Method and apparatus for effectively producing trifluoroamine oxide

An oxide and trifluoroamine technology, applied in the field of effectively preparing trifluoroamine oxide, can solve the problems of uncertainty, synthesis method risk, yield and gas purity are not fully recognized, etc., to reduce the reaction time, The effect of improving raw yield, high yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

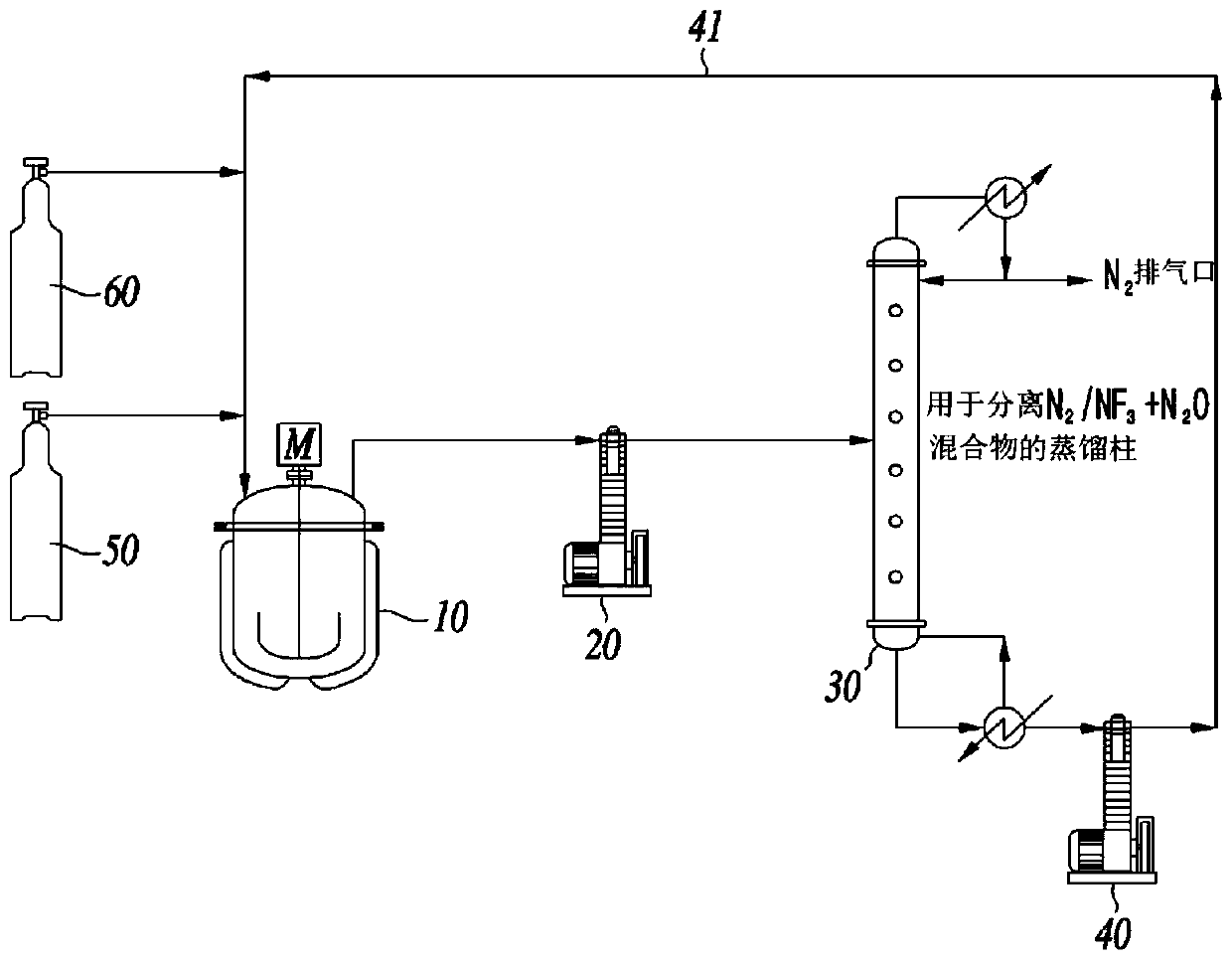

[0025] In one aspect of the present invention, the present invention provides the preparation method of trifluoroamine oxide, it comprises the following steps:

[0026] In the presence of a reaction catalyst, the intermediate product is produced by reacting nitrogen trifluoride with nitrous oxide, wherein the nitrogen-containing gas (N 2 ) of unreacted gas is removed and instead additional injection of nitrogen trifluoride and nitrous oxide; and

[0027] Trifluoroamine oxide is produced by reacting this intermediate product with sodium fluoride.

[0028] The trifluoroamine oxide (F) provided by one aspect of the present invention will be described in detail step by step below. 3 NO) preparation method.

[0029] First, the preparation method of trifluoroamine oxide provided according to one aspect of the present invention comprises the following steps: in the presence of a reaction catalyst, an intermediate product is produced by reacting nitrogen trifluoride with nitrous oxi...

