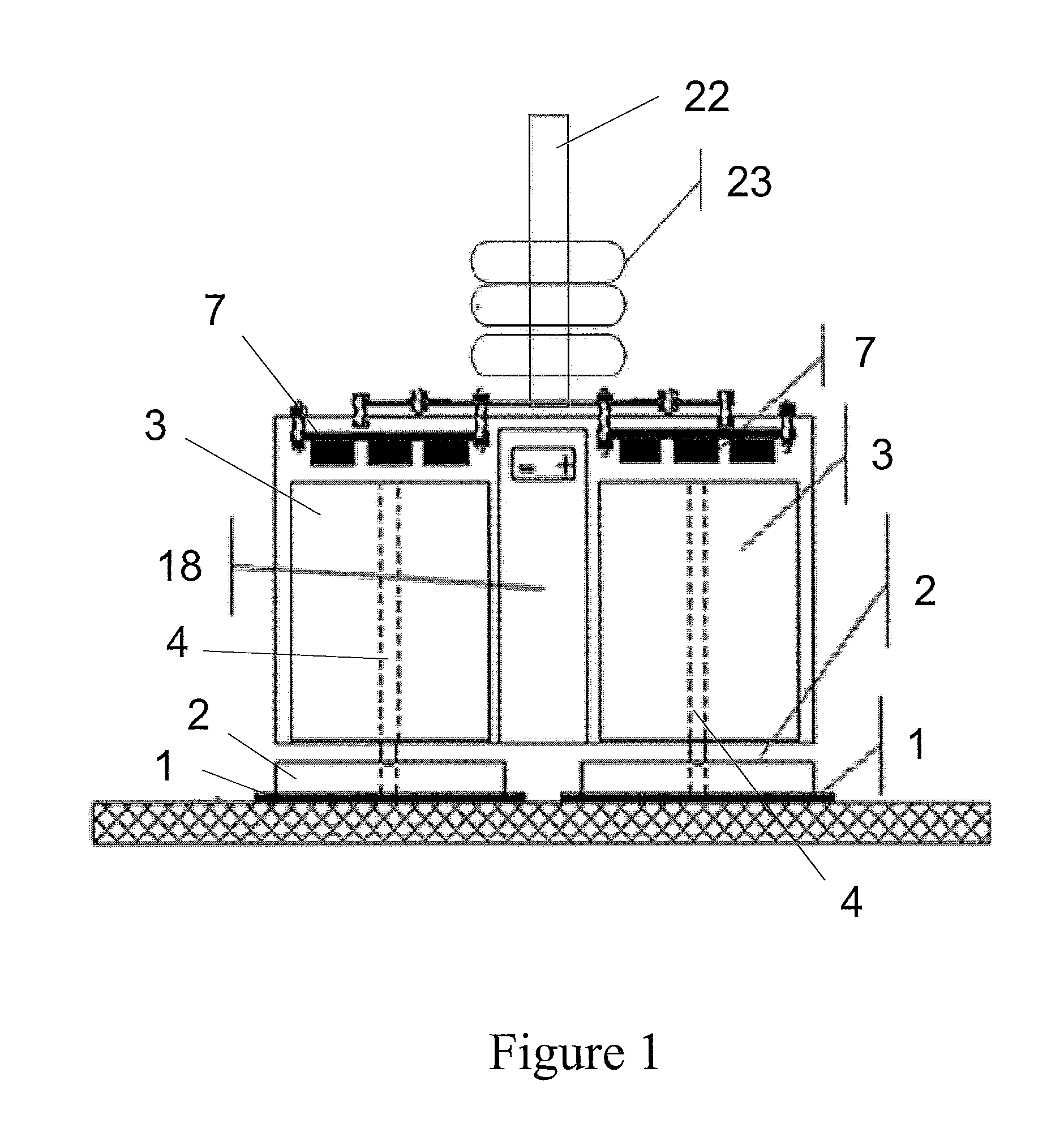

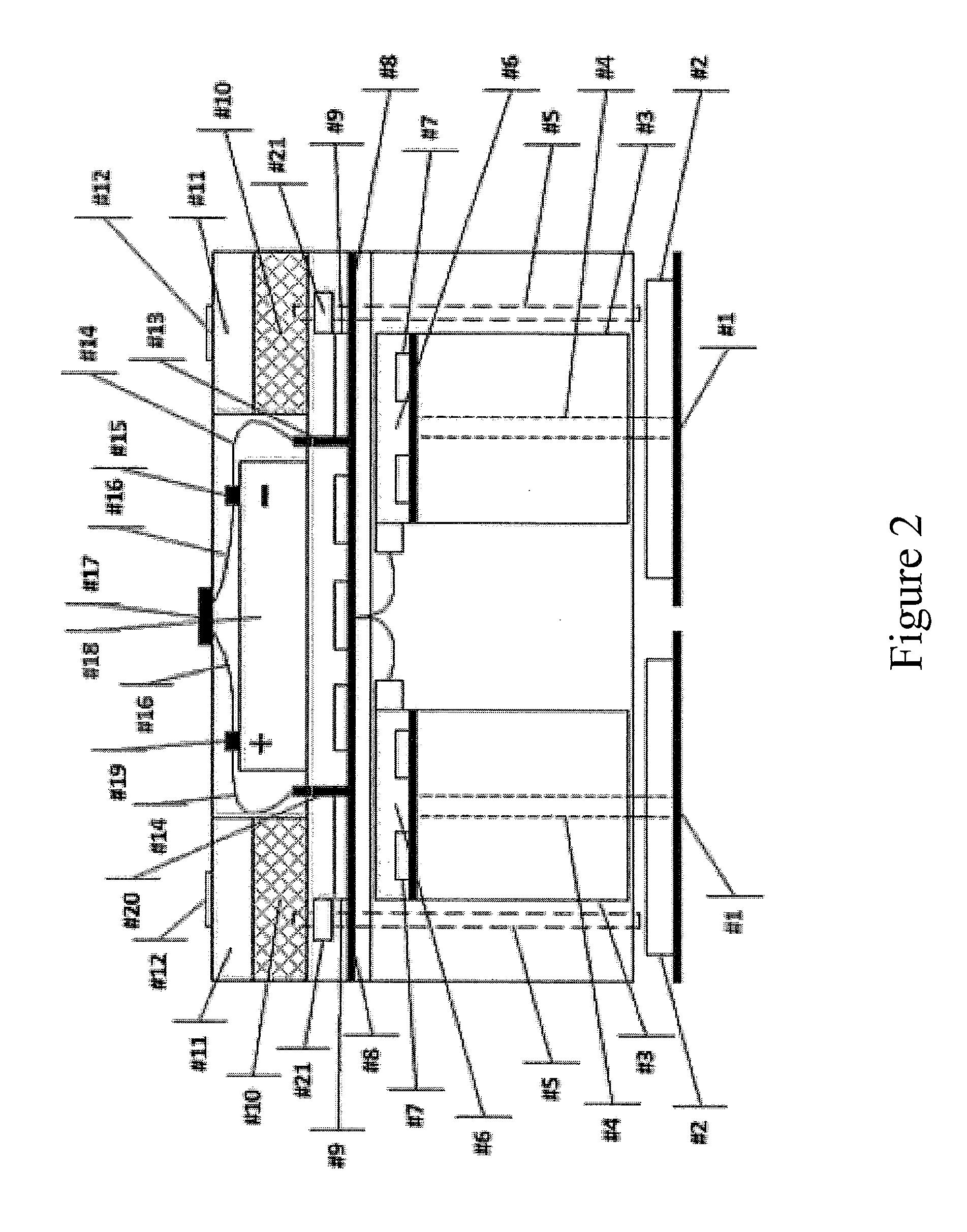

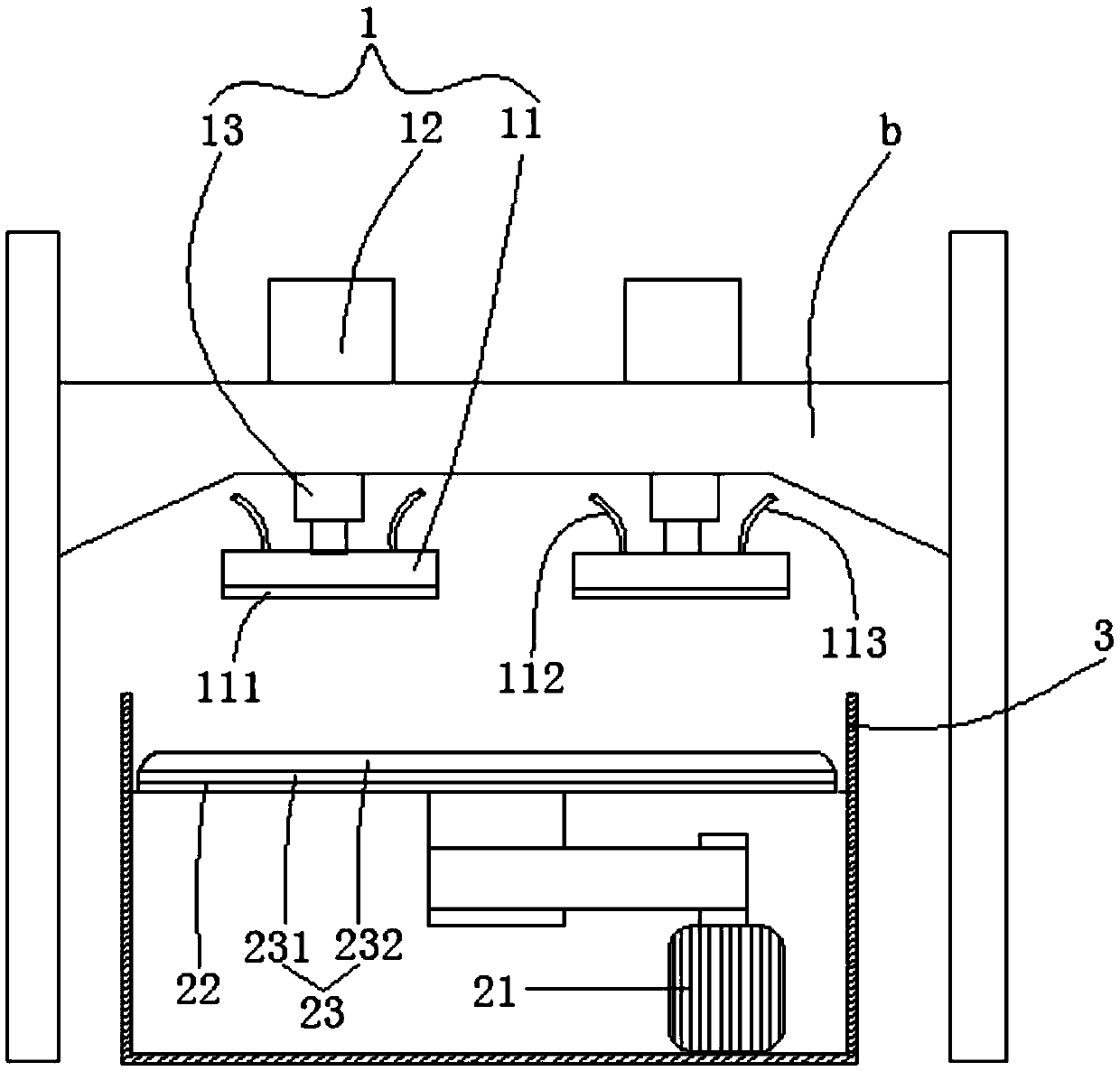

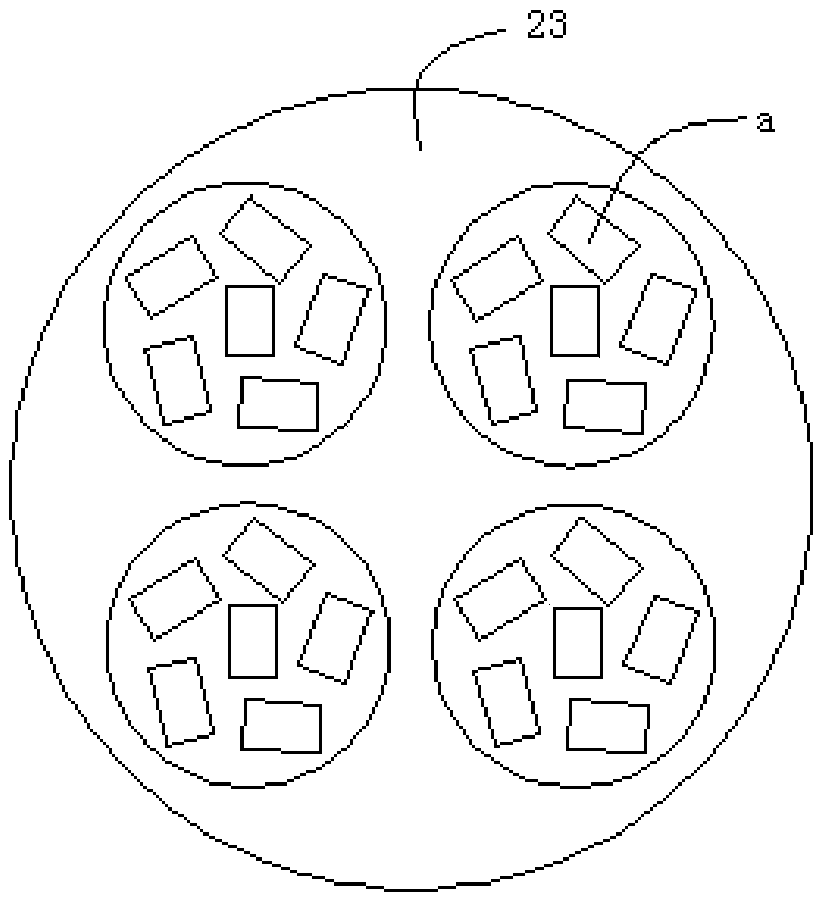

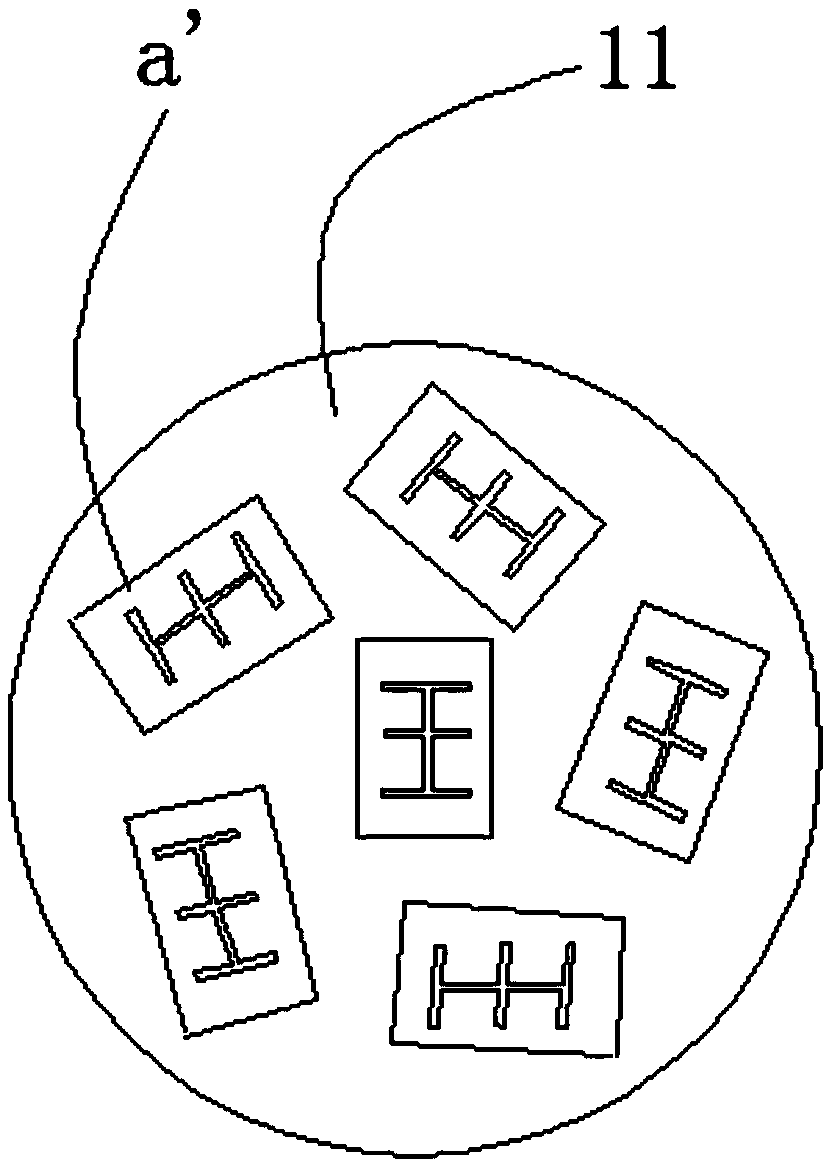

Polishing machine for polishing inner screens of mobile phones

InactiveCN105500140ALower requirementAvoid scratchesGrinding headsGrinding work supportsMotor driveDevice form

