Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48 results about "Nitrogen Protoxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nitrogen protoxide General Information. Nitric oxide or Nitrogen monoxide is a chemical compound with chemical formula NO. This gas is an important signaling molecule in the body of mammals including humans and is an extremely important intermediate in the chemical industry.

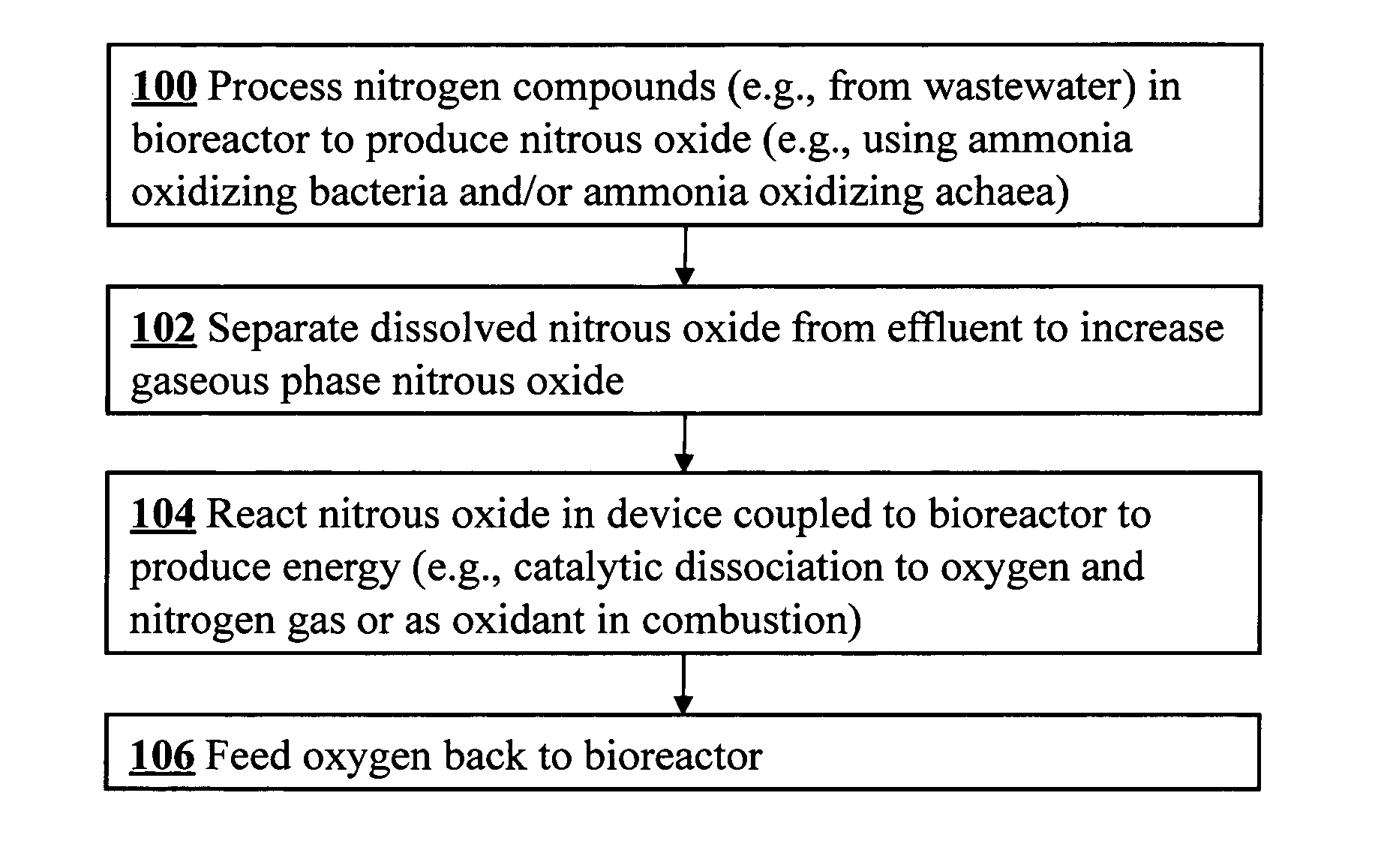

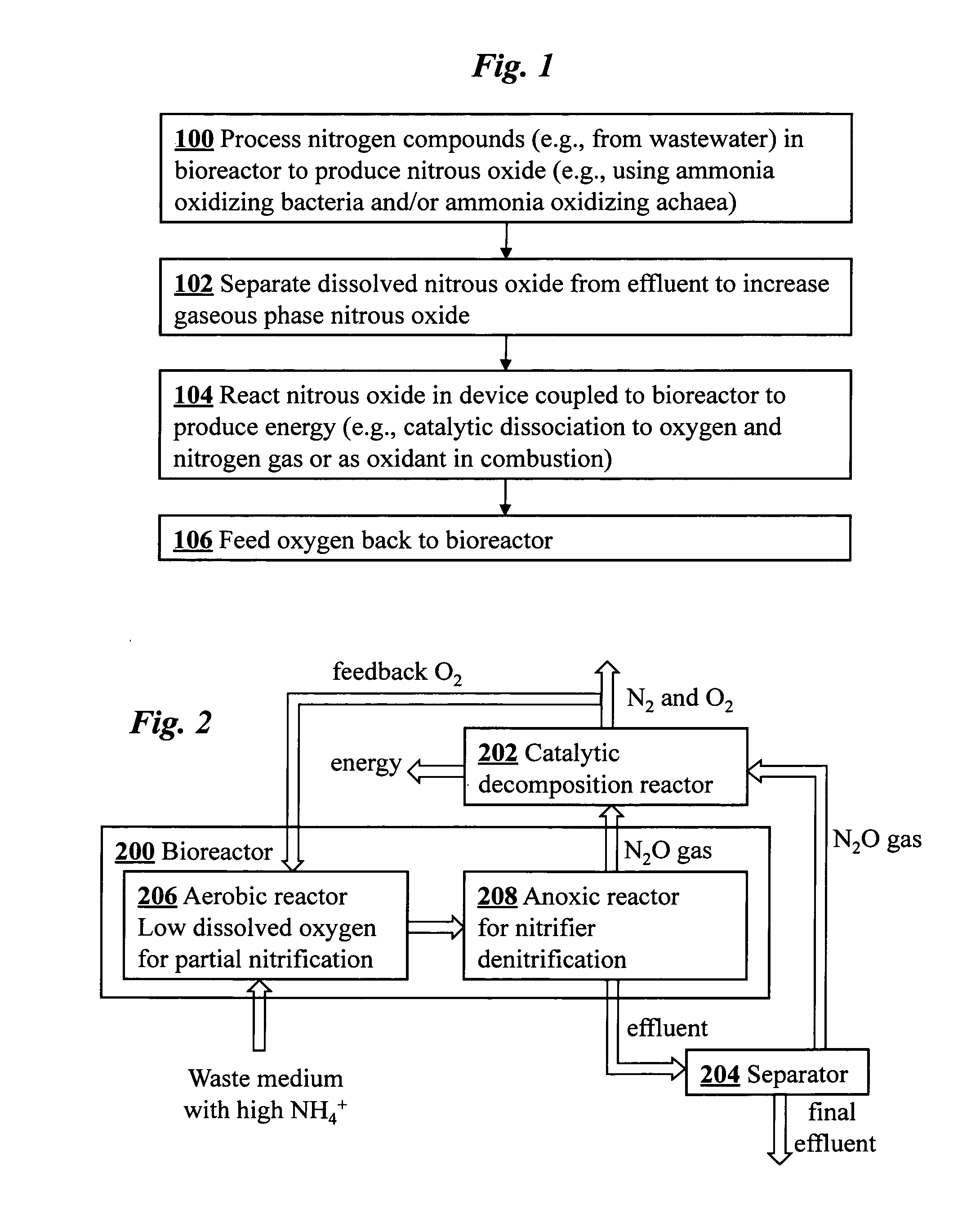

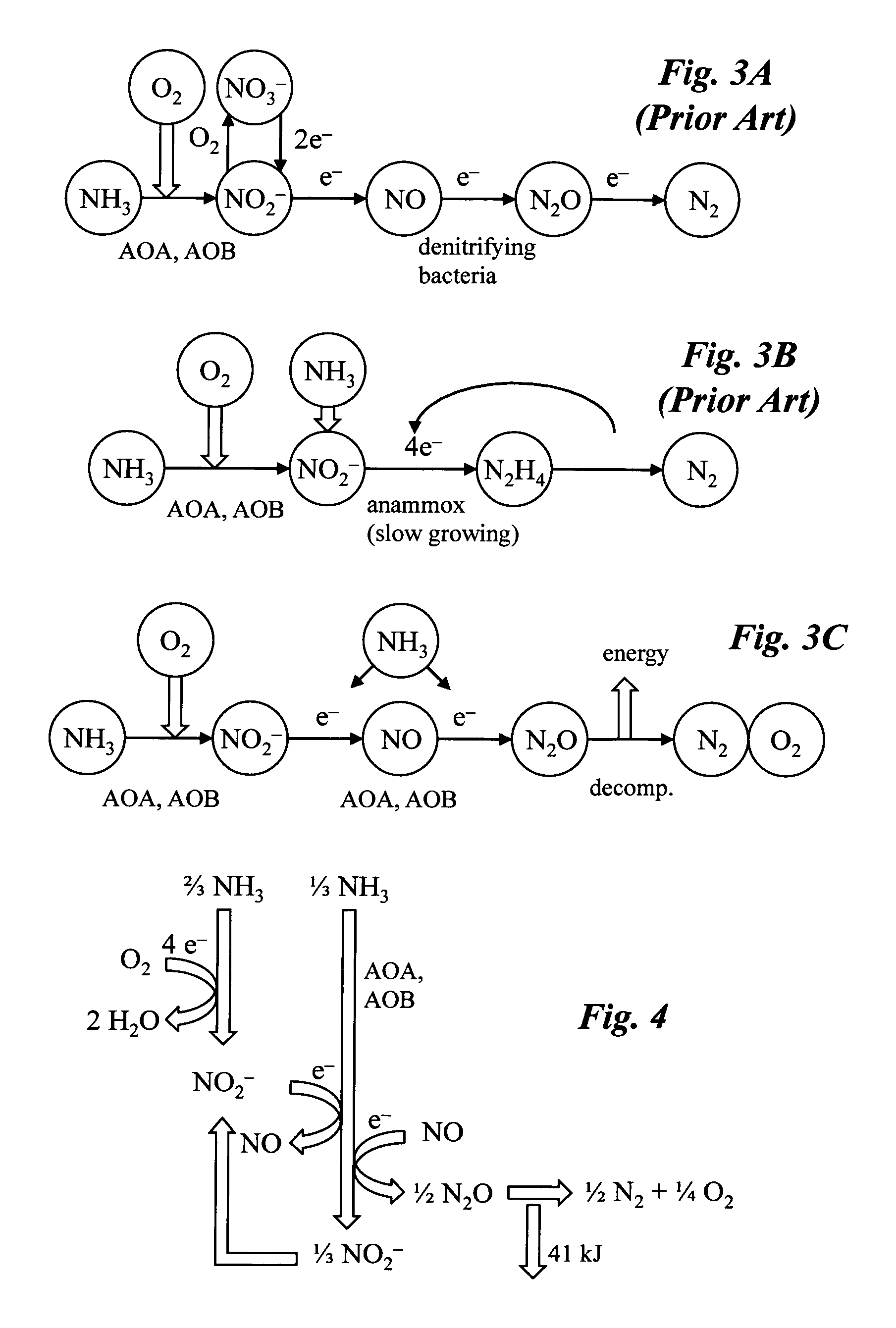

Microbial production of nitrous oxide coupled with chemical reaction of gaseous nitrous oxide including phosphorus recovery and nitrite reduction to nitrous oxide

InactiveUS20120309071A1Minimize N2O productionProducer of clean energyWater treatment parameter controlOxygen/ozone/oxide/hydroxideChemical reactionGas phase

