Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41 results about "Phenetidine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Used in the manufacture of acetophenetidin.

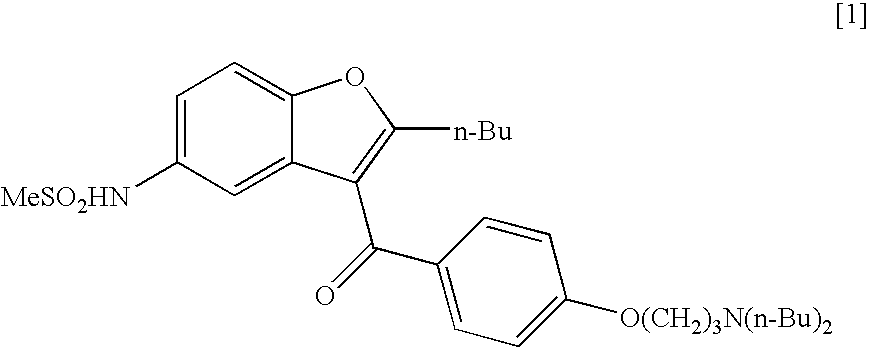

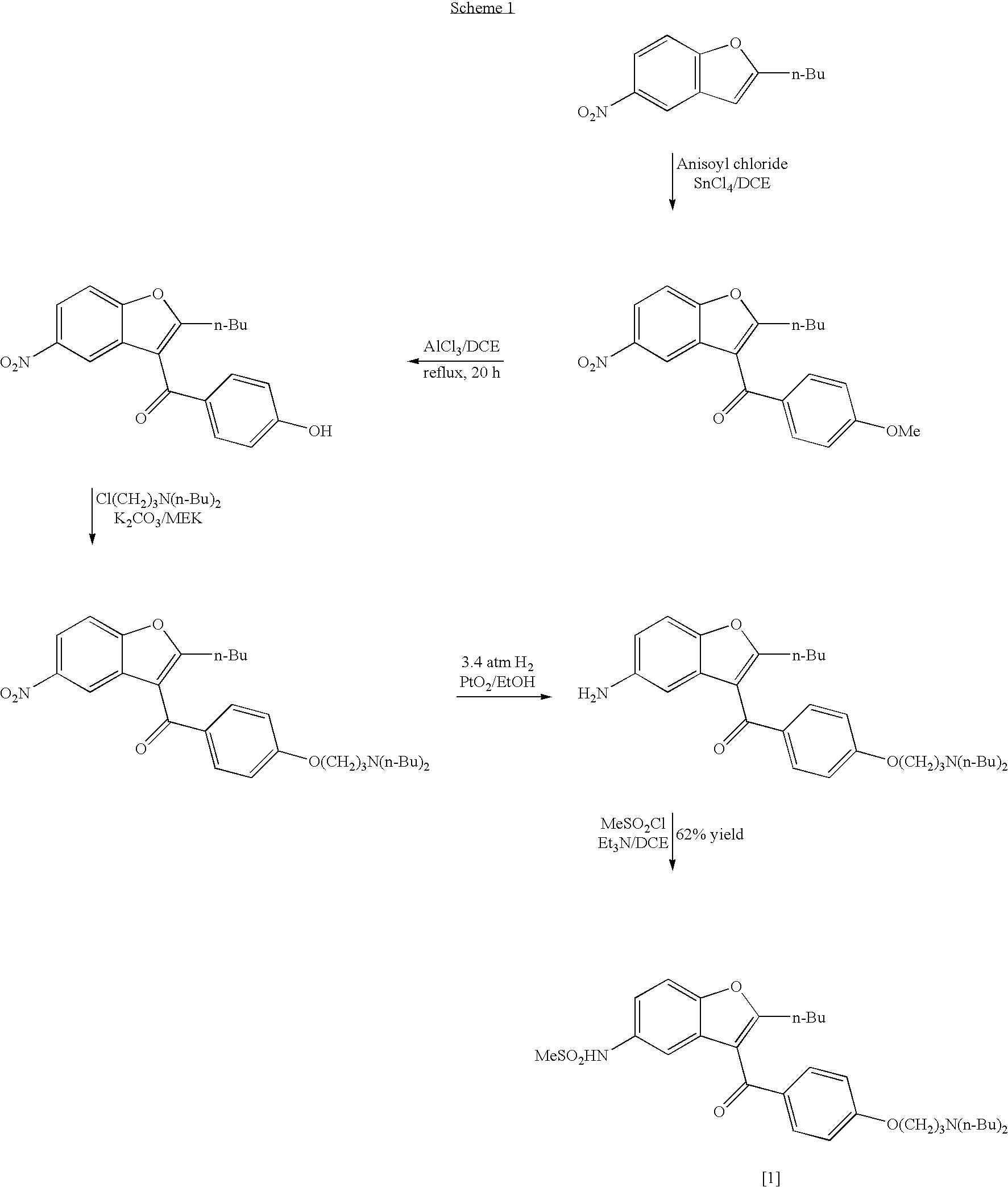

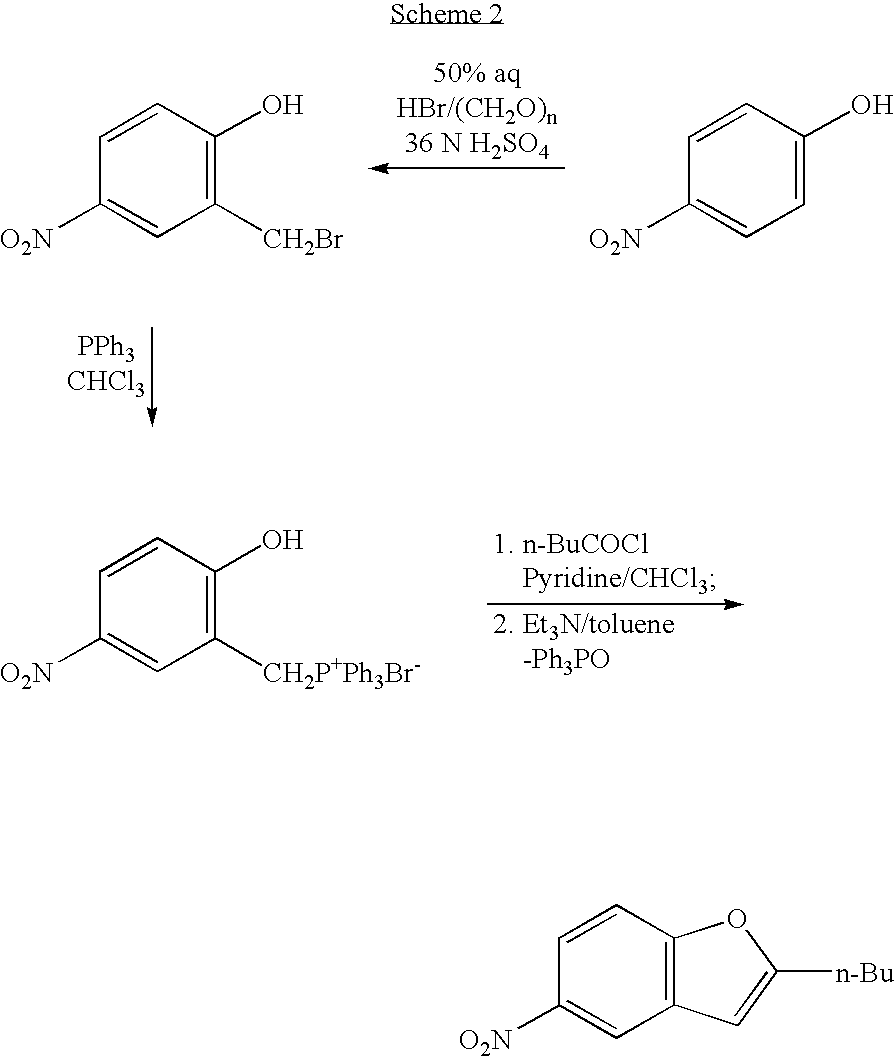

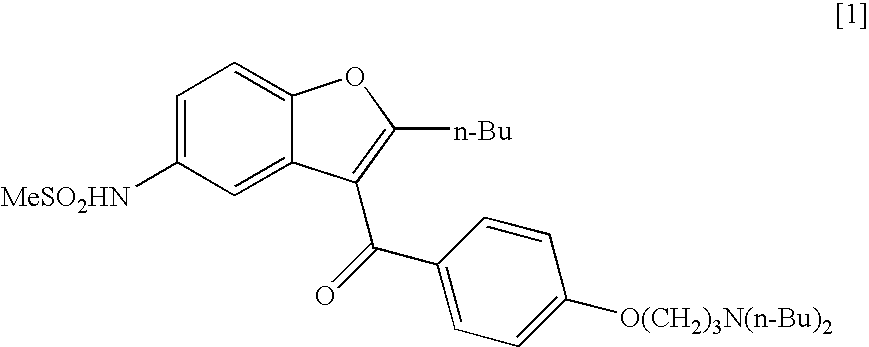

Process for the preparation of dronedarone

InactiveUS20050049302A1High yieldLow costBiocideCarbamic acid derivatives preparationAluminium chlorideDronedarone

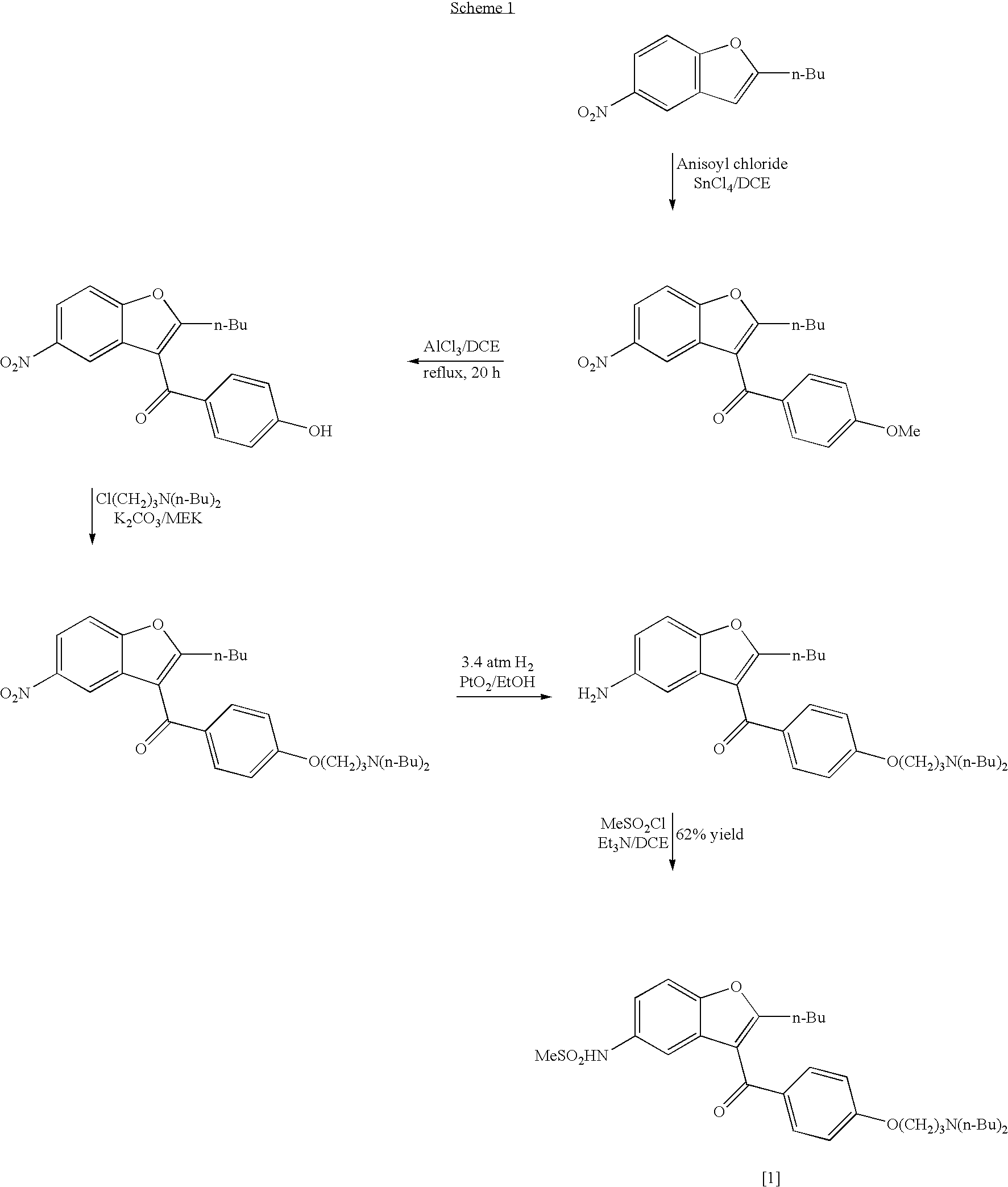

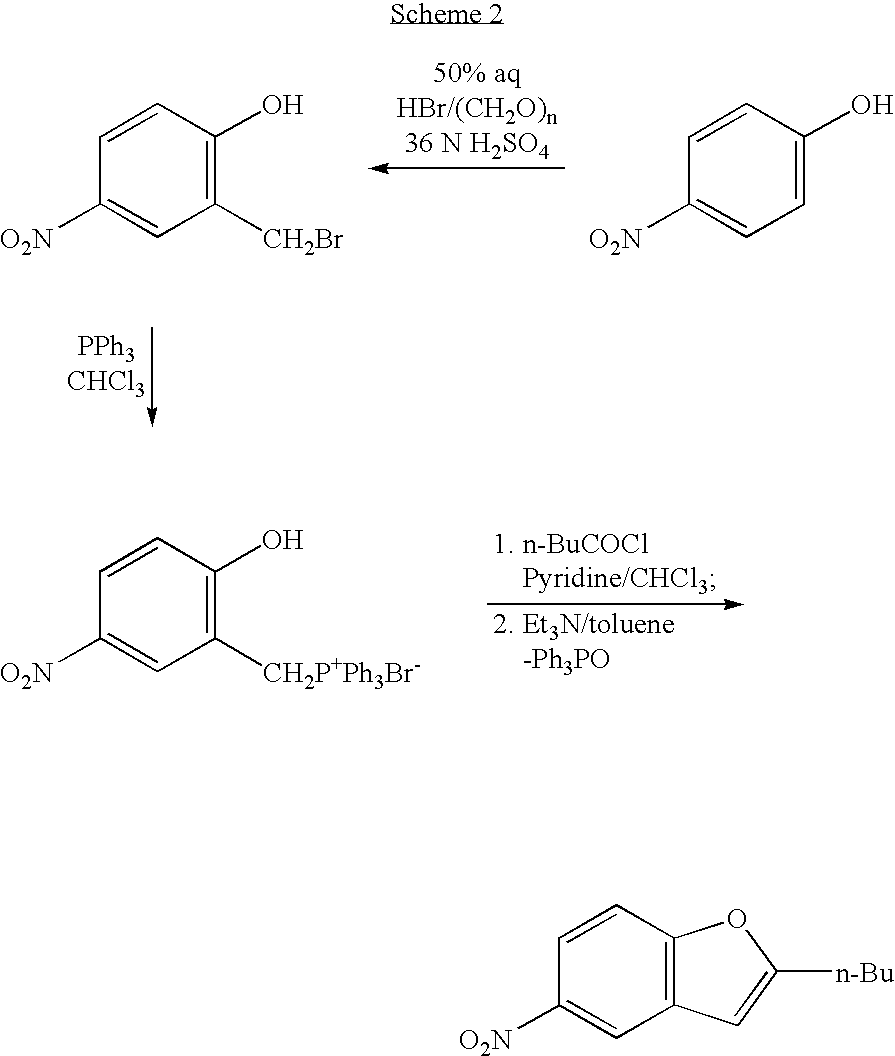

The present invention provides, according to an aspect thereof, a novel process for the preparation of dronedarone [1] and pharmaceutically acceptable salts thereof. According to a preferred embodiment, the process comprises N-acetylating of p-anisidine or p-phenetidine with acetic anhydride, reacting of the obtained N-(4-alkoxyphenyl)acetamide with 2-bromohexanoyl chloride or bromide in the presence of aluminum chloride or bromide to obtain N-[3-(2-bromohexanoyl)-4-hydroxyphenyl]acetamide [6a], converting the compound [6a] into 2-butyl-5-benzofuranamine hydrochloride [12a] and subsequently converting [12a] into [1] or pharmaceutically acceptable salts thereof. In accordance with another aspect of this invention, there are provided novel intermediates, inter alia the novel compounds [6a] and [12a]. The novel intermediates of the present invention are stable, solid compounds, obtainable in high yields, which can be easily purified by crystallization and stored for long periods of time.

