Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

167 results about "Rocket propellant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rocket propellant is the reaction mass of a rocket. This reaction mass is ejected at the highest achievable velocity from a rocket engine to produce thrust. The energy required can either come from the propellants themselves, as with a chemical rocket, or from an external source, as with ion engines.

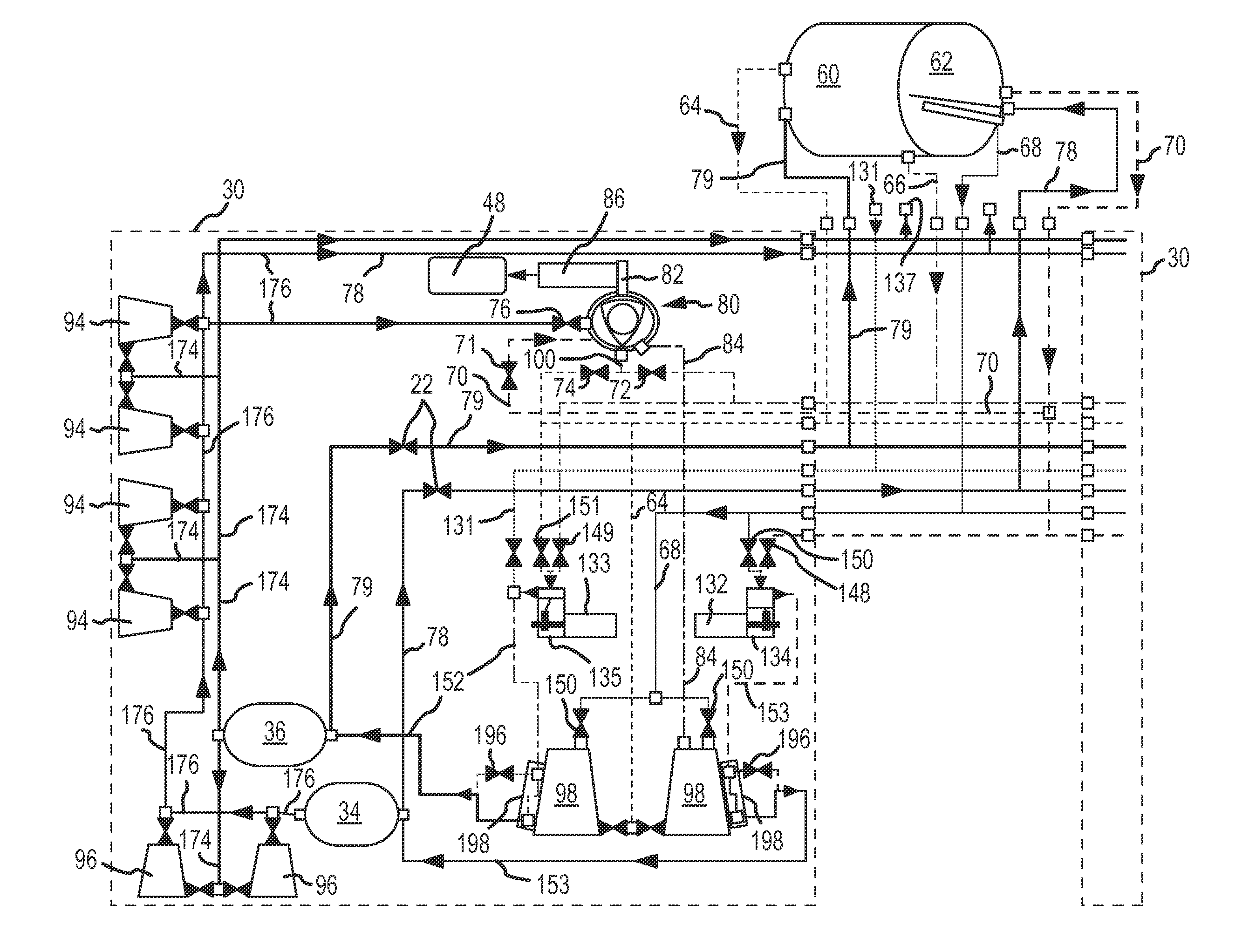

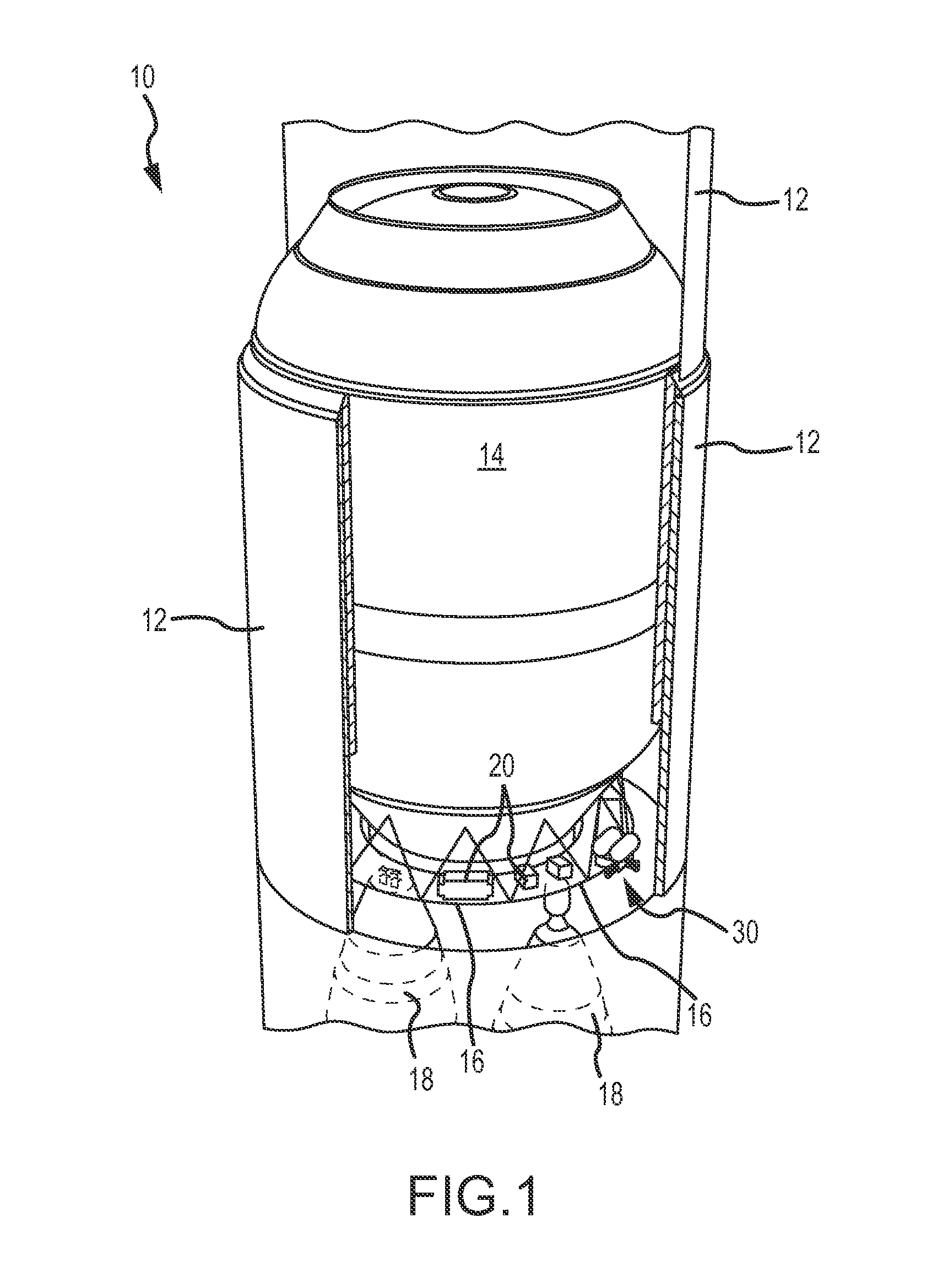

Integrated vehicle fluids

ActiveUS20120227374A1Reduce peak pressureIncrease in temperatureLaunch systemsCosmonautic propulsion system apparatusSpace vehicleModularity

A system and methods are provided for combining systems of an upper stage space launch vehicle for enhancing the operation of the space vehicle. Hydrogen and oxygen already on board as propellant for the upper stage rockets is also used for other upper stage functions to include propellant tank pressurization, attitude control, vehicle settling, and electrical requirements. Specifically, gases from the propellant tanks, instead of being dumped overboard, are used as fuel and oxidizer to power an internal combustion engine that produces mechanical power for driving other elements including a starter / generator for generation of electrical current, mechanical power for fluid pumps, and other uses. The exhaust gas from the internal combustion engine is also used directly in one or more vehicle settling thrusters. Accumulators which store the waste ullage gases are pressurized and provide pressurization control for the propellant tanks. The system is constructed in a modular configuration in which two redundant integrated fluid modules may be mounted to the vehicle, each of the modules capable of supporting the upper stage functions.