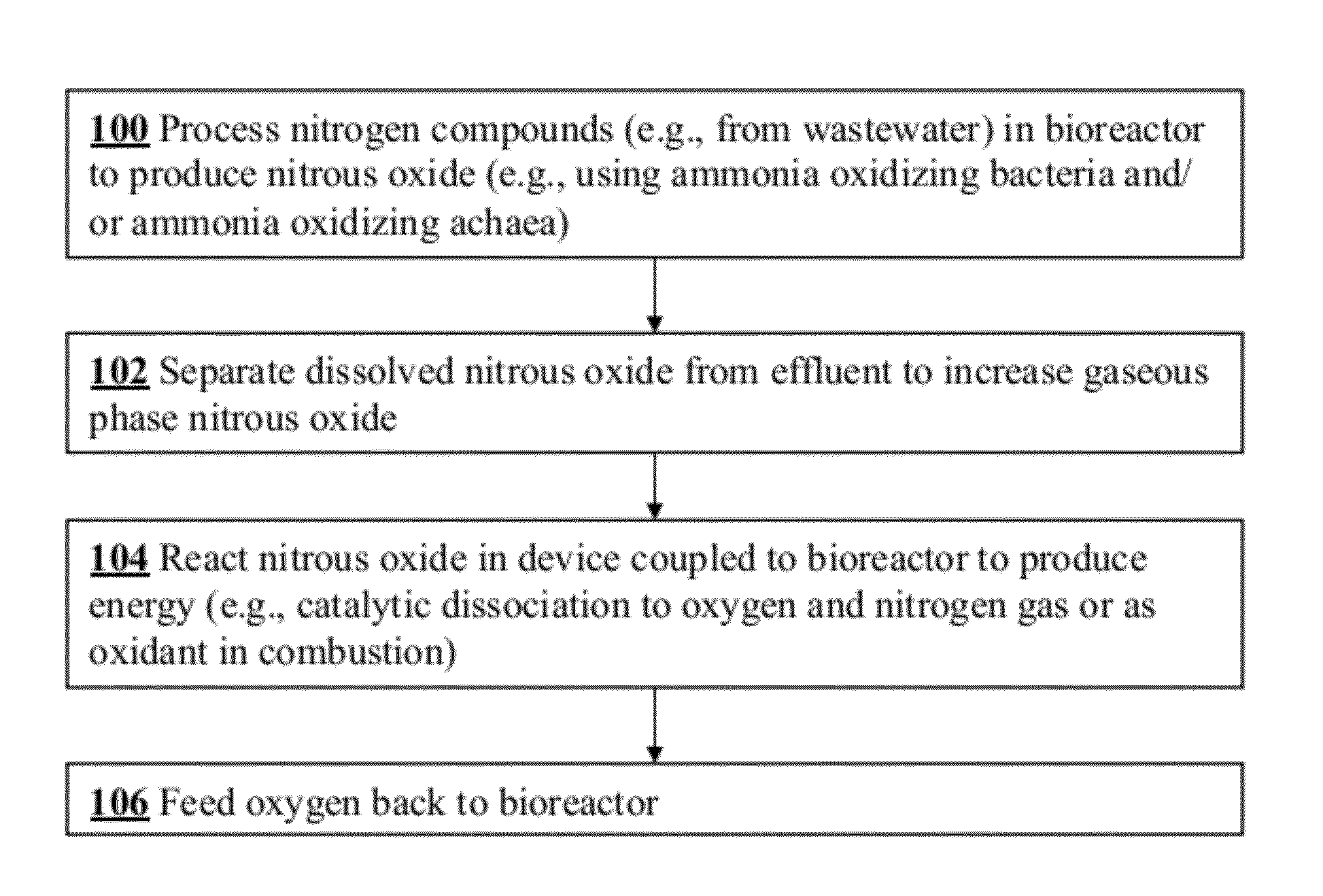

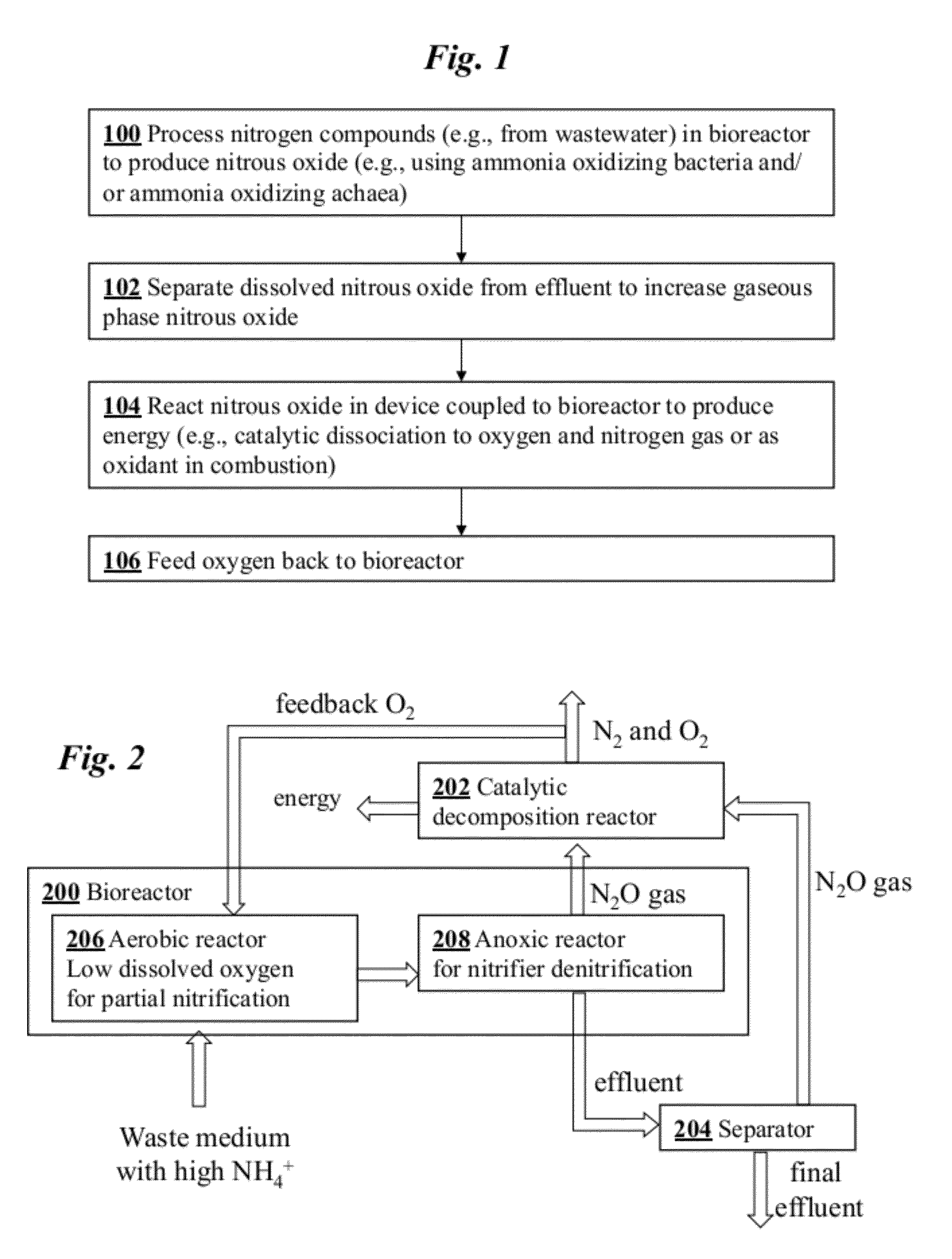

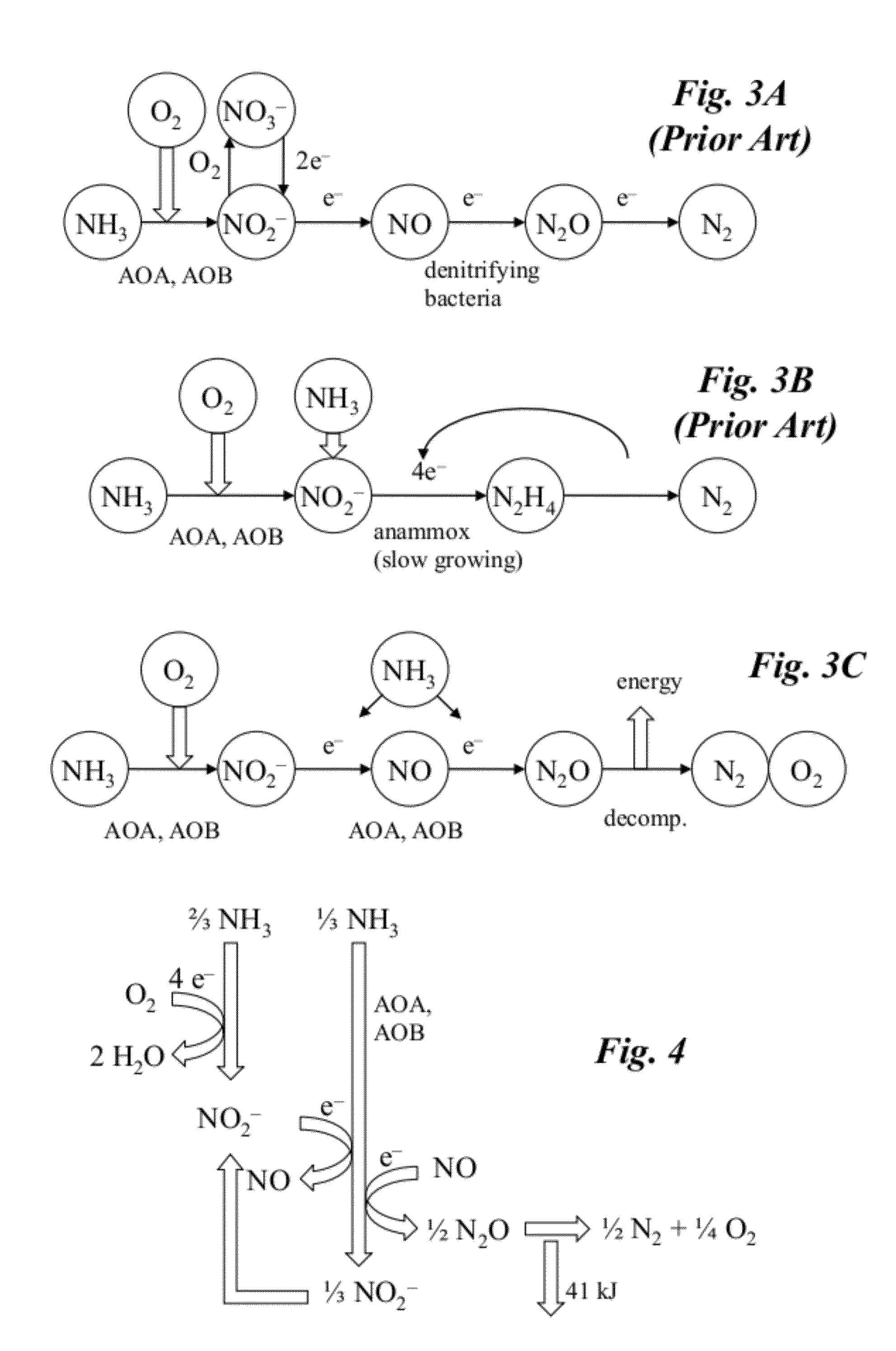

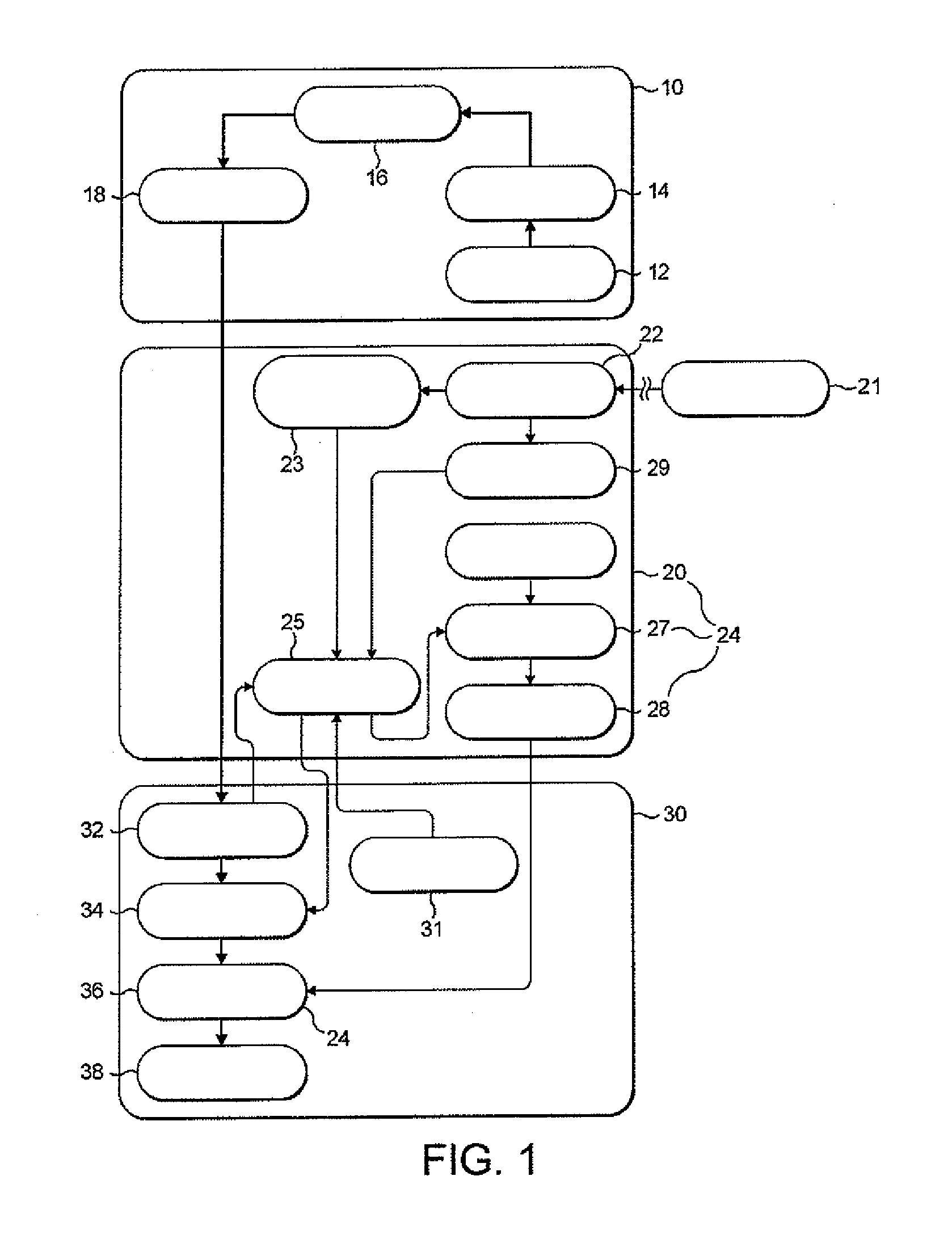

A method to produce N2O from organic nitrogen and / or reactive nitrogen in waste uses a bioreactor coupled to a hardware reactor device in which the N2O is consumed in a gas phase chemical reaction, e.g., catalytic decomposition to form oxygen and nitrogen gas. Heat from the exothermic reaction may be used to generate power. The N2O may alternatively be used as an oxidant or co-oxidant in a combustion reaction, e.g., in the combustion of methane.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

High pressure processing of a substance utilizing a controlled atmospheric environment

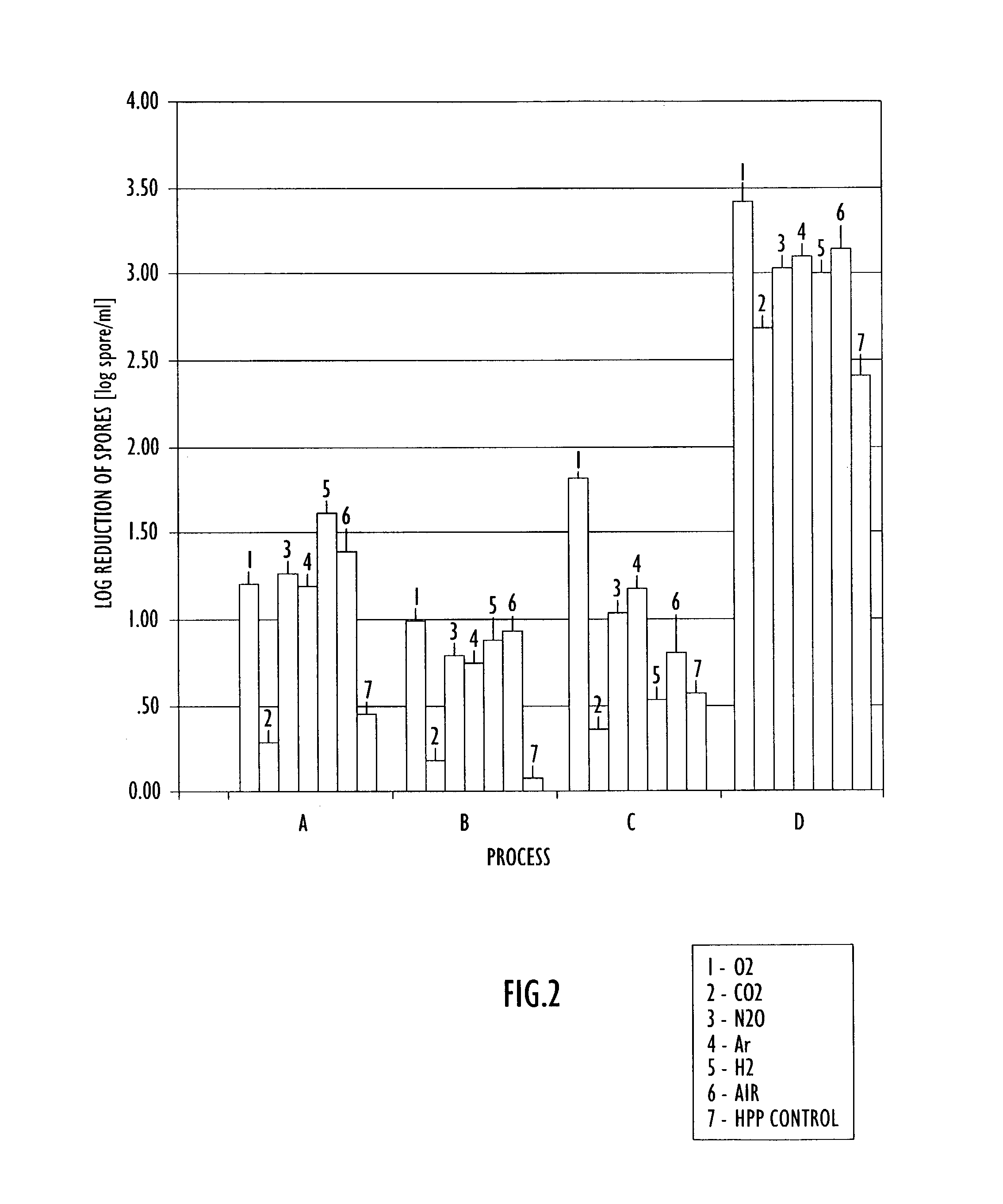

InactiveUS20030170356A1Slow growth ratePrevent spoilageFatty acid hydrogenationFood preservationKryptonNitric oxide

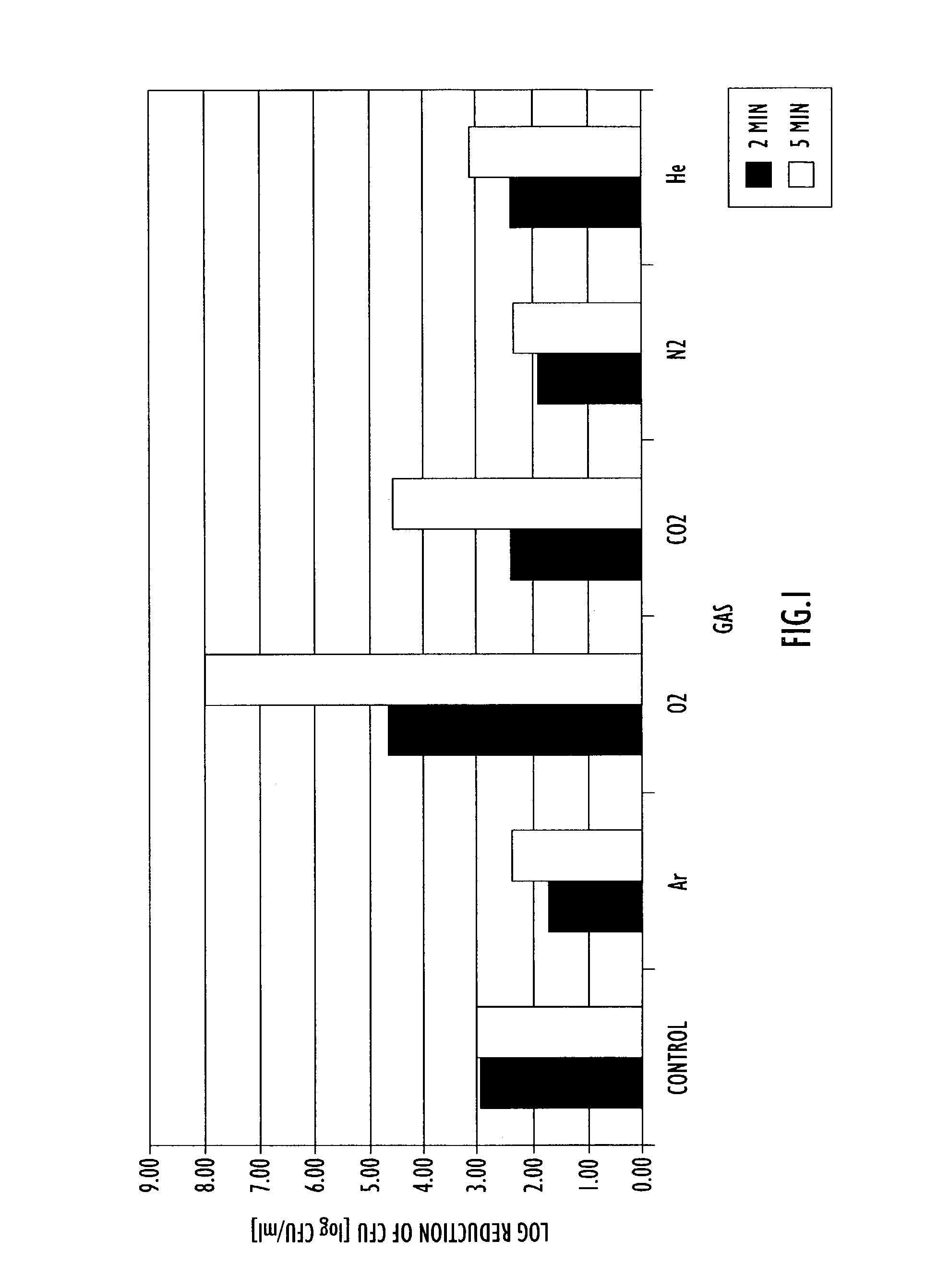

A method of processing a substance, such as a food item, utilizing high pressure processing includes providing an enclosed environment including the substance and one or more of the following gases: carbon monoxide, carbon dioxide, nitrogen, nitric oxide, nitrous oxide, hydrogen, oxygen, helium, argon, krypton, xenon and neon. The enclosed environment including the substance and at least one gas is subjected to high pressure processing and sealed in a container. The high pressure processing may occur prior to or after sealing the substance in the container. Control of the amount and type of gases in the enclosed environment including the substance enhances the biocidal efficacy of high pressure processing as well as ensuring desirable sensory qualities of the substance during storage.