Embodiment 1

[0079] Step 1: 200 grams (0.92 moles) of antimony pentafluoride (SbF 5 ) into a stainless steel 1-liter high-pressure reactor and use the internal F 2 Gas passivation, the high pressure reactor was equipped with magnetic drive, anchor stirrer and jacket. Add 130.6 g (1.84 mol) of nitrogen trifluoride (NF 3 ) and 80.96 grams (1.84 moles) of nitrous oxide (N 2 O), and tightly seal the reactor. The stirring speed was maintained at 200 rpm and the reaction temperature was increased to 150°C.

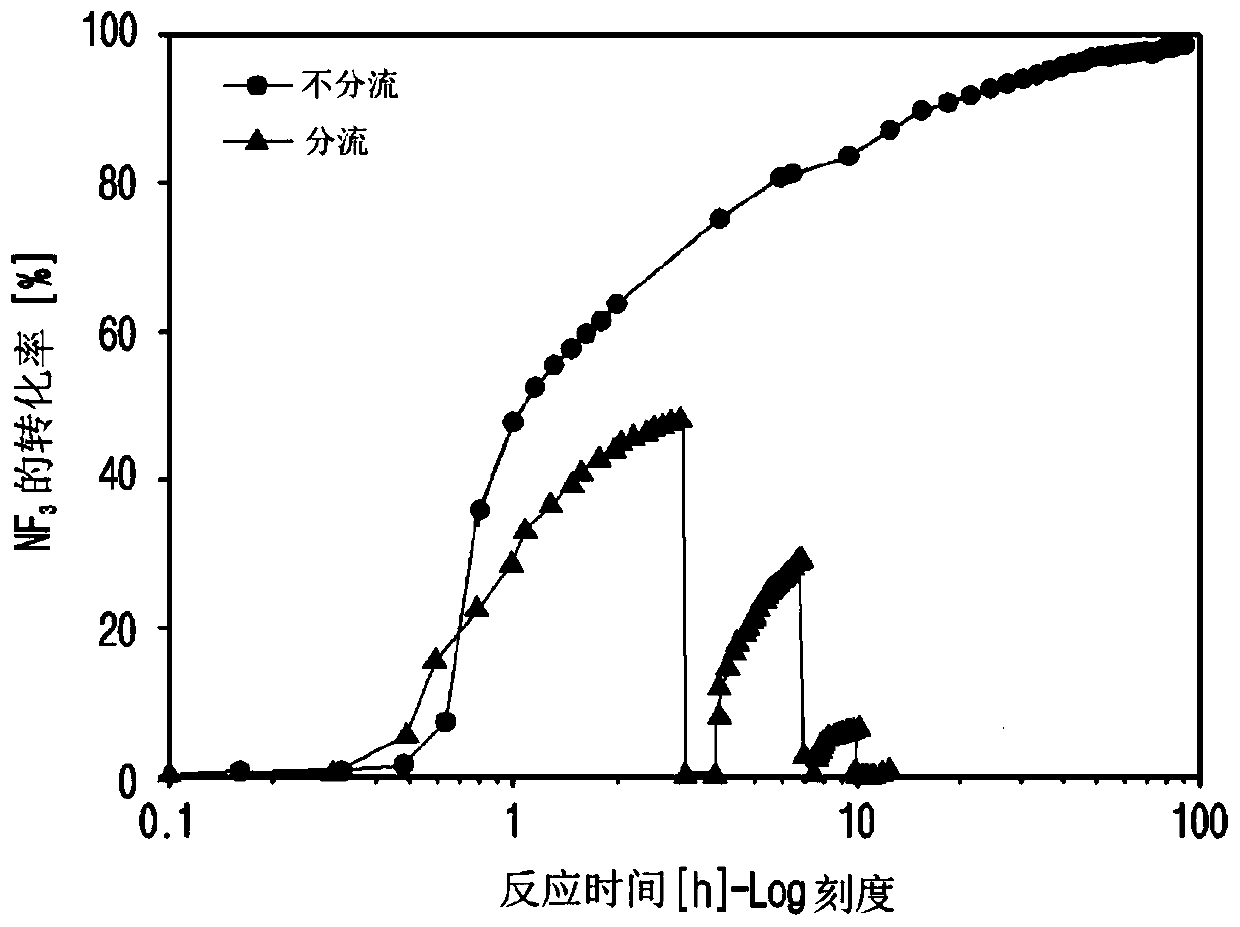

[0080] Reaction progress such as reaction conversion was followed by gas chromatography TCD and 5% fluorocol / carbopack B column to track the N produced in the reaction 2 Monitor with consumption of nitrogen trifluoride and nitrous oxide. When the average conversion rate of antimony pentafluoride based on nitrogen trifluoride and nitrous oxide reaches 70%-80%, the reaction gas N 2 / NF 3 / N 2 O is removed and pure nitrogen trifluoride and nitrous oxide are injected. Gas venting and ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com