Owner:UNITED LAUNCH ALLIANCE

Method and apparatus for stimulating wells with propellants

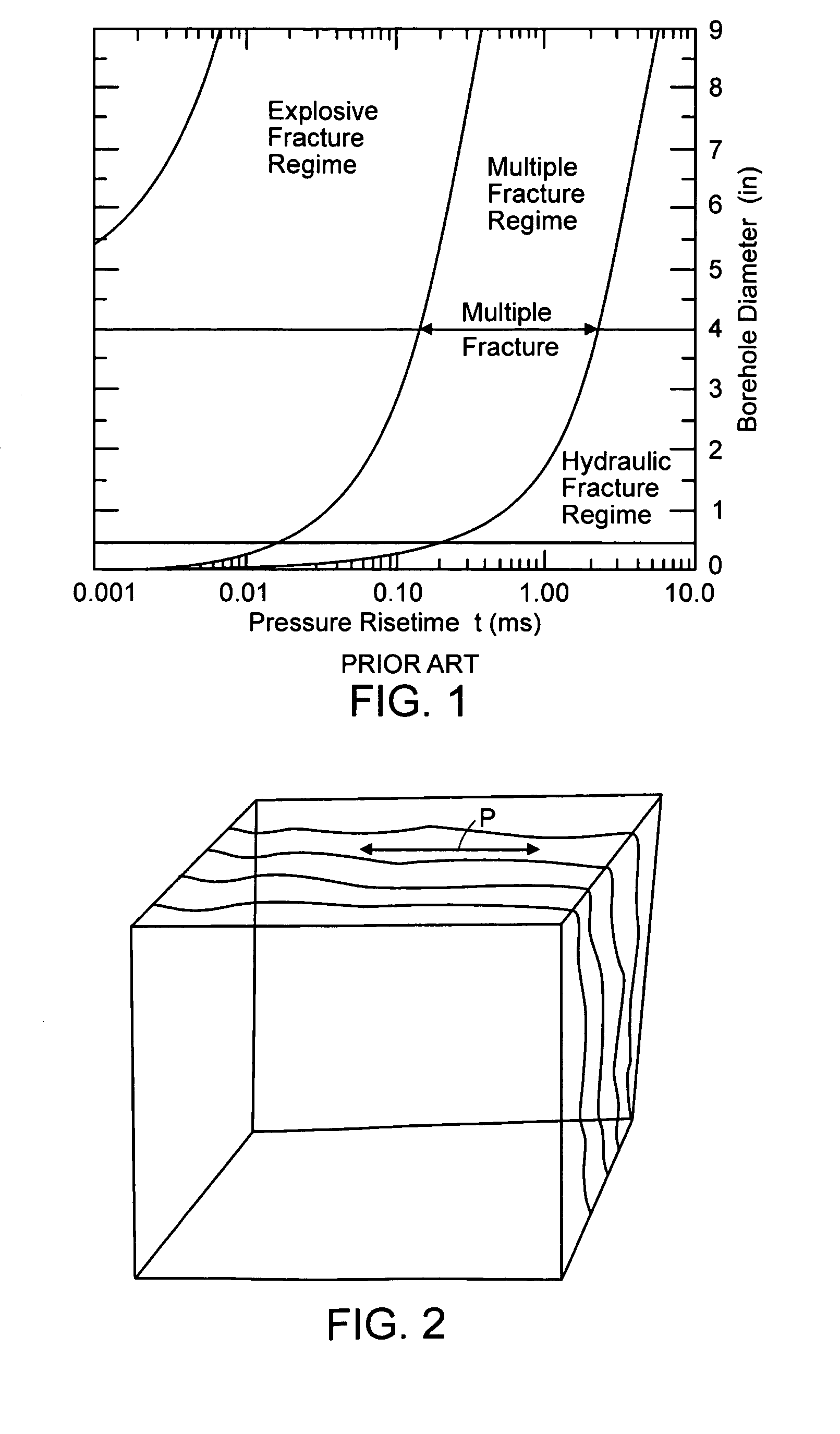

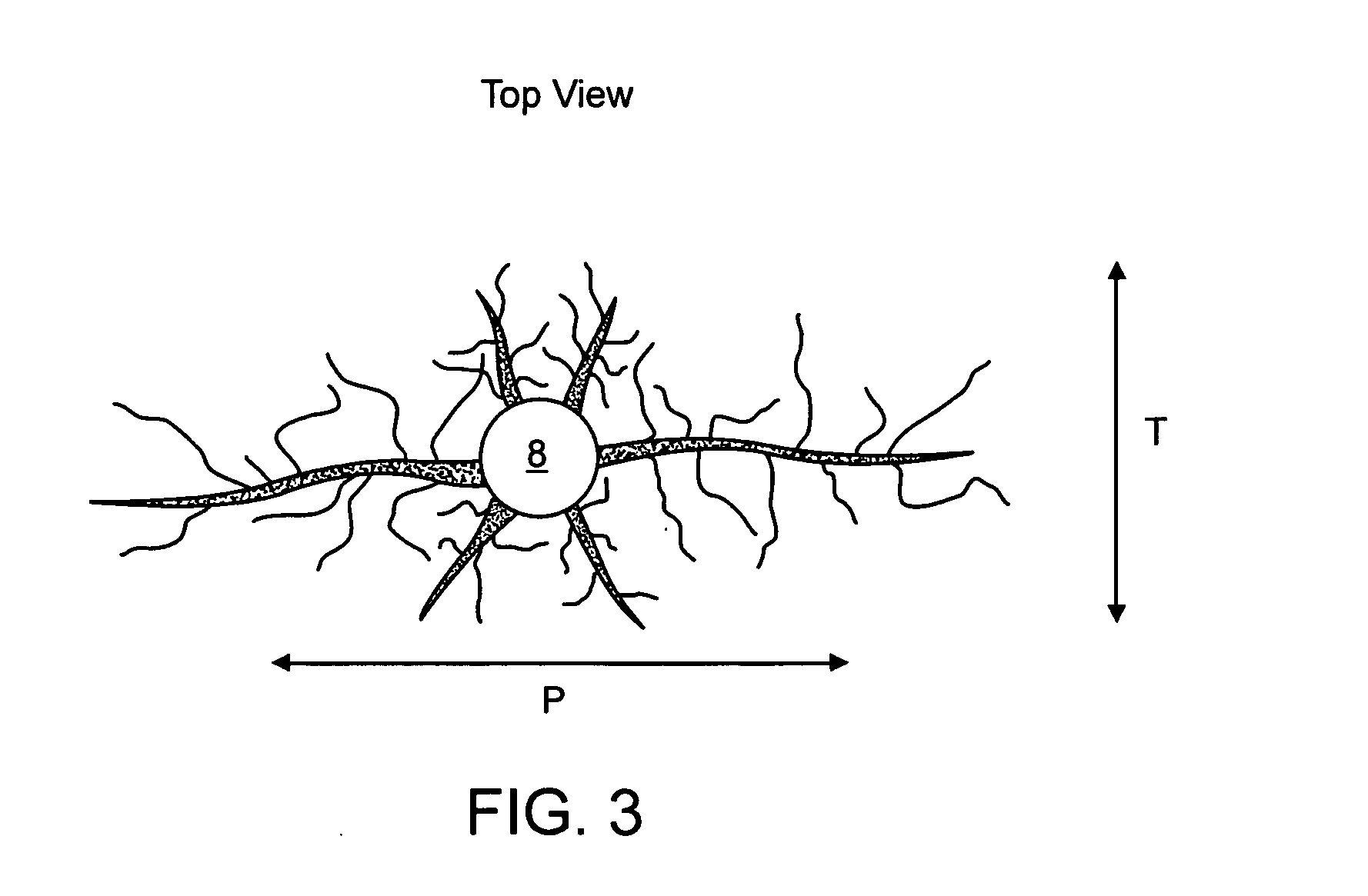

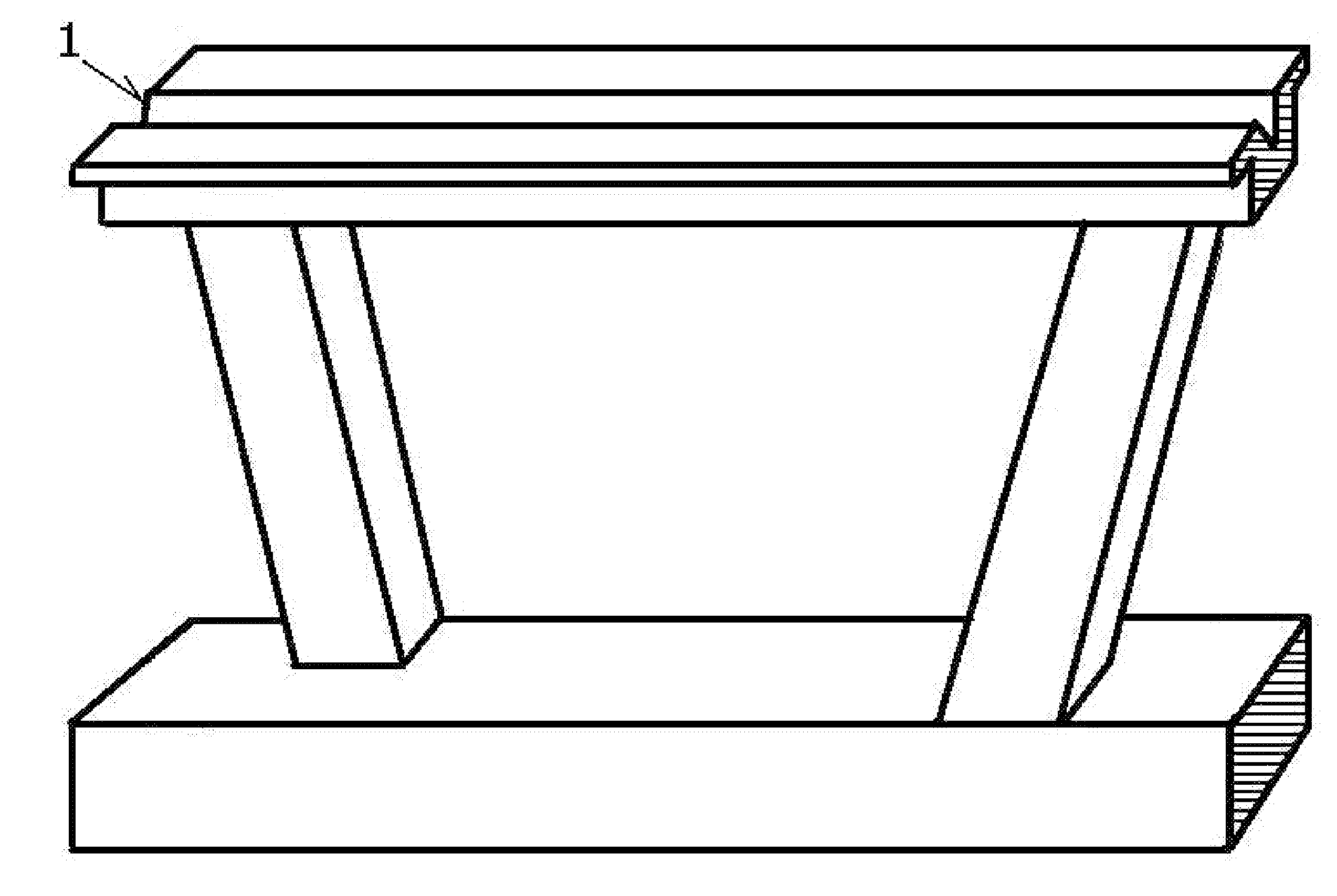

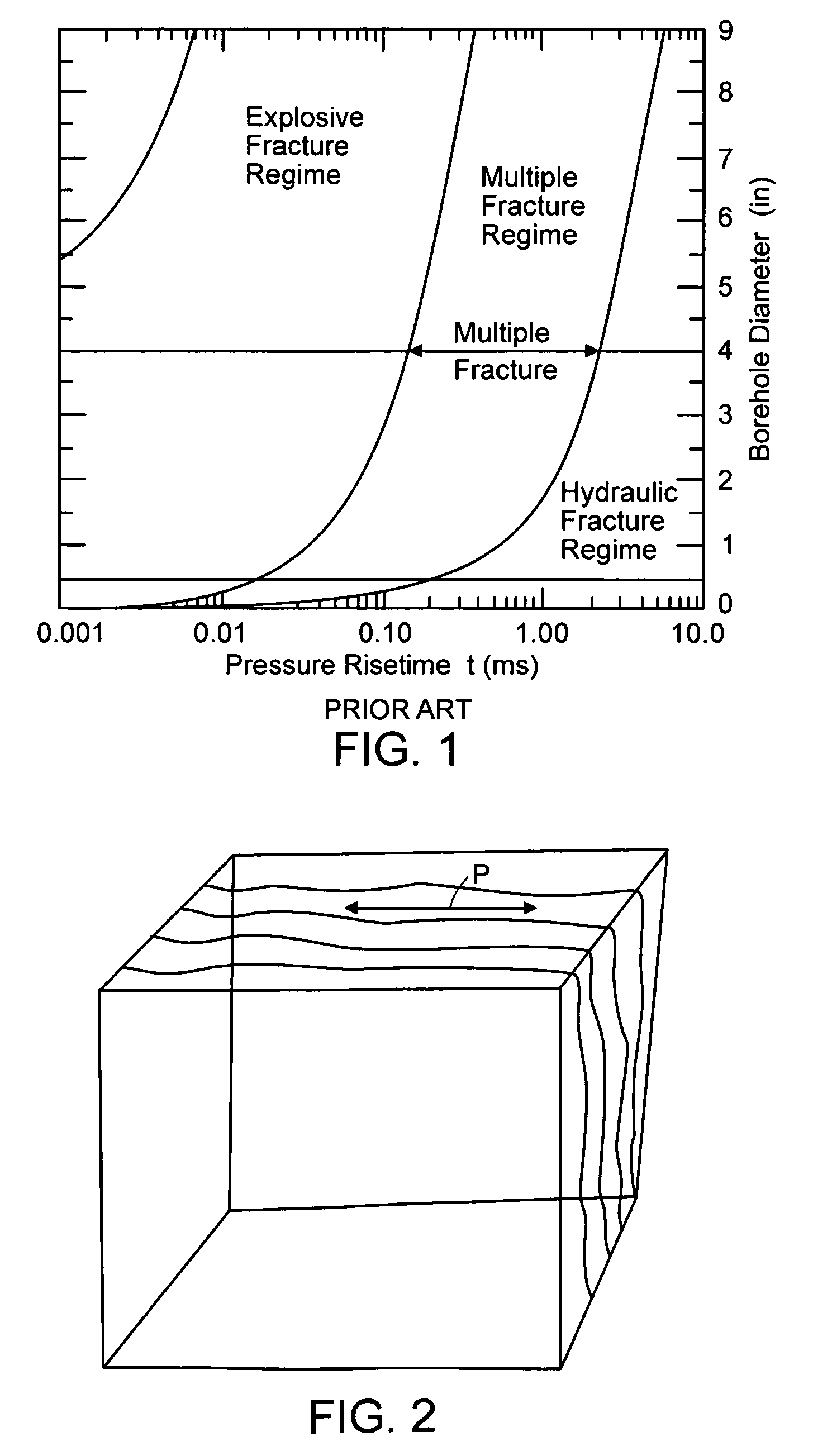

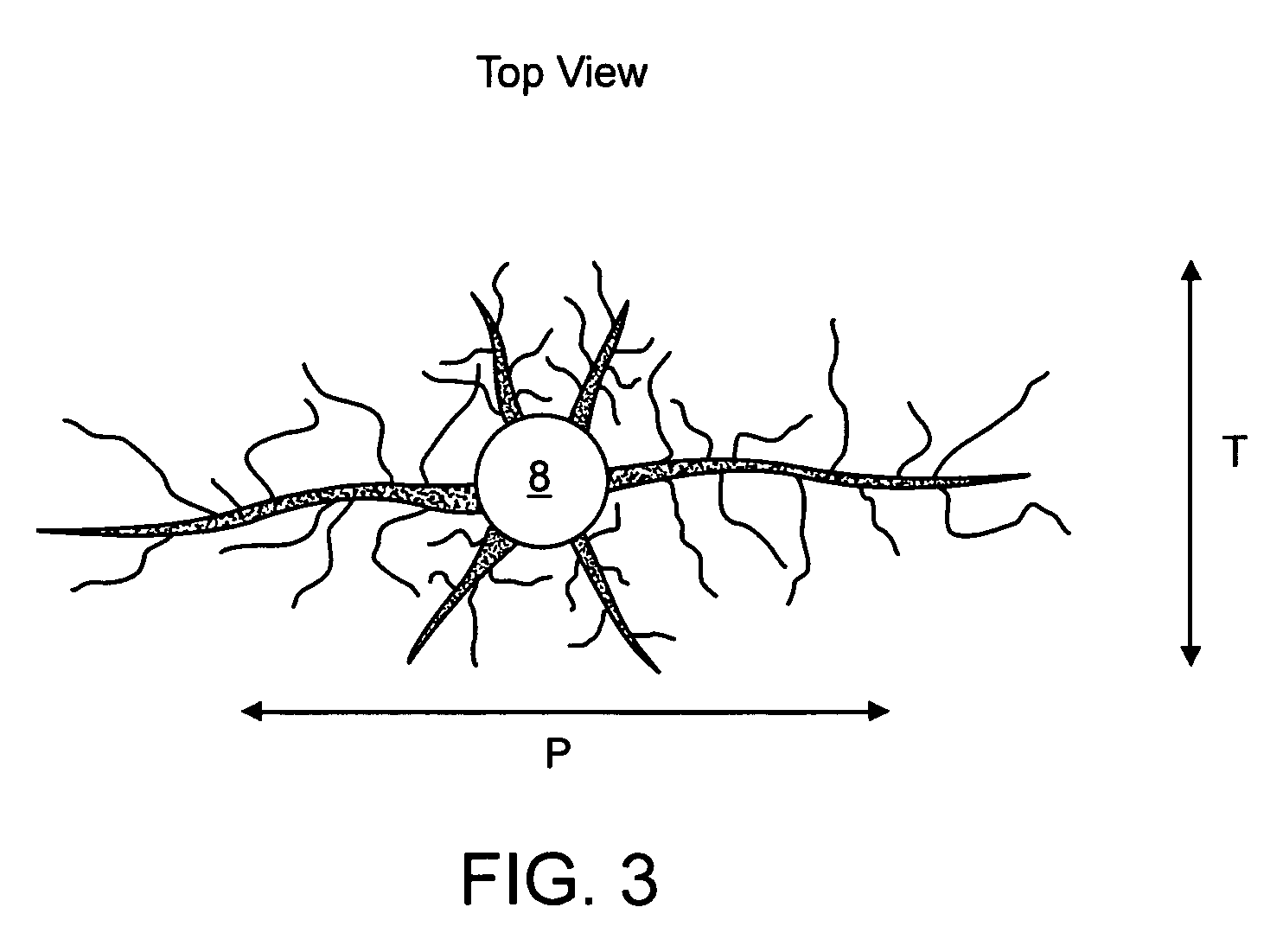

ActiveUS20060185898A1Multiple fracture regimeExtend fractureBlasting cartridgesNuclear explosivesPorosityEngineering

The present invention relates to apparatus and methods to stimulate subterranean production and injection wells, such as oil and gas wells, utilizing rocket propellants. Rapid production of high-pressure gas from controlled combustion of a propellant, during initial ignition and subsequent combustion, together with proper positioning of the energy source in relation to geologic formations, can be used to establish and maintain increased formation porosity and flow conditions with respect to the pay zone.

