Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

413 results about "Motor vehicle airbag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fabric coating compositions providing excellent resistance to seam combing, particularly for use on automotive airbag fabrics

InactiveUS6348543B1Highly cost-effectiveEasy to handlePedestrian/occupant safety arrangementWoven fabricsYarnAirbag deployment

This invention relates to a new adhesive coating composition, particularly for use on airbag fabrics, which is composed of a crosslinked blend of a polyalkyl- or polyphenylsiloxane with vinyl functionality and a copolymer of ethylene and methyl acrylate. This coating provides excellent adhesive properties to the coated fabric, in that it restricts the movement, when put under stress, of the yarns constricting that fabric, which are situated adjacent to seams in the fabric. This reduces the effect known in the trade as combing. Fabric treated with this material in the mainer described herein, requires a marked increase in the amount of force required for this yarn movement. This distortion of the fabric can be detrimental in an automotive airbag, in that, it may result in the loss of inflating air, and under extreme conditions may result in a seam failure.

Owner:MILLIKEN & CO

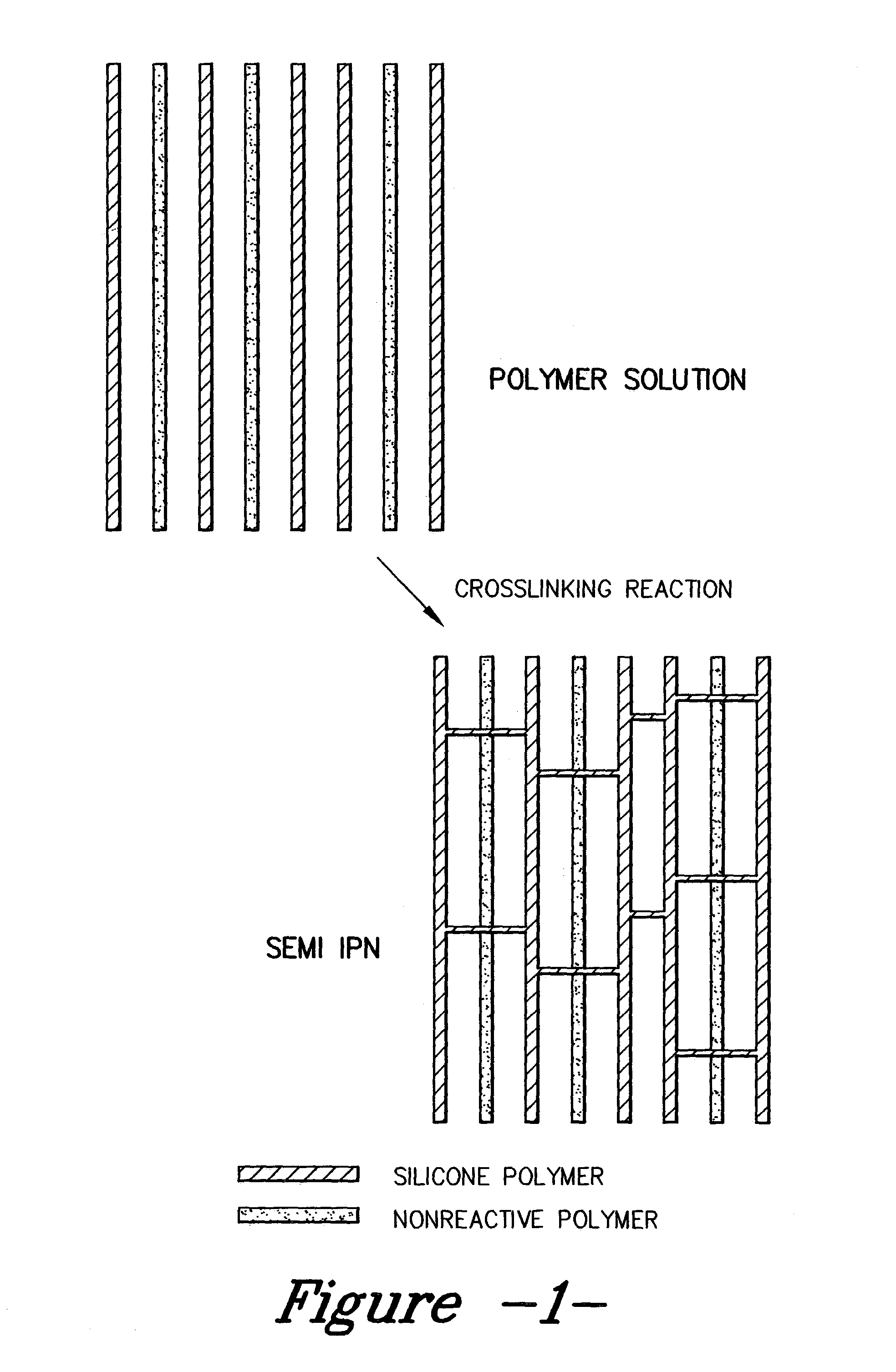

Polymer coating blends

InactiveUS7132170B2Improve adhesionAbility to efficientlyPedestrian/occupant safety arrangementFibre typesPolymer sciencePolymer coatings

An adhesive coating composition for fabric substrates, such as automotive airbags. The coating is formed from a blend including a silicone polymer and a second polymer which is thermodynamically compatible with silicone. In particular, the second polymer has a cohesion parameter (δ / MPa1 / 2) that is similar to that of silicone so that any thermodynamic barrier to the second polymer dissolving in silicone is removed.

Owner:MILLIKEN & CO

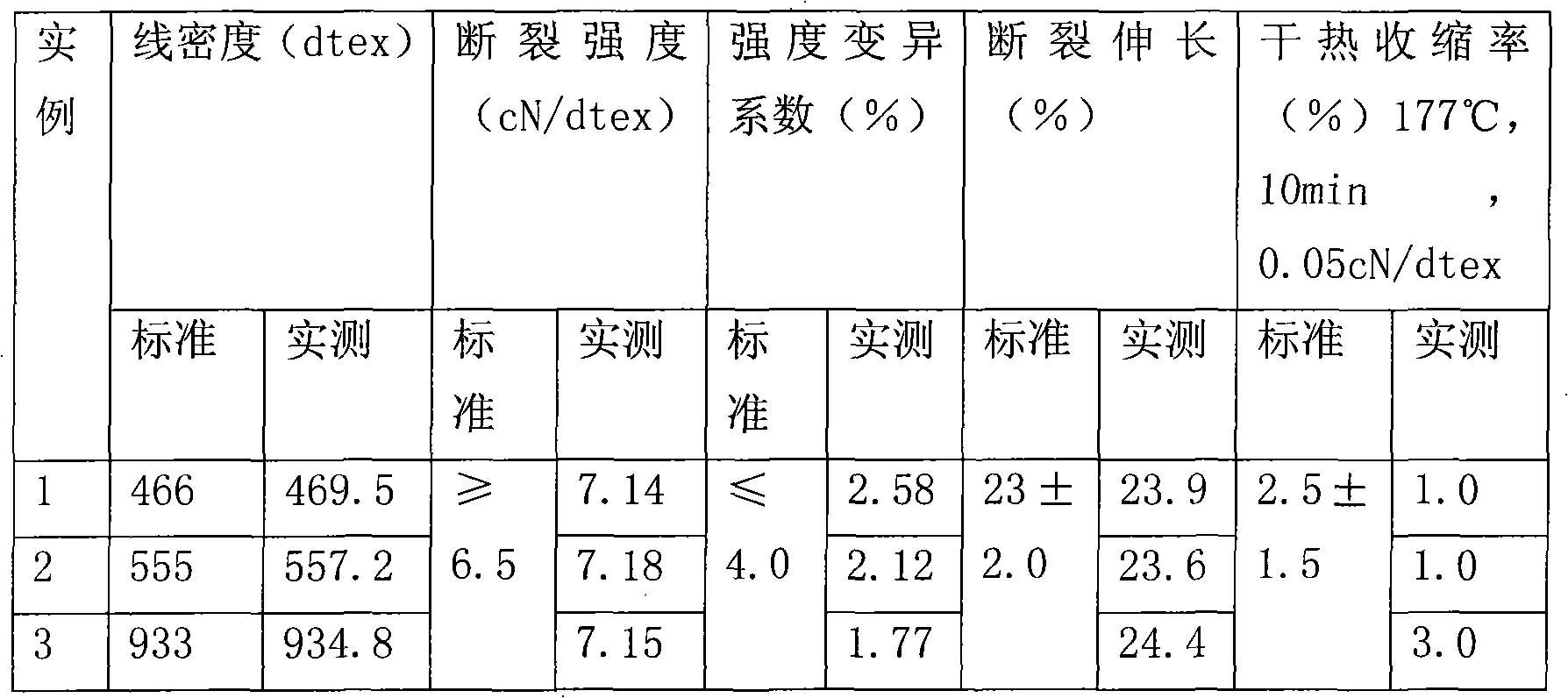

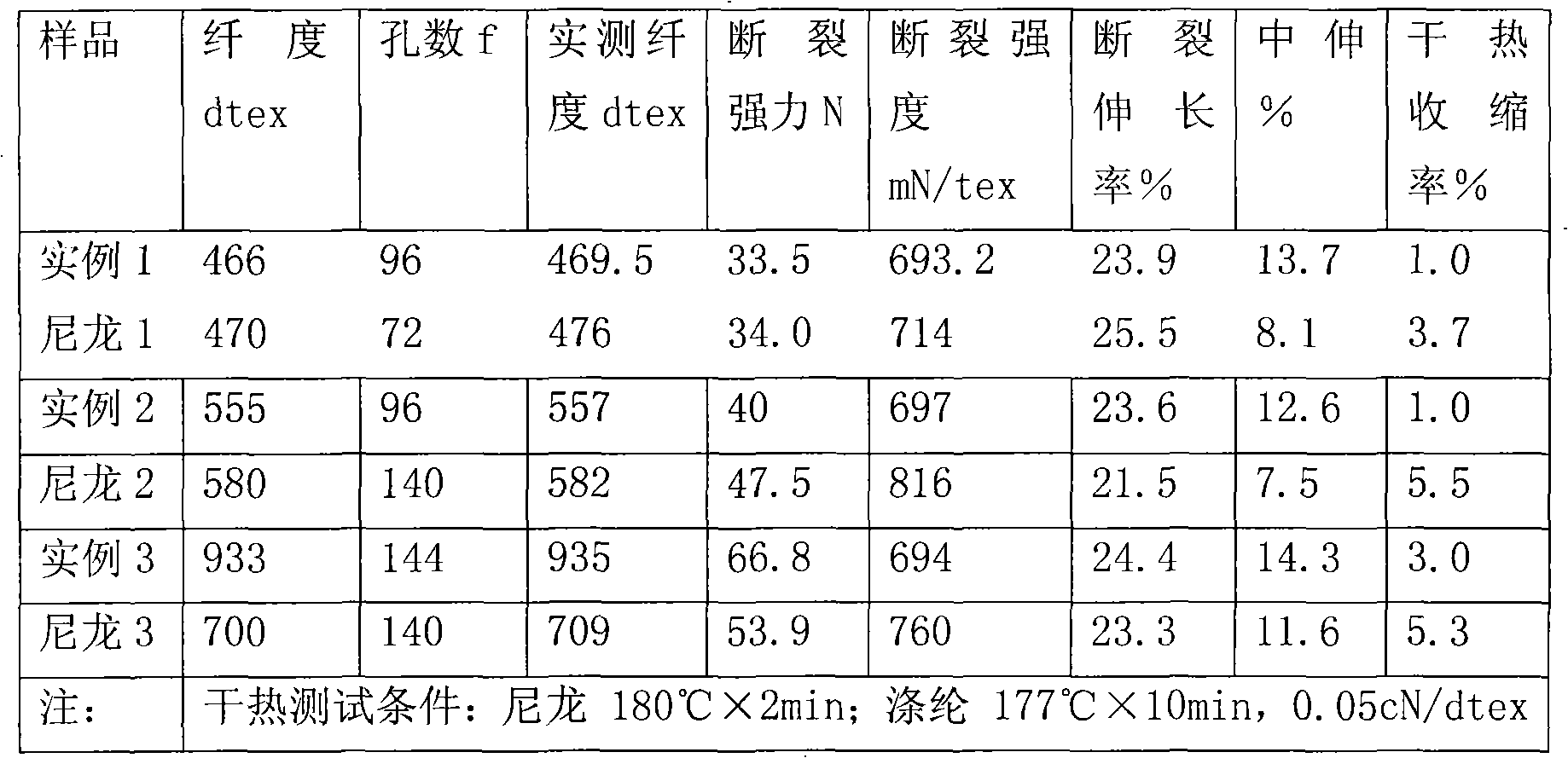

Process for producing polyester industrial fiber for processing safe air bag of automobile

ActiveCN101634052AHeat resistantAging resistantArtificial filament heat treatmentMelt spinning methodsPolyesterEngineering

The invention relates to a process for producing a polyester industrial long fiber for processing a safe air bag of an automobile, which sequentially comprises the following steps: A. processing a polyester slice with high viscosity: enabling the viscosity of the polyester slice to reach 1.0-1.1dl / g; B. melting and spinning: transmitting the polyester slice after solid phase polymerization to a spinning screw rod extruder, melting in a spinning screw rod, entering a spinning assembly by a metering pump and extruding from a fiber spray plate with a diameter of 190 mm to 220 mm to spin fusant, , then heating by a slow cooling heater, carrying out cooling for molding by a side-molding blowing device and then entering a spinning passage; C. stretching and winding: oiling the surface of a fiber and carrying out second-grade high-speed stretching with the total stretching multiple being 5.0 to 5.8, carrying out high-temperature loosing thermoforming at 230 DEG C-250 DEG C and carrying out winding for molding in the range of the winding process speed of 2,500-3,000 m / min to prepare a finished product. The fiber for the safe air bag, which is produced by the process, can completely replace a nylon 66 fiber, is used for spinning terylene safe air bag fabrics and greatly reduces the processing cost.

Owner:ZHEJIANG HAILIDE NEW MATERIAL

Air bag device for car

An airbag device for a car may include an inflator positioned between first and second seats and generating an operating gas, a chamber part receiving the operating gas generated by the inflator and expanding between the first and second seats, a tether part connected to the chamber part to control a deployment shape of the chamber part, and a locking release part connected to the tether part at an inner surface or side surface of the chamber part which removes the connection to the tether part according to a control signal.

Owner:HYUNDAI MOBIS CO LTD

Preparation method for super fine denier polyester filaments

InactiveCN102965745AHigh strengthLow elongationFilament/thread formingArtificial filament heat treatmentFiberPolyester

The invention relates to the technical field of preparation methods for polyester filaments, particularly to a preparation method for super fine denier polyester filaments. The preparation method adopts super bright PET chips as raw materials to implement the production through the steps of pre-crystallization, drying, extrusion, filtering, distribution of spinning box bodies, filament splitting by a metering pump, filament spraying, lateral air blowing, winding and packing of finished products. According to the preparation method adopted by the invention, finally finished fibers have the performances of high strength, low elongation, low heat shrinkage and the like; the breaking strength of the fibers is larger than 7.0 cN / dtex; the breaking elongation of the fibers is less than 14%; the boiling water shrinkage of the fibers is less than 1.8%; and the dry heat shrinkage is less than 4.5%. And at the same time, the preparation method has the characteristics of short production flow, high spinning speed, fewer broken filaments, fewer broken ends, low production cost and the like, and is not only used for top grade sewing threads, embroidery threads and fishing nets, but also heavily applied in various vehicle airbags, base camp tent fabrics and various industries adopting high strength fibers as auxiliary materials or reinforcing materials.

