Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about "Nitrocellulose explosive compositions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

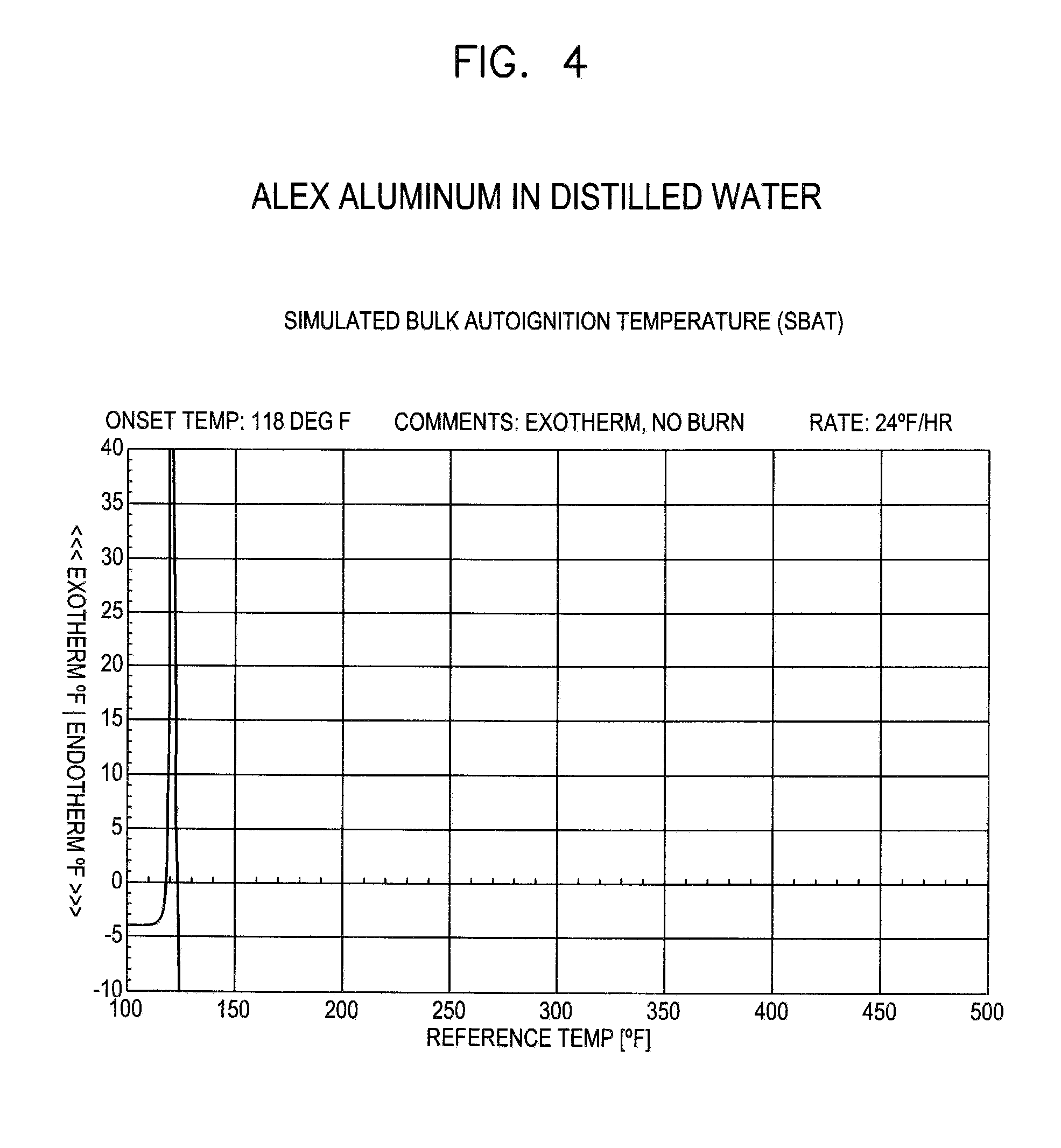

Non-toxic, heavy-metal free sensitized explosive percussion primers and methods of preparing the same

ActiveUS8206522B2Metal azide explosive compositionsMetal fulminate explosive compositionsEngineeringOxidizing agent

A non-toxic, non-hydroscopic percussion primer composition and methods of preparing the same, including at least one explosive component that has been traditionally considered a moderately insensitive explosive or secondary explosive, and at least fuel particle component having a particle size of about 1.5 microns to about 12 microns, which allows the use of moderately active metal oxidizers. The sensitivity of the primer composition is created by the interaction between the moderately insensitive explosive and the fuel agent such that traditional primary explosives such as lead styphnate or DDNP are not needed. The primer composition also eliminates the risks and dangers associated with traditional nano-sized fuel particles.

Owner:FEDERAL CARTRIDGE

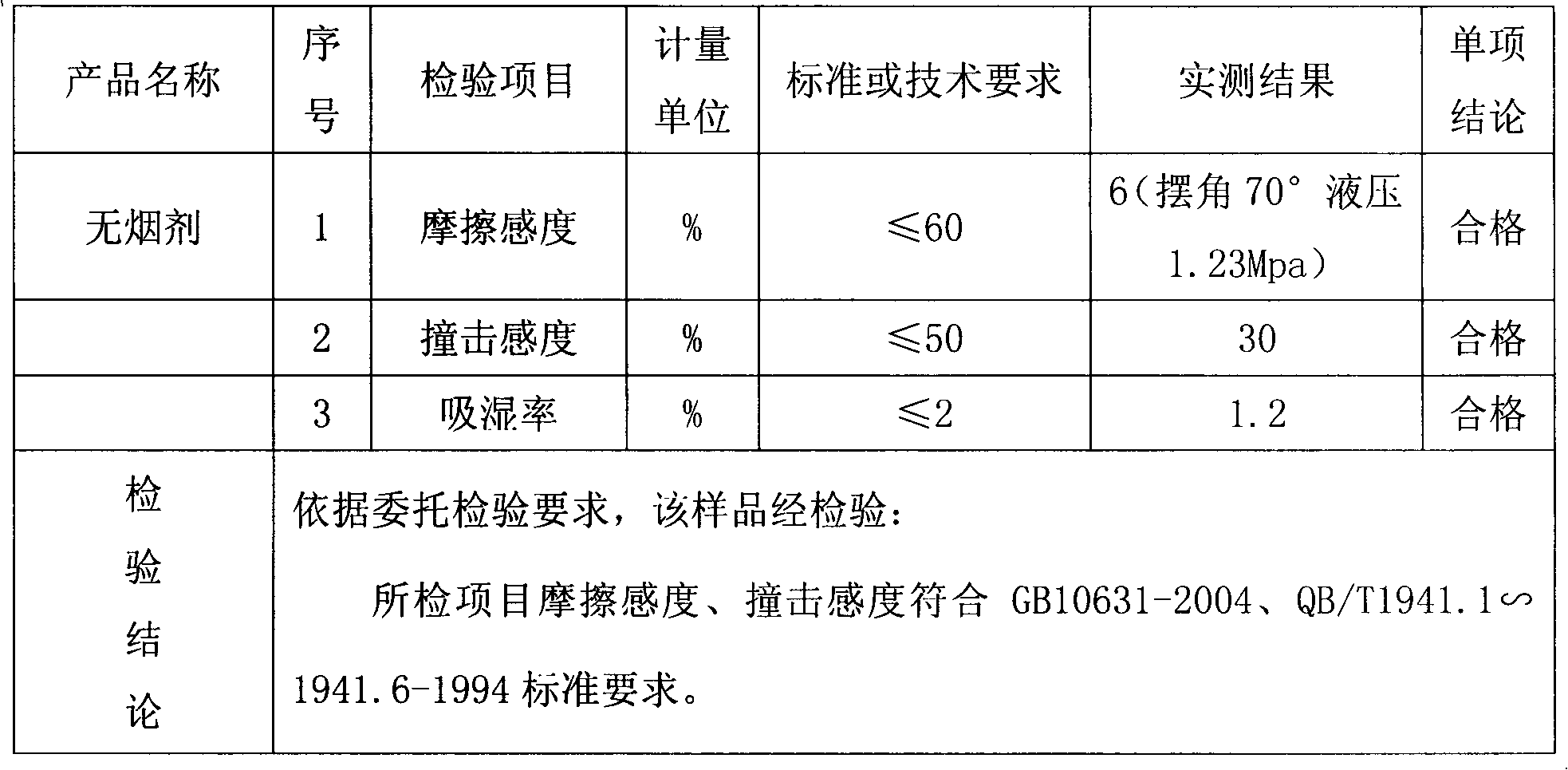

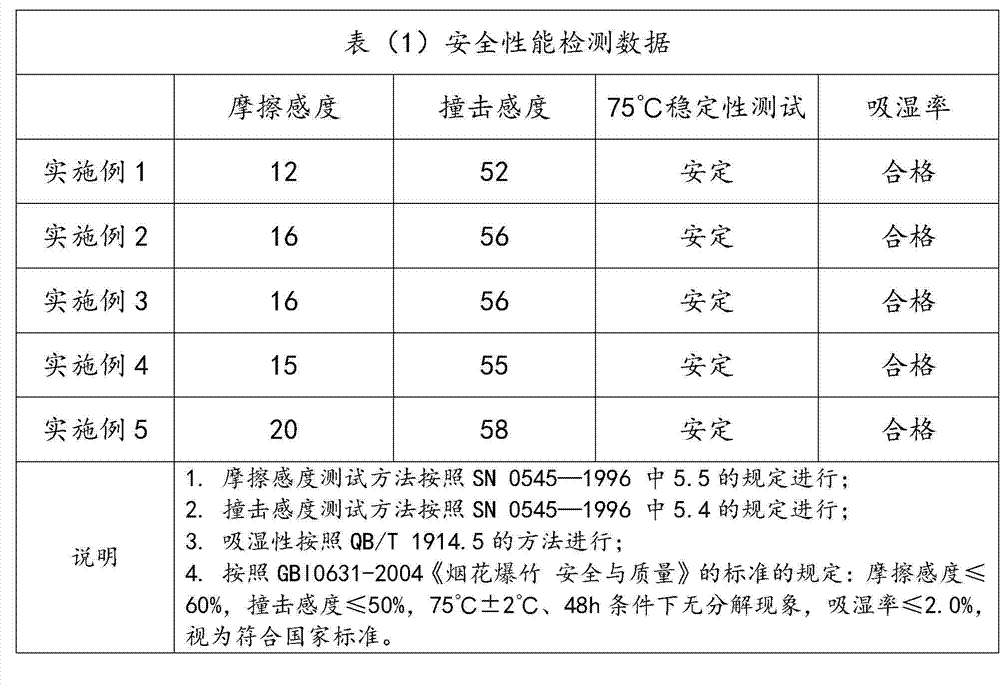

Microporous smokeless firework explosive and preparation method thereof

ActiveCN101844954AImprove securityReduce generationNitrocellulose explosive compositionsCelluloseNon solvent

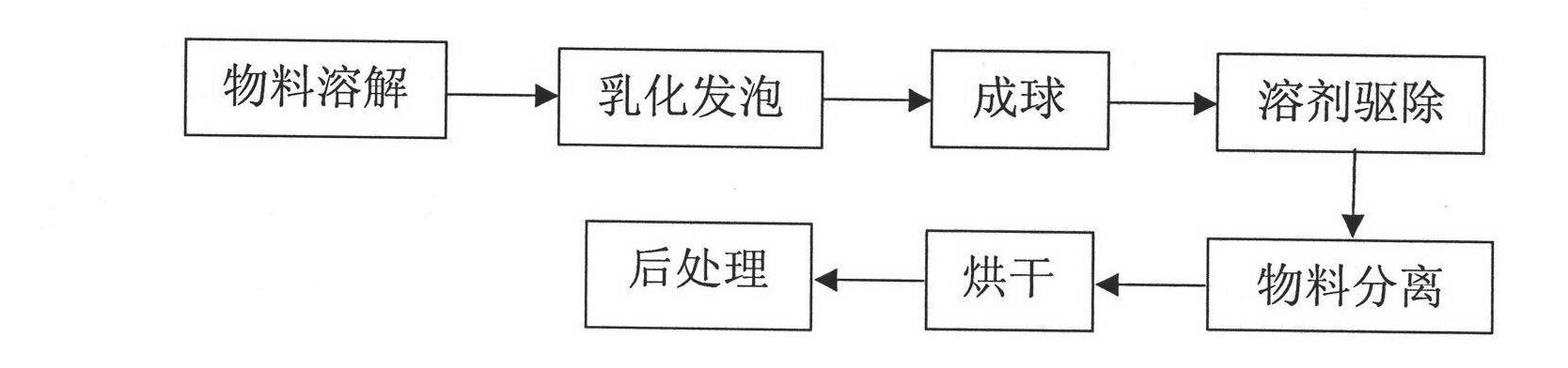

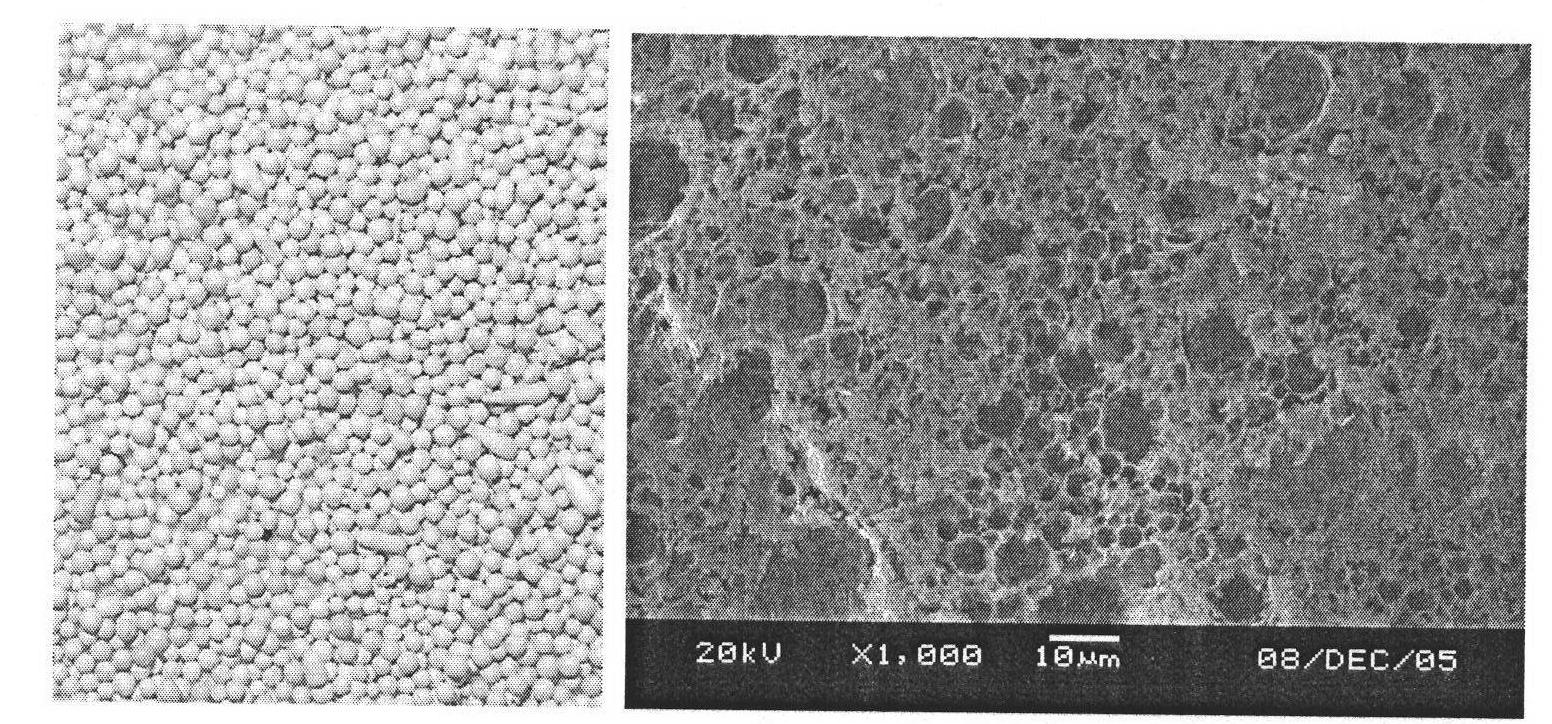

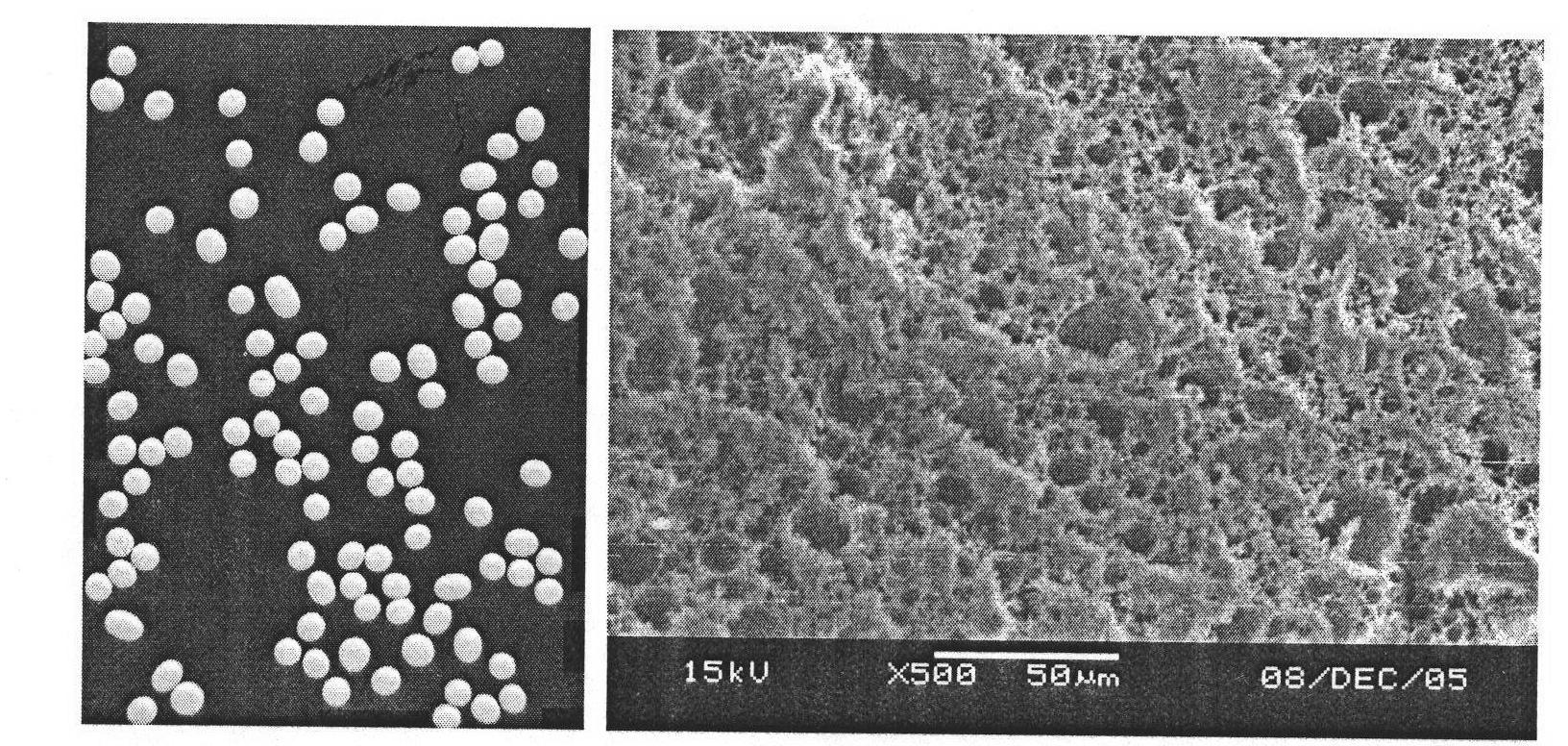

The invention discloses microporous smokeless firework explosive and a preparation method thereof. The preparation method comprises the following steps of: dissolving scrapped military smokeless explosive containing nitrated cellulose into a solvent to form macromolecular sol, emulsifying and foaming the sol to form paint emulsion, dispersing the paint emulsion into a non-solvent medium under stirring action to form balls, then driving the solvent, separating the materials, and drying the materials to obtain explosive particles with microporous structures on the inner part for emitting and dissecting fireworks. The smokeless firework explosive has high fire transfer rate and adjustable stacking density and particle size because of a large amount of microporous structures on the inner part, the appearance of the microporous smokeless firework explosive is approximately spherical or oblate, the particle size is controllable, the stacking density is 0.05 to 0.4 g / cm<3>, and the aperture of the inner part is 0.01 to 500 microns in variety.