Owner:ISP INVESTMENTS LLC

Process for the preparation of dronedarone

InactiveUS7312345B2High yieldLow costBiocideCarbamic acid derivatives preparationAluminium chlorideAcetic anhydride

The present invention provides, according to an aspect thereof, a novel process for the preparation of dronedarone [1] and pharmaceutically acceptable salts thereof. According to a preferred embodiment, the process comprises N-acetylating of p-anisidine or p-phenetidine with acetic anhydride, reacting of the obtained N-(4-alkoxyphenyl)acetamide with 2-bromohexanoyl chloride or bromide in the presence of aluminum chloride or bromide to obtain N-[3-(2-bromohexanoyl)-4-hydroxyphenyl]acetamide [6a], converting the compound [6a] into 2-butyl-5-benzofuranamine hydrochloride [12a] and subsequently converting [12a] into [1] or pharmaceutically acceptable salts thereof. In accordance with another aspect of this invention, there are provided novel intermediates, inter alia the novel compounds [6a] and [12a]. The novel intermediates of the present invention are stable, solid compounds, obtainable in high yields, which can be easily purified by crystallization and stored for long periods of time.

Owner:ISP INVESTMENTS LLC

Preparation of polyimide film

The invention discloses a preparation method of a polyimide film, which relates to a preparation method of a high molecular polymer film. The invention aims at providing a synthesis method of a polybenzoxazole imide film containing a single oxazole ring, which solves the problem of poor film forming ability of polybenzoxazole imide containing a dual oxazole ring under a condition without sacrificing the thermal property of a polymer. The method includes the following steps: firstly, 5-amido-2-(phenetidine)benzoxazole and N, N'-dimethylacetamide are mixed and stirred and added with aromatic dianhydride and then a polyamide acid is obtained after reaction is finished; secondly, the polyamide acid prepared in the first step is casted into film and dried; thirdly, heat treatment is carried out; and fourthly, the polyimide film is obtained through water boiling and stripping. The polyimide film prepared by the method is good in thermal property, strong in acid resistance and high in mechanical property. The preparation method is simple and has good film forming performance.

Owner:HARBIN INST OF TECH

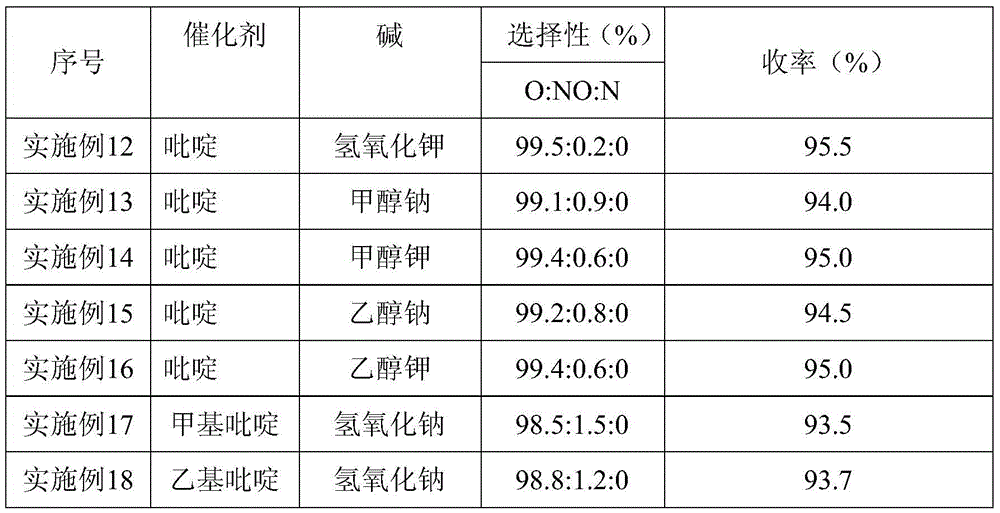

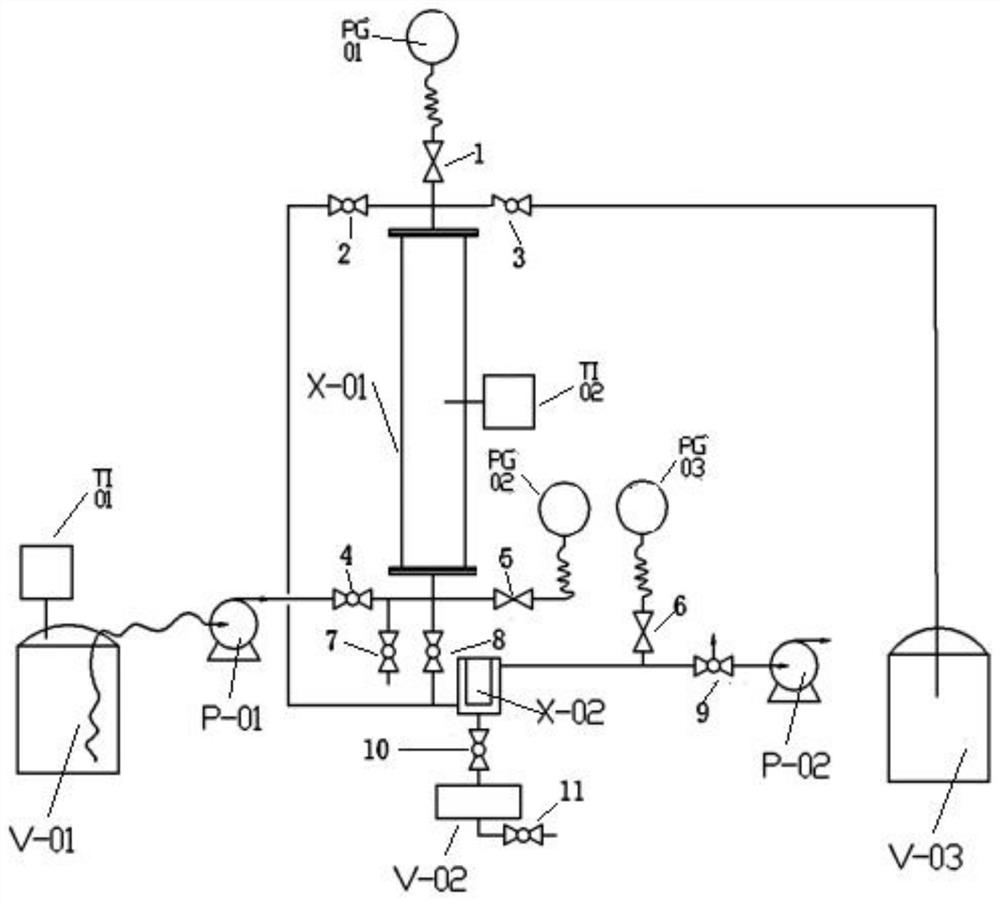

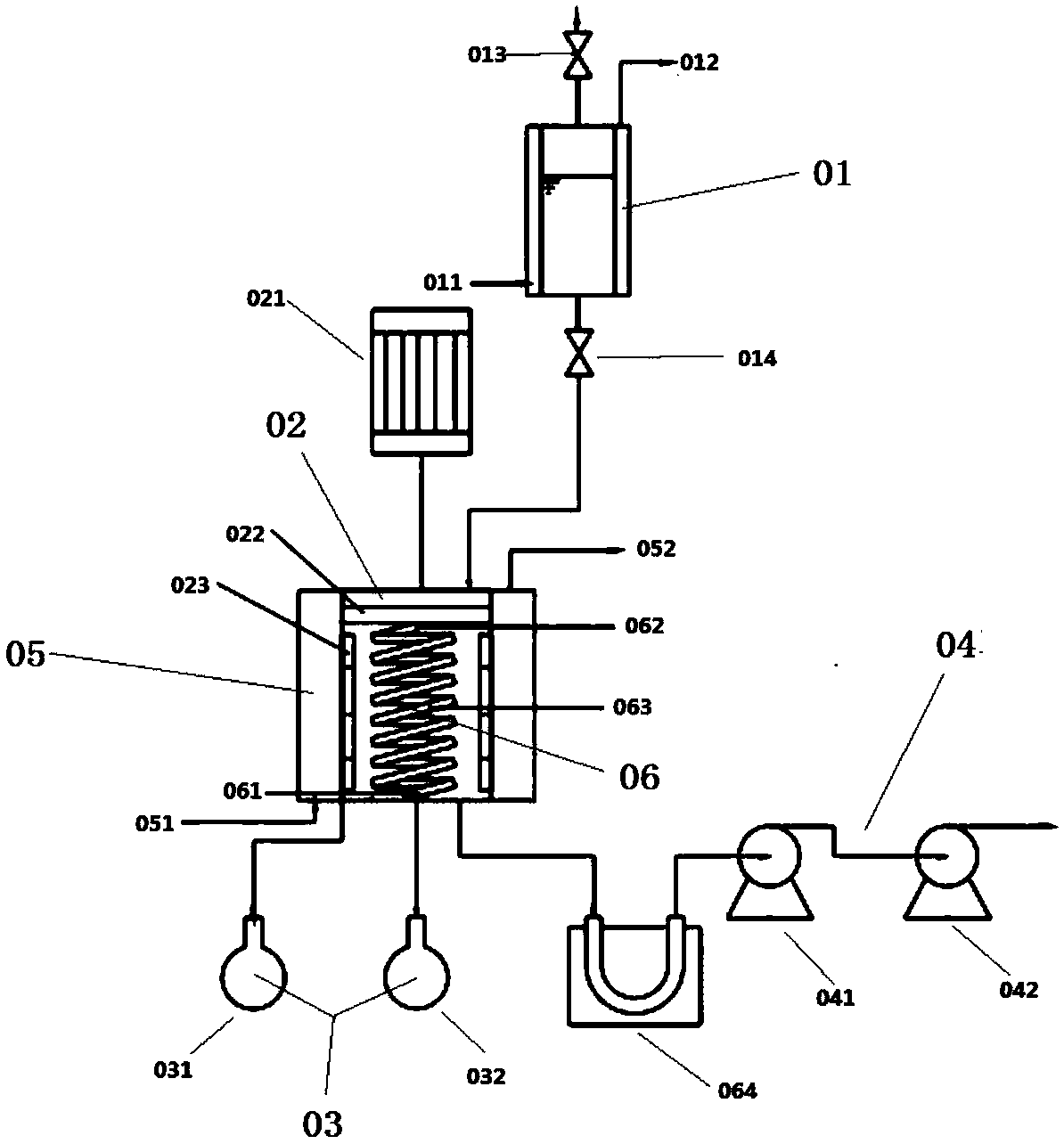

A kind of production method of ethoxyquinoline

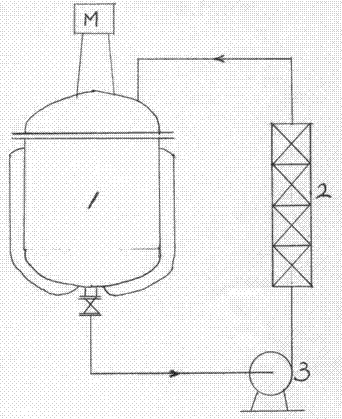

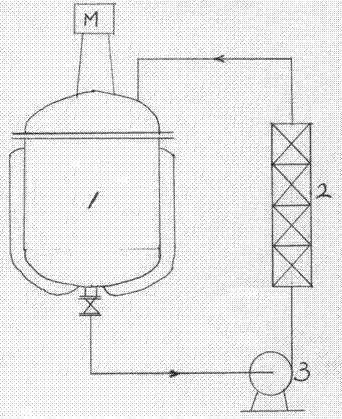

InactiveCN102285918ALower overall pressure dropReduce energy consumptionOrganic chemistryEtherQuinoline

The invention discloses a production method of ethoxyquinoline, which adopts the circulation between the static mixer and the reactor. Compared with the reactor, the static mixer can ensure the forced mixing and contact of the whole liquid flow, greatly The mass transfer effect is increased, and the pressure drop and energy consumption of the static mixer are low, which reduces the production cost. The total reaction time is 23-26 hours, the conversion rate of p-aminophenetole is greater than 97.0%, and the content of p-aminophenethyl ether in the ethoxyquinoline product is less than 0.4wt%.

