Method for preparing aluminum nanoparticles coated with dispersion stabilizers by liquid-phase chemical reduction method

A technology of dispersion stabilizer and reduction method, which is applied in the direction of nanotechnology, can solve the problems of high equipment requirements, low requirements for experimental equipment, large particle size, etc., and achieve simple preparation process, easy access to raw materials, and high product purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

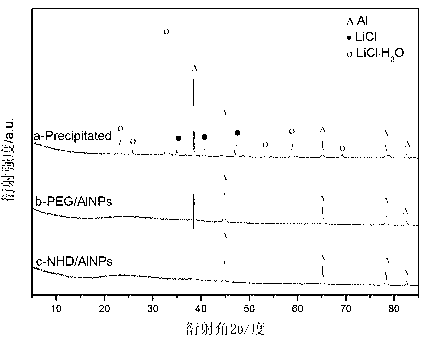

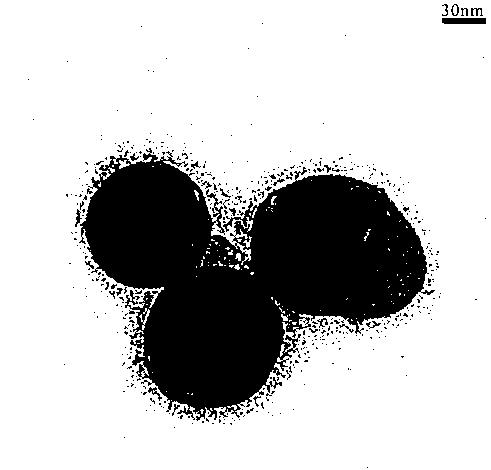

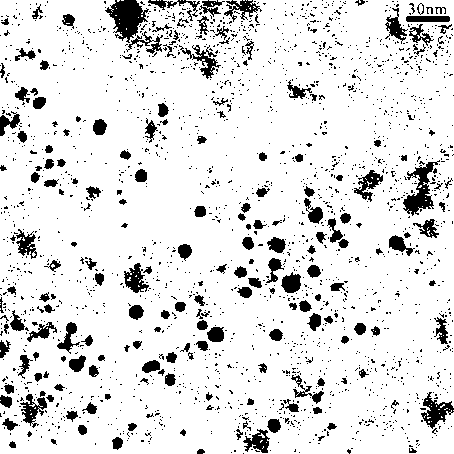

Method used

Image

Examples

Embodiment 1

[0032] a. Purification of mesitylene: In a separatory funnel, wash commercially available mesitylene with concentrated sulfuric acid (generally, 95% to 98% sulfuric acid aqueous solution by mass percentage) until it is colorless and transparent, and then use distilled water, mass percent Wash with 8% NaOH aqueous solution and distilled water until neutral, then wash with CaH 2 Dry, then distill to obtain pure mesitylene, add desiccant-activated 4A molecular sieve (preferably activated 4A molecular sieve treated at 450-600°C for 4-6 hours), put it in a desiccator for standby;

[0033] b. Dispersion of aluminum chloride in mesitylene: take pure mesitylene and aluminum chloride at a mass ratio of pure mesitylene: aluminum chloride of 50 to 200:1, under anhydrous and oxygen-free conditions , add pure mesitylene into a dry (anhydrous) reactor, pump out the air in the reactor, then add aluminum chloride, raise the temperature to 80°C, and disperse the aluminum chloride in the In me...

Embodiment 2

[0039] a. Purification of mesitylene: In a separatory funnel, wash commercially available mesitylene with concentrated sulfuric acid (generally, 95% to 98% sulfuric acid aqueous solution by mass percentage) until it is colorless and transparent, and then use distilled water, mass percent Wash with 10% NaOH aqueous solution and distilled water until neutral, and then wash with CaH 2 Dry, then distill to obtain pure mesitylene, add desiccant-activated 4A molecular sieve (preferably activated 4A molecular sieve treated at 450-600°C for 4-6 hours), put it in a desiccator for standby;

[0040] b. Dispersion of aluminum chloride in mesitylene: take pure mesitylene and aluminum chloride at a mass ratio of pure mesitylene: aluminum chloride of 50 to 200:1, under anhydrous and oxygen-free conditions , add pure mesitylene into a dry (i.e. anhydrous) reactor, pump out the air in the reactor, then add aluminum chloride, raise the temperature to 85°C, and disperse the aluminum chloride in ...

Embodiment 3

[0046] A method for preparing aluminum nanoparticles coated with a dispersion stabilizer by a liquid-phase chemical reduction method comprises the following steps:

[0047] a. Purification of mesitylene: In a separatory funnel, wash commercially available mesitylene with concentrated sulfuric acid (generally, 95% to 98% sulfuric acid aqueous solution by mass percentage) until it is colorless and transparent, and then use distilled water, mass percent Wash with 5% NaOH aqueous solution and distilled water until neutral, and then wash with CaH 2 Dry, then distill to obtain pure mesitylene, add desiccant-activated 4A molecular sieve (preferably activated 4A molecular sieve treated at 450-600°C for 4-6 hours), put it in a desiccator for standby;

[0048] b. Disperse aluminum chloride in mesitylene: take pure mesitylene and aluminum chloride at a mass ratio of 50 to 200:1 for pure mesitylene: aluminum chloride, under anhydrous and oxygen-free conditions, Add pure mesitylene into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com