Owner:AIR LIQUIDE AMERICA INC +1

Microbial production of nitrous oxide coupled with chemical reaction of gaseous nitrous oxide

InactiveUS20110207061A1Treatment with aerobic and anaerobic processesSustainable biological treatmentSequencing batch reactorFiber

A bioreactor designed to produce N2O from organic nitrogen and / or reactive nitrogen in waste is coupled to a hardware reactor device in which the N2O is consumed in a gas phase chemical reaction, e.g., catalytic decomposition to form oxygen and nitrogen gas.Heat from the exothermic reaction may be used to generate power. The N2O may alternatively be used as an oxidant or co-oxidant in a combustion reaction, e.g., in the combustion of methane. The bioreactor may have various designs including a two-stage bioreactor, a hollow-fiber membrane bioreactor, or a sequencing batch reactor. The bioreactor may involve Fe(II)-mediated reduction of nitrite to nitrous oxide.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Gas treatment methods

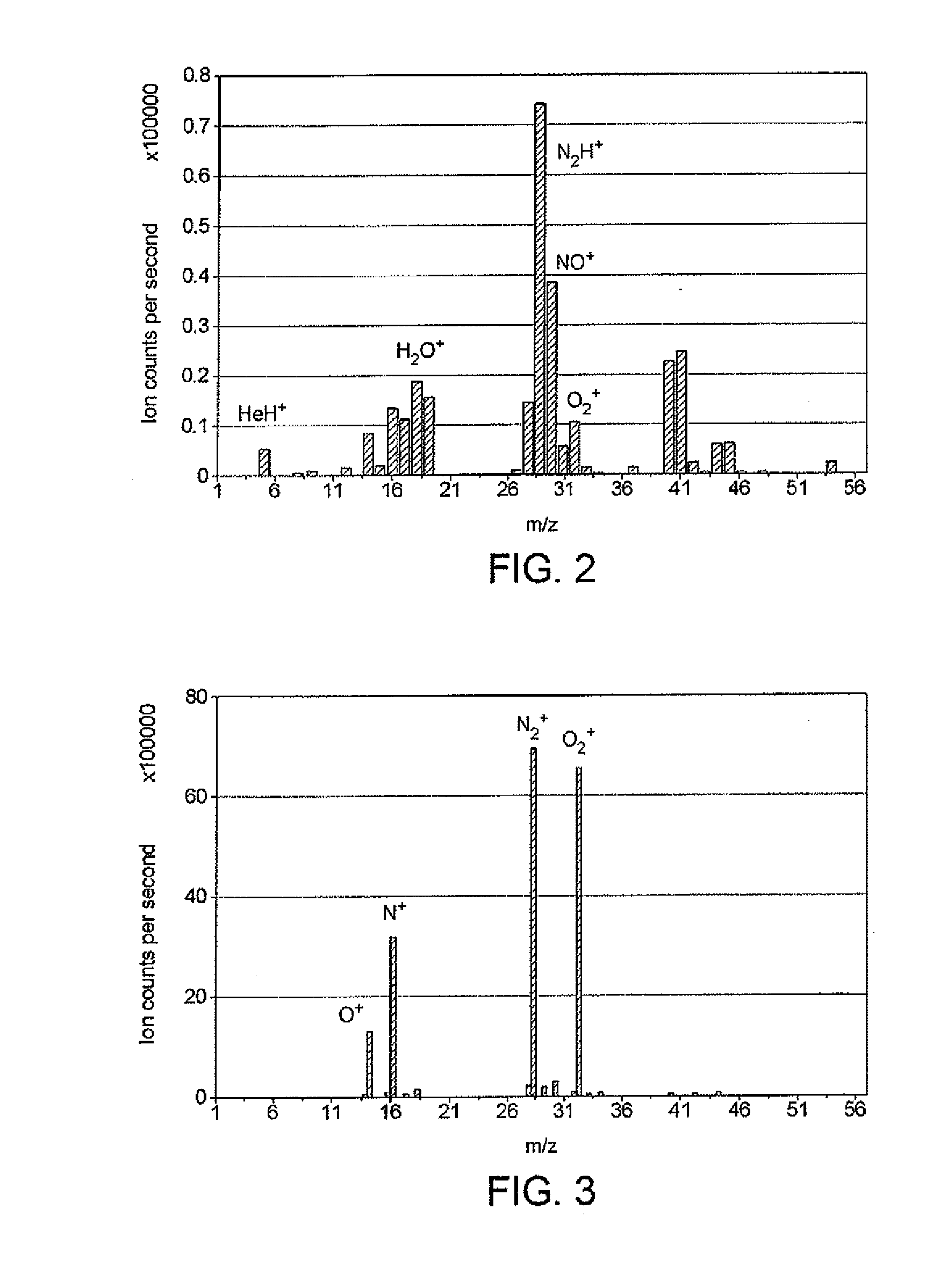

InactiveUS20120094250A1Reduce in quantityHigh ionisation energyGum massageTeeth fillingOral treatmentNoble gas

A method of oral treatment comprises passing a flow of a gas mixture from a pressure vessel containing the gas mixture through a generator of non-thermal plasma; applying a partially ionising electrical potential to the flow of the gas mixture in the plasma generator, and thereby forming a non-thermal gaseous plasma in the gas mixture, and causing the flow of the gas mixture downstream of the plasma generator to perform the oral treatment. The gas mixture comprises (a) a noble gas selected from helium and argon and mixtures thereof, and (b) an additive gas selected from water vapour, air, oxygen, nitrogen, hydrogen, carbon monoxide, carbon dioxide, nitrous oxide and nitric oxide and mixtures of any two or more thereof. The additive gas forms up to 1% by volume of the gas mixture. The oral treatment may be the cosmetic whitening of teeth, the non-clinical cleaning of teeth or the in situ cleaning of orthodontic braces, amongst others.

Owner:LINDE AG

Catalyst for decomposing nitrous oxide, process for producing the same and method for decomposing nitrous oxide

The invention relates to a catalyst for decomposing nitrous oxide, which is [1] a catalyst comprising a support having supported thereon aluminum, magnesium and rhodium, [2] a catalyst comprising an alumina support having supported thereon magnesium and rhodium, [3] a catalyst comprising a support having supported thereon rhodium, the support comprising a spinel crystalline composite oxide formed by magnesium and at least a part of aluminum, [4] a catalyst comprising a support having supported thereon aluminum, rhodium and at least one metal selected from zinc, iron, manganese and nickel, [5] a catalyst comprising an alumina support having supported thereon rhodium and at least one metal selected from zinc, iron, manganese and nickel, or [6] a catalyst comprising a support having supported thereon rhodium, the support comprising a spinel crystalline composite oxide formed by at least a part of aluminum and the at least one metal selected from zinc, iron, manganese and nickel. The catalyst is not easily deteriorated in the activity due to moisture, favored with low-temperature decomposition activity and capable of reducing the amount of NOx generated to the allowable concentration or less. The invention also relates to a process for producing the catalyst and to a method for decomposing nitrous oxide.

Owner:SHOWA DENKO KK

Nitrification inhibitor treatment of grazed pasture soils

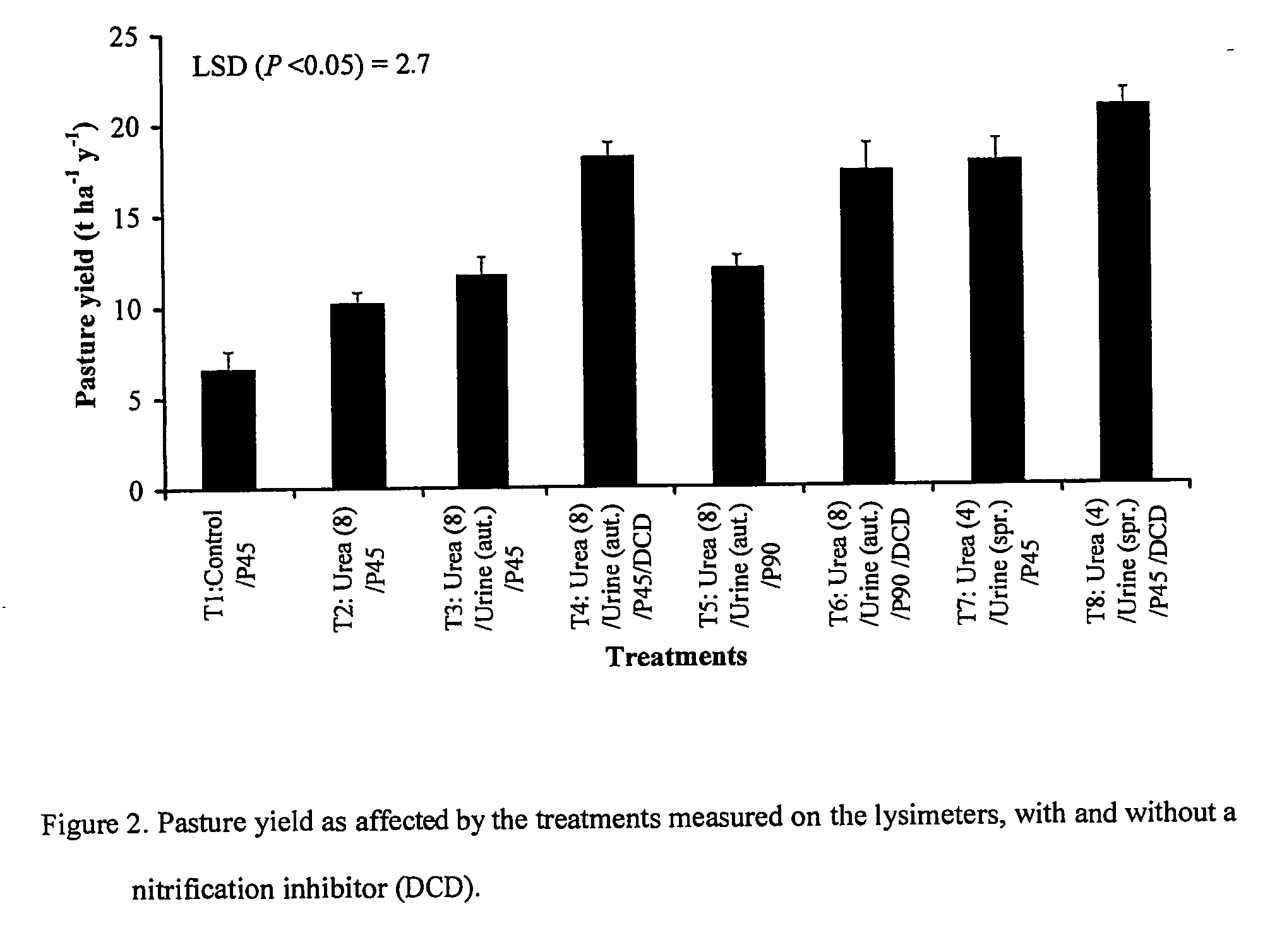

InactiveUS20060089260A1Emission reductionReduce potassium, calcium and magnesium leachingBiocideFertilising methodsSoil scienceNitrification inhibitors

A nitrification inhibitor treatment used as a soil mangement tool on grazed pasture soils. The treatment includes the application of nitrification inhibitors in solution form and / or line particle suspension form and / or in crystalline form to treat the whole area of grazed pasture soils to: reduce nitrate leaching; reduce nitrous oxide emissions; reduce postassium, calcium and magnesium leaching; and increase pasture production in both the animal urine patch areas and non-urine patch areas. The nitrification inhibitors can be applied in conjunction with irrigation water, by a spray vehicle or in a similar way to the application of agricultural chemicals.