The invention provides a polishing machine for polishing inner screens of mobile phones. The polishing machine comprises a grinding disc assembly and a polishing assembly, wherein the grinding disc assembly is arranged on the upper part of a portal frame; the polishing assembly is arranged on the lower part of the portal frame; the grinding disc assembly is provided with a plurality of grinding mechanisms; each grinding mechanism comprises a grinding disc, a first motor and a cylinder; each first motor drives the corresponding grinding disc to rotate; each cylinder drives the corresponding grinding disc to lift and fall; a polishing assembly is arranged on the bottom of each grinding disc; the polishing assembly comprises a second motor, a base and a polishing blanket for accommodating the inner screens of the mobile phones; the polishing blanket is arranged on the base; and the base is connected with a second motor. A plurality of carrying regions corresponding to a plurality of grinding mechanisms are arranged on the polishing blanket; and a concave region which corresponds to the corresponding polishing assembly and is used for accommodating the inner screens of the mobile phones is formed in each carrying region. Compared with the prior art, the polishing machine has the grinding discs which are driven separately, each grinding disc and the corresponding driving device form the corresponding grinding mechanism, polishing quality can be improved, requirements on the driving devices are low relatively, and vacuum adsorption can be realized without the aid of trays.

Owner:ANHUI RUIFU PHOTOELECTRIC TECH CO LTD

Finishing varnish coating device for high-pressure laminate

PendingCN106881640AHigh speedImprove uniformityGrinding carriagesGrinding drivesElectric machineryLeather belt

The invention discloses a finishing varnish coating device for a high-pressure laminate. The finishing varnish coating device comprises an outer frame, wherein a top frame is fixedly connected to the top of the outer frame; a first motor is fixedly connected to one side of the bottom of the inner wall of the top frame; the output shaft of the first motor is connected with a first belt in a transmission manner through a rotary wheel; besides, one side, far away from the first motor, of the first belt is in transmission connection with a moving device; the moving device is fixedly connected with the inner wall of the top frame through a middle shaft; and one side of the moving device penetrates through the top of the outer frame and extends to the outer frame. The invention relates to the technical field of finishing varnish coating devices. By adopting the finishing varnish coating device for the high-pressure laminate, an automatic finishing varnish coating aim is realized; movement of a grinding rod can be driven by the moving device, so that automatic finishing varnish coating for plates is realized; finishing varnish coating speed is greatly improved; working load of workers is reduced; time and labor are saved; finishing varnish coating uniformity is improved; and the height of the grinding rod can be adjusted according to different thicknesses of plates, so that the finishing varnish coating device can be applicable to more plates.

