Polyaniline derivative and preparation method thereof

A derivative, polyaniline technology, applied in the field of polyaniline derivative materials and their preparation, can solve the problems such as Chinese patents and documents of aniline/o-ethoxyaniline that have not yet been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

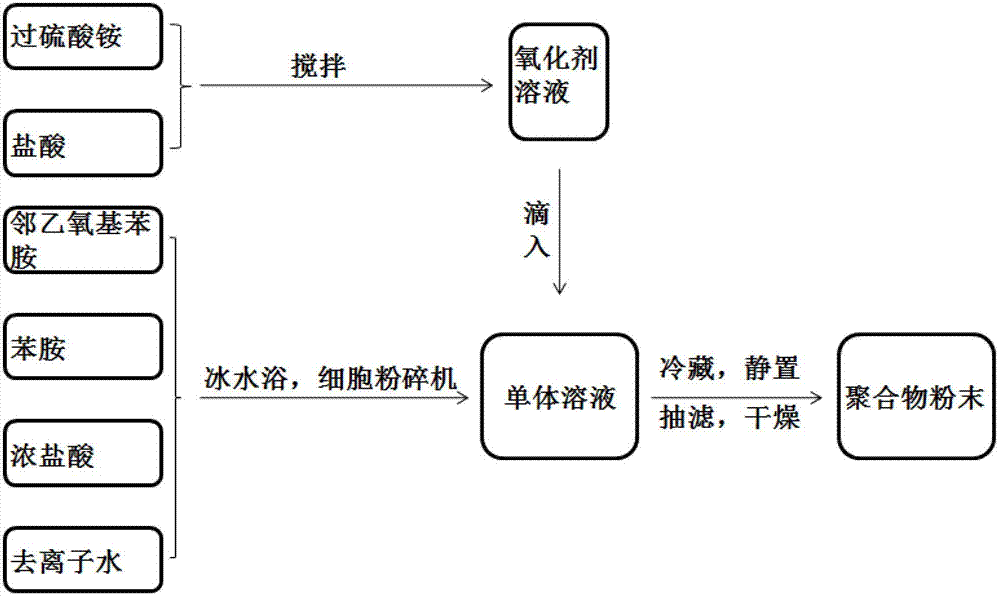

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: 1., be that -0.08Mpa~-0.07Mpa temperature is 110 ℃~120 ℃ underpressure distillation aniline and o-ethoxyaniline monomer with vacuum pump at pressure to obtain pure o-ethoxyaniline and aniline, Standby; ②, according to the aniline: o-ethoxyaniline ratio of 1:0 (mass ratio), add 0.03mol aniline and 2.5ml concentrated hydrochloric acid in a 100ml small beaker, then add deionized water to dilute to 30ml, put it Put the beaker and the water bath into the cell pulverizer in an ice-water bath at 0°C, insert the ultrasonic rod about 1cm away from the bottom of the beaker, and ultrasonicate for half an hour to mix the aniline and o-ethoxyaniline evenly; The concentrations of ammonium sulfate and hydrochloric acid are both 1mol / L. Slowly stir the oxidant solution evenly and then slowly drop it into the monomer solution. The whole reaction lasts for about 2 hours; ④. After the reaction is completed, put the reaction solution in the refrigerator for 24 hours ; ⑤, take...

Embodiment 2

[0021] Embodiment 2: 1., be that -0.08Mpa~-0.07Mpa temperature is 110 ℃~120 ℃ underpressure distillation aniline and o-ethoxyaniline monomer with vacuum pump at pressure to obtain pure o-ethoxyaniline and aniline, Standby; ②, according to aniline: o-ethoxyaniline 1:0.15 (mass ratio), add 0.03mol aniline and 0.0045mol o-ethoxyaniline and 2.5ml concentrated hydrochloric acid in a 100ml small beaker and then add deionized Dilute it with water to 30ml, put it in an ice-water bath at 0°C, put the beaker and water bath into the cell pulverizer, insert the ultrasonic rod about 1cm away from the bottom of the beaker, and ultrasonicate for half an hour to mix the aniline and o-ethoxyaniline evenly; ③. Configure 30ml of oxidant solution, in which the concentrations of ammonium persulfate and hydrochloric acid are both 1mol / L. Slowly stir the oxidant solution evenly and then slowly drop it into the monomer solution. The whole reaction lasts for about 2 hours; ④. After the reaction is comp...

Embodiment 3

[0022] Embodiment 3: 1., be that -0.08Mpa~-0.07Mpa temperature is 110 ℃~120 ℃ underpressure distillation aniline and o-ethoxyaniline monomer with vacuum pump at pressure and obtain pure o-ethoxyaniline and aniline, Standby; ②, according to the ratio of aniline: o-ethoxyaniline 1:0.3 (mass ratio), add 0.03mol aniline and 0.009mol o-ethoxyaniline and 2.5ml concentrated hydrochloric acid into a 100ml small beaker and then add deionized Dilute it with water to 30ml, put it in an ice-water bath at 0°C, put the beaker and water bath into the cell pulverizer, insert the ultrasonic rod about 1cm away from the bottom of the beaker, and ultrasonicate for half an hour to mix the aniline and o-ethoxyaniline evenly; ③. Configure 30ml of oxidant solution, in which the concentrations of ammonium persulfate and hydrochloric acid are both 1mol / L. Slowly stir the oxidant solution evenly and then slowly drop it into the monomer solution. The whole reaction lasts for about 2 hours; ④. After the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com