Owner:NANTONG HUALUN CHEM FIBER

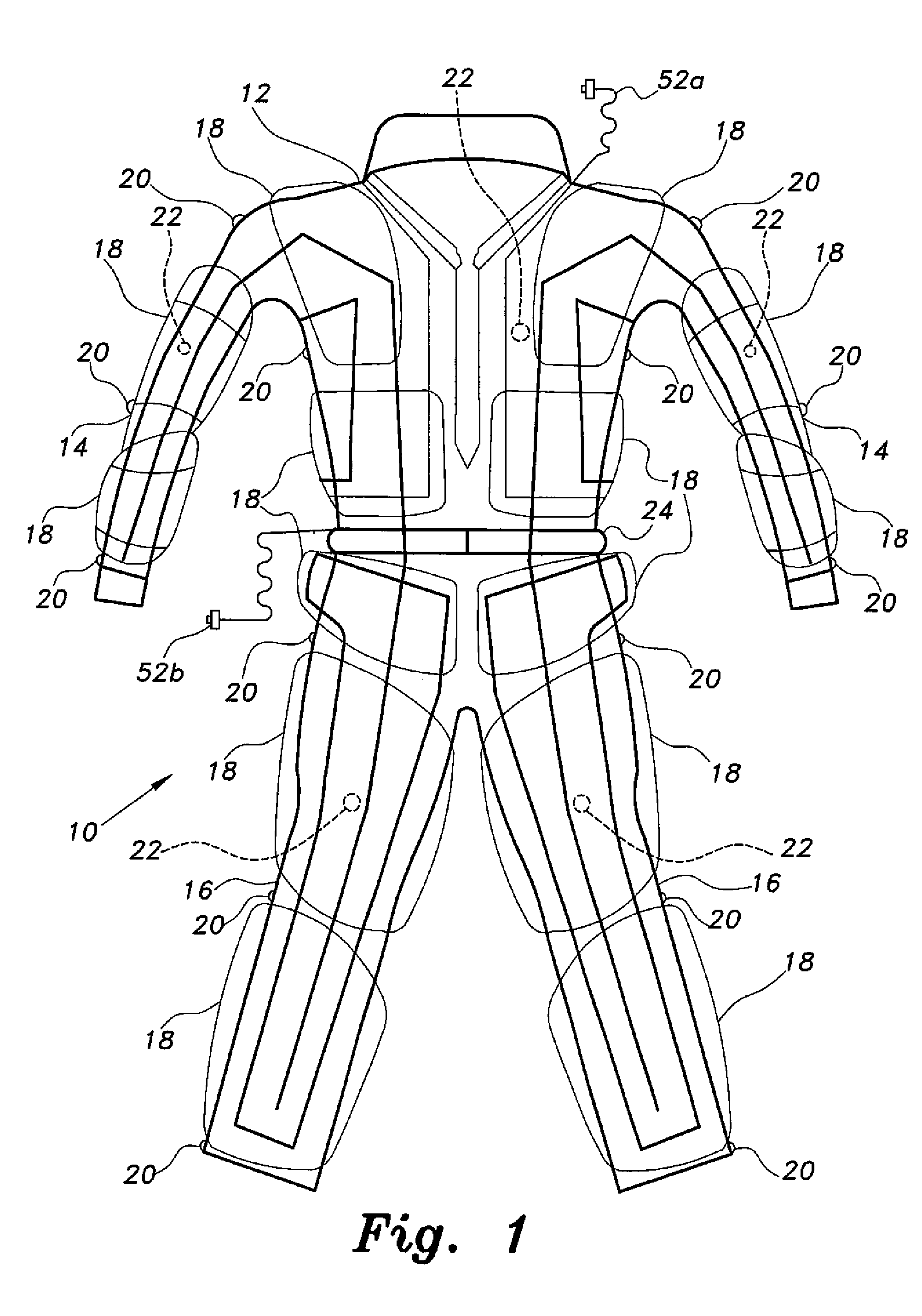

Protective suit

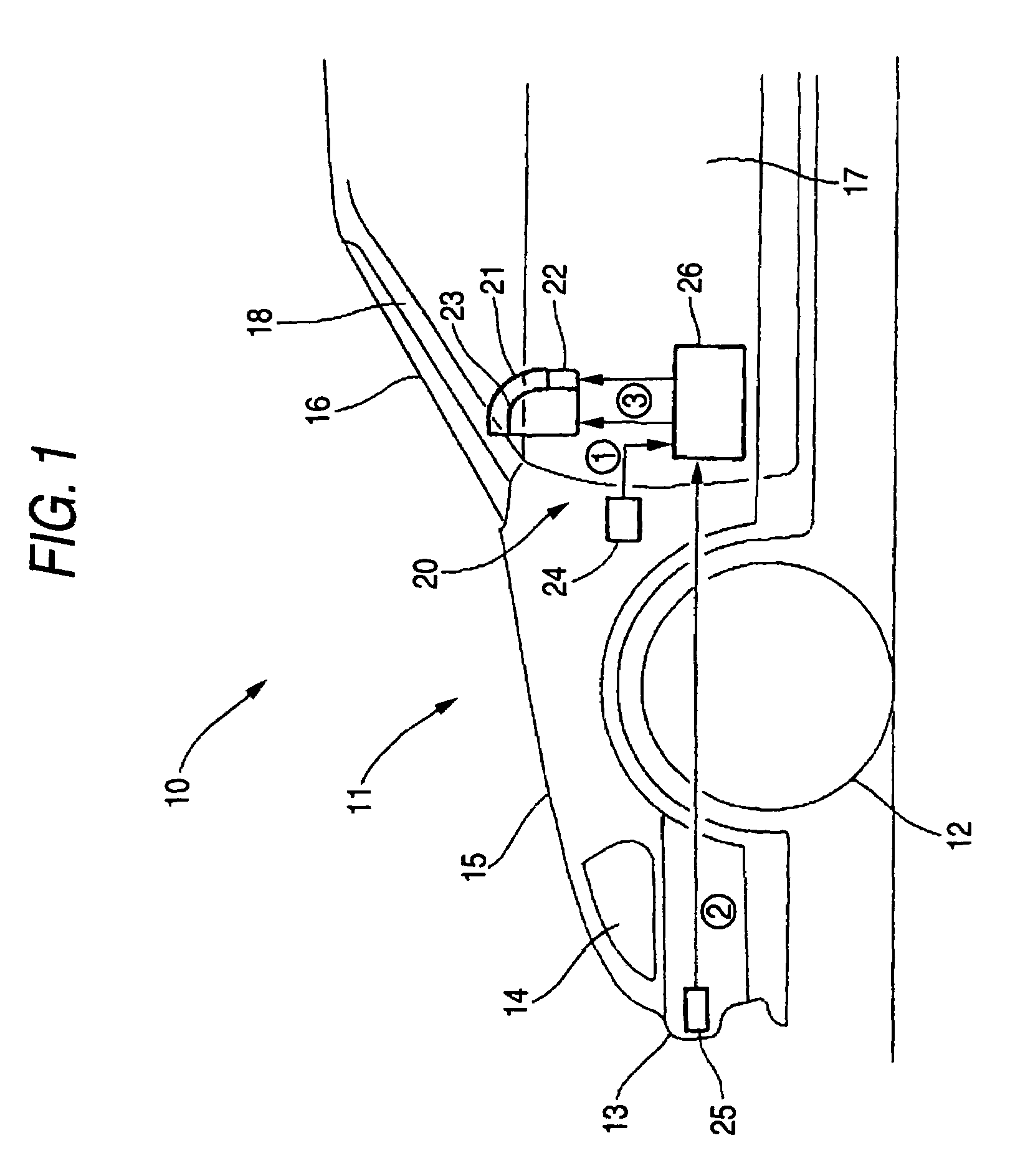

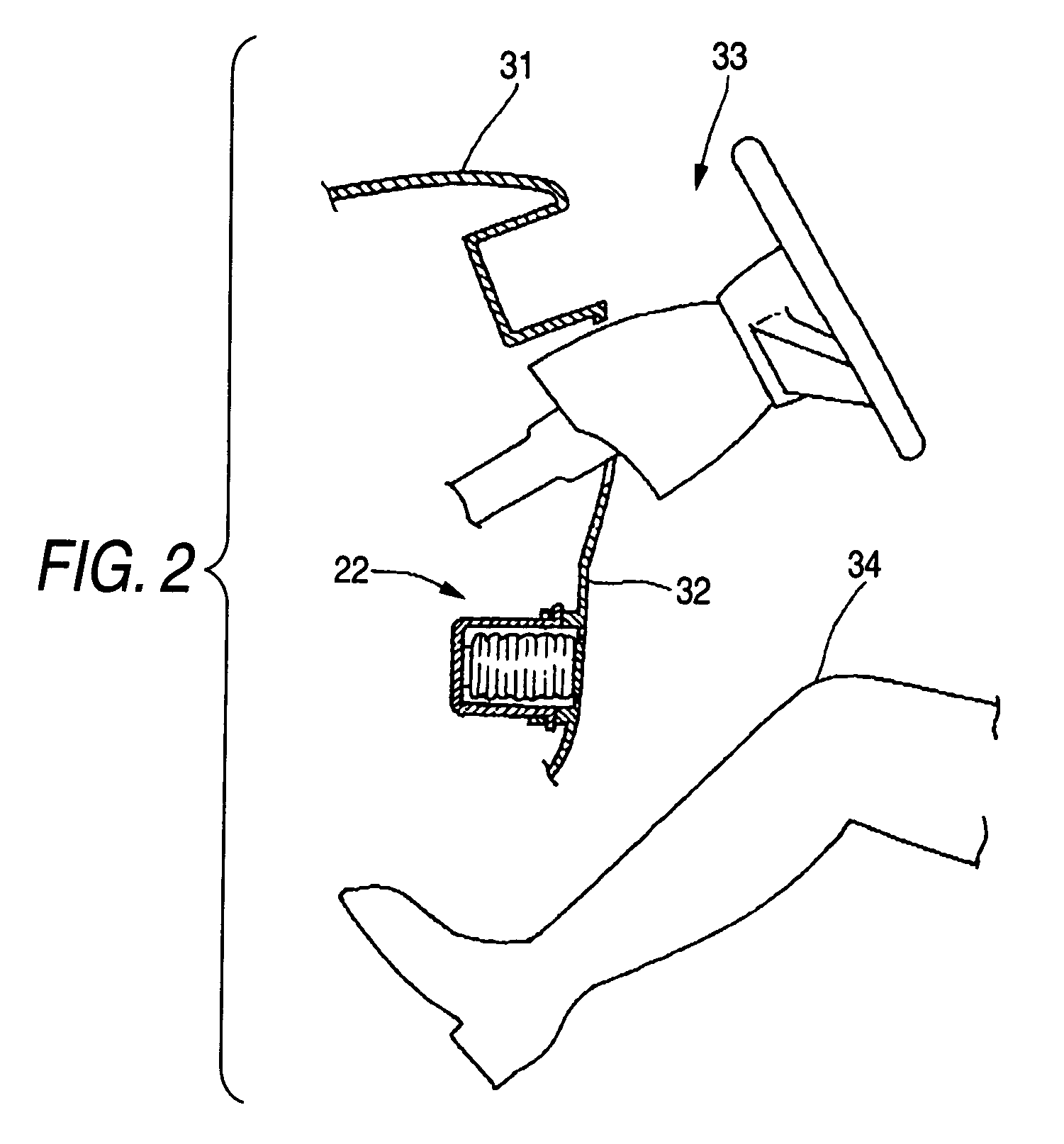

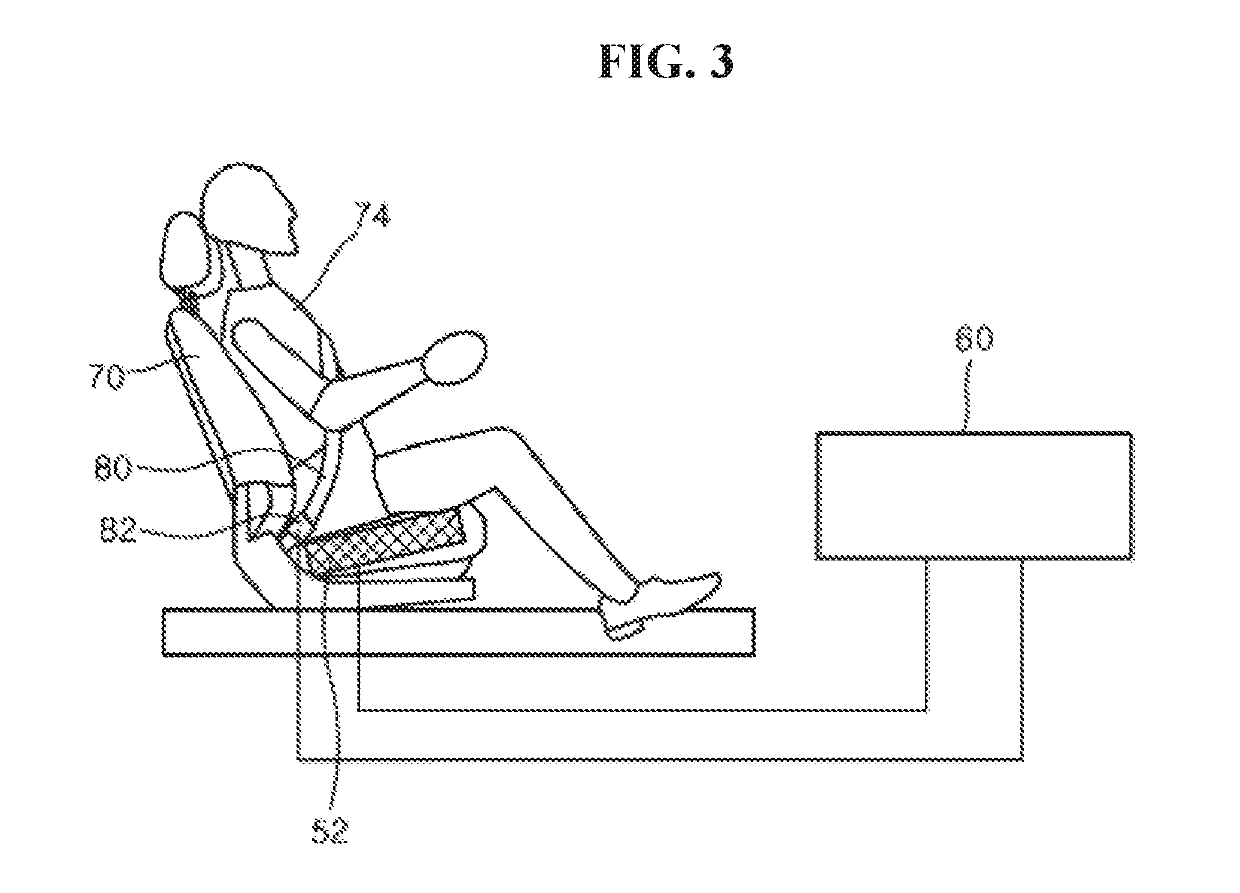

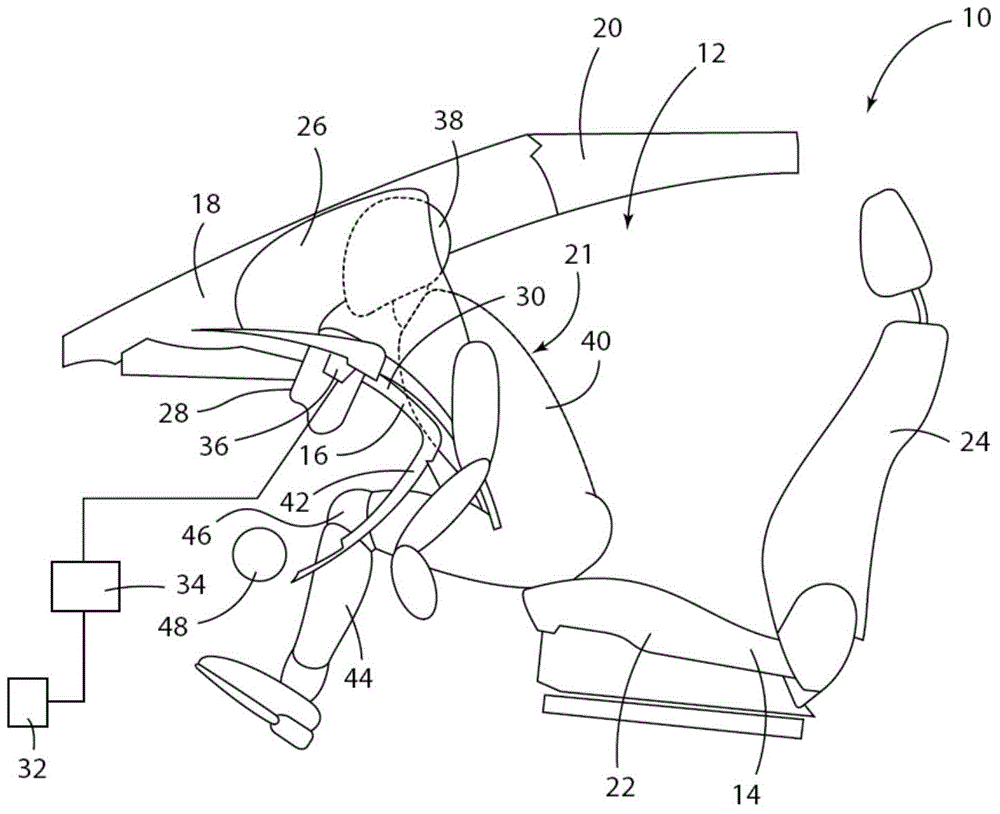

InactiveUS8662528B1Avoid startingReadily apparentPedestrian/occupant safety arrangementCycle safety equipmentsMobile vehicleElectronic systems

The protective suit is for use by persons engaged in various potentially hazardous activities, but is particularly well adapted for wear by motorcyclists and others engaged in motorsports activities. The suit is equipped with airbags that differ from conventional automotive airbags in that the present airbags deflate more slowly to protect the wearer of the suit over a few seconds in an accident. The suit is also equipped with warning lights that are actuated in the event of an accident. The suit is electronically connected to a belt having various electronic systems capable of monitoring the condition of the motor vehicle and the wearer of the suit through sensors in the vehicle and suit. The suit is further electronically connected to the vehicle, the vehicle having a lockout system that prevents the vehicle from being started until the suit, belt, and helmet are properly connected and operable.

