A kind of recycling method of pyridoxal manganese-containing wastewater

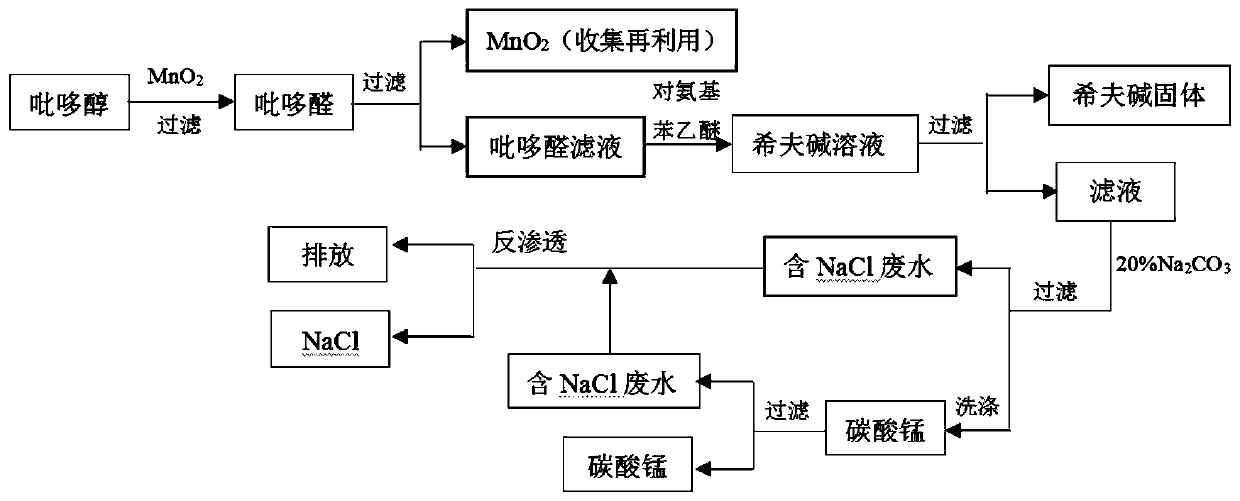

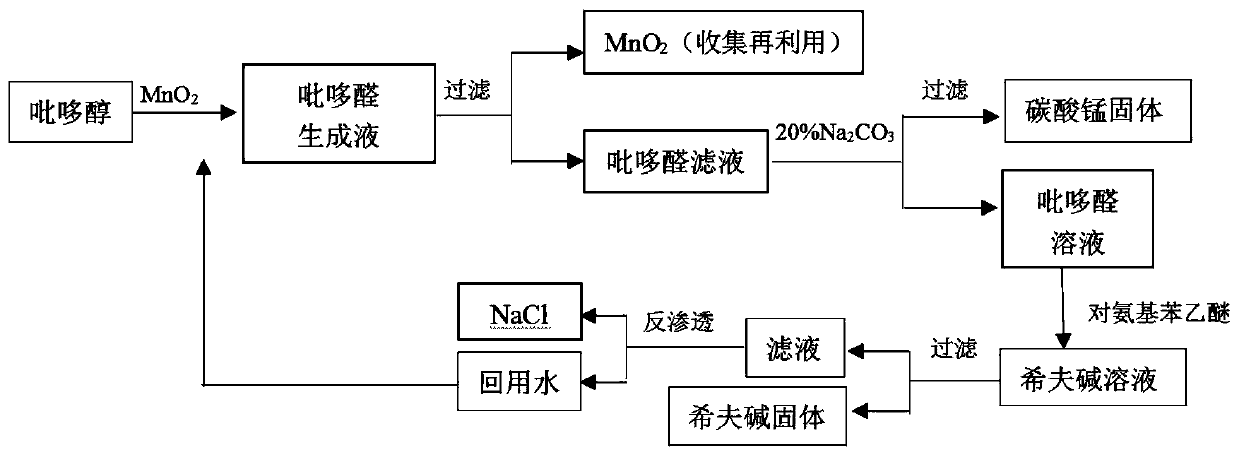

A technology for pyridoxal and waste water, which is applied to the improvement of process efficiency and organic chemistry, can solve the problems of reduced Schiff base yield, increased cost, and poor quality of manganese carbonate, so as to save treatment costs, reduce production, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