Owner:上海福达精细材料有限公司

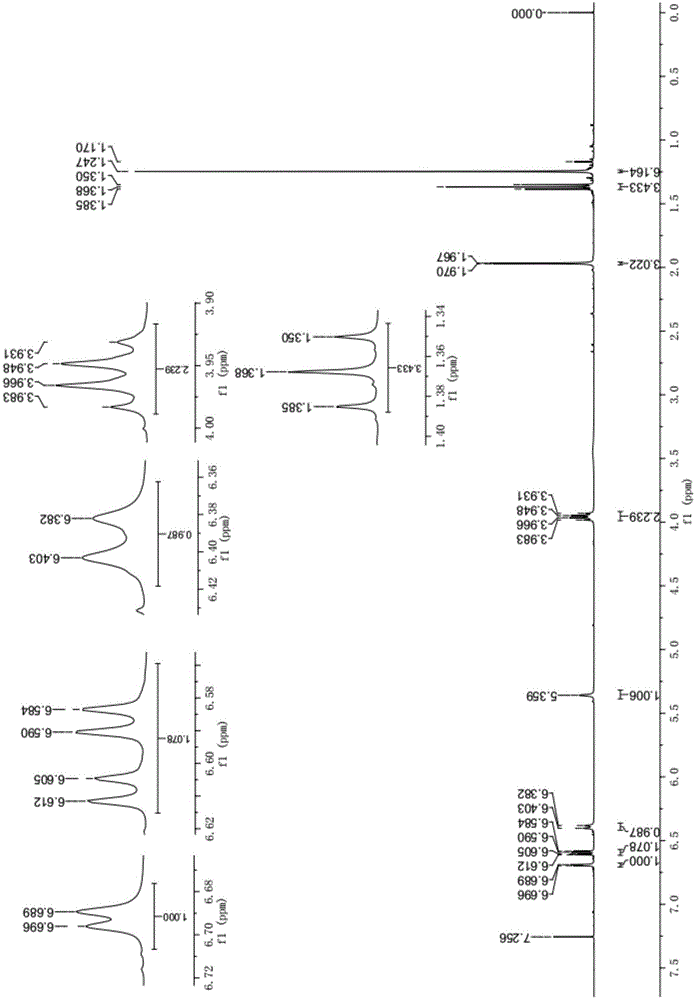

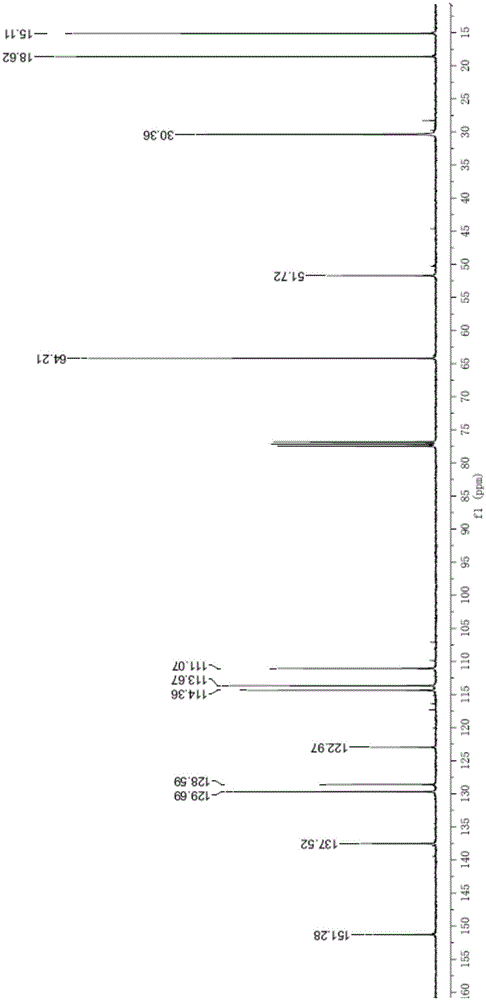

Method for producing ethoxyquin

The invention discloses a method for producing ethoxyquin, and relates to the field of chemical synthesis. The method includes the following steps: (1) adding p-phenetidine, a composite catalyst, and methylbenzene into a heatable reactor, adding acetone into the reactor under a heating condition to complete a condensation reaction, so as to obtain reacting liquid; (2) cooling the reacting liquid obtained in the step (1) to room temperature, adding an alkali liquor to neutralize the reacting liquid until the pH value is neutral, separating out the lower-layer catalyst and the remaining alkali liquor, and then adding water for water extraction to obtain the product mixed solution; (3) carrying out reduced pressure distillation on the product mixed solution obtained in the step (2) to obtain the ethoxyquin product. According to the invention, a p-toluenesulfonic acid / iodine composite catalyst is adopted for the preparation of ethoxyquin, and the catalyst matching ratio is adjusted, so that the product yield is improved while the production period is shortened, and the process cost is reduced.

Owner:XIAMEN UNIV

Industrial production method for ethoxy quinoline

The invention relates to an industrial production method for ethoxy quinolone. The industrial production method comprises the following steps: adding p-phenetidine, a diluent and a home-made chelate catalyst serving as raw materials into a reaction kettle; heating to 125-165 DEG C; dropwise adding acetone to perform a synthetic reaction; preserving heat for half an hour after finishing dropwise adding of the acetone; recovering the diluent by distilling; fractionating under a reduced pressure to obtain the ethoxy quinolone. The ethoxy quinolone is over 98 percent in purity, is less than 0.5 percent in raw material residues, and is over 90 percent in total yield.

Owner:张加明 +1

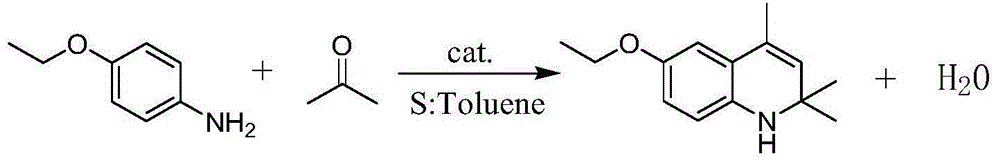

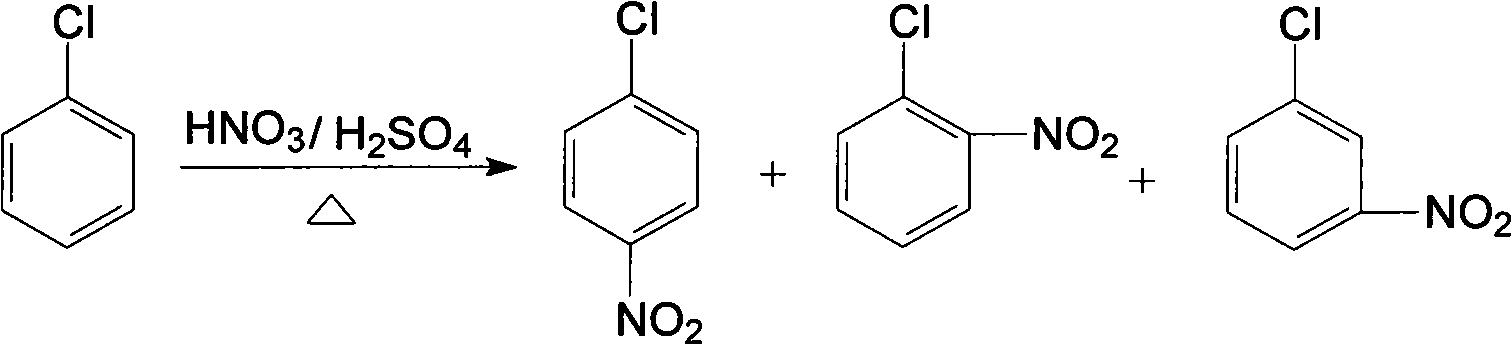

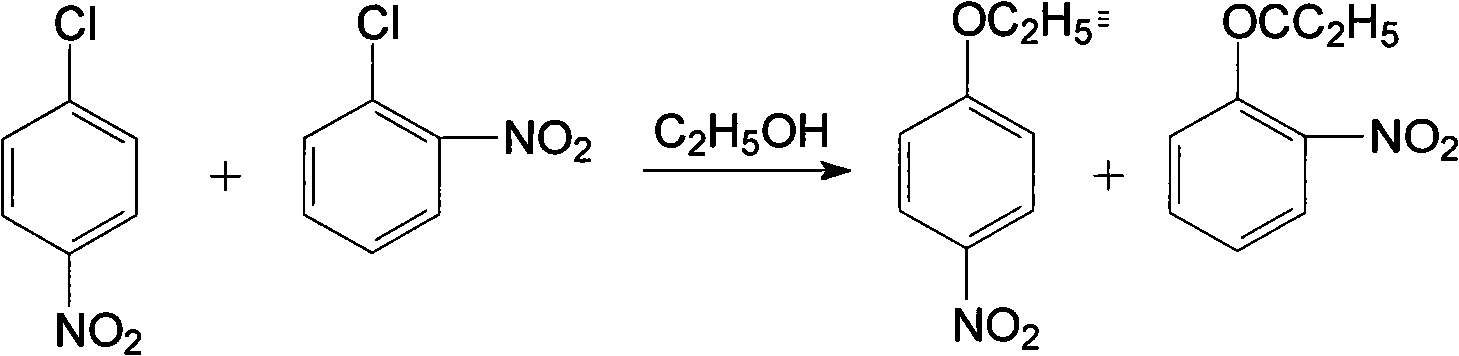

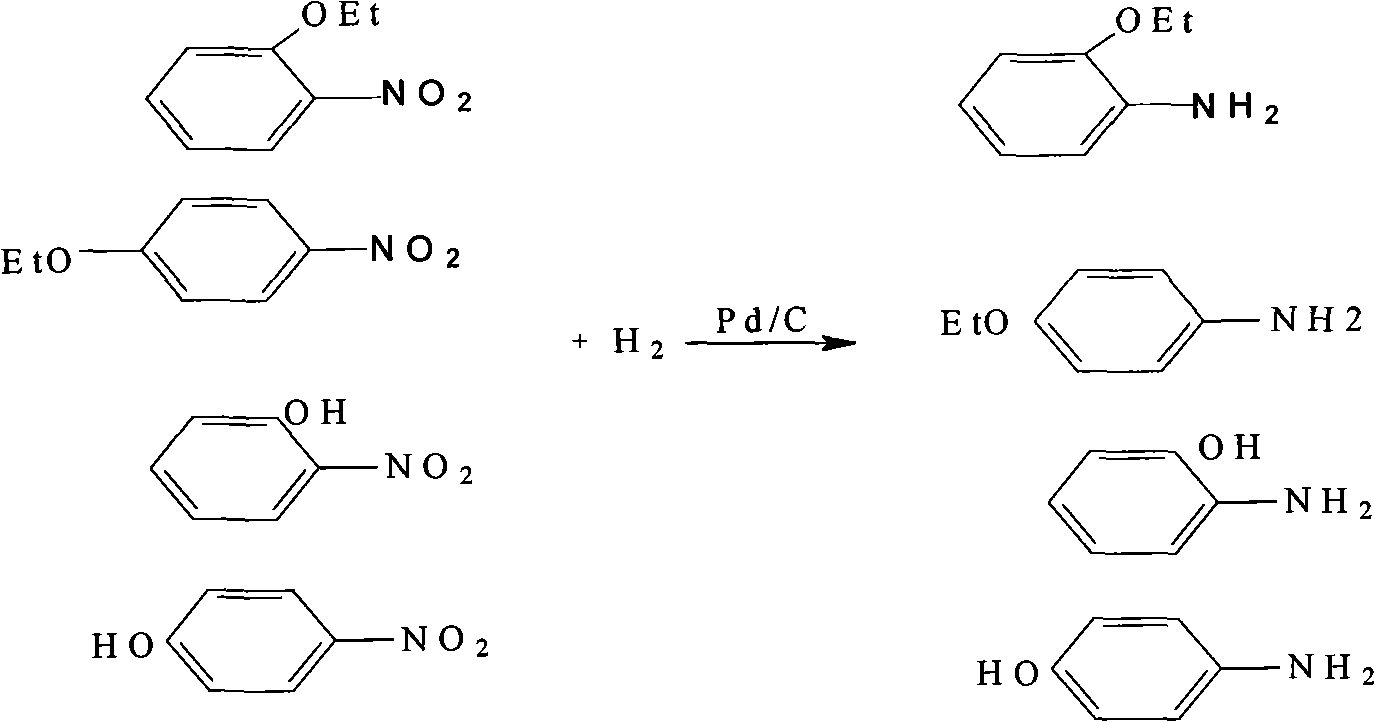

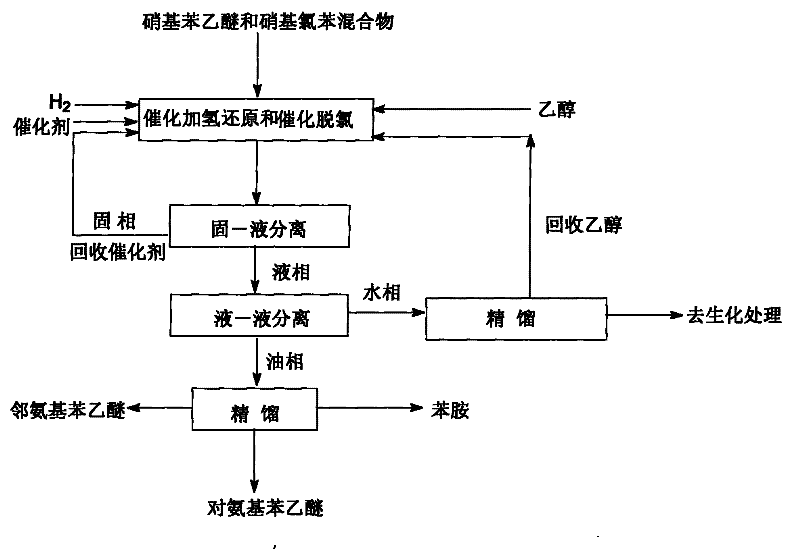

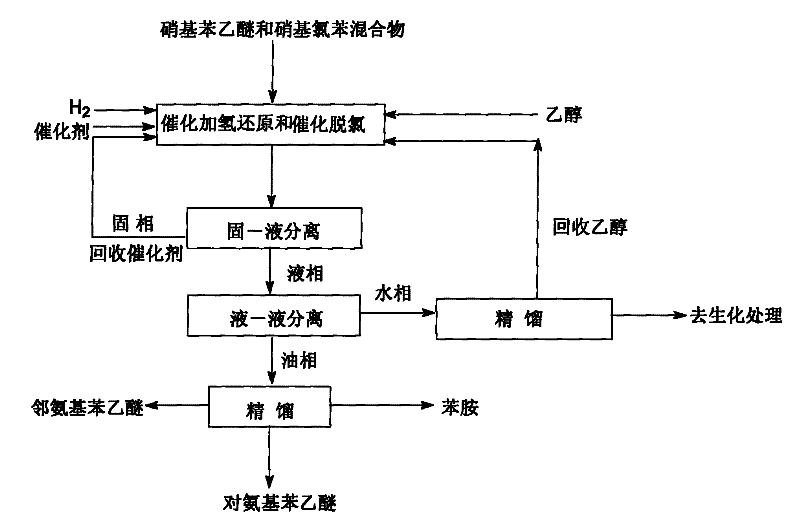

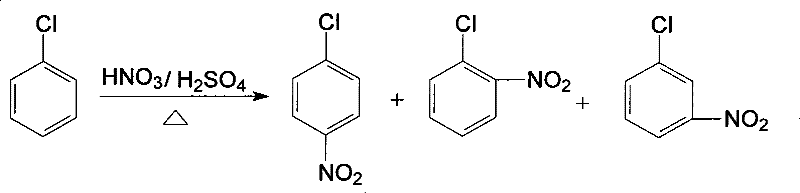

Process for preparing phenetidine and amino phenol by using mixture of nitrophenetol and nitrophenol as raw materials

ActiveCN101307003AReduce generationLow costOrganic compound preparationAmino compound preparationDistillationOil phase

The invention relates to a process for preparing phenetidine and aniline by taking a mixture of nitrophenetol and nitrochlorobenzene as a raw material. The process comprises the following steps that: (1) a step of the catalytic hydrogenation reaction and the catalytic dechlorination reaction, during which, ethanol is taken as a solvent, the mixture of the nitrophenetol and the nitrochlorobenzene is taken as the raw material, catalyst is added, hydrogen is aerated; (2) a step of the solid-liquid separation, during which, solid and liquid in the material obtained from the step (1) after the catalytic hydrogenation reaction and the catalytic dechlorination reaction are separated, a liquid phase comprises phenetidine, aniline, ethanol, hydrochloride and water and is utilized in the next step; (3) a step of the liquid-liquid separation, during which, the oil phase-water phase liquid-liquid separation is performed in the material obtained in the step (2), the phenetidine and aniline in the oil phase is utilized in the next step; (4) a step of distillation separation, during which, the distillation separation is performed in the oil phase to produce the products of para aminophenyl ethyl ether, o-phenetidineand aniline. The process for preparing the aminoanisole and the aniline has the advantages that: (1) the cost is low, the preliminary treatment step is saved, and the process is simple; (2) the process is clean, the energy consumption is low, and the 'three wastes' are little; (3) the purity of the product is high.