Owner:ABDULAZIZ ALI GH S GH

Polypropylene thermoplastic elastomer for automobile safety airbag cover board and preparation method thereof

The invention discloses a polypropylene thermoplastic elastomer for an automobile safety airbag cover board; the polypropylene thermoplastic elastomer comprises 21-48% of high melt strength polypropylene (HMSPP), 10-50% of olefin polymer, 10-40% of styrenic thermoplastic elastomer and 2-15% of compatilizer by weight; a preparation method of the polypropylene thermoplastic elastomer comprises the steps as follows: adding the above components to a double-screw extruder respectively according to a proportion, melting, mixing and dispersing, setting a temperature of each section of the extruder at 230-265 DEG C, extruding and granulating to obtain the product finally. As the high melt strength polypropylene (HMSPP) is adopted as a matrix resin of the thermoplastic elastomer, and the olefin polymer and the styrenic thermoplastic elastomer are used for toughening synergistically, the prepared elastomer material has excellent high temperature and low temperature bursting properties and can meet the requirements that the automobile safety airbag cover board cannot be deformed to fly out and torn excessively during high temperature blasting (85 DEG C.) and does not generate fragments during low temperature blasting (-35 DEG C.); and therefore, the polypropylene thermoplastic elastomer can replace the conventional thermoplastic polyolefin (TPO) to apply to different types of automobile safety airbag cover boards.