Owner:NANJING UNIV OF SCI & TECH

Castable double base solid rocket propellant containing ballistic modifier pasted in an inert polymer

InactiveUS6024810AHigh sensitivityLow smokeCosmonautic propulsion system apparatusNitrocellulose explosive compositionsDetonationBurn rate

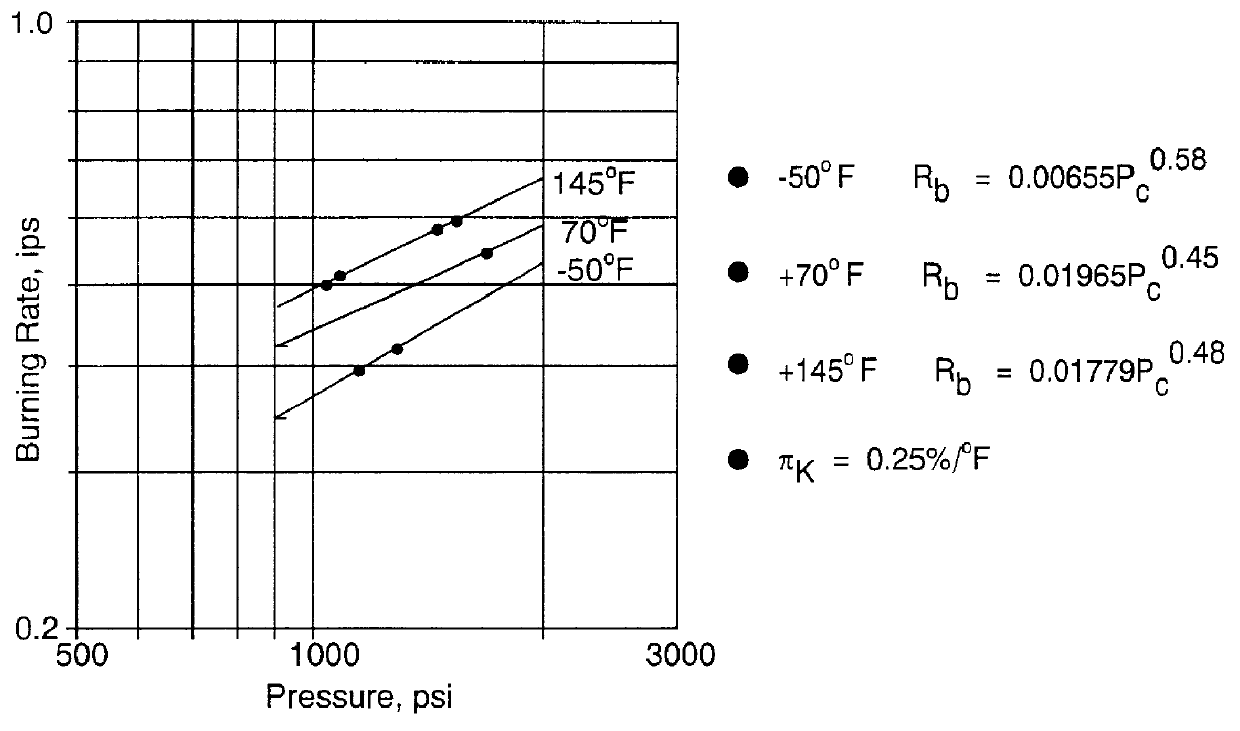

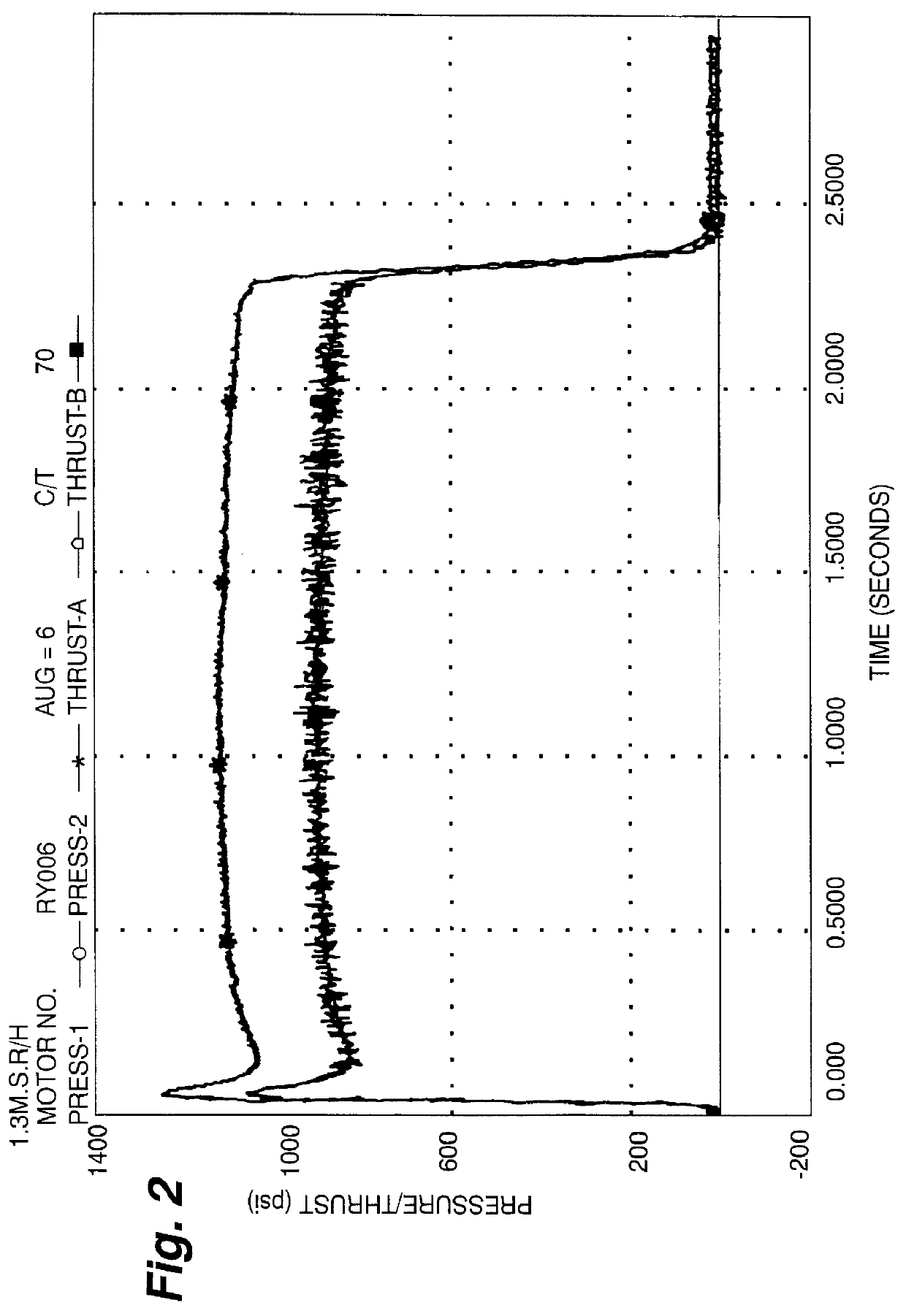

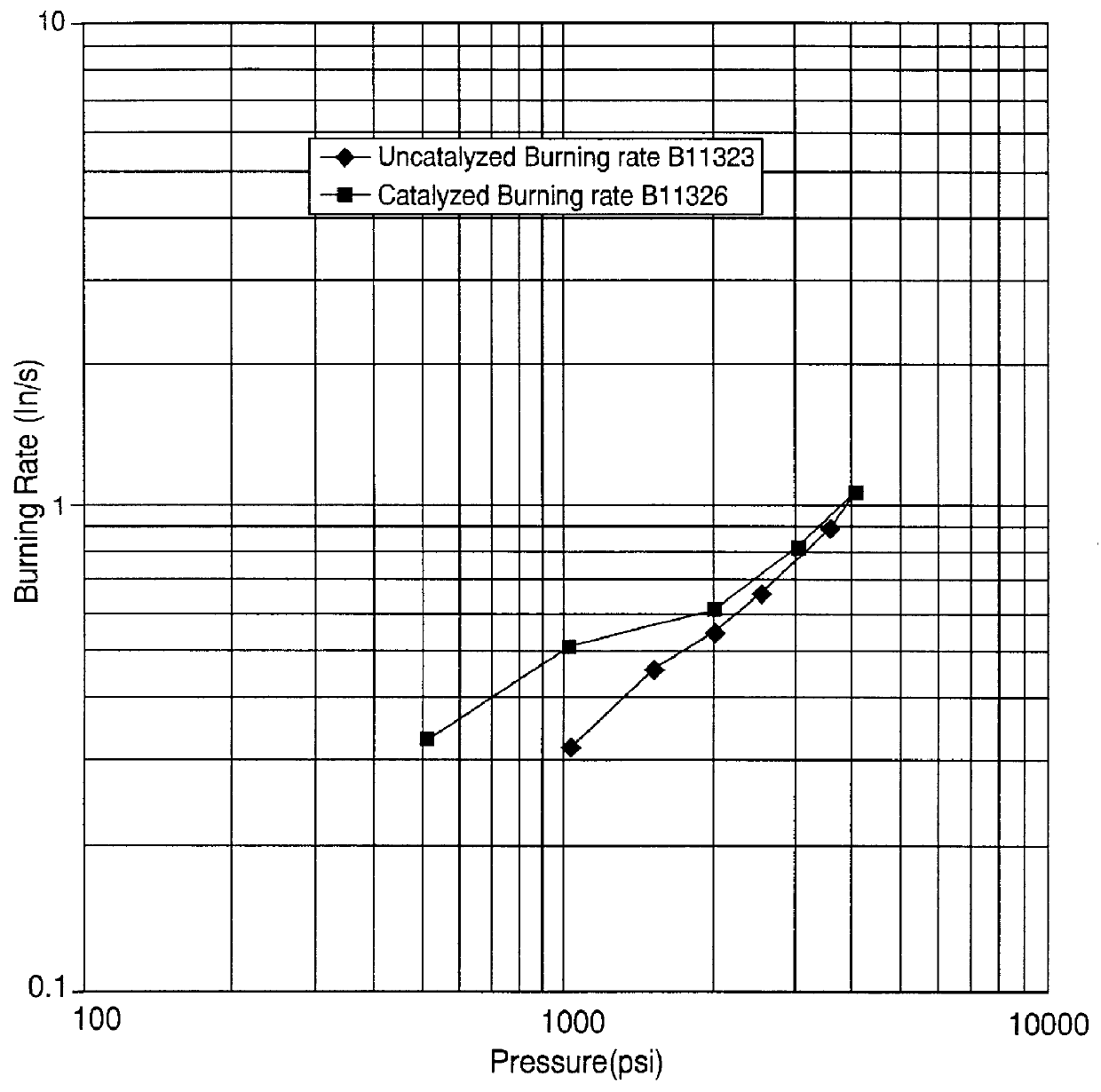

Castable propellant formulations are provided including reduced toxicity ballistic modifiers that do not adversely increase the sensitivity of the propellant to shock detonation. Failure to adequately control the propellant burn rate often results in unacceptable performance of the propellant. Carbon can act as an effective ballistic, but not to the extent of metal compounds. It has been found that pasting a ballistic modifier, including ballistic modifiers containing lead, in an inert polymer modifies the burn rate of propellants while allowing the use of a reduced amount of modifier to achieve the same desired burn rate modification as the prior art, and therefore creating reduced shortcomings associated with the ballistic modifiers. Accordingly, the use of from about 1% to about 6% burn rate modifier wherein the burn rate modifier includes a ballistic modifier pasted in an inert polymer is taught as an effective burn rate modifier in a propellant, in order to provide reduced toxicity means for modifying the propellant burn rate without increasing the sensitivity of the propellant to shock detonation.