Owner:江苏仁欣化工股份有限公司

Commodity theft-proof dye

The invention relates the dyestuff agent used for commodity anti-theft, comprising 8-12% water-based ink, 52-58% deicing fluid, 2-4% auxiliary coloring agent and demineralized water. The water-based ink is made by mixing the water-soluble dye, acrylic resin, acrylic ester emulsion, dispersing agent, defoaming agent and silicone, or by water-soluble acid dye or basic dye direct dyeing. The deicing fluid is ethylene alcohol or ethyl ether or ethylene glycol monobutyl ether or ethylene glycol diethyl ether or glyceryl alcohol or triethanolamine. The auxiliary coloring agent is p-nitrophenol or o-aminoazotoluene or o-phenetidine or orasol. The product can't deposit, differentiate and coagulate for long time, and the method keeps coloring agent effective.

Owner:上海齐林助剂有限公司

Process for preparing phenetidine and amino phenol by using mixture of nitrophenetol and nitrophenol as raw materials

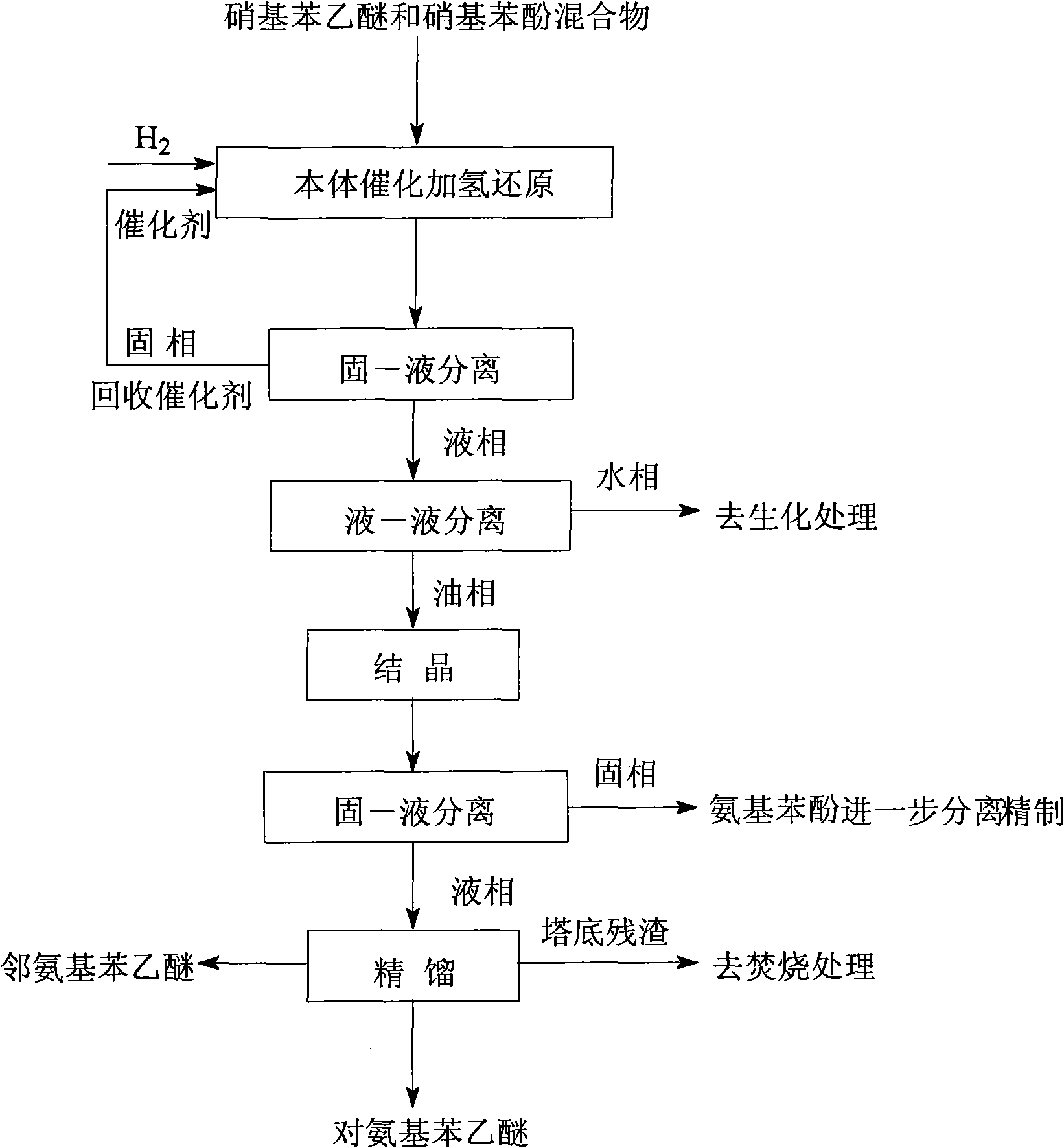

ActiveCN101307001AReduce generationLow costOrganic compound preparationChemical recyclingDistillationOil phase

The invention relates to a process for preparing phenetidin and amino phenol by taking a mixture of nitrophenetol and nitrophenol as a raw material. The process comprises the following steps that: (1) a step of the catalytic hydrogenation reaction to a body, during which, the mixture of the nitrophenetol and the nitrophenol is taken as the raw material, catalyst is added, hydrogen is aerated; (2) a step of the solid-liquid separation, during which, solid and liquid in the material obtained from the step (1) after the catalytic hydrogenation reaction are separated, a liquid phase is utilized in the next step; (3) a step of the liquid-liquid separation, during which, the oil phase-water phase liquid-liquid separation is performed in the material obtained in the step (2), an oil phase is utilized in the next step; (4) a step of crystallization; (5) a step of solid-liquid separation, during which, solid and liquid of the material crystallized in the step four are separated, the solid phase is paraaminophenol and ortho-aminophenol, the phenetidine in the liquid phase is utilized in the next step; (6) a step of distillation separation, during which, the products of para aminophenyl ethyl ether and o-phenetidine are obtained. The process for preparing the aminoanisole and the aniline has the advantages that: the cost is low, the preliminary treatment step is saved, and the process is simple; and the process is clean, the energy consumption is low, and the 'three wastes' are little.

Owner:江苏仁欣化工股份有限公司

Anti-aging agent AW preparation method

The invention belongs to the technical field of fine chemical industry, and relates to an anti-aging agent AW preparation method, wherein the anti-aging agent AW is prepared under the action of a catalyst by using p-phenetidine and acetone as raw materials, the catalyst is a titanate-based catalyst, the reaction temperature is 100-200 DEG C, the reaction time is 3-10 h, a molar ratio of p-phenetidine to acetone is 1:1-6, a molar ratio of titanate to p-phenetidine is 0.0005-0.05:1, the single-pass conversion rate can achieve more than 97% based on p-phenetidine, and the AW content of the product can reach 99.5%. According to the present invention, the anti-aging agent AW is prepared by using the titanate-based catalyst, such that the advantages of simple operation, low catalyst consumption,low cost, high content of effective body and the like can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

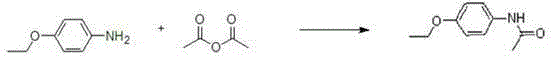

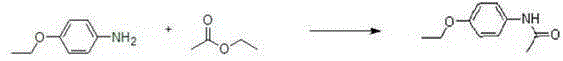

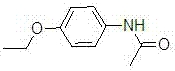

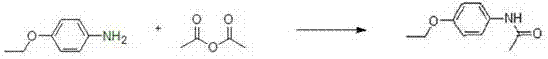

Preparation and crystallization method of phenacetin

ActiveCN105237431AHigh yieldImprove stabilityOrganic compound preparationCarboxylic acid amide separation/purificationChemical industryOrganic solvent

The invention discloses a preparation and crystallization method of phenacetin, and belongs to the field of chemical industry. According to the preparation and crystallization method, p-phenetidine is reacted with an acid in water so as to obtain a p-phenetidine salt; the p-phenetidine salt is reacted with an anhydride in a buffer solution system; after reaction, a mixed solution of water and an organic solvent is added into an obtained reaction solution, and phenacetin crystals are obtained via stirring. Product yield is high; two-step reaction total yield is higher than 92%; the obtained products are crystalline solids; stability is high; purity is high, and is higher than 99%; reaction time is short; reaction conditions are mild; product separation operation is simple; direct filtering separation can be carried out after reaction; and batch production period is shortened greatly.