Owner:LINCOLN UNIVERSITY +1

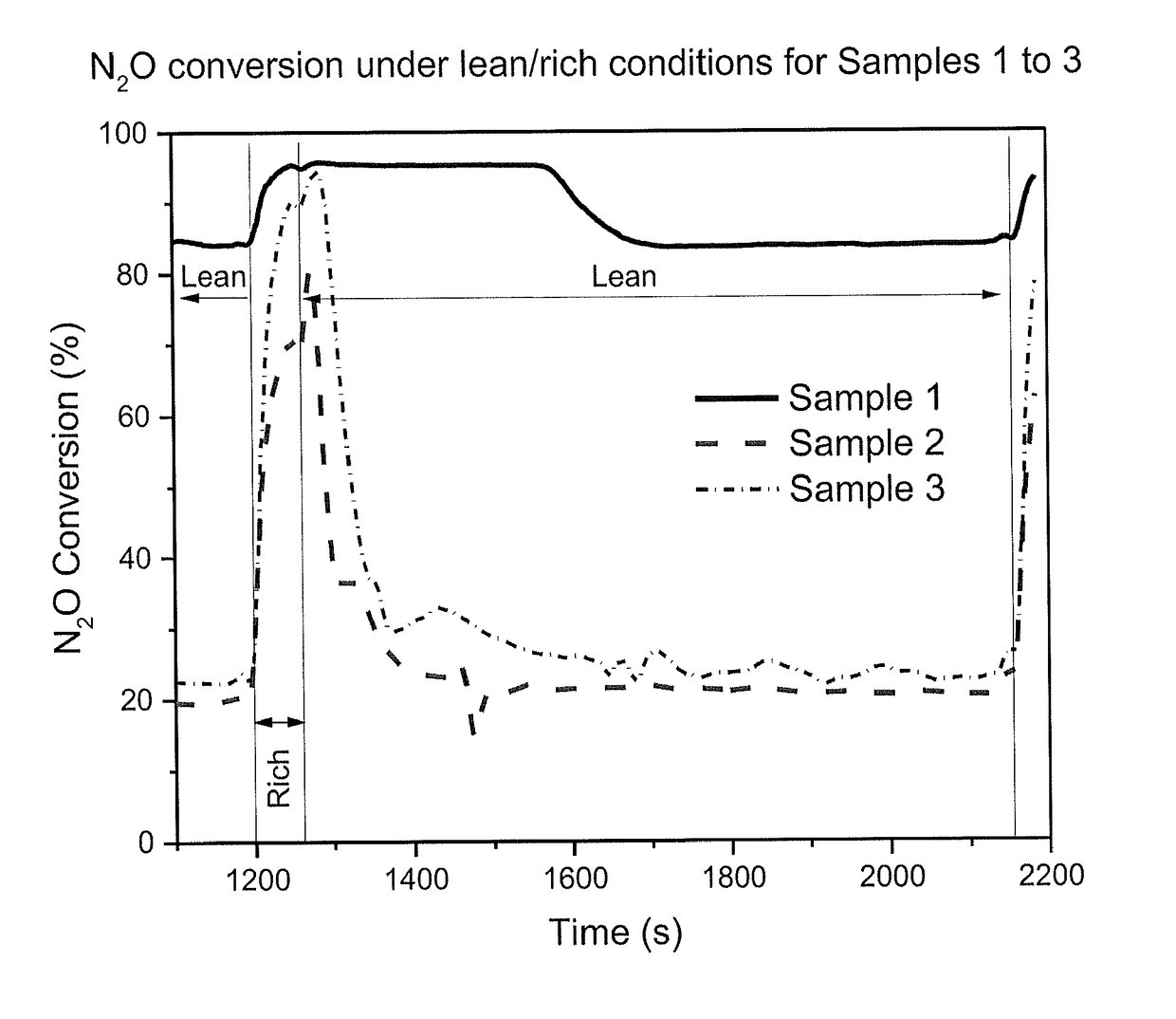

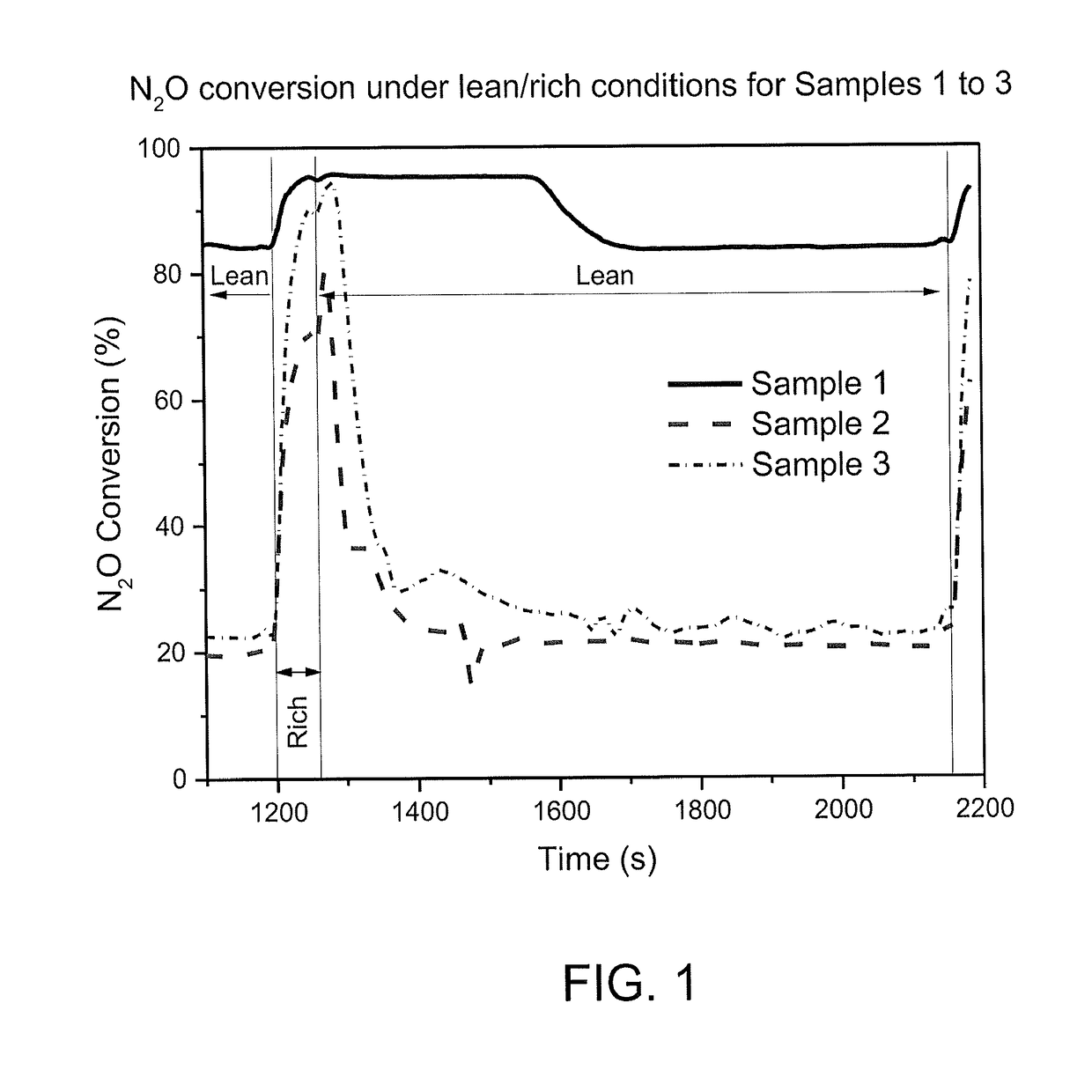

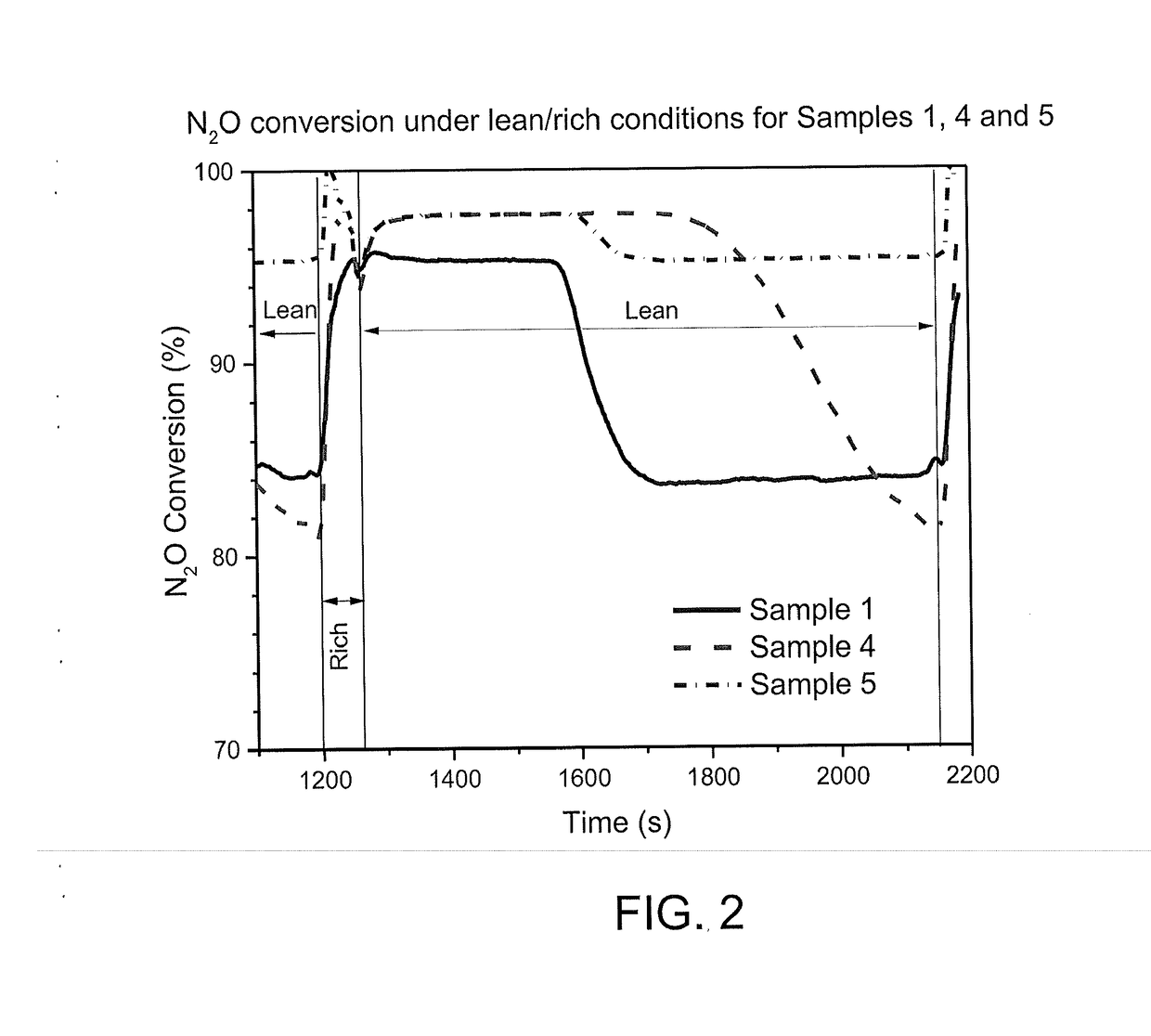

Nitrous oxide removal catalysts for exhaust systems

A nitrous oxide (N2O) removal catalyst composite is described, which includes: a N2O removal catalytic material on a carrier, wherein the catalytic material comprises a platinum group metal (PGM) component on a ceria-containing support having a single phase, cubic fluorite crystal structure. The catalytic material is effective to decompose nitrous oxide (N2O) to nitrogen (N2) and oxygen (O2) and / or to reduce N2O to N2 and water (H2O) and / or (CO2) under conditions of an exhaust stream of an internal combustion engine operating under conditions that are stoichiometric or lean with periodic rich transient excursions. Methods of making and using the same are also provided.

Owner:BASF CORP

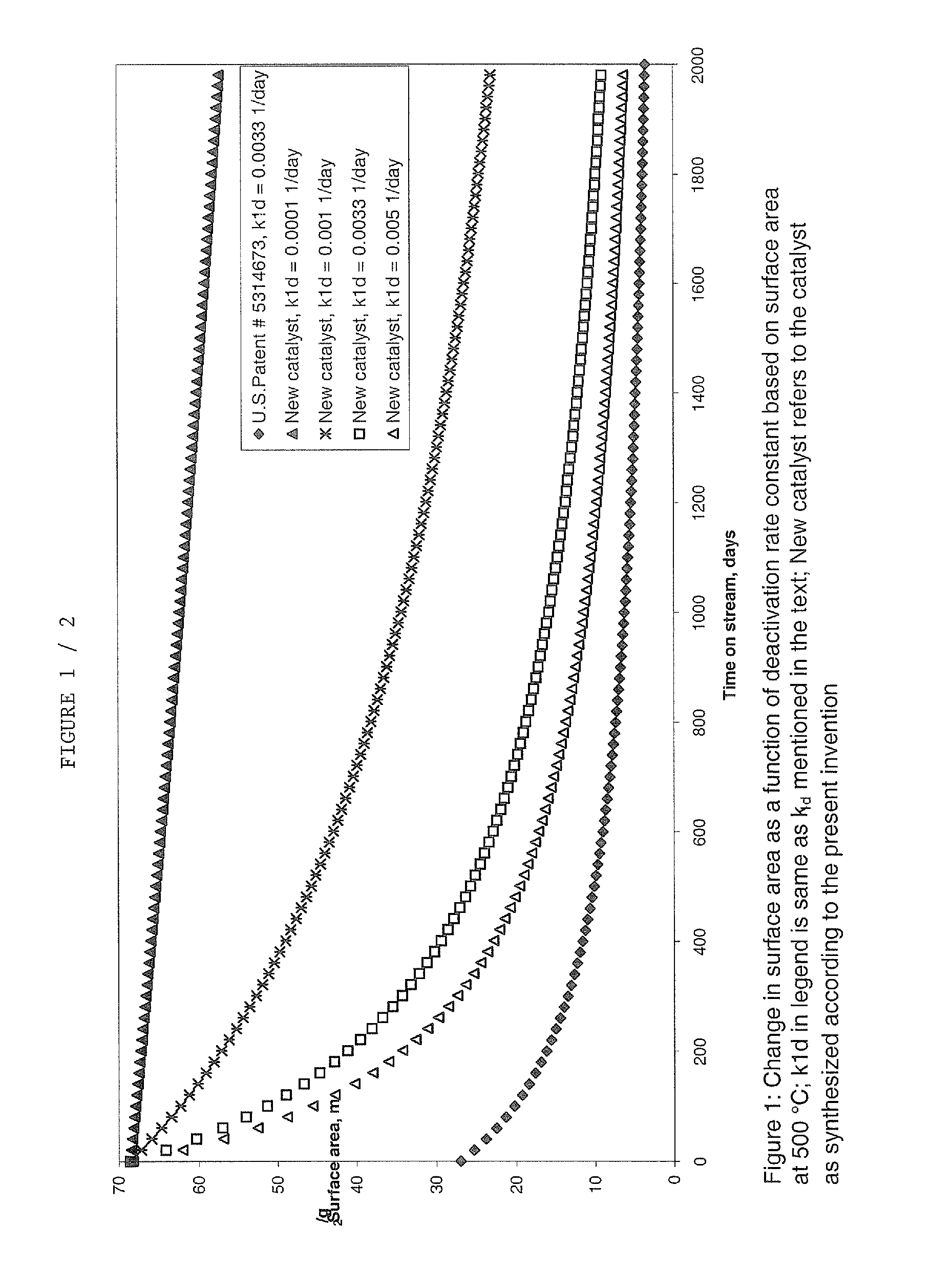

Catalyst and process for the conversion of nitrous oxide

A catalyst composition and a process for using it to decompose nitrous oxide into nitrogen and oxygen are disclosed. The catalyst composition has surface area of about 1 to about 200 m2 / g after exposure to a calcination temperature of between about 400° C. and about 900° C., or about 1 to about 100 m2 / g after exposure to a calcination temperature of between about 400° C. and about 950° C.

Owner:INVISTA NORTH AMERICA R L

Aerobic nitritation of ammonia and integrated anammox processes

ActiveUS20190039926A1Reduce volume of airLow mole ratioWater treatment parameter controlWater treatment compoundsNitrate anionAnammox

Processes are disclosed for the microbial nitritation of ammonia that attenuate the production of at least one of nitrate anion and nitrous oxide. The processes use an ME biocatalyst having a highly porous, hydrophilic polymeric structure with ammonia-oxidizing microorganisms substantially irreversibly retained therein. The processes are particularly useful for integration with anammox processes.

Owner:MICROVI BIOTECH

Aerobic nitritation of ammonia and integrated anammox processes

ActiveUS10584047B2Emission reductionImprove toleranceWater treatment parameter controlWater treatment compoundsNitrate anionHydrophilic polymers

Processes are disclosed for the microbial nitritation of ammonia that attenuate the production of at least one of nitrate anion and nitrous oxide. The processes use an ME biocatalyst having a highly porous, hydrophilic polymeric structure with ammonia-oxidizing microorganisms substantially irreversibly retained therein. The processes are particularly useful for integration with anammox processes.

Owner:MICROVI BIOTECH

Mixed oxides catalysts

Mixed oxides catalysts usable in particular in the full oxidation to CO2 and H2O of volatile organic compounds (VOC), in the decomposition of nitrogen protoxide to nitrogen and oxygen and the combustion of CO, H2 and CH4 off gases in fuel cells, comprising oxides of manganese, copper and La2O3 and / or Nd2O3, having a percentage composition by weight expressed as MnO, CuO, La2O3 and / or Nd2O3 respectively of 35-56%, 19-31% and 20-37%. The oxides are supported on inert porous inorganic oxides, preferably alumina.

Owner:SUD CHEM CATALYSTS ITAL SRL

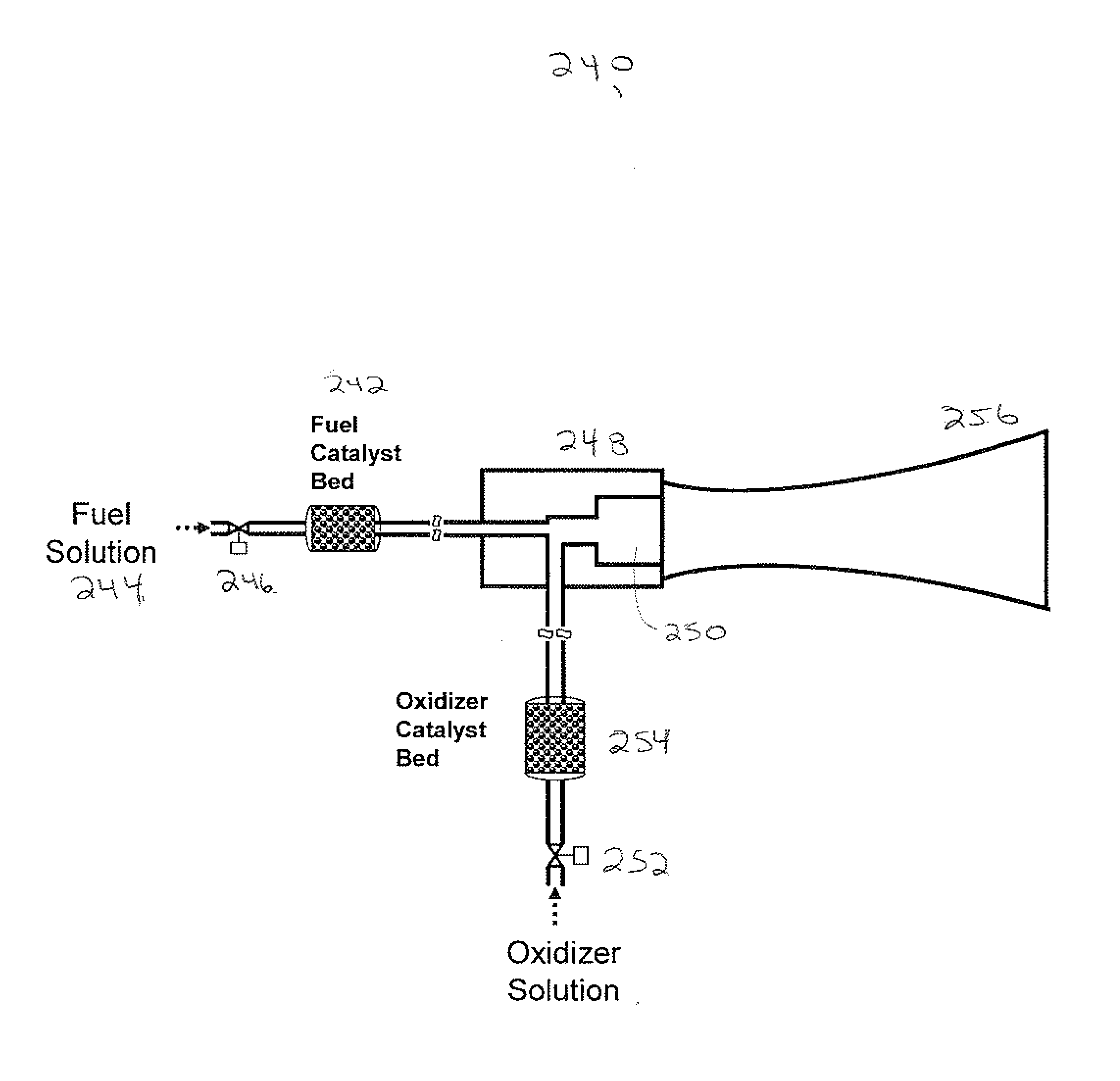

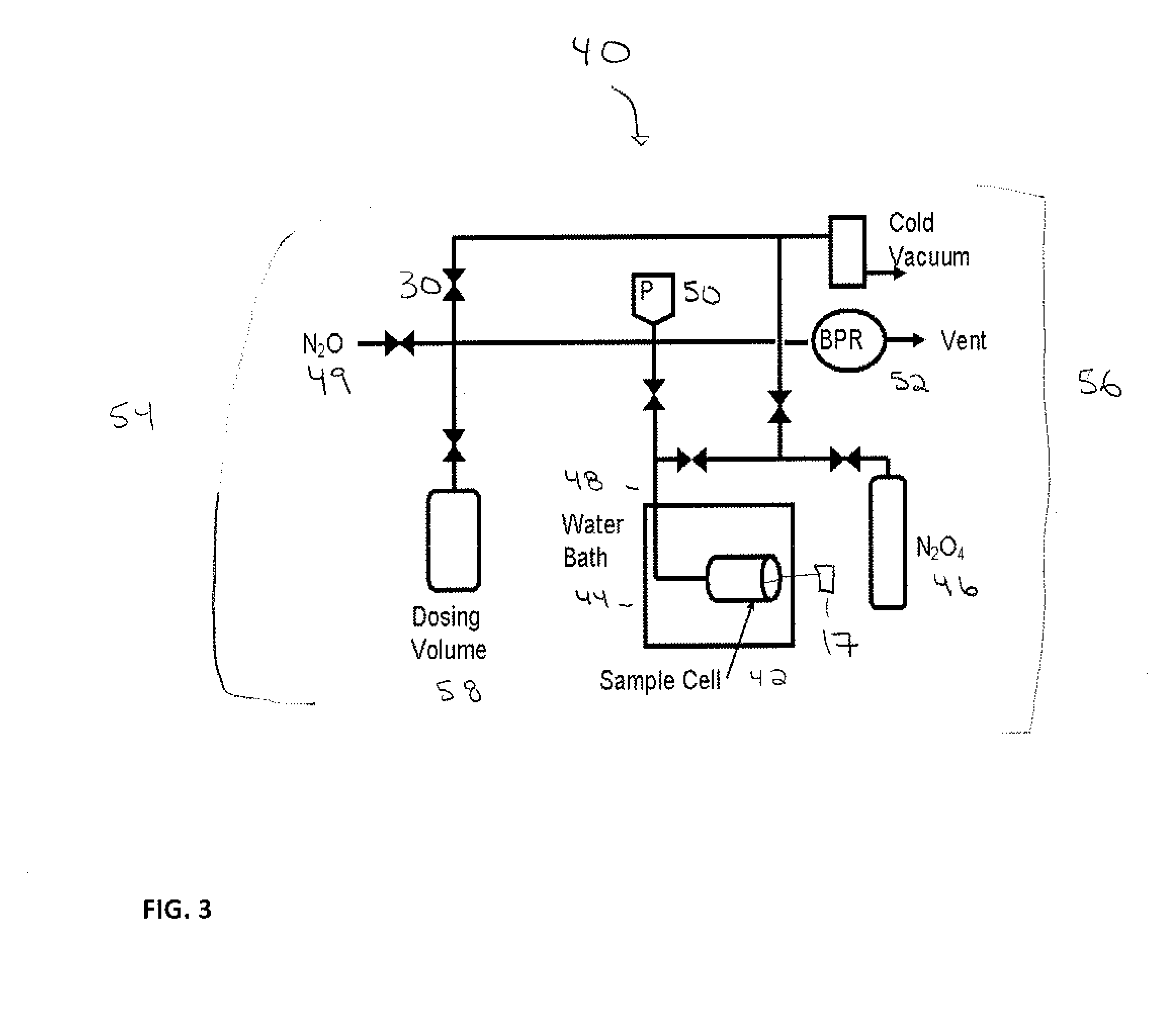

Oxidizer compound for rocket propulsion

InactiveUS20130205754A1Promotes spontaneous ignitionTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionNitrogen tetroxideCombustor