Owner:SEEKFORD DALE B

Oxidizer package for propellant system for rockets

An oxidizer package for a propellant system for a motor in which the oxidizer is separated from fuel grain, the oxidizer package comprising oxidizer material and an ignition system therefor in a wrapping or sealing material. A hybrid rocket comprising oxidizer material and fuel grain, the oxidizer material being separated from the fuel grain and being in the form of a single package or plurality of packages of oxidizer material and an ignition system therefor, said packages generally conforming to the shape of the rocket. A grid of a pyrotechnic material. A propulsion system for a hybrid rocket comprising oxidizer material in a matrix, mesh, wool, foamed metal or wires of structural or pyrotechnic material.

Owner:CESARONI ANTHONY JOSEPH +4

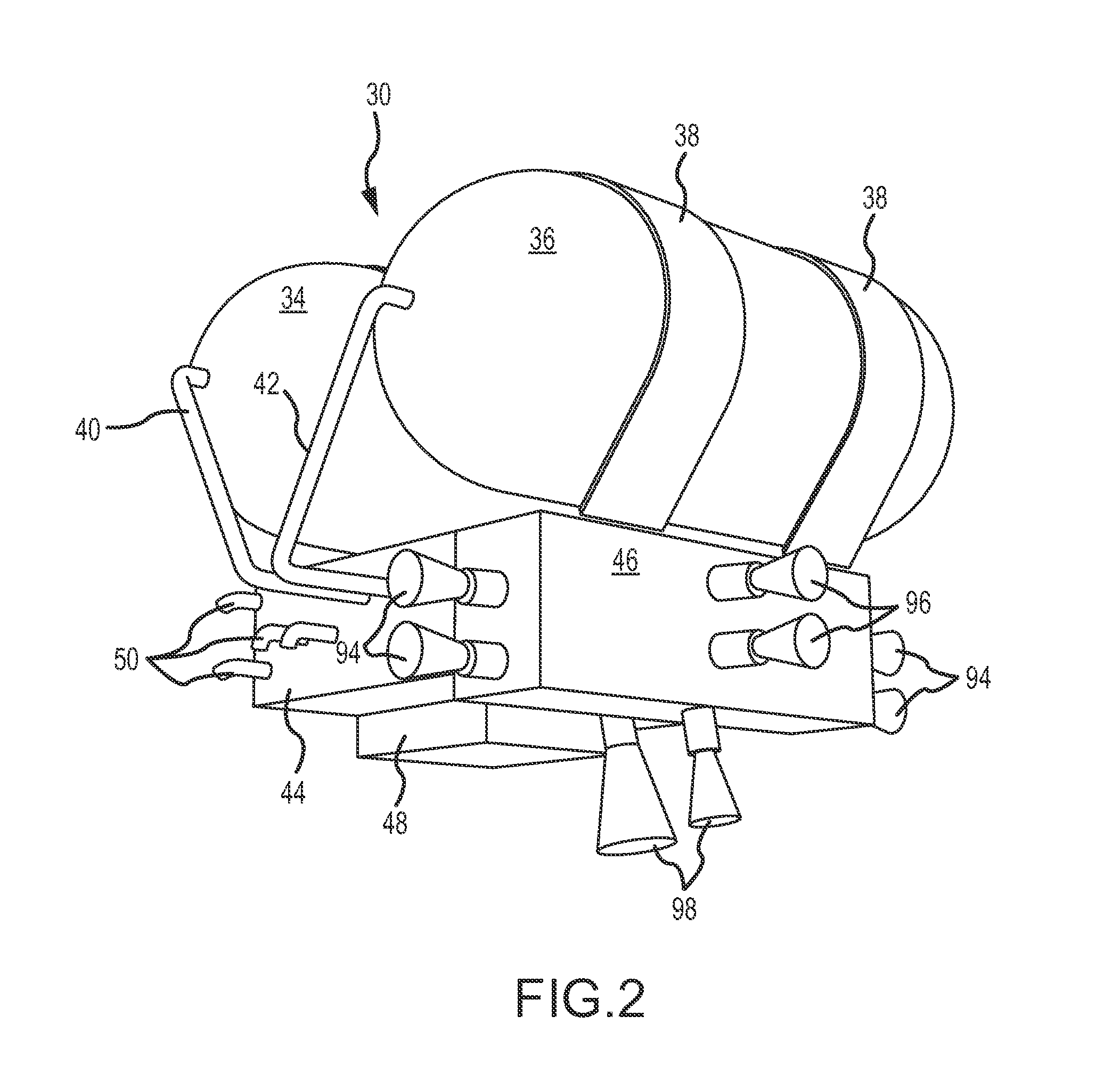

Spacecraft Launch and Exploration System

InactiveUS20110042521A1Maximum flexibilityMaximum safetyCosmonautic ground equipmentsLaunch systemsSingle stageOn board

This invention is a launch-to-space, refuel and return system which comprises: a unique circular and straight maglev track and maglev sled spacecraft launcher; a single stage-to-LEO spacecraft (Mother Spacecraft); an orbiting space platform (OSP); a currently utilized Space Shuttle is altered to improve its safety, range, longevity and versatility which serves as a prototype for the Mother Spacecraft design. The Mother Spacecraft is releasably attached to the maglev sled and propulsion for the maglev sled is supplied by magnetic propulsion and on-board rocket propulsion. The collapsible OSP can fit into the Space Shuttle storage bay and is remotely deployed. The OSP is a refueling depot for the Mother Spacecraft, the Space Shuttle, as well as a rendezvous point for various space missions. A single, liquid, non-cryogenic rocket fuel is standardized throughout the entire system which eliminates: all vertical launches; all expendables; all solid rocket propellants.

Owner:SAMPLE DANIEL S

Method and apparatus for stimulating wells with propellants

ActiveUS7565930B2Multiple fracture regimeExtend fractureBlasting cartridgesNuclear explosivesPorosityEngineering

The present invention relates to apparatus and methods to stimulate subterranean production and injection wells, such as oil and gas wells, utilizing rocket propellants. Rapid production of high-pressure gas from controlled combustion of a propellant, during initial ignition and subsequent combustion, together with proper positioning of the energy source in relation to geologic formations, can be used to establish and maintain increased formation porosity and flow conditions with respect to the pay zone.