Owner:济南鼎皓医药科技有限公司

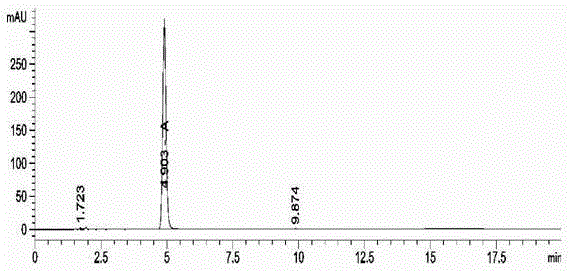

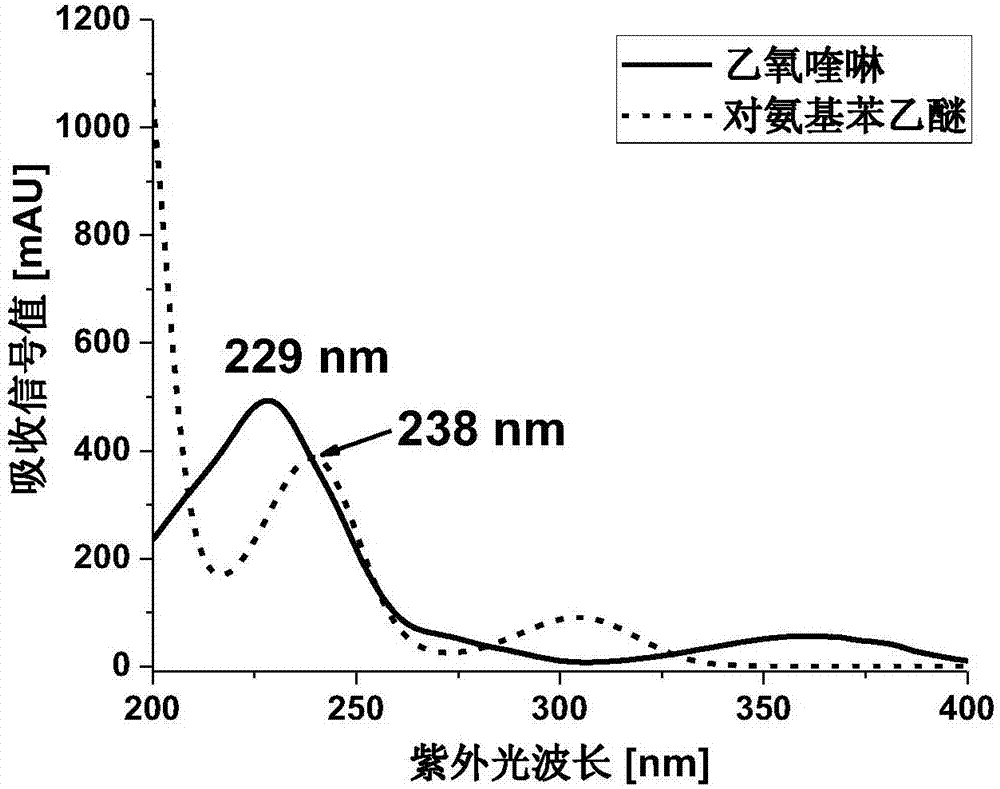

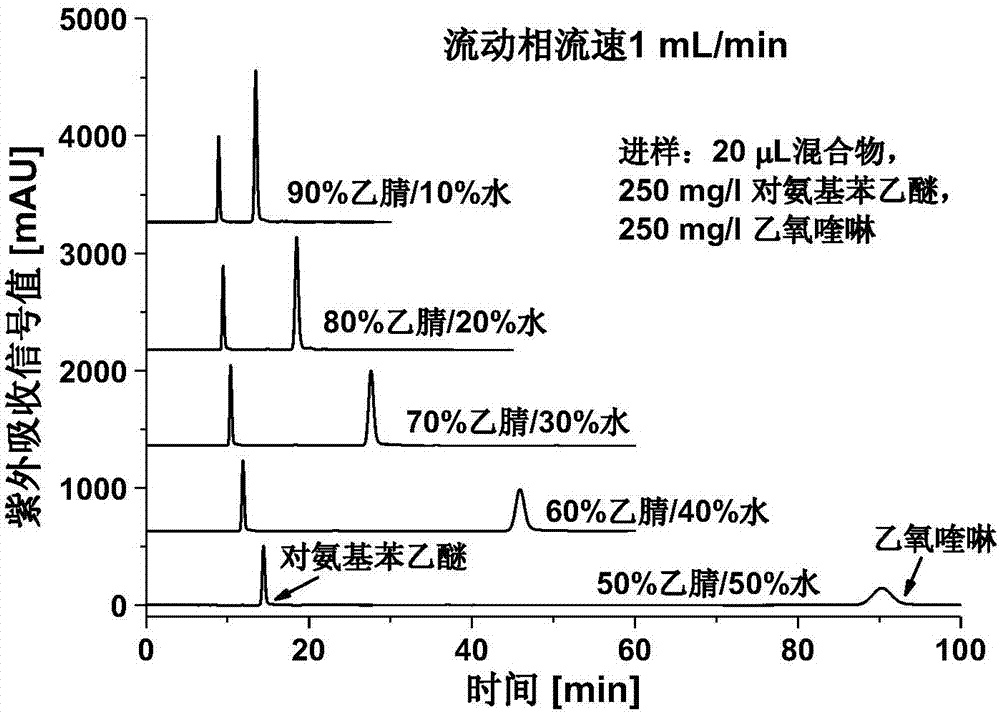

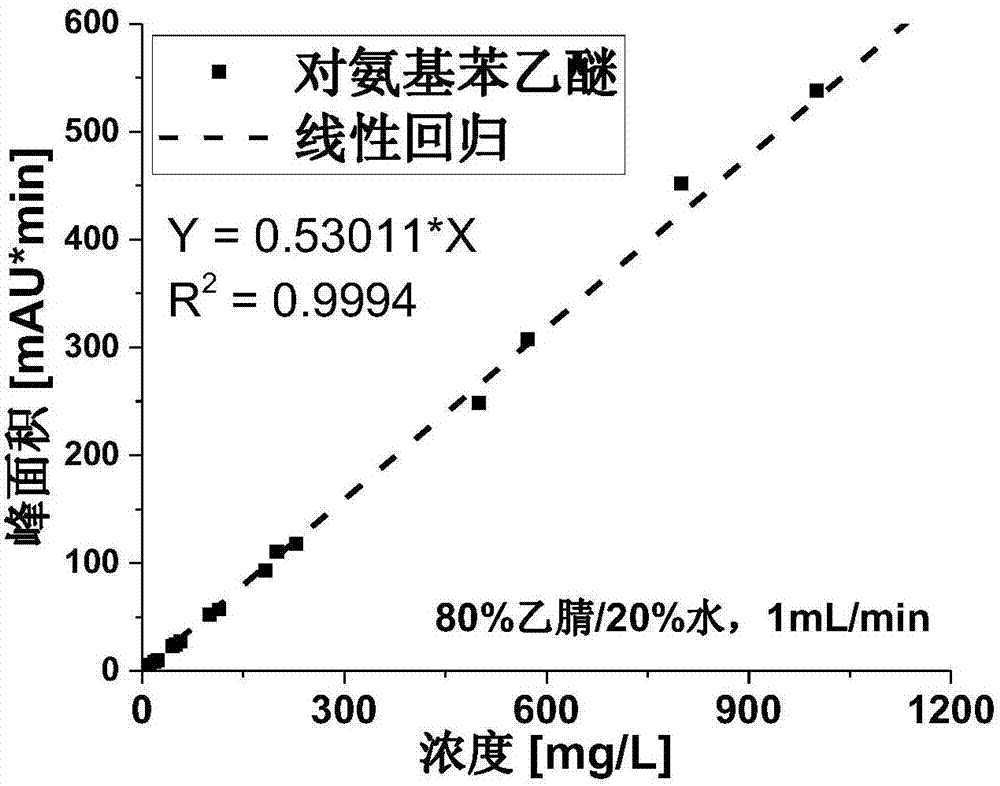

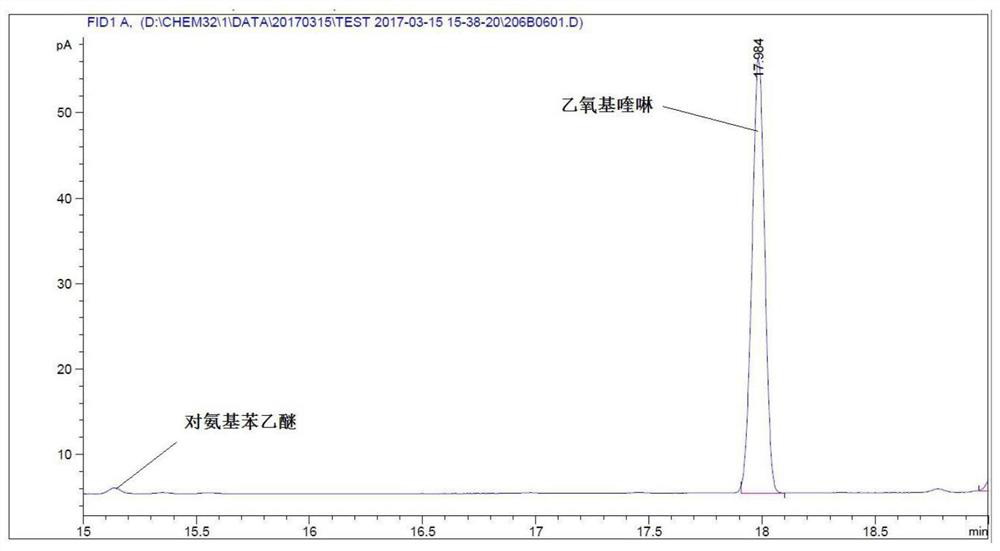

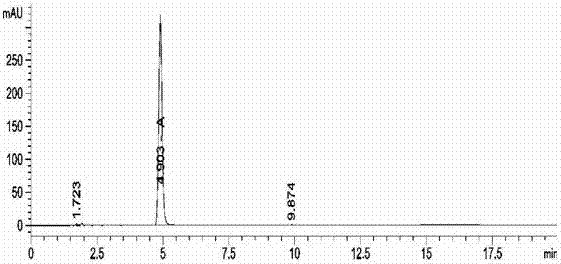

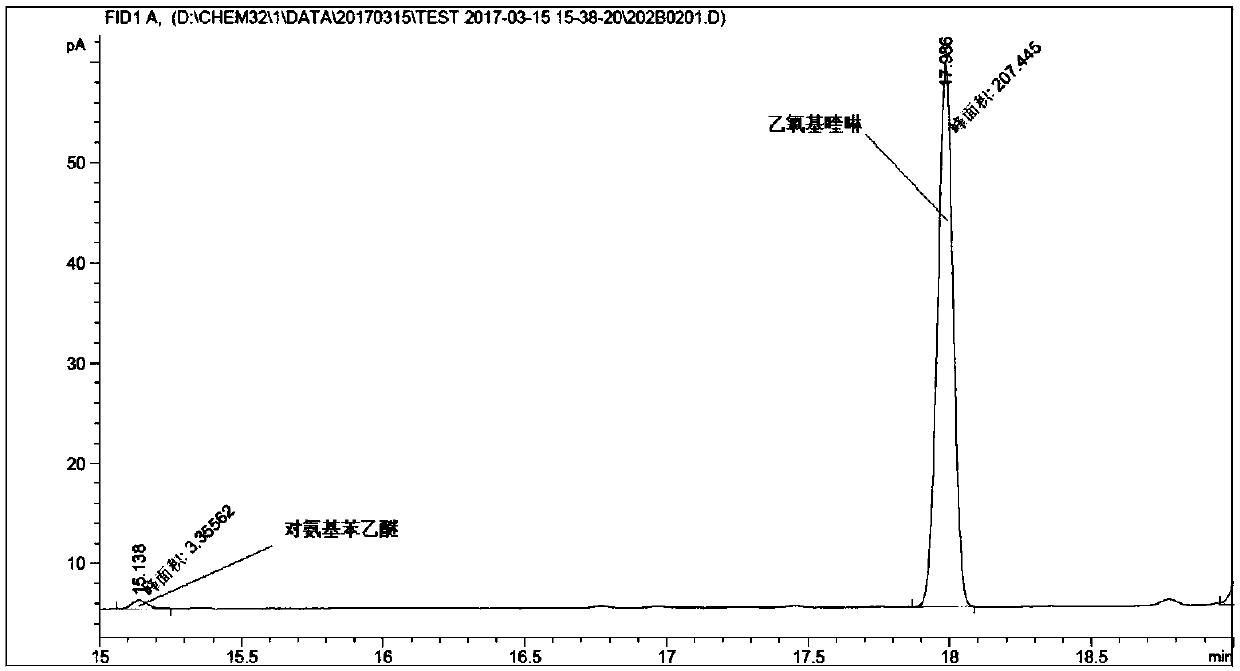

Detection method for content of p-phenetidine impurity in ethoxyquinoline product

InactiveCN107422045AImprove stabilityStrong data reproducibilityComponent separationColumn temperatureSilica gel

A high performance liquid chromatography analysis method for a p-phenetidine impurity in an ethoxyquinoline product includes the steps of: 1) preparation of an ethoxyquinoline product solution: weighing 1 g of a sample solution in a 50 ml volumetric flask, and diluting the sample solution with an acetonitrile organic solvent to certain volume, and filtering the solution to prepare a to-be-detected sample; 2) performing HPLC quantitative analysis to the ethoxyquinoline product and the p-phenetidine impurity therein by using a non-polar HPLC column with an ultraviolet detector being 200-400 nm in wavelength, wherein the stationary phase is a 10 [mu]m reversed-phase chromatographic column silica gel filler and the mobile phase is a mixture liquid of liquid chromatography-pure acetonitrile and deionized water, liquid chromatography detection conditions including: column temperature being 30 DEG C, sampling size being 100 [mu]L and wavelength being 238 nm. The analysis method can completely separate the ethoxyquinoline and p-phenetidine, has accurate analysis result and high analysis efficiency, and is simple in sample treatment.

Owner:EAST CHINA UNIV OF SCI & TECH +1

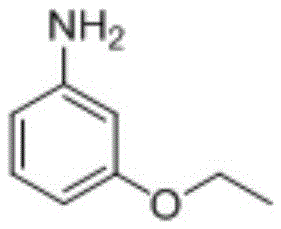

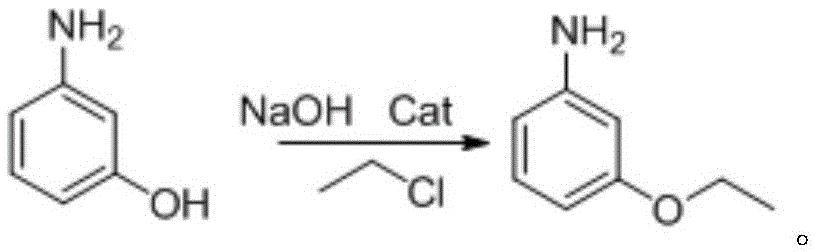

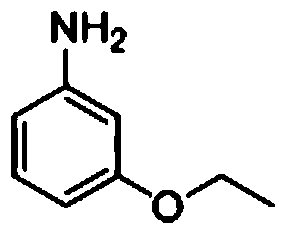

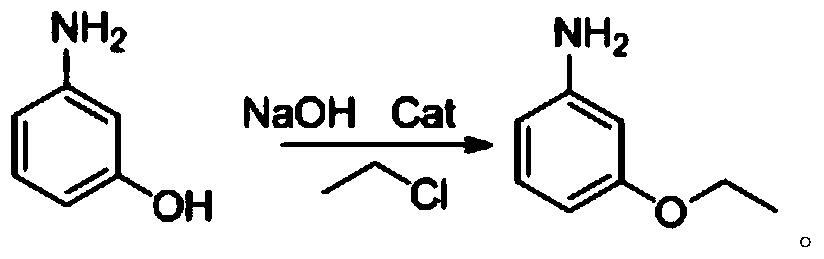

Synthesis method of m-phenetidine by one-pot reaction

ActiveCN105481702AEasy to operateFew reaction stepsOrganic compound preparationAmino-hyroxy compound preparationM-aminophenolDistillation

The invention discloses a synthesis method of m-phenetidine by a one-pot reaction. The method comprises the following steps: m-aminophenol, alkali and a solvent are thrown into a reaction vessel, and then only an alkylating agent or a catalyst and an alkylating agent are added at the same time, after materials are added, the reaction vessel is enclosed, and stirring is carried out for 0.5-1 hour at room temperature; the temperature is raised to 40-80 DEG C, a reaction is carried out for 1-8 hours, after the reaction, obtained reaction solution is cooled to room temperature and filtered, and filtrate is obtained; reduced pressure distillation for the filtrate is carried out, and m-phenetidine is obtained. The synthesis method of m-phenetidine has the characteristics of low reaction temperature, high safety performance, convenient operation, high purity and high yield of the product, etc.

Owner:ZHEJIANG HONGSHENG CHEM IND

Preparation method of anti-aging agent AW

PendingCN114315714AReduce consumptionLow costOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystProcess engineering

The invention belongs to the technical field of fine chemical engineering, and relates to an anti-aging agent AW and a preparation method thereof. The anti-aging agent AW is prepared by taking p-aminophenetole and acetone as raw materials under the action of a composite catalyst consisting of hydrochloric acid and a sulfonic acid catalyst. According to the technical scheme provided by the invention, p-aminophenetole and acetone are used as raw materials to prepare the anti-aging agent AW under the action of the composite catalyst, and an intermittent or continuous production process can be adopted. The conversion per pass of p-aminophenetole can reach 99% or above, the AW content of the product can reach 99.5-99.8%, and compared with the prior art, the method has the advantages that the operation is simple, the catalyst consumption is low, the cost is lower, and the content is higher.

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD +1

A kind of adsorption impurity removal method of high-purity ethoxyquinoline

The invention belongs to the separation and purification of materials in the field of chemical industry, and specifically relates to an adsorption and impurity removal method for high-purity ethoxyquinoline, an adsorption device designed to ensure the effective separation of product ethoxyquinoline and impurity p-aminophenethyl ether, and obtain high-purity ethoxyquinoline Pure, high value-added product ethoxyquinoline. First, a fixed bed is used to separate the impurity p-aminophenethyl ether. When the adsorbent is saturated, the adsorbent is regenerated by washing with eluent and vacuum high-temperature desorption to complete the entire adsorption-desorption cycle. The invention can effectively separate ethoxyquinoline and p-aminophenetole, greatly improve the purity of the product ethoxyquinoline, and ensure that the concentration of p-aminophenetole in the product is less than 2.5ppm. The method has broad application prospects in the field of ethoxyquinoline production and separation and purification.

Owner:TAIXING RUITAI CHEM

A kind of high-efficiency gasoline detergent and preparation method thereof

ActiveCN109181797BIncrease repulsionIncrease the number ofLiquid carbonaceous fuelsPtru catalystSolid acid

The invention discloses a high-efficiency gasoline detergent and a preparation method thereof, which belong to the technical field of a detergent. The method obtains a solid acid high-efficiency catalyst by using zirconium oxychloride and tungsten phosphate, a boric acid ester additive is added to modify an intermediate, and has good dispersing property in gasoline, the polyisobutylene segment chain in the molecules is combined and bounded with the oily particles to prevent carbon deposition, and the fuel thermal stability and oxidation resistance can be kept. The method introduces the boric acid ester additive in the preparation process of a clean active additive, so that the mechanical life prolongation and fuel consumption control can be realized. The p-phenetidine and glycerol are catalyzed by the catalyst, which increases an alkylation structure of an ethoxy group and an amino group, and the purpose of eliminating the detonation combustion can be achieved. The method adds n-octylalcohol and n-dodecyl alcohol for mixing to promote the combustion of gasoline, so that the cleaning effect in a fuel process is exerted. The high-efficiency gasoline detergent solves the problems that the current gasoline detergents have poor cleaning and carbon-removal effects, cannot reduce fuel consumption, and cannot prevent engine wear.

