A kind of production method of ethoxyquinoline

An ethoxyquinoline and production method technology, applied in the direction of organic chemistry and the like, can solve the problems of increased energy consumption, increased production cost, large resistance, etc., and achieves low pressure drop and energy consumption, reduced production cost, and increased transmission. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

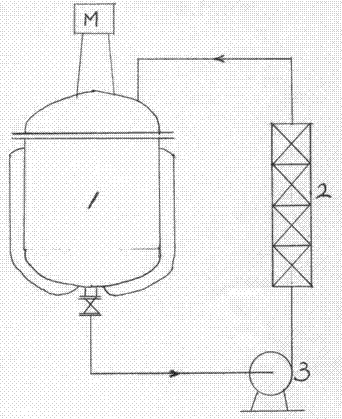

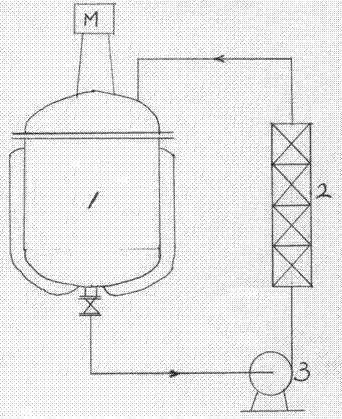

Image

Examples

Embodiment 1

[0010] Add 1000 kilograms of p-aminophenethyl ether, 100 kilograms of toluene and 125 kilograms of p-toluenesulfonic acid in the reactor, open the circulating pump under heating to circulate the material between the static mixer and the reactor, when the temperature of the reactor material reaches Add 1050 kg of acetone dropwise at 140°C for 24 hours to carry out dehydration and cyclization, stop adding acetone after the conversion rate of p-aminophenethyl ether reaches 97.0% by gas chromatography, and then keep warm for 1 hour to neutralize Wash with water, distill the obtained organic layer, separate and remove toluene and unreacted p-aminophenetole, distill at 150-200°C at still temperature to obtain 1500 kilograms of ethoxyquinoline, and the content of ethoxyquinoline is 96.5wt%. The aminophenetole content is 0.30wt%.

Embodiment 2

[0012] Add 1000 kilograms of p-aminophenethyl ether, 100 kilograms of toluene and 125 kilograms of p-toluenesulfonic acid in the reactor, open the circulating pump under heating to circulate the material between the static mixer and the reactor, when the temperature of the reactor material reaches Add 1050 kg of acetone dropwise at 150°C for 26 hours for dehydration and cyclization, stop adding acetone after the conversion rate of p-aminophenethyl ether reaches 98.5% by gas chromatography, and then keep warm for 1 hour to neutralize Wash with water, distill the obtained organic layer, separate and remove toluene and unreacted p-aminophenetole, distill at 150-200°C at still temperature to obtain 1450 kilograms of ethoxyquinoline, and the content of ethoxyquinoline is 97.5wt%. The content of aminophenetole is 0.1wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com