Owner:AEROJET ROCKETDYNE INC

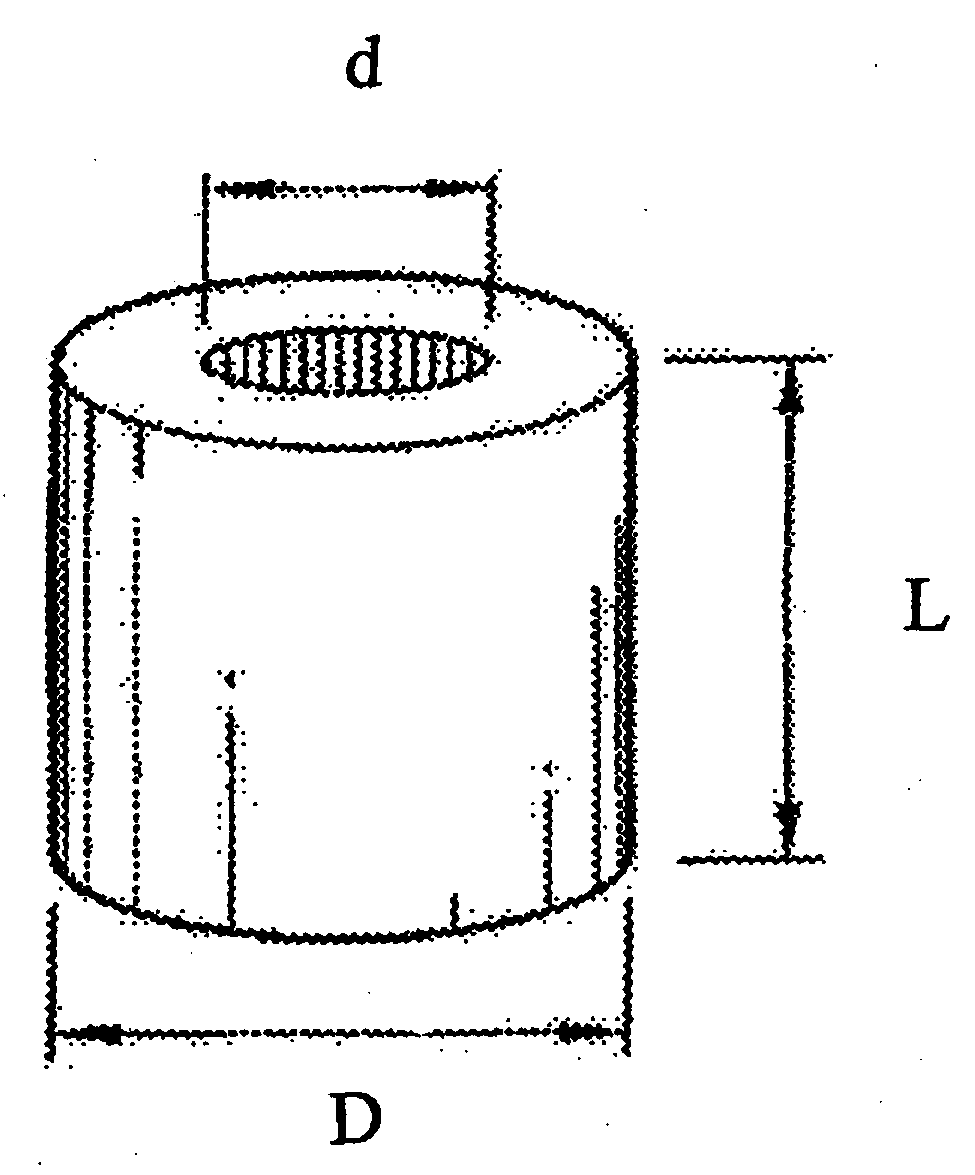

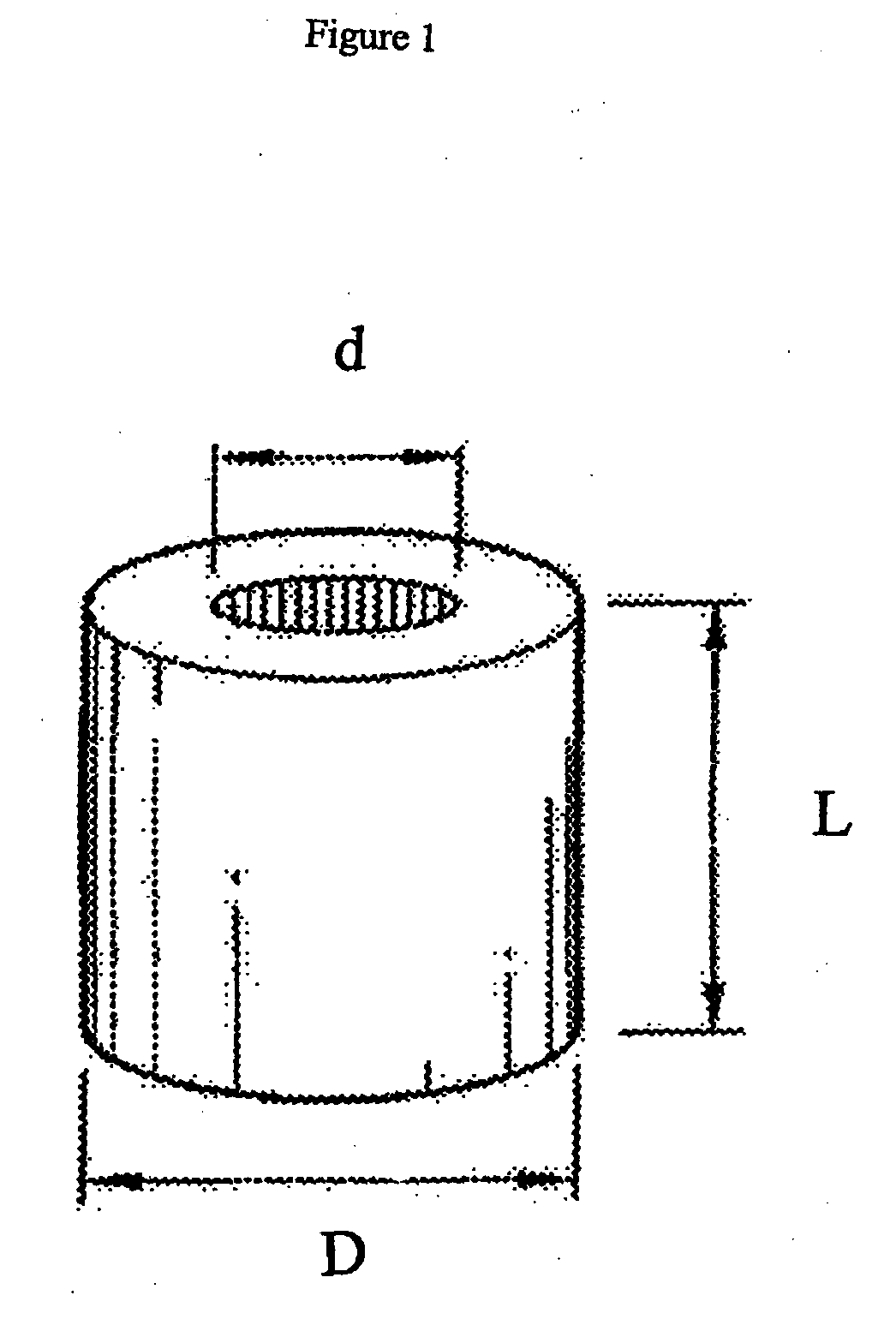

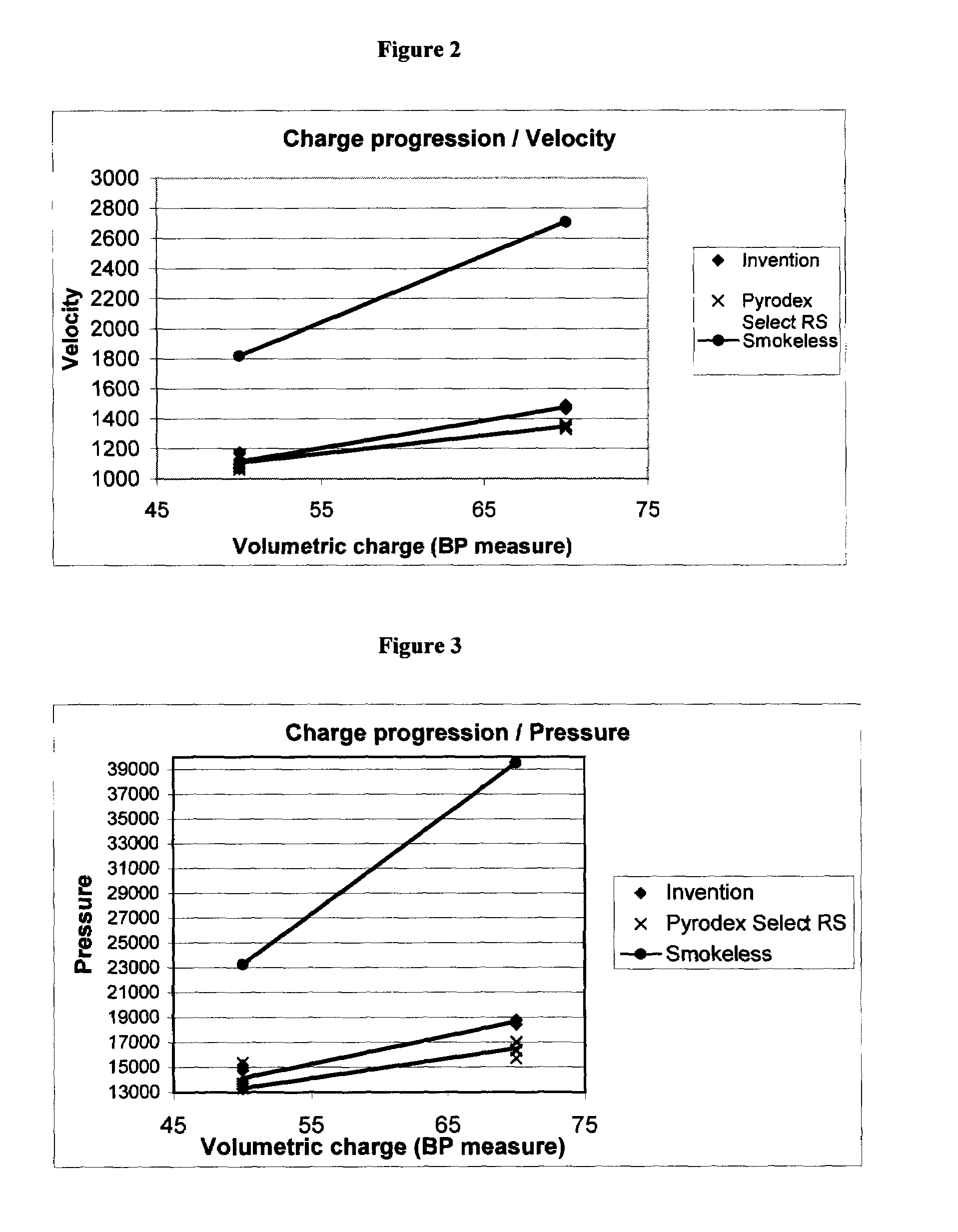

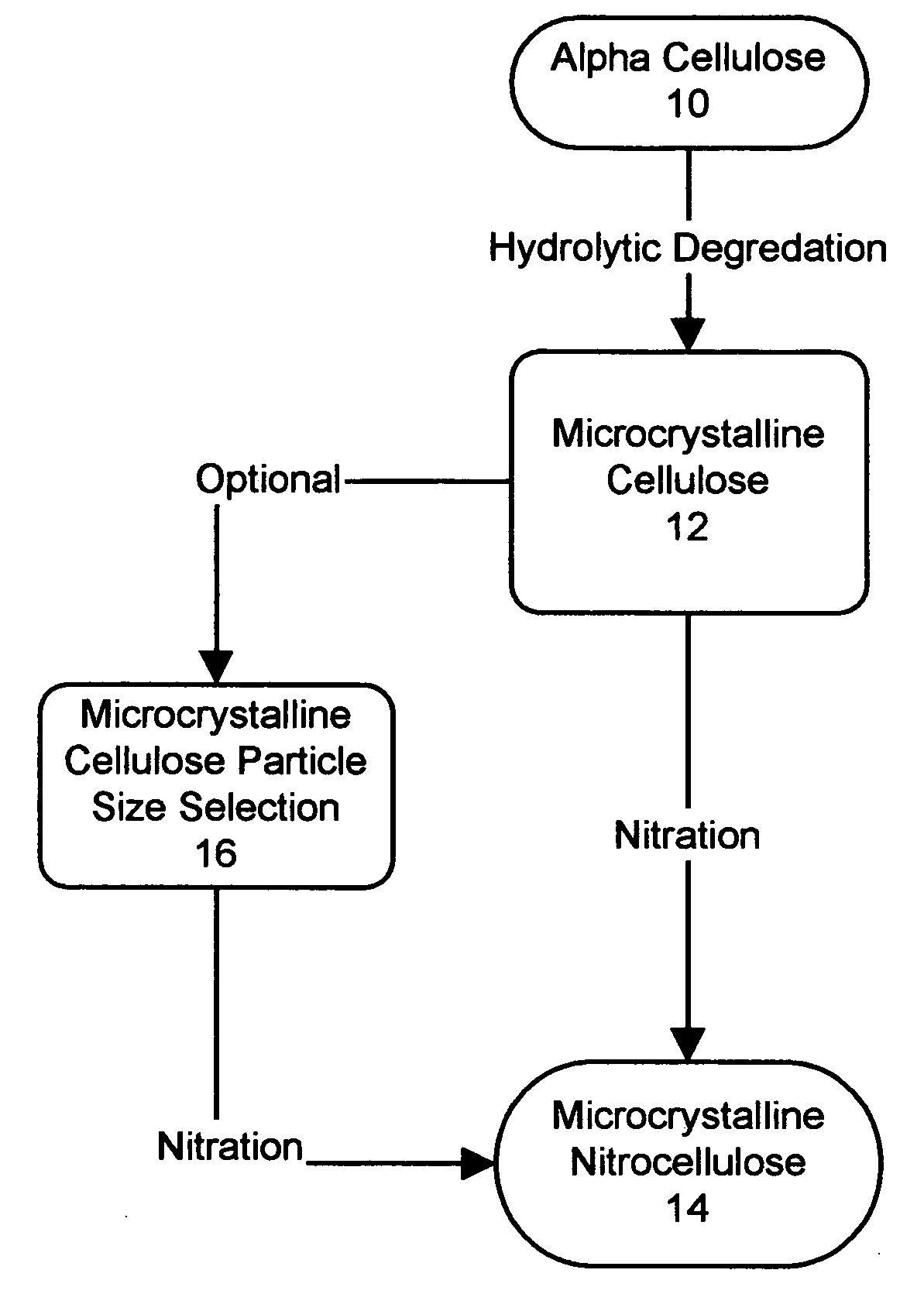

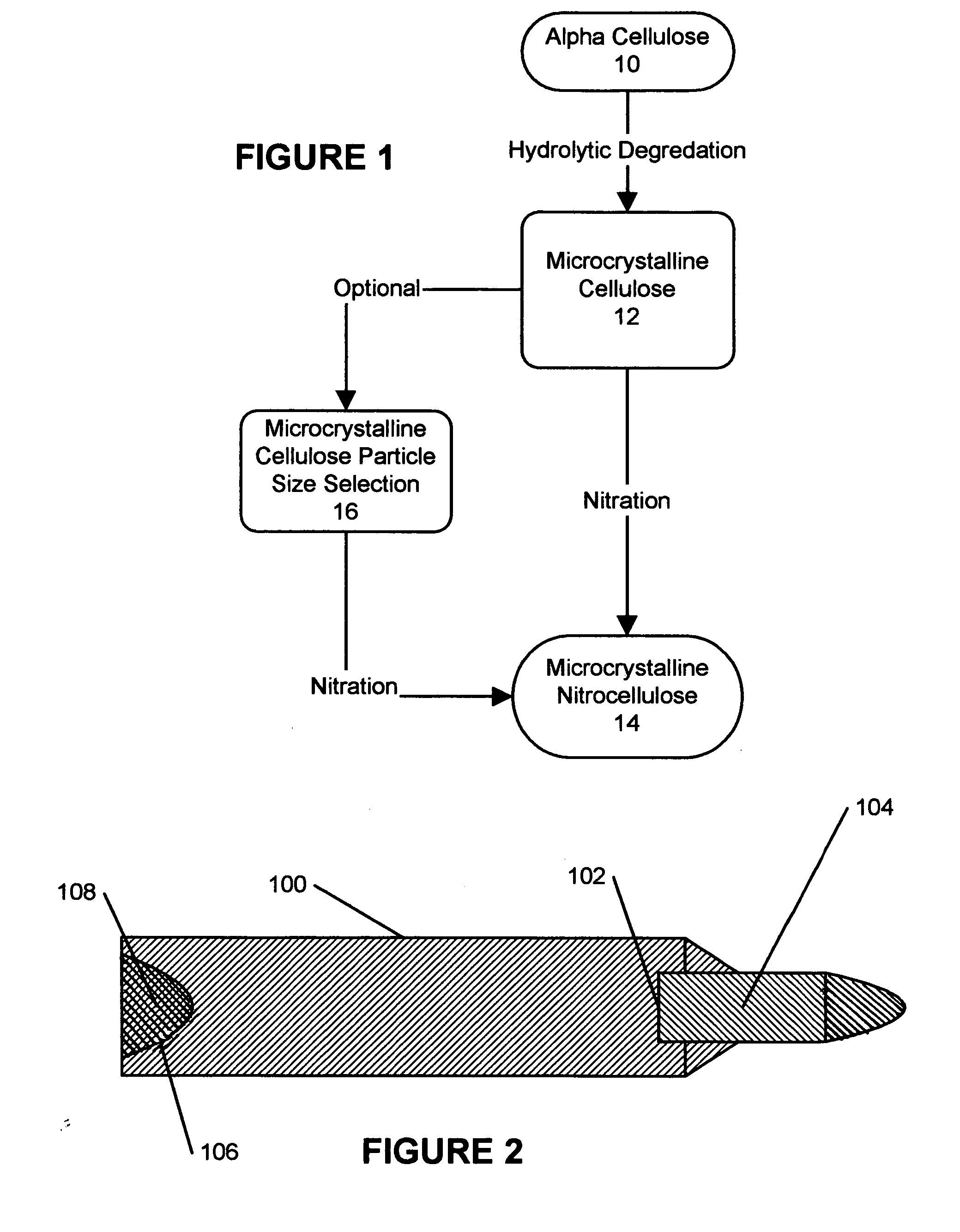

Microcrystalline Nitrocellulose Pyrotechnic Compositions

InactiveUS20070068610A1Degradation of combustionHard and durableNitrocellulose explosive compositionsExplosive working-up apparatusNitrocellulosePyrotechnic composition

Owner:NICKEL RUSSELL R

Non-toxic, heavy-metal free sensitized explosive percussion primers and methods of preparing the same

A non-toxic, non-hydroscopic percussion primer composition and methods of preparing the same, including at least one explosive component that has been traditionally considered a moderately insensitive explosive or secondary explosive, and at least fuel particle component having a particle size of about 1.5 microns to about 12 microns, which allows the use of moderately active metal oxidizers. The sensitivity of the primer composition is created by the interaction between the moderately insensitive explosive and the fuel agent such that traditional primary explosives such as lead styphnate or DDNP are not needed. The primer composition also eliminates the risks and dangers associated with traditional nano-sized fuel particles.

Owner:FEDERAL CARTRIDGE

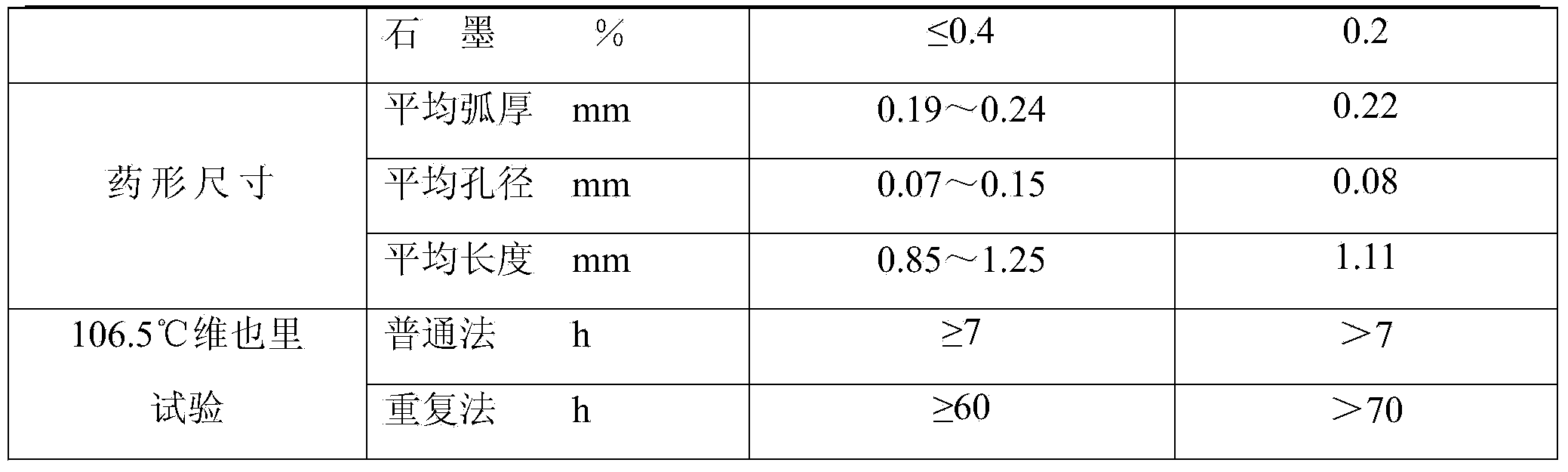

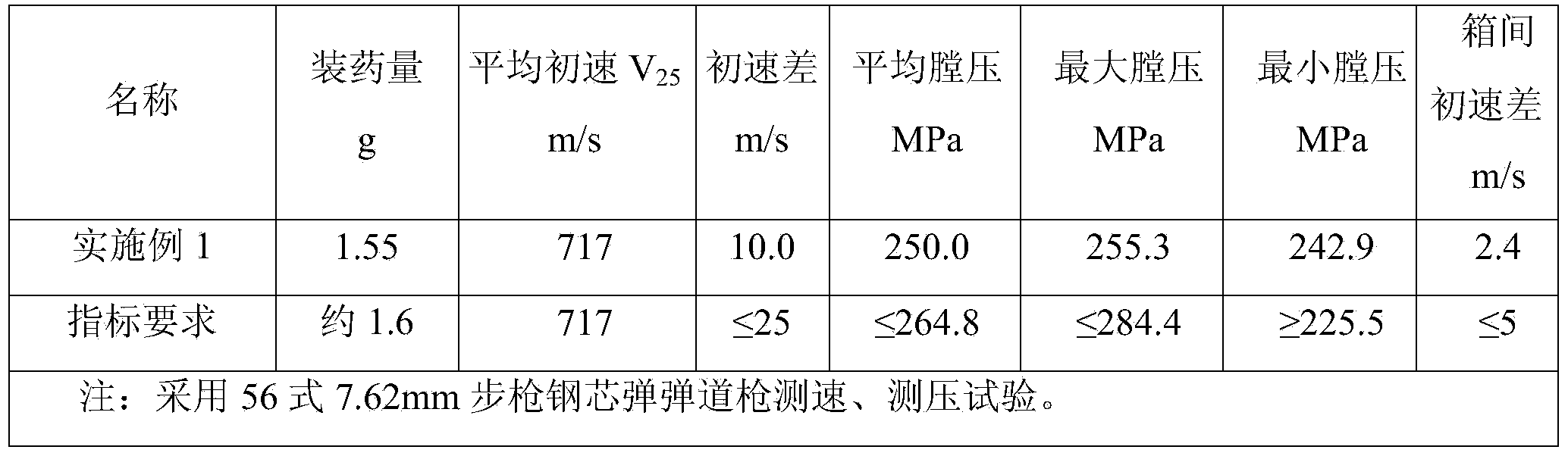

Wood pulp nitrocellulose single-base propellant and preparation method thereof

ActiveCN104003825ALess impuritiesImprove performanceNitrocellulose explosive compositionsNitrocelluloseSolvent