Owner:青岛涌泉华能源科技有限公司

A kind of preparation and crystallization method of phenacetin

ActiveCN105237431BHigh yieldImprove stabilityOrganic compound preparationCarboxylic acid amide separation/purificationChemical industryOrganic solvent

The invention discloses a preparation and crystallization method of phenacetin, and belongs to the field of chemical industry. According to the preparation and crystallization method, p-phenetidine is reacted with an acid in water so as to obtain a p-phenetidine salt; the p-phenetidine salt is reacted with an anhydride in a buffer solution system; after reaction, a mixed solution of water and an organic solvent is added into an obtained reaction solution, and phenacetin crystals are obtained via stirring. Product yield is high; two-step reaction total yield is higher than 92%; the obtained products are crystalline solids; stability is high; purity is high, and is higher than 99%; reaction time is short; reaction conditions are mild; product separation operation is simple; direct filtering separation can be carried out after reaction; and batch production period is shortened greatly.

Owner:济南鼎皓医药科技有限公司

The method for one-pot synthesis of m-aminophenethyl ether

ActiveCN105481702BEasy to operateFew reaction stepsOrganic compound preparationAmino-hyroxy compound preparationM-aminophenolDistillation

Owner:ZHEJIANG HONGSHENG CHEM IND

Preparation process of o-aminophenetole

PendingCN114478277ANo need for high temperature and high pressureImprove securityOrganic compound preparationAmino-hyroxy compound preparationNitrobenzeneDrug product

The invention relates to a preparation process of o-aminophenetole, which is characterized in that nitrobenzene, sulfuric acid and ethanol mixture are used as raw materials to prepare the o-aminophenetole, and the process is used for preparing the o-aminophenetole and ammonium sulfate through the steps of catalytic hydrogenation reduction, solid-liquid separation, water addition for dissolution, solid-liquid separation, acid-base neutralization, oil-water separation and the like. According to the method, nitrobenzene is adopted to replace o-nitrochlorobenzene, high temperature and high pressure are not needed, three wastes are not discharged, the method is a safe, environment-friendly and efficient o-aminophenetole synthesis process, and the purity of the obtained product reaches 99.90% or above and completely reaches the drug standard.

Owner:江苏普洛德化学科技有限公司

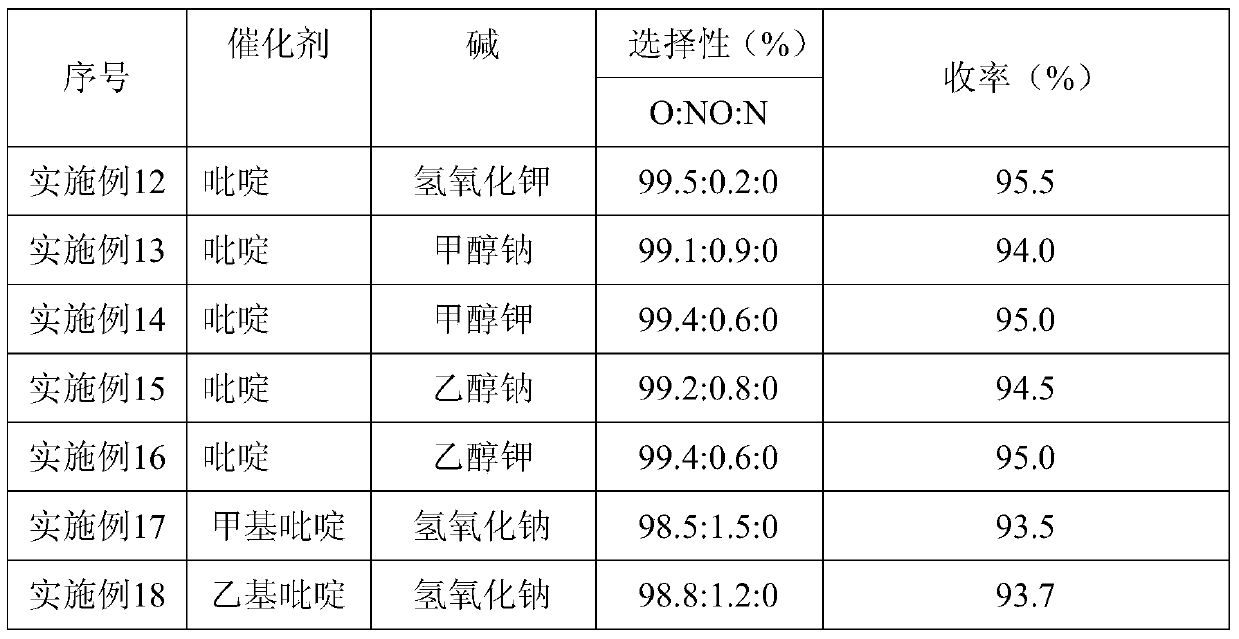

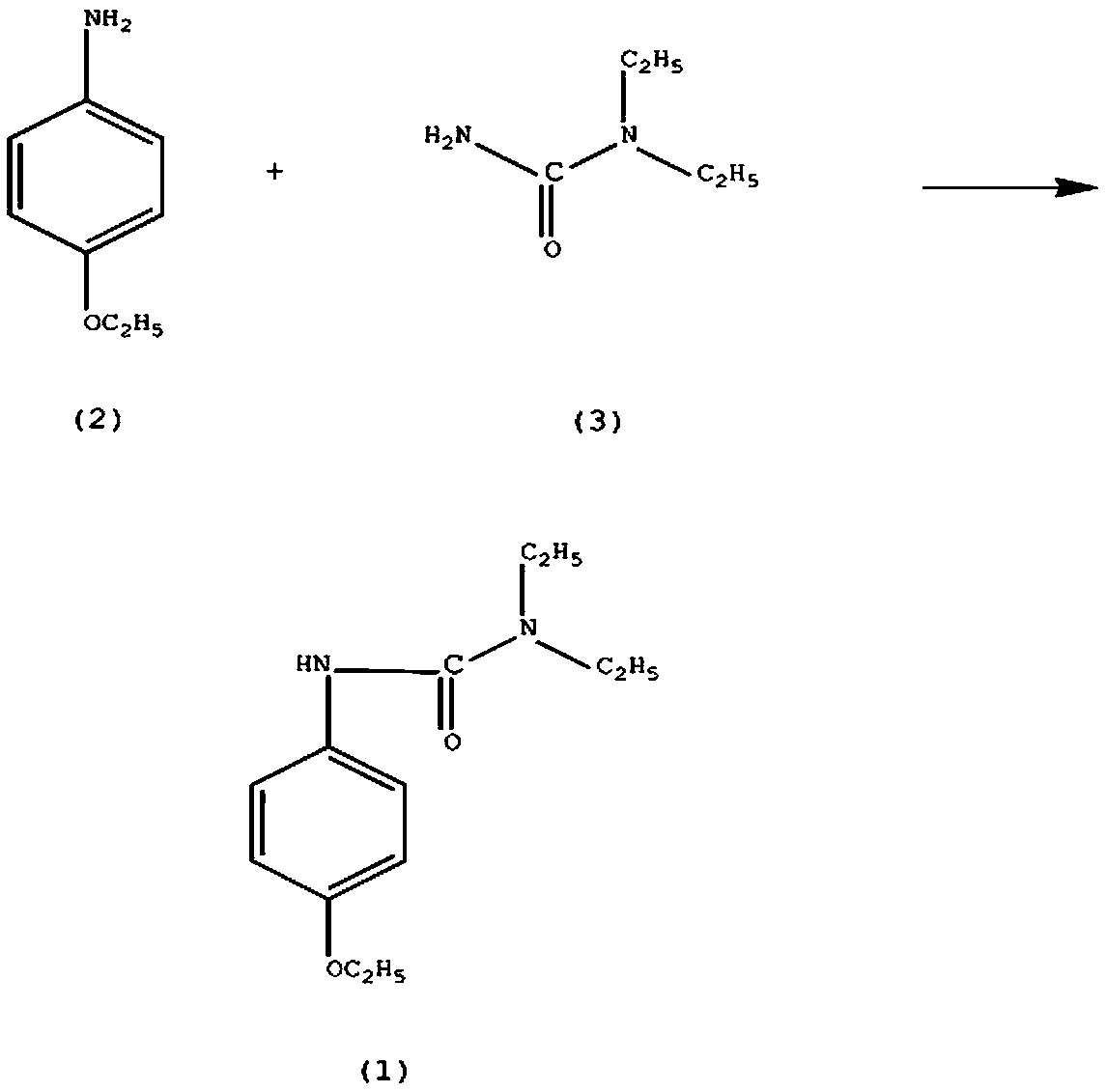

Synthesis method of celiprolol drug intermediate 3-(4-enthoxyphenyl)-1,1-diethylurea

InactiveCN105503658AReduce intermediate linksLow reaction temperatureUrea derivatives preparationOrganic compound preparationFiltrationSynthesis methods

A synthesis method of celiprolol drug intermediate 3-(4-enthoxyphenyl)-1,1-diethylurea comprises steps as follows: 0.22 mol of p-phenetidine, 0.45-0.47 mol of sodium hydrogen sulfite and 80-90 ml of tetrahydrofuran are added to a reaction container provided with a stirrer and a dropping funnel, the stirring speed is controlled within 130-160 rpm, the solution temperature is controlled within 35-40 DEG C, 0.25-0.27 mol of N,N-diethylamino formamide is dropwise added, the addition time is controlled within 4-5 h, the solution is stirred continuously to react for 30-35 h, 300-350 ml of a sodium chloride solution is added, the pH of the solution is adjusted to range from 4 to 5 with an oxalic acid, the solution reacts continuously for 4-5 h, solids are separated out, the solution is cooled to the temperature of 10-15 DEG C, filtration, washing with a salt solution, dehydration with a dehydrating agent and recrystallization in hexane are performed, and 3-(4-enthoxyphenyl)-1,1-diethylurea is obtained.

Owner:CHENGDU DONG DIAN AI ER TECH

Method for preparing ethoxyquinoline by wo3/ac/so3h synergistic catalysis

The invention discloses a WO 3 / AC / SO 3 H synergistically catalyzes the method for preparing ethoxyquinoline, and in a reactor equipped with a stirrer, a thermometer and a condenser tube, add p-aminophenethyl ether, toluene and WO 3 / AC / SO 3 H catalyst; when the reaction solution reaches the temperature, add acetone dropwise to the reactor; after the dropwise addition of acetone is completed, reflux the reaction, and TLC detects the end point of the reaction; neutralize with aqueous sodium bicarbonate solution, stand to separate, and extract the water phase with toluene , Combine the organic phases; dry over anhydrous sodium sulfate, filter, evaporate the solvent under normal pressure, and then distill under reduced pressure to obtain brown viscous oily liquid ethoxyquinoline. The present invention uses solid catalyst WO with two functions of superacid and sulfonic acid 3 / AC / SO 3 H synergistically catalyzes the condensation of p-aminophenethyl ether and acetone to prepare ethoxyquinoline, which can significantly shorten the reaction time, reduce by-products, and is easy to operate, and has industrial application prospects.

