A kind of adsorption impurity removal method of high-purity ethoxyquinoline

A technology of pure ethoxyquinoline and ethoxyquinoline, applied in the field of adsorption and impurity removal process of high-purity ethoxyquinoline, can solve the problem that the concentration of p-aminophenethyl ether cannot meet the new international standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

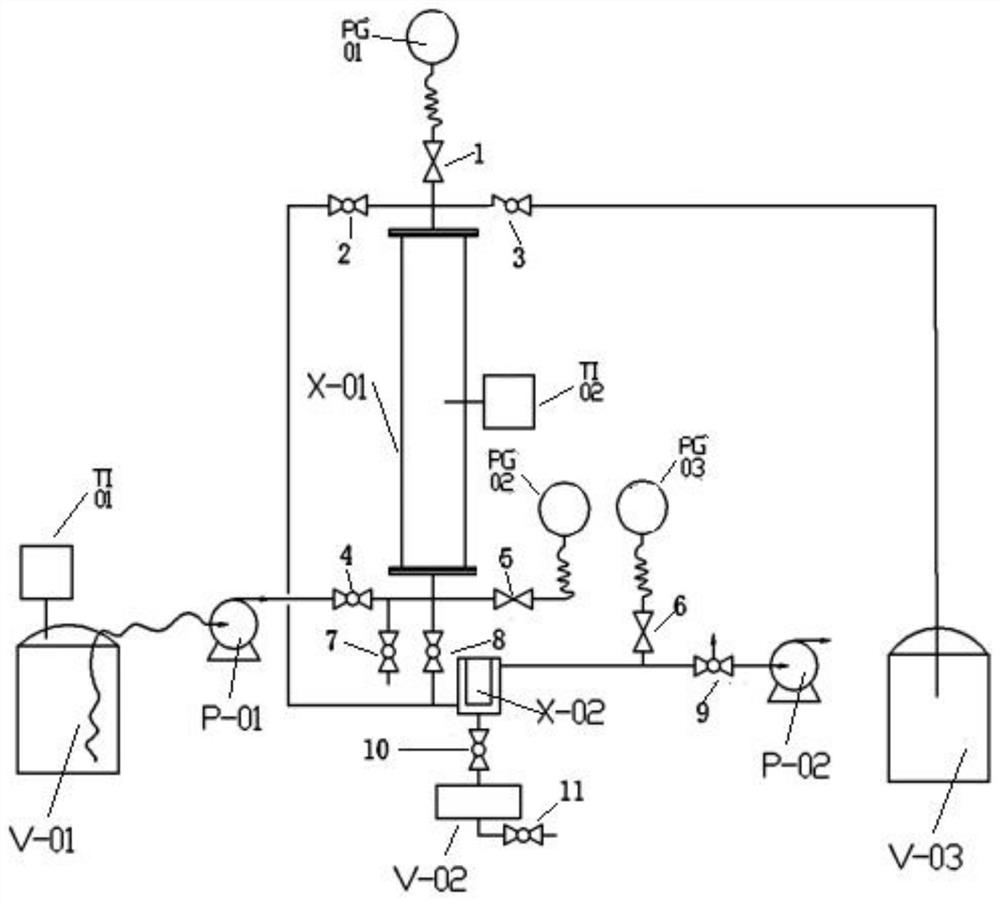

Method used

Image

Examples

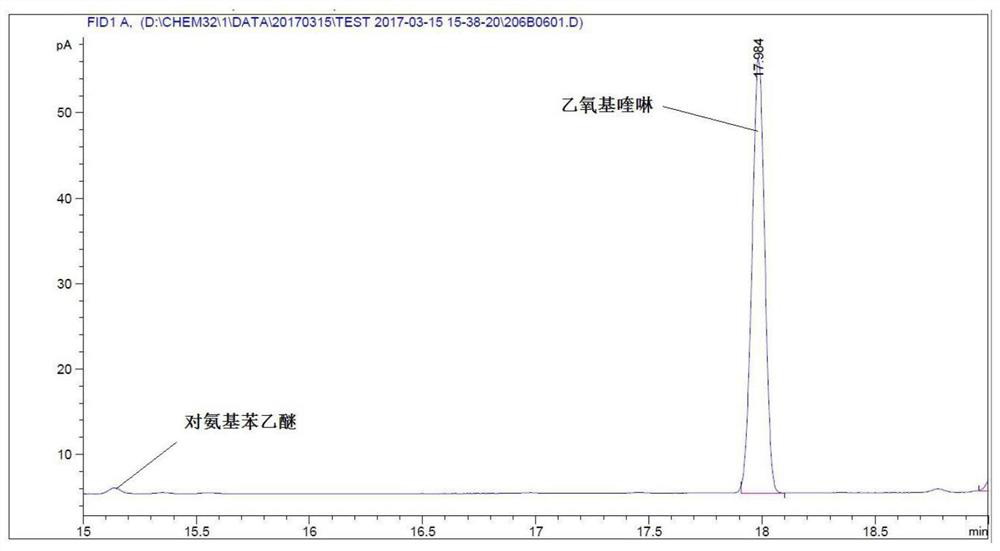

Embodiment 1

[0039] (1) The ethoxyquinoline pretreatment with the p-aminophenethyl ether content of 100 ppm ensures that there is no solid matter in the crude oil and then carries out the adsorption operation;

[0040] (2) 5kg of ethoxyquin in the raw material tank was preheated to 30°C through a jacket heat exchanger, and passed through the filled alumina adsorption column from bottom to top at a flow rate of 5BV / h through a gear pump, while controlling the adsorption process The temperature is constant at 90 °C, and the qualified products flow out through the top of the adsorption column and enter the product tank;

[0041] (3) After the adsorption filler is saturated, the flow rate of ammonia water is controlled to be 5BV / h, the temperature is 30°C, and the washing is performed for 2h. After washing, the vacuum degree was controlled to be 2 mbar, the desorption temperature was 100 °C, and the desorption was carried out for 4 h. The adsorption tower can perform adsorption work again, an...

Embodiment 2

[0044] (1) The ethoxyquinoline pretreatment with the p-aminophenethyl ether content of 100 ppm ensures that there is no solid matter in the crude oil and then carries out the adsorption operation;