Owner:江苏中天消防设备有限公司

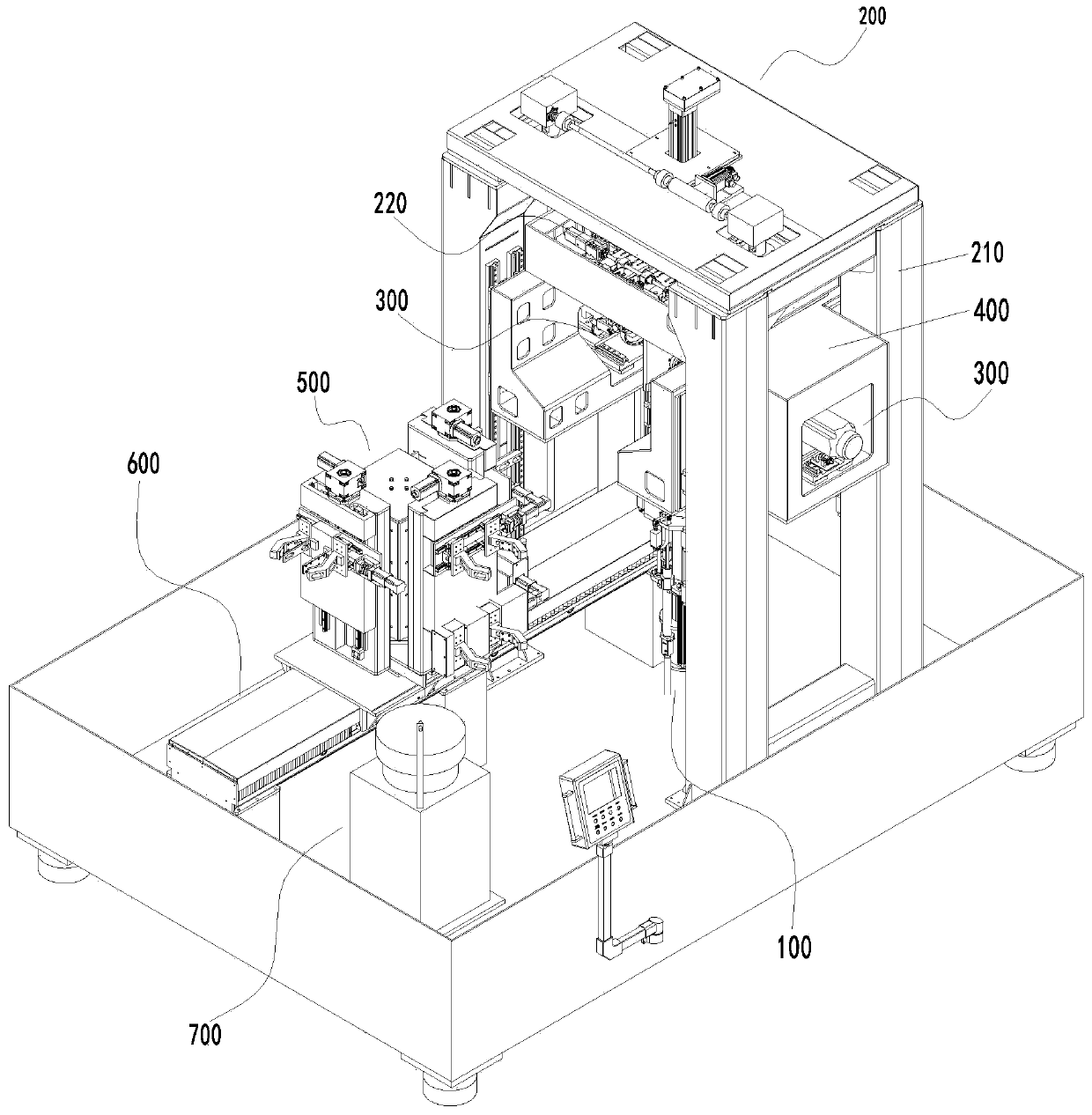

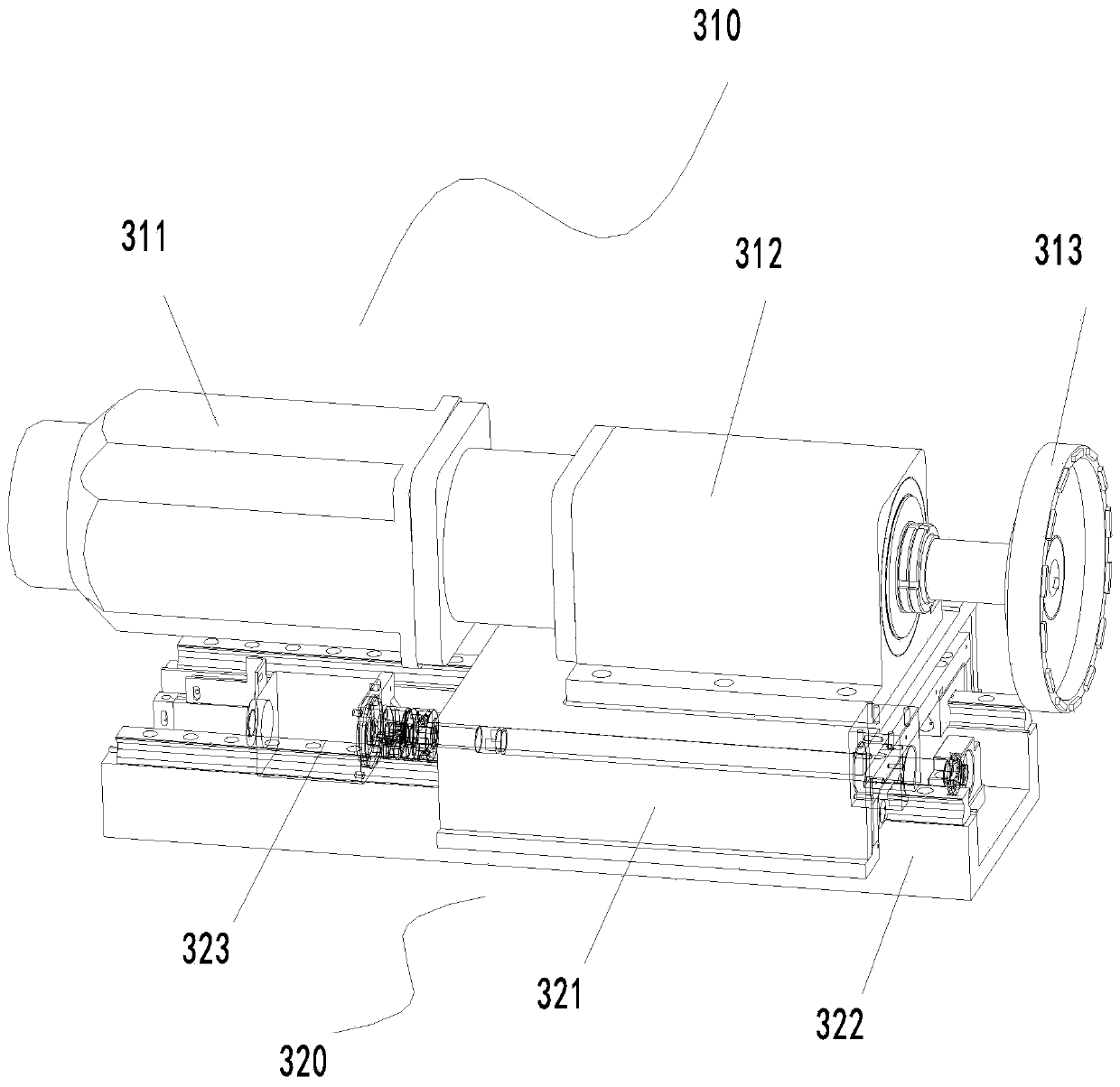

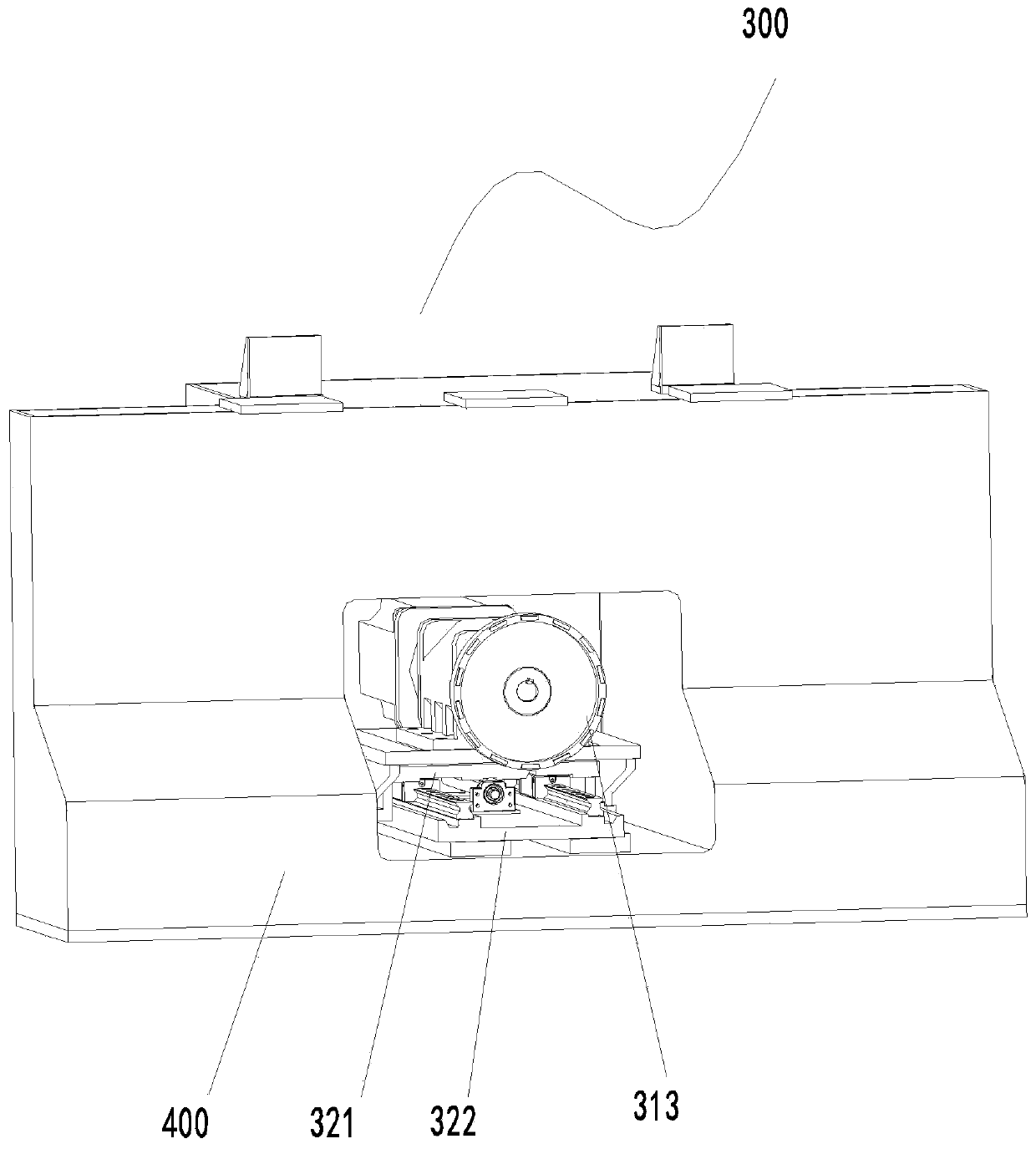

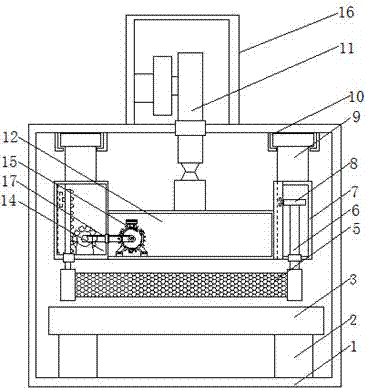

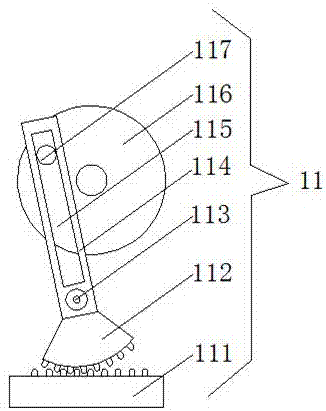

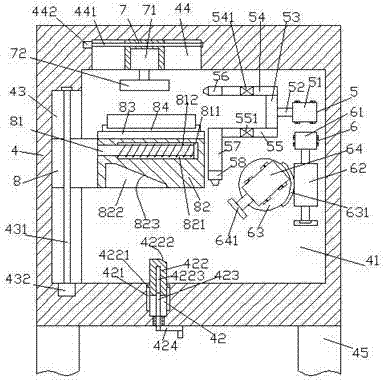

Precise composite molding grinding machine for numerical control linear guide rail

InactiveCN105415113AReduce mutual interferenceAvoid mutual interferenceGrinding carriagesGrinding drivesNumerical controlPortal frame

The invention discloses a precise composite molding grinding machine for a numerical control linear guide rail. The precise composite molding grinding machine comprises a U-shaped base. The U-shaped base is provided with an embedded grinding workbench which is driven by a drive device and can horizontally move in the longitudinal direction. The embedded grinding workbench is provided with a magnetic clamp used for fixing the guide rail. A portal frame is arranged above the U-shaped base. A beam of the portal frame is provided with a first transverse drive mechanism and a second transverse drive mechanism. The first transverse drive mechanism is connected with a first vertical grinding head mechanism through a first vertical drive mechanism, and the second transverse drive mechanism is connected with a second vertical grinding head mechanism through a second vertical drive mechanism. A vertical bearing frame is arranged in front of the portal frame and provided with a third transverse drive mechanism. The third transverse drive mechanism is connected with a horizontal grinding head mechanism through a third vertical drive mechanism. Due to the fact that the first vertical grinding head mechanism, the second vertical grinding mechanism and the horizontal grinding head mechanism are used for grinding the two side faces and the installing bottom face of the guide rail at the same time, workpieces do not need to be clamped many times, the machining efficiency and the grinding precision can be greatly improved, and the product quality is guaranteed.

Owner:JIANGMEN INTIN NUMERICAL CONTROL MACHINE TOOL CO LTD

Machine tool

ActiveUS20150251290A1Grinding wheel securing apparatusRevolution surface grinding machinesSlide plateMachine tool

A sanding machine, with a machine bed, two vertical supports arranged laterally at the machine bed, with a bridge displaceable on the vertical supports in a horizontal, linear Y-axis, with an X-sled displaceable at the bridge in a horizontal, linear X-axis, with a Z-sled displaceable at the X-sled in a vertical, linear Z-axis, with an operating spindle supported at the Z-sled, particularly a sanding spindle, with a machine table and a magazine wheel comprising tool holders for sanding disks, and which is rotational about an axis parallel in reference to the Z-axis, with the operating spindle being able to remove a tool from a tool holder and place it there when this tool holder is rotated into an exchange position, with the tool magazine being arranged underneath the machine table and in the area of the exchange position.