The present disclosure generally pertains to a rocket propulsion oxidizer compound that is a solution, is a homogenous and stable liquid at room temperature and includes nitrous oxide and nitrogen tetroxide. In addition, an apparatus is provided for burning a fuel and nitrous oxide / nitrogen tetroxide. The apparatus has a combustor, a catalyst, a nitrous oxide / nitrogen tetroxide supply passage for directing the nitrous oxide / nitrogen tetroxide to a contact position with the catalyst, and a fuel supply passage for supplying the fuel to the combustor. The catalyst acts to facilitate decomposition of the nitrous oxide / nitrogen tetroxide, while the combustor burns the fuel, the decomposed nitrous oxide / nitrogen tetroxide and / or nitrous oxide / nitrogen tetroxide decomposed in the reaction.

Owner:CFD RES CORP

Process for catalytic decomposition of nitrogen protoxide

A process for removing nitrogen protoxide from gas mixtures which contain it, comprising contacting with a catalyst which contains mixed oxides of copper, manganese and rare earth metals in an amount expressed as percentage by weight of CuO, MnO and rare earth metal oxide in the lowest state of valency of 20-45% CuO, 50-60% MnO, and 5-20% rare earth metal oxide.

Owner:SUD CHEM CATALYSTS ITAL SRL

Compositions and methods for reducing atmospheric methane and nitrous oxide emissions

PendingCN112839523AReduce carbon creditsMicroorganism based processesPharmaceutical delivery mechanismAnimal fecesZoology

The subject invention provides compositions and methods for reducing atmospheric methane and / or nitrous oxide emissions using livestock feed additives and / or supplements. In preferred embodiments, a composition comprising a beneficial microorganism and / or a growth by-product thereof is contacted with animal feed and / or drinking water prior to the animal ingesting it. The composition is capable of, for example, controlling methanogenic microorganisms within the animal's digestive system, and thus, reducing the amount of enteric methane emissions produced from the animal and from the animal's waste.

Owner:LOCUS IP CO LLC

Method and device for disinfecting and sterilizing plastic packaging containers

InactiveCN104906611ANo secondary pollutionWill not deformLavatory sanitoryChemicalsUltravioletEthyl acetate

The invention discloses a method and a device for disinfecting and sterilizing plastic packaging containers. According to the invention, the disinfecting and sterilizing purpose is achieved by performing photochemical reaction by virtue of sequentially adding 5-10mg / m<3> ethyl acetate, a nitrogen oxide composed of nitrous oxide, nitrogen tetroxide and nitrogen dioxide, 0.1-0.3% of ferrous and 35-45% of hydrogen peroxide to generate radical ions which have a strong oxidation property. The method and the device disclosed by the invention have the beneficial effects that the plastic packaging containers are disinfected and sterilized by generating the radical ions, without secondary pollution and plastic deformation, thus avoiding ageing due to the action of ultraviolet ray and prolonging the service life and time; the plastic packaging containers after being disinfected and sterilized by the radicals are free from water stain residue and good in effect.

Owner:CHANGZHOU UNIV

Mixed oxides catalysts

Mixed oxides catalysts usable in particular in the full oxidation to CO2 and H2O of volatile organic compounds (VOC), in the decomposition of nitrogen protoxide to nitrogen and oxygen and the combustion of CO, H2 and CH4 off gases in fuel cells, comprising oxides of manganese, copper and La2O3 and / or Nd2O3, having a percentage composition by weight expressed as MnO, CuO, La2O3 and / or Nd2O3 respectively of 35-56%, 19-31% and 20-37%. The oxides are supported on inert porous inorganic oxides, preferably alumina.

Owner:SUD CHEM CATALYSTS ITAL SRL

Method for preparing nitrocompounds from nitrogen suboxides

InactiveCN103396315AIncrease profitAtom economy is highNitro compound preparationPhosphomolybdic acidNitro compound

he invention discloses a method for preparing nitrocompounds from nitrogen suboxides. Under the acceleration of molecular oxygen, nitrogen suboxides, such as nitrogen monoxide, nitrogen dioxide, nitrous oxide, nitrogen trioxide, nitrogen tetroxide and the like, reacts with heterocyclics under the actions of heteropoly acid salts (such as aluminosilicate, phosphate aluminosilicate, sodium phosphomolybdate and the like), transition metal oxides, triphenylphosphine metal organic complexes and transition metal ion clay catalysts to obtain the nitrocompounds. The method disclosed by the invention is used for substituting the traditional industrial preparation method for preparing nitrocompounds from nitrogen pentoxide, nitric acid, nitrate, nitrate ester and other high-valence nitrogen (V) compounds; and the invention enhances the atom utilization ratio of the industrial nitrocompound preparation reaction by nitrification, and has the characteristic of atom economy in industrial preparation of nitrocompounds.

Owner:彭新华

Compositions and Methods for Reducing Atmospheric Methane and Nitrous Oxide Emissions

PendingUS20210315952A1Improve scalabilityImprove water absorptionAnimal feeding stuffPharmaceutical delivery mechanismZoologyFeed additive

The subject invention provides compositions and methods for reducing atmospheric methane and / or nitrous oxide emissions using livestock feed additives and / or supplements. In preferred embodiments, a composition comprising a beneficial microorganism and / or a growth by-product thereof is contacted with animal feed and / or drinking water prior to the animal ingesting it. The composition is capable of, for example, controlling methanogenic microorganisms within the animal's digestive system, and thus, reducing the amount of enteric methane emissions produced from the animal and from the animal's waste.

Owner:LOCUS SOLUTIONS IPCO LLC

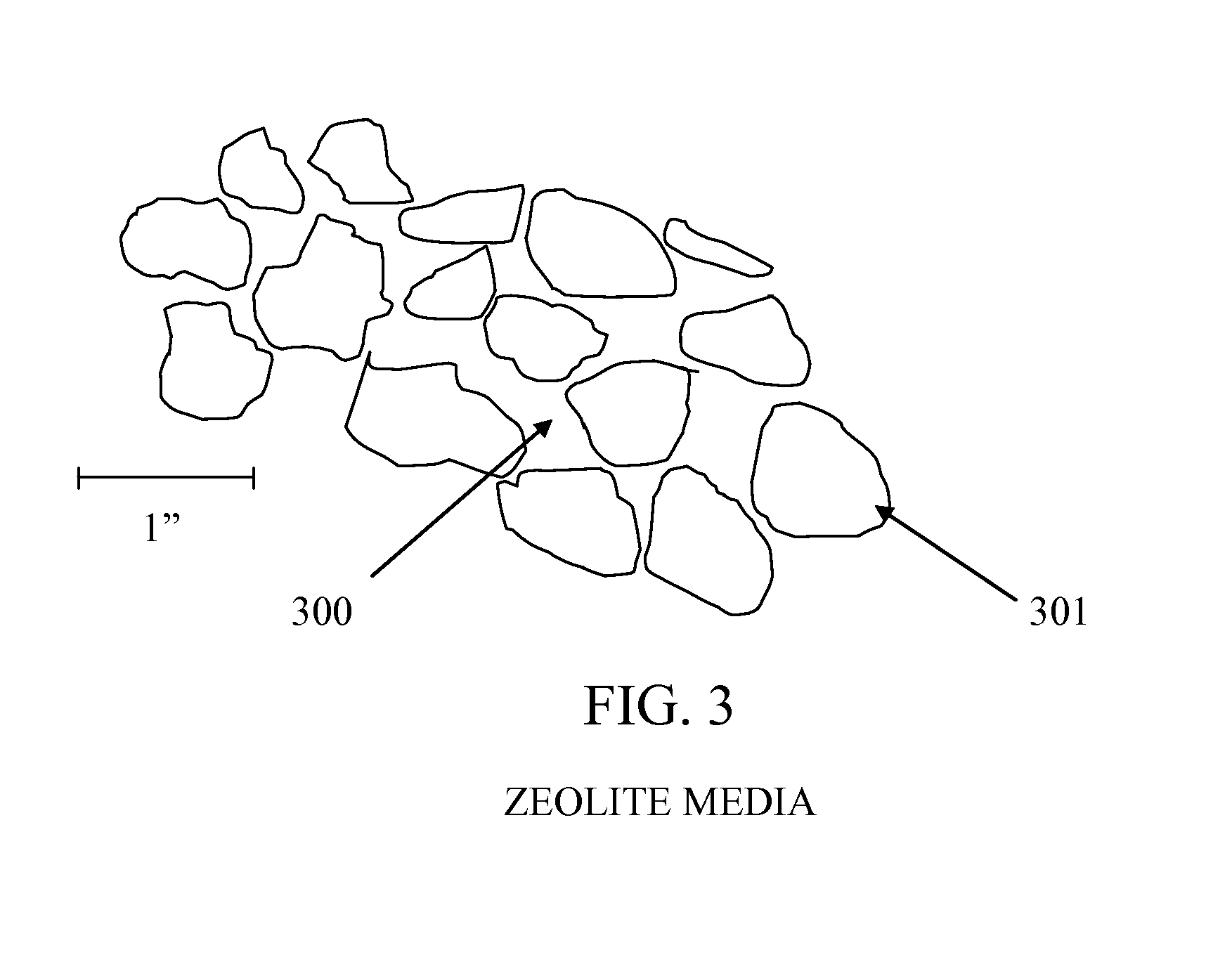

Method for producing phenol by oxidizing benzene through nitrous oxide

InactiveCN102020535AAvoid inactivationEasy to inactivateOrganic chemistryMolecular sieve catalystsBenzeneMolecular sieve

The invention relates to a process method for producing phenol by selectively oxidizing benzene through nitrous oxide, comprising the following steps of: placing a Fe-ZSM-5 molecular sieve catalyst on a distribution plate inside a fixed fluidized bed reactor; firstly activating the Fe-ZSM-5 molecular sieve catalyst by using helium at 400-600 DEG C; then introducing a gas containing the nitrous oxide and the benzene from the lower end inside the fixed fluidized bed reactor at normal pressure; controlling the reaction gas velocity of the gas between 0.040m / s and 0.072m / s through the gas distribution plate so that catalyst granules contact with the gas in a suspended state in the fixed fluidized bed reactor to carry out continuous reaction at the temperature between 300 DEG C and 500 DEG C and the normal pressure, wherein the mol ratio of the raw material benzene / N2O is between 4 and 16; and condensing and separating reaction products to obtain the phenol. The invention enables the Fe-ZSM-5 molecular sieve catalyst to contact with reaction fluids in the suspended state by utilizing the fixed fluidized bed reactor, therefore sliding velocity higher than terminal granule velocity exists between the gas and a solid; and in addition, the invention not only has very high contact efficiency, but also is beneficial to carrying out mass transfer between the gas and the solid and desorbing a product, i.e. the phenol, thereby alleviating the coking deactivation of the Fe-ZSM-5 molecular sieve catalyst.

Owner:BEIJING UNIV OF CHEM TECH

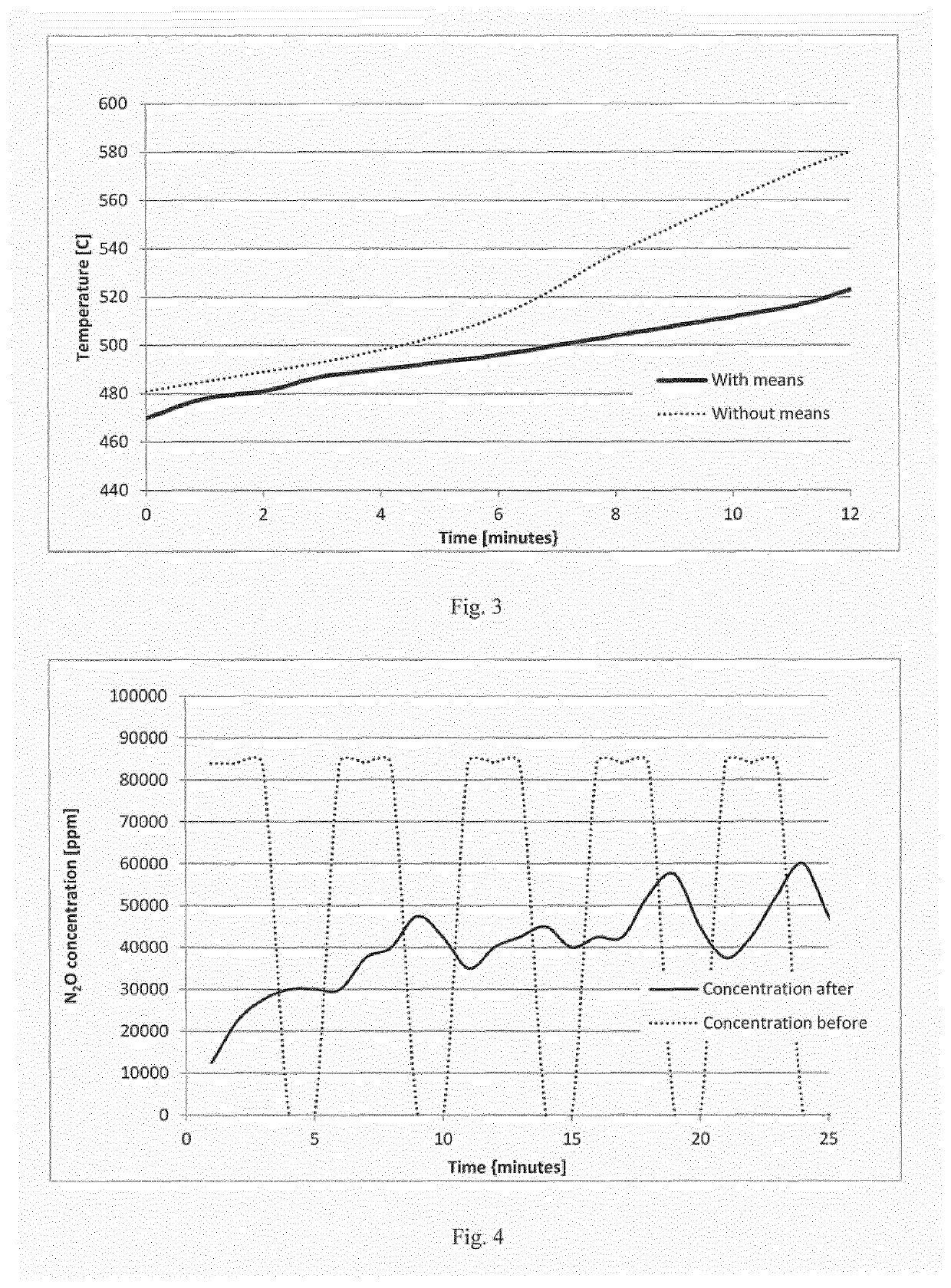

Method and device for reduction of nitrogen protoxide

The invention relates to a method and device for reducing nitrogen protoxide formed by catalytic combustion of ammonia and oxygen into nitrogen protoxide. The invention provides the use of a catalyst system comprising at least a first catalytic array and at least a second catalytic array for the catalytic combustion of ammonia and oxygen into nitrogen protoxides, first catalytic array being a platinum rhodium array and upstream second catalyst array being a platinum rhodium array with 2 to 4 weight % of rhodium.

