Monocrystalline silicon rod cutting and grinding all-in-one machine

An all-in-one machine, cutting and grinding technology, applied in the direction of grinding frame, gantry grinding machine, grinding machine parts, etc. Low cost, high cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

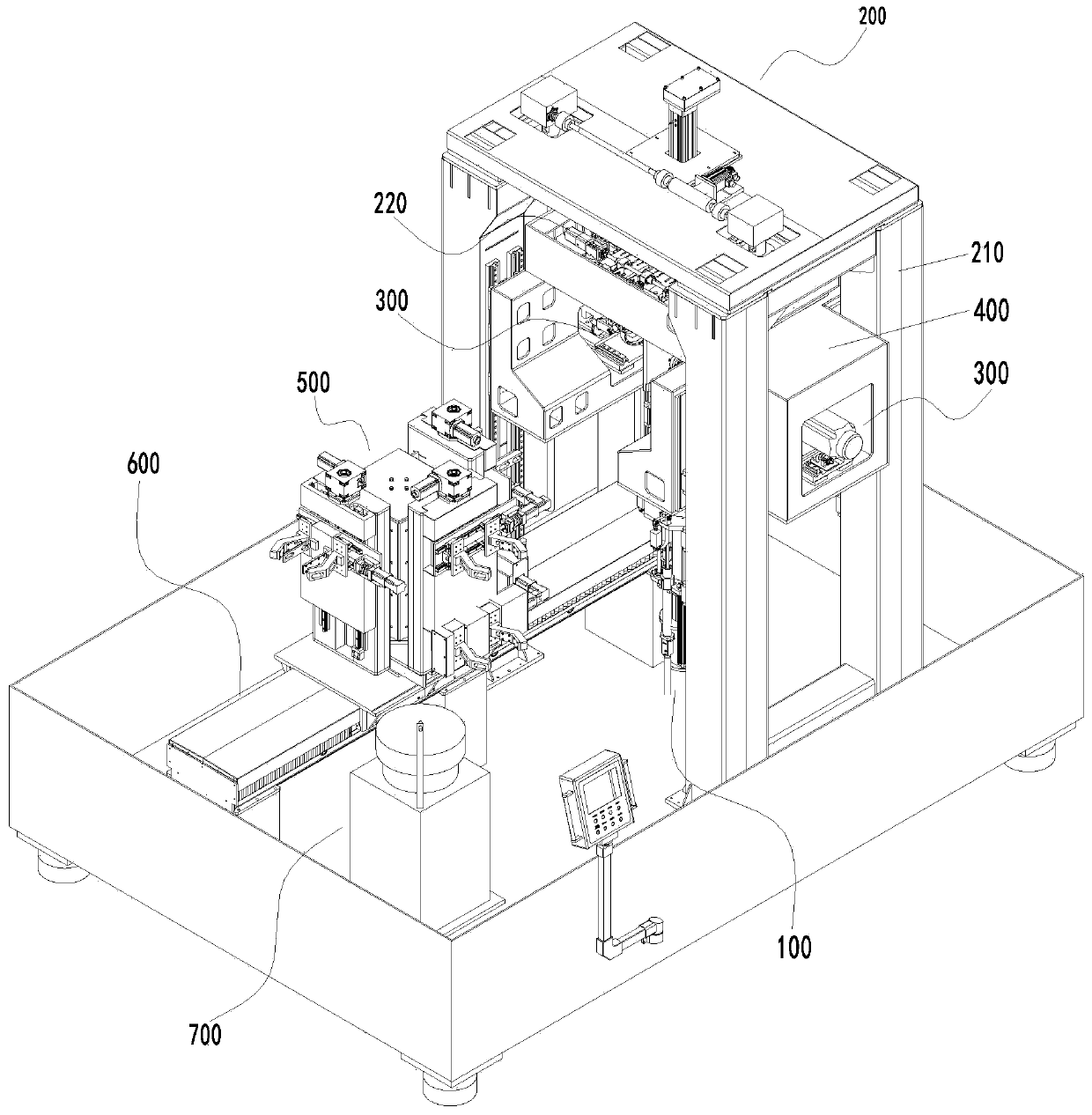

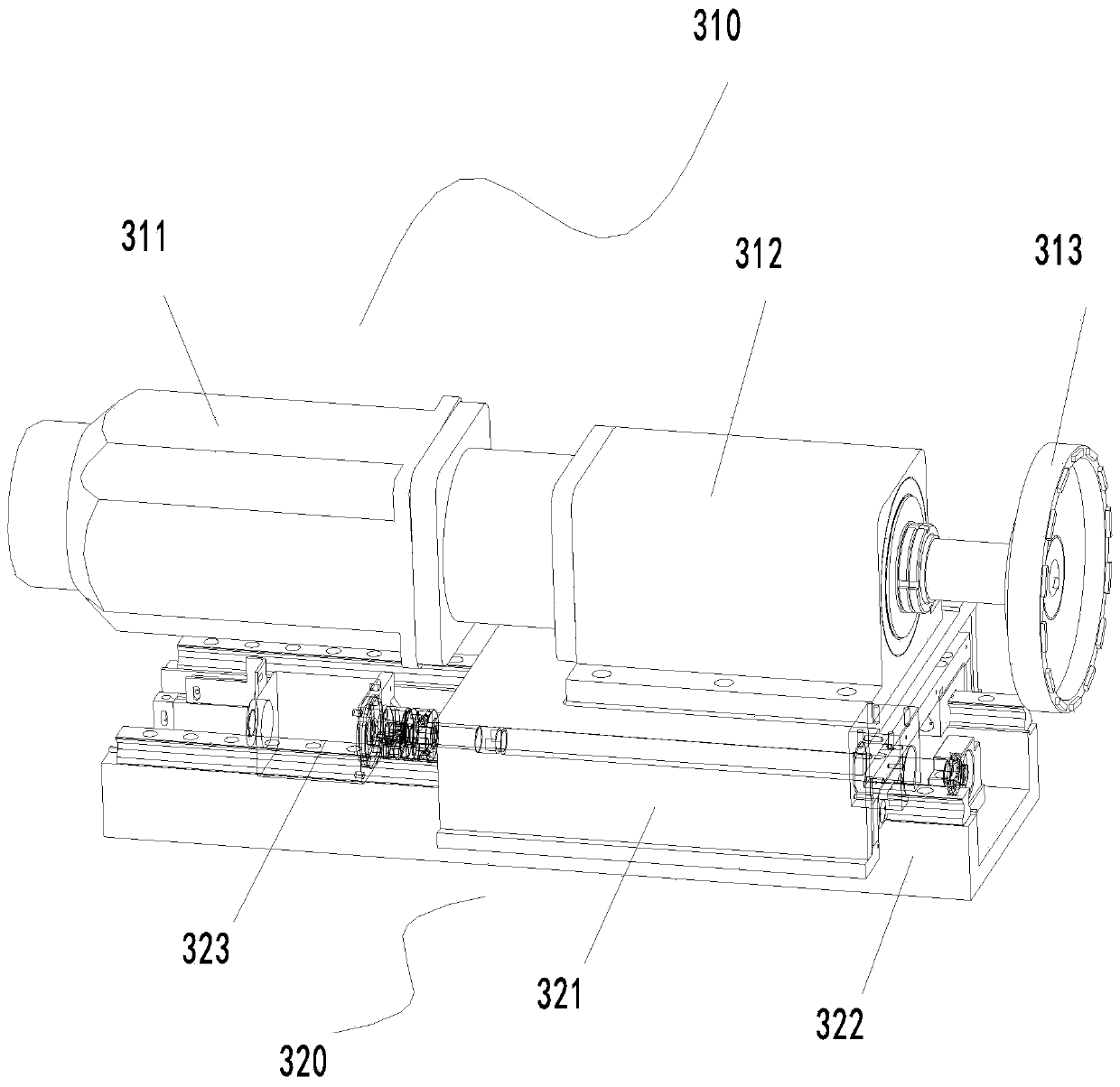

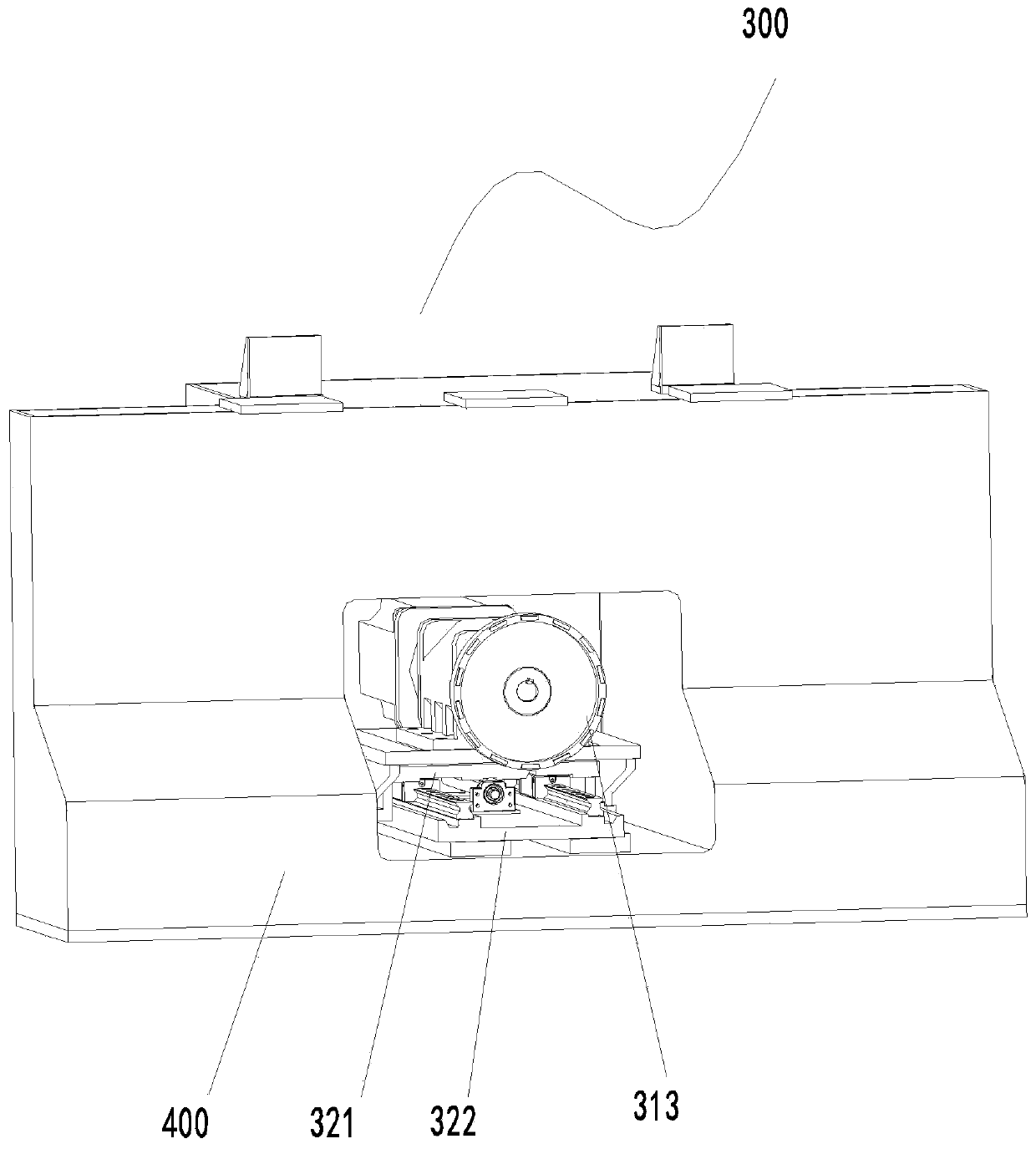

[0076] Please also refer to Figure 1 to Figure 13 , the present invention provides an integrated cutting and grinding machine for monocrystalline silicon ingots. The integrated cutting and grinding machine can be used to square the single crystal silicon ingot 800 and polish the square material 920 after squaring. The equipment has strong versatility. Specifically, the integrated cutting and grinding machine includes a clamping tool 100, a cutting operation mechanism 200 and a grinding and polishing mechanism 300;

[0077] The clamping tool 100 is used to clamp the silicon crystal bar to be cut and ground, so as to prevent the silicon crystal bar from shaking during squaring or polishing, which affects the processing accuracy;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com