Owner:ADELBERT HAAS GMBH

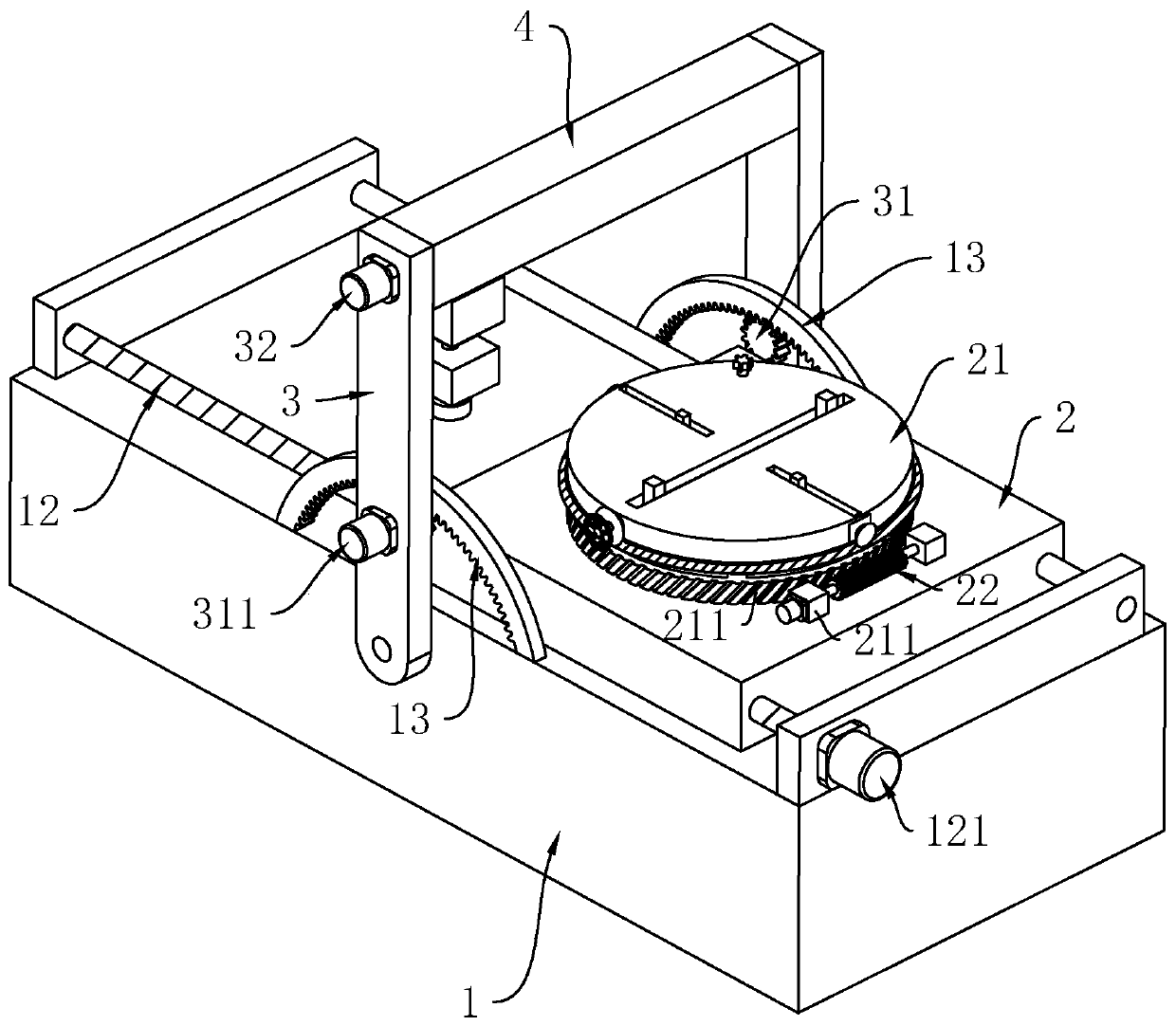

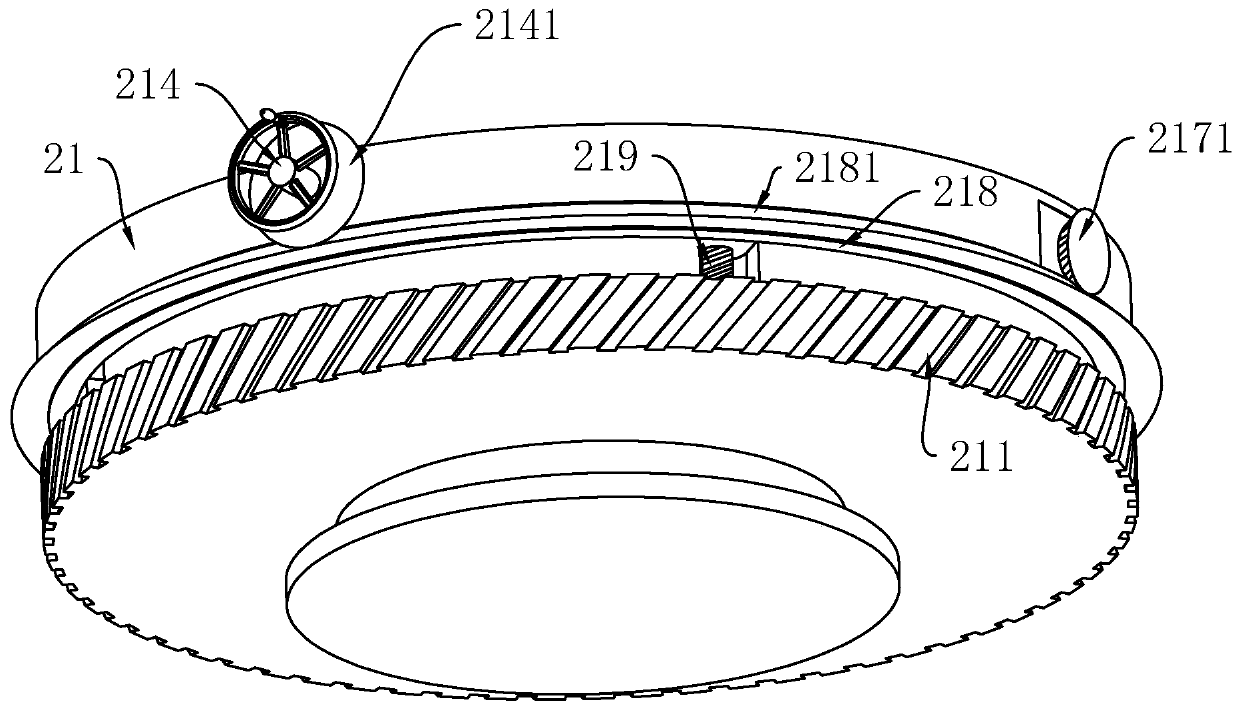

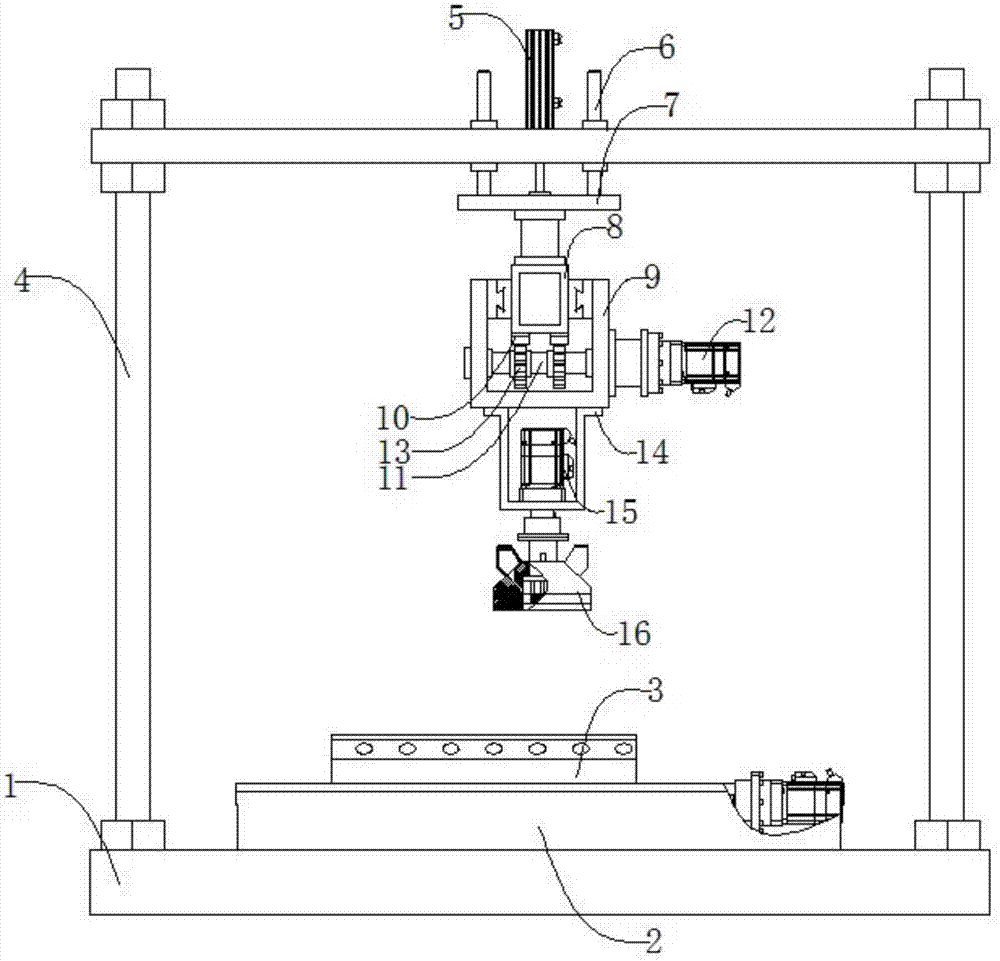

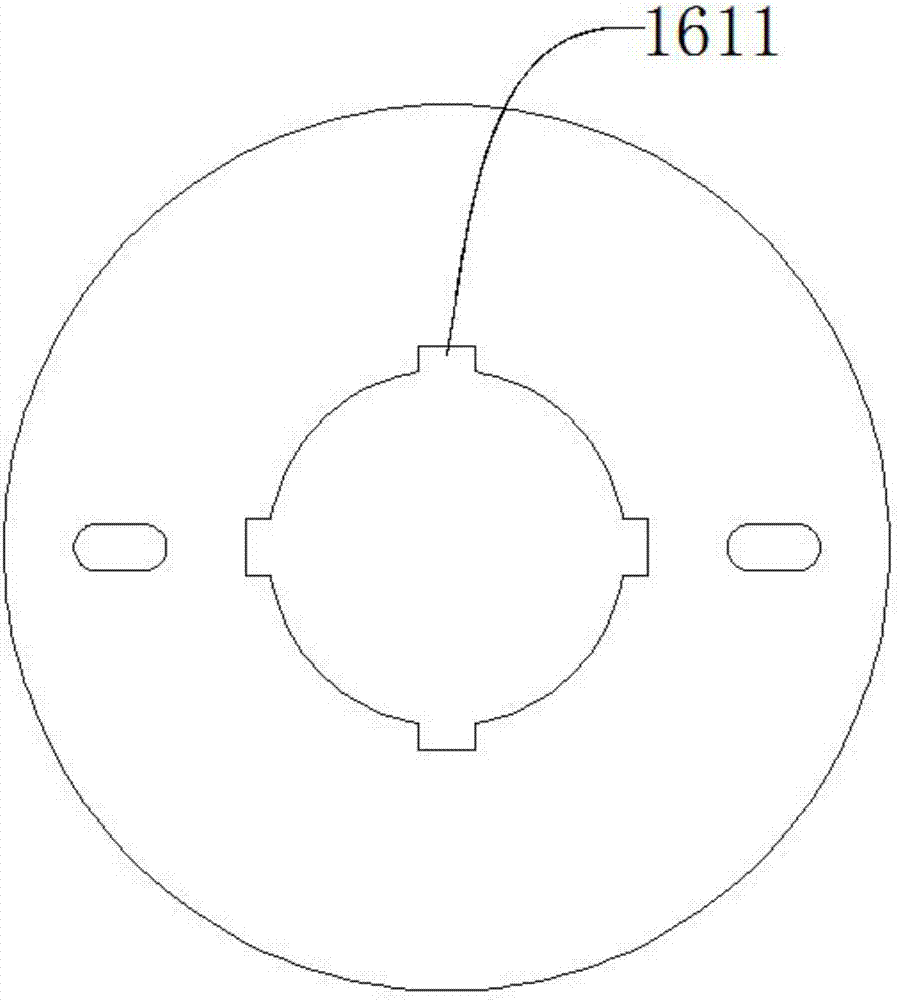

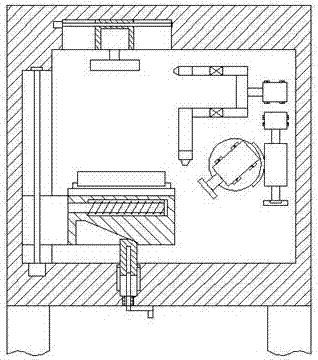

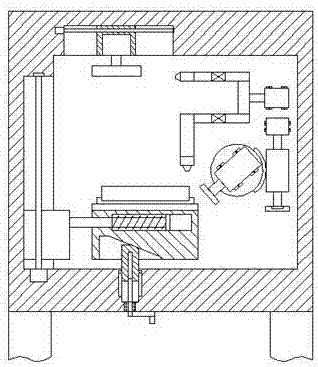

Polishing device of disk type parts

InactiveCN108326652AImprove grinding accuracyImprove processing efficiencyGrinding carriagesGrinding drivesLocking mechanismEngineering

The invention discloses a polishing device of disk type parts. The polishing device of the disk type parts comprises a base, a portal frame, a rotation mechanism, a locking mechanism, a polishing mechanism, a transverse movement mechanism, a lifting mechanism and a controller. The lifting mechanism is jointly composed of a servo air cylinder, a lifting plate, locating rods and locating sleeves. The locking mechanism is jointly composed of a first limiting block, a first locking screw, a first adjusting handle, a second limiting block, a second threaded hole, a second locking screw and a secondadjusting handle. The portal frame is fixed to the base. The transverse movement mechanism is jointly composed of a transverse movement shell, a first bearing seat, a second bearing seat, a lead screw, a fixing rod and a servo motor. The polishing mechanism is jointly composed of a sliding groove, a sliding block, a polishing motor, a rotating shaft and a polishing wheel. The polishing device ofthe disk type parts has the beneficial effects of being simple in structure and high in practicability.

Owner:葛映东

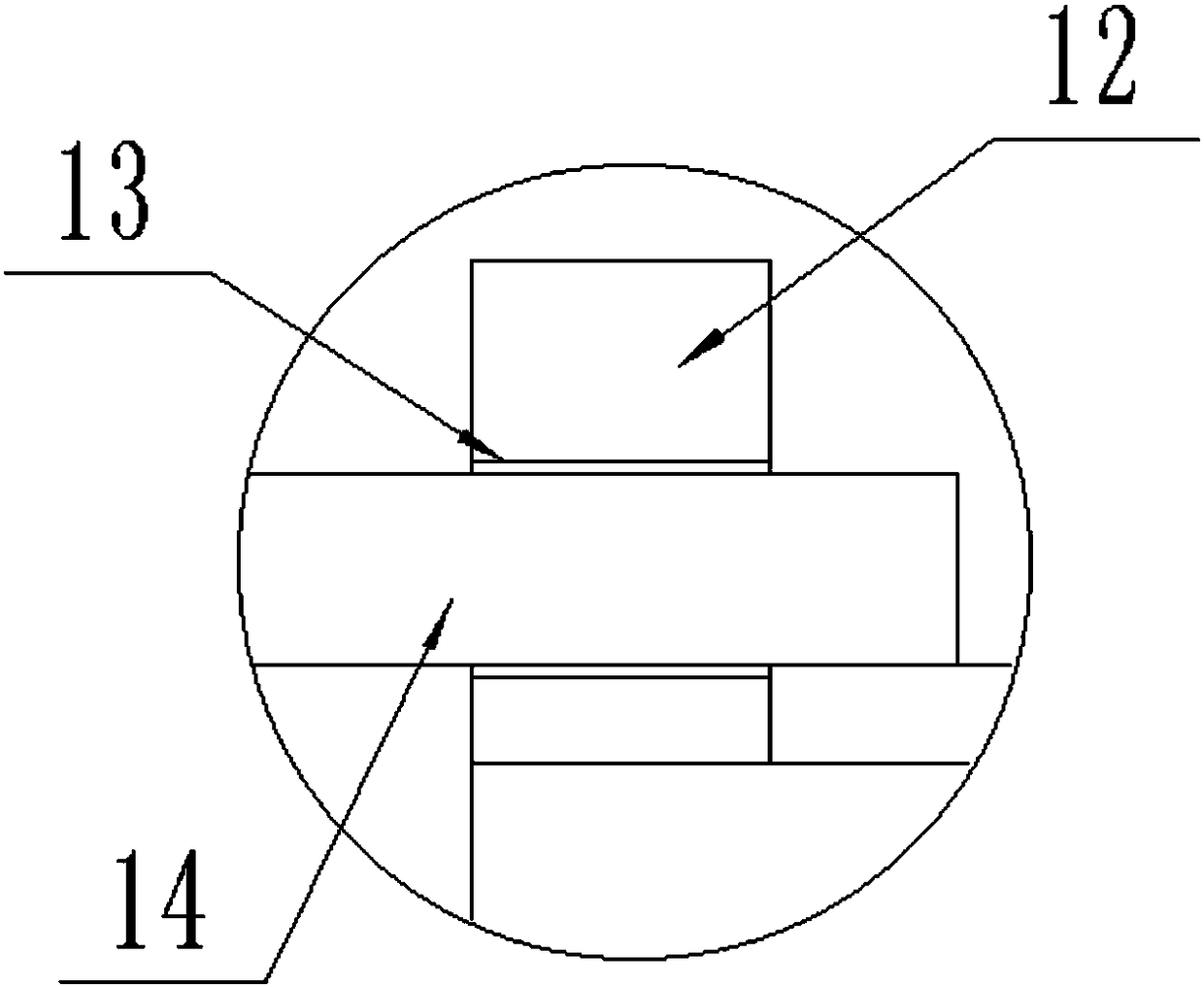

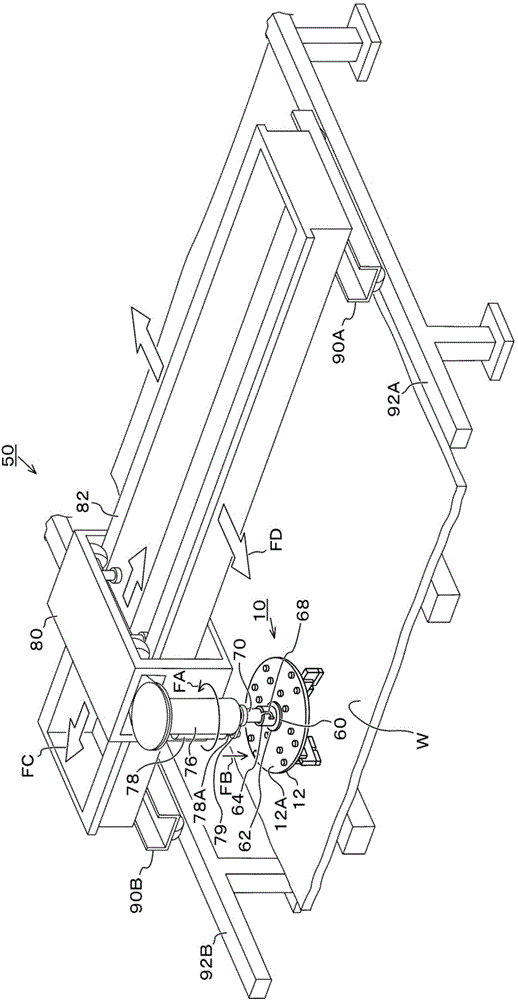

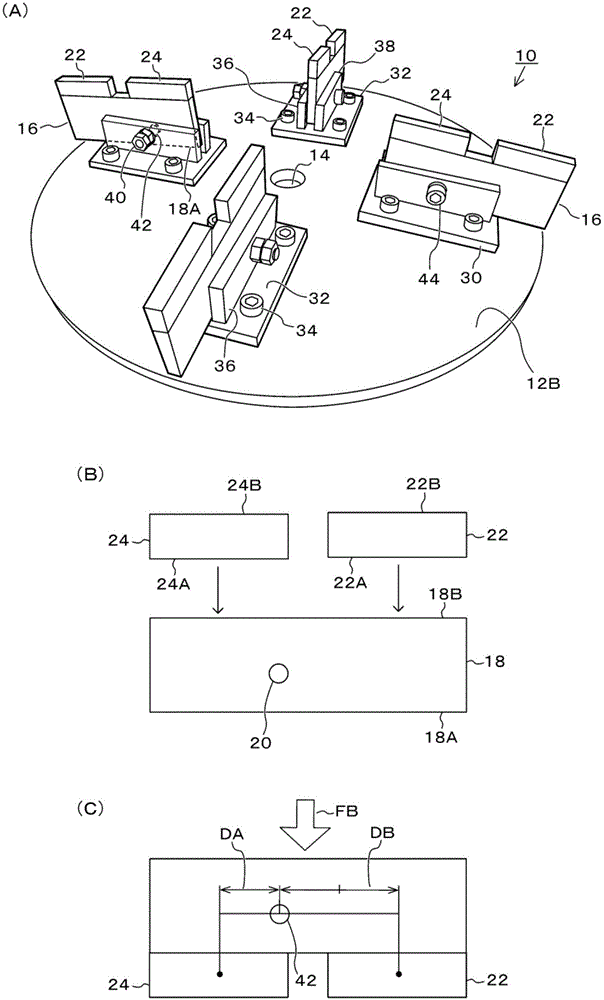

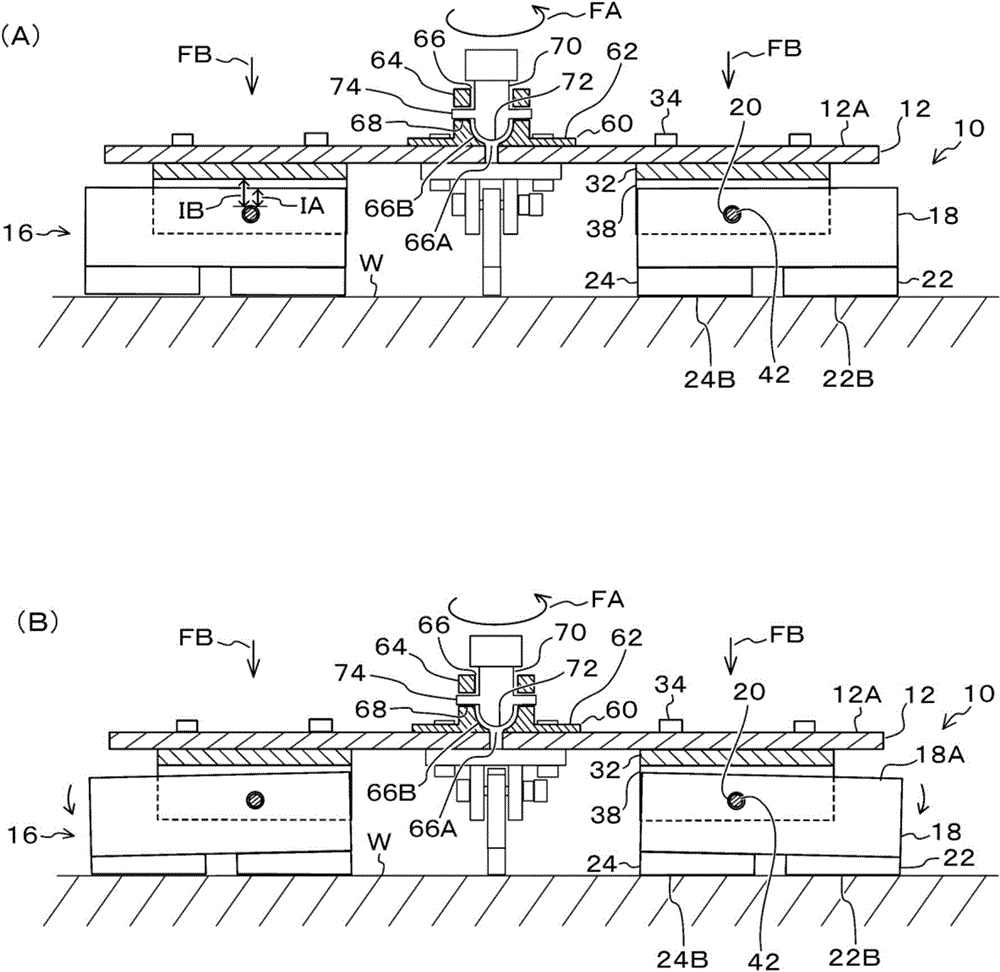

Grinder and grinding machine

ActiveCN104972388AEven contactEasy to followLapping machinesLapping toolsEngineeringMechanical engineering

A grinder includes a rotatable disk to be pressed to a workpiece; a plurality of grinding bodies provided on one principal surface of the disk so as to cross a circumferential direction of the disk, each having a grinding stone chip on a side contacting the workpiece; and support devices, each supporting each of the grinding bodies so that the grinding stone chip swings with respect to the principal surface. Each support device supports each grinding body at a position at which an abrasion amount of the grinding stone chip is made uniform when the disk is rotated while being pressed to the workpiece so that a pressure to be applied to the grinding stone chip on an outer peripheral side of the disk becomes smaller than a pressure to be applied to the grinding stone chip on an inner peripheral side of the disk.