Owner:TIANJIN KINGFA NEW MATERIAL

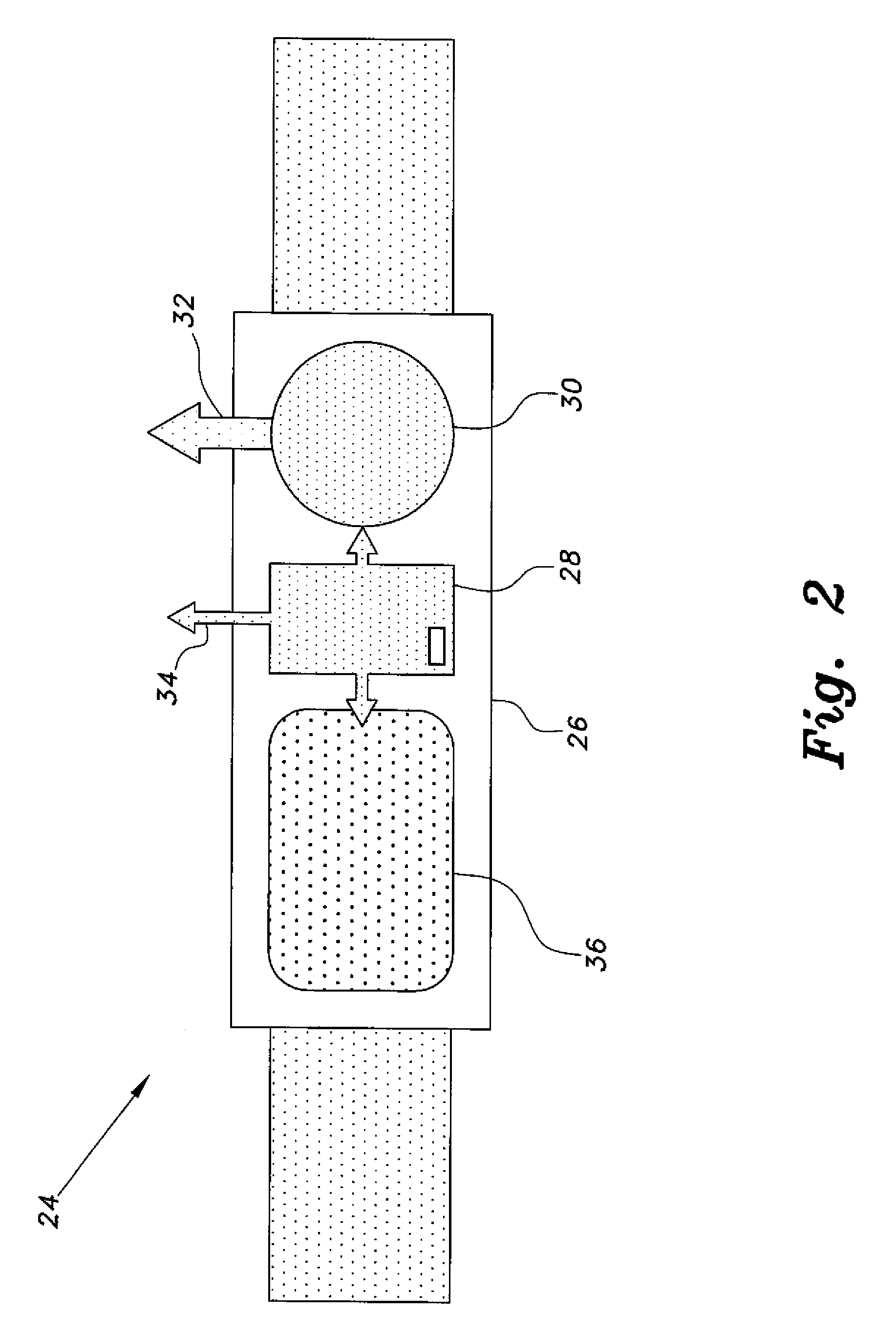

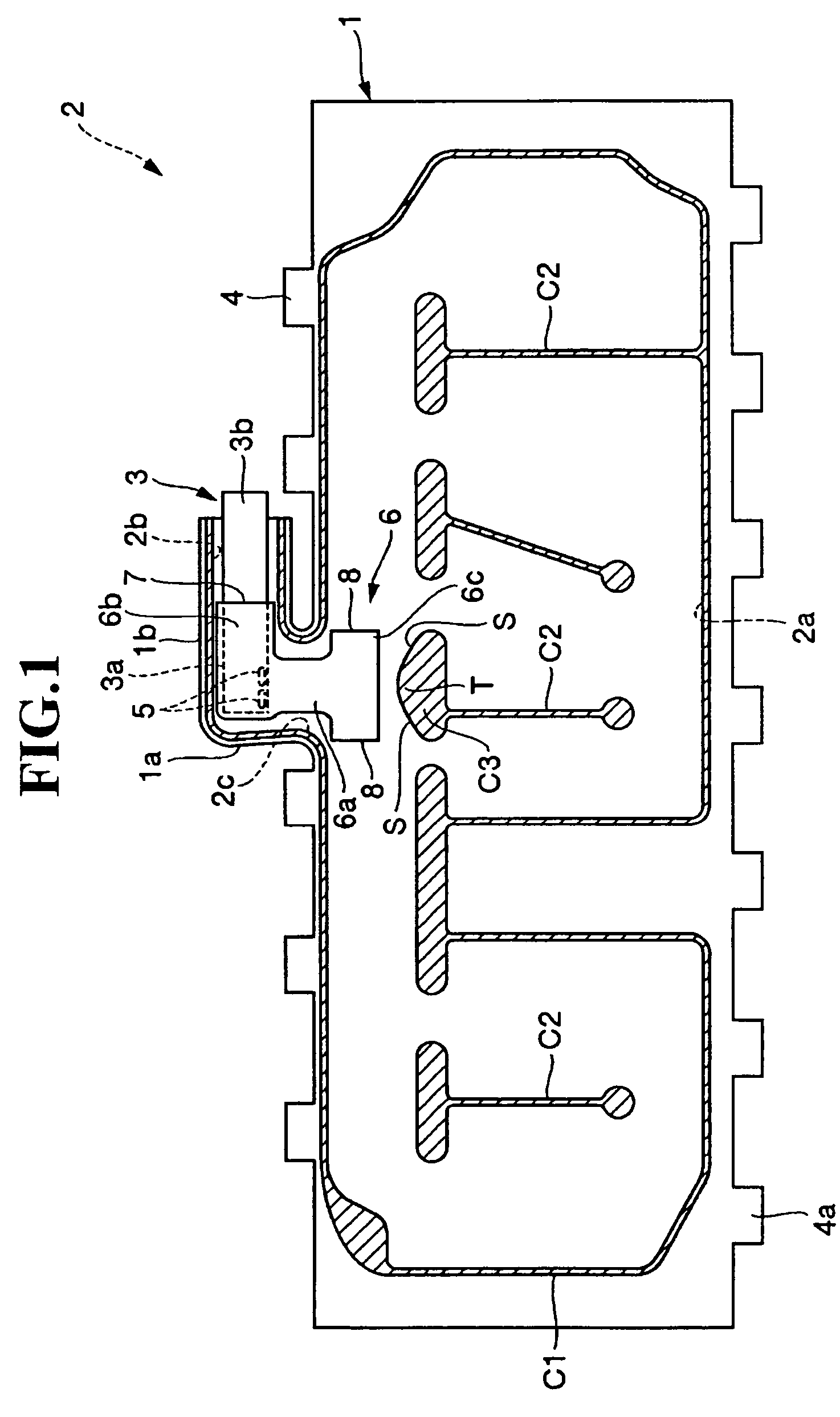

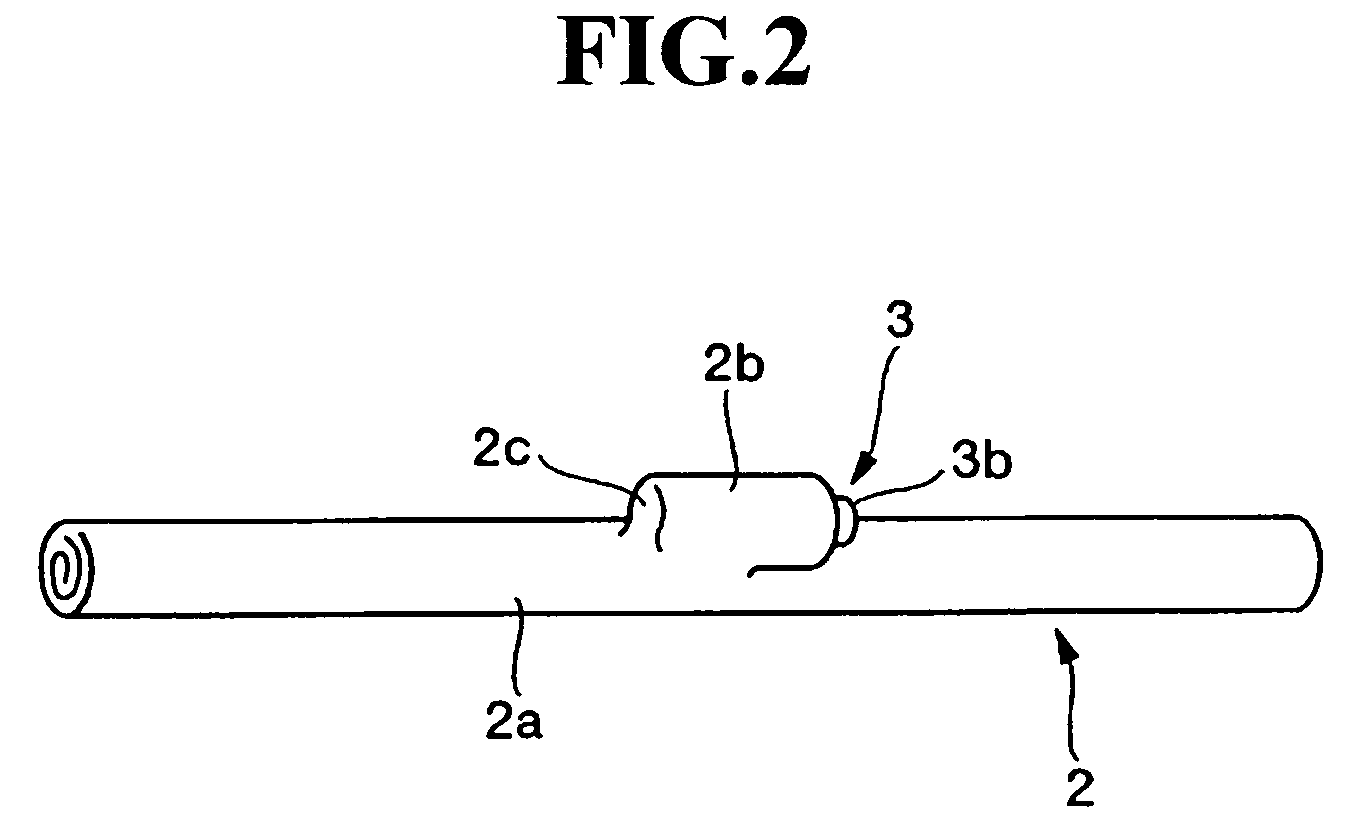

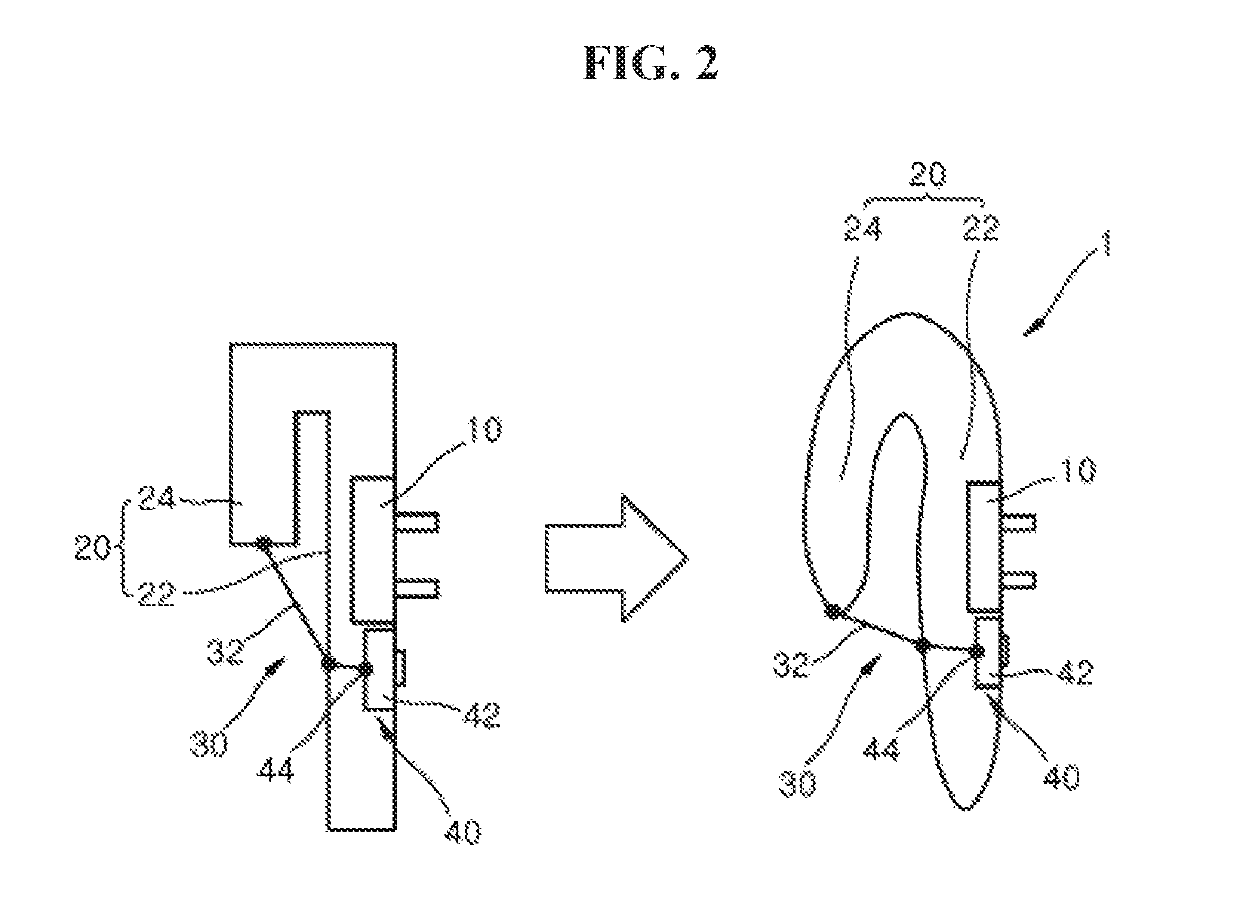

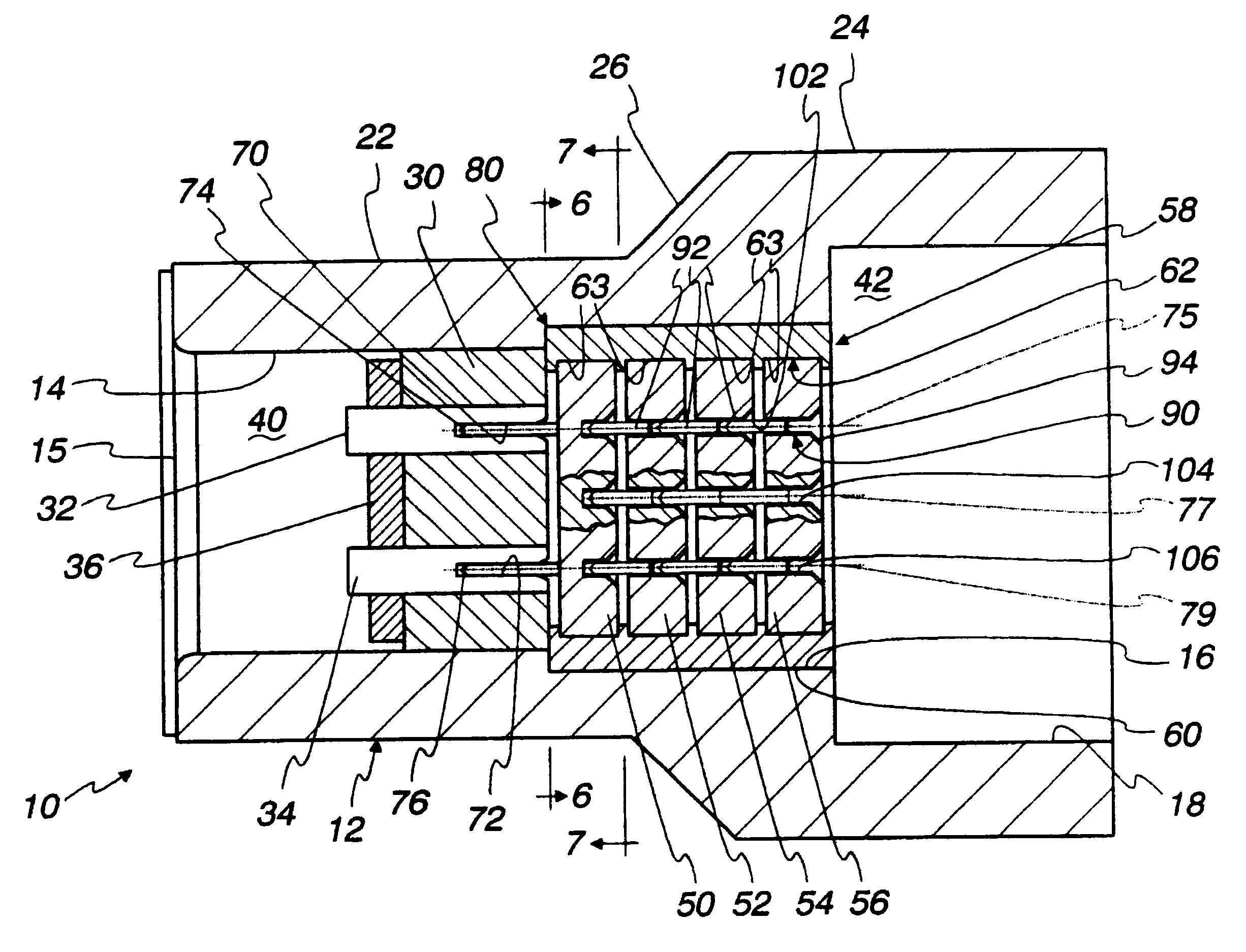

Application specific integrated circuit package and initiator employing same

An initiator for an inflator of an automotive airbag restraint system includes a housing and a wall dividing the housing into two parts, one for housing a firing element of the initiator, and one for receiving at least one application specific integrated circuit which performs functions of a portion of an electronic control unit. A mounting element is located in the second part of the housing, and at least one application specific integrated circuit is carried by the mounting element. The mounting element and two or more application specific integrated circuits may be provided as a package, in which at least two application specific integrated circuits are mounted in a stacked condition to form an application specific integrated circuit stack. The application specific integrated circuits are configured such that predetermined electrical circuit locations of adjacent ones of the application specific integrated circuits to be interconnected are aligned. The package includes connectors for electrically interconnecting these predetermined electrical circuit locations in adjacent ones of the application specific integrated circuits in the stack.

Owner:AUTOLIV ASP INC

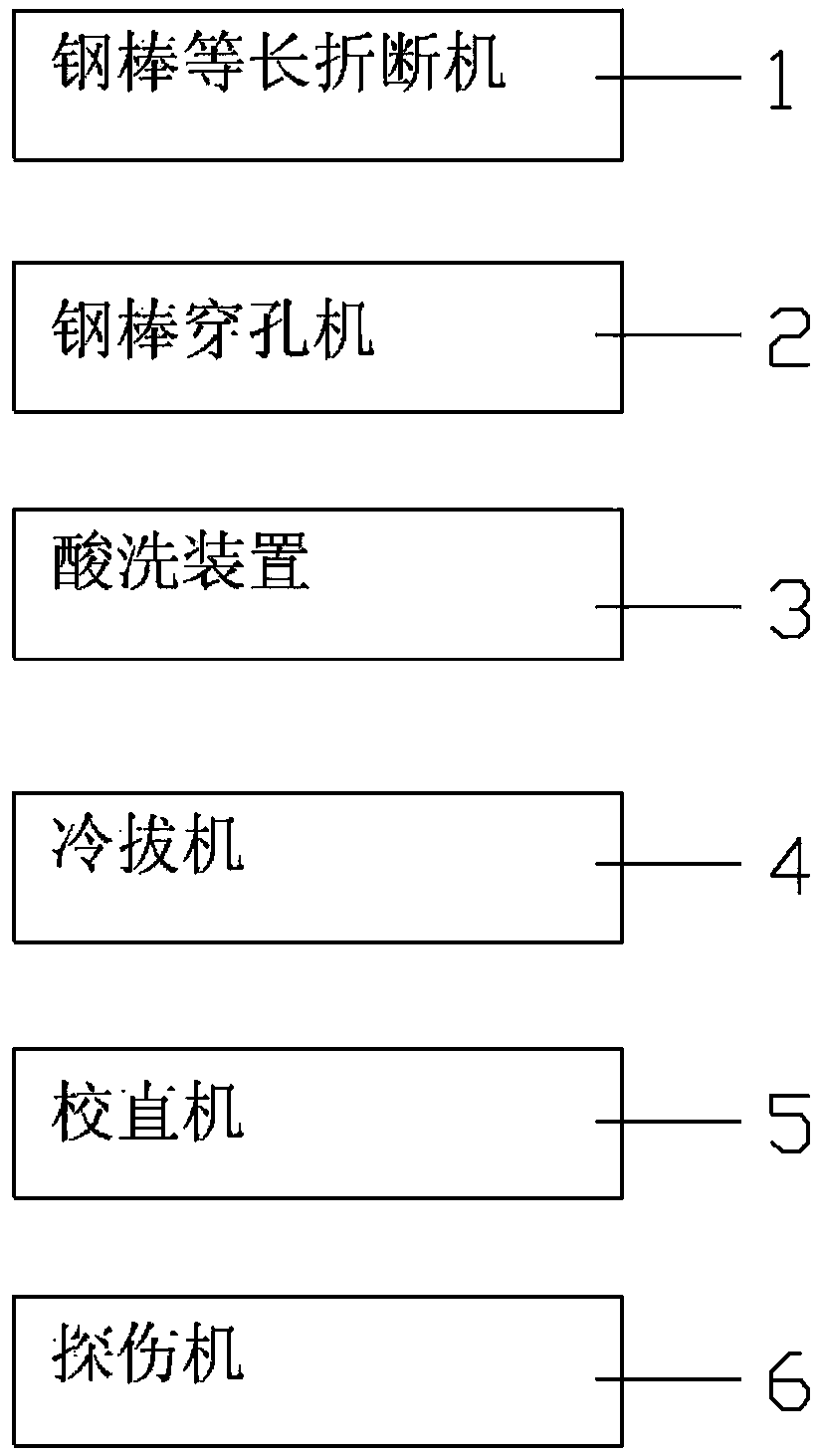

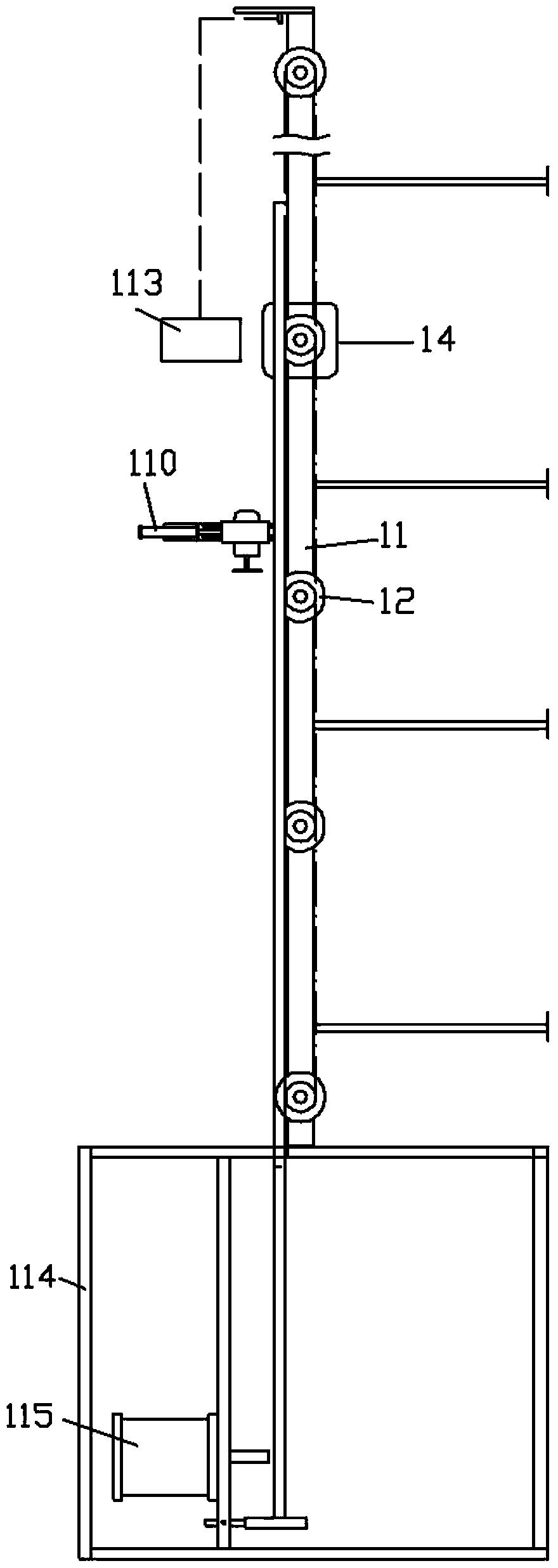

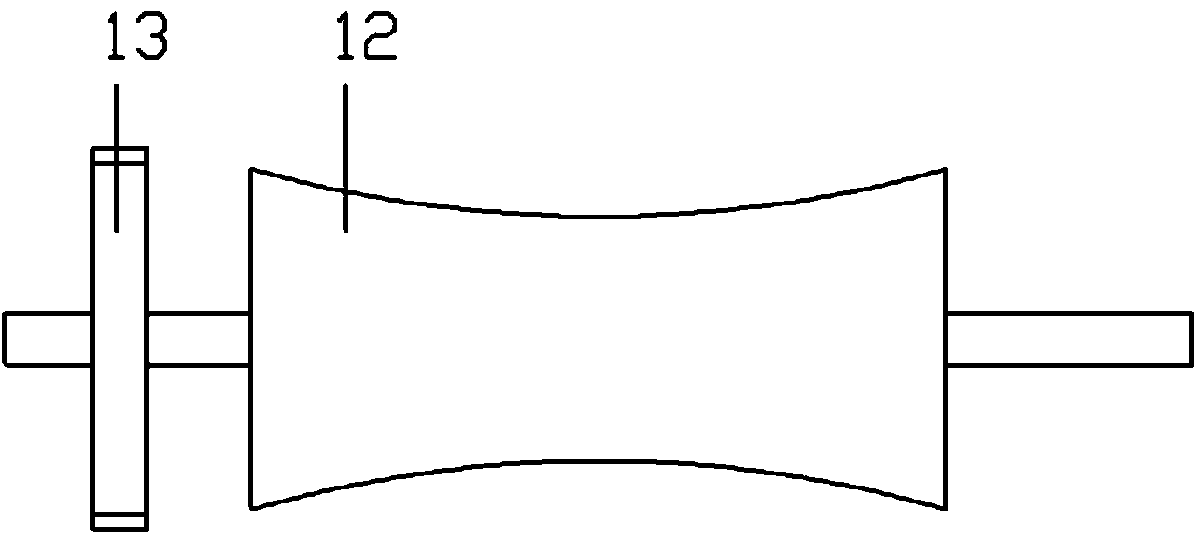

Automobile safety air bag steel pipe production line

ActiveCN104325294AHigh degree of automationAvoid safety accidentsMetal-working feeding devicesOther manufacturing equipments/toolsProduction lineSemi automatic

The invention relates to an automobile safety air bag steel pipe production line. A steel bar equal-length breaking machine adopts an automatic equal-length opening cutting method, and is used for breaking a steel bar; a straightening machine is additionally provided with a safety material delivery roll; a detection machine adopts a low-frequency eddy detection device and a high-frequency eddy detection device; the detection machine is provided with two discharging devices with structures that a discharging rod is inserted into an U-shaped groove hole in a sleeving way, a discharging arm and a rotary arm are fixedly arranged on each discharging rod, the other end of each rotary arm is hinged to a piston rod of a discharging air cylinder, a support roll is arranged on each discharging bracket, a receiving cloth belt bypasses a support rod and is wound on a receiving and discharging cloth roll, a roll shaft of each receiving and discharging cloth roll is fixedly connected with an output shaft of a gear reducer, an input shaft of each gear reducer is fixedly connected with a rotary shaft of a discharging motor, and the two discharging devices are symmetrically arranged at the two sides of a conveying roller. The automobile safety air bag steel pipe production line has the advantages that the steel bar equal-length breaking machine has a high automation degree; the steel pipe straightening machine adopts the rubber roll to deliver the material, so as to avoid the safety accidents; the detection mechanism adopts the semi-automatic charging method, so the manual labor intensity is decreased, and the surface and the inner wall of the steel pipe can be simultaneously detected.

Owner:ZHEJIANG XCC GRP CO LTD

Automotive airbag device

An airbag is formed from fabric layers joined at a seam, and gas generator inflates the airbag by means of gas expelled from the gas generator's insertion end which has been inserted into the airbag. A gas guide is formed in the airbag in order to direct gas from the gas generator into the airbag and includes a pouch-shaped gas guide member in which are formed gas injection nozzles and an attachment orifice. The insertion end of the gas generator is inserted into the attachment orifice with the gas injection nozzles facing an interior of the airbag. A convex-shaped seam is included where the fabric layers are joined, and is disposed in opposition to the gas guide member. The gas guide member comes into contact with the convex-shaped seam as a result of the pressure of the flow of gas from the gas generator through the gas guide member.