Owner:SEEKFORD DALE B

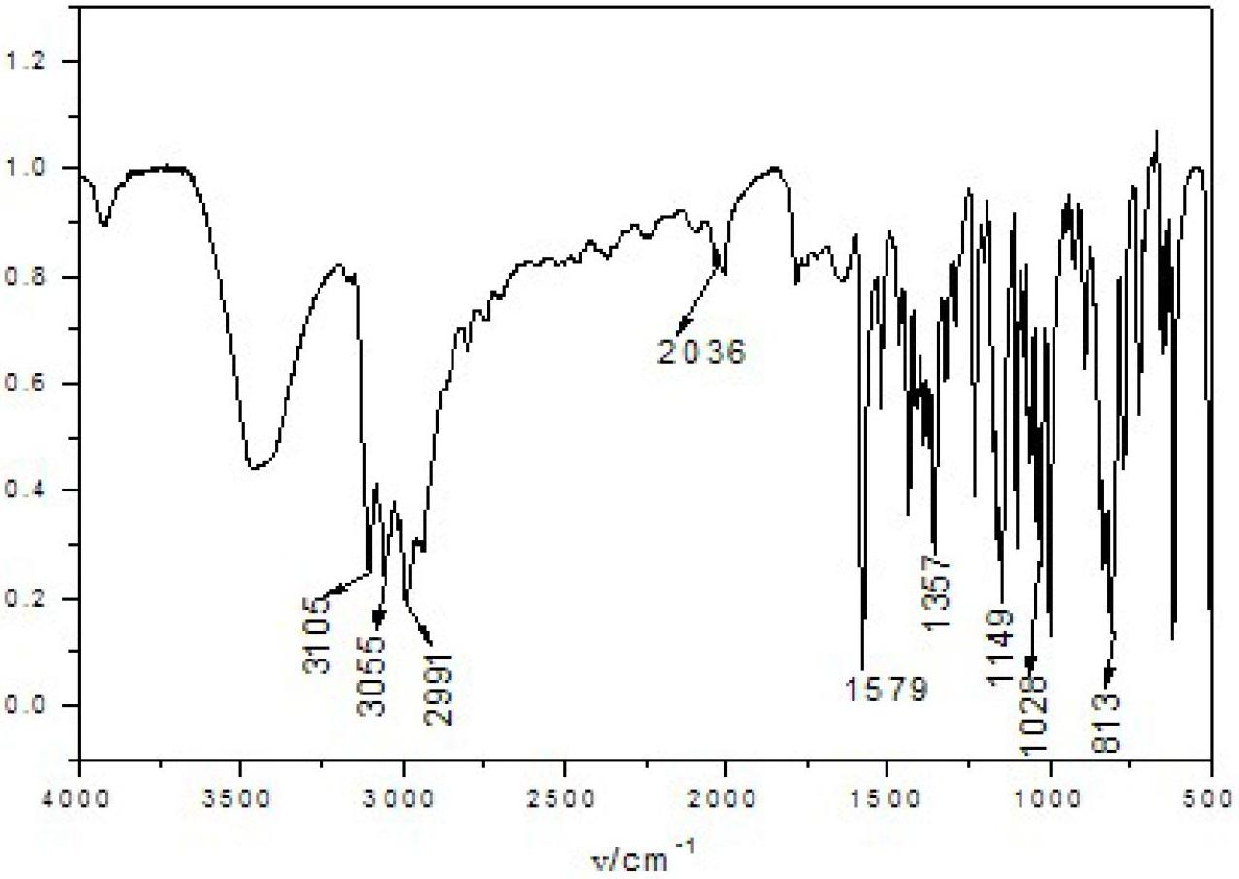

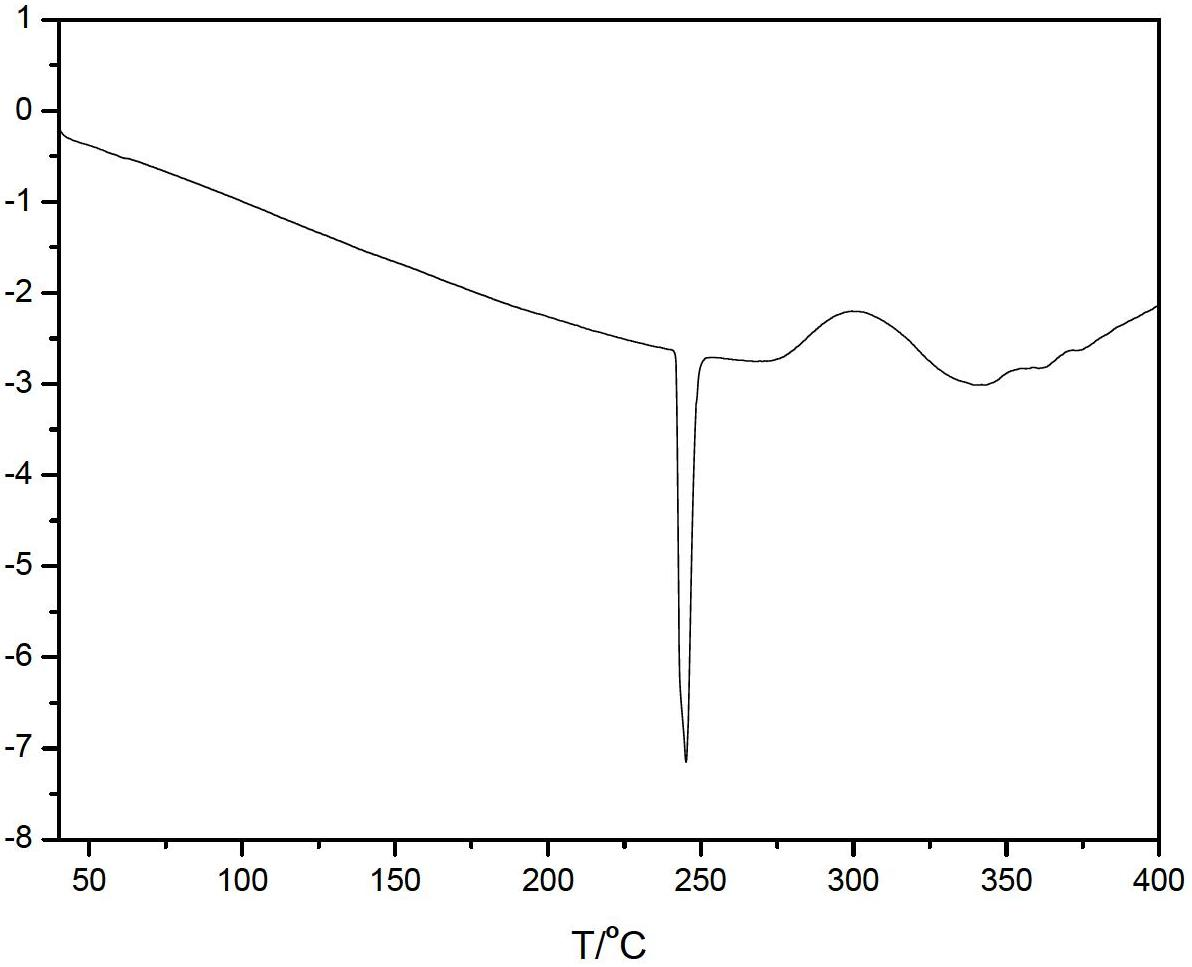

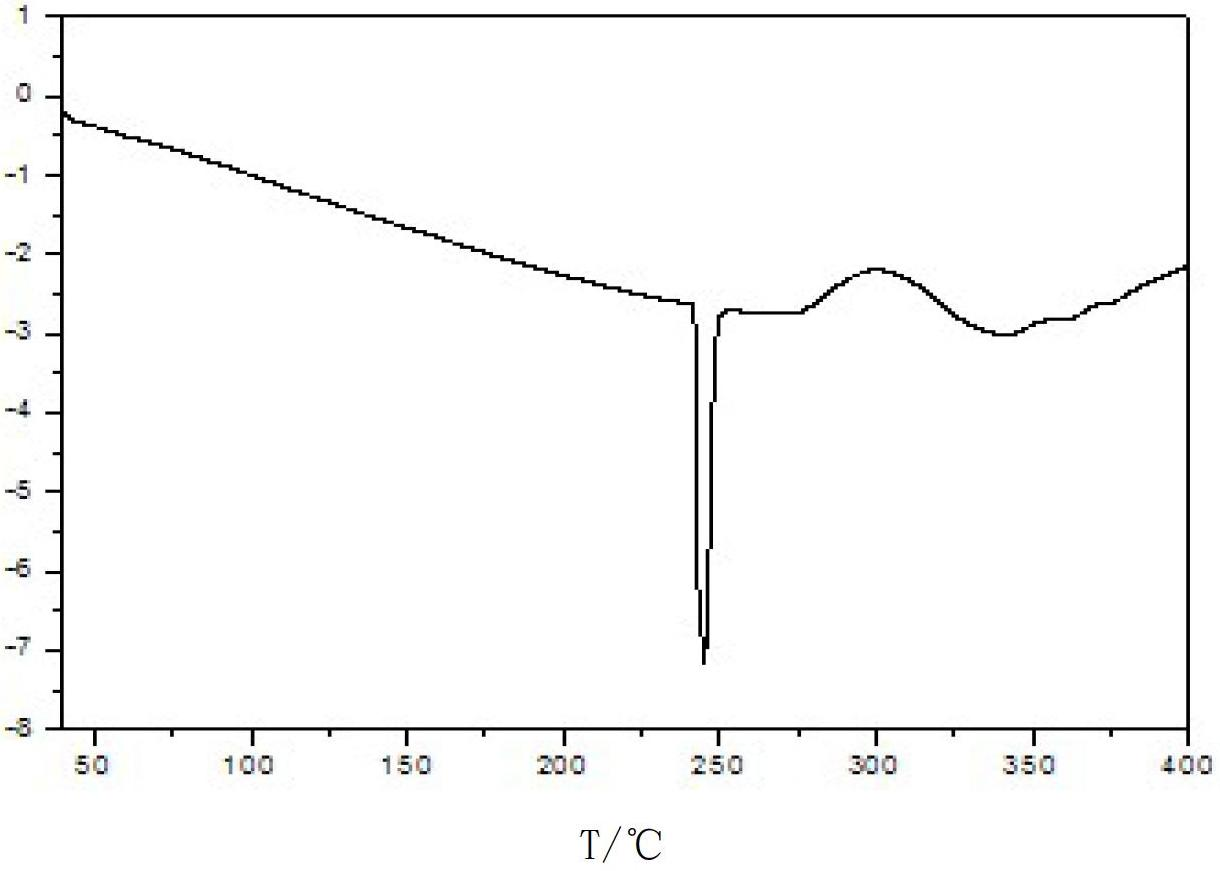

Ferrocene high-nitrogen ionic compound and preparation method thereof

InactiveCN102675376AImprove thermal stabilityImprove catalytic performanceMetallocenesSteam pressureTetrazole

Owner:SHAANXI NORMAL UNIV

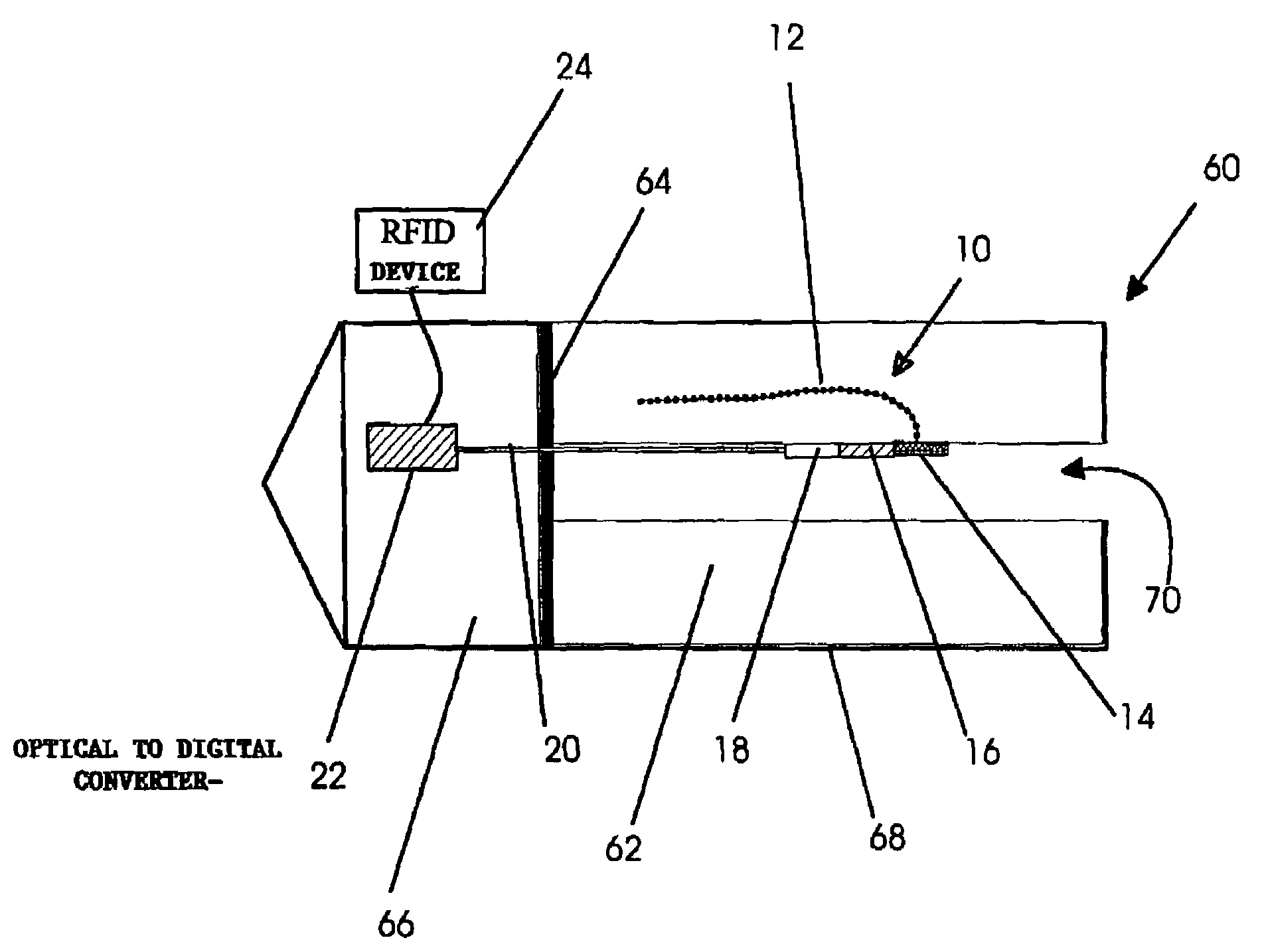

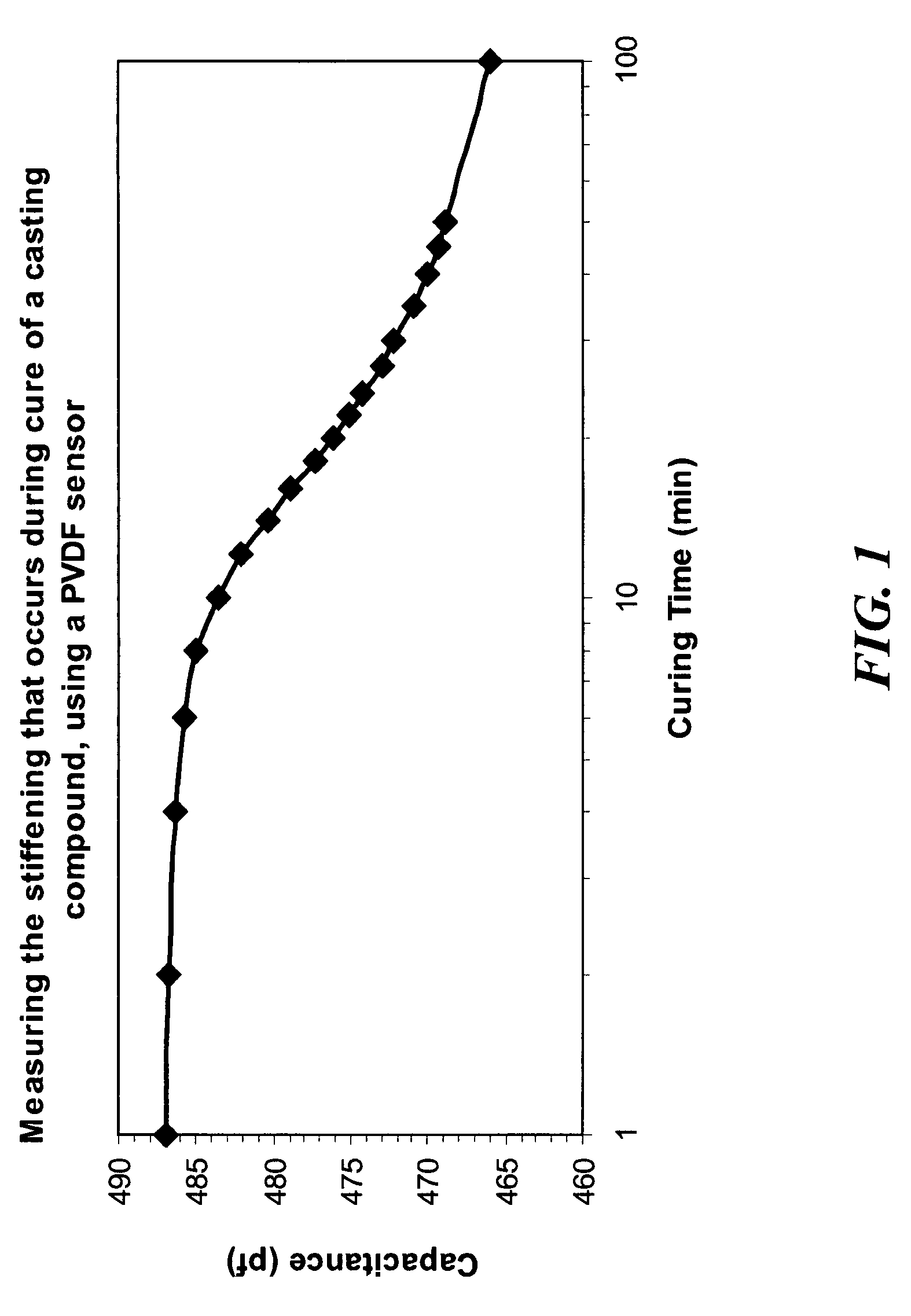

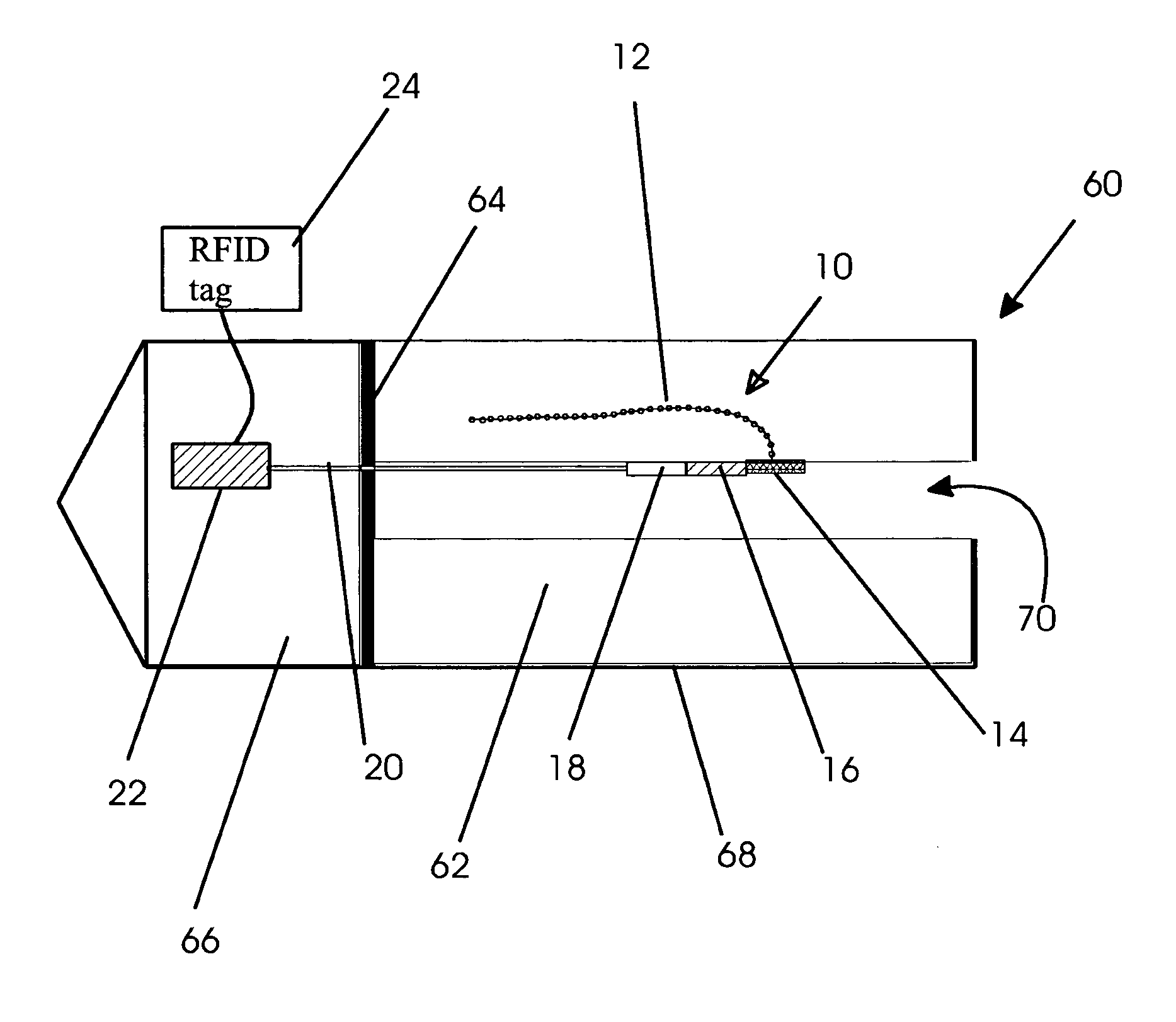

Method for measuring the health of solid rocket propellant using an embedded sensor