Owner:MILANO SEISAKUSYO

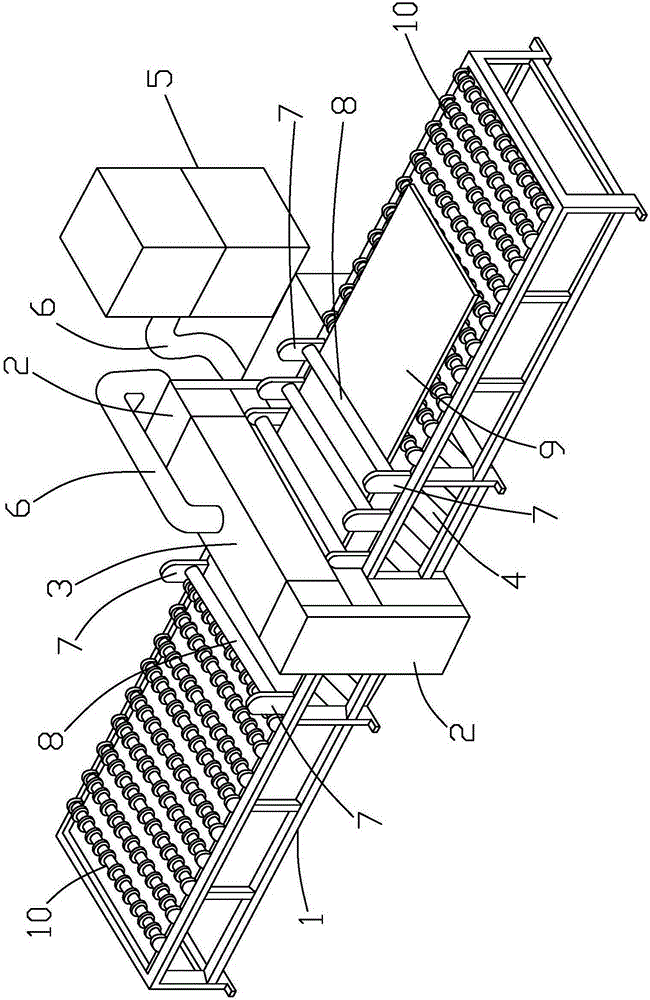

Surface treatment device and treatment method for household solid wood board production

ActiveCN114800093ASatisfy double-sided automatic grinding operationImprove processing efficiencyEdge grinding machinesStationary drilling machinesSolid woodPunching

The invention relates to the technical field of furniture board production equipment, in particular to a surface treatment device for household solid board production, which comprises a left support frame, a first portal frame, a limiting mechanism, a side edge grinding mechanism, a treatment mechanism, a right support frame, a second portal frame and a punching mechanism, two discharging conveying belts are installed at the top of the right supporting frame, and a turn-over mechanism is arranged at the end, close to the processing mechanism, of the left supporting frame. Through mutual cooperation of all the mechanisms, automatic feeding operation, two-side-edge grinding operation, front-back-side grinding operation, automatic punching operation and automatic discharging operation on solid wood boards can be achieved; the full-automatic double-sided solid wood board grinding machine is high in automation degree, the production cycle is shortened, solid wood boards can be turned over in the conveying process, double-sided automatic grinding operation of the solid wood boards is met, the machining efficiency and effect of the solid wood boards are improved, and the overall equipment is high in practicability.

Owner:山东鲁班世家门业有限公司

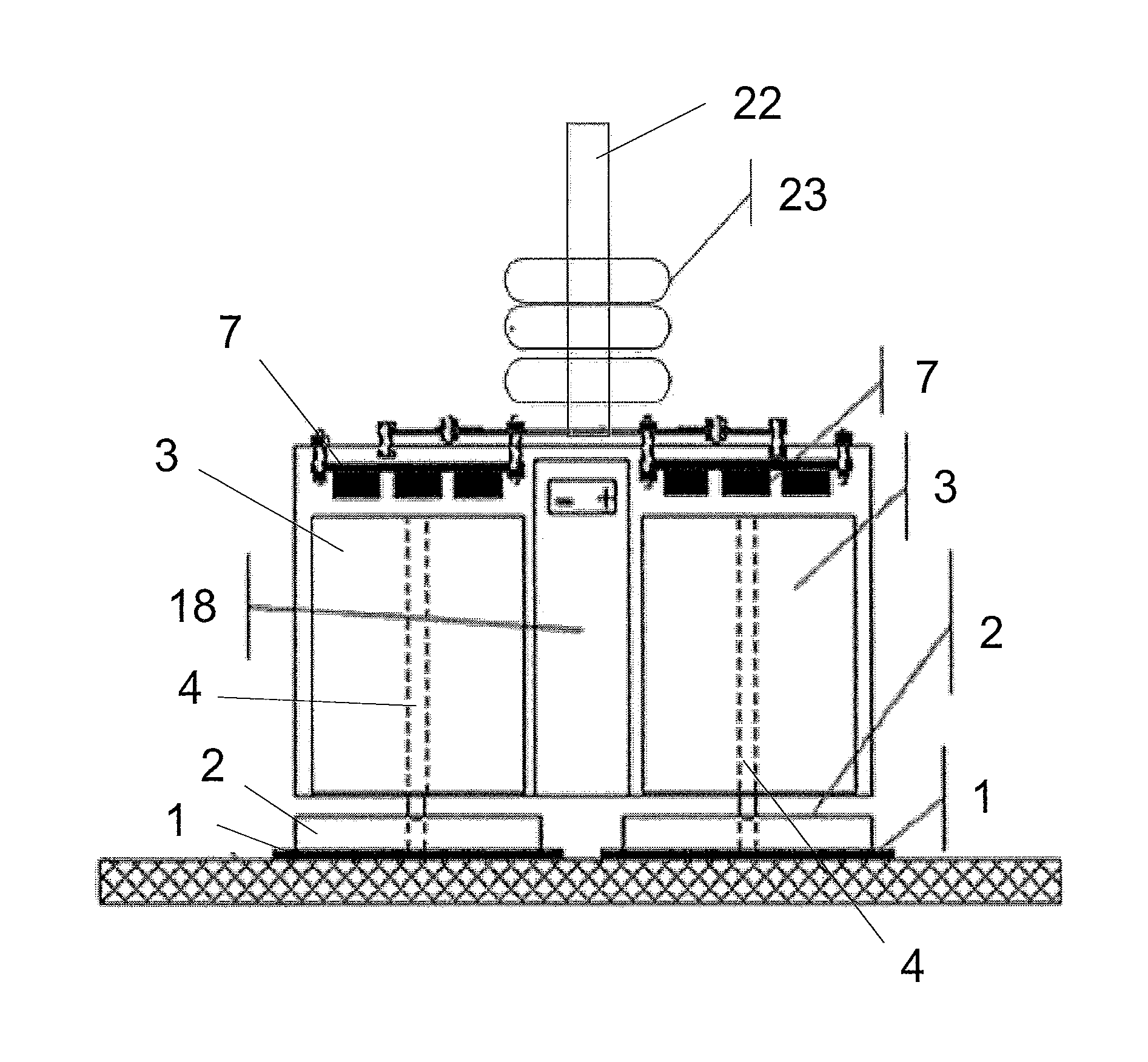

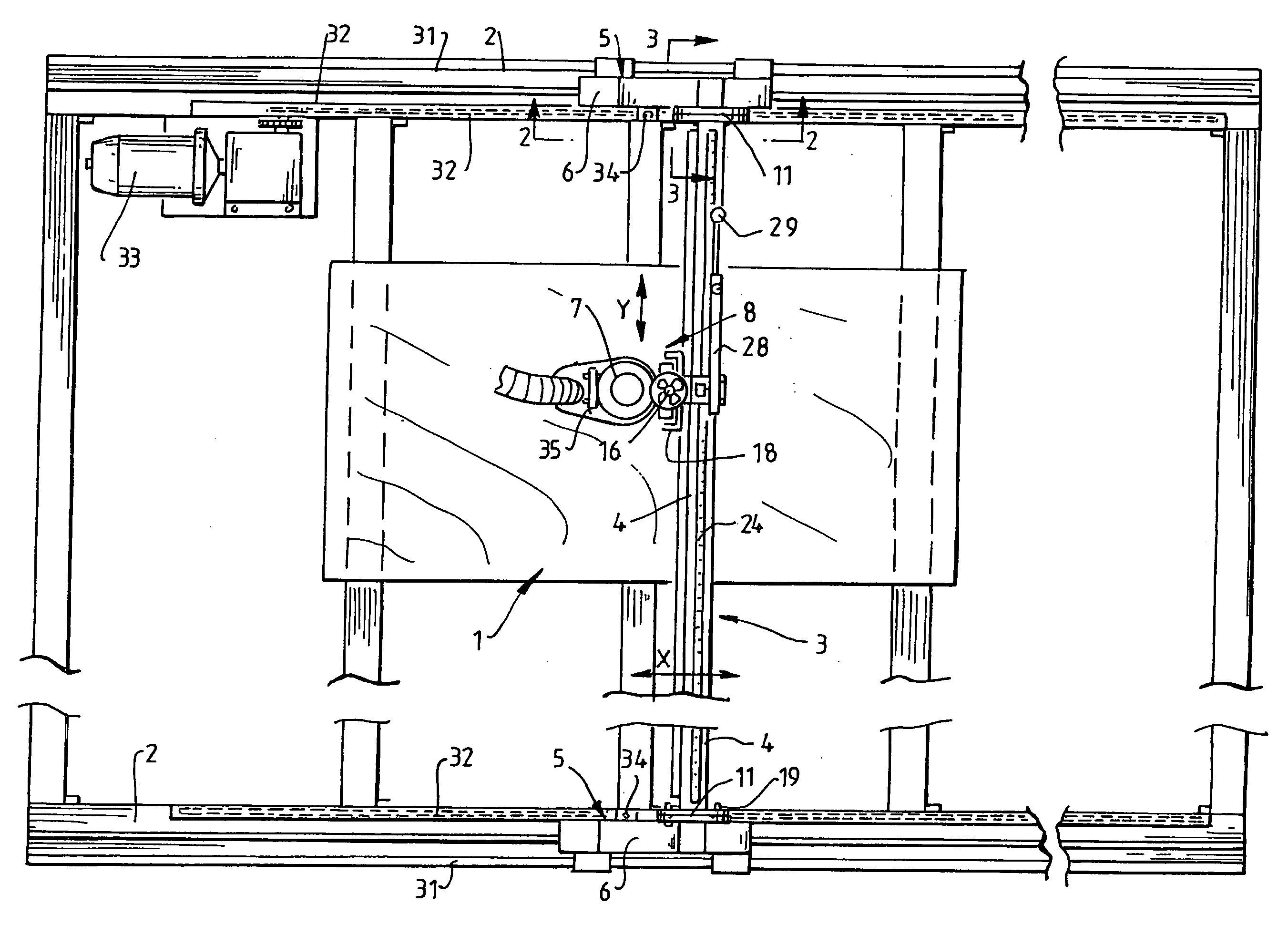

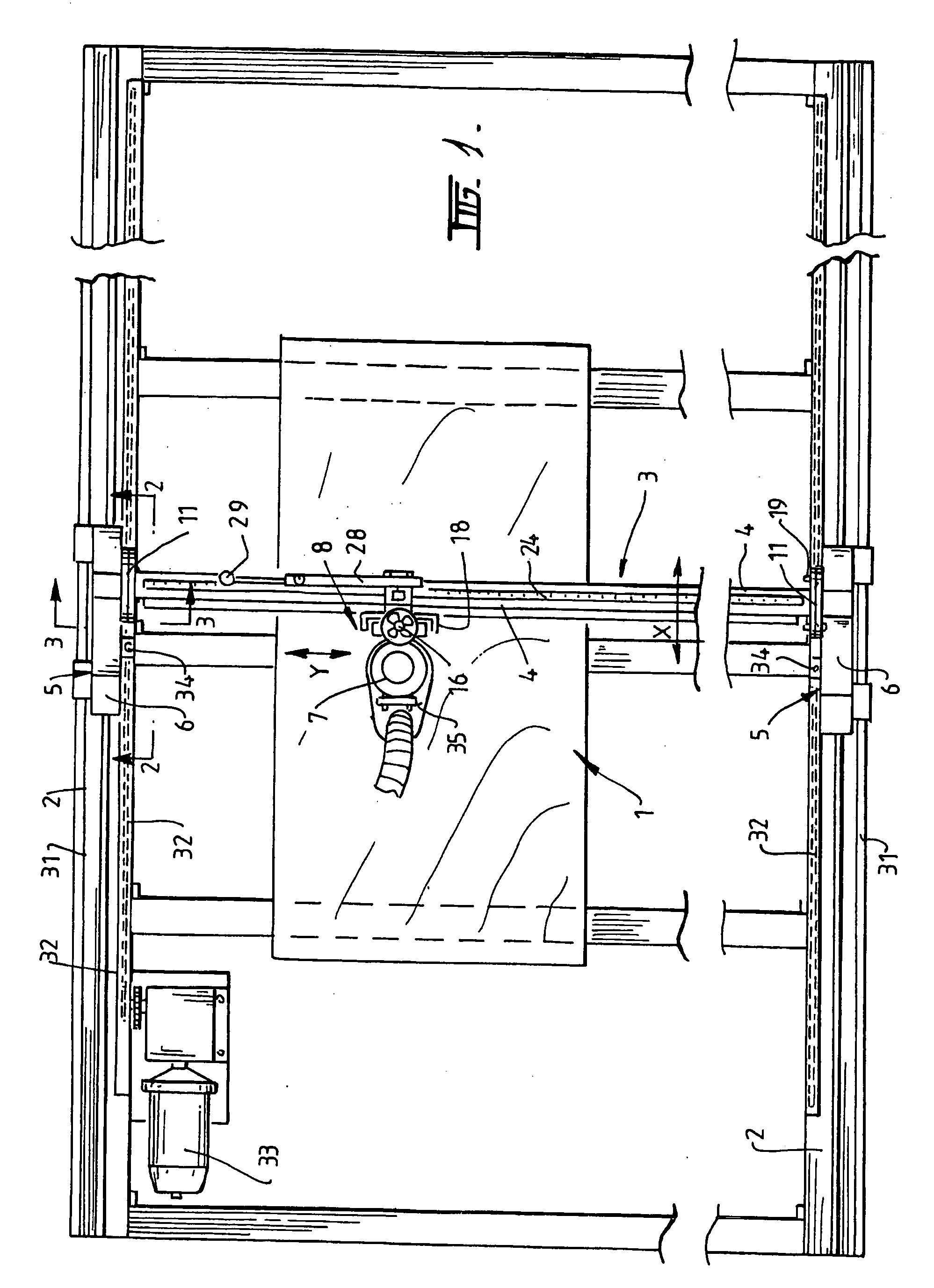

Planer/sander wood machine

A guide for a machine tool or tool drive (7) means for moving a surfacing tool over the substantial surface of a work piece (1), said guide comprising a guide means adapted for positioning over said work piece, said guide means including two horizontal spaced apart guide rails (2) and a gantry (3) adapted for linear travel in an X-axis along said guide rails wherein said gantry includes a gantry rail (4) adapted to bridge said spaced apart guide rails, a pair of gantry arms (5) fitted to either end of said gantry rail each gantry arm having a gantry foot for co-operating with said guide rail wherein said tool drive (7) is fitted to said gantry by a gantry mount adapted for lateral movement along the length of said gantry Y-axis, said mount including a vertical Z-axis height adjustment face plate (9) for mounting said tool drive wherein the fitting of said gantry rail to said guide rails is adjustable about said X-axis and the fitting of said tool drive to said gantry mount is adjustable about said Y-axis such that the cutting face of a tool fitted to said drive can be adjusted to correspond to the surface on planar face of said work piece without the need to clamp said work piece to said guide.