Owner:AUTOLIV DEV AB

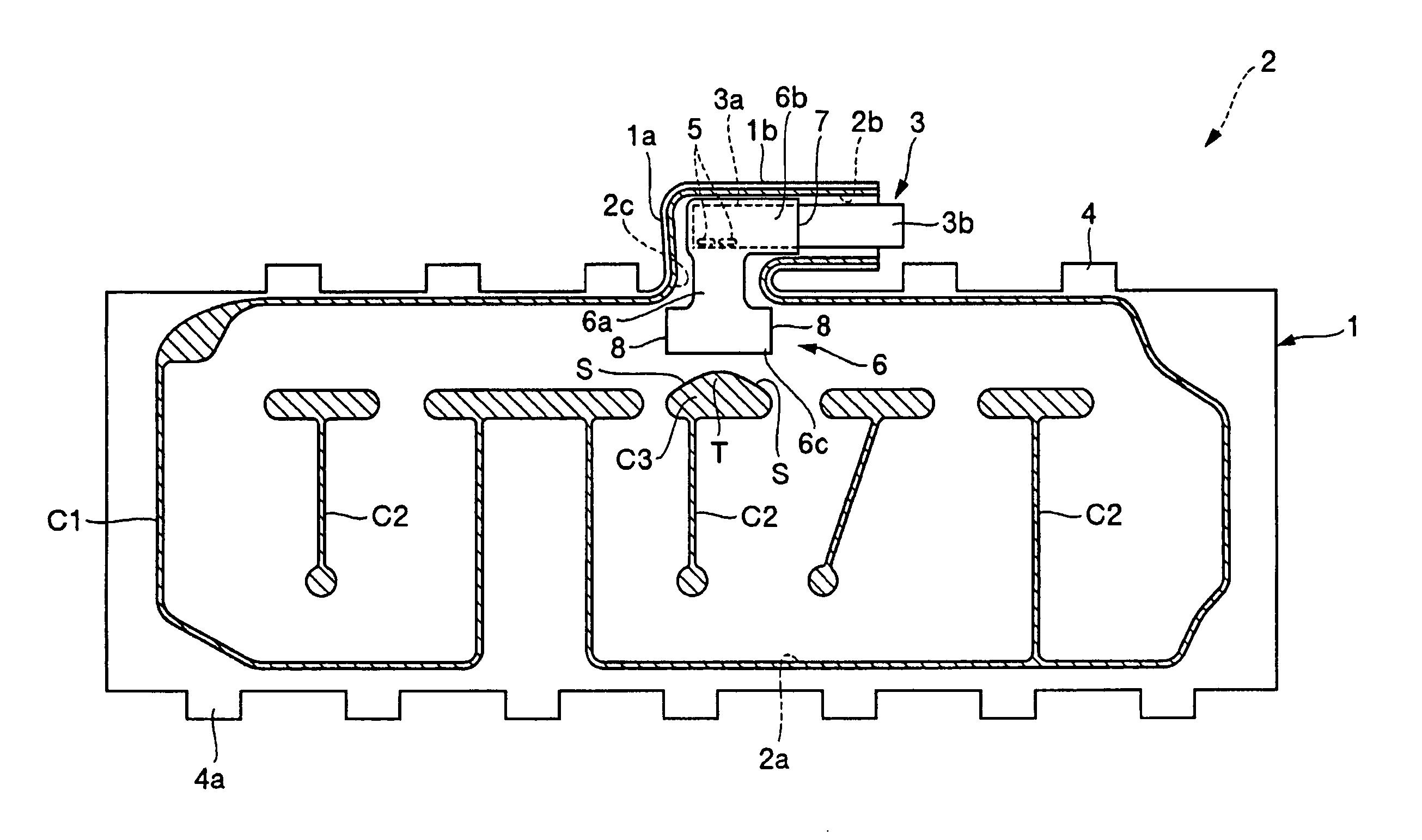

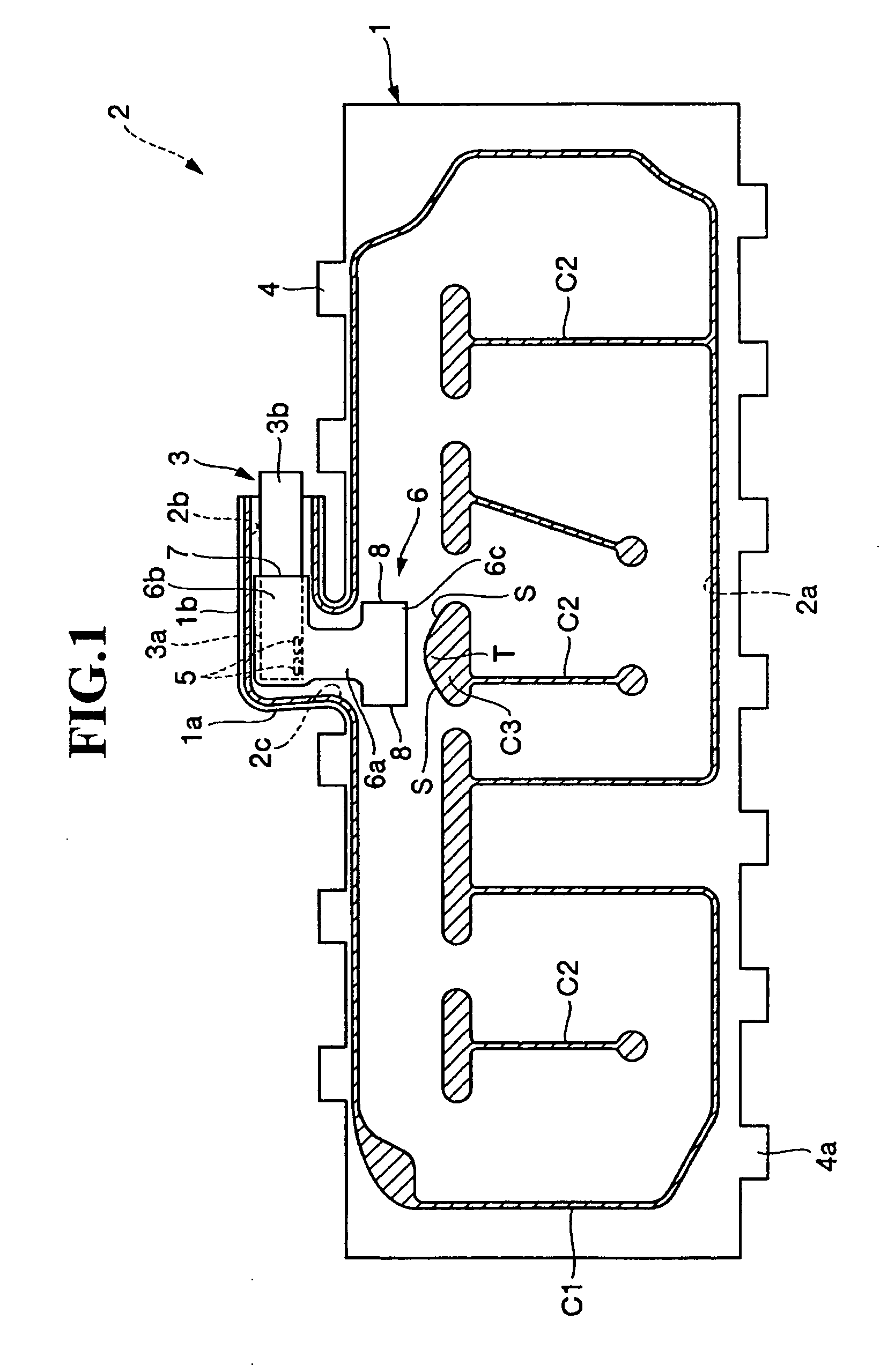

Automotive air bag device

InactiveUS7249781B2Deploy an air bag more uniformlyUniform deploymentPedestrian/occupant safety arrangementEngineeringAtmospheric pressure

An automotive air bag device has a panel, a folded bag installed in a deeper portion behind the panel, a cover provided in the panel and a connecting member that connects a vehicle body side with the cover. The air bag is inflated by virtue of a gas pressure to push open the cover provided so that the air bag deploy into a passenger compartment, the cover is mounted in the panel so as to be separated from the panel when the air bag is inflated and the connecting member controls a protrusion of the air bag into a passenger compartment.

Owner:HONDA MOTOR CO LTD

Air bag device for car

Owner:HYUNDAI MOBIS CO LTD

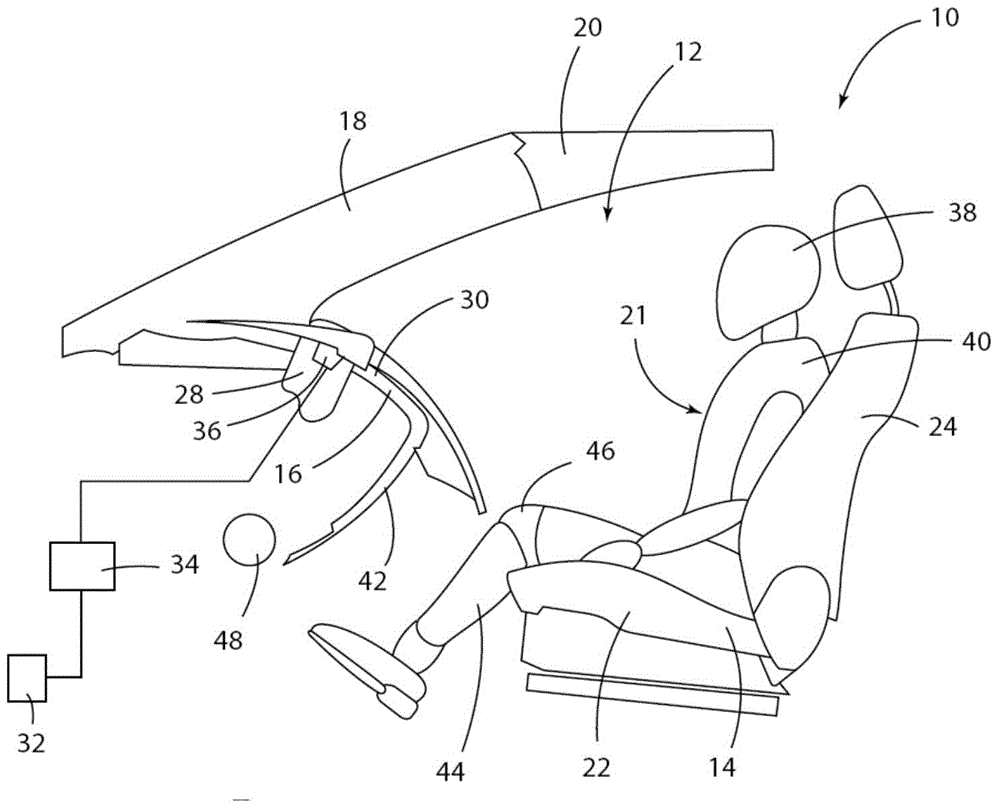

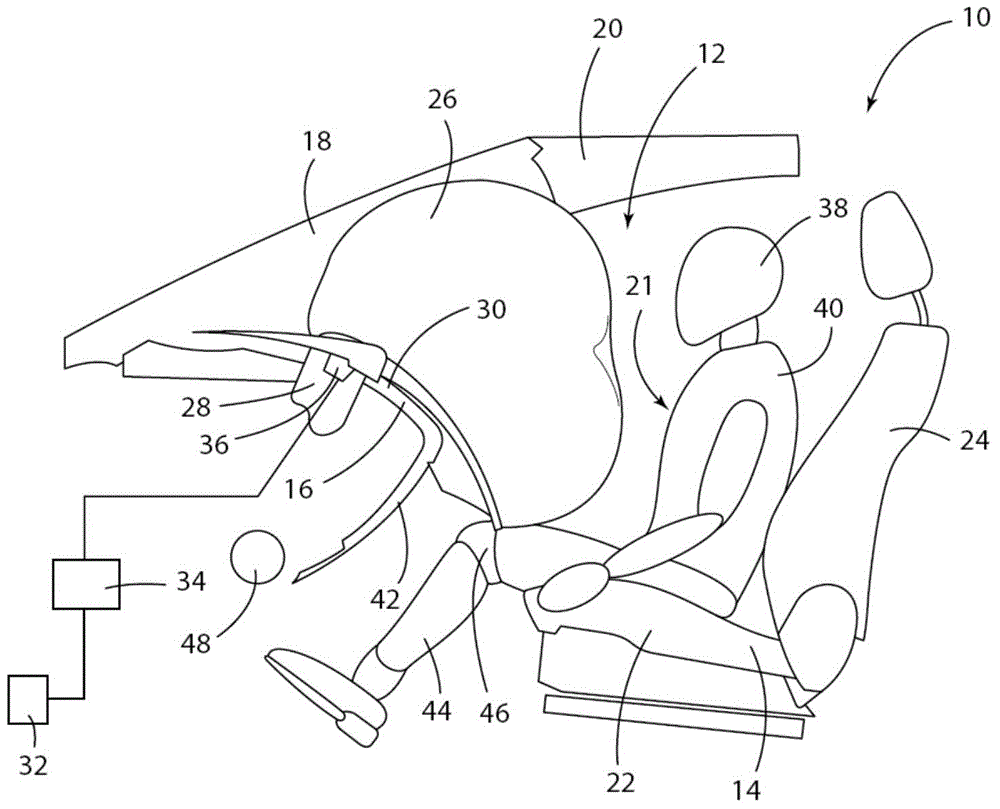

Head, torso and knee combo airbag

A motor vehicle airbag system comprises a dual chambered combined head, torso, and knee airbag having a head and torso chamber and a lower extremities chamber in fluid communication with the head and torso chamber. A multidirectional inflator substantially simultaneously inflates both of the head and torso chamber and the lower extremities chamber. The head and torso chamber in the inflated condition acts against a head and a torso of the motor vehicle occupant to generate a restraining force against the occupant to mitigate contact of the occupant head and torso with the upper portion of the instrument panel during the impact event. The lower extremities chamber in the inflated condition acts against the pair of knees of the occupant to mitigate contact of the knees of the occupant with the lower portion of the panel during the impact event.

Owner:FORD GLOBAL TECH LLC

Thermoplastic elastomer alloy material for manufacturing automobile safe airbag lid

InactiveCN1966560AImprove mechanical propertiesMeet performance indicatorsPedestrian/occupant safety arrangementElastomerLow speed

This invention relates to thermal plastic elastomer (TPE) alloy materials used to manufacture mobile airbag cover, which is characterized by using SEBS I and SEBS II, polyolefin elastomer (POE), polypropylene (PP) rubber filling oil, high and low temperature modifier, antioxidants and other additives as the raw materials. The preparation method includes: mixing SEBS I, SEBS II, and rubber filling oil with a high-speed machine at low-speed to obtain the oil-filled SEBS, adding POE I, POE II, polypropylene, antioxidants, and other additives in the high-speed machine and mixing at high speed, adding oil-filled SEBS and mixing at high-speed, extruding, and granulating. The advantages of this invention are as follows: brittle transition temperature is below minus 40degreeC, materials are not softening at 80degreeC, the material has good heat-resistance (100degreeC, seven days aging experiments, properties dropped < 50%) and high-outdoor (UV) properties, and the material can be processed easily and color directly without paint.