The invention relates to a wood pulp nitrocellulose single-base propellant and a preparation method thereof and belongs to the technical field of propellant preparation. The method for preparing the single-base propellant comprises the following steps: by taking wood pulp nitrocellulose as a main raw material of the single-base propellant, expelling water and plastifying, sequentially companding, cutting, screening, removing solvent, desensitizing the gloss and drying according to the conventional single-base propellant technical technology, and thus obtaining the single-base propellants of various different article numbers of which the internal trajectory performance meets the index requirement, such as 2 / 1 camphor tree and 4 / 7 stone. The wood pulp nitrocellulose single-base propellant comprises the following components in percentage by mass: 80-98 percent of wood pulp nitrocellulose, 1-2 percent of stabilizing agent, 1-5 percent of volatile component, 0-6 percent of desensitization agent and 0-7 percent of other supplementary elements. According to the preparation method, the problem that the raw material of the single-base propellant depends on linters nitrocellulose is solved, and the strategic supplies reserves are expanded.

Owner:LUZHOU NORTH CHEM IND

Non-toxic percussion primers and methods of preparing the same

A percussion primer composition including at least one explosive, at least one nano-size non-coated fuel particle having natural surface oxides thereon, at least one oxidizer, optionally at least one sensitizer, optionally at least one buffer, and to methods of preparing the same.

Owner:FEDERAL CARTRIDGE

Smokeless cellulose

ActiveCN102795949ASolve smokeSolve the smoke problemNitrocellulose explosive compositionsSolventChemistry

The invention discloses a smokeless cellulose which is used for preparing fireworks. The smokeless cellulose is a solid-state micropowder or particle agent. The invention is characterized in that the smokeless cellulose is prepared by nitrating plant fiber and comprises the following components in parts by weight: 100 parts of plant fiber, 40-80 parts of 60-98% nitric acid, 10-50 parts of 60-98% sulfuric acid, 0.5-5 parts of diphenylamine, 0.5-5 parts of camphor, 1-10 parts of sodium carbonate and 50-100 parts of solvent, wherein the plant fiber is one or mixture of pulverized corn cob, corn stalk, bamboo, boon, peanut shell, reed and sugar cane waste residue in any weight ratio; the mixture of nitric acid and sulfuric acid is used as a nitrating agent; the mixture of diphenylamine and camphor is used as a stabilizer; and the solvent is alcohol, banana oil, aether or acetone. The invention has the advantages of high safety, high stability, no smoke, no smell, no toxicity, no dust, environmental protection and the like.

Owner:浏阳市华金烟花制造有限公司

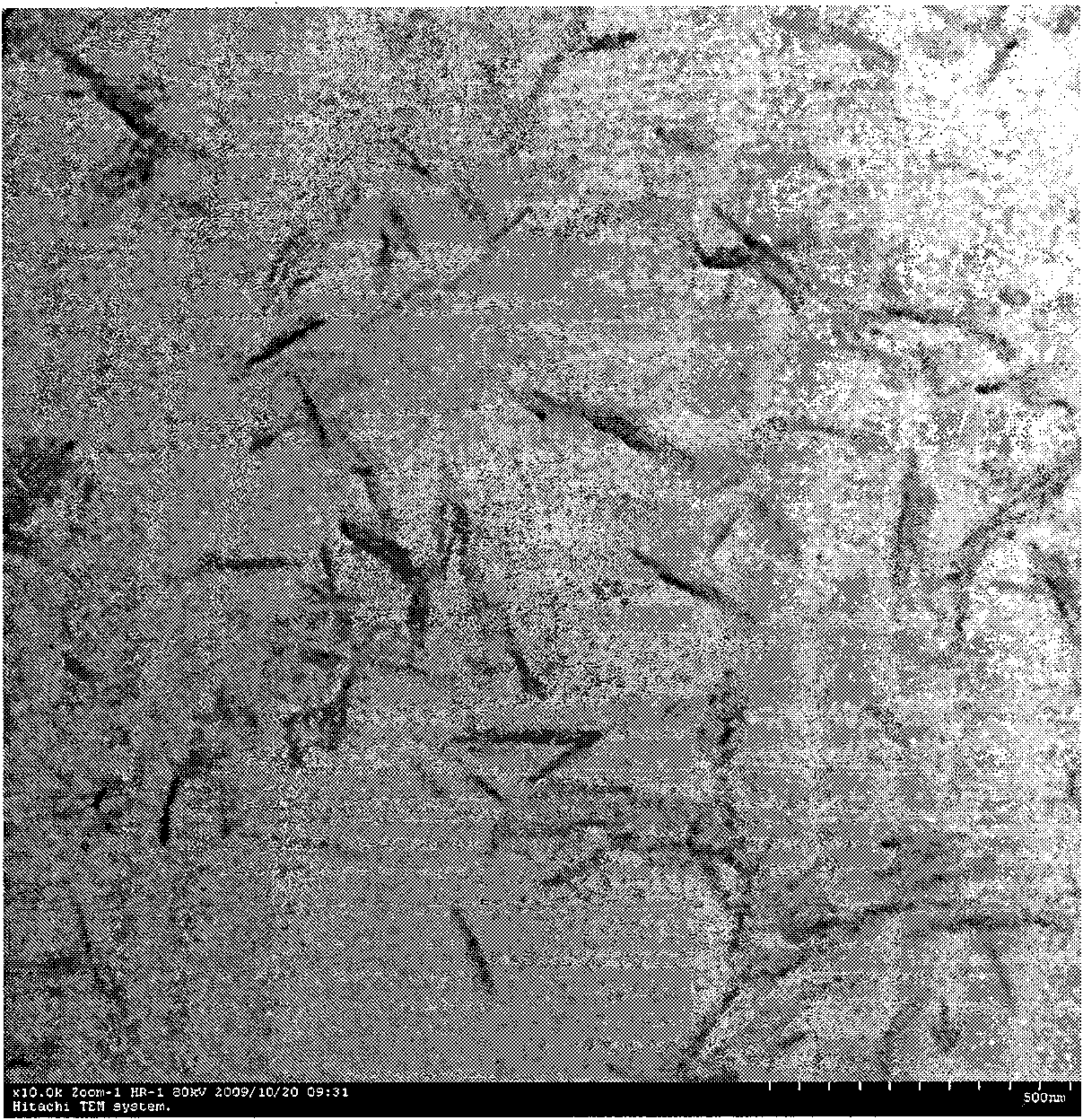

Method for preparing nanometer nitro celluloses

ActiveCN101838332AReduced nitrification timeImprove stabilityNitrocellulose explosive compositionsPressure gas generationWater bathsFiltration

The invention relates to a method for preparing nanometer nitro celluloses, and belongs to the technical field of special chemical engineering. The preparation method comprises the following steps of: 1, performing ultrasonic pre-treatment on cotton cellulose powder in ice bath, and performing pumping filtration and drying on the cotton cellulose powder for later use; and soaking the cellulose powder in sulfuric acid solution at a certain concentration, controlling a solid-liquid ratio within 17.5 to 50g / mL, stirring the mixed solution to perform reaction in water bath at the temperature of between 45 and 75 DEG C for certain time, adding water to dilute the mixed solution, performing the centrifugal separation on the reaction solution until a pH value of the mixed solution is 6 to 7, and ultrasonically dispersing the mixed solution to obtain the stable nanometer cellulose crystal whisker suspension; 2, adding a proper amount of nitric acid into the nanometer cellulose crystal whisker suspension so as to make the nanometer cellulose crystal whisker suspension reach the needed concentration, adding water to dilute the mixed solution, and performing centrifugation and washing until the pH value of the mixed solution is 6 to 7; and 3, moving precipitates to an evaporating dish, and performing vacuum drying on the precipitates at the temperature of 50 DEG C to obtain the nanometer nitro cellulose powder. In the method, because the composition of the acid is single, the post-treatment and the reutilization of the acid are convenient; and the nitrifying time is shortened, and the stability is improved; and the nanometer nitro celluloses can be used as the energetic reinforcing materials.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Nitrocellulose Composition And Uses Therefor

InactiveUS20090199938A1Easy to burnNitrocellulose explosive compositionsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsNitrocelluloseMethyl group

A nitrocellulose composition comprises an admixture comprising: from about 75 weight percent to about 85 weight percent nitrocellulose; and from about 15 weight percent to about 25 weight percent camphor, based upon the weight of the admixture; and from about 1 weight percent to about 5 weight percent of a stabilizer (based on the total weight of the composition), wherein the stabilizer is chosen from the group consisting of N,N-Diethyl-N,N′-diphenylurea, N,N′-Dimethyl-N,N′-diphenylurea, 1,1-Diphenylurea, N-methyl-N,N′-diphenylurea, 1-Ethyl-3,3′-diphenylurea, Diphenylamine, 2-Nitro-diphenylamine, 4-Nitro-diphenylamine; Triphenylamine; p-Nitro-N-methylaniline, p-Nitro-ethylaniline, soybean oil, castor oil, sodium silicate, lactic acid amide, and benzonate; and from about 1 weight percent to about 5 weight percent of azodicarbonic acid diamide, based on the total weight of the composition. The composition is heated at a temperature sufficient to cause it to polymerize, after which it is formed into sheets, from which components for munitions, such as artillery, small arms, modular artillery charge systems and mortar increments are formed. The components of the mortar increments are joined together, and after being filled with a propellant composition, one or more mortar increments is attached to a mortar shell.

Owner:KAUFMANN & GOTTWALD ZELLULOID & PLASTIKWARENFAB

Non-toxic percussion primers and methods of preparing the same

A percussion primer composition including at least one explosive, at least one nano-size non-coated fuel particle having natural surface oxides thereon, at least one oxidizer, optionally at least one sensitizer, optionally at least one buffer, and to methods of preparing the same.

Owner:FEDERAL CARTRIDGE

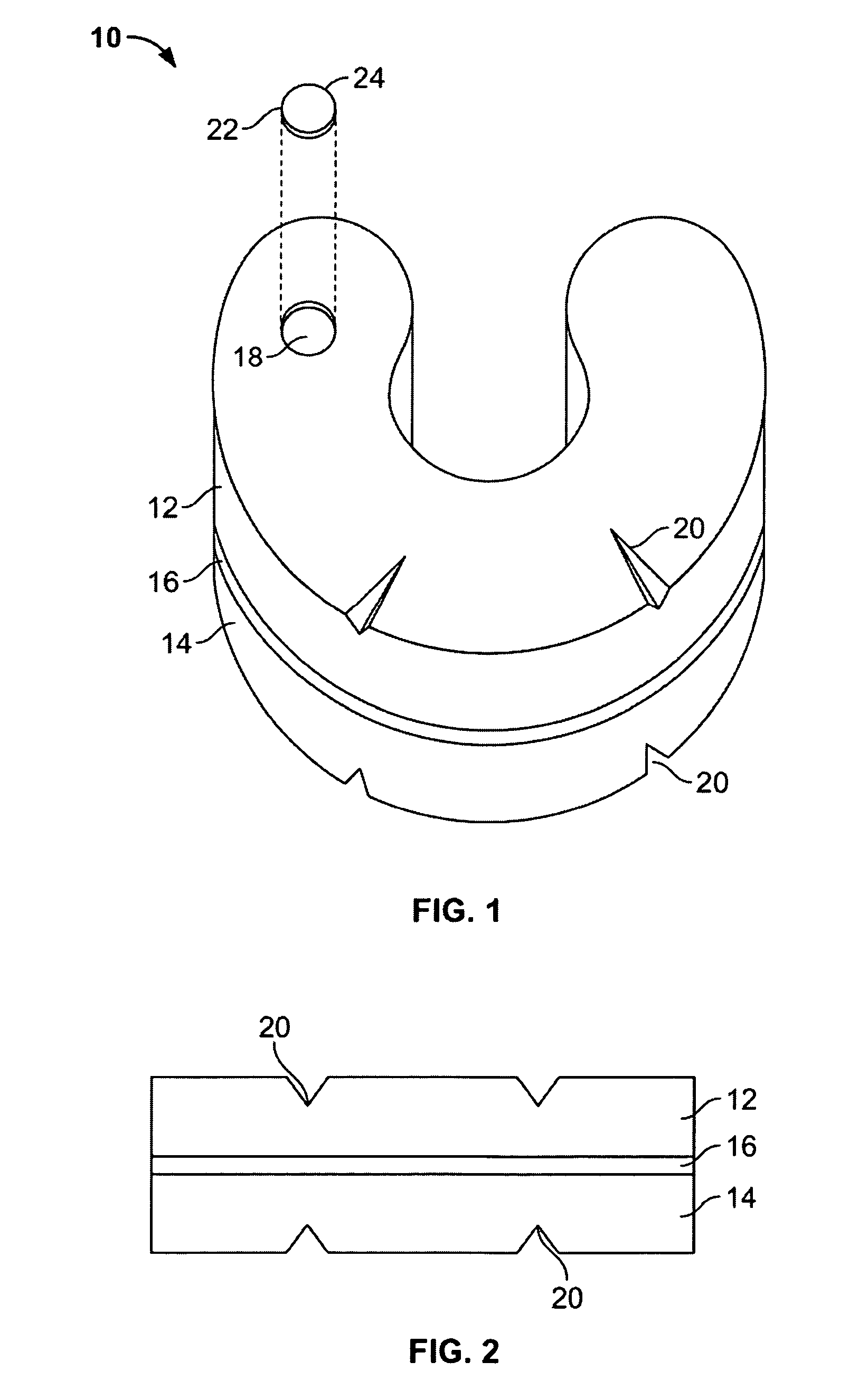

Method of manufacturing multi-layered propellant grains

ActiveUS20150284301A1Low viscosityDifferent rate of burningNitrocellulose explosive compositionsExplosive working-up apparatusIndustrial equipmentViscosity

A method of manufacturing a multi-layered propellant grain is provided. The method of the present disclosure simplifies the setup necessary to produce multi-layered propellants by using industrial equipment that is more energy and space efficient than the machinery that is conventionally employed for such processes. The method comprises providing a first propellant formulation; providing a die configured to provide a structure having an outer shell and a hollow interior when material is extruded therethrough; extruding the first propellant formulation through said die, to produce a first propellant layer having an outer shell defining a hollow interior in the form channel having open ends; providing a second propellant formulation, said second propellant formulation being of low viscosity; injecting said second propellant formulation into said channel defined by said first propellant layer to form a second propellant layer disposed in said channel; and hardening said second propellant layer. The first and second propellant layers have different rates of burning.

Owner:GENERAL DYNAMICS ORDNANCE & TACTICAL SYST CANADA VALLEYFIELD INC

Processing method of single-base powder and double-base powder for fireworks

InactiveCN103524278AWon't explodeGood compatibilityNitrocellulose explosive compositionsFiberFireworks

The invention discloses a processing method of single-base powder and double-base powder for fireworks. The processing method comprises the following steps: (1) removing impurities from technical materials, preparing raw materials, namely, a. removing sundries such as metals contained in the single-base powder and the double-base powder, and b. watering for humidifying; (2) processing wet powder, namely, a. putting the materials in a pulverizer, pulverizing the materials to powder with 40-100 meshes, and b. carrying out centrifugal dewatering, namely, dewatering and drying by using a centrifugal machine, wherein the dewatering time is 20-25 minutes, and the water content is 10-15%; (3) screening and grading, namely, a. screening under the condition of wetting, and 40-60 mesh wet powder and 60-80 mesh wet powder, b. screening powder with 80-100 or above meshes by using water, and c. grading and packaging the screened wet powder; (4) processing dry powder, namely, a. carrying out electric heating drying on the wet powder or drying the wet powder in the sun, wherein the drying temperature is 35 to 65 degrees, the time is 20-24 hours, and the water content of the powder is 1-5%, and b. cooling for 2-4 hours at a natural temperature, and mechanically cooling for 1 hour, thus obtaining the single-base powder and the double-base powder for fireworks; and (5) packaging finished products, namely, sealing and packaging by using anti-static and damp-proof fiber woven bags, and putting the finished products in storages. The processing method has the advantages of simple and convenient processing, good safety and the like.

