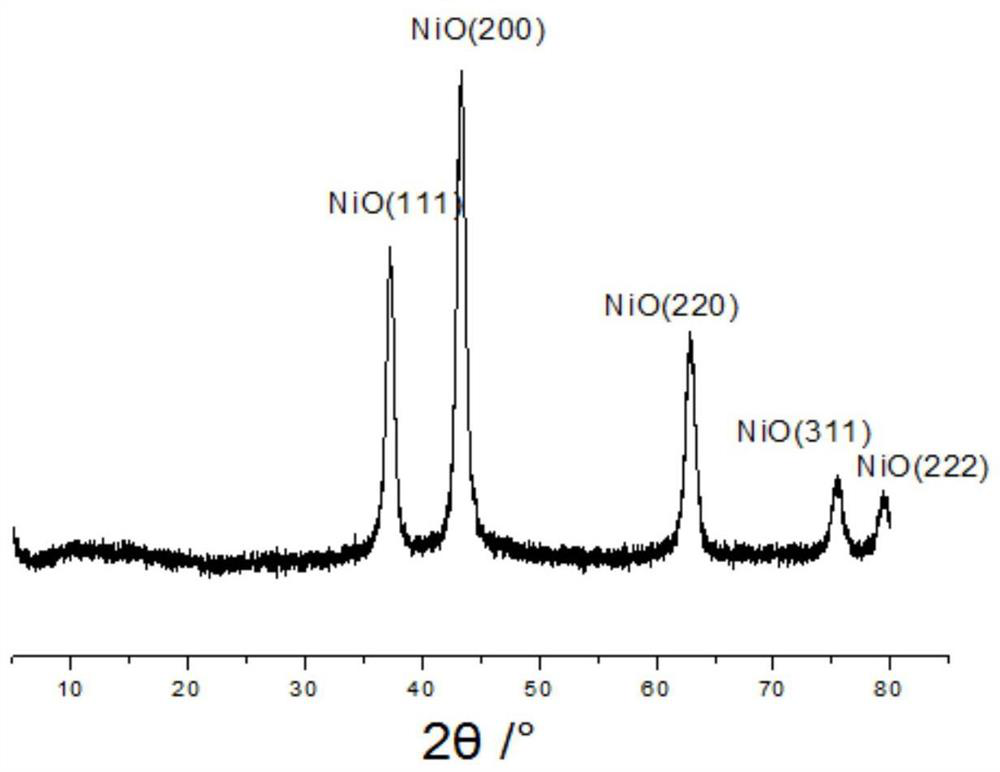

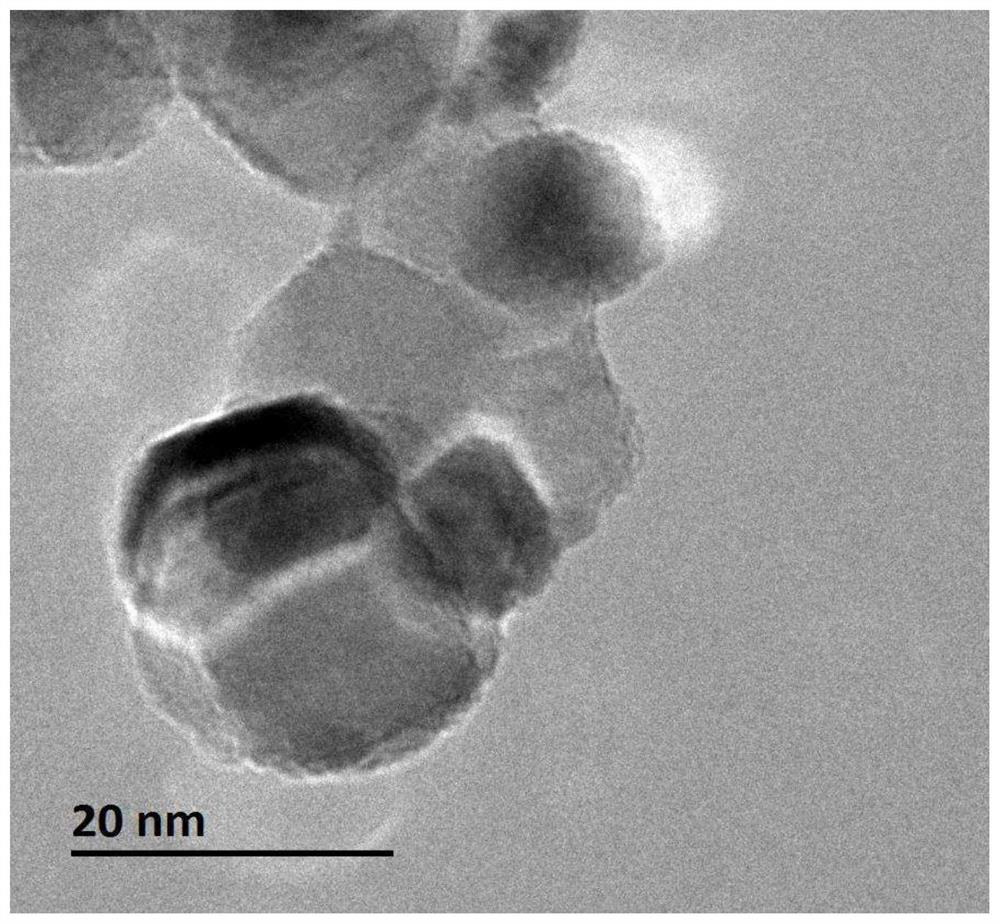

Carbon-coated nickel oxide nanocomposite, preparation method and application thereof

A nano-composite material, nickel oxide technology, applied in the field of catalysis, can solve the problems of restricting the large-scale application of precious metal catalysts, high price, increasing industrial costs, etc., and achieves good industrial application prospects, excellent activity, and the effect of reducing air pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] A second aspect of the present invention also provides a method for preparing the aforementioned carbon-coated nickel oxide nanocomposite, comprising the following steps:

[0049] The nickel-containing compound and the polyvalent organic carboxylic acid are placed in a solvent and mixed to form a homogeneous solution;

[0050] removing the solvent in the homogeneous solution to obtain the precursor;

[0051] The precursor is pyrolyzed in an inert atmosphere or a reducing atmosphere;

[0052] The pyrolyzed product is subjected to oxygen treatment to obtain a nanocomposite material.

[0053] Specifically, the precursor is a water-soluble mixture, which refers to a nickel-containing water-soluble mixture obtained by dissolving a nickel-containing compound and a polyvalent organic carboxylic acid in a solvent such as water and ethanol into a homogeneous solution, and then directly evaporating and removing the solvent. Sexual mixture. The aforementioned temperature and pr...

Embodiment 1

[0074] This example is used to illustrate the preparation of the carbon-coated nickel oxide nanocomposite material of the present invention.