Owner:TRT SHANGHAI ENG PLASTICS

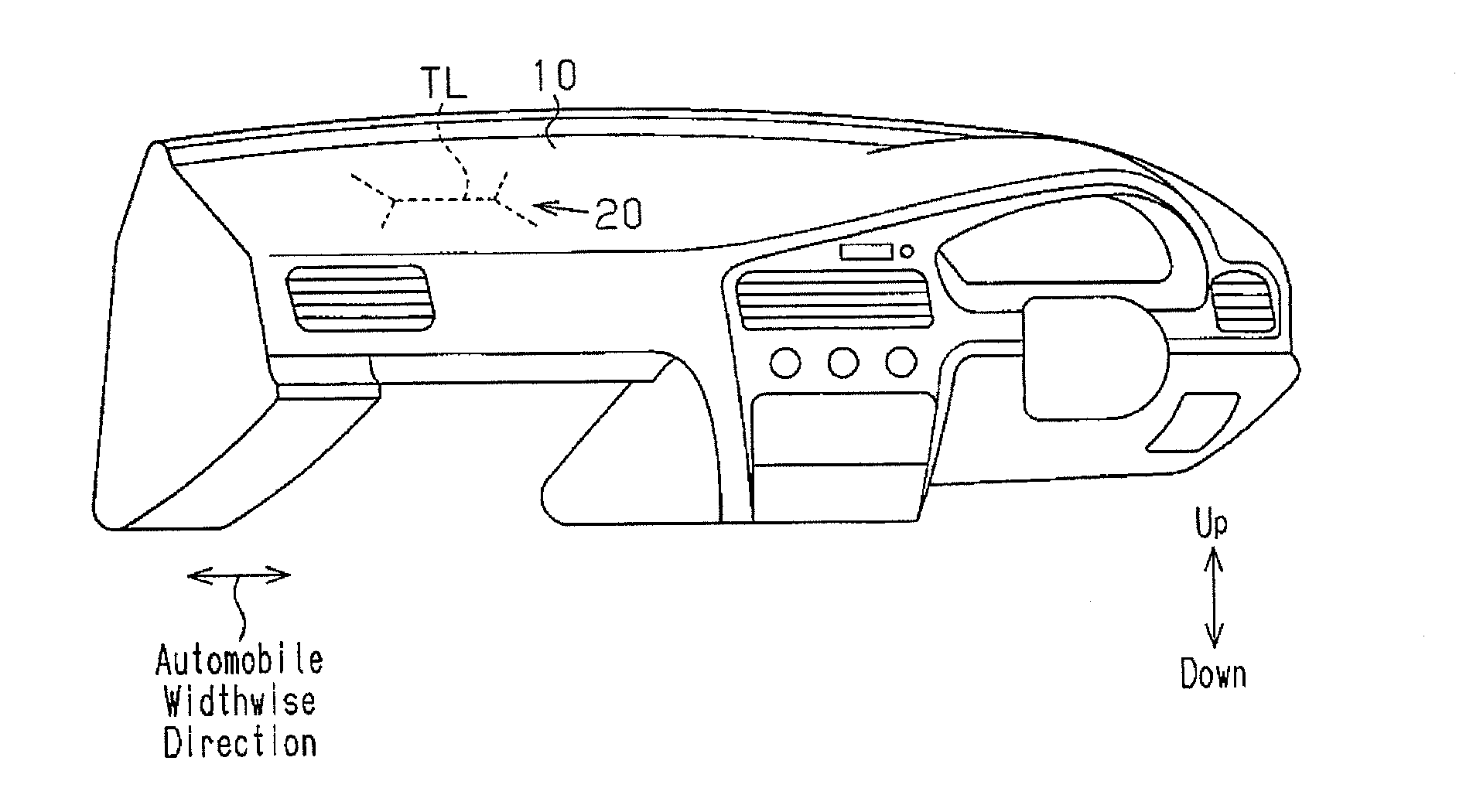

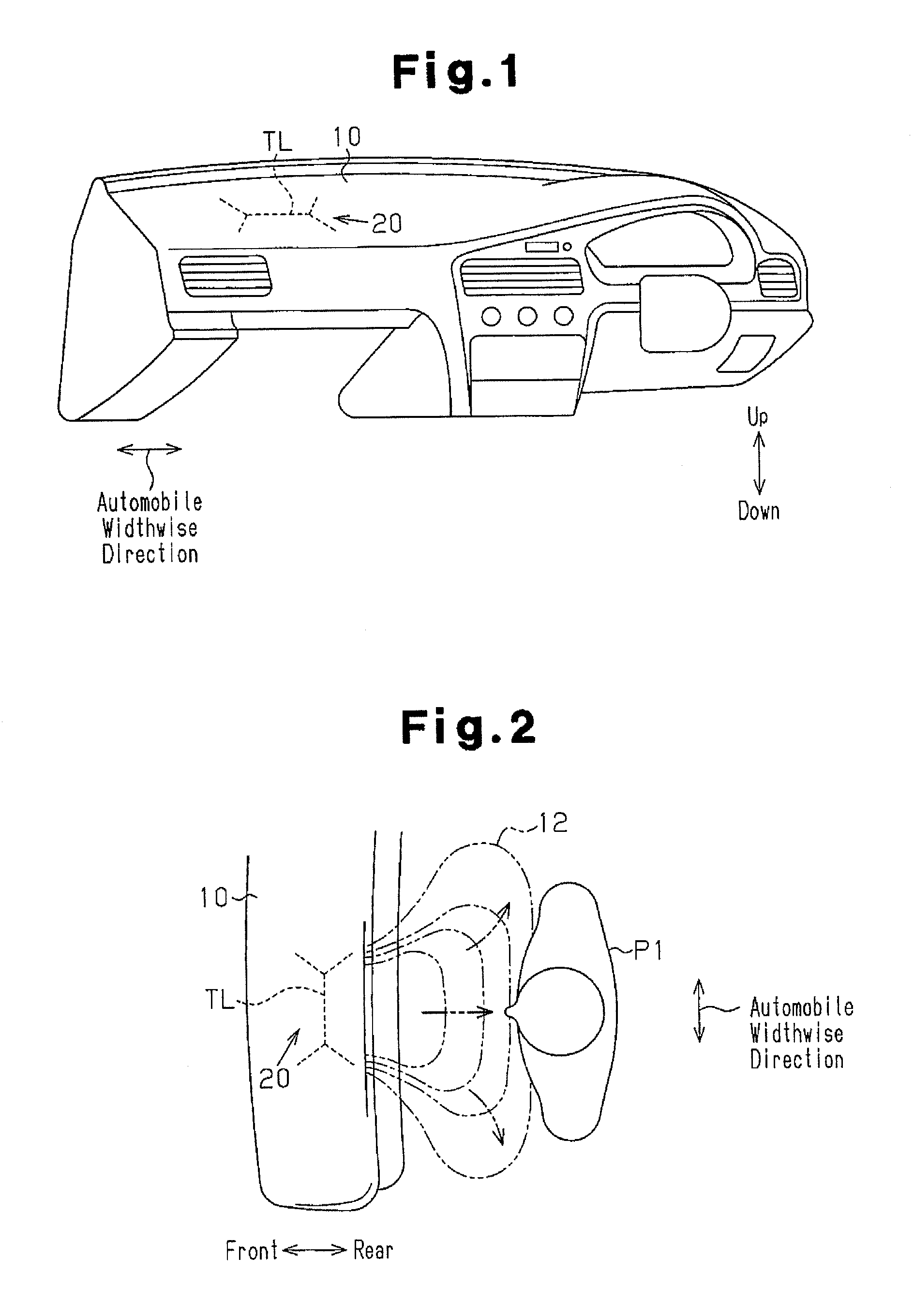

Air bag device for automobile

InactiveUS20080296876A1Avoid interferencePedestrian/occupant safety arrangementMechanical engineeringMotor vehicle airbag

Owner:TOYOTA JIDOSHA KK

Automatic ignition powder for gas generator of air bag restraint system of automobile and preparation method of automatic ignition powder

ActiveCN105777458AEasy to igniteAppropriate thermal decomposition temperatureNon-explosive/non-thermic compositionsDecompositionRare earth

The invention provides automatic ignition powder for a gas generator of an air bag restraint system of an automobile and a preparation method of the automatic ignition powder.The automatic ignition powder contains fuel, oxidant and flame accelerator; the flame accelerator is rare earth and perovskite type composite metal oxide; the general formula of the flame accelerator is La1-xAxMnO3, wherein A is Ce and / or Cu, and x is greater than zero and less than one.According to the automatic ignition powder, the specific flame accelerator is adopted and can effectively promote a redox reaction in the powder, thereby thermal decomposition of the automatic ignition powder is promoted, the decomposition temperature of the powder is lowered, and automatic ignition performance of the powder is improved.

Owner:BYD CO LTD

Application specific integrated circuit package and initiator employing same

An initiator for an inflator of an automotive airbag restraint system includes a housing and a wall dividing the housing into two parts, one for housing a firing element of the initiator, and one for receiving at least one application specific integrated circuit which performs functions of a portion of an electronic control unit. A mounting element is located in the second part of the housing, and at least one application specific integrated circuit is carried by the mounting element. The mounting element and two or more application specific integrated circuits may be provided as a package, in which at least two application specific integrated circuits are mounted in a stacked condition to form an application specific integrated circuit stack. The application specific integrated circuits are configured such that predetermined electrical circuit locations of adjacent ones of the application specific integrated circuits to be interconnected are aligned. The package includes connectors for electrically interconnecting these predetermined electrical circuit locations in adjacent ones of the application specific integrated circuits in the stack.

Owner:AUTOLIV ASP INC

Gas generant composition

InactiveUS20020023699A1Carbon monoxide and nitrogen oxides are decreasedImprove efficiencyNon-explosive/non-thermic compositionsPressure gas generationPtru catalystTetrazole

A gas generant is provided which decreases toxic components, in particular carbon monoxide and nitrogen oxides, in generated gas to a concentration practical as an air bag system for automobile. A nitrogen-containing organic compound such as a compound containing amino group or amido group or a tetrazole derivative and a oxygen-containing inorganic oxidizer such as KNO3, Sr(NO3)2 or KClO4 are essential components. Therewith one or more metal oxides are contained in the mixed catalyst of the gas generant composition. The oxide is selected from manganese dioxide having a specific surface area not less than 50 m2 / g; copper oxide having a specific surface area not less than 1 m2 / g; molybdenum oxides such as molybdenum dioxide, molybdenum trioxide, molybdic acid and ammonium molybdate; and copper oxides, cobalt oxides, iron oxides and siver oxides.