Owner:周健

Method for preparing cellulose nitrate for explosive from wood pulp

InactiveCN102219861ASolve the costPrice stabilityNitrocellulose explosive compositionsEnvironmental resistanceNitrocellulose

The invention relates to a method for preparing cellulose nitrate for an explosive from wood pulp, in particular relates to a preparation method of cellulose nitrate for an explosive and belongs to the technical field of cellulose preparation. The method is characterized by comprising the following steps: adding 20-30 parts by weight of wood pulp in 500 parts by weight of mixed acid, carrying outmiddle-low temperature nitration reaction and then washing; and then successively carrying out boil washing, shredding and refine washing so as to obtain the cellulose nitrate for the explosive. In the preparation method of the cellulose nitrate, the wood pulp is used as a raw material, which is not a precedent in the field of military cellulose nitrate, thereby broadening the use range of the raw material in nitrated cellulose production, and simultaneously, the wood pulp is cheaper than cotton linter and can be used as the raw material of energy-containing nitrated cotton for production, thereby greatly solving the cost problem of the raw material; and at the same time, the environmental protection pressure problem brought by a large amount of cotton dust, black liquid and acidic wastewater which are generated in the processes of cotton opening, boiling, bleaching and drying refined cotton when a nitrated cotton product is prepared by utilizing the cotton linter as the raw material is solved.

Owner:SICHUAN NITROCELLULOSE CORP

Propellant compositions

InactiveUS6607618B1Without usingLess sensitiveNitrocellulose explosive compositionsNitrocellulosePlasticizer

The present invention shows a munitions propellant. The propellant has a nitrocellulose component is about fifty-two percent (52.0%) of the propellant. This is either a nitrocellulose having twelve and six-tenths percent (12.6%) nitrogen, or a combination of a nitrocellulose having twelve and six-tenths percent (12.6%) nitrogen and a nitrocellulose having thirteen and thirty-five one hundredths percent (13.35%) nitrogen, and in which the average nitrogen proportion is thirteen and five one-hundredths percent (13.05%).The propellant also has a nitroester-based plasticizer and a non-nitroester-based plasticizer. The nitroester-based plasticizer comprises about thirty-four percent (34.0%) of the propellant by weight, and comprises diethylene glycol dinitrate (DEGDN). The non-nitroester-based plastizier comprises from about three percent (3.0%) to about four percent (4.0%) by weight and comprises di-normal propyl adipate (DNPA). In addition, about seven percent (7.0%) of the propellant by weight of the composition is nitroguanidine (NQ).