Owner:OWEN LESLIE JOHN

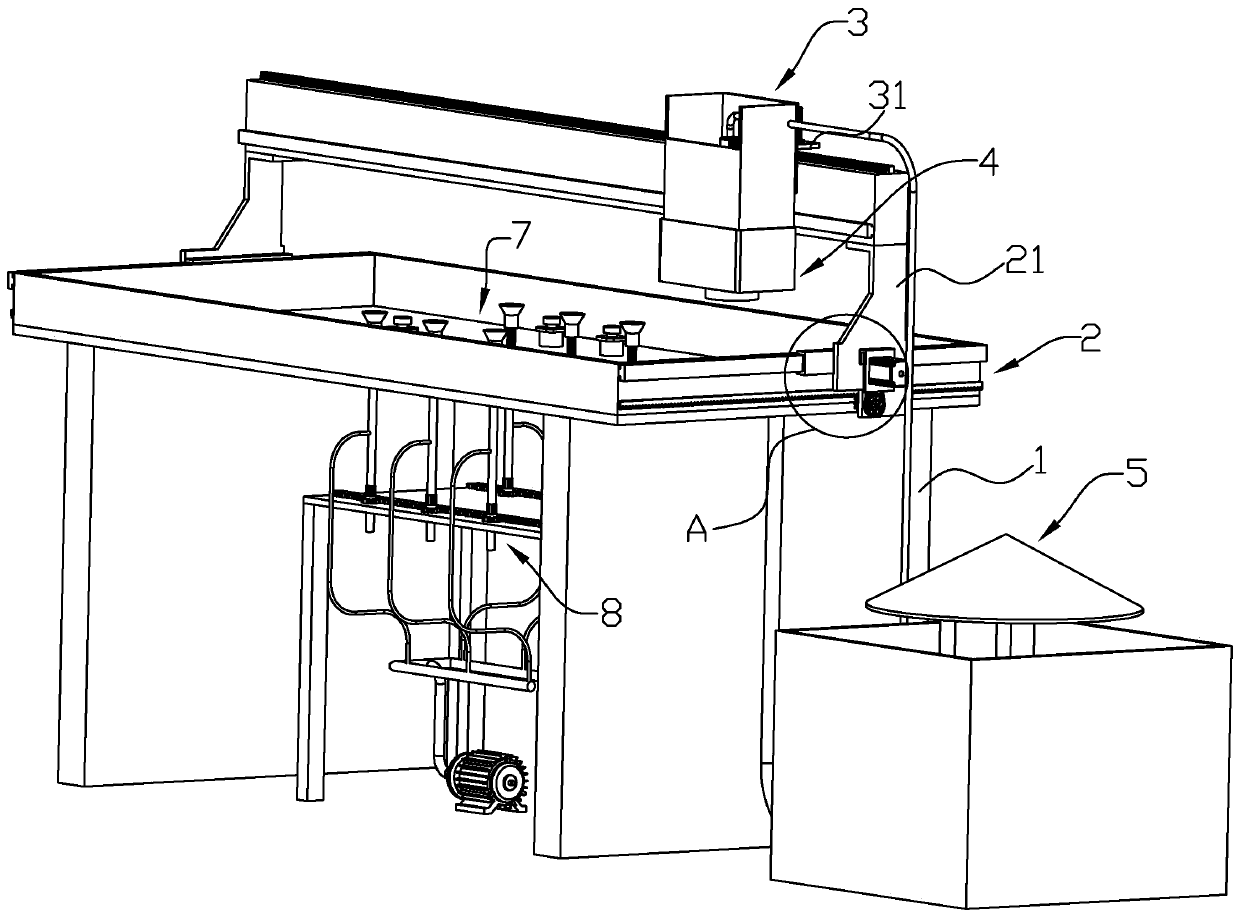

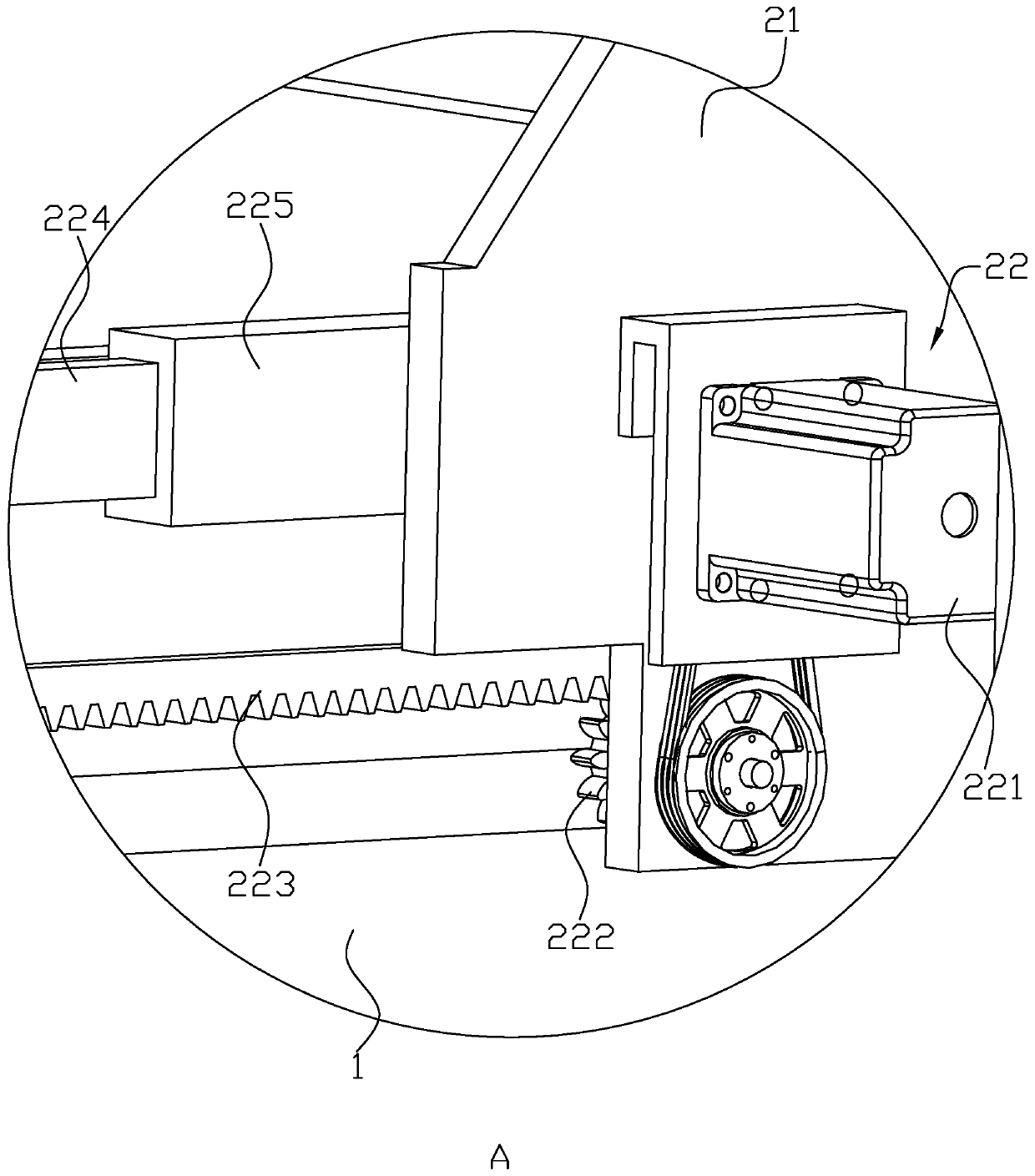

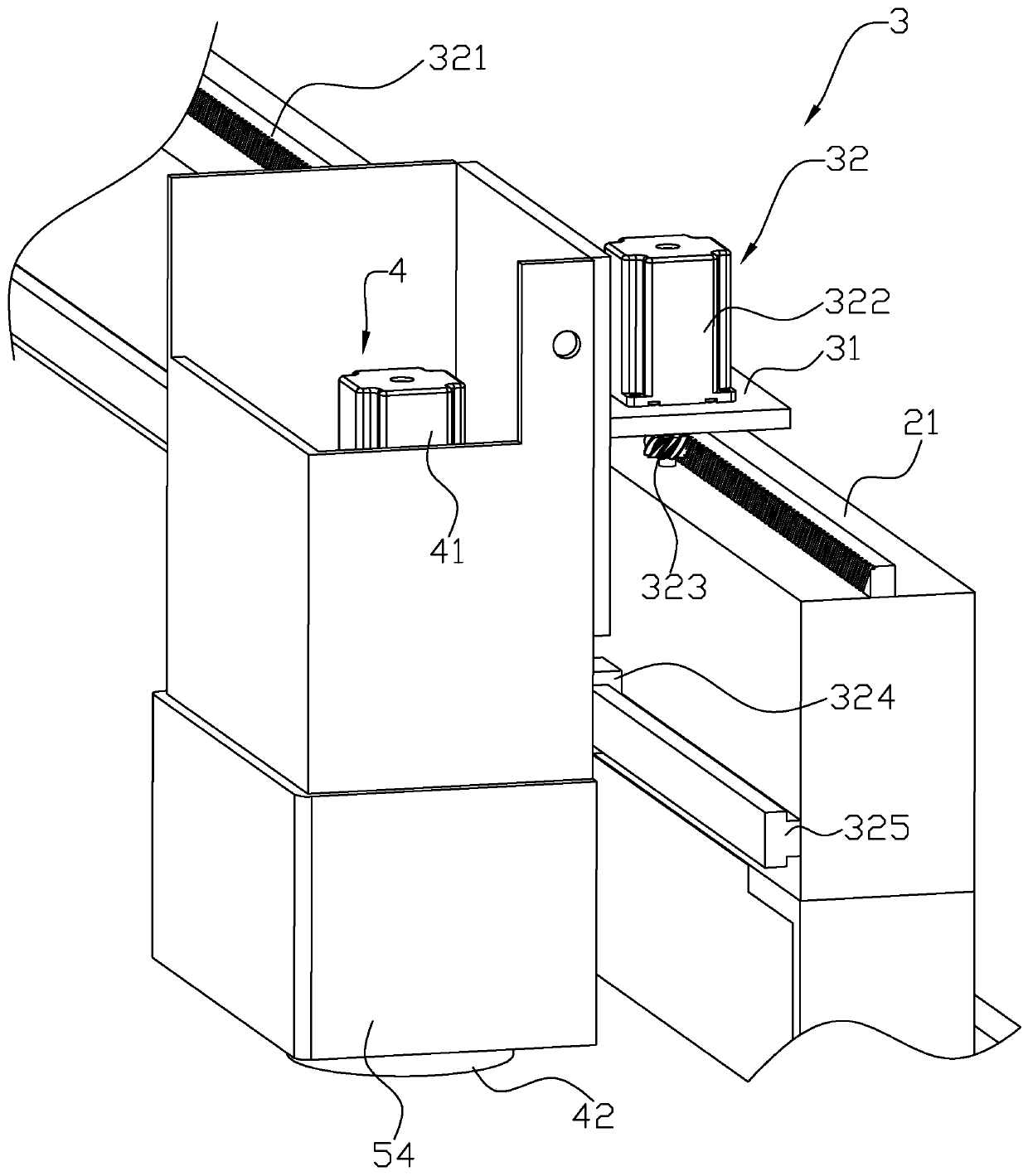

Grinding machine for toughened glass production

ActiveCN110561209AEasy to polishPrecise positioningGrinding drivesGrinding work supportsDrive motorEngineering

The invention discloses a grinding machine for toughened glass production, and relates to the technical field of toughened glass production. According to the technical scheme, the grinding machine comprises a machine table, an X-direction device, a Y-direction device and a cooling device. The X-direction device comprises a portal frame and an X-direction driving mechanism. The Y-direction device comprises a base and a Y-direction driving mechanism, and a grinding mechanism is arranged on the base and comprises a driving motor and a grinding wheel. A positioning device is installed on the machine table and comprises a fixing mechanism and a positioning mechanism. The fixing mechanism comprises a plurality of through holes, a plurality of negative pressure pipes and a negative pressure assembly which is arranged in the machine table and used for making the negative pressure pipes generate negative pressure. The top of each negative pressure pipe communicates with a suction cup. The positioning mechanism comprises a plurality of air cylinders which are vertically arranged on the top of the machine table and limiting rods which are in threaded connection with the tops of piston rods ofthe air cylinders in a one-to-one correspondence mode. By arranging the positioning device, glass can be conveniently positioned so that the glass can be grinded.

Owner:CHAOHU CITY WEIYE GLASS CO LTD

Wood polishing device

The invention discloses a wood polishing device comprising a working platform. Both the front and the rear of the upper surface of the working platform are provided with baffles; first transverse slides are arranged at the upper surface of the working platform and located at the outer side of each baffle; a first motor-driven trolley is arranged in each of the first transverse slides, the top surfaces of all the first motor-driven trolleys are together connected with a door type bracket, and a vertical slide is arranged at the bottom surface of a beam of the door type bracket. A second motor-driven trolley is arranged in the vertical slide; a first micro motor-driven push rod with a downward driving end is arranged on the lower surface of the second motor-driven trolley, the driving end ofthe first micro motor-driven push rod is provided with a first small-sized rotating motor with a rotating end towards the left; and the rotating end of the first small-sized rotating motor is fixedlyconnected with a second small-sized rotating motor with a forward rotating end. The wood polishing device has the beneficial effects that the corners of wood can be polished, the working platform canbe cleaned and tidied after the polishing is finished, and produced fragments can be removed to avoid cleaning omission.