Owner:DAICEL CHEM IND LTD

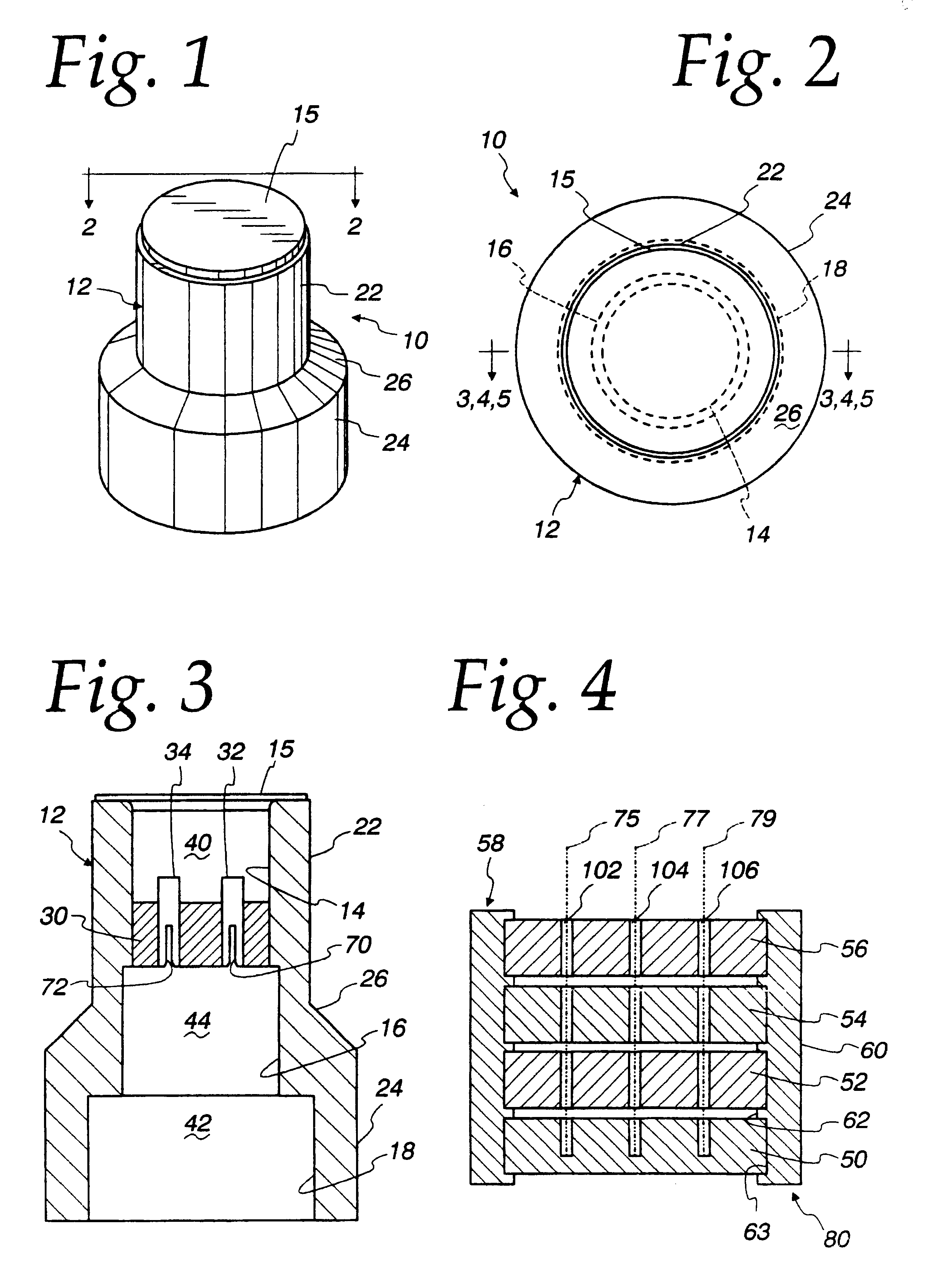

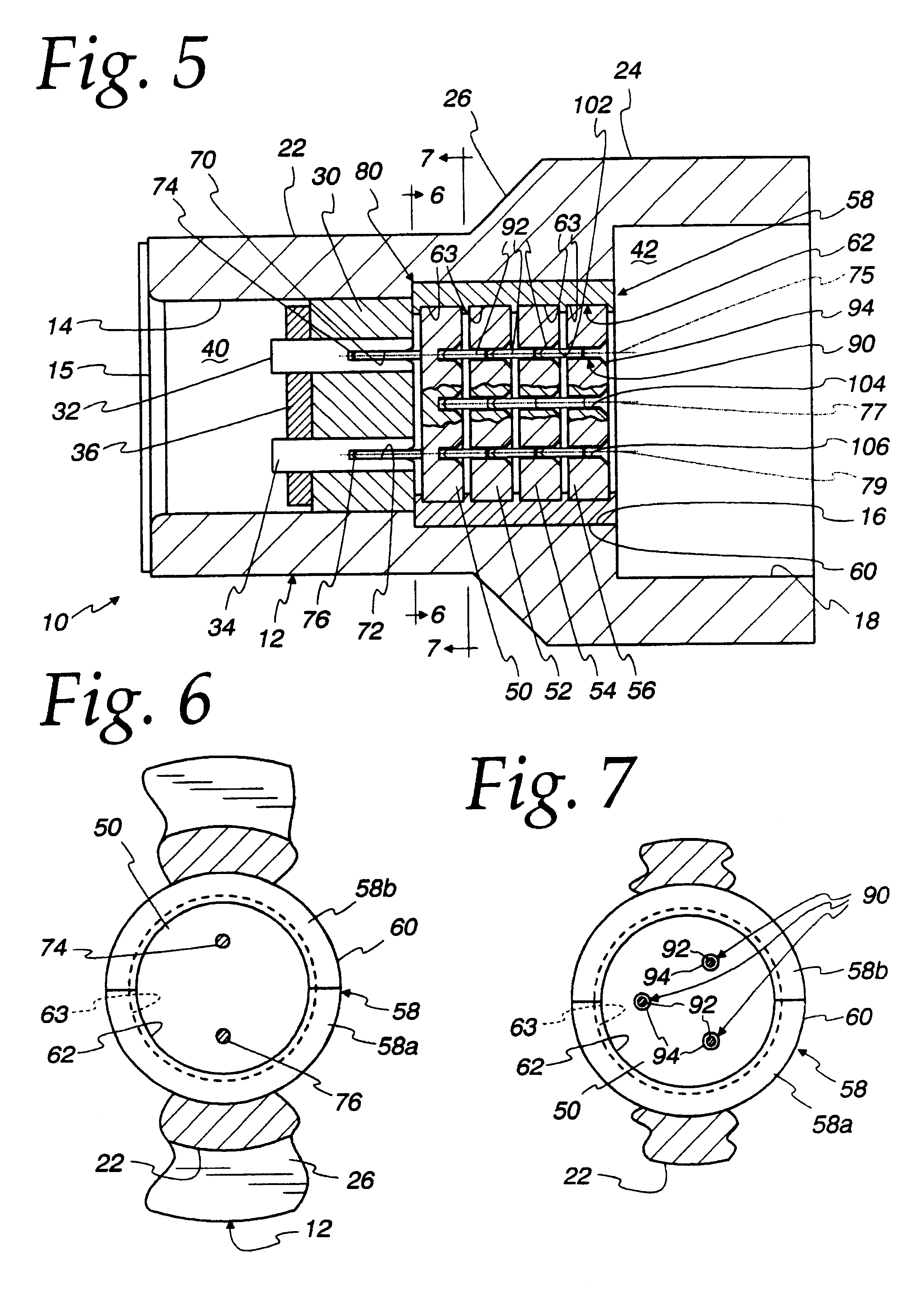

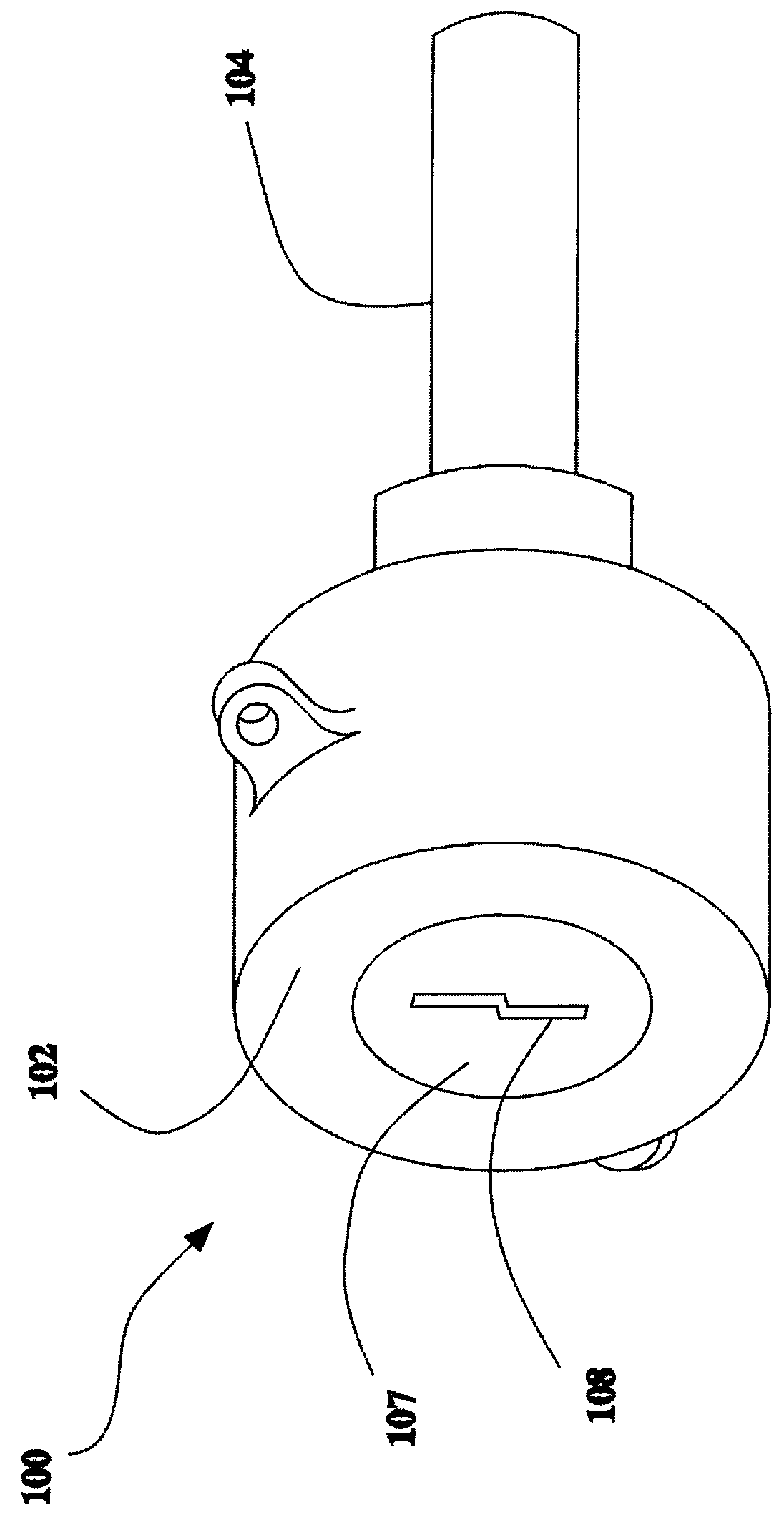

Key operated rotary switch for disabling an automobile air bag supplemental restraint system

InactiveUS6122944AReduce stepsFree spinsBuilding locksPedestrian/occupant safety arrangementElectricityDetent

A key operated switch is provided for disabling an automobile air bag passive restraint system. The two or four position switch includes a housing, a rotor, a plurality of rotationally actuated electrical switch elements, a key ejecting mechanism, and a positive positioning detent. The switch assembly is arranged such that a transverse surface of the rotor defining a key slot is accessible through the housing. The key slot allows an operating key to be manually inserted into the rotor. In or order to insert the key, however, the therein, a certain minimum amount of force must be applied to the key sufficient to overcome the key ejecting mechanism. In the absence of such minimum insertion force, the key ejecting mechanism will act expel the key from the rotor. Once inserted into the rotor, the key may be manually rotated which causes corresponding rotation of the rotor. The rotation of the rotor in turn, actuates select electrical switch elements attached to the rotor, according to the angular position of the rotor. The electrical switch elements define a plurality of distinct switch states, each corresponding to a particular angular position of the rotor. Finally, the positive positioning detent forces the rotor to an angular position corresponding one of the distinct switch states defined by the electrical switch elements during those periods when no external torque is being applied to the rotor.

Owner:METHODE ELETRONICS INC

Gas generating agent for automobile safe gasbag and preparing method thereof

InactiveCN101234943AEasy to mold and releaseImprove adsorption capacityPressure gas generationCarboxymethyl celluloseSesquioxide

The invention discloses an automobile airbag gas generating agent and a preparation method thereof. The invention is characterized in that 30 to 50 percent of guanidine nitrate, 5 to 20 percent of basic cupric nitrate, 10 to 25 percent of strontium nitrate, 3 to 10 percent of ammonium perchlorate, 2 to 6 percent of iron sesquioxide, 2 to 10 percent of sodium carboxymethyl cellulose and 2 to 5 percent of caoline taken in accordance with the weight percentages are mixed thoroughly; after distilled water is added, the mixture is heated and kneaded and cooled for granulation; obtained particles are then dried and sieved to get the gas generating agent. Raw materials for products to be made with the method of the invention are easy to acquire and have low prices. The production process is safe and conducive to safety of automobile occupants and also to environment protection.

Owner:烟台安泰德汽车安全系统有限公司

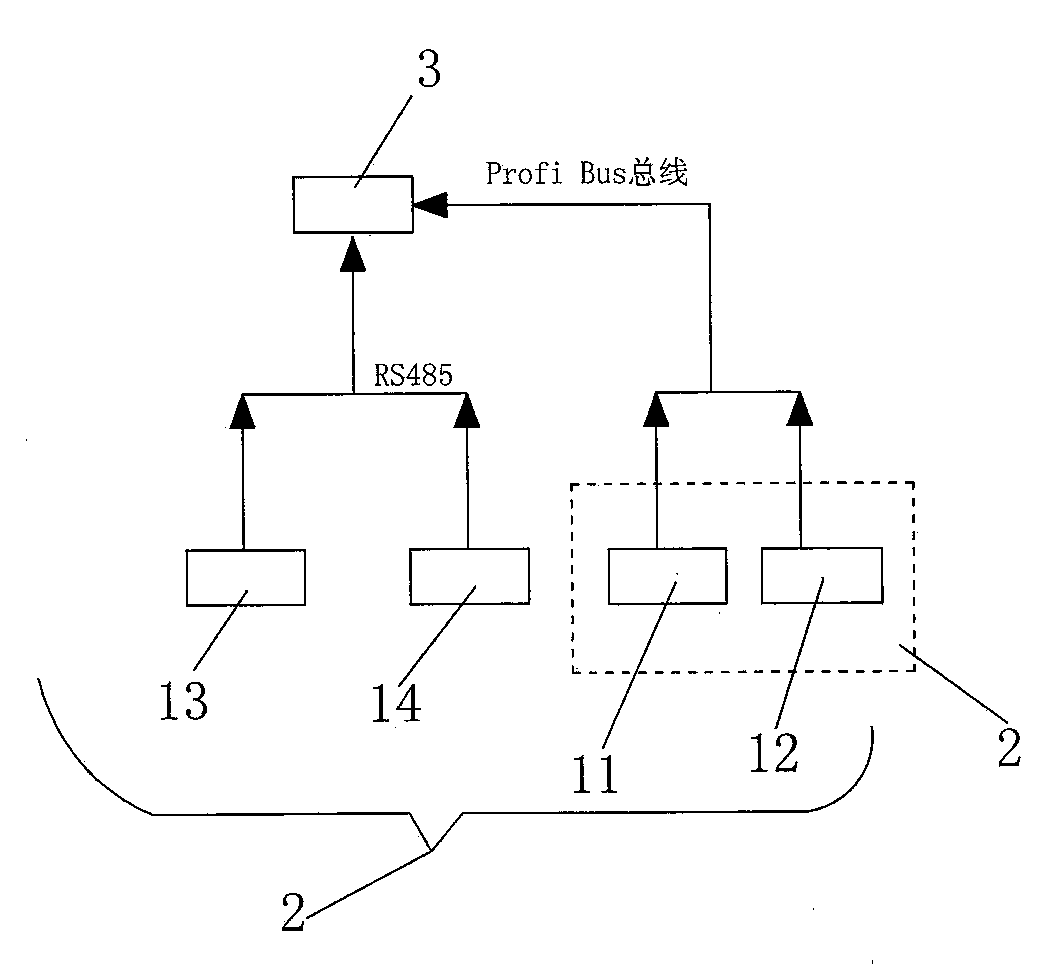

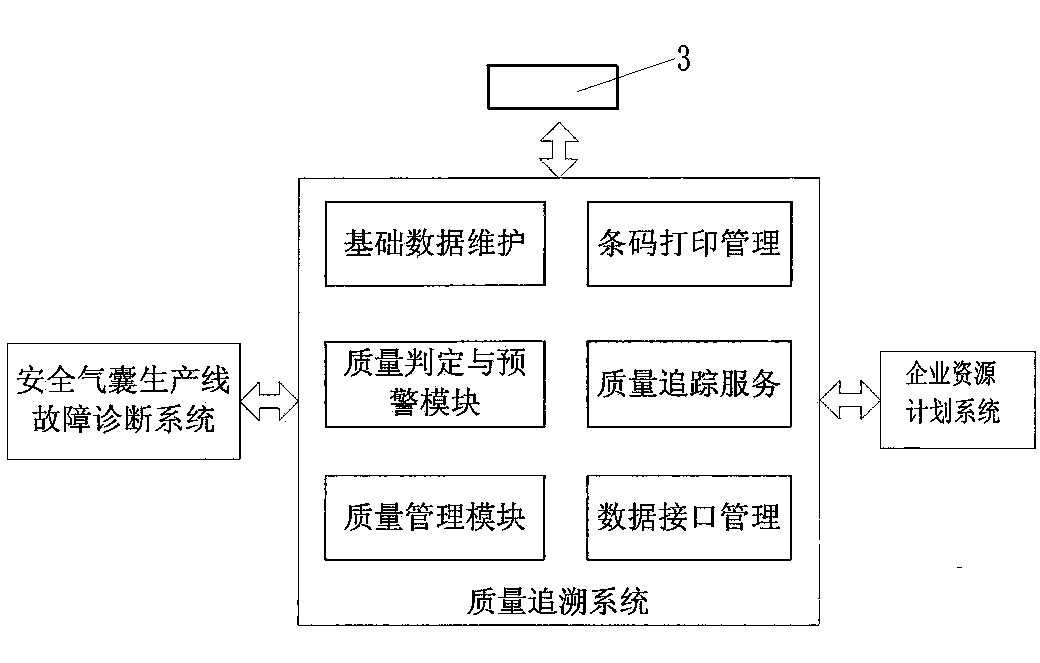

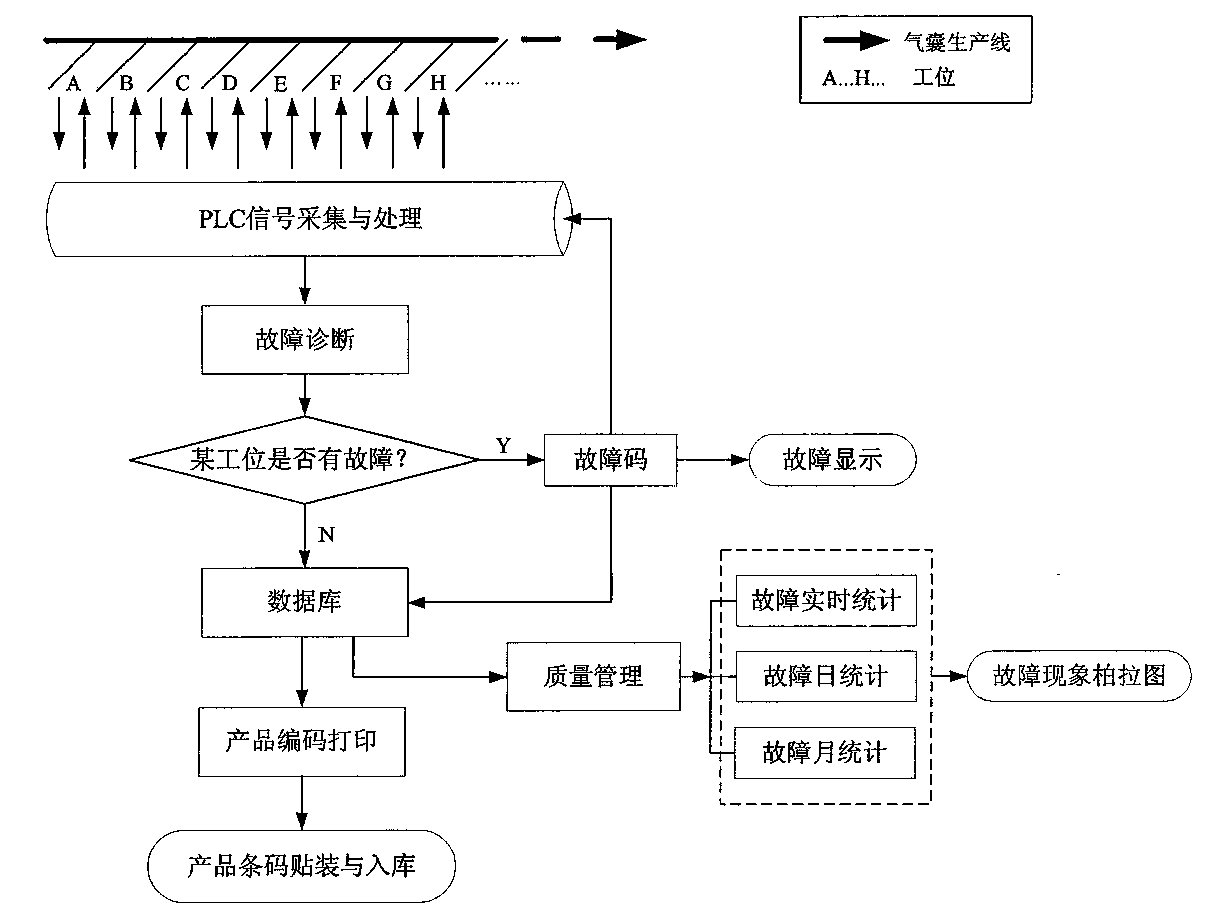

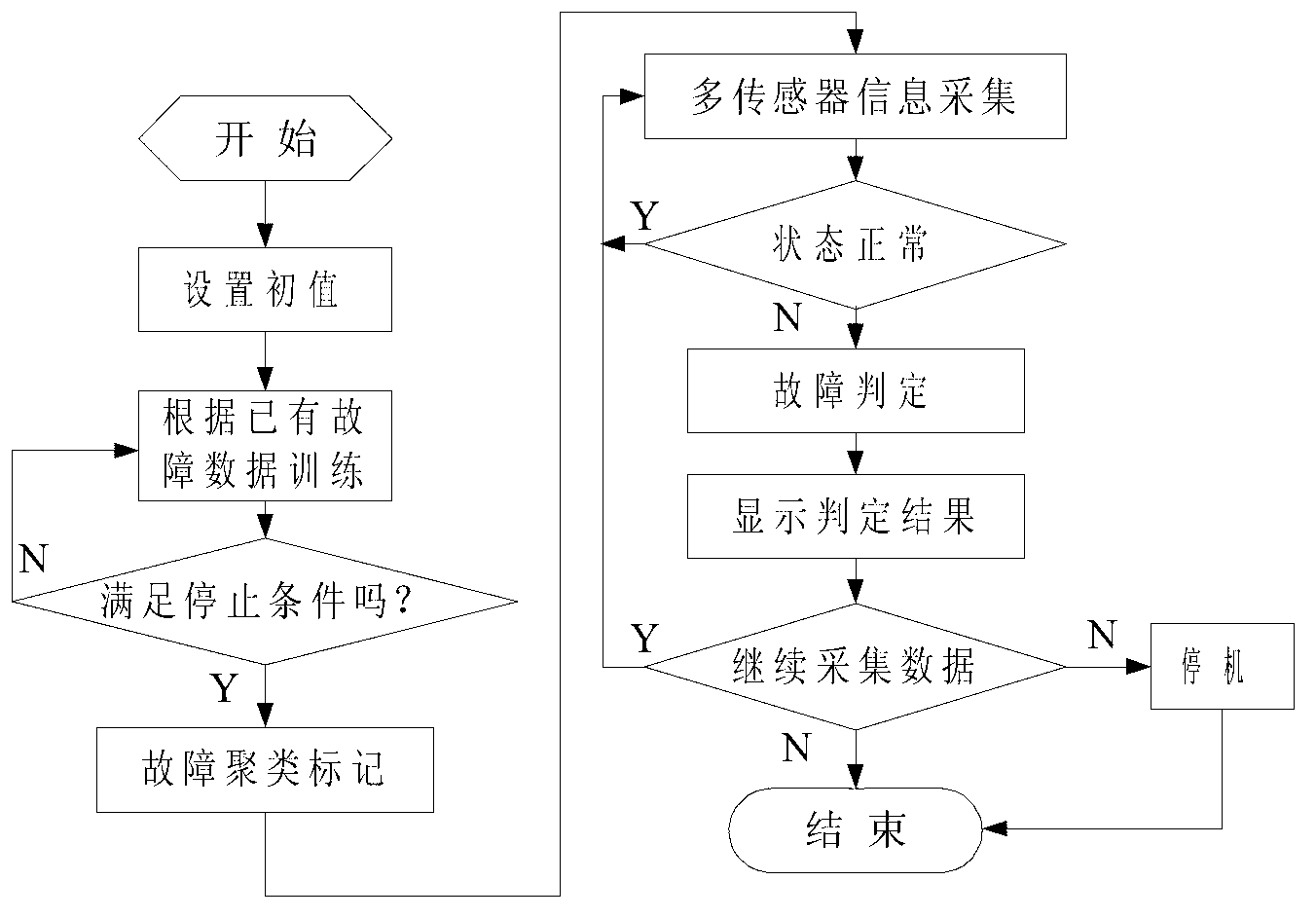

Quality traceability system for bag-folding process of automobile safety air bag production line