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

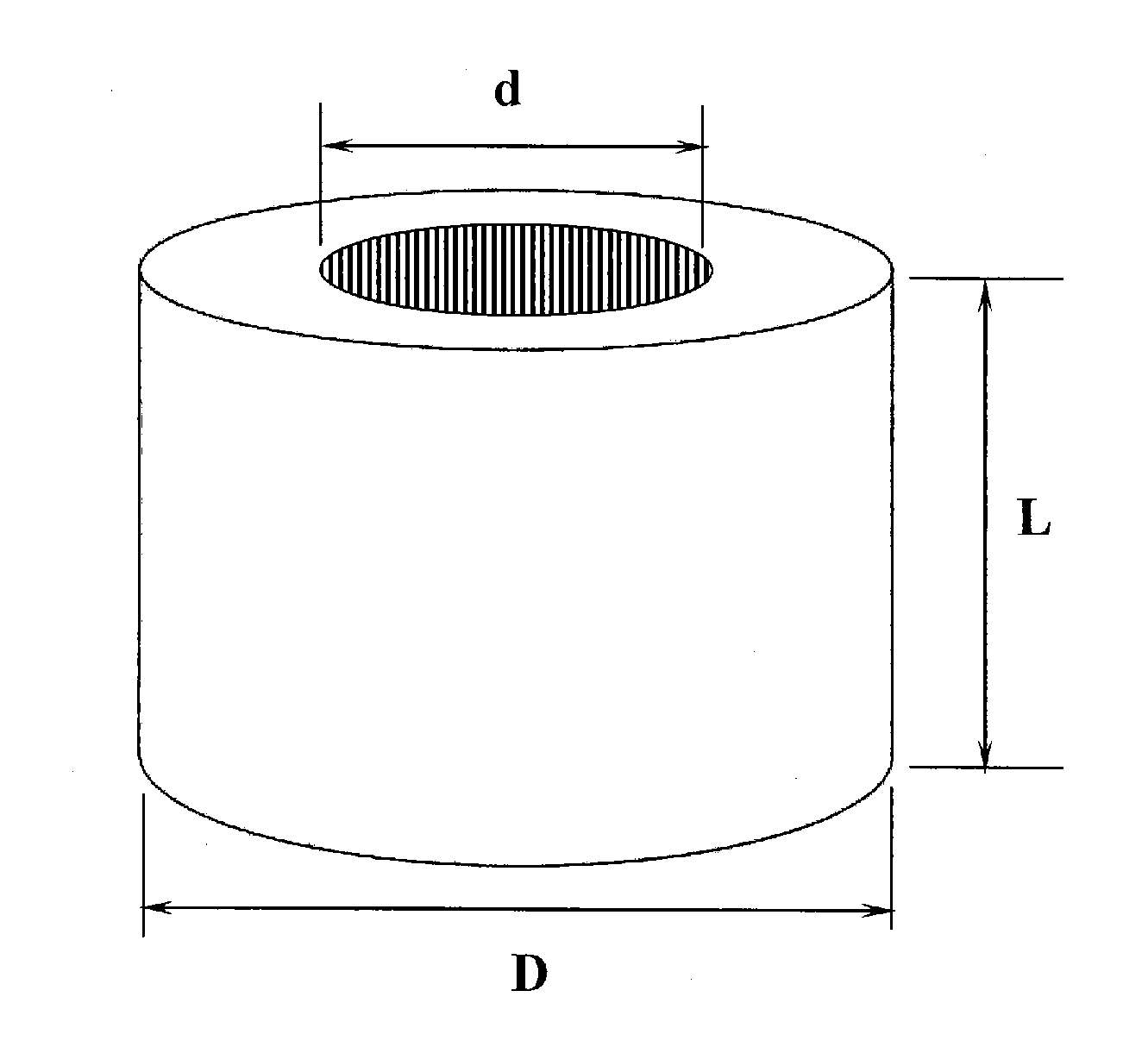

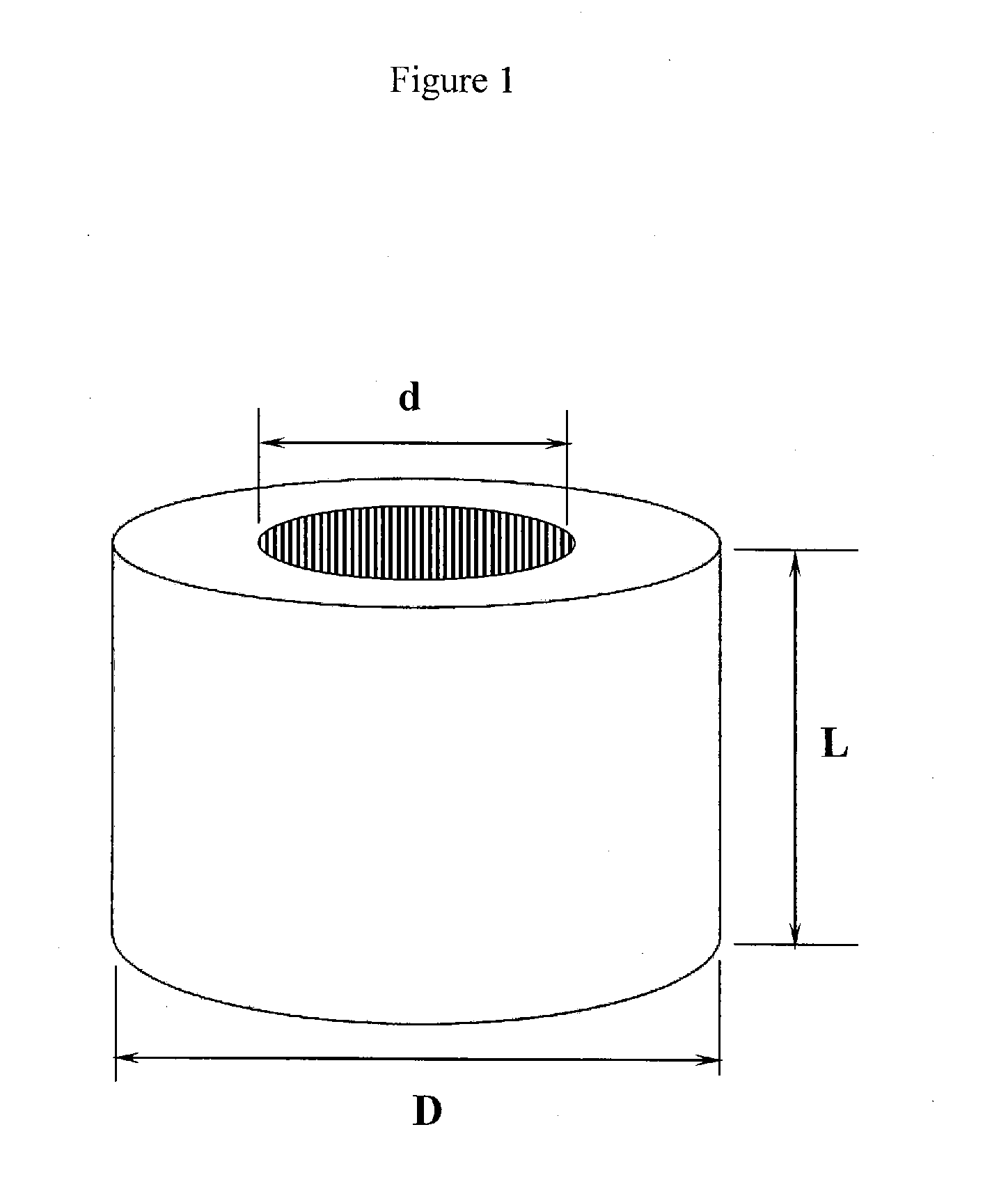

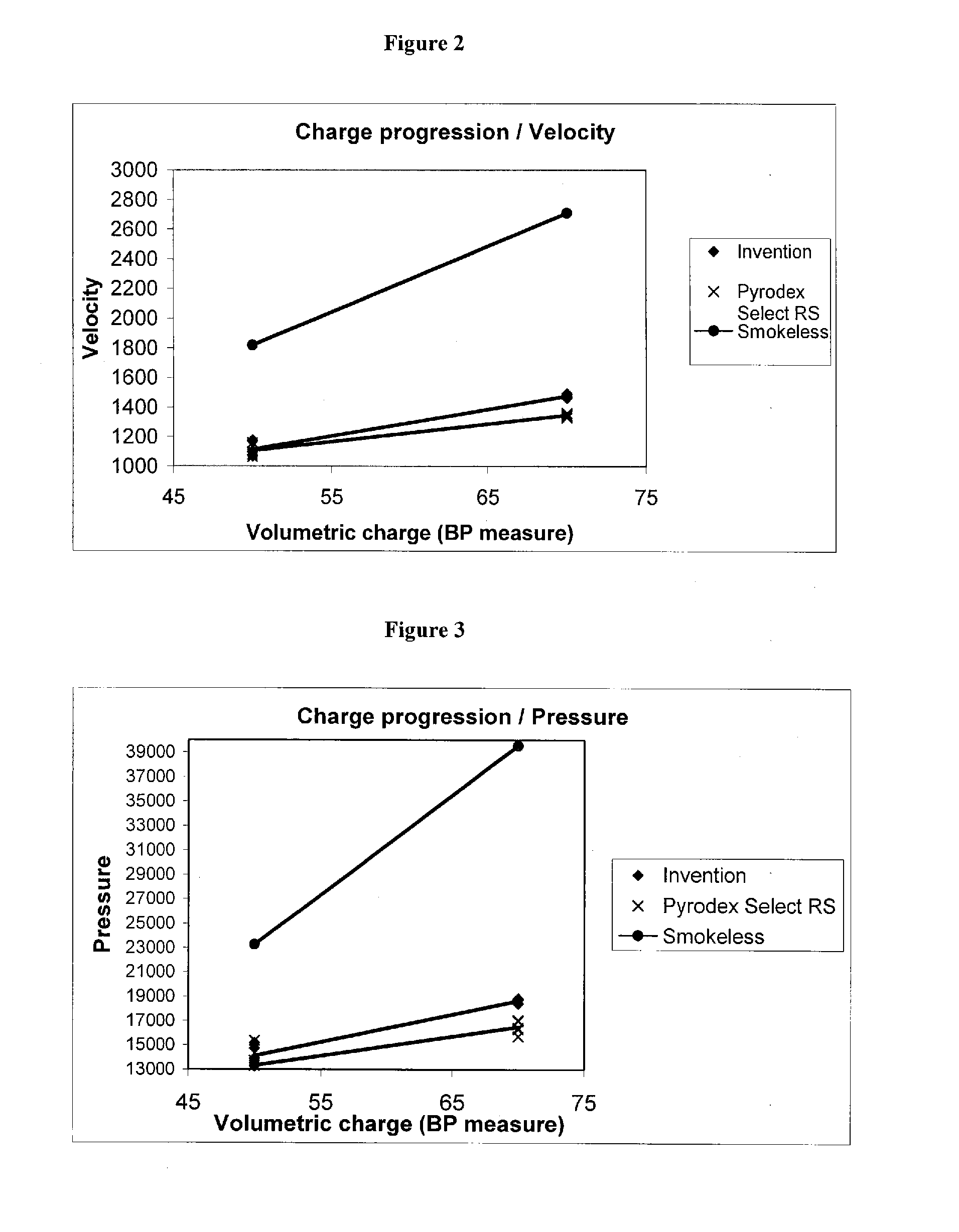

Black Powder Substitutes for Small Caliber Firearms

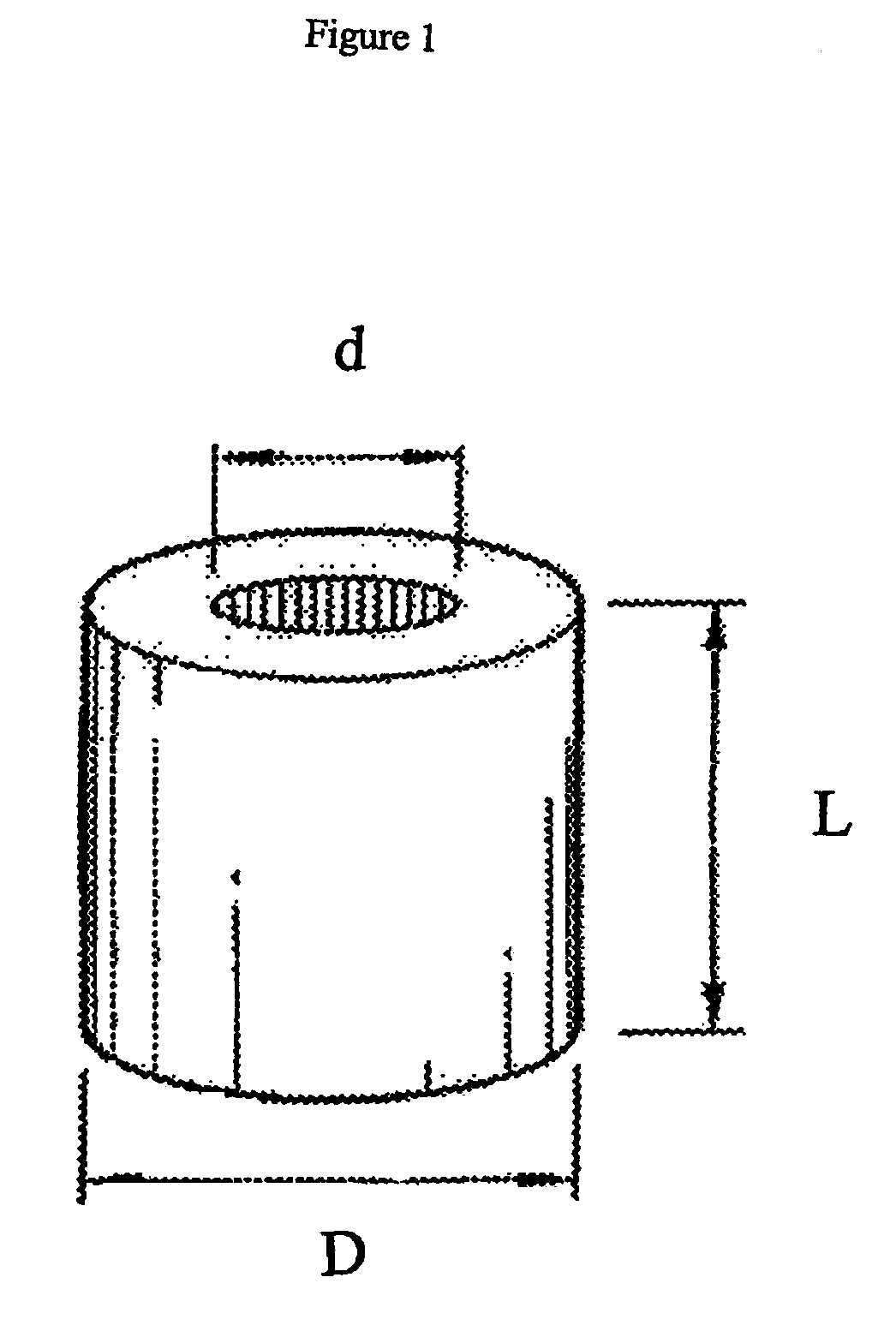

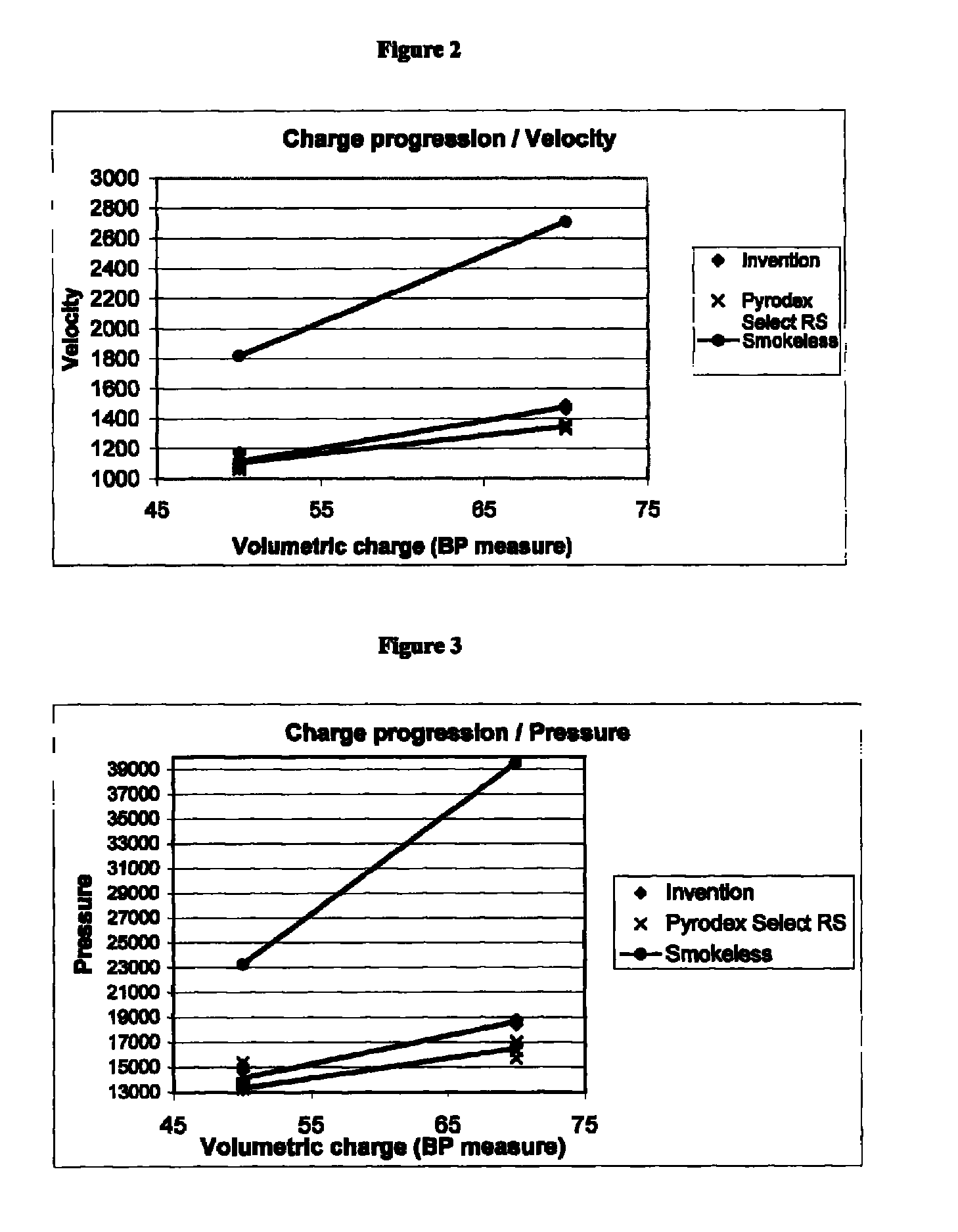

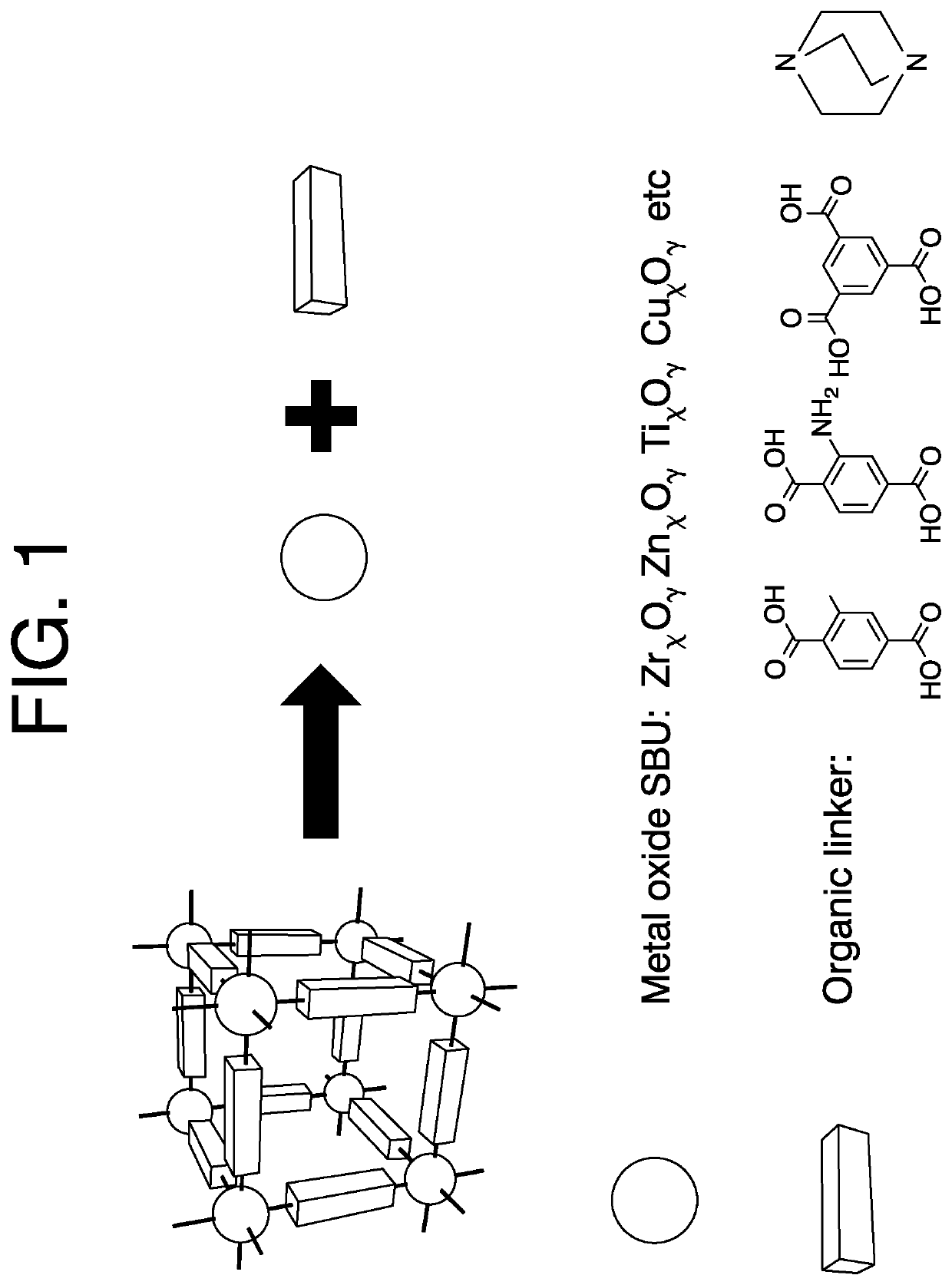

Propellant compositions are provided herein for use in small arms cartridges. Such propellant compositions include from about 70 to about 90% by weight of a cellulose-based organic fuel, from about 5 to about 30% by weight of a non-azide, nitrogen-containing primary organic oxidizer and from about 0.5 to about 10.0% by weight of a secondary nitrate, perchlorate, chlorate of peroxide oxidizer. Preferably, such compositions are in the form of extruded shaped hollow cylindrical grains having a length in the range of 0.030 to 0.200 inch, a diameter in the range 0.040 to 0.070 inch, and having a coaxial opening there through having a wall grain thickness in the range 0.008 to 0.016 inch. Ignition grains are also provided for use alone or in a mixture with the propellant compositions. When used in a small caliber firearm or muzzleloader, the temperature of combustion is at a level that ensures substantially complete combustion of the fuel during firing so that the products of combustion are mostly gaseous.

Owner:GENERAL DYNAMICS ORDNANCE & TACTICAL SYST CANADA VALLEYFIELD INC

Propellant and process for producing a propellant

InactiveUS20110284140A1Easy to useProcess controlLoomsNitrocellulose explosive compositionsAcetic acidAlcohol

A propellant for guns includes at least one energy carrier, nitrocellulose and cellulose acetate butyrate. At least part of the nitrocellulose is alcohol-soluble nitrocellulose. The nitrocellulose serves as a binder and for that purpose is present in a concentration of at least 15% by weight in the propellant. A process for producing a propellant is also provided.

Owner:DIEHL BGT DEFENCE GMBH & CO KG

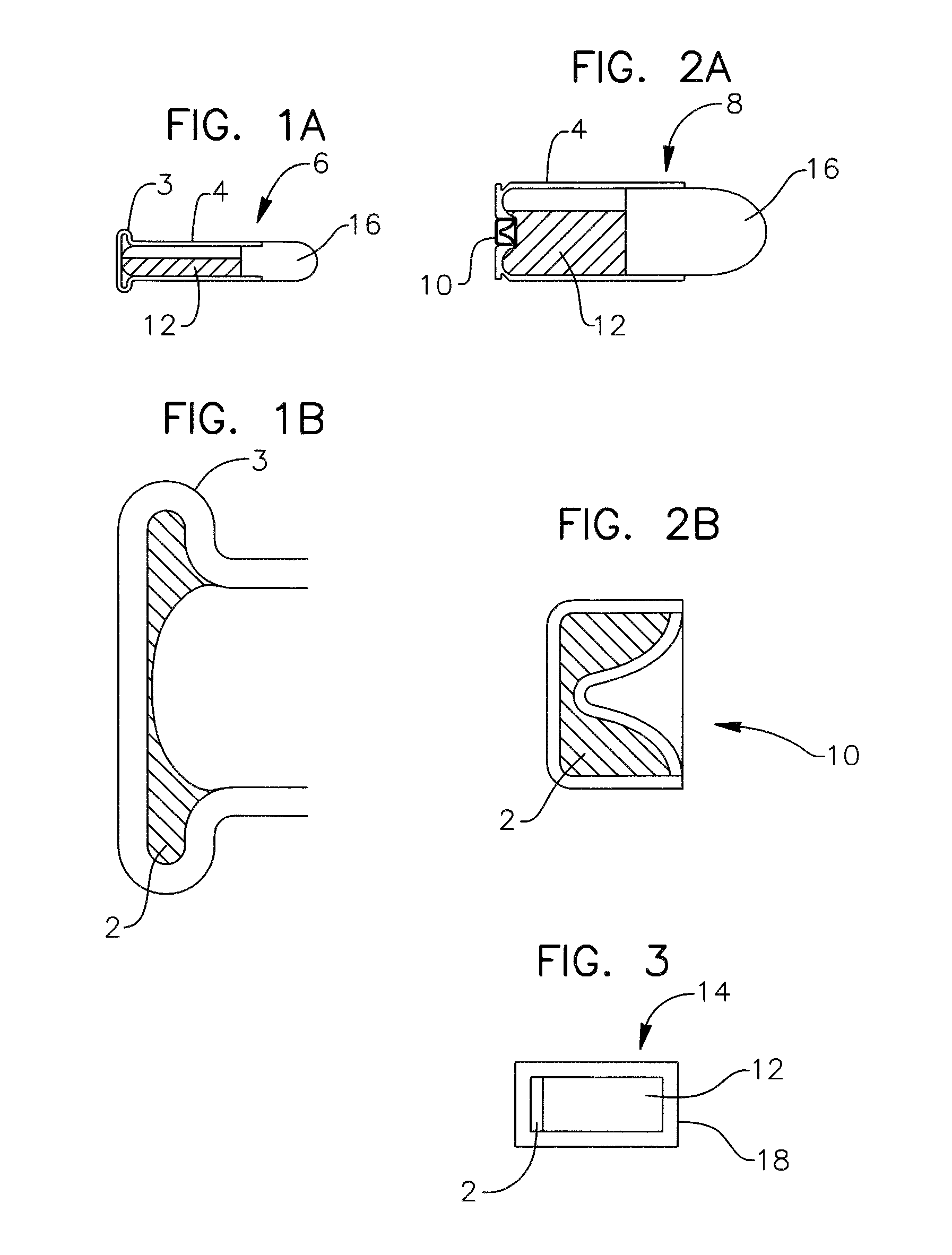

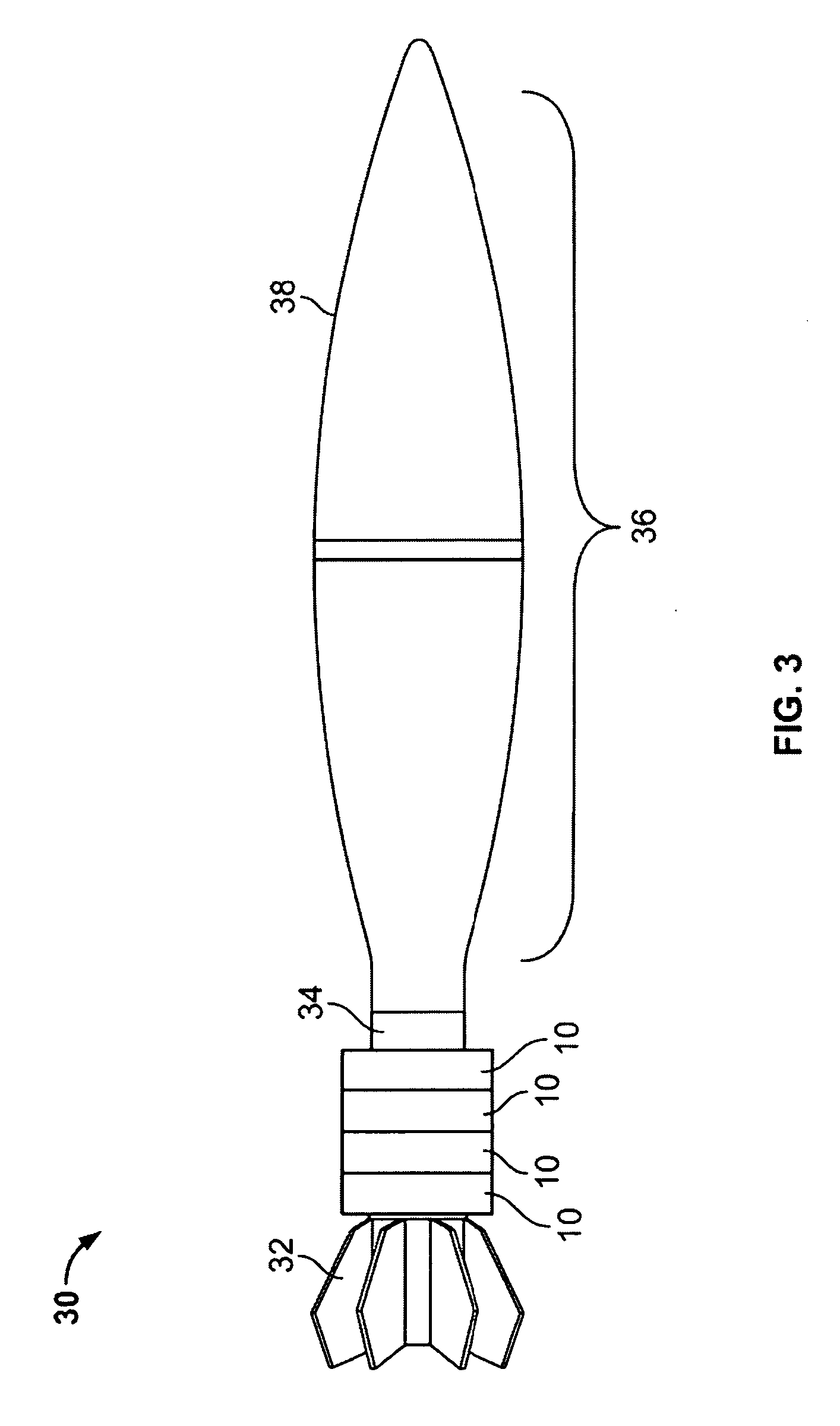

Foamed celluloid process using expandable beads

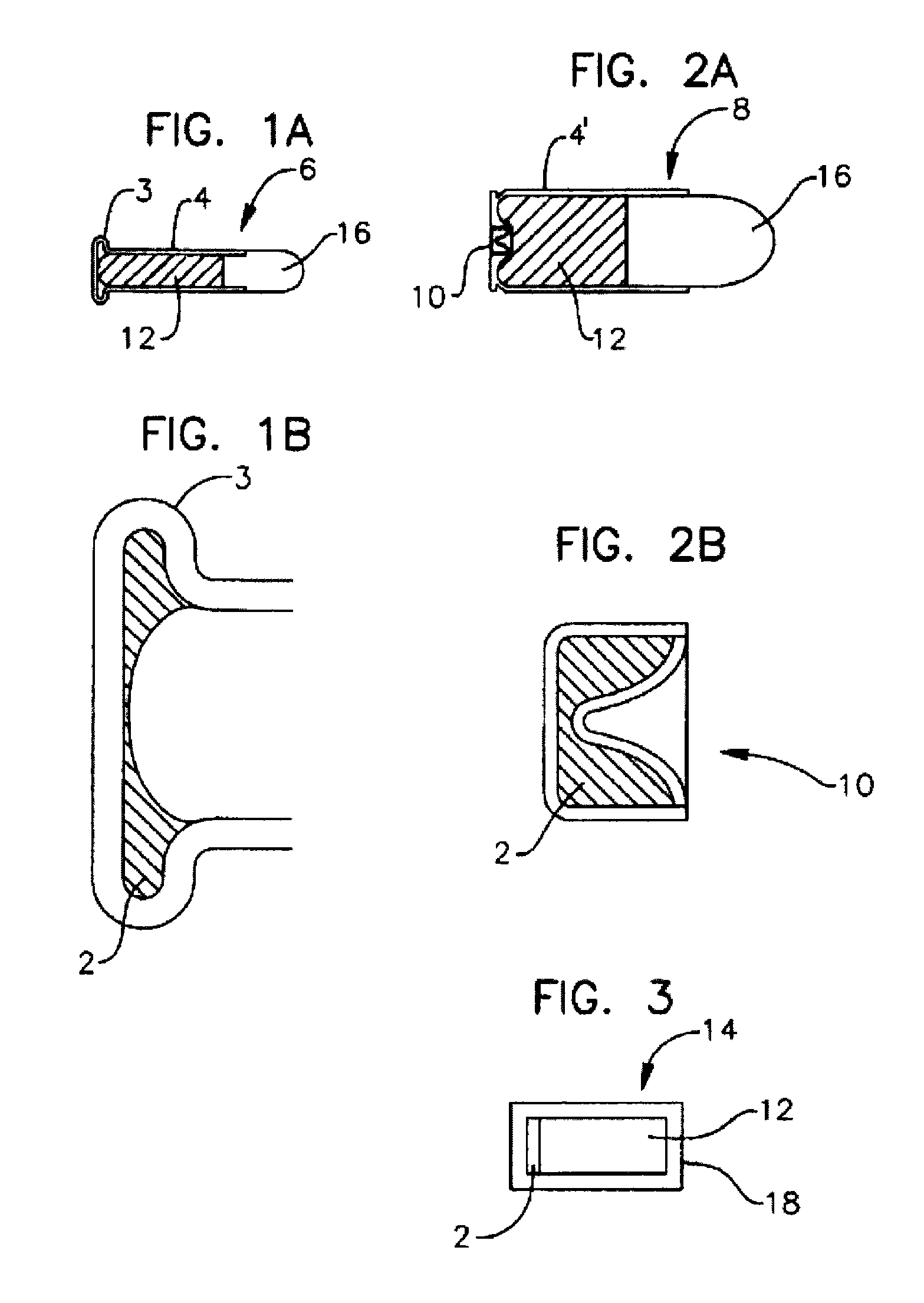

ActiveUS8696838B1Simple geometryLow densityLoomsNitrocellulose explosive compositionsHigh densityCelluloid

