Polishing machine for polishing inner screens of mobile phones

A mobile phone internal screen and scanner technology, applied in the field of scanners, to achieve the effect of simple and simple sweeping process, saving resources and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

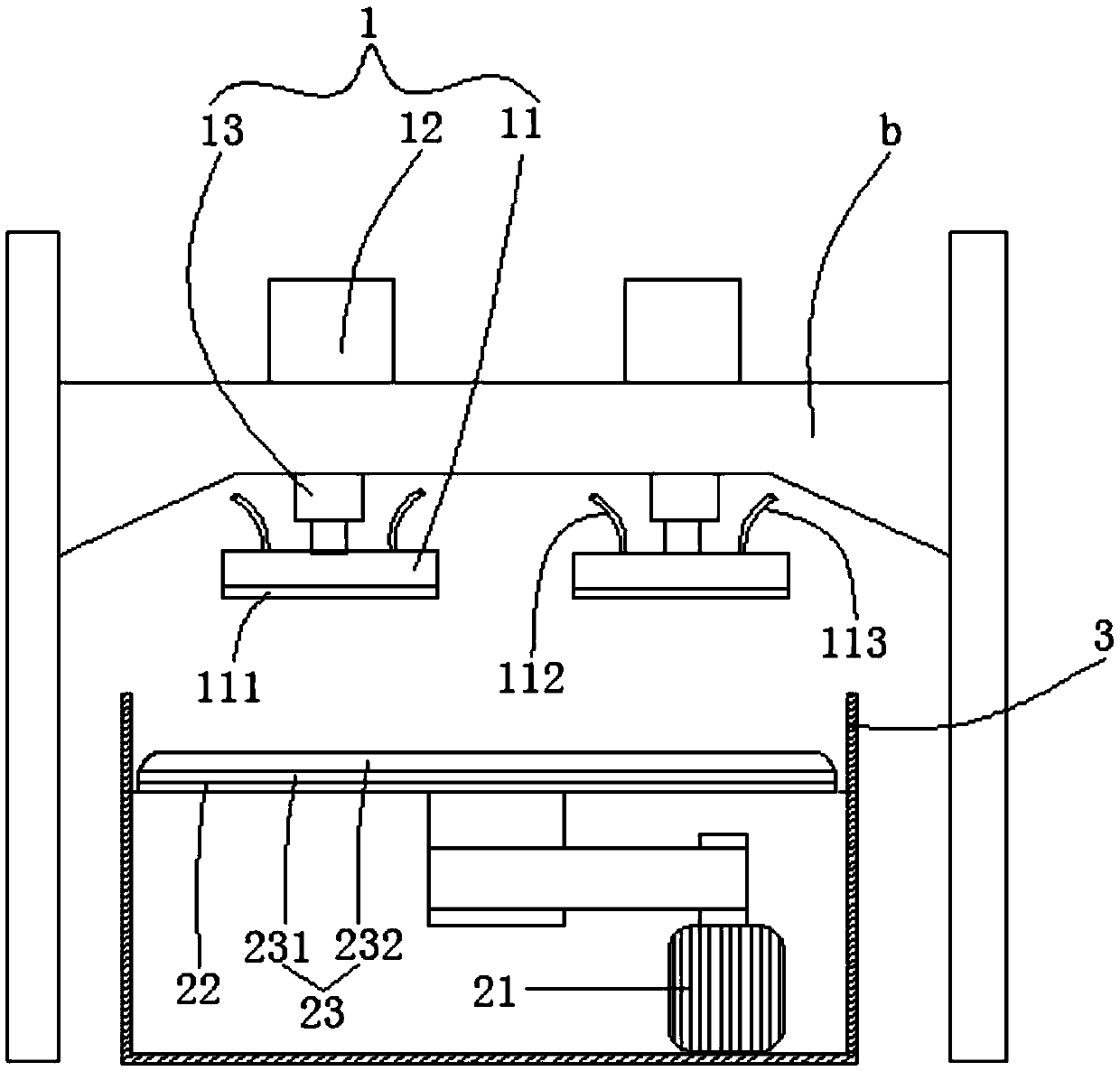

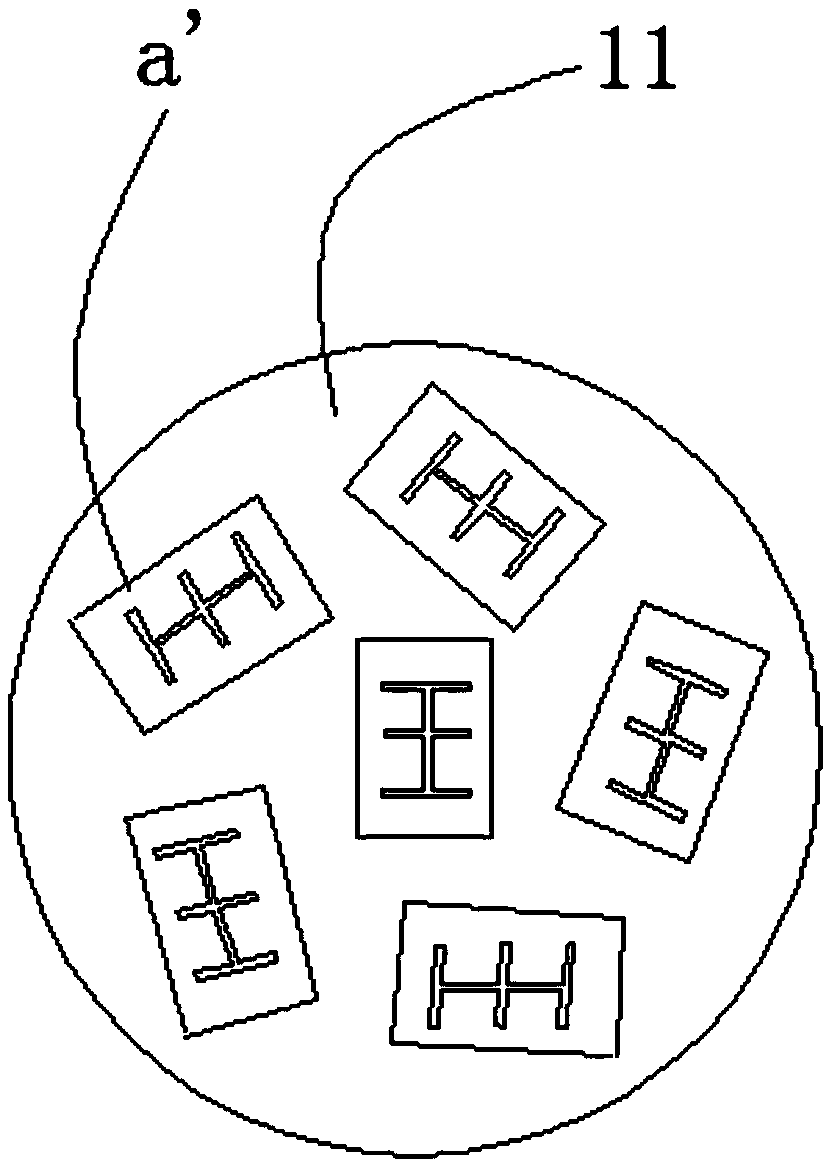

[0026] Such as figure 1 As shown, a light sweeping machine used for sweeping the inner screen of a mobile phone includes a gantry b, a grinding disc assembly fixed on the upper part of the gantry b, and a light sweeping assembly