Owner:福建省光泽县瓯盛木业有限公司

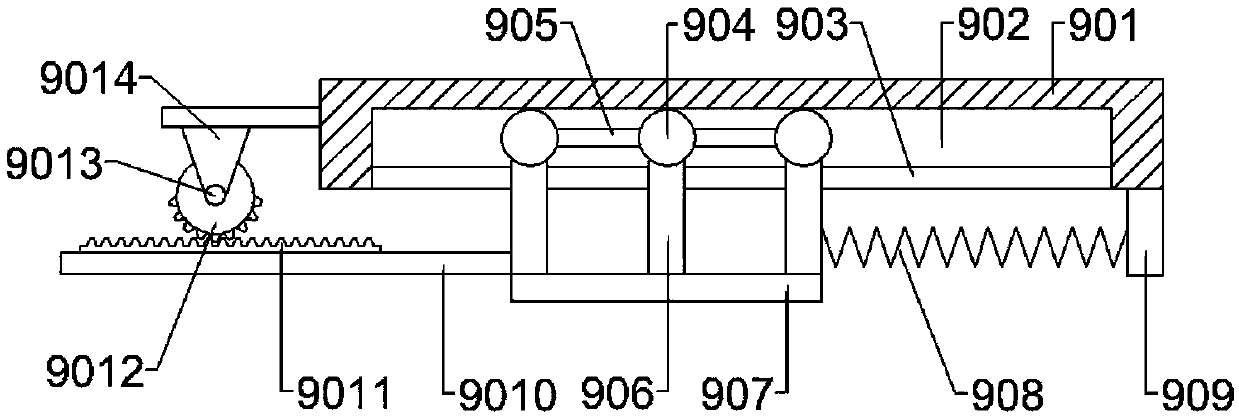

Longitudinal moving type PCB board grinding device

PendingCN107511729AEven contactSimple structureGrinding carriagesGrinding drivesGear wheelControl engineering

The invention discloses a longitudinal moving type PCB board grinding device which comprises a base, an X-axis feeding mechanism, a carrying die, a door frame, an air cylinder, a guide rod, a supporting plate, a square pipe, a first support, a rack, a rotating shaft, a servo motor, a gear, a second support, a speed adjusting motor and a board grinding mechanism. A PCB is placed in the carrying die. The air cylinder moves downwards to push a template mechanism to make contact with the PCB. The speed adjusting motor works to drive the board grinding mechanism to conduct board grinding treatment on the PCB. The servo motor works to drive the rotating shaft to rotate, and therefore the gear is driven to rotate. Due to the fact that the gear is engaged with the rack, the servo motor can drive the board grinding mechanism to move longitudinally. Meanwhile, the X-axis feeding mechanism can drive the PCB placed in the carrying die to move transversely, and therefore automatic board grinding can be conducted on the PCB. The longitudinal moving type PCB board grinding device is simple in structure and capable of automatically conducting board grinding treatment on the PCB, meanwhile, abrasive materials make even contact with the PCB, board grinding is even and continuous, and the automation degree is high. Meanwhile, integrated design is adopted, and the cost is effectively reduced.

Owner:SUZHOU WUTONG ELECTRONICS CO LTD

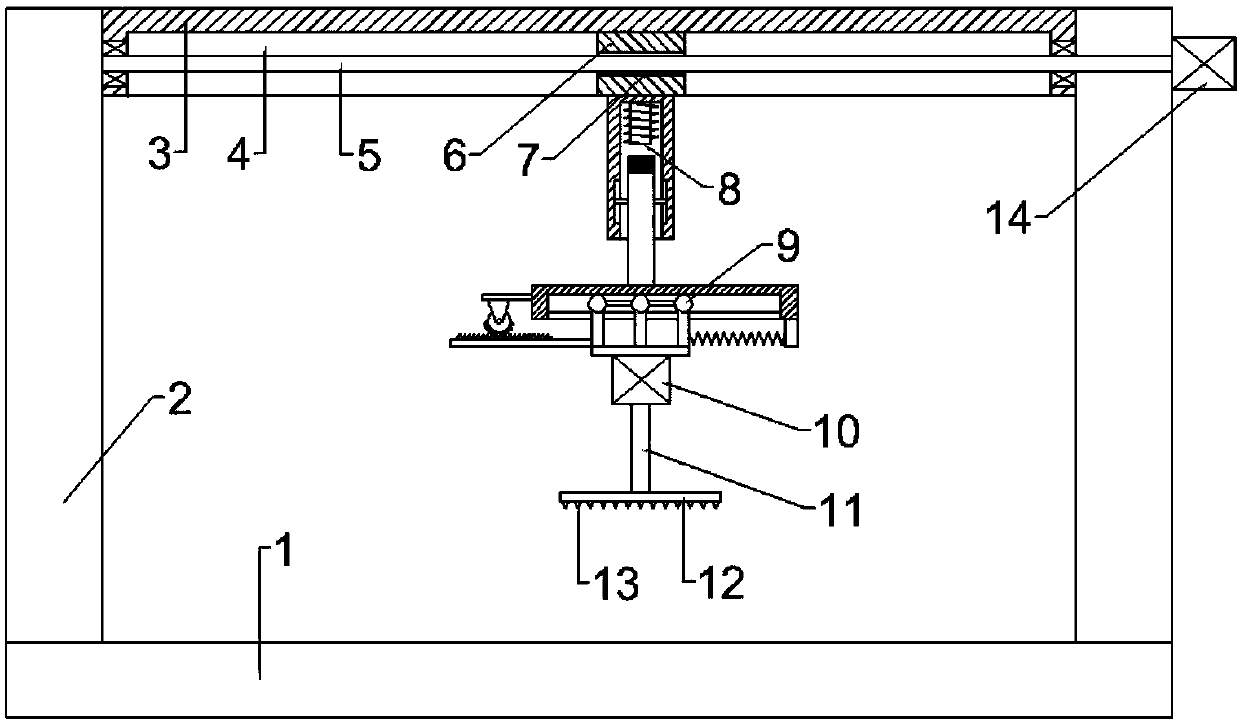

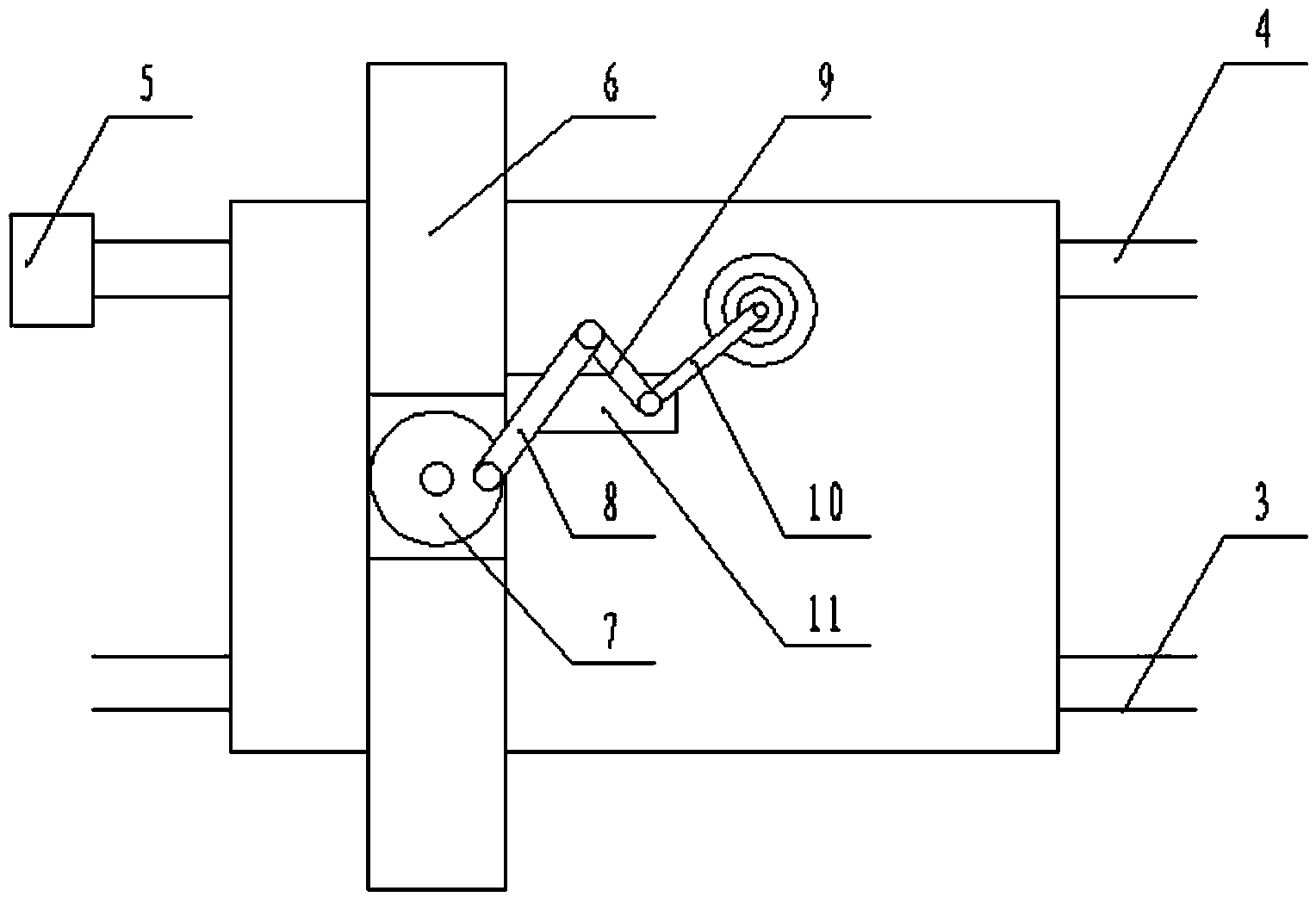

Plane polishing device

The invention relates to a plane polishing device which is suitable for grinding and polishing of surfaces of workpieces such as optical elements and amorphous film substrates. The plane polishing device comprises a grinding wheel, a sliding table and a workpiece moving mechanism, wherein the grinding wheel is square, the disc surface granularity of the grinding wheel becomes larger gradually from left to right in the long side direction, the grinding wheel is installed on the sliding table, a roller lead screw and a linear guide rail are installed below the sliding table and are placed horizontally in parallel, a motor is installed at one end of the roller lead screw, the sliding table moves horizontally under the action of the roller lead screw and the linear guide rail, the workpiece moving mechanism comprises a portal frame which is fixed above the grinding wheel, and a cam-linkage mechanism is installed on the portal frame. The plane polishing device is simple and compact in structure, low in cost, high in automation degree, and capable of conducting different degrees of machining on workpieces from rough grinding to fine polishing by means of the gradient design of the abrasive grain of a square grinding disc.