A method of manufacture of foamed celluloid molded products, involving three steps for the manufacture of higher density (0.7 to 1.25 gm / cc) foamed celluloid products or simple geometry lower density (0.2 to 0.7 gm / cc) foamed celluloid products, and four steps for the manufacture of lower density foamed celluloid products of any geometry. The three step process involving: (1) providing small, uniform, pieces of celluloid; (2) presoaking the pieces in a physical blowing agent (PBA) under pressure; and (3) foaming at raised temperature a controlled quantity of the presoaked pieces in a mold—to obtain the desired shape and density. For a lower density foamed celluloid product, of any moldable geometry, the steps are to: (1) small pieces of celluloid, that (2) have been presoaked in a PBA, are (3) pre-expanded to an intermediate density, and then (4) foam the desired lower density foamed product in a mold at raised temperature.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

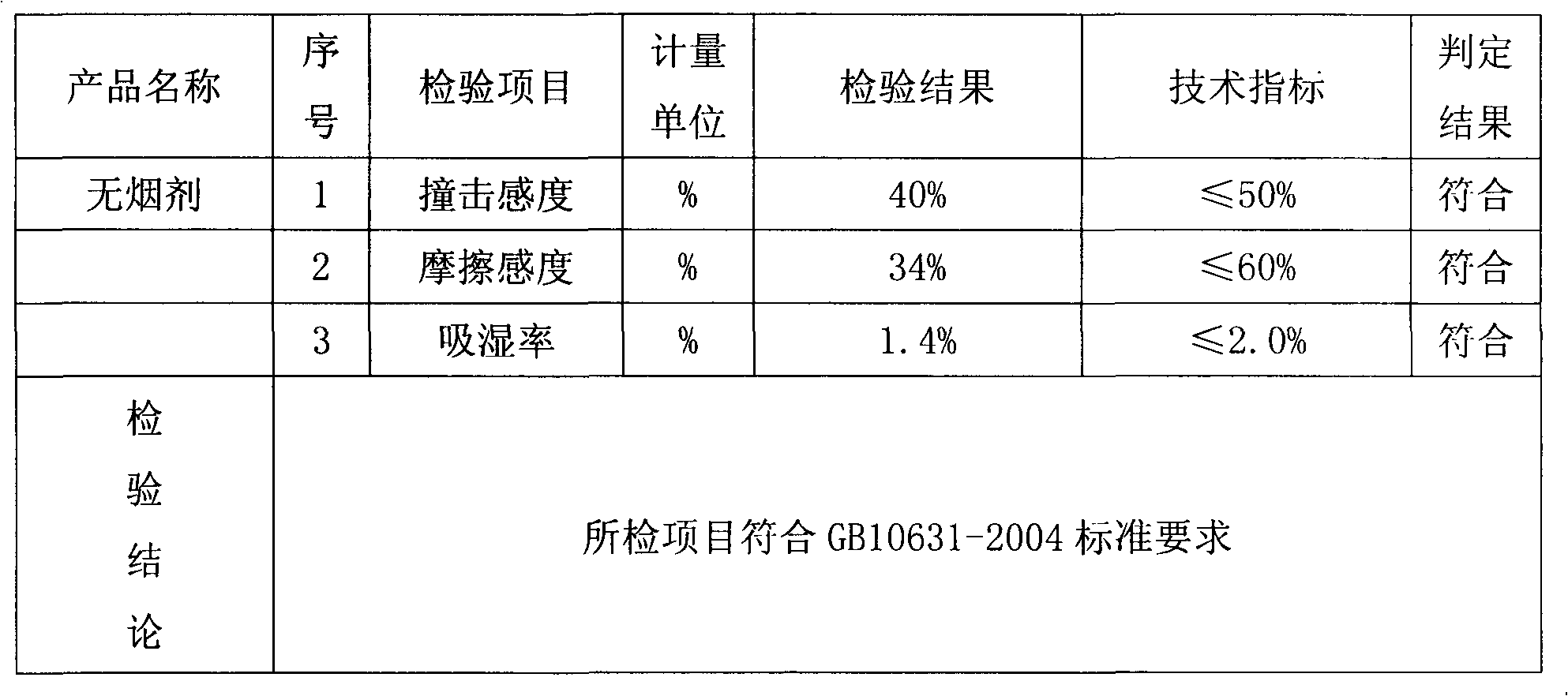

Method for sensitizing microporous smokeless firework explosive

InactiveCN101844955AFiring speed is fastImprove ignition performanceNitrocellulose explosive compositionsInorganic oxygen-halogen salt explosive compositionsNon solventCellulose

The invention discloses a method for sensitizing microporous smokeless firework explosive, which comprises the following steps of: dissolving scrapped military smokeless explosive containing nitrated cellulose into a solvent to form macromolecular sol, emulsifying and foaming the sol to form paint emulsion, dispersing the paint emulsion into a non-solvent medium under stirring action to form balls, then driving the solvent to obtain explosive particles suspended in the solution and provided with micropores, separating the explosive particles suspended in the solution and provided with micropores, sensitizing the explosive particles separated from the solution of the suspended explosive particles and provided with micropores, and drying the explosive particles to obtain an explosive particle finished product, wherein the sensitizing mode is to add a sensitizing agent into the explosive particles separated from the solution of the suspended explosive particles in a form of aqueous solution or solid. The sensitizing process improves the fire transfer speed of the explosive particles and improves the ignition performance thereof, and the fire transfer speed of the explosive particles is improved by 10 to 200 percent under a normal pressure condition.

Owner:NANJING UNIV OF SCI & TECH

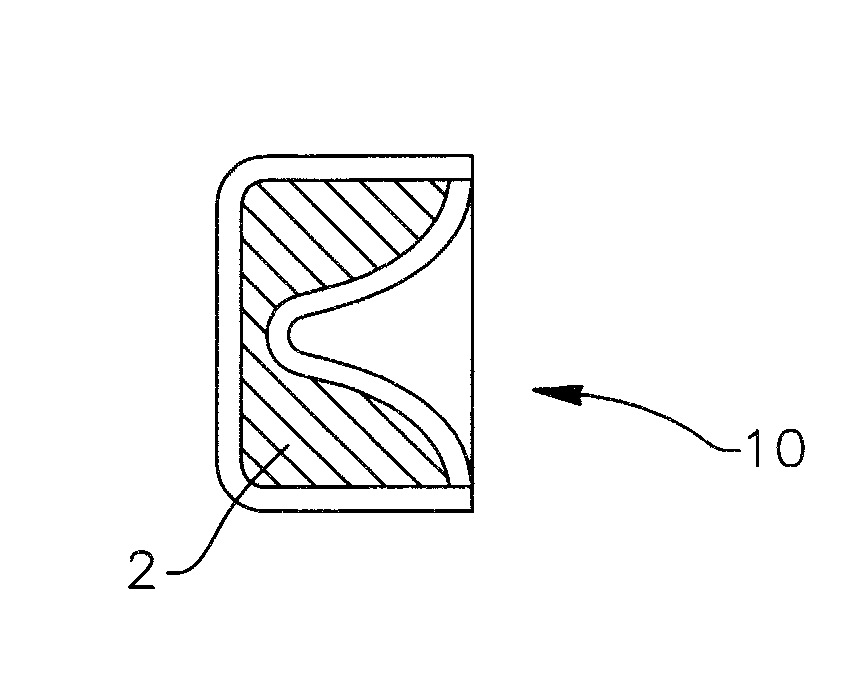

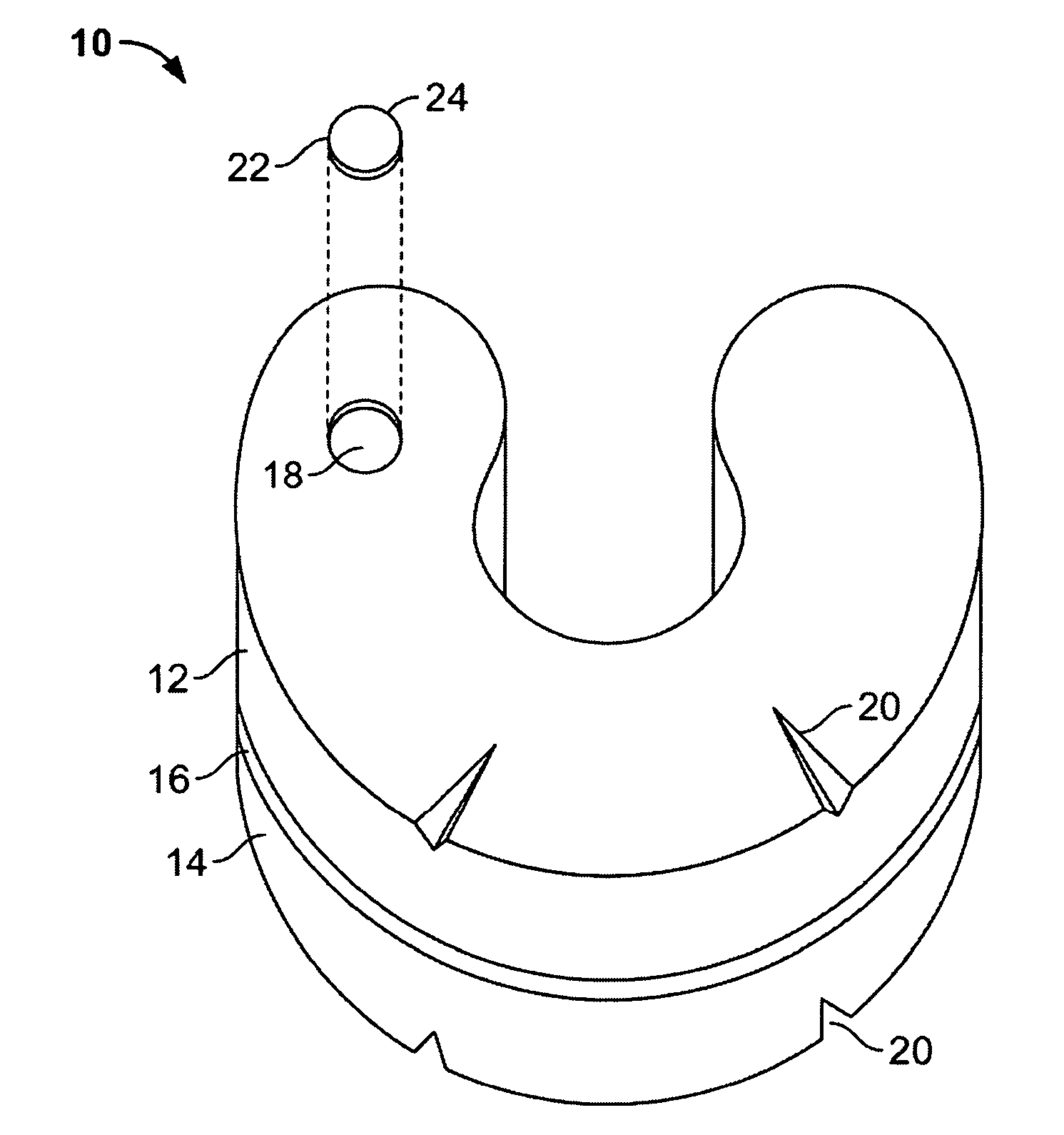

Foamed celluloid combustible material

By using generally known chemically, physically, or a combination thereof, means to foam celluloid, a foamed celluloid material is invented with a density of less than about 1.25 gm / cm3, which material is relatively low cost, very fast burning, very low residue, easily moldable, and which material exhibits good mechanical strength, and provides a good water barrier. These characteristics make this foamed celluloid a preferred choice for military artillery propellant charge bags, military mortar and civilian fireworks increment charges, combustible cartridges, flare housings, igniter tubes, as well as, closure disks, combustible enclosures and components thereof, among other applications.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Method for manufacture of microcrystalline nitrocellulose

InactiveUS20060180253A1Nitrocellulose explosive compositionsExplosive working-up apparatusNitrocelluloseShell molding

A microcrystalline nitrocellulose composition for use in an energetic high-nitrogen fuel, which exhibits the plastic characteristics of colloided nitrocellulose, suitable for forming, molding, or compacting, and a method of manufacturing the same.

Owner:NICKEL RUSSELL R +1

Explosive composition for fireworks and method for manufacturing the same

InactiveUS6982014B1Laborious processNitrocellulose explosive compositionsNitroparaffin explosive compositionsNitro compoundNitrocellulose

A method for preparing a pyrotechnic composition which comprises preparing a composition in a gel form using nitrocellulose and a nitro compound other than nitrocellulose, adding an oxidizing agent, a combustible material and a color rendering agent to the composition, followed by mixing, forming the resultant mixture into a desired shape, and then drying; and a pyrotechnic composition obtainable by using the method. This method can be used for simplifying a production process while maintaining the effect of a star and a lance used in a pyrotechnic composition, particularly in a firework composition.

Owner:NIPPON KAYAKU CO LTD

Black Powder Substitutes for Small Caliber Firearms

Propellant compositions are provided herein for use in small arms cartridges. Such propellant compositions include a cellulose-based organic fuel, a non-azide, nitrogen-containing primary organic oxidizer and a secondary nitrate, perchlorate, chlorate of peroxide oxidizer. Preferably, such compositions are in the form of extruded shaped hollow cylindrical grains having dimensions that makes it loadable in a muzzleloader firearm or small calibre firearm cartridge case. Ignition grains are also provided for use alone or in a mixture with the propellant compositions. When used in a small calibre firearm or muzzleloader, the temperature of combustion is at a level that ensures substantially complete combustion of the fuel during firing so that the products of combustion are mostly gaseous.

Owner:RACETTE MATHIEU +2

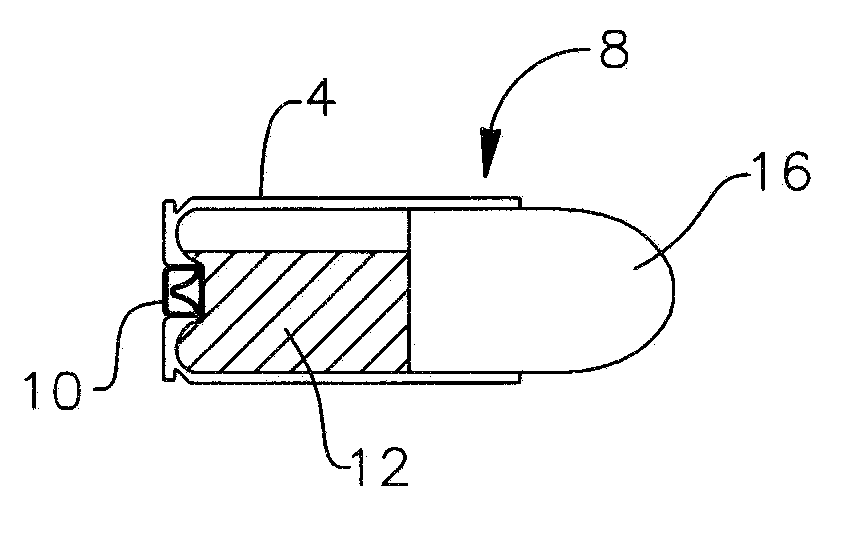

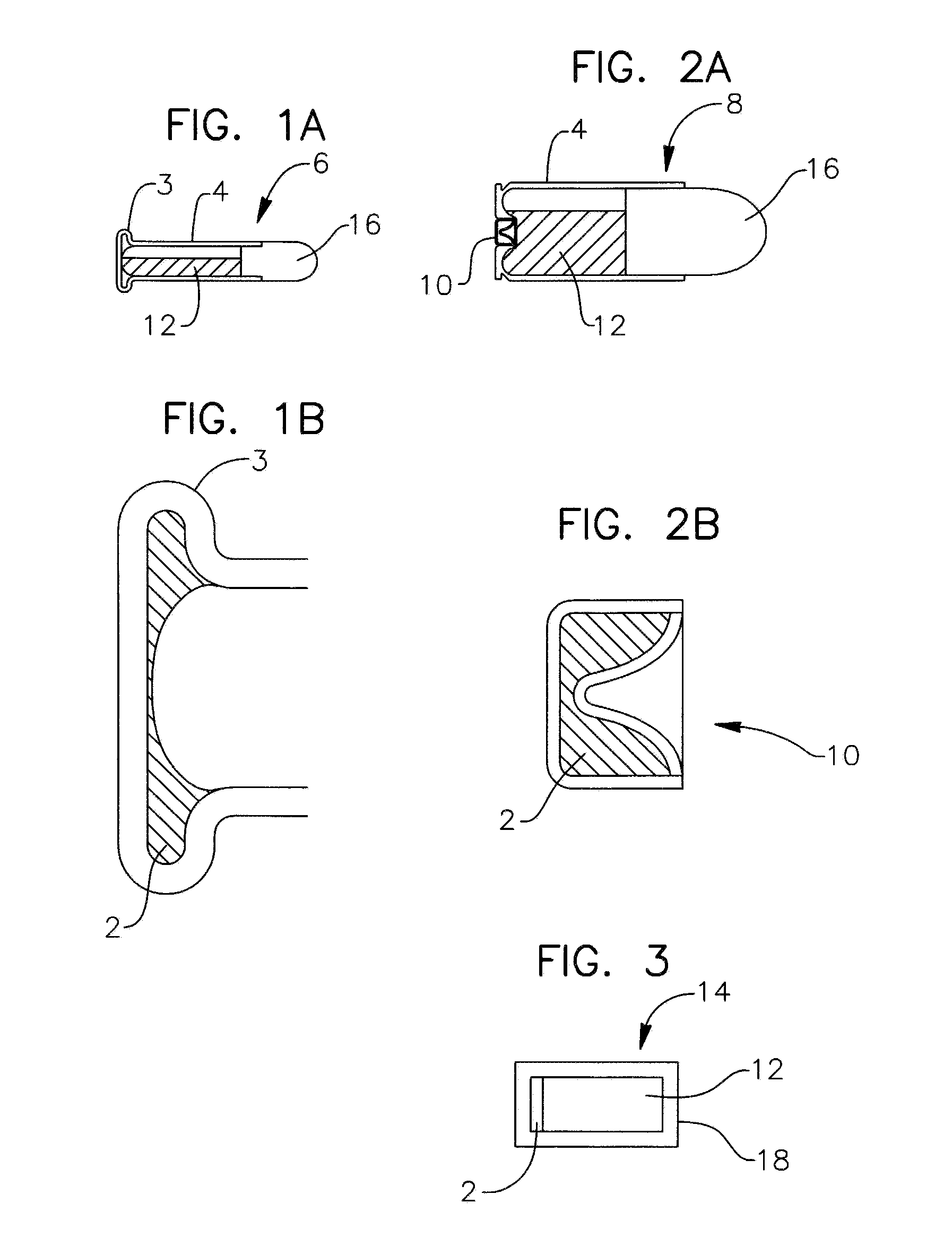

Electrically ignitable caseless propellant charge, the production and use thereof

InactiveUS20160046536A1Improve liquidityGood storage stabilityNon-explosive fillers/gelling/thickening agentsNitrocellulose explosive compositionsElectricityNitrocellulose

Electrically ignitable caseless propellant charge in the form of a caseless propellant tablet (5), characterised in that it is obtainable by mixing together of at least one current-conductive material in dissolved or dispersed form or powder form and graphite in powder form, together with nitrocellulose, with or without addition of further additives, and subsequent compaction to form a propellant tablet, the production and use thereof, and related subject matter of the invention. Uses include: use of the propellant charge in a bolt-driving tool for installing bolts, as an explosive charge in a warning shot device, as a gas-generating element in airbags, for driving cutting devices, for driving pressing devices (for example for squeezing tong-like elements together) or as a propellant charge in small calibre rifles for sporting purposes, or for captive bolt devices for animal slaughtering.