Owner:淮安市润龙科技有限公司

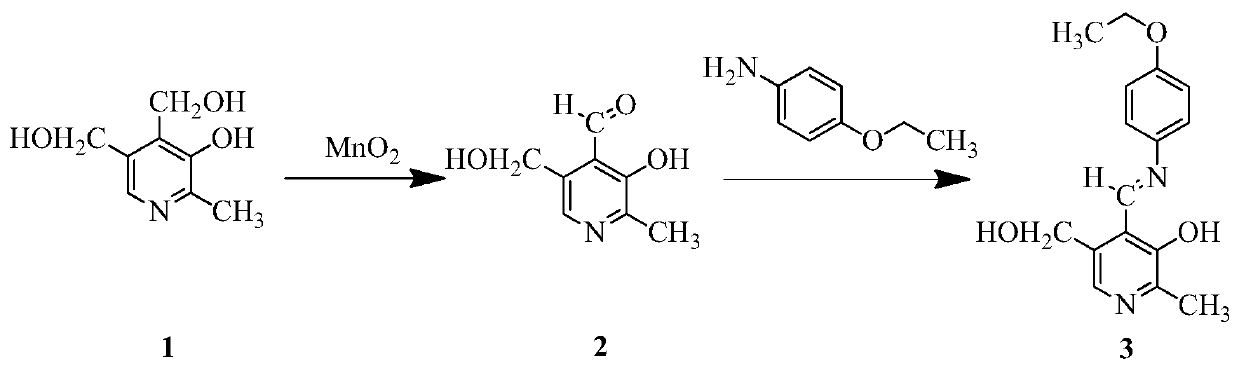

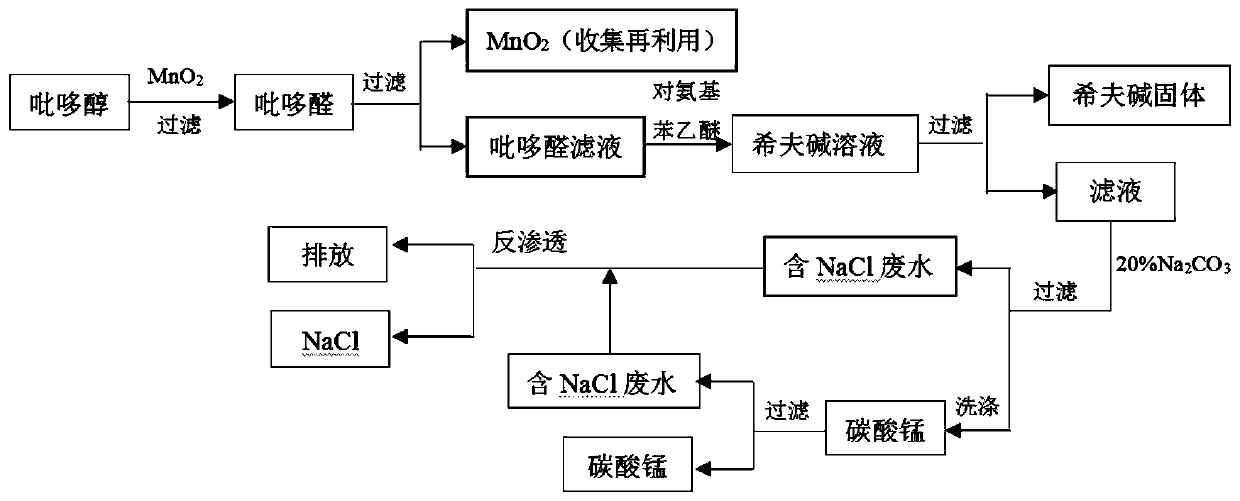

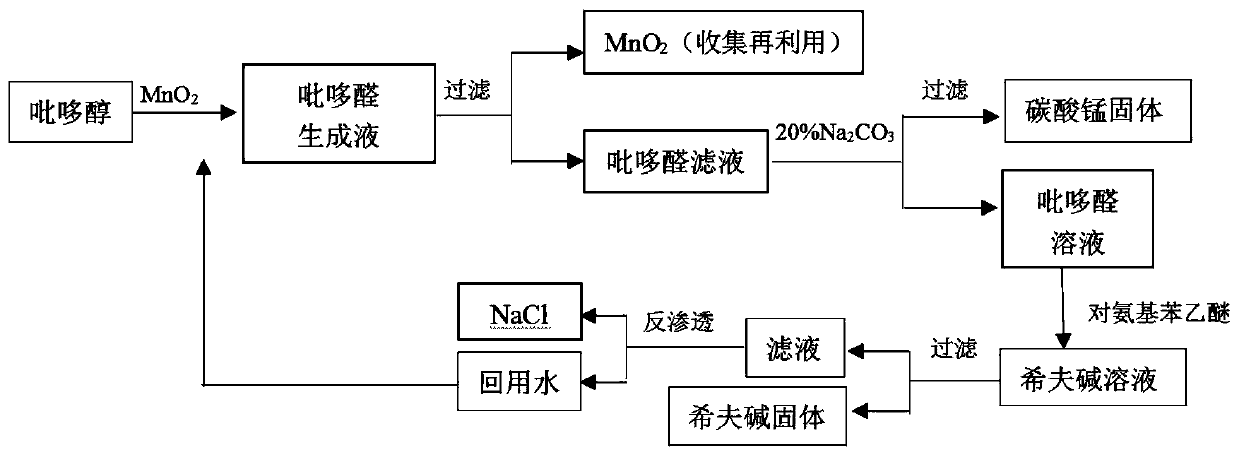

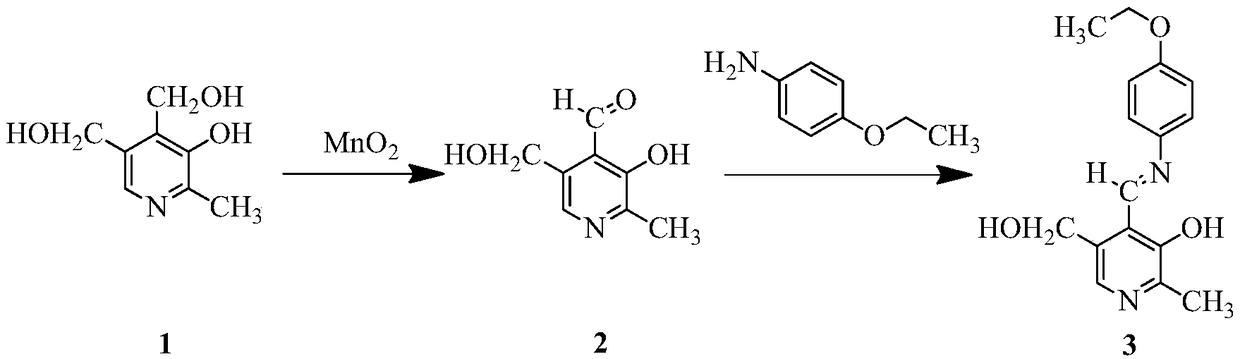

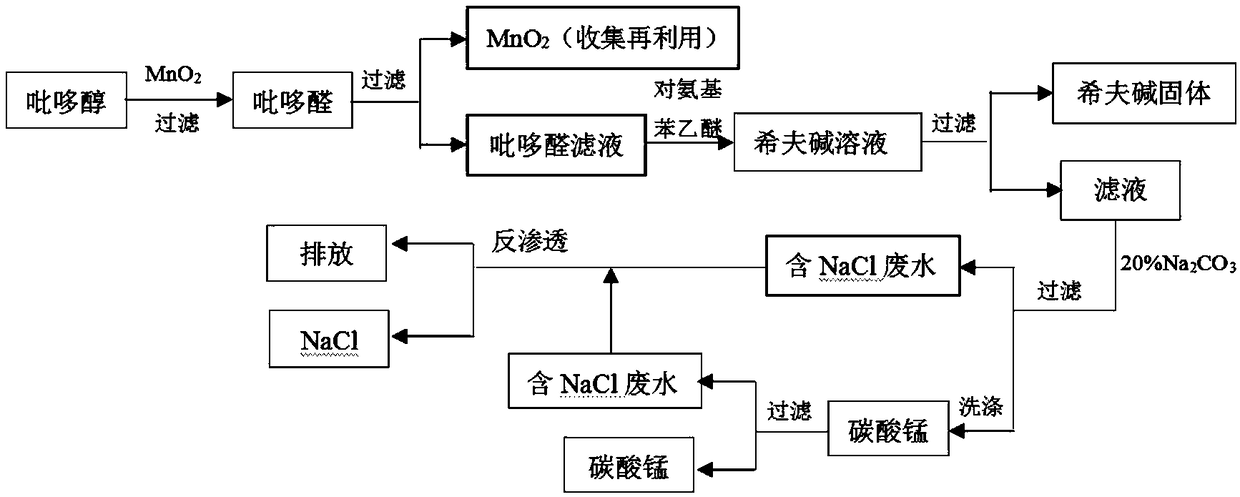

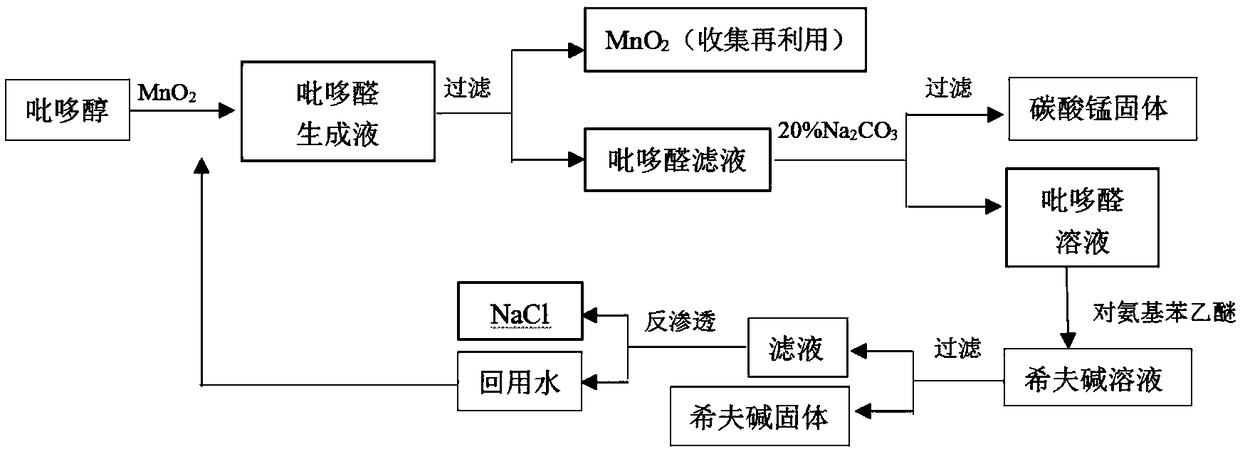

A kind of recycling method of pyridoxal manganese-containing wastewater

ActiveCN108754160BReduce concentrationHigh yieldOrganic chemistryProcess efficiency improvementSodium bicarbonateManganese(II) carbonate

The invention discloses a recycling method for pyridoxal manganese-containing wastewater and belongs to the technical field of wastewater treatment. The method includes the steps that manganese-containing pyridoxal filtrate with manganese dioxide filtered out after filtering and a sodium carbonate solution or a sodium bicarbonate solution are subjected to a first-time reaction, then filtering is performed, and a pyridoxal solution and manganese carbonate solids are obtained; filtering is performed after the pyridoxal solution and p-phenetidine are subjected to a second-time reaction, and Schiff base solids and filtrate are obtained; and finally, the filtrate is filtered, and NaCL solids and recycled water are obtained. By utilizing the method, the concentration of Mn2+ in the pyridoxal manganese-containing wastewater can be effectively lowered to 0.5 mg / L, the manganese removing rate is increased to 95%, and the Schiff base yield is increased to 90%; and besides, the purity of manganese carbonate recycled through the method reaches up to 90%, and quality is good.

Owner:江苏香地化学有限公司

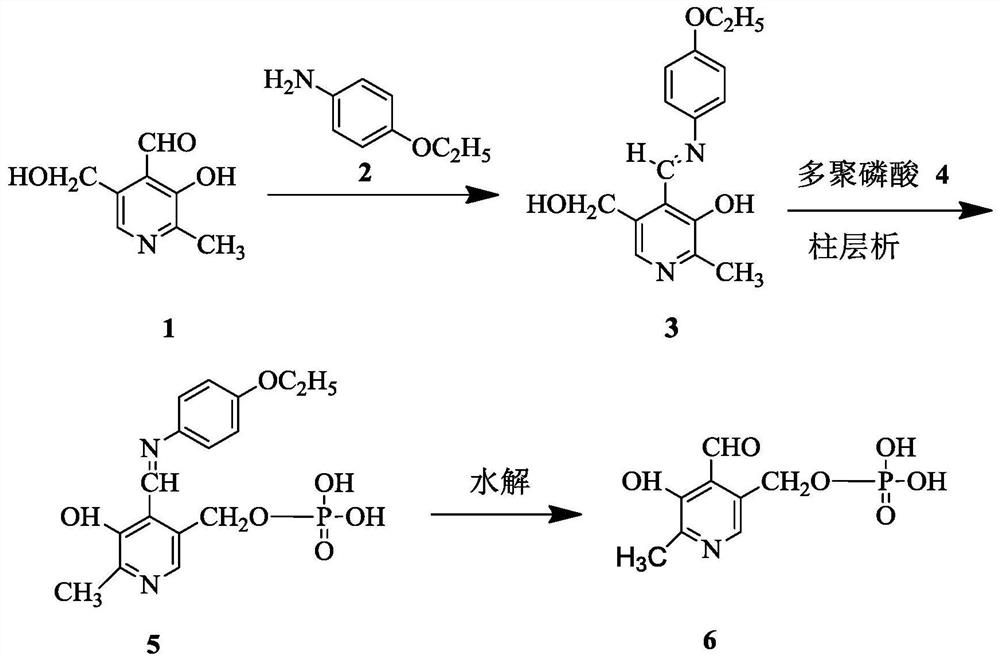

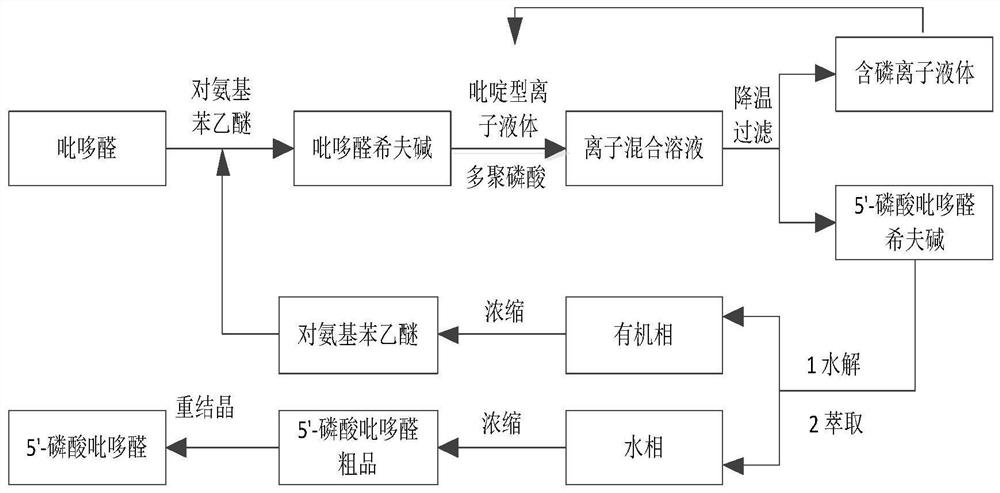

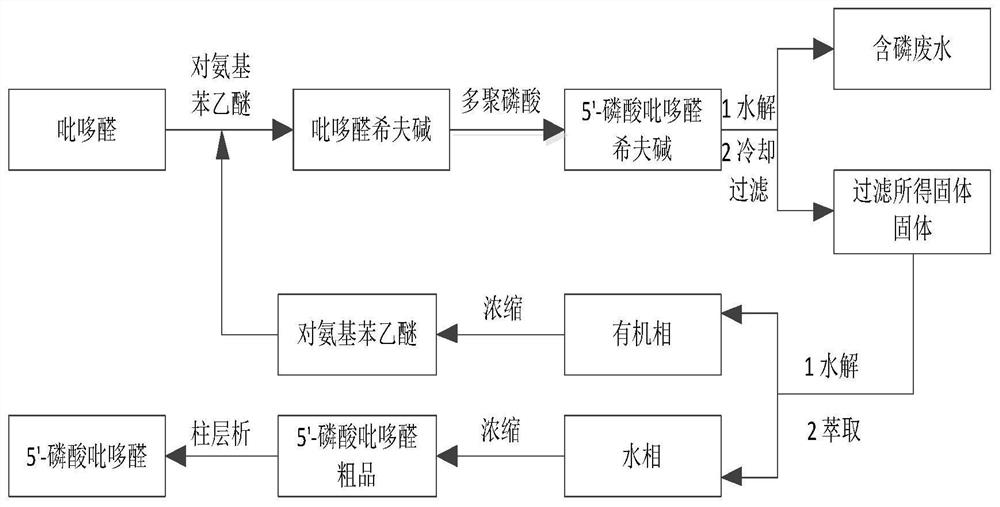

A kind of synthetic technique of 5'-pyridoxal phosphate

InactiveCN109021012BReduce usageStir evenly and reactGroup 5/15 element organic compoundsPhosphatePhosphoric acid

Owner:NANTONG SANE BIOLOGICAL +1

Preparation process of o-aminophenetole

InactiveCN113402403ANo need for high temperature and high pressureImprove securityOrganic compound preparationAmino-hyroxy compound preparationNitrobenzeneDrug product

The invention relates to a preparation process of o-aminophenetole. The is characterized in that nitrobenzene, sulfuric acid and ethanol mixture are used as raw materials to prepare the o-aminophenetole; and the process is used for preparing the o-aminophenetole and ammonium sulfate through the steps of catalytic hydrogenation reduction, solid-liquid separation, water addition for dissolution, solid-liquid separation, acid-base neutralization, oil-water separation and the like. According to the method, nitrobenzene is adopted to replace o-nitrochlorobenzene, high temperature and high pressure are not needed, three wastes are not discharged, and the method is a safe, environment-friendly and efficient o-aminophenetole synthesis process; and the purity of the obtained product reaches 99.90% or above and completely reaches the drug standard.