Owner:HERAEUS MATERIALS TECHNOLOGY GMBH & CO KG

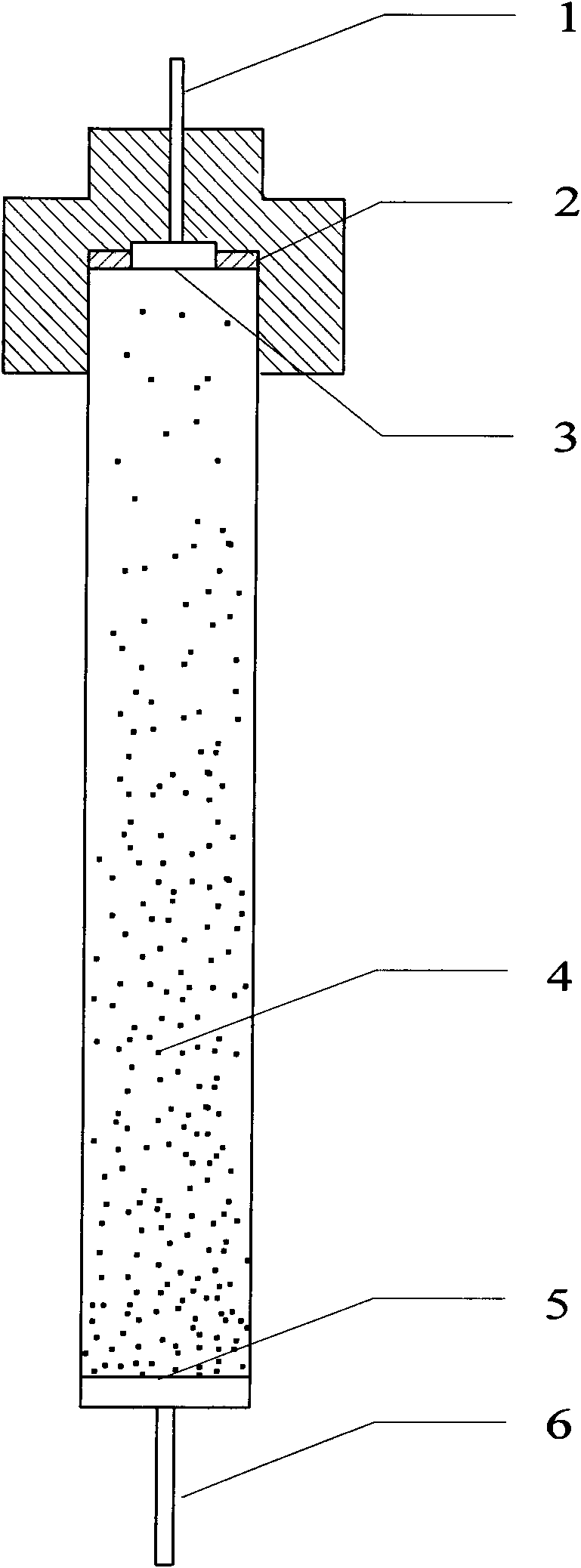

Self-Regenerating Zeolite Reactor for Sustainable Ammonium Removal

InactiveUS20160207809A9Increase switching capacityLow infrastructure costIon-exchanger regenerationWater contaminantsCation-exchange capacityIon exchange

Owner:COLLISON ROBERT SPENCER

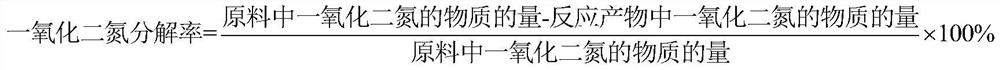

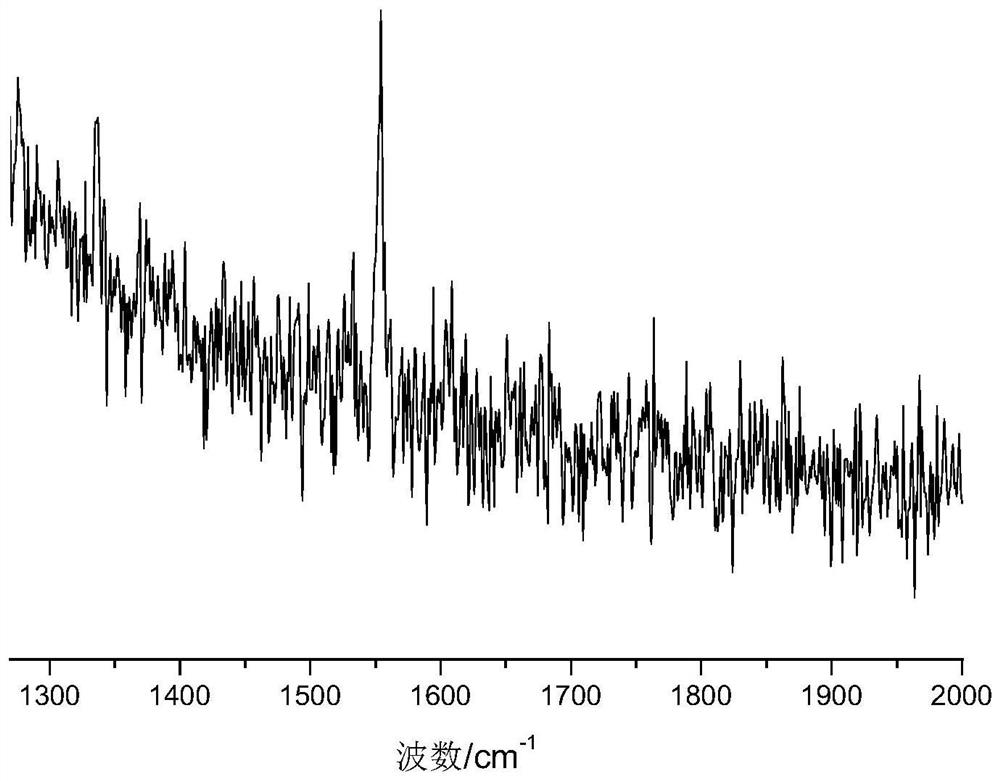

Catalyst for decomposing nitrous oxide, preparation method of catalyst and nitrous oxide decomposition method

PendingCN113600202AHigh activityImprove high temperature resistanceNitrous oxide captureGas treatmentAlkaline earth metalPtru catalyst

The invention provides a catalyst for decomposing nitrous oxide, a preparation method of the catalyst and a nitrous oxide decomposing method. The catalyst simultaneously comprises oxide of transition metal, an auxiliary agent, a modified element and a binder, the auxiliary agent comprises any one or a combination of at least two of an alkali metal oxide, an alkaline earth metal oxide, a lanthanum oxide, a cerium oxide or a zinc oxide; the modified element comprises yttrium element and / or neodymium element; and the binder comprises silicon oxide and / or aluminum oxide. The catalyst is high in activity, good in temperature resistance and excellent in cycle stability, the preparation method is a one-step synthesis method, the preparation process is simple and pollution-free, the decomposition method is low in bed temperature, additional heating of gas is not needed, high-quality steam is produced as a byproduct, and the operation cost is reduced.