[0045](2) 5kg of ethoxyquin in the raw material tank is preheated to 30°C through a jacket heat exchanger, and passed through the adsorption column filled with macroporous adsorption resin from bottom to top at a flow rate of 3BV / h through a gear pump, while controlling The temperature of the adsorption process is constant at 80 °C, and the qualified products flow out through the top of the adsorption column and enter the product tank;

[0046] (3) After the adsorption filler is saturated, the flow rate of toluene is controlled to be 5BV / h, the temperature is 30°C, and the washing is performed for 2h. After washing, the vacuum degree was controlled to be 1 mbar, the desorption temperature was 95 °C, and the desorption was carried out for 4 h. The adsorption tower can perform adsor...

Embodiment 3

[0049] (1) The ethoxyquinoline pretreatment with the p-aminophenethyl ether content of 100 ppm ensures that there is no solid matter in the crude oil and then carries out the adsorption operation;

[0050] (2) 5kg of ethoxyquin in the raw material tank is preheated to 30° C. through a jacket heat exchanger, and passed through a packed zeolite molecular sieve adsorption column from bottom to top at a flow rate of 5BV / h by a gear pump, while controlling the adsorption process The temperature is constant at 90 °C, and the qualified products flow out through the top of the adsorption column and enter the product tank;

[0051] (3) After the adsorption filler is saturated, the flow rate of acetone is controlled to be 5BV / h, the temperature is 30°C, and the washing is performed for 2h. After washing, the vacuum degree was controlled to be 1 mbar, the desorption temperature was 95 °C, and the desorption was carried out for 4 h. The adsorption tower can perform adsorption work again,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com