Owner:FISCHERWERKE ARTUR FISCHER GMBH & CO KG

Propulsion system for the acceleration of projectiles

ActiveUS20120138201A1Increase valueReadily availableLoomsNitrocellulose explosive compositionsChemical structureNitrocellulose

The propulsion system for the acceleration of projectiles is based on nitrocellulose and contains a crystalline energy carrier on a nitramine base and an inert plasticising additive. The nitramine compound contains a structural element of the general chemical structure formula R—N—NO2, where R is a residual.The nitramine compound is present in a concentration in the range from 1 to 35% by weight, in particular in the range from 5 to 25% by weight. The nitramine compound is preferably RDX. The inert plasticising additive is a water-insoluble polyoxo compound, if necessary in combination with a substance containing carboxyl groups. In layers near the surface an increased concentration can be present. The inert plasticising additive is present in a concentration of 1 to 5% by weight.

Owner:NITROCHEM WIMMIS

Black powder substitutes for small caliber firearms

Owner:GENERAL DYNAMICS ORDNANCE & TACTICAL SYST CANADA VALLEYFIELD INC

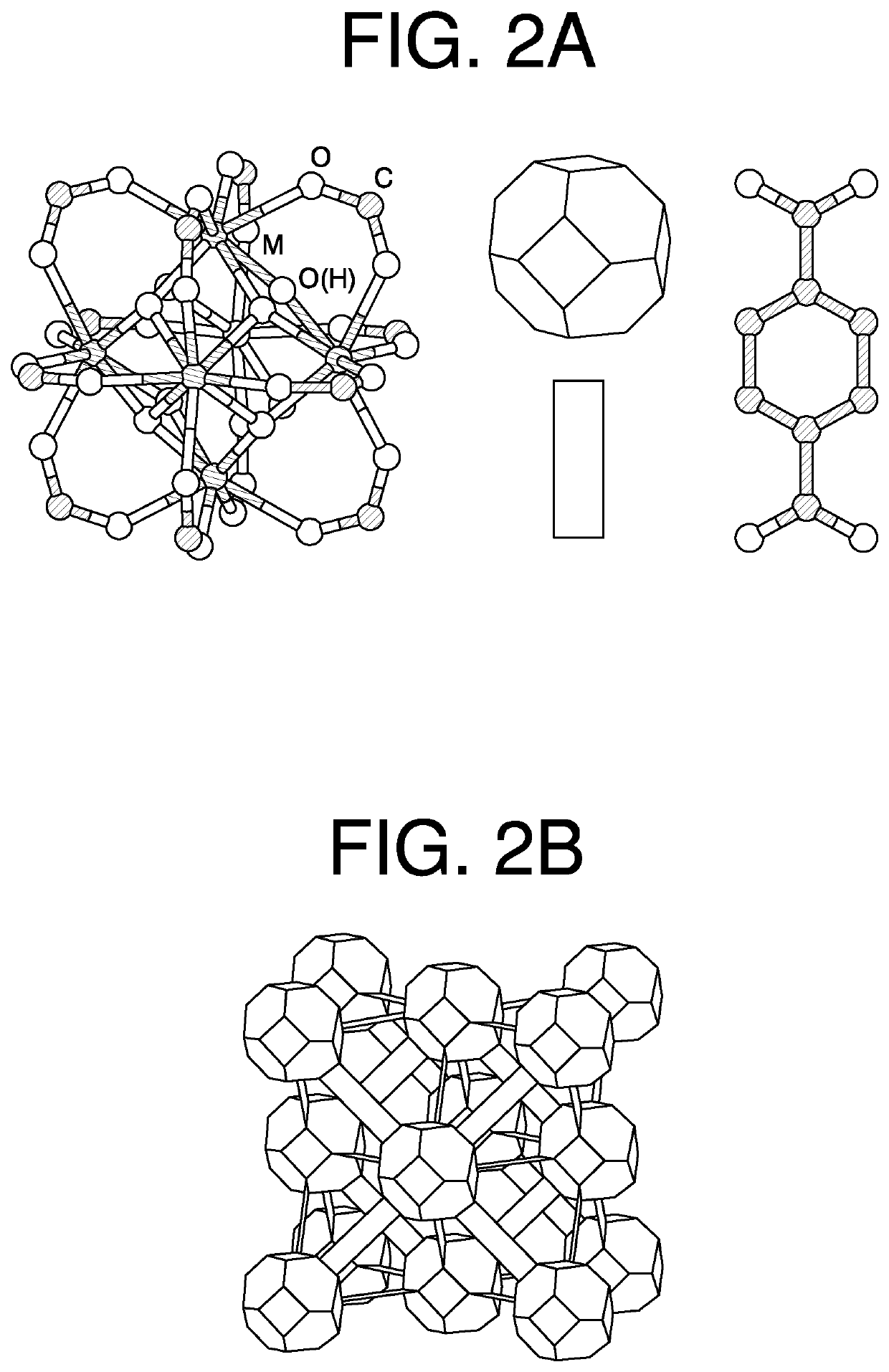

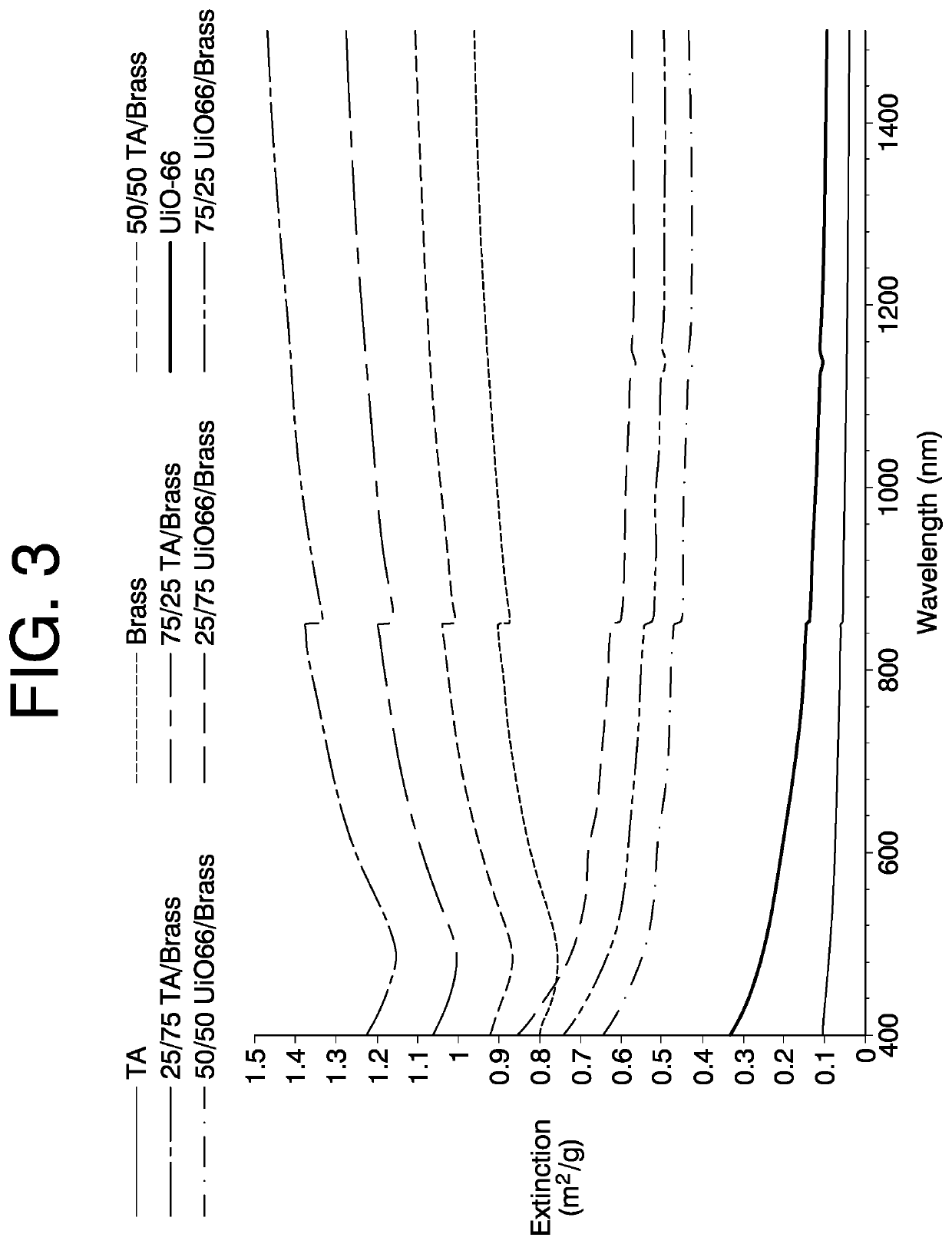

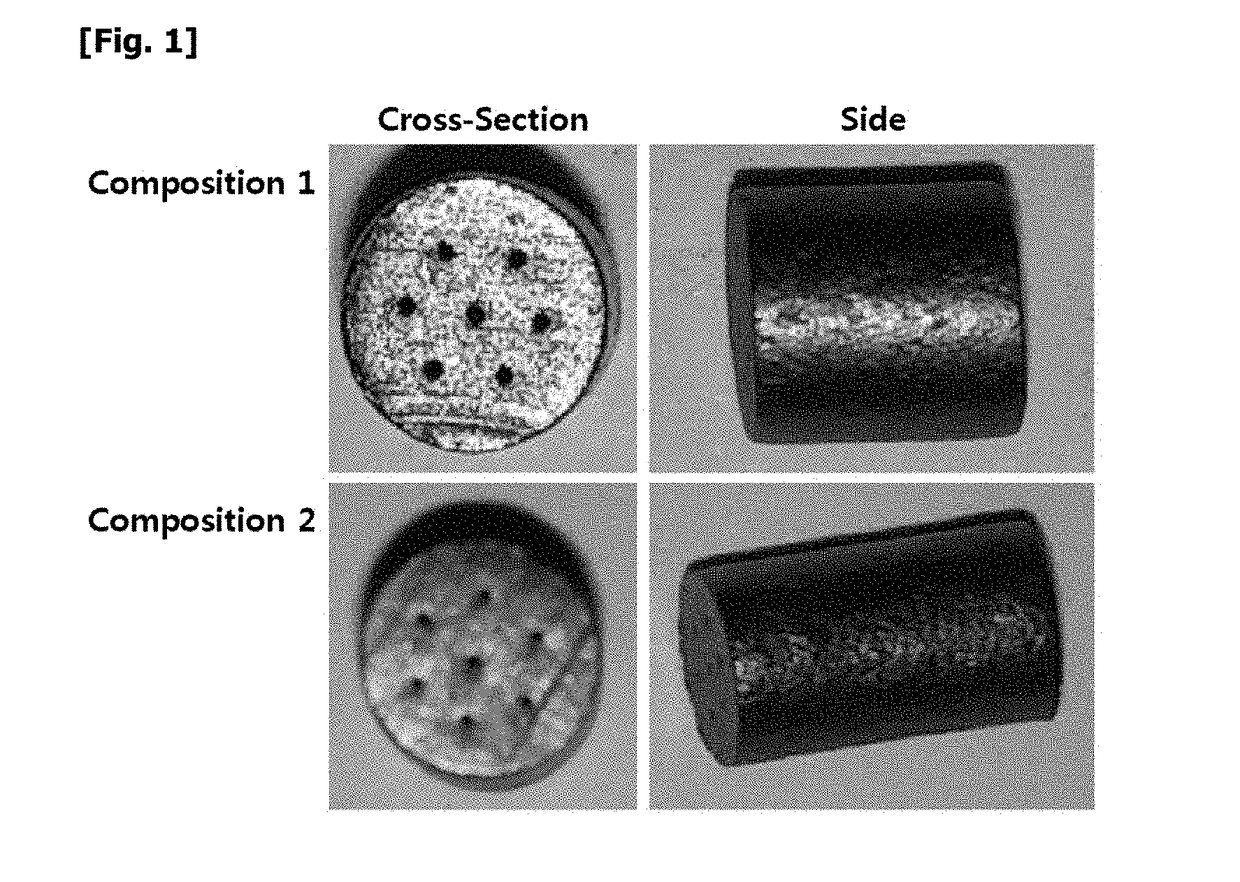

Pyrotechnic smoke obscurants containing metal-organic frameworks and composites thereof

ActiveUS10717685B1Reduce light transmittanceAmmunition projectilesGroup 4/14 organic compounds without C-metal linkagesMetal-organic frameworkEngineering

A multispectral smoke obscurant composition effective in reducing transmittance in the visual, infrared, and ultraviolet regions of the electromagnetic spectrum, comprising at least one metal organic framework (“MOF”), at least one fuel, at least one oxidizer, and optionally one or more additives selected from the group consisting of binders, coolants, and accelerants. The MOF or MOF composite is present from about 10 to 90 weight percent of the smoke obscurant composition, while the fuel and the oxidizer in combination comprise about at least 10 weight percent of the smoke obscurant composition.

Owner:UNITED STATES OF AMERICA

Propellant compositions comprising nitramine oxidants

InactiveUS20170233306A1Good physical compatibilityStable interior ballistics characteristicNitrocellulose explosive compositionsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsNitrocelluloseNitrate

The present invention relates to a high energy-containing propellant composition and a use thereof. The propellant composition of the present invention is a propellant composition for guns, including: (a) 55 to 85 wt % of a nitrocellulose binder; (b) 10 to 35 wt % of a nitramine oxidant; (c) 1 to 4 wt % of a plasticizer having both a nitrate group and a nitramine group; and (d) 0.5 to 3 wt % of a stabilizer. The propellant composition of the present invention significantly improves a physical compatibility between the nitrocellulose binder and the oxidant using a plasticizer containing both a nitrate group and a nitramine group, leading to stable interior ballistics characteristics from low temperature to high temperature as well as improvement on the characteristics of an extrudate. Accordingly, the propellant composition of the present invention may be effectively applied to an ammunition for guns due to an excellent physical property and interior ballistic stability thereof.

Owner:AGENCY FOR DEFENSE DEV

Nitrocellulose paper for firework

ActiveCN101475421AShorten the soaking timeMeet environmental protection requirementsNitrocellulose explosive compositionsFireworksNitrocelluloseFireworks

The invention discloses nitrocellulose paper for fireworks. Base paper is soaked in a medicament mixing solution and is subjected to specific treatment to prepare the nitrocellulose paper; the water content is between 20 and 30 percent; the base paper is pure cotton fibre paper; according to proportion, concentrated sulfuric acid and concentrated nitric acid are poured into a vessel, are mixed, are stirred and are kept stand to form the functional medicament mixing solution; the functional medicament mixing solution has the nitrifying function on changing the performance of a cotton product; the specific treatment comprises preparation of the functional solution, soaking, washing through clean water, detection by test paper, roasting, drying, sealing and storage; the soaking temperature of the medicament solution is between 30 and 70 DEG C; the soaking time for the base paper is between 10 and 45 seconds; the nitrocellulose paper can be used as paper for the lighting background and invisible covering of stage fireworks and subtitle pattern fireworks, paper for wrapping combined fireworks or an effect drug body of a display shell or paper for a paste ball of a ball shell of the display shell; and by coating technology, the nitrocellulose paper is coated and adhered with a layer of pasty colorful medicament, is coiled into a tube barrel shape or is cut into small sections and isused as an effect barrel of fireworks and an effect body of a display shell ball.

Owner:浏阳象形精品烟花出口制造有限公司

Smokeless firework propellant

InactiveCN102826942AImprove securityImprove moisture resistanceNitrocellulose explosive compositionsCelluloseFireworks

The invention discloses a smokeless firework propellant. The composition comprises the following ingredients in parts by weight: 30-50 parts of one of guanidine nitrate or nitroguanidine, 20-40 parts of diethylene glycol dinitrate, and 20-40 parts of cellulose nitrate. The smokeless firework propellant has the beneficial effects that smoke occurrence quantity and air residue are small in burning,no smoke is generated through visual inspection; the safety performance meets the national standard requirement; the moisture resistance is good, the medicine is stable, the storage performance has no abnormality for a long time (within five years); the economy is good, and the popularization and application are easy: the production cost is low and slightly higher than the military nitrate, and the increase rate can not exceed 10%; and under same conditions, the using amount accounts for 45-55% of military nitrate.

Owner:湖南省浏阳金生花炮有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com