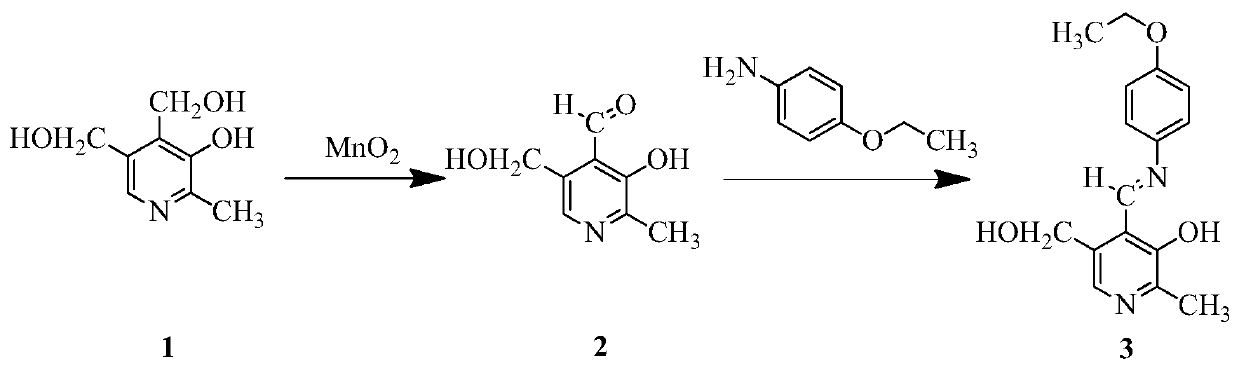

Method used

Image

Examples

Embodiment 1

[0036] Specific steps are as follows:

[0037] (1) with water as a reaction solvent, and manganese dioxide (30g) as an oxidant, the raw material pyridoxine (40g) is oxidized into pyridoxal to obtain a manganese-containing pyridoxal solution;

[0038] (2) 500mL of manganese-containing pyridoxal solution was added to the clean flask of 1000mL, and the manganese-containing pyridoxal solution was subjected to suction filtration to obtain manganese-containing pyridoxal filtrate and solid manganese dioxide, and the solid manganese dioxide was collected and reused ;

[0039] (3) Cool the manganese-containing pyridoxal to 35°C, and slowly add Na with concentrations of 5%, 10%, 15%, and 20% to the manganese-containing pyridoxal filtrate. 2 CO 3 The solution was adjusted to pH 7, and after 30 min of reaction, white manganese carbonate precipitate was produced, and the manganese carbonate solid and the pyridoxal solution were separated by suction filtration;

[0040] (4) pyridoxal sol...

Embodiment 2

[0045] Specific steps are as follows:

[0046] (1) with water as a reaction solvent, and manganese dioxide (30g) as an oxidant, the raw material pyridoxine (40g) is oxidized into pyridoxal to obtain a manganese-containing pyridoxal solution;

[0047] (2) 500mL of manganese-containing pyridoxal solution was added to the clean flask of 1000mL, and the manganese-containing pyridoxal solution was subjected to suction filtration to obtain manganese-containing pyridoxal filtrate and solid manganese dioxide, and the solid manganese dioxide was collected and reused ;

[0048] (3) The manganese-containing pyridoxal was cooled to 35° C., and the Na of the concentration of 15% was slowly added to the manganese-containing pyridoxal filtrate. 2 CO 3 The solution was adjusted to pH 5, 6, 7, 8, 9, 10 respectively, and after 30 min of reaction, white manganese carbonate precipitate was produced, and the manganese carbonate solid and the pyridoxal solution were separated by suction filtration;...

Embodiment 3

[0054] Specific steps are as follows:

[0055] (1) with water as a reaction solvent, and manganese dioxide (30g) as an oxidant, the raw material pyridoxine (40g) is oxidized into pyridoxal to obtain a manganese-containing pyridoxal solution;

[0056] (2) 500mL of manganese-containing pyridoxal solution was added to the clean flask of 1000mL, and the manganese-containing pyridoxal solution was subjected to suction filtration to obtain manganese-containing pyridoxal filtrate and solid manganese dioxide, and the solid manganese dioxide was collected and reused ;

[0057] (3) The manganese-containing pyridoxal was cooled to 35°C, and the NaHCO with a concentration of 15% was slowly added to the manganese-containing pyridoxal filtrate. 3 The solution was adjusted to pH 8, reacted for 10, 15, 20, 25, and 30 min respectively to produce white manganese carbonate precipitation, and the manganese carbonate solid and the pyridoxal solution were separated by suction filtration;

[0058]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com