located at the lower part of the gantry b. Grinding disc assembly comprises a plurality of grinding mechanism 1, and grinding mechanism 1 comprises grinding disc 11, first motor 13 and cylinder 12, and grinding disc 11 is connected with first motor 13 and cylinder 12 in turn, and cylinder 12 is fixed on the gantry b. The first motor 13 drives the grinding disc 11 to rotate, and the cylinder 12 drives the first motor 13 and the grinding disc 11 to ascend and descend.

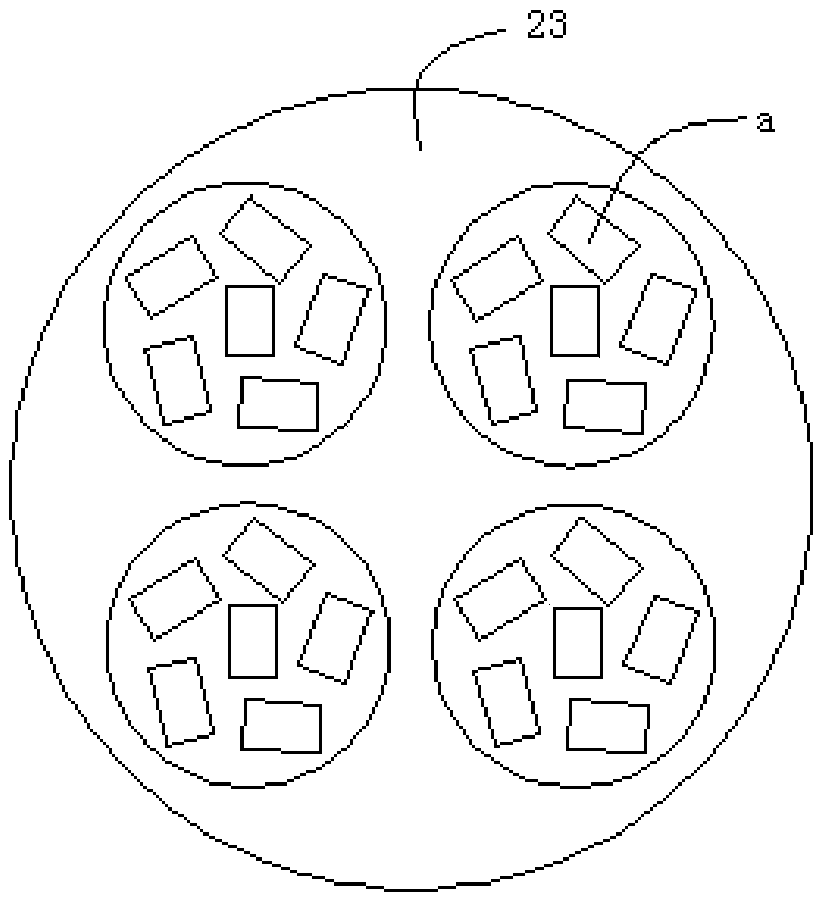

[0027] Such as figure 1 , figure 2 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com