Owner:SHANGHAI HUAFON NEW MATERIAL R&D TECH CO LTD +1

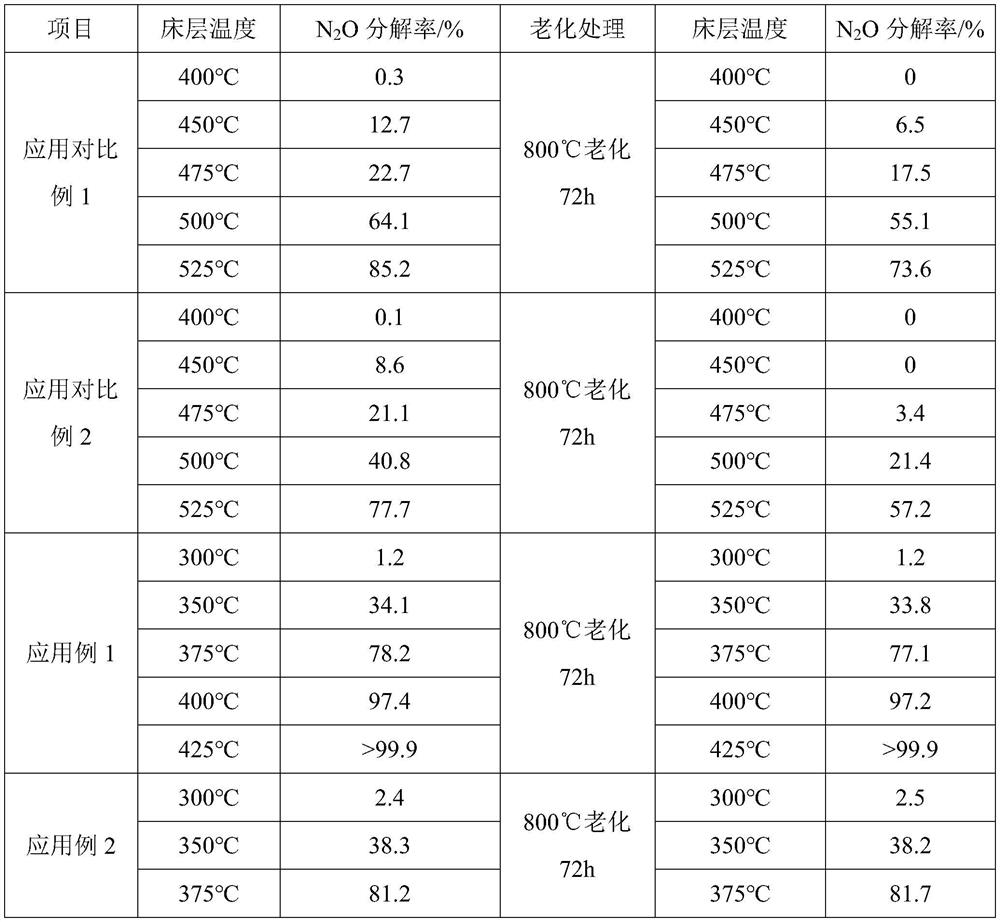

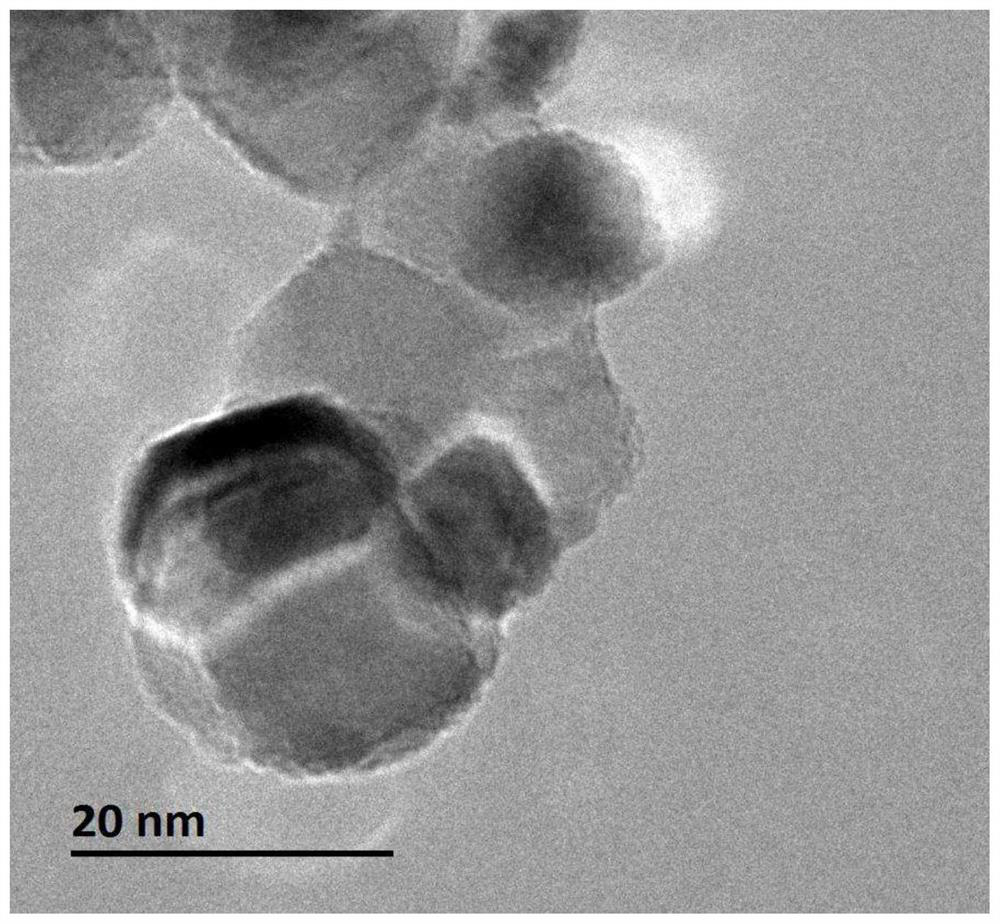

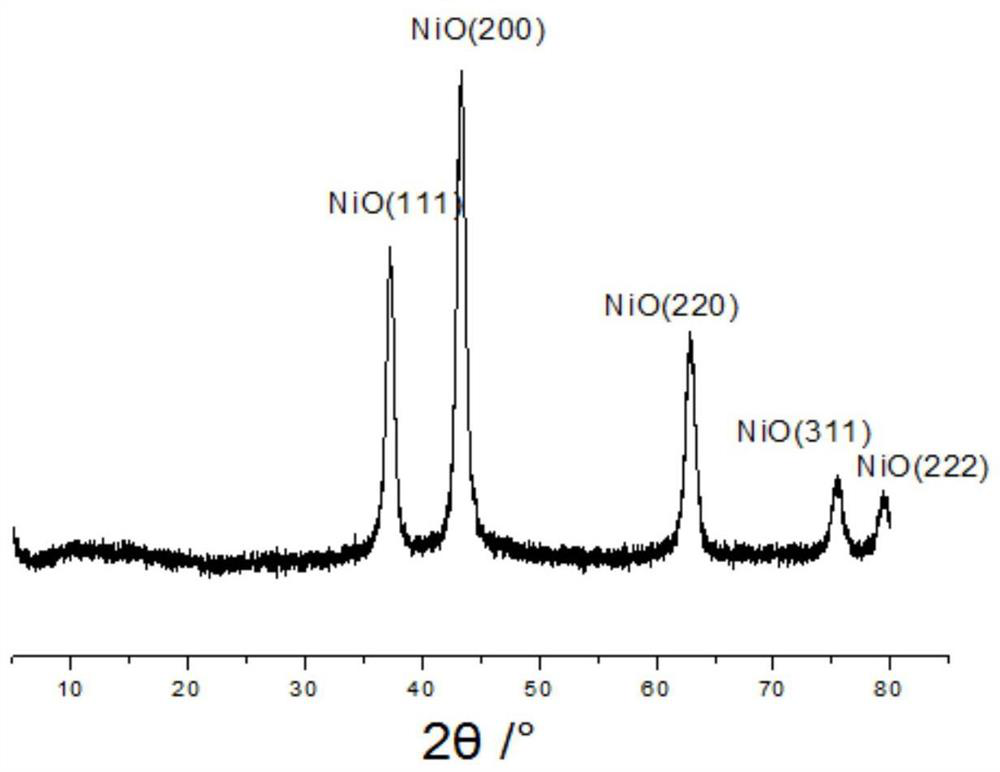

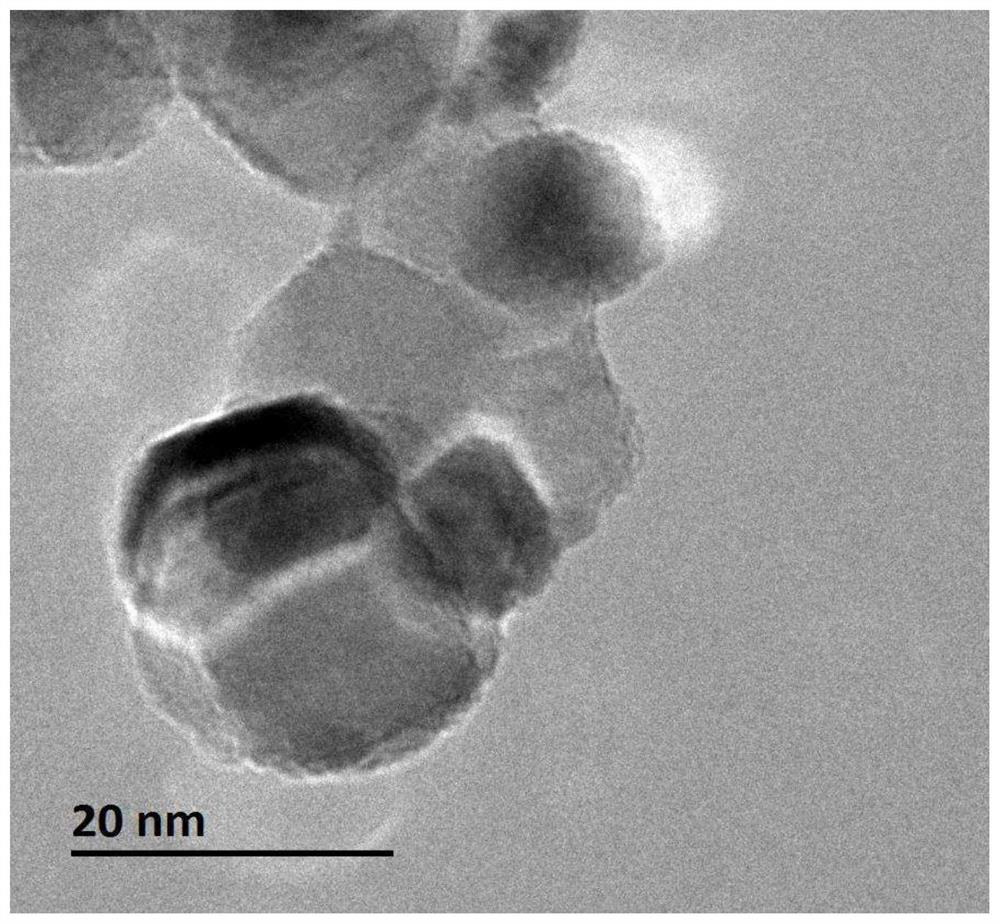

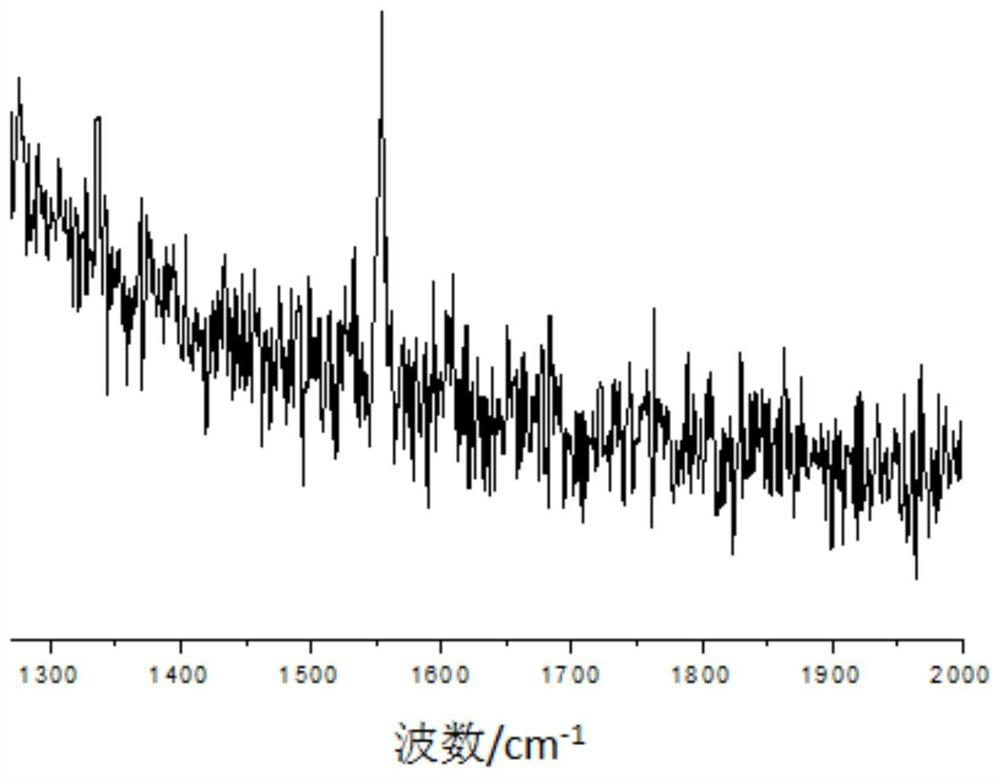

Carbon-coated nickel oxide nano composite material and preparation method and application thereof

ActiveCN113751008AReduce pollutionHigh activityNitrous oxide captureMaterial nanotechnologyHigh concentrationAlkaline earth metal

The invention provides a carbon-coated nickel oxide nano composite material and a preparation method and application thereof. The method comprises a method for catalytically decomposing nitrous oxide by adopting a catalyst containing the nano composite material. The nano composite material comprises a nuclear membrane structure with an outer membrane and an inner core, the outer membrane is a graphitized carbon membrane, the inner core comprises nickel oxide nano particles, the nano composite material further comprises second metal, the second metal is alkali metal and / or alkaline earth metal, and the molar ratio of the second metal to nickel is 0.01-0.3. When the nanometer composite material doped with the alkali metal and / or the alkaline earth metal is used for catalyzing the decomposition reaction of nitrous oxide, the catalytic activity can be further improved, the problem of eliminating high-concentration N2O generated in the production process of adipic acid plants, nitric acid plants and the like can be solved, and the nanometer composite material has good industrial application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for catalytic decomposition of nitrogen protoxide

A process for removing nitrogen protoxide from gas mixtures which 5 contain it, comprising contacting with a catalyst which contains mixed oxides of copper, manganese and rare earth metals in an amount expressed as percentage by weight of CuO, MnO and rare earth metal oxide in the lowest state of valency of 20-45% CuO, 50-60% MnO, and 5-20% rare earth metal oxide.

Owner:SUD CHEM CATALYSTS ITAL SRL

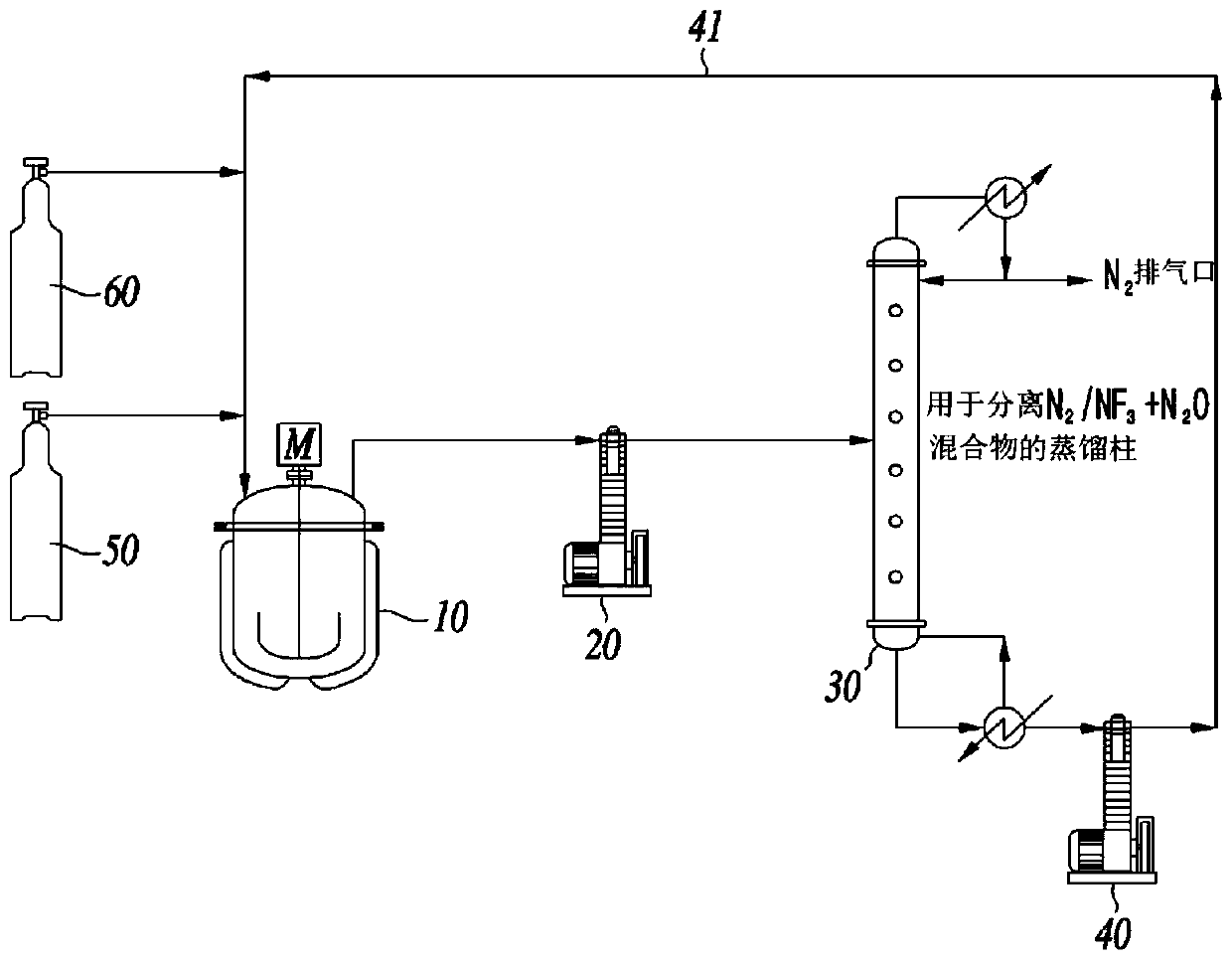

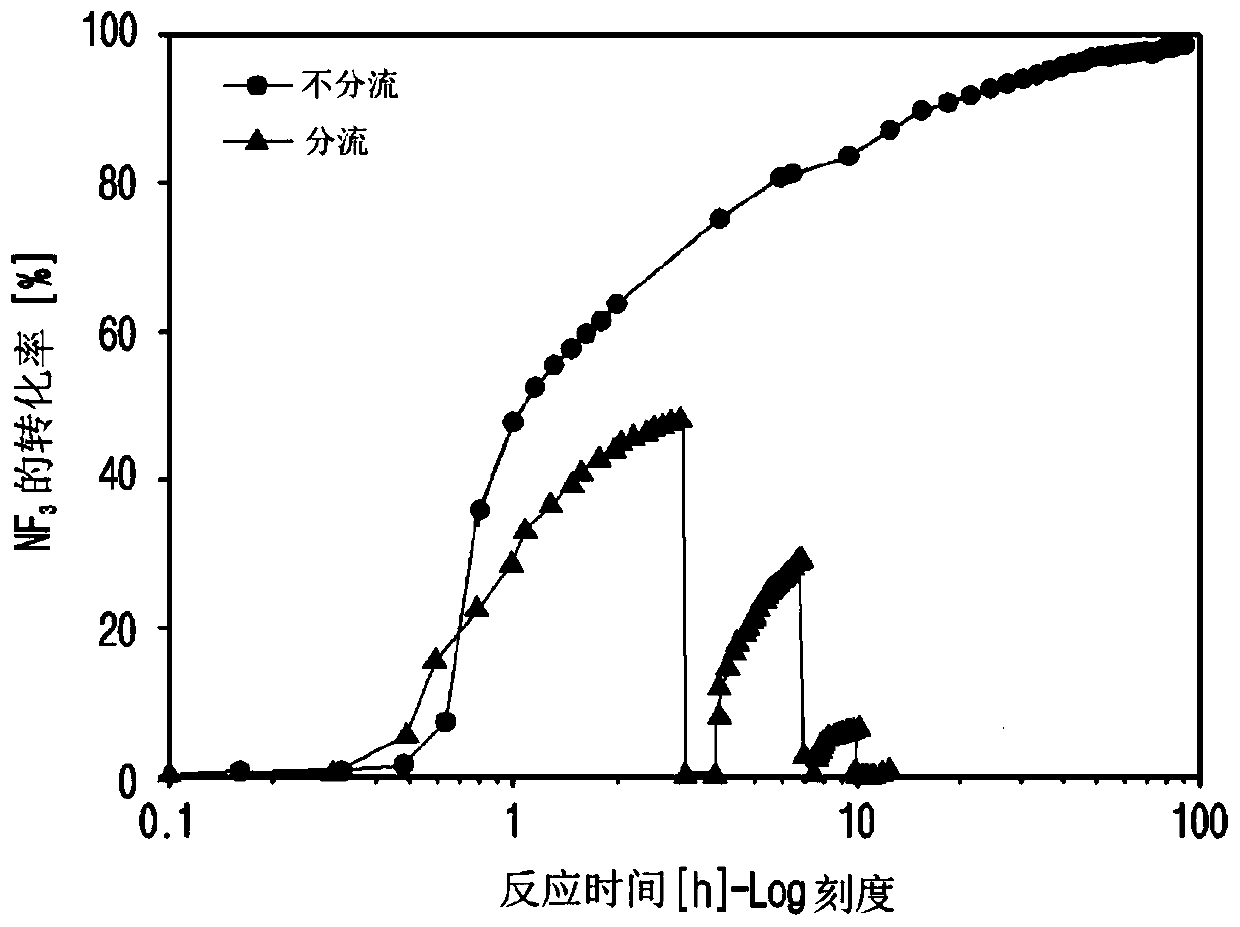

Method and apparatus for effectively producing trifluoroamine oxide

ActiveCN111479775AShort reaction timeImprove production yieldCatalytic liquid-gas reactionDistillation separationPtru catalystPhysical chemistry

Disclosed is a method for producing trifluoroamine oxide, the method comprising: a step for producing an intermediate product by reacting nitrogen trifluoride and nitrous oxide in the presence of a reaction catalyst, wherein unreacted gas including nitrogen (N2) generated by the reaction is removed, and nitrogen trifluoride and nitrous oxide are further injected to produce the intermediate product; and a step for producing trifluoroamine oxide by reacting the intermediate product with sodium fluoride.

Owner:KOREA RES INST OF CHEM TECH +1

Process for preparation of nitrogen oxides and nitric acid from nitrous oxide

ActiveUS10723624B2Reduce the amount requiredAmount of moreOrganic compound preparationHigh temperature gas-gas reactionNitrogen oxidesEnvironmental engineering

Described herein is an improved conversion of nitrous oxide (N2O) present as a by-product in a chemical process to NOx which can be further converted to a useful compound or material, such as nitric acid.