InactiveCN103389721AEasy Browse ModeTotal factory controlProgramme total factory controlSql serverSoftware design

The invention discloses a quality traceability system for a bag-folding process of an automobile safety air bag production line. The system comprises an information collection device, a PLC (programmable logic controller) system and a computer processing system, wherein the information collection device acquires various parameters of each station in the bag-folding process of the air bag production line in real time and transmits information to the computer processing system; a fault diagnosis system based on multi-sensor information fusion performs fault diagnosis and early warning on data; the acquired data and fault information are stored in an SQL Server 2005 database; algorithms in a software design are written by a Java language; a front interface adopts a dynamic web page manner which is realized by HTML (hypertext markup language), DIV (data in voice), CSS (computer system simulation) and Jsp (java server pages) codes; and the fault statistic result is displayed in a graphic manner, and simultaneously, information statistics and inquiry of the bag-folding process in the web page manner provides a more convenient browsing mode. The traceability system adopts bar coding information as the unique identification of a product, so that the historical data tracing function of the product in the bag-folding process is achieved, and the dynamic adjustment of the whole air bag folding process is achieved.

Owner:CHANGCHUN UNIV OF TECH

Low-alloy high-strength steel

The invention relates the low-alloy high-strength steel. The weight percents of the components are as follows: C<=0.12, Mn: 1.25-1.75, Si: 0.45-0.75, S<=0.015, P<=0.015, S+P<=0.025, Mo0: 0.5-0.25, V: 0.06-0.11, Ni<=0.50, Cu<=0.20, Al<=0.015, O<=30ppm, and the left is Fe. The method comprising the following steps: using the above materials, using electric furnace and vacuum degasified to smelt. The low-alloy high-strength steel has high purity and fine grain structure. The material can be used to make air valve of vehicle safe steam pocket.

Owner:WUXI CHICHENG SPECIAL STEEL VENDITION

Polyester fabrics for airbag and preparation method thereof

ActiveUS20120043742A1Secures superior mechanicalSecures flexibilityFibre treatmentPedestrian/occupant safety arrangementFiberPolyester

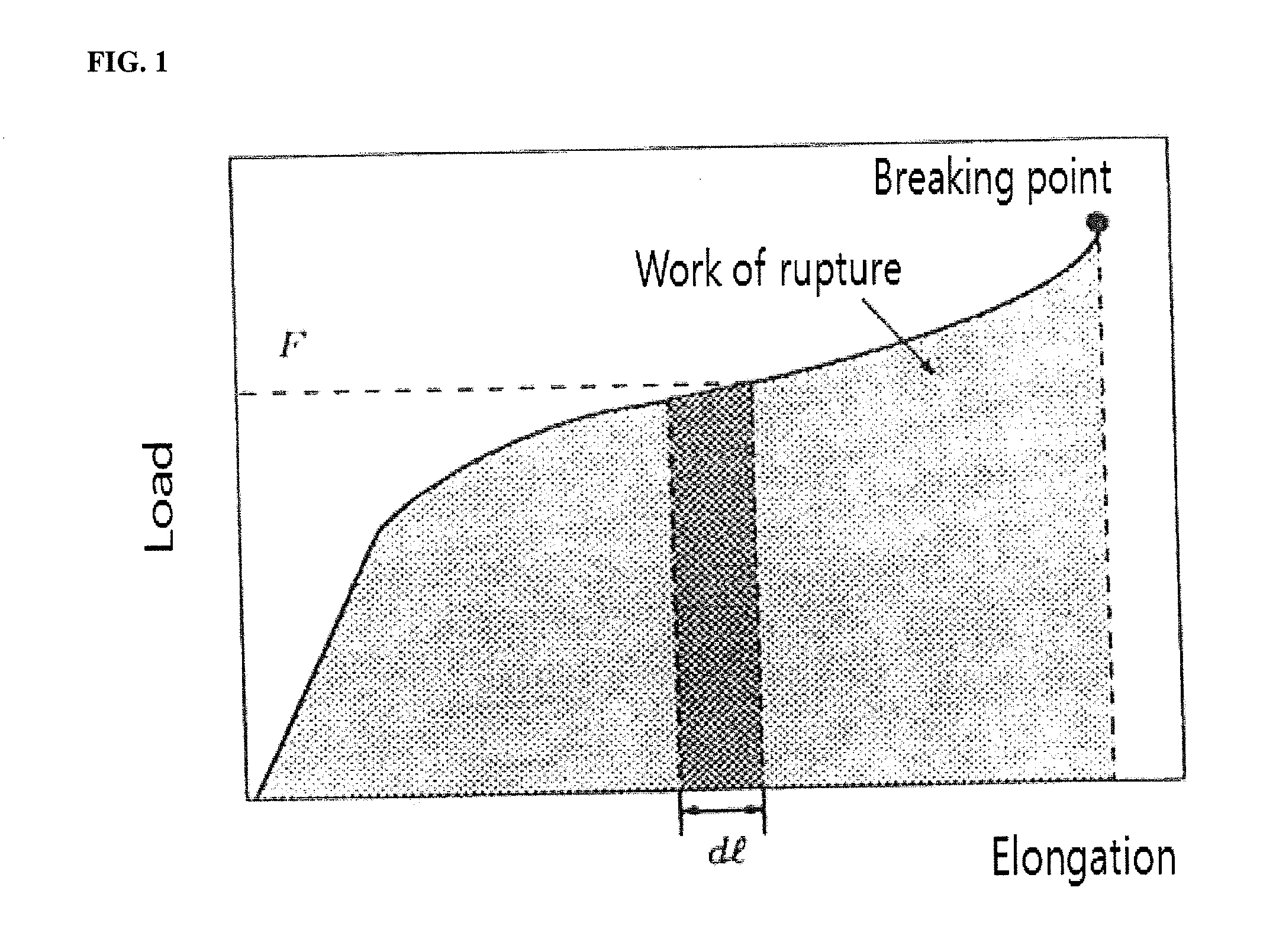

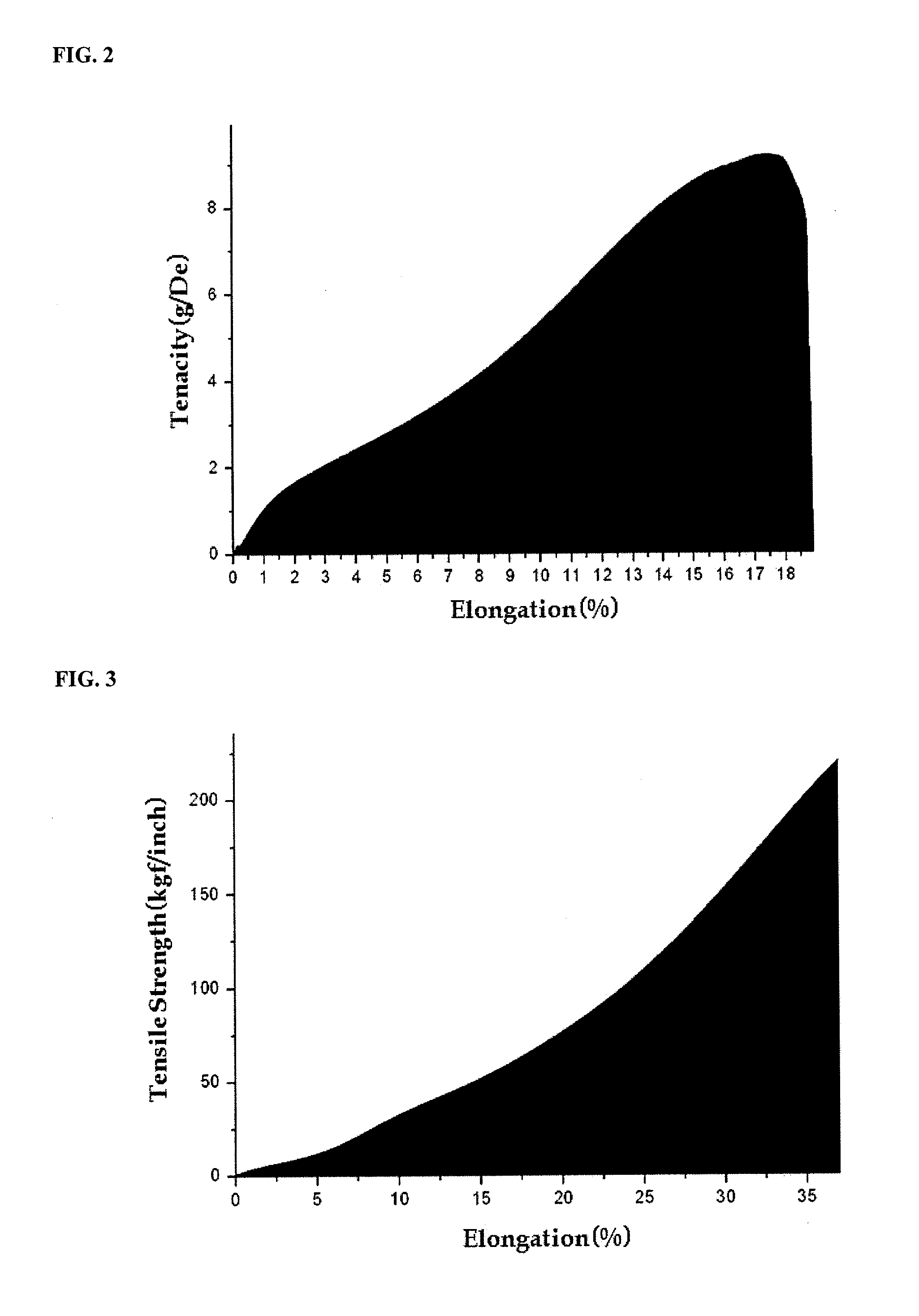

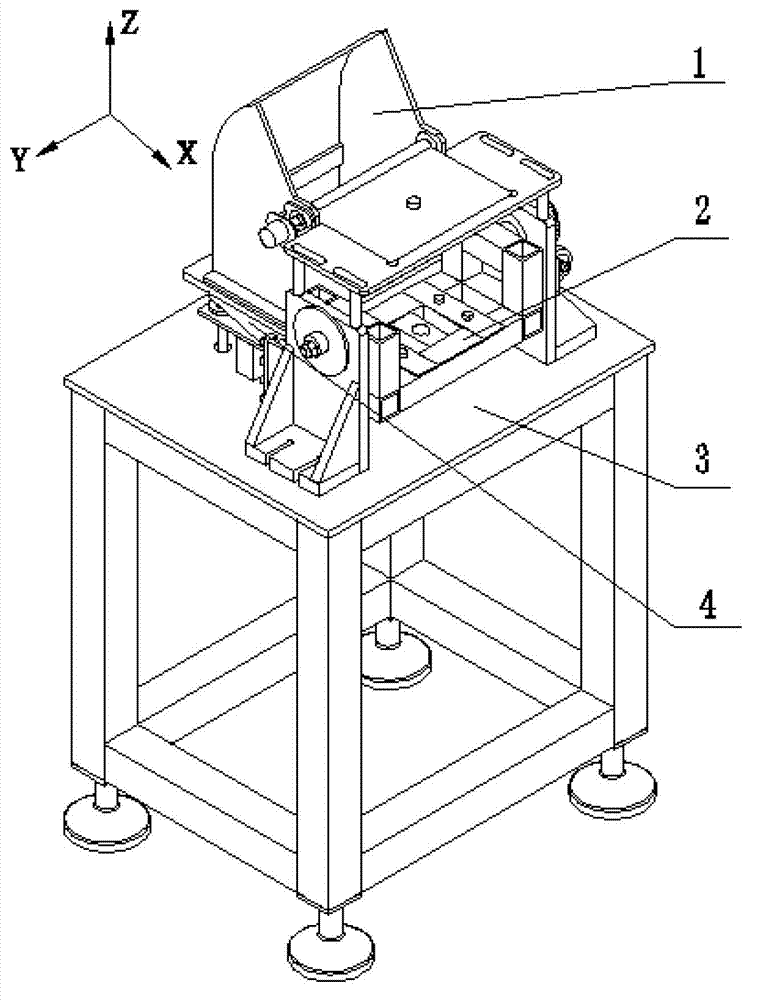

Disclosed is a fabric for an airbag including a polyester fiber, and particularly to a polyester fabric for an airbag of which toughness is 3.5 to 6.0 kJ / m3 and tearing strength measured according to the ASTM D 2261 TONGUE method is 18 to 30 kgf, wherein the fabric includes polyester fiber of which toughness is 70 to 95 J / m3, a method of preparing the same, and an airbag for a car including the same.

Owner:KOLON IND INC

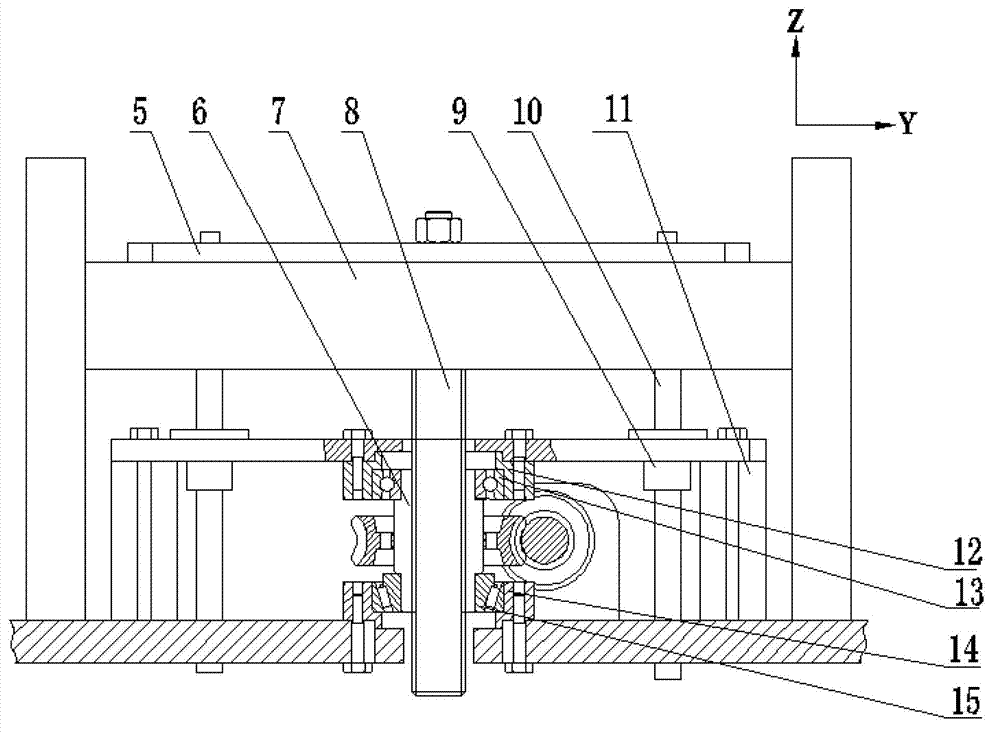