Owner:嘉兴市恒工精密机械有限公司

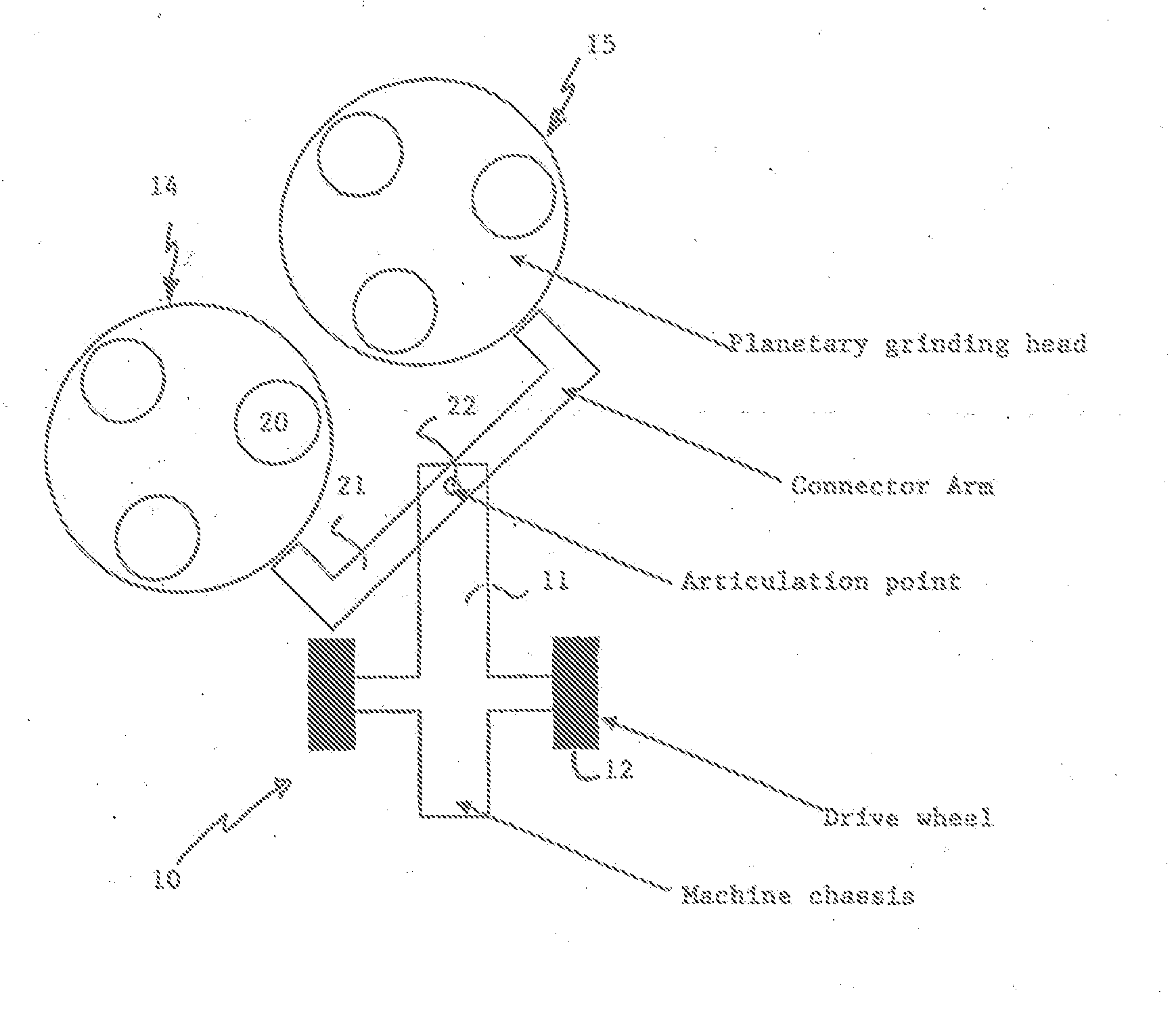

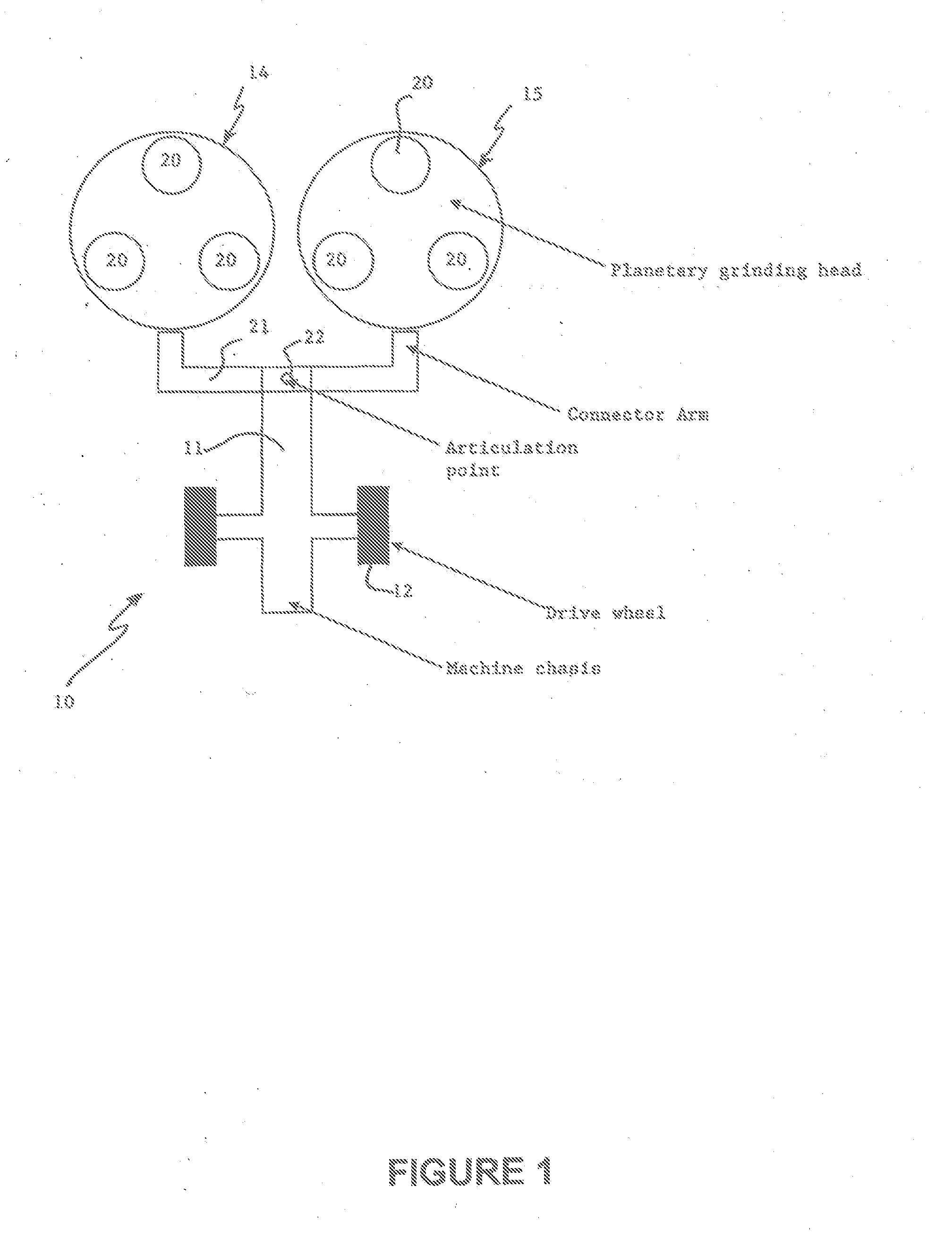

Grinding apparatus

A grinding apparatus for grinding a floor, the apparatus comprising a body having a travelling mechanism which enables the body to travel across a floor while the apparatus is grinding; a first grinding head incorporating at least one grinding tool and having an operable configuration in which the first grinding head is able to grind a first floor portion; and a second grinding head incorporating at least one grinding tool and having an operable configuration in which the second grinding head is able to grind a second floor portion; wherein the first and second grinding heads are mountable to the body whereby their positions relative to the body are able to be varied.

Owner:VEEN HLDG

Machine for smoothing and/or polishing slabs of stone material, such as natural or agglomerated stone, ceramic and glass

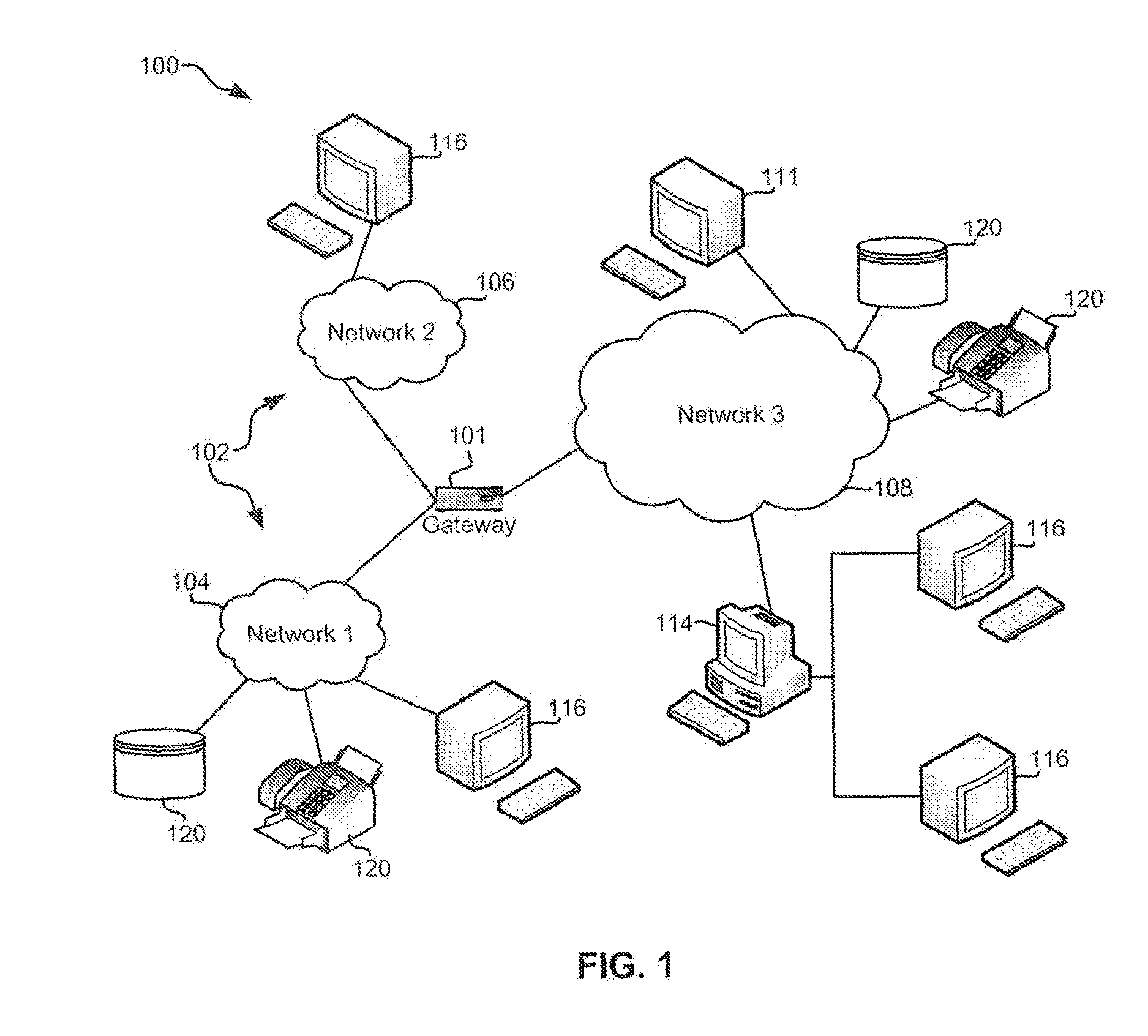

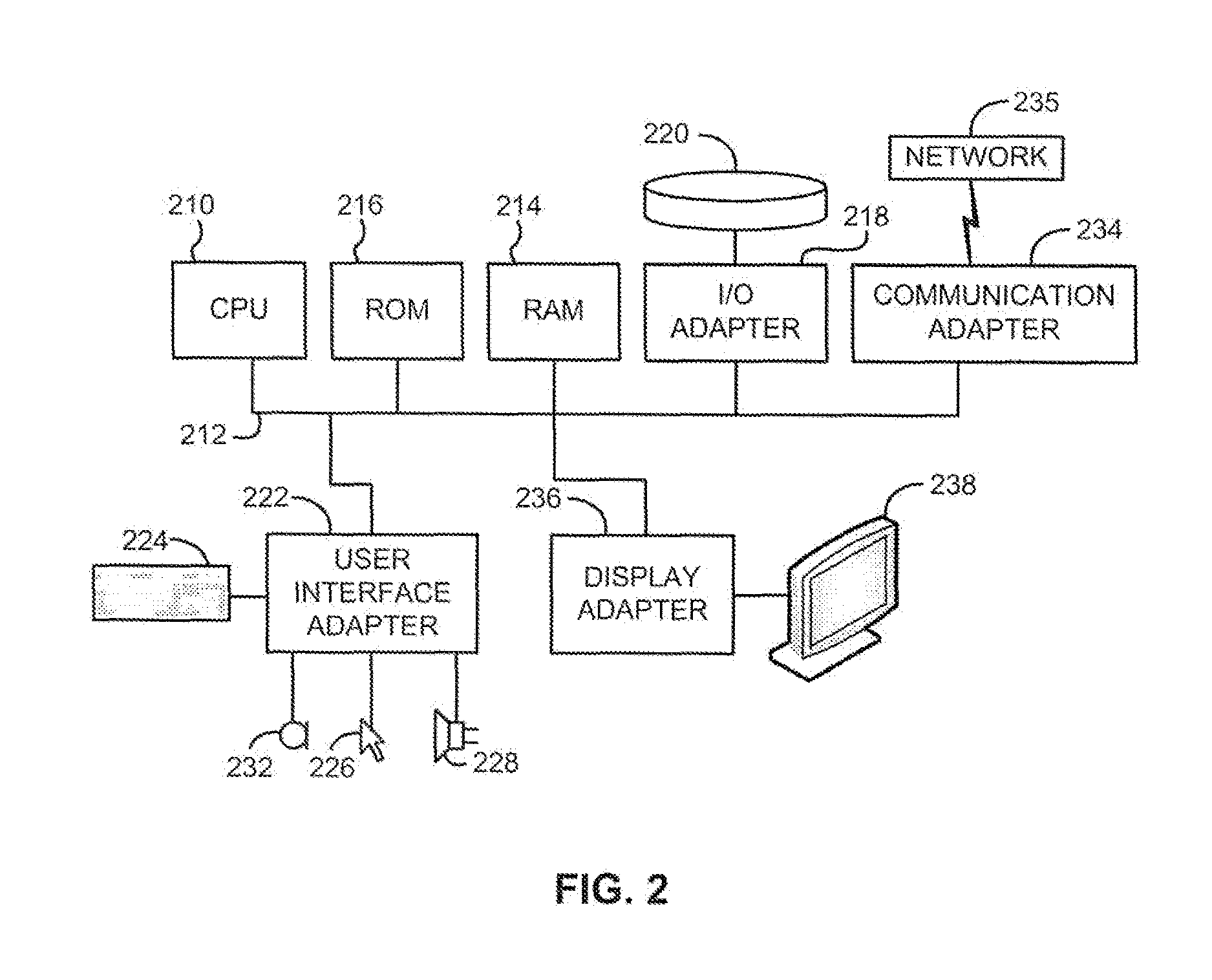

According to one embodiment, a method for handling congestion in a network includes determining that there is congestion on a first device in a network, setting a congestion indicator in a header of a packet to indicate an amount of congestion at the first device, sending the packet to all devices that send traffic to the first device, receiving the packet having the multi-bit indicator in a header thereof at a device that sends traffic to the first device, and reducing a congestion window by a factor of between about 5% and about 50% based on a severity of the congestion indicated by the multi-bit indicator, wherein the congestion window is reduced by a greater factor when the congestion is indicated as being more severe. Other systems and methods for handling congestion in a network are described according to more embodiments.

Owner:TONCELLI LUCA

Board plane processing device

InactiveCN106670905AEasy to fixSave human effortGrinding carriagesGrinding feedersEngineeringWood plank

The invention discloses a board plane processing device. The board plane processing device comprises a workbench, wherein a fixing and polishing mechanism and a fixing and moving mechanism are arranged on the upper surface of the workbench, and an elastic protective layer is arranged on the side surface of each first clamp plate. The board plane processing device has the beneficial effects that the device can fix a board well when performing plane processing on the board and performs automatic polishing processing, and manpower is liberated well.

Owner:CHENGDU PUJIANG KEXIAN TECH

Furniture panel grinding device facilitating feeding

InactiveCN109249287AOperation saves time and effortImprove polishing efficiencyGrinding drivesGrinding feedersEngineeringMechanical engineering

The invention relates to the field of furniture, in particular to a furniture panel grinding device facilitating feeding. In order to achieve the technical purposes that time and labor are saved during operation, the polishing efficiency is high, and feeding is facilitated, the furniture panel grinding device facilitating feeding comprises a fixing base, a first motor, a first supporting plate, asecond motor, a first gear, a rack, a fixed block, a polishing machine, an installation plate, a first sliding rail, a first slider, a first bearing pedestal, a first rotary shaft, a second supportingplate, a third supporting plate, a placement plate, an electric conveying roller, a second gear, a second slider, a second sliding rail, a second bearing pedestal, a third gear, a second rotary shaft, a third rotary shaft, a fourth gear, a third bearing pedestal and a fourth supporting plate. The furniture panel grinding device has the advantages that time and labor are saved during operation, the polishing efficiency is high, and feeding is facilitated.

Owner:佛山市顺德区卡芬迪家具有限公司

Grinding machine with single-sided chamfering grinding function

ActiveCN107052964AAvoid pollutionSimple structureEdge grinding machinesGrinding carriagesEngineeringScrew thread

The invention discloses a grinding machine with a single-sided chamfering grinding function. The grinding machine comprises a machine body with supporting posts at two sides, wherein a grinding cavity is arranged in the machine body; a first slide slot is formed in the inner wall at the left side of the grinding cavity; a second slide slot is formed in a position, close to one side of the first slide slot, on the top wall in the grinding cavity; a first slide cavity is arranged in the bottom wall in the grinding cavity; a first threaded rod is arranged in the first slide slot; a first slide block is connected on the first threaded rod in a screw-thread fit mode; a grinding table is arranged at the right side of the first slide block; a fourth slide slot is formed in the bottom end surface of the grinding table; a second slide cavity is arranged in the grinding table; a limiting slide block is connected in the second slide cavity in a sliding fit mode; and a guide slide rod which extends towards the left side is fixedly arranged at the left side end of the limiting slide block. The grinding machine is simple in structure, is reasonable in design, can automatically complete grinding and chamfering-trimming work, can realize regulation on dust-absorbing as well as a chambering-trimming angle, is convenient to operate, saves time and labor, improves working efficiency and reduces labor intensity.

Owner:海通智能装备(江苏)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com