InactiveUS7652488B1Reduce capacitancePoor impedance matchingResistance/reactance/impedenceForce measurementElectricityShear modulus

The invented method for measuring the health of a solid rocket propellant includes embedding at least one piezoelectric capacitance sensor in the propellant, where the capacitance of the sensor is a function of a modulus of the propellant, and where the position is selected to measure manifestations of stress failure as a consequence of changes in the shear modulus. The capacitance of the sensor is measured at a predetermined frequency. The capacitance of the piezoelectric capacitance sensor is converted into a digital representation which is then converted into the digital representation of a modulus (or gradient modulus). In subsequent analysis, the modulus (or gradient of the modulus) is correlated to the health of the solid rocket propellant.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Thermoplastic polymer propellant compositions

Owner:CESARONI ANTHONY JOSEPH

Gas-oxygen-kerosene rocket-engine pressurizing delivery system and small-rocket-engine propellant supplying system

The invention relates to the field of rocket-engine propellant delivery systems, in particular to a gas-oxygen-kerosene rocket-engine pressurizing delivery system and a small-rocket-engine propellantsupplying system. The pressurizing delivery system comprises an oxygen supplying system, a fuel oil supplying system and a blowing-off system; the oxygen supplying system comprises an oxygen storage tank valve assembly, a first stop valve, a first one-way valve and a second one-way valve; the oxygen storage tank valve assembly, the first stop valve and the first one-way valve are sequentially communicated through a pipe, the second one-way valve is communicated with the blowing-off system, and an outlet of the first one-way valve and an outlet of the second one-way valve are connected with a thrust chamber through the same pipe; the fuel oil supplying system is connected with the blowing-off system to enter the thrust chamber through the pipe. The gas-oxygen-kerosene rocket-engine pressurizing delivery system in the technical scheme is compared with a liquid-oxygen-kerosene rocket propellant delivery system, complex design such as pressurization-system gas-liquid phase transition, delivery-system low-temperature two-phase flow and engine pre-cooling are not required to be considered, and the complex degree and the quality of the system structure are also greatly reduced.

Owner:BEIHANG UNIV

Methods of making double base casting powder

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Castable double base solid rocket propellant containing ballistic modifier pasted in an inert polymer

InactiveUS6024810AHigh sensitivityLow smokeCosmonautic propulsion system apparatusNitrocellulose explosive compositionsDetonationBurn rate

Castable propellant formulations are provided including reduced toxicity ballistic modifiers that do not adversely increase the sensitivity of the propellant to shock detonation. Failure to adequately control the propellant burn rate often results in unacceptable performance of the propellant. Carbon can act as an effective ballistic, but not to the extent of metal compounds. It has been found that pasting a ballistic modifier, including ballistic modifiers containing lead, in an inert polymer modifies the burn rate of propellants while allowing the use of a reduced amount of modifier to achieve the same desired burn rate modification as the prior art, and therefore creating reduced shortcomings associated with the ballistic modifiers. Accordingly, the use of from about 1% to about 6% burn rate modifier wherein the burn rate modifier includes a ballistic modifier pasted in an inert polymer is taught as an effective burn rate modifier in a propellant, in order to provide reduced toxicity means for modifying the propellant burn rate without increasing the sensitivity of the propellant to shock detonation.

Owner:AEROJET ROCKETDYNE INC

High burning rate tactical solid rocket propellant, and related method

InactiveUS8986473B1Improve solubilityNon-explosive fillers/gelling/thickening agentsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsCombustionHeat conducting

The invention is a composition for a high burning-rate solid rocket propellant, where the composition includes a binder compounded with a soluble energetic additive; a metallic fuel; and an oxidative fuel. The resulting composition has a tactical Class 1.3 hazard rating, and a linear regression rate that is substantially equivalent to a tactical Class 1.1 hazard rating obtainable using solid rocket propellants. The composition may include a heat-conducting element, a plasticizer, a curing component, a combustion catalyst, and curing catalyst.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

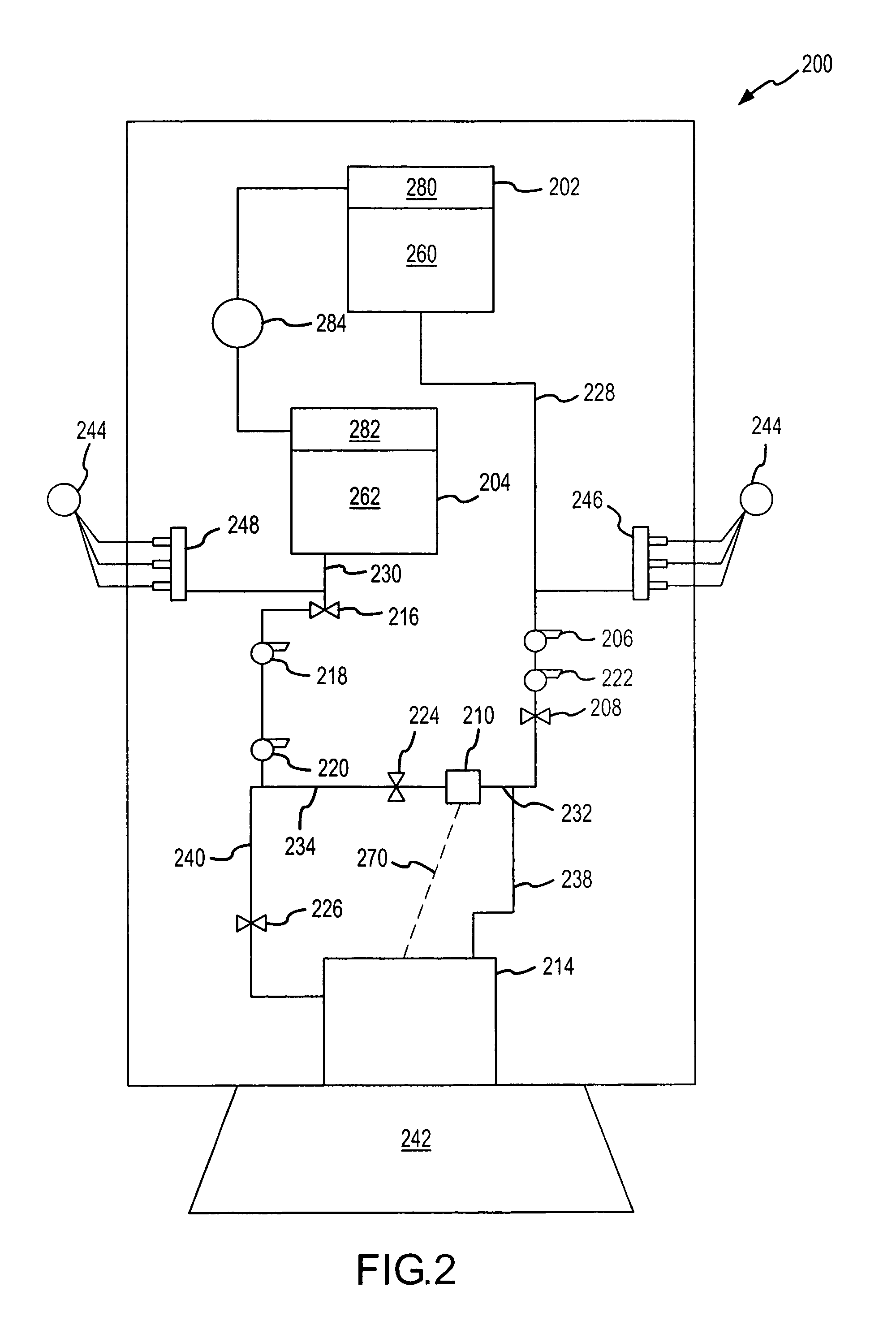

Propellant management system and method for multiple booster rockets

InactiveUS7477966B1Quantity minimizationIncrease the throttle” of this rocketCosmonautic vehiclesCosmonautic power supply systemsSpace launchRocket propellant

Propellant management systems and methods are provided for controlling the delivery of liquid propellants in a space launch vehicle utilizing multiple rockets. The propellant management systems and methods may be configured to enable substantial simultaneous depletion of liquid propellants in each of a plurality of active rockets during operation of various booster stages of the launch vehicle.

Owner:LOCKHEED MARTIN CORP

2-octyl-3,4-di(7-diisocyanateheptyl)-1-hexylcyclohexane and its preparation method and use

InactiveCN101100448AEasy to industrializeEasy to operatePreparation from carboxylic acid nitrogen analoguesElastomerIsomerization

Production of 2-octyl-3,4-di(7-isocyanate caprylic)-1-hexyl cyclohexane and fatty isocyanate containing it is carried out by hydrogenation catalyzing for dimmer acid between room temperature to 280 deg. C, dewatering for generated saturated dimmer acid, reacting with sulfurous chloride, reacting dimeric acid acyl bromide with sodium azide to generate dimeric acid azide, isomerization decomposing to convert into final product. It can be used to produce polyurethane varnish, elastomer, adhesive, spinning finishing agent and rocket impeller.

Owner:刘林学 +1

Aliphatic diisocyanate and preparation method and purposes thereof

ActiveCN101805270AHigh yieldEasy to operatePreparation from carboxylic acid nitrogen analoguesPolyureas/polyurethane adhesivesElastomerChemical structure