Owner:ASCEND PERFORMACE MATERIALS OPERATIONS LLC

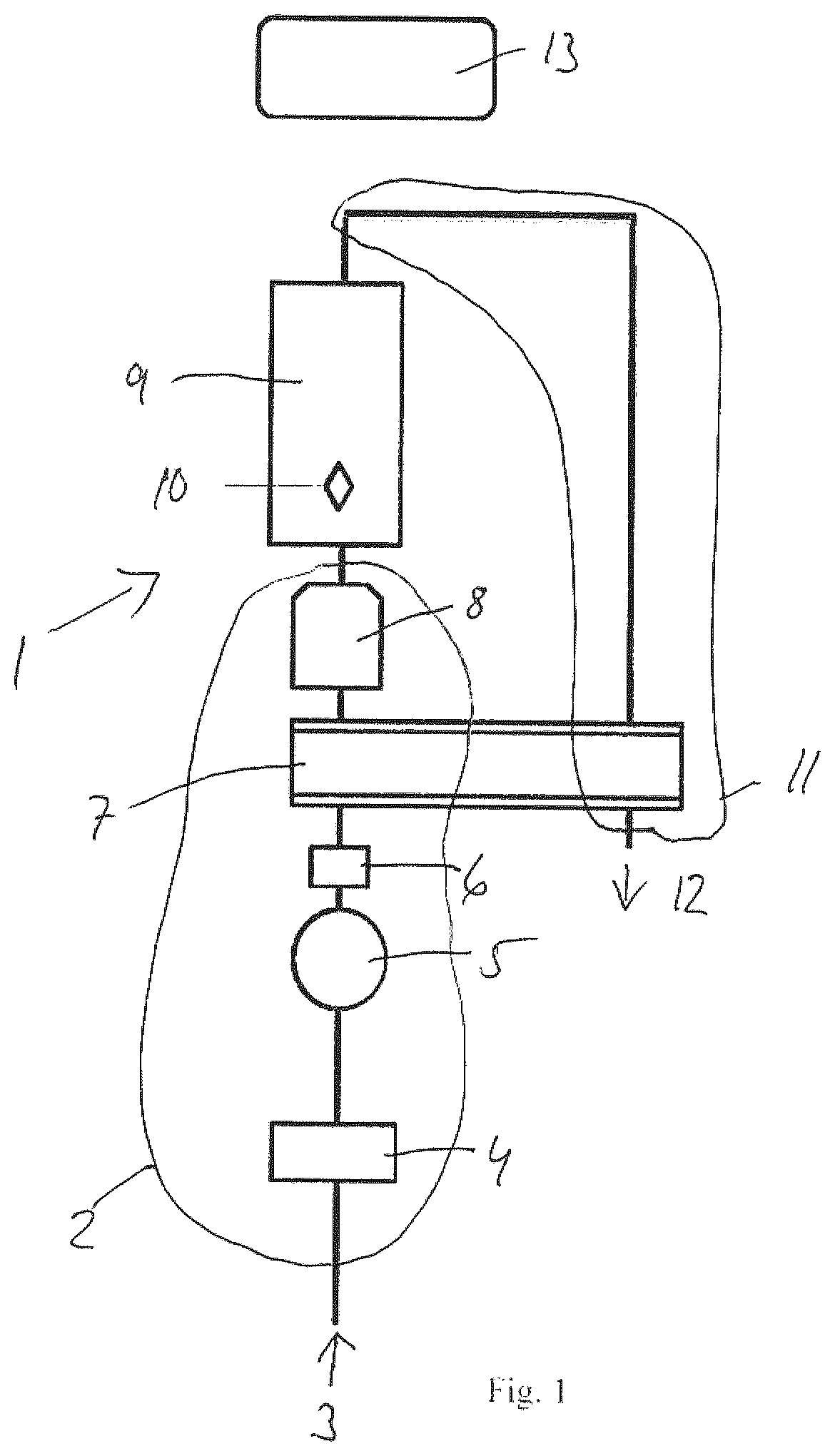

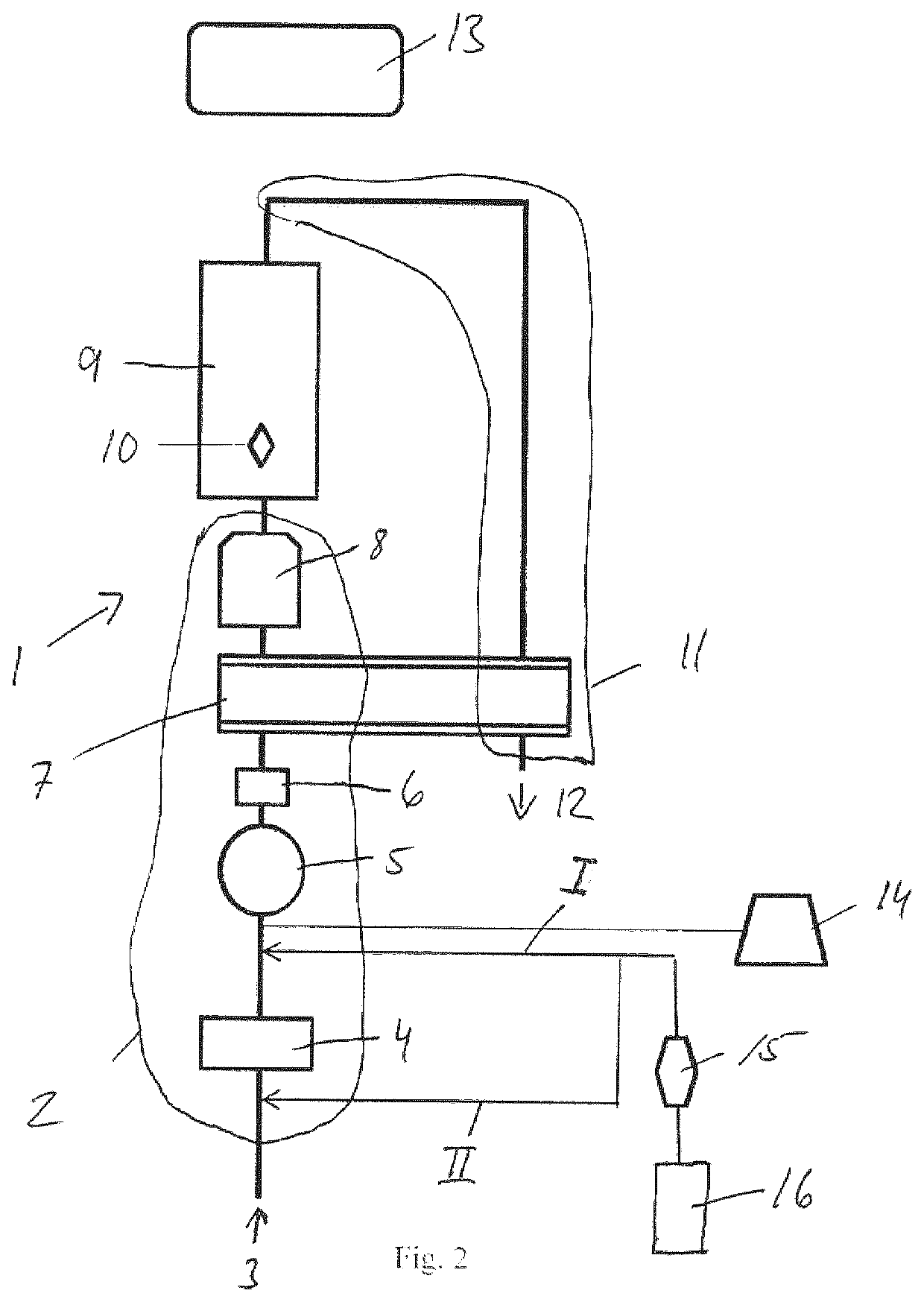

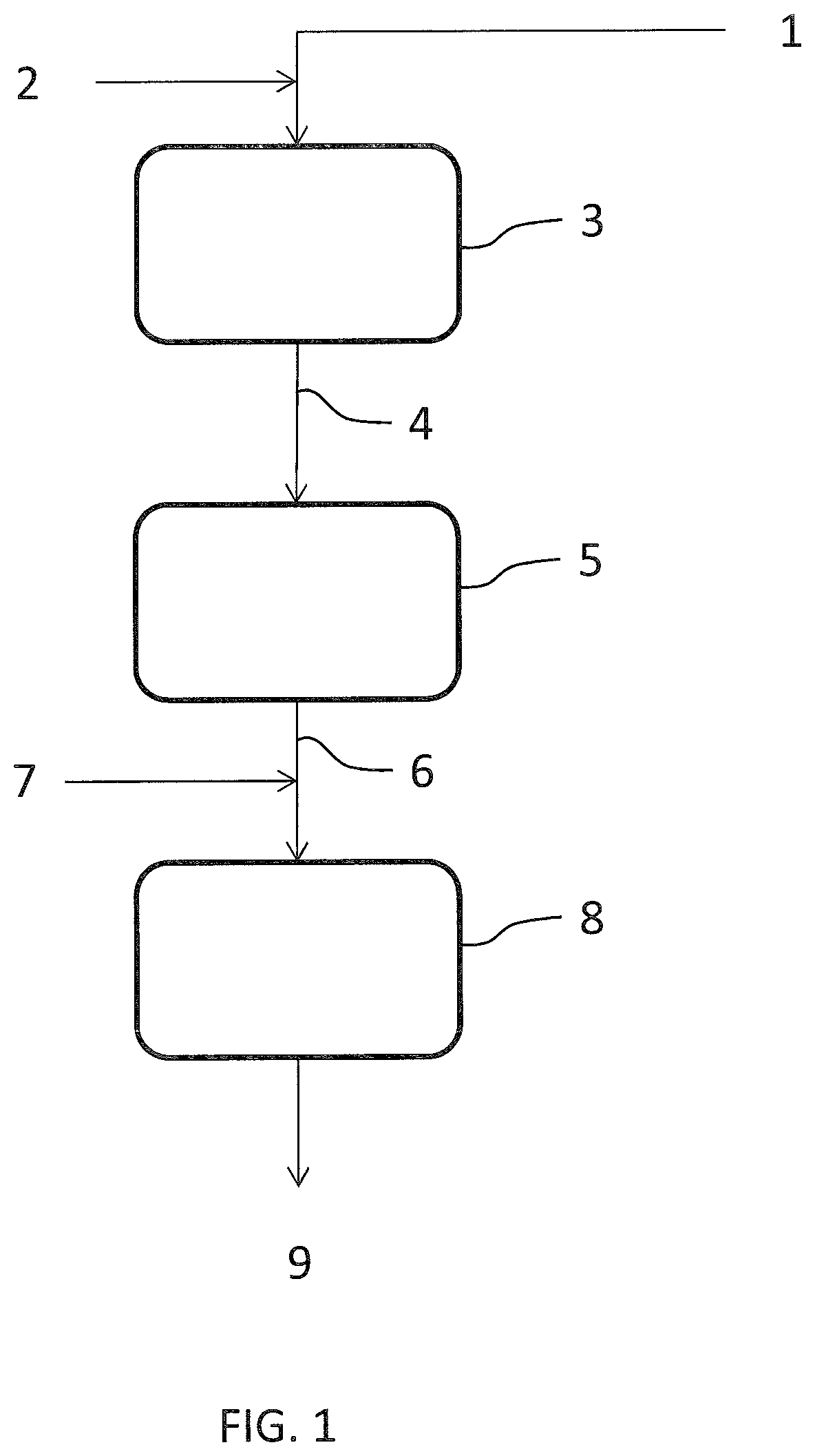

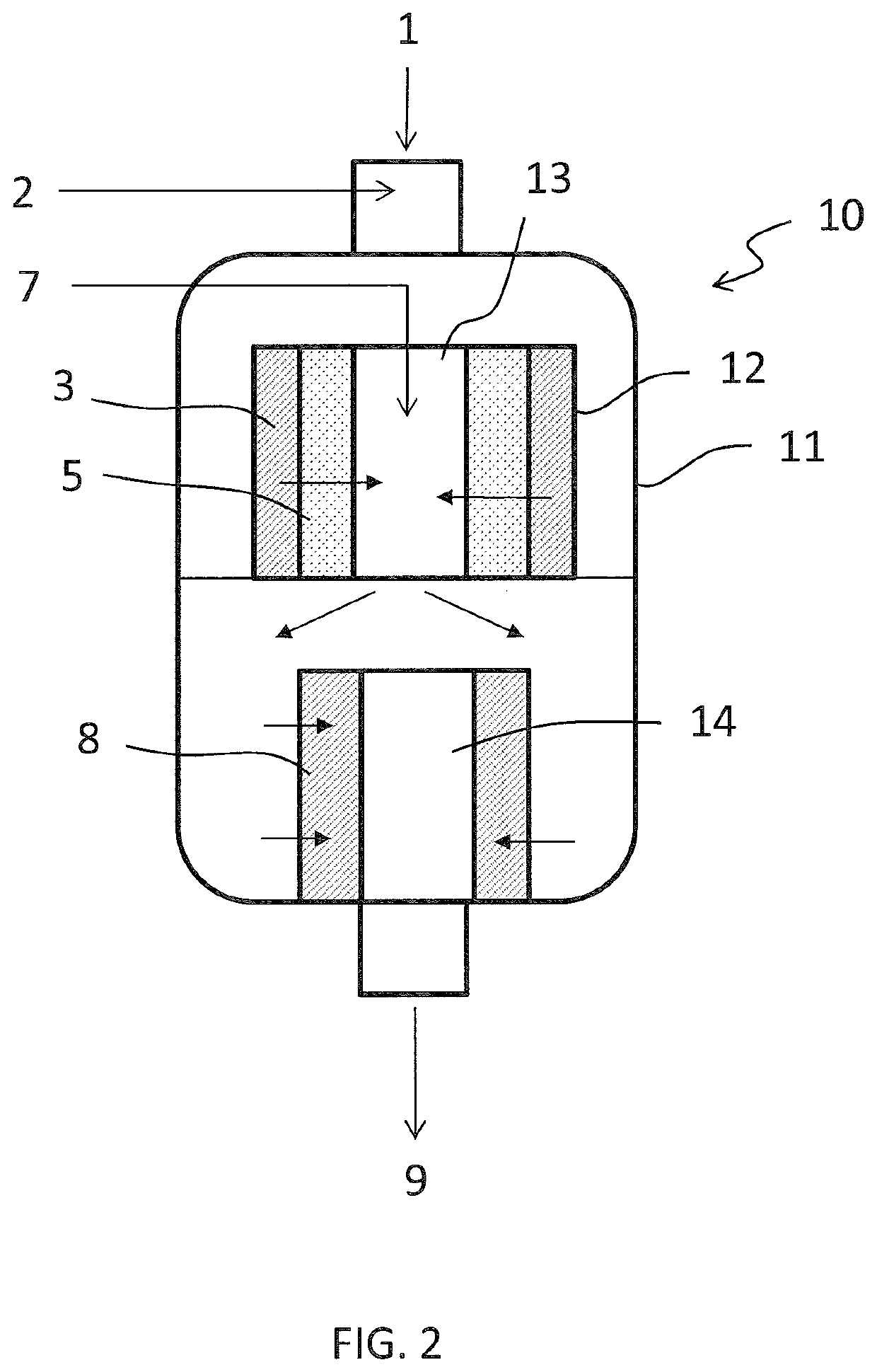

Apparatus for catalytic decomposition of nitrous oxide in a gas stream

ActiveUS20210146075A1Avoid destructionReduce concentrationRespiratorsNitrous oxide capturePtru catalystDesorption

The invention relates to an apparatus (1) for catalytic decomposition of nitrous oxide in a gas stream derived from exhalation air from a patient. The apparatus (1) comprises an inlet arrangement (2) with a gas inlet (3) for the exhalation air, an outlet arrangement (11) with a gas outlet (12) for an outlet gas, and between these arrangements a through-flow decomposition chamber (9) containing a catalyst material. According to the invention the apparatus is provided with a nitrous oxide adsorption / desorption means (4) in the inlet arrangement (2) for level out variations in the concentration of nitrous oxide fed to the decomposition chamber (9).

Owner:MEDCLAIR AB

Method and apparatus for removing NOx and N2O from a gas

ActiveUS11325069B2Reduce and eliminate riskMore regulationNitrous oxide captureGas treatmentNitrogen oxidesEnvironmental engineering

Method for reducing the content of nitrogen oxides NOx and nitrous oxide N2O in an input gas, comprising the steps of: treating said gas with a first amount of a NOx reducing agent in a first de-NOx catalytic bed; treating the effluent of said first de-NOx catalytic bed in at least one de-N2O catalytic bed for removal of N2O; treating the effluent of said at least one de-N2O catalytic bed with a second amount of a NOx reducing agent in a second de-NOx catalytic bed.

Owner:CASALE SA

Carbon-coated nickel oxide nanocomposite, preparation method and application thereof

ActiveCN112755993BReduce pollutionHigh activityNitrous oxide captureGas treatmentHigh concentrationPtru catalyst

The invention provides a carbon-coated nickel oxide nanocomposite material and a preparation method and application thereof. The nanocomposite material contains a nuclear membrane structure with an outer membrane and an inner core, the outer membrane is a graphitized carbon membrane, and the inner core contains nickel oxide nanoparticles , wherein the carbon content accounts for no more than 5wt% of the nanocomposite material. The nanocomposite has excellent activity as a catalyst, which can effectively catalyze the decomposition of nitrous oxide, which is helpful to solve the high concentration of N produced in the production process of adipic acid plants and nitric acid plants. 2 The elimination of O is of great significance for protecting the environment and reducing air pollution, and has a good industrial application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

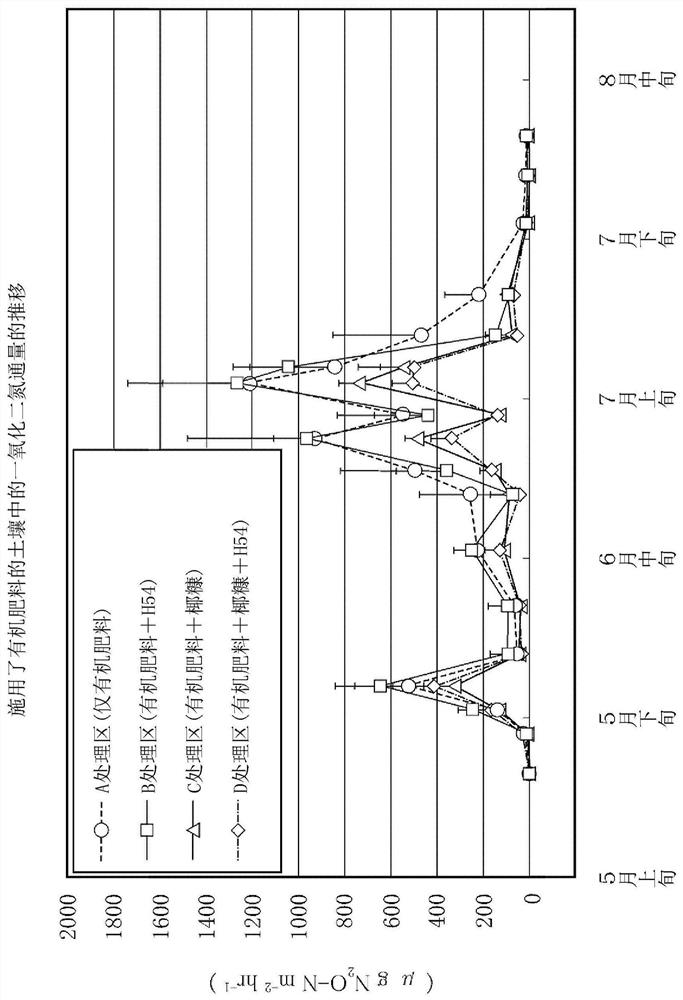

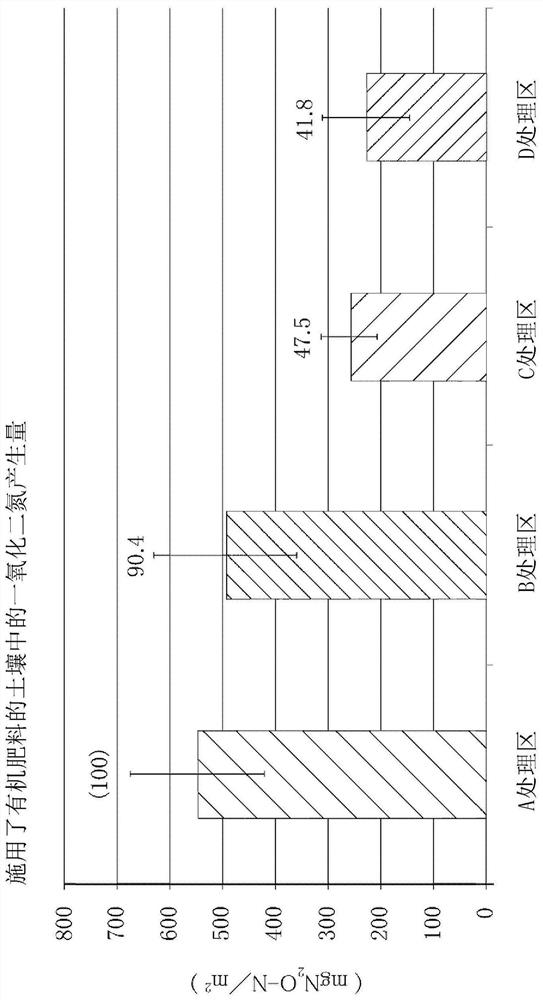

Nitrous oxide reducing material for agricultural land and method for reducing nitrous oxide production in agricultural land

The present invention provides a nitrous oxide reducing material for agricultural land, which can reduce the production of nitrous oxide caused by nitrogen-containing substances applied to the agricultural land regardless of the soil quality and utilization form of the agricultural land. A nitrous oxide reducing material for agricultural land, which is used for reducing nitrous oxide generated by nitrogen-containing substances such as fertilizers, composts, and harvest residues used in agricultural land and released into the atmosphere. A material for reducing nitrous oxide, characterized in that it contains, as a main component, a fungal-eating soil animal activating substance that activates the proliferation or activity of the fungi-eating soil animal, and that the fungi-eating soil animal feeds and survives. A fungus that produces nitrous oxide in the nitrogen-containing substance used in the agricultural field is produced in the agricultural field.

Owner:NIIGATA PREFECTURE +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com