[0075] (1) Weigh 10 g of nickel carbonate and 10 g of citric acid into a beaker containing 100 mL of deionized water, stir at 70° C. to obtain a homogeneous solution, and continue to heat and evaporate to dryness to obtain a solid precursor.

[0076] (2) placing the solid precursor obtained in step (1) in a porcelain boat, then placing the porcelain boat in the constant temperature zone of the tube furnace, feeding nitrogen with a flow rate of 100 mL / min, and heating at a rate of 4 °C / min The temperature was raised to 600° C., the heating was stopped after 2 hours of constant temperature, and the mixture was cooled to room temperature under a nitrogen atmosphere to obtain a black solid.

[0077] (3) the black solid obtained in step (2) is placed in the porcelain boat, then the porcelain boat is placed in the constant temperature zone of...

Embodiment 2

[0082] This example is used to illustrate the preparation of the carbon-coated nickel oxide nanocomposite material of the present invention.

[0083] (1) Weigh 10 g of nickel acetate and 10 g of citric acid into a beaker containing 100 mL of deionized water, stir at 70° C. to obtain a homogeneous solution, and continue to heat and evaporate to dryness to obtain a solid precursor.

[0084] (2) placing the solid precursor obtained in step (1) in a porcelain boat, then placing the porcelain boat in the constant temperature zone of the tube furnace, feeding nitrogen with a flow rate of 100 mL / min, and heating at a rate of 2 °C / min The temperature was raised to 650° C., the heating was stopped after 2 h, and the mixture was cooled to room temperature under a nitrogen atmosphere to obtain a black solid.

[0085] (3) the black solid obtained in step (2) is placed in the porcelain boat, then the porcelain boat is placed in the constant temperature zone of the tube furnace, and the flo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com