Owner:浙江优创材料科技股份有限公司

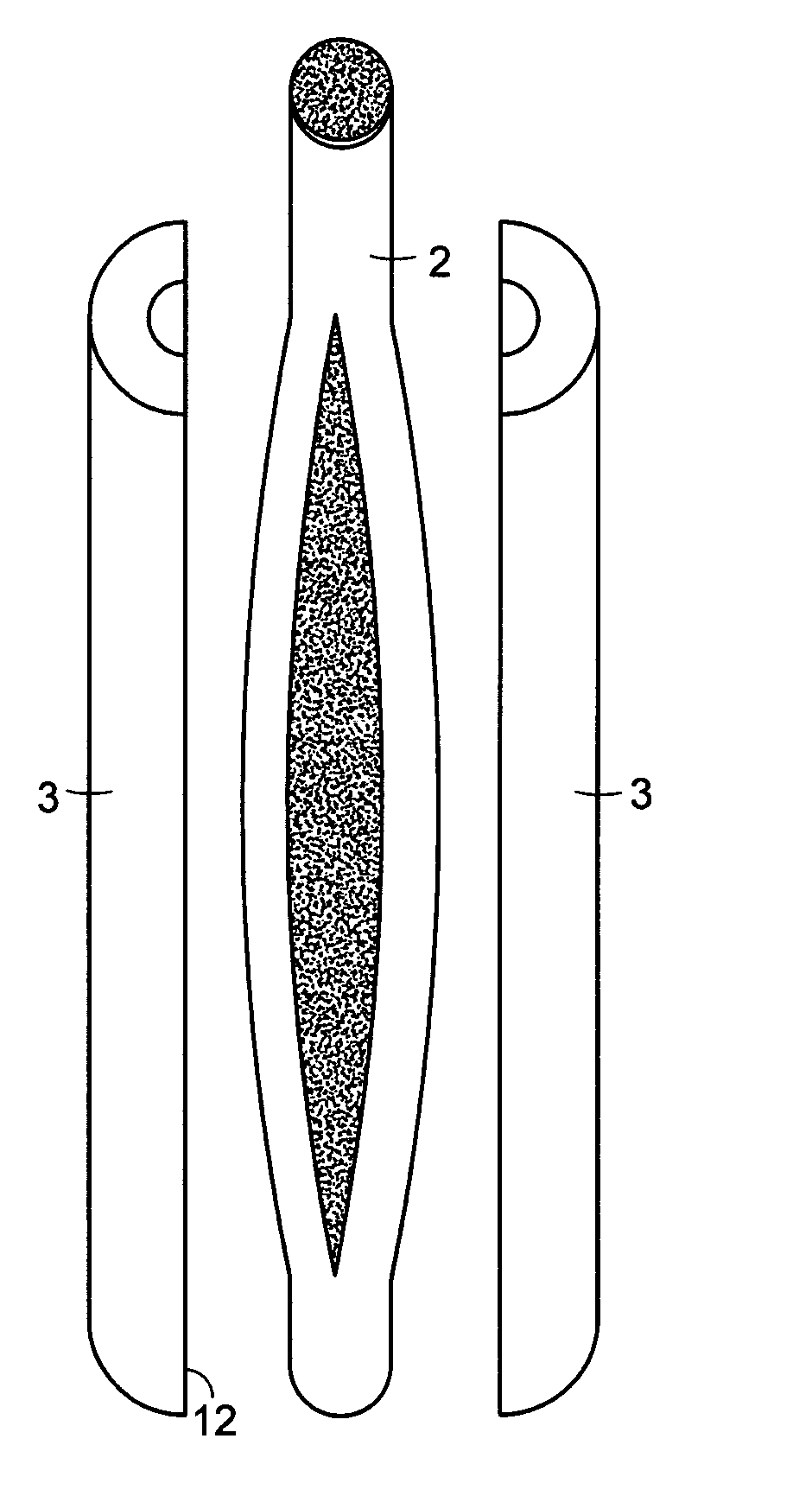

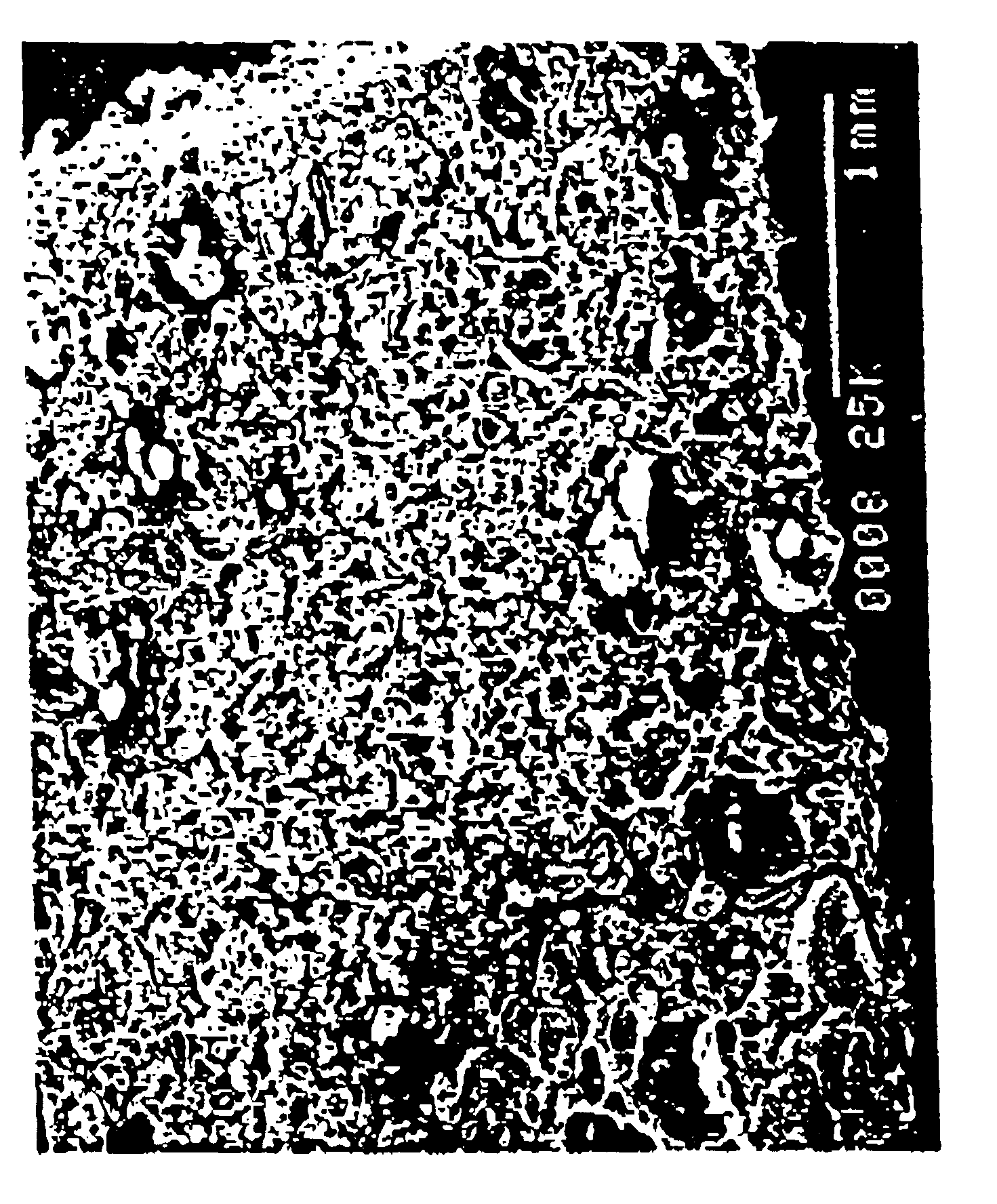

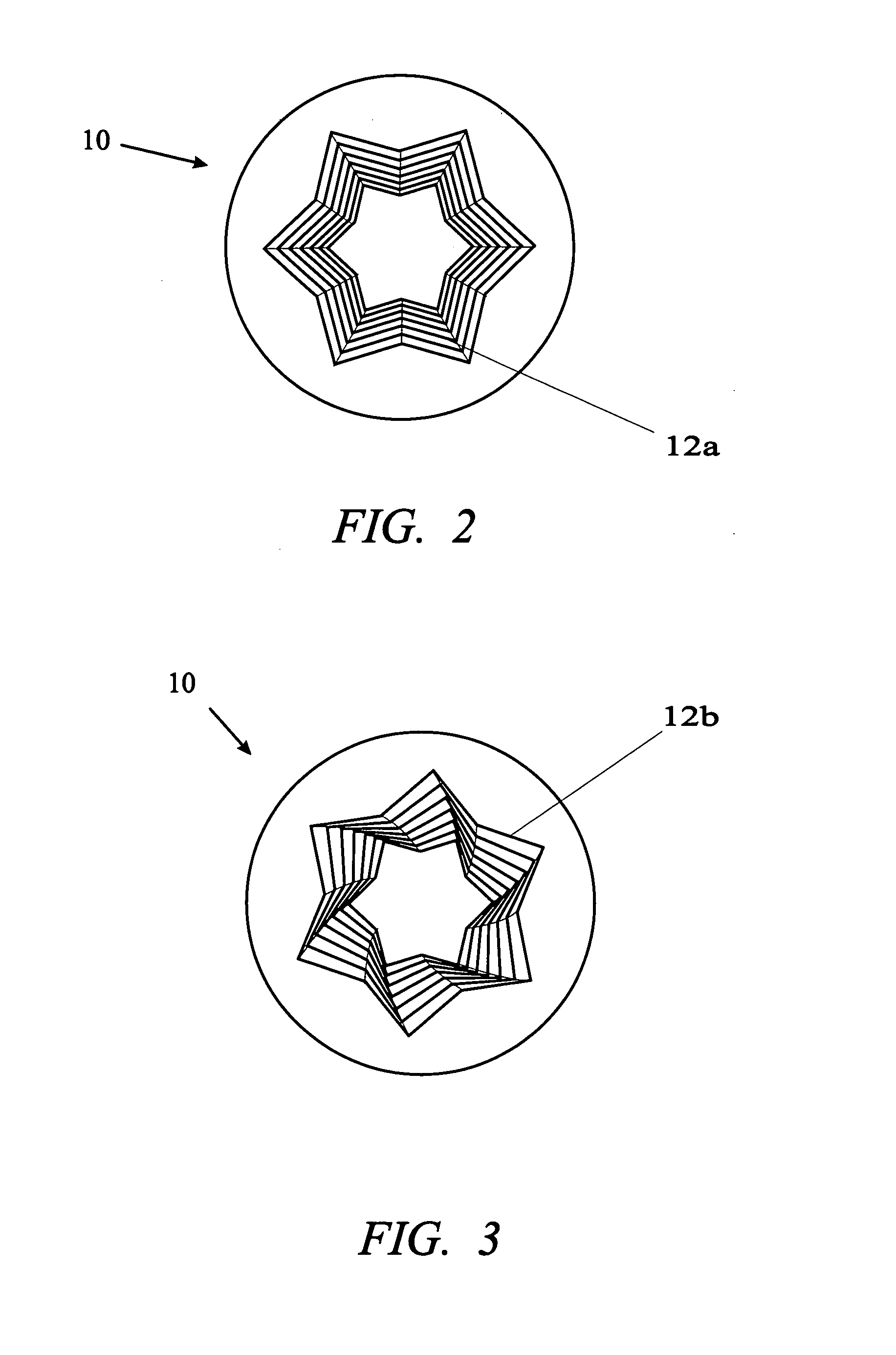

Higher-performance solid-rocket propellants and methods of utilizing them

InactiveUS8465607B1Less toolingSystem tailorableCosmonautic vehiclesCosmonautic propulsion system apparatusShell moldingRocket propellant

A method, and a related material, for utilizing high performance solid rocket propellants, which are molding powders. A propellant molding powder are selected to have a design burning rate and a tailored compaction profile. A morphology of a center-port of a rocket is selected for the design burn rate and a spin-rate. The molding powder is compacted isostatically around a core through application of triaxial pressure therein forming a solid rocket propellant charge with the selected center-port shape. The solid rocket propellant charge is placed in a cartridge or a case. The cartridge is selected from various types of cartridges and specialty charges. The solid rocket propellant molding powders are highly filled with metallic fuels, and have a binder in the range of 4% to 18%, which at least partially coats the surface of the molding powder.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Four rockets and brake systems for motor vehicles

The invention discloses four brake rockets and brake systems for motor vehicles, and relates to the technologies of machine manufacturing and jet propulsion. In the invention, a single component liquid rocket, a dual component liquid rocket, a solid rocket and a solid-liquid mixed rocket, and six motor vehicle brake systems respectively formed by the four rockets are provided; and the original delivery system is eliminated, when emergency braking is required, the brake rocket is started immediately and responds quickly in centiseconds, and a rocket propellant rapidly burns to generate high-pressure high-temperature gas which is jet out at high speed from a tail pipe, so that a powerful thrust is erupted to counteract the inertia force of a vehicle, shorten the prints of tires, reduce traffic accidents and improve the safety of the vehicle. The rockets and brake systems for motor vehicles are suitable for long distance coaches, large trucks, sport utility vehicles, tool vehicles, motorcycles, electric vehicles, hybrid electric vehicles, special vehicles, various cars, pickup trucks, racing cars, tricycles for agricultural use and quadricycles for agricultural use, and are especially suitable for various vehicles which need to be driven for a long distance and driven on mountain roads.

Owner:李开超

Oxidizer package for propellant system for rockets

Owner:CESARONI ANTHONY JOSEPH +2

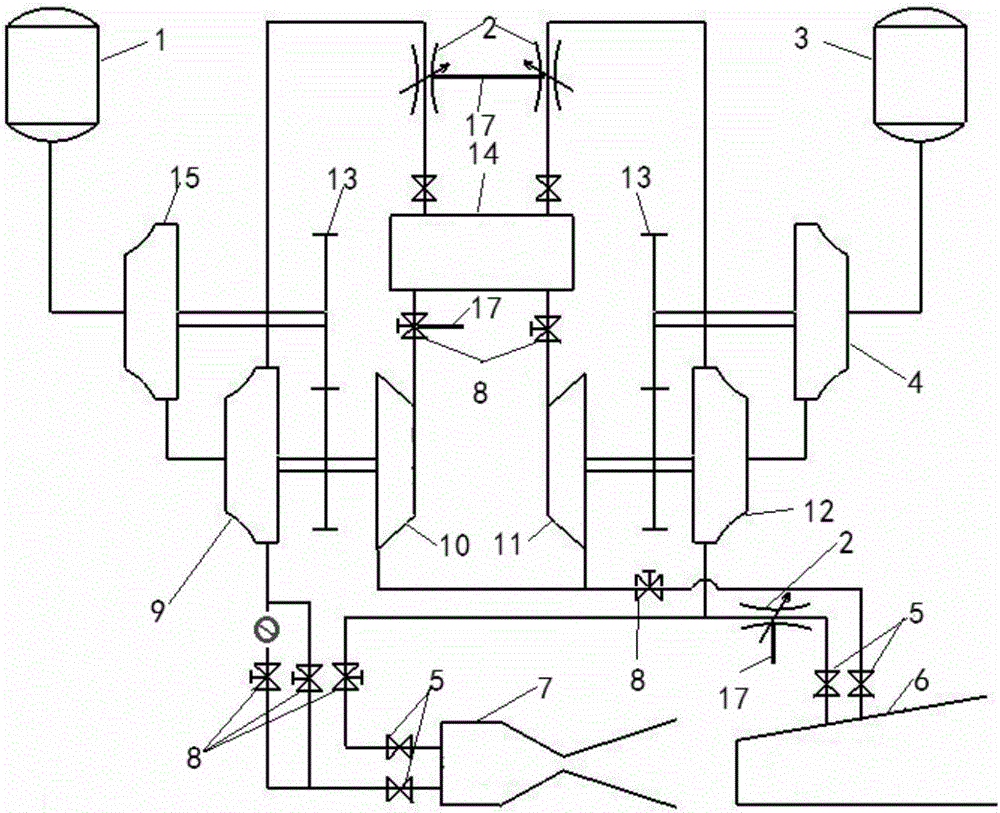

Integrated propellant supply system of rocket based combined circulating engine

InactiveCN106321284AImprove performanceSimple structureRocket engine plantsRam jet enginesKeroseneRocket propellant

The invention discloses an integrated propellant supply system of a rocket based combined circulating engine. The integrated propellant supply system consists of a liquid oxygen path supply system, a kerosene path supply system and a fuel gas system; the liquid oxygen path supply system provides an oxidant for the engine; the kerosene path supply system provides fuels for the engine; the fuel gas system provides turbine driving fuel gas for a turbine; and the liquid oxygen path supply system and the kerosene path supply system are symmetrically arranged with respect to a fuel gas generator 14. The supply system takes a fuel gas generator circulating system with a simple structure as a basic structural form for discharging the turbine driving fuel gas into a low-pressure ramjet flow path to carry out complementary combustion, so that an engine complementary combustion circulating system with a relatively simple structure and excellent performance is formed; moreover, the system has a large range of regulating capacity, and also meets supply needs of a main rocket propellant and engine secondary fuels of the rocket based combined circulating engine. The propellant supply system increases an energy utilization rate and improves engine performance, and can be used for wide-envelop multi-mode RBCC engine system integrating.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Nano nickel fuel oil additive

The invention relates to energy and environment filed, and discloses a nano nickel fuel oil additive. The nano nickel fuel oil additive comprises the following raw materials by weight percent: 0.3%-0.8% of metal nickel nano powder, 5%-10% of methyl tert-butyl ether, 10%-15% of C5 alcohol, 5%-10% of C6 alcohol, 53.2%-72.7% of methyl alcohol, 5%-8% of rocket propellant and 2%-3% metal oxide or metal inorganic salt. The nano nickel fuel oil additive can be applied to various fuel oil such as gasoline, diesel fuel, blended fuel oil, heavy oil, bio-oil and the like, and can be widely applied to automobiles, heavy vehicles, trains, steamships, boilers and the like. The nano nickel fuel oil additive has good catalytic and cracking effects and can enable fuel oil to burn completely and evenly, thereby improving unit fuel oil calorific value so as to achieve optimum burning effect, decreasing pollution emission, clearing carbon deposition in an engine, increasing motive power, lowering noise, and achieving energy saving and emission reduction effects.

