Longitudinal moving type PCB board grinding device

A PCB board and grinding board technology, which is applied in the direction of grinding drive devices, portal grinding machine tools, grinding machines, etc., can solve the problems of abrasives and PCB board contact grinding board, PCB copper layer damage, poor grinding effect, etc. Achieve the effect of uniform and continuous grinding plate, high degree of automation and uniform contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

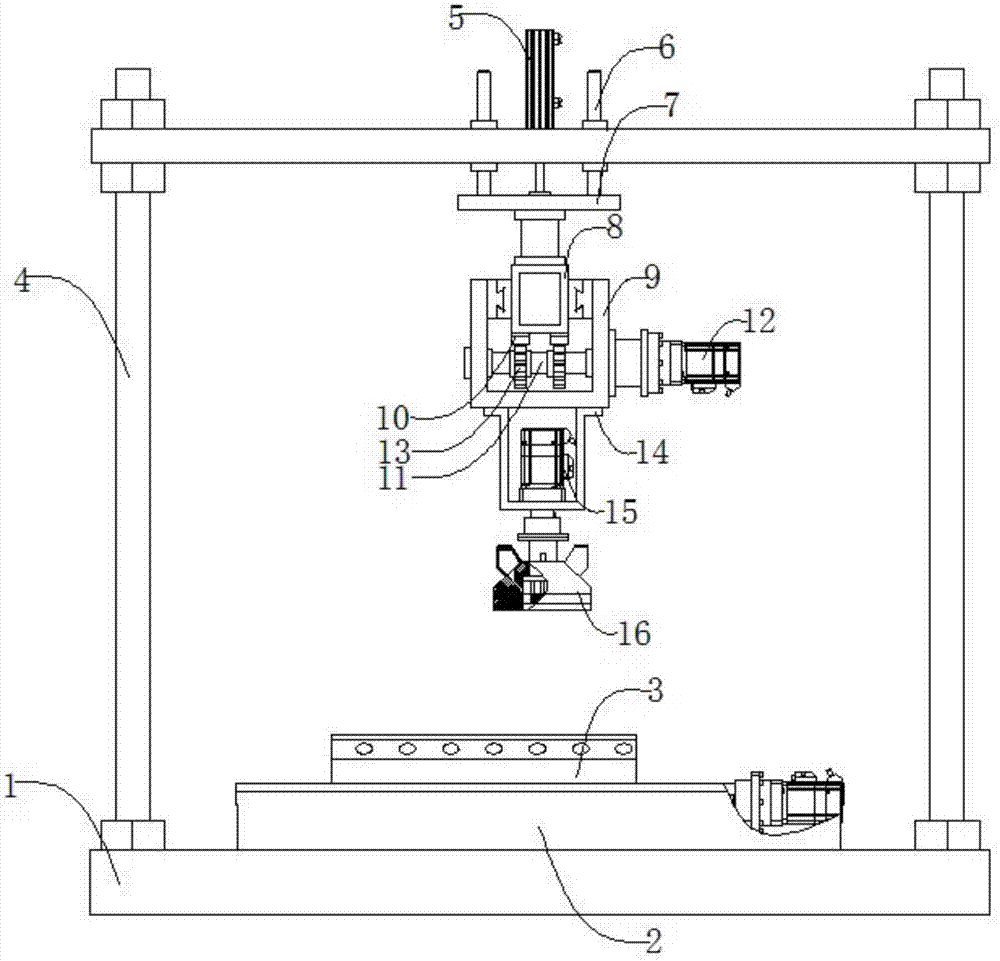

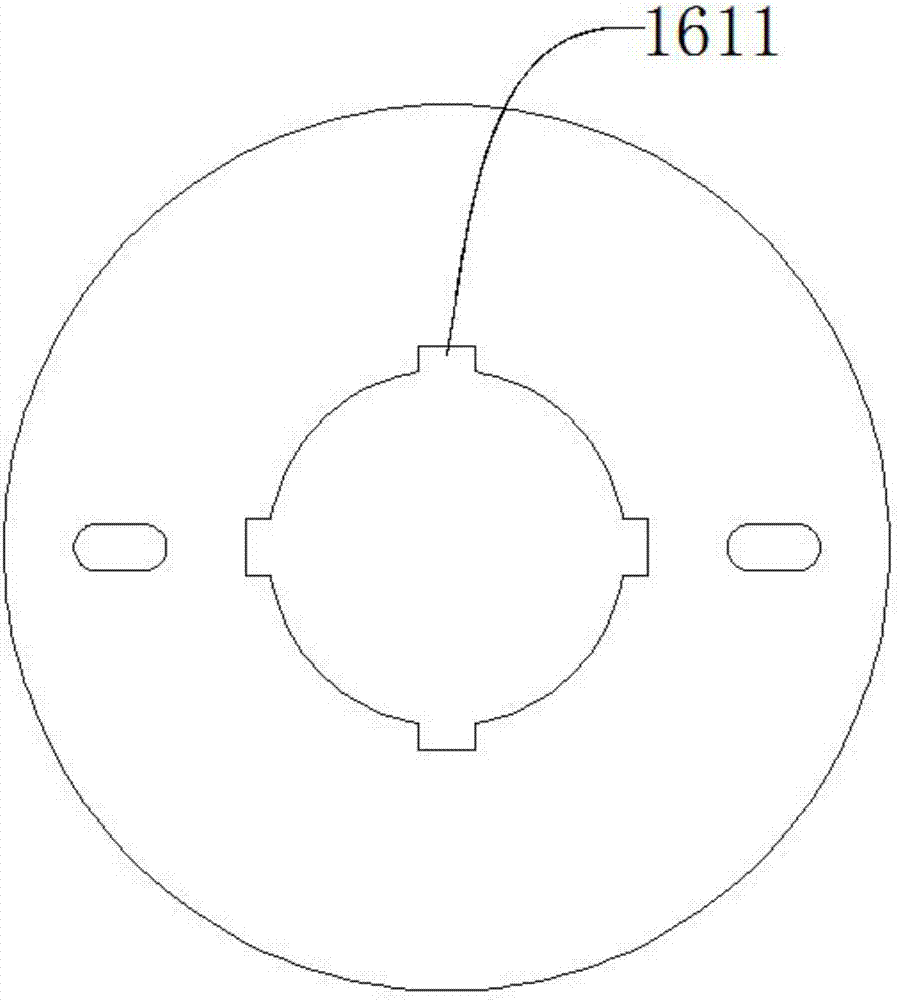

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4As shown, a vertically traveling PCB board grinding device includes a base 1, an X-axis feed mechanism 2, a placement mold 3, a door frame 4, a cylinder 5, a guide rod 6, a supporting plate 7, a square tube 8, a first Support 9, rack 10, rotating shaft 11, servo motor 12, gear 13, second support 14, speed regulating motor 15, grinding plate mechanism 16, described X-axis feed mechanism 2 is located at the upper end of base 1, described X The shaft feed mechanism 2 is threadedly connected with the base 1, the placement mold 3 is located at the upper end of the X-axis feed mechanism 2, the placement mold 3 is threaded with the X-axis feed mechanism 2, and the door frame 4 is located at the base 1 upper end, the door frame 4 is threadedly connected with the base 1, the cylinder 5 is located at the upper end of the door frame 4, the cylinder 5 is threaded with the door frame 4, and the guide rod 6 runs through the door f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com