Owner:江苏普洛德化学科技有限公司

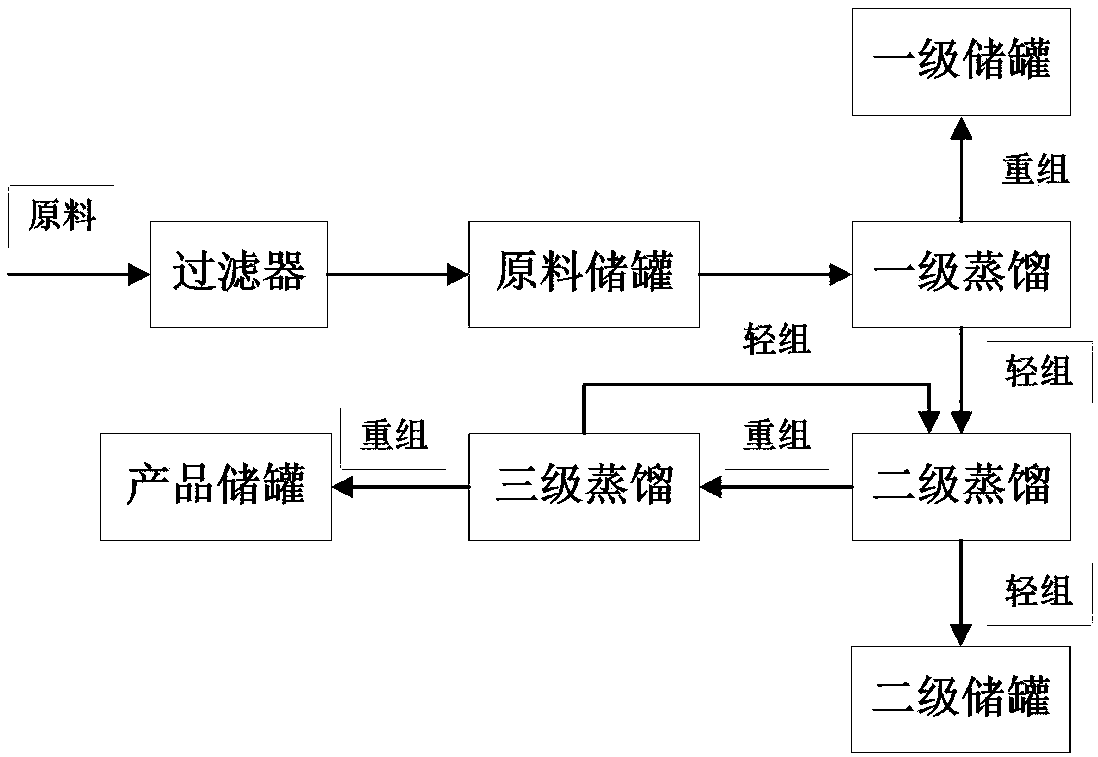

Method for extracting high-purity ethoxyquin by using multi-stage molecular distillation technology

The invention relates to a method for extracting high-purity ethoxyquin by using a multi-stage molecular distillation technology, and belongs to the field of deep processing of antioxidants. Accordingto the method, high-boiling-point impurities are removed from an ethoxyquin crude product by using first-stage molecular distillation to obtain a subsequent raw material; the p-phenetidine concentration in the raw material is reduced to 200 ppm by using second-stage molecular distillation; and finally the p-phenetidine concentration is reduced to less than 40 ppm through third-stage molecular distillation so as to meet the requirements of the European Union. According to the present invention, with the method, ethoxyquin and p-phenetidine can be effectively separated, such that the purity ofthe product ethoxyquin can be greatly improved, and the high-purity and high-added value product ethoxyquin can be obtained; and the method has broad application prospects in the field of ethoxyquin production and separation and purification.

Owner:TAIXING RUITAI CHEM

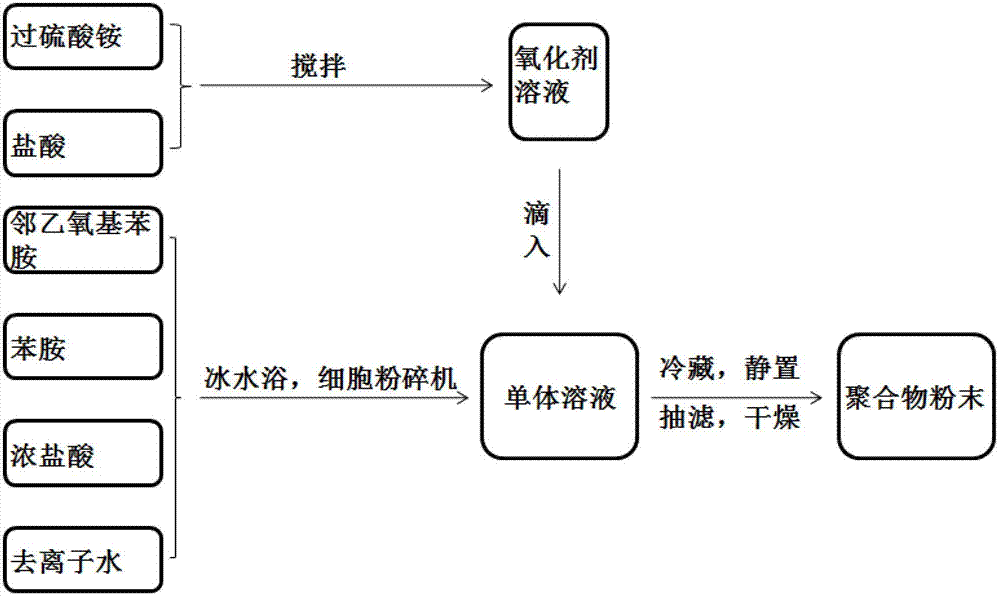

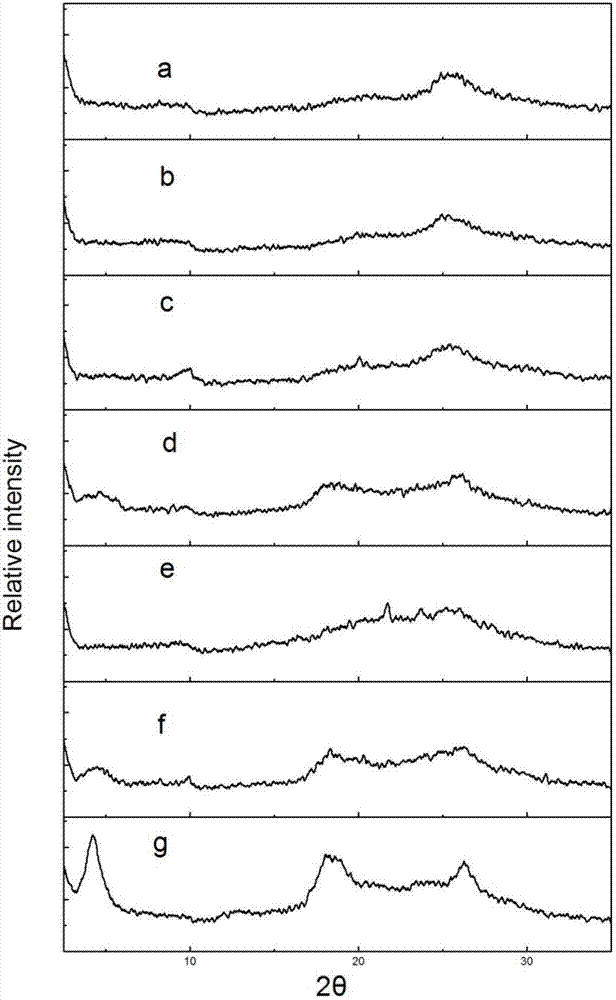

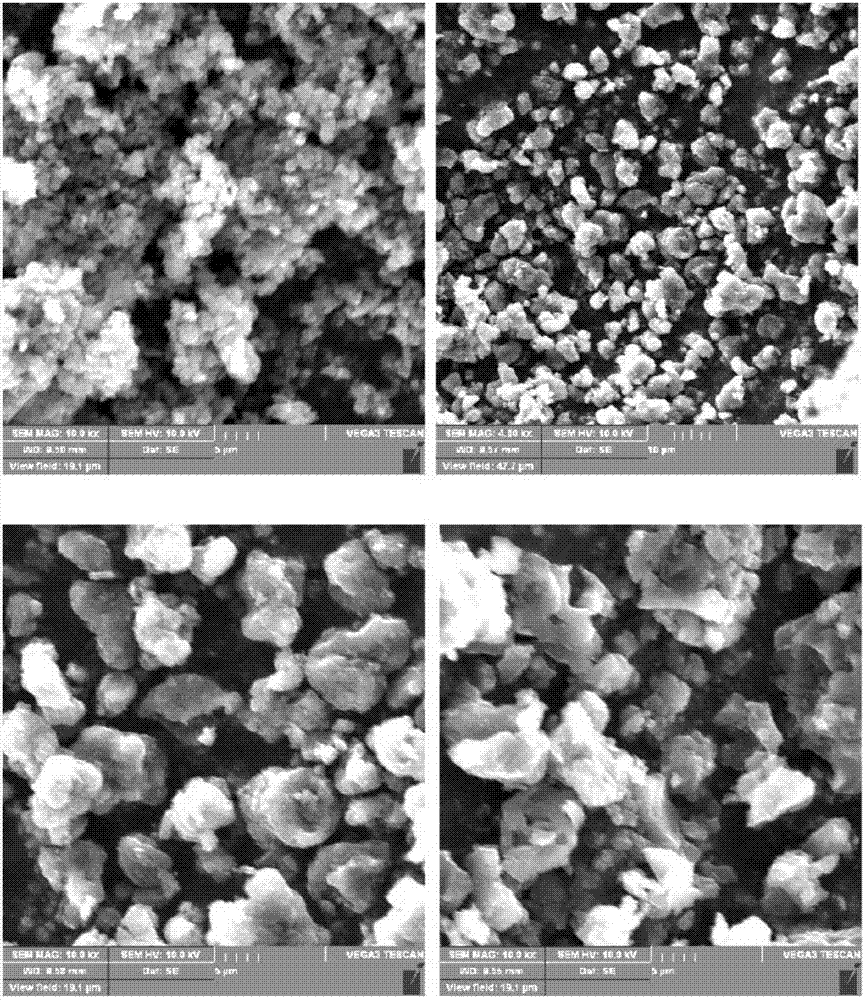

Polyaniline derivative and preparation method thereof

The invention relates to a polyaniline derivative and a preparation method thereof. The polyaniline derivative is characterized in that the components of the raw material comprise monomer aniline and monomer o-phenetidine, between which the quantity relative ratio is (0-1):(0-2). The preparation method comprises the following steps: achieving reduced pressure distillation of both the aniline and the o-phenetidine through a vacuum pump to obtain purified monomer aniline and monomer o-phenetidine; mixing the monomer aniline and the monomer o-phenetidine in proportion, adding deionized water into the mixture for dilution and then performing ultrasonography for half an hour; and dropping oxidant solution into the diluted mixture, pickling and leaching through dilute hydrochloric acid after reaction, then washing and leaching till the filtrate is colorless to obtain polymer powder, and drying the polymer powder in room temperature to obtain the polyaniline derivative. The invention has the benefits that on one hand, regulation and control of the electric conductivity of polyaniline are carried out in different orders of magnitudes, and on the other hand, the solubility of the polymer in different solvents is improved. The polyaniline derivative prepared by the method can be used for manufacturing electrochromic films with moderate electric conductivity, wide color change interval, long cycle time and high-speed response.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Ethoxy chinoline production method

InactiveCN100402500CIncrease productivityHigh Feed Grade RequirementsOrganic chemistryFood additiveQuinoline

The invention discloses a Method for production of ethyoxyl quinoline, using phenetidine and acetone to be raw matetial, doing dehydration condensation reaction between 140-160 deg C in the condition of acid catalyst and dissolvent exist. In response anaphase, replacing the dissolvent of water separater, transforming the phenetidine completely in one reaction. Using this method can omit the step of rectification; this will improve the production efficiency, make the p-phenetidine of ethyoxyl quinoline less than 1wt% and make the quality of product reach the standard of food additive.

Owner:上海福达精细材料有限公司 +1

Recycling method for pyridoxal manganese-containing wastewater

ActiveCN108754160AReduce concentrationHigh yieldOrganic chemistryProcess efficiency improvementSodium bicarbonateManganese

The invention discloses a recycling method for pyridoxal manganese-containing wastewater and belongs to the technical field of wastewater treatment. The method includes the steps that manganese-containing pyridoxal filtrate with manganese dioxide filtered out after filtering and a sodium carbonate solution or a sodium bicarbonate solution are subjected to a first-time reaction, then filtering is performed, and a pyridoxal solution and manganese carbonate solids are obtained; filtering is performed after the pyridoxal solution and p-phenetidine are subjected to a second-time reaction, and Schiff base solids and filtrate are obtained; and finally, the filtrate is filtered, and NaCL solids and recycled water are obtained. By utilizing the method, the concentration of Mn2+ in the pyridoxal manganese-containing wastewater can be effectively lowered to 0.5 mg / L, the manganese removing rate is increased to 95%, and the Schiff base yield is increased to 90%; and besides, the purity of manganese carbonate recycled through the method reaches up to 90%, and quality is good.

Owner:江苏香地化学有限公司

Process for preparing phenetidine and amino phenol by using mixture of nitrophenetol and nitrophenol as raw materials

ActiveCN101307003BReduce generationLow costOrganic compound preparationAmino compound preparationDistillationOil phase

The invention relates to a process for preparing phenetidine and aniline by taking a mixture of nitrophenetol and nitrochlorobenzene as a raw material. The process comprises the following steps that: (1) a step of the catalytic hydrogenation reaction and the catalytic dechlorination reaction, during which, ethanol is taken as a solvent, the mixture of the nitrophenetol and the nitrochlorobenzene is taken as the raw material, catalyst is added, hydrogen is aerated; (2) a step of the solid-liquid separation, during which, solid and liquid in the material obtained from the step (1) after the catalytic hydrogenation reaction and the catalytic dechlorination reaction are separated, a liquid phase comprises phenetidine, aniline, ethanol, hydrochloride and water and is utilized in the next step;(3) a step of the liquid-liquid separation, during which, the oil phase-water phase liquid-liquid separation is performed in the material obtained in the step (2), the phenetidine and aniline in the oil phase is utilized in the next step; (4) a step of distillation separation, during which, the distillation separation is performed in the oil phase to produce the products of para aminophenyl ethylether, o-phenetidineand aniline. The process for preparing the aminoanisole and the aniline has the advantages that: (1) the cost is low, the preliminary treatment step is saved, and the process is simple; (2) the process is clean, the energy consumption is low, and the 'three wastes' are little; (3) the purity of the product is high.

Owner:江苏仁欣化工股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com