Owner:楼忠长

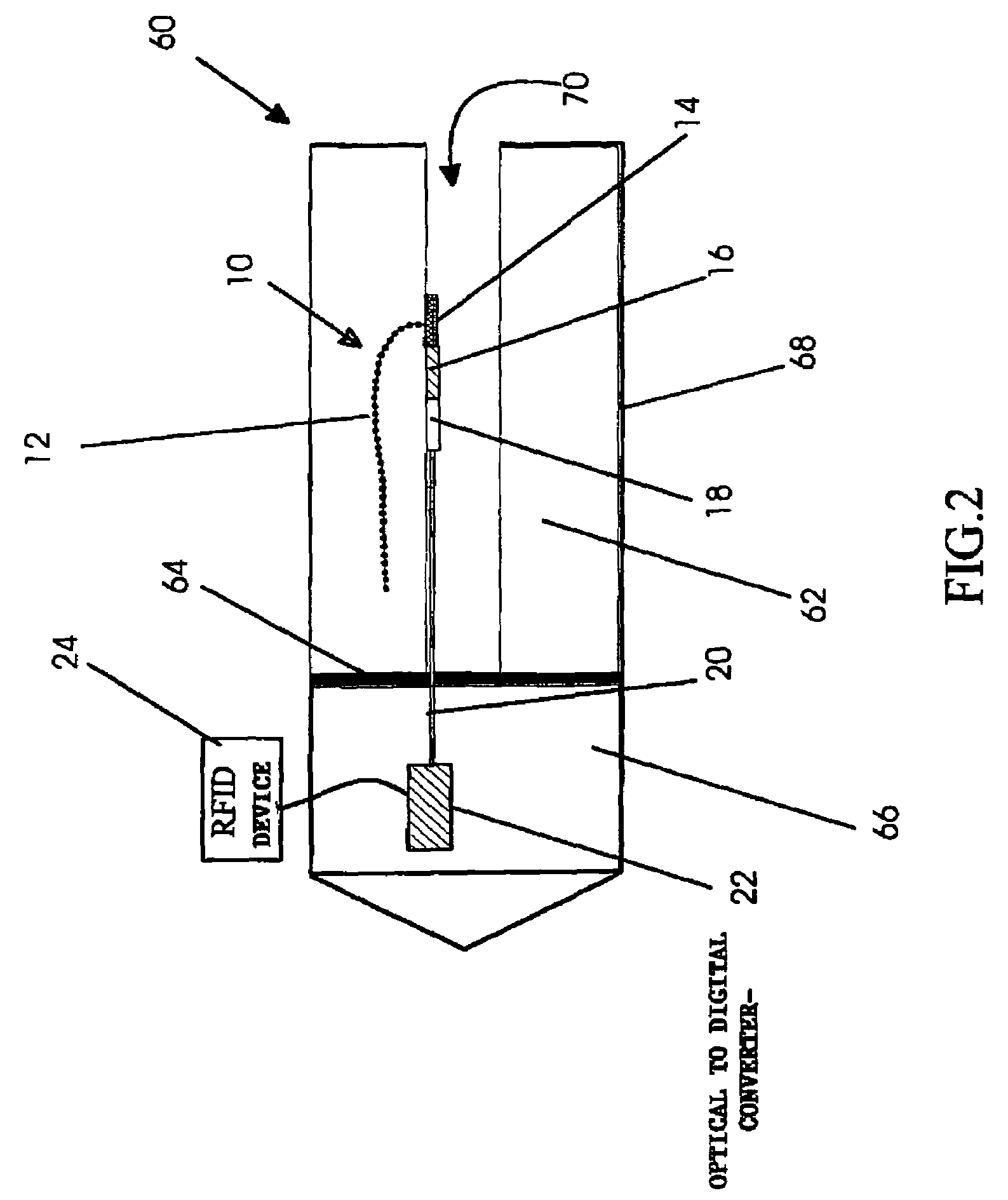

Apparatus for measuring the health of solid rocket propellant using an embedded sensor

InactiveUS7926356B1Reduce capacitancePoor impedance matchingForce measurementUsing electrical meansElectricityCapacitance

An invented apparatus for nondestructively remotely measuring the health of an energetic material, includes a piezoelectric capacitance sensor having an exterior surface that is substantially inert to the energetic material. The piezoelectric capacitance sensor provides an analog signal that is commensurately responsive to the modulus of material in intimate contact with the sensor. The apparatus also includes an interrogator for interrogating the sensor as to a capacitance of the piezoelectric capacitance sensor. The interrogator converts the analog signal of the capacitance into a digital representation. The apparatus further includes a means of communicating the digital representation to a remote communication device.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

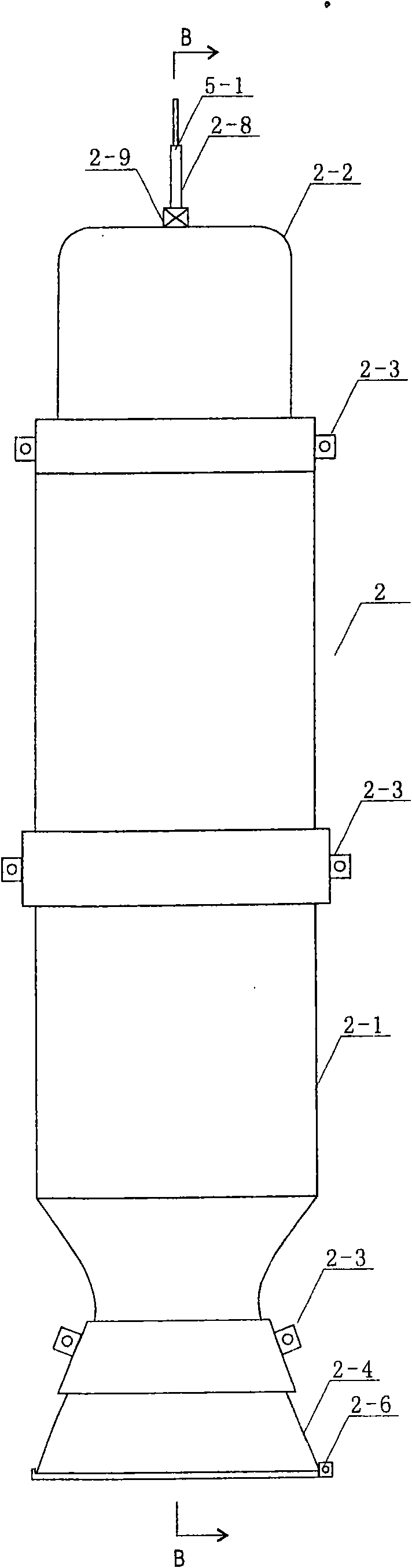

Zero-second dropping-off normal-temperature propellant adding and discharging connector for carrier rocket and method

ActiveCN110002015AShedding evenlyEnsure safe takeoffCosmonautic ground equipmentsBlock and tackleTower

The invention relates to a zero-second dropping-off normal-temperature propellant adding and discharging connector for a carrier rocket and a method. The zero-second dropping-off normal-temperature propellant adding and discharging connector for the carrier rocket comprises a connector ground part, a connector on-rocket part, a first pulley set, a second pulley set, a third pulley set, a recoveryrope, a traction rope, a counterweight, an air cylinder and a ball lock; the connector on-rocket part is mounted on a propellant storage tank of the carrier rocket, the second pulley set and the air cylinder are mounted on a launching tower, the connector ground part is connected with the connector on-rocket part through the ball lock, the counterweight is connected with the connector ground partthrough the second pulley set and the recovery rope, and the air cylinder is connected with the ball lock through the third pulley set, the traction rope and the first pulley set. The connector between a ground normal-temperature propellant filling pipeline and the on-rocket propellant storage tank can drop off reliably after zero-second ignition for taking off of the carrier rocket.

Owner:SHANGHAI AEROSPACE SYST ENG INST

Subjective-objective explosive with high crystal density and preparation method of subjective-objective explosive

ActiveCN106831278AImprove thermal stabilityAchieve stabilizationNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsExplosive ingredient compoundingCell cavityHydroxylamine

The invention discloses a preparation method of a subjective-objective explosive with high crystal density. The preparation method comprises the following steps: respectively preparing a fresh hydroxylamine solution and a CL-20 explosive solution, mixing the two solutions, oversaturating the solutions by using a recrystallization technique, driving cocrystallization of CL-20 with hydroxylamine, thereby obtaining the subjective-objective explosive crystal which is highly ordered in molecular accumulation, is periodically arranged and prepared through cocrystallization of CL-20 with hydroxylamine. The invention further discloses the subjective-objective explosive with high crystal density. The molecular ratio of the subjective-objective explosive with high crystal density is 2:1, the hydroxylamine is embedded into unit cell cavities of CL-20, then the crystal density of the explosive can be up to 2.0g.cm<-1> or greater, relatively good thermal stability can be achieved, and meanwhile stable preparation of the hydroxylamine is achieved. The subjective-objective explosive prepared by using the preparation method has the potential of increasing air release quantity, increasing the detonation velocity and the detonation pressure and improving comprehensive properties of explosives, and has wide application prospects in advanced weapon payloads and rocket propellants.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

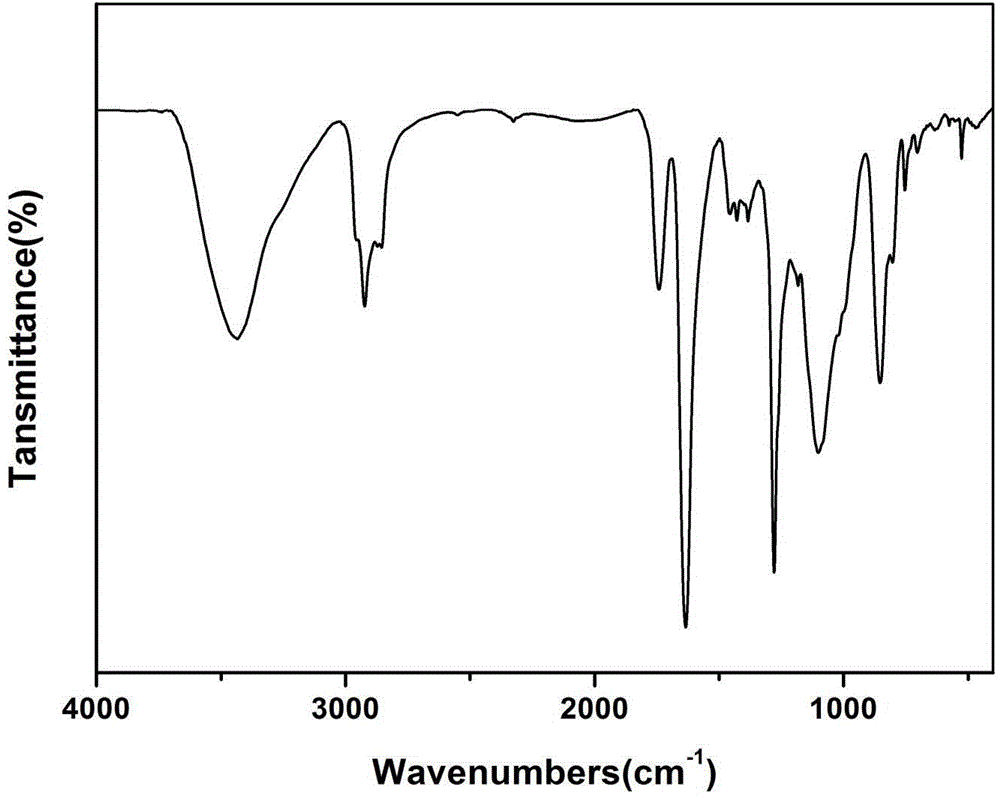

Fullerene ethylenediamine nitrate as well as preparation method and application thereof

InactiveCN103274949AEasy to prepareEasy to separate and purifyOrganic compound preparationAmino compound preparationEthylenediamineNitrate

The invention discloses a fullerene ethylenediamine nitrate as well as a preparation method and an application thereof. Firstly, fullerene C60 and ethylenediamine are taken as raw materials, fullerene ethylenediamine is prepared by the aid of a nucleophilic addition principle, and the fullerene ethylenediamine reacts with nitric acid so that the fullerene ethylenediamine nitrate is obtained. The fullerene ethylenediamine nitrate has the advantages of oxidant ammonium nitrate (AN), can avoid disadvantages of hygroscopicity, and crystal transformation of AN, and can be used as an oxidant to be applied in a novel solid rocket propellant or explosive.

Owner:SOUTHWEAT UNIV OF SCI & TECH

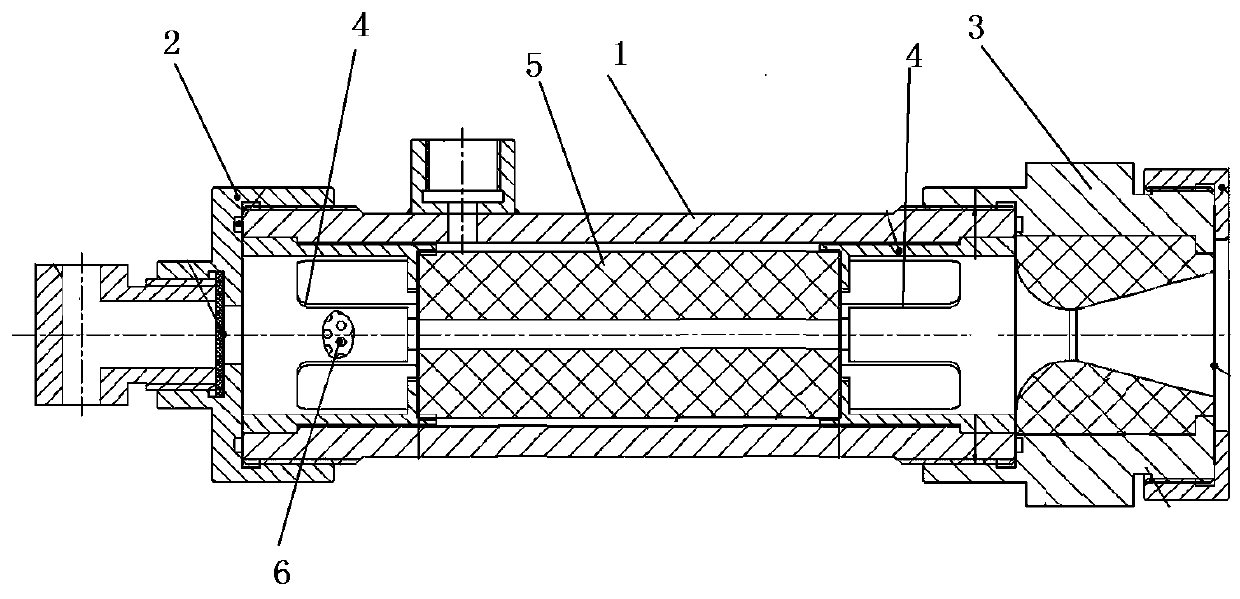

Test engine for testing solid rocket propellant

InactiveCN110886669AEasy to passPrevent tamperingRocket engine plantsCombustion chamberRocket propellant

The invention discloses a test engine for testing a solid rocket propellant. The test engine comprises a combustion chamber shell body, one end of the combustion chamber shell is provided with a top cover, and the other end of the combustion chamber shell is connected with a nozzle assembly; the inner part of the combustion chamber shell is provided with a propellant loading combustion chamber, the two ends of the inner part of the combustion chamber shell are each provided with a propellant column support of a hollowed-out structure, the two propellant column supports are oppositely arranged,propellant columns are installed between the two propellant column supports, and a gunpowder bag is arranged at the end, close to the top cover of each propellant column support; the propellant columns are cylindrical, and a central shaft is provided with an inner hole; and the end face of each propellant column is in contact clamping with the corresponding propellant column support, and a gap exists between the outer side wall of each propellant column and the inner wall of the combustion chamber shell. The propellant columns are stable in combustion, small in ablation and accurate in measurement, and the test engine is simple in structure, convenient to assemble and reusable.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH

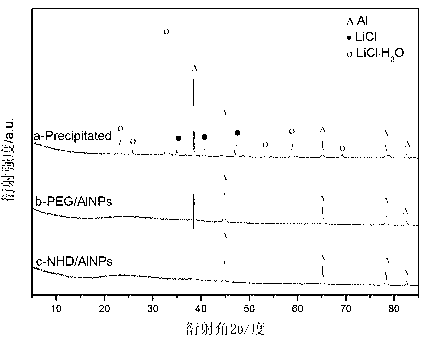

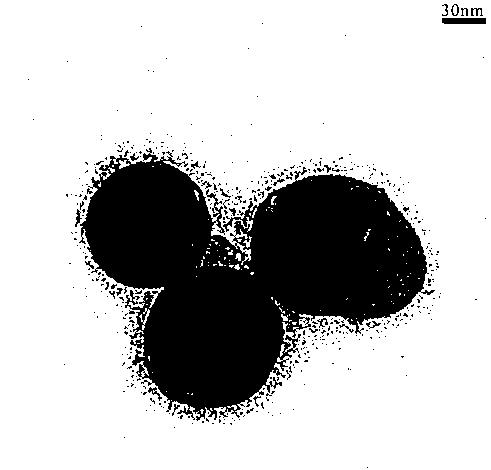

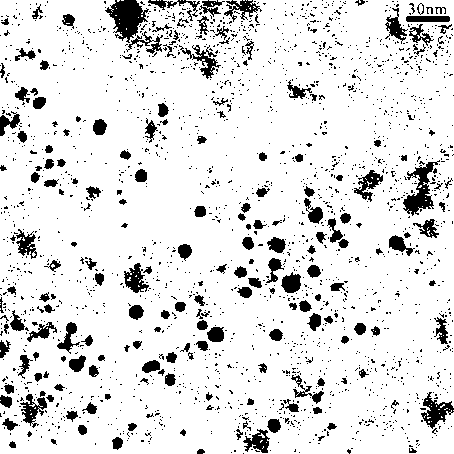

Method for preparing aluminum nanoparticles coated with dispersion stabilizers by liquid-phase chemical reduction method

InactiveCN103056388AAvoid reunionProvides antioxidant protectionNanotechnologyDispersityAluminium chloride

The invention discloses a method for preparing aluminum nanoparticles coated with dispersion stabilizers by a liquid-phase chemical reduction method. The method is characterized by including: purifying commercially available mesitylene; dispersing aluminum chloride in the mesitylene; and in the presence of nitrogen, adding polyethylene glycol or polyethylene glycol dimethyl ether serving as the dispersion stabilizer and lithium aluminum hydride in the mesitylene dispersed with the aluminum chloride according to the mass ratio of 1-2.5:0.5-1:0.5-1 among the aluminum chloride, the lithium aluminum hydride and the dispersion stabilizer, stirring for reacting 12-24 hours at the temperature of 164-166 DEG C, cooling, performing centrifugal separation, abandoning supernatant liquid, removing residual mesitylene solvents, washing by low-temperature methyl alcohol, performing ultrasonic washing and centrifugal separation, abandoning supernatant liquid and performing vacuum drying for lower materials so that the aluminum nanoparticles coated with the dispersion stabilizers are obtained. The prepared aluminum nanoparticles coated with the dispersion stabilizers are uniform in size and good in dispersity, have certain activity and are applicable to the fields of rocket propellants, explosives and powders, solar back plates and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Propellant formulation

InactiveUS7011722B2Improve balanceEasy to processExplosive working-up apparatusAlkali metal salt explosive compositionsMean diameterParylene

A solid heterogeneous, high performance rocket propellant, operable at high pressure with a burn rate relatively insensitive to changes in pressure and temperature, is disclosed. The propellant includes a binder formed from the reaction of a hydroxy terminated polybutadiene with a diisocyanate, ammonium perchlorate as an oxidizer, aluminum as a fuel, and iron oxide as a burn rate modifier. The ammonium perchlorate is a multimodal mixture of large paryticles with a weight mean diameter of about 70 to about 110 μm and small particles having a weight mean diameter of about 7.5 to about 15 μm. The propellant may also include bonding agents, curing catalysts, a plasticizer, antioxidant / peroxide scavengers, and pot life extenders.

Owner:NORTHROP GRUMMAN SYST CORP

Fullerene poly(glycidyl nitrate), preparation method and application thereof

InactiveCN104311427AGreat development potentialGood market prospectNitric acid ester preparationPressure gas generationChemical structureCombustion

The invention relates to fullerene poly(glycidyl nitrate), a preparation method and an application thereof, wherein the fullerene poly(glycidyl nitrate) has the chemical structure formula represented by a formula (I). The invention further relates to the preparation method, which comprises: adopting monomethyl-terminated poly(glycidyl nitrate) (PGN) and malonyl chloride as raw materials, carrying out the esterification and bromination two-step reaction to prepare bromomalonate dipoly(glycidyl nitrate), and reacting with fullerene to prepare the fullerene poly(glycidyl nitrate). According to the present invention, the fullerene derivative can be used in the solid rocket propellant as a novel energetic combustion catalyst; and experiment results prove that the product yield can be 82%, and the platform combustion rate can be increased by 65% while the pressure index is reduced to 0.21 when the product of the present invention is applied in the solid propellant as the novel combustion catalyst. The formula I is defined in the instruction, wherein n is 2-20.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Amine azide propellant

InactiveUS6962633B1Organic chemistryOrganic compound preparationCombinatorial chemistryRocket propellant

A novel family of amine azides having a cyclic structure therein is disclosed. These compounds have attractive properties as rocket propellants.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

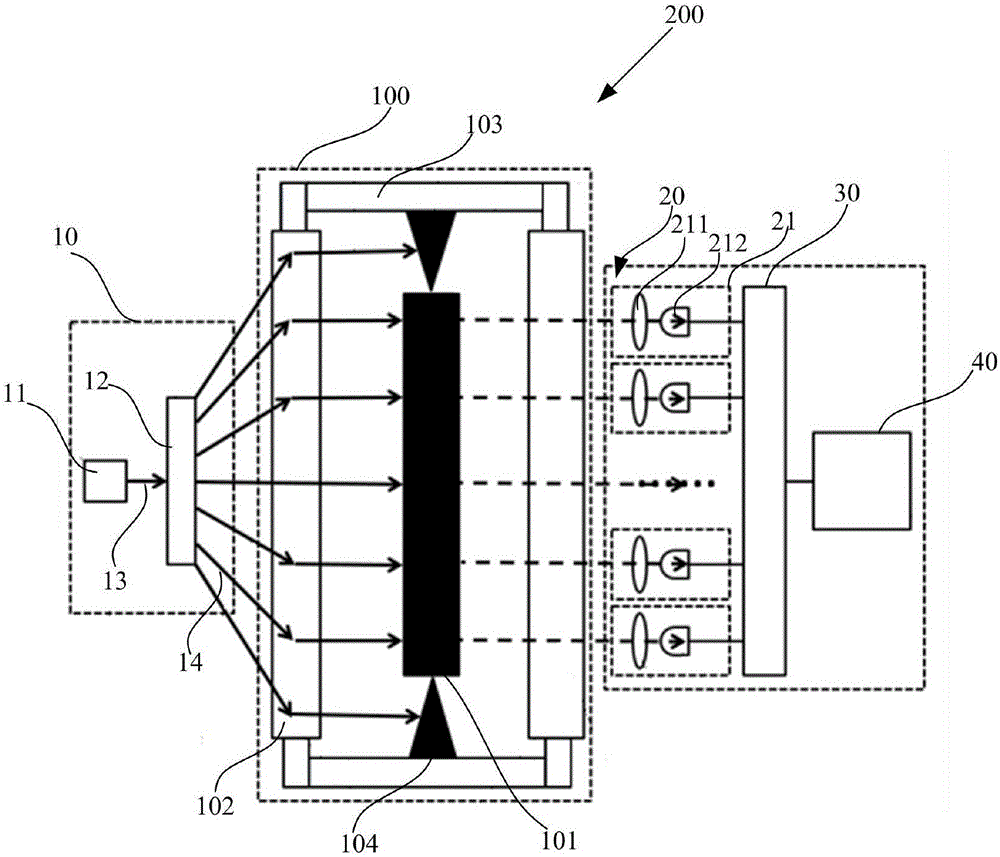

Dynamic testing device and dynamic testing method for burning speed of initiative laser type solid rocket propellant

ActiveCN106353449AOvercoming vulnerability to stressOvercome precisionChemical analysis using combustionDevices using time traversedOptoelectronicsContact mode

The invention provides a dynamic testing device and a dynamic testing method for a burning speed of an initiative laser type solid rocket propellant. The dynamic testing device comprises a laser emitting part, a photovoltaic conversion part and a signal processing part, wherein the laser emitting part comprises a laser emitting unit and a laser slice light converting unit; the photovoltaic conversion part is used for receiving the transmission light of the laser slice light passing through the powder strip and converting a light signal of the transmission light into an electric signal; the signal processing part is used for processing the electric signal, acquiring the data corresponding to the electric signal and acquiring the burning speed of the powder strip on the basis of the data; the photovoltaic conversion part comprises a plurality of photovoltaic conversion units which are arranged longitudinally and in parallel with the powder strip; the photovoltaic conversion units are parallel to each other and are vertical to the powder strip. The burning speed of the propellant can be dynamically acquired by recording the condition of the change in mutational site of the transmission light signal along with the time after the powder strip is ignited. The dynamic testing device and dynamic testing method for the burning speed of the initiative laser type solid rocket propellant provided by the invention can overcome the defects of easiness in being influenced by pressure and low test precision of a photoelectric method and have the advantages of simple structure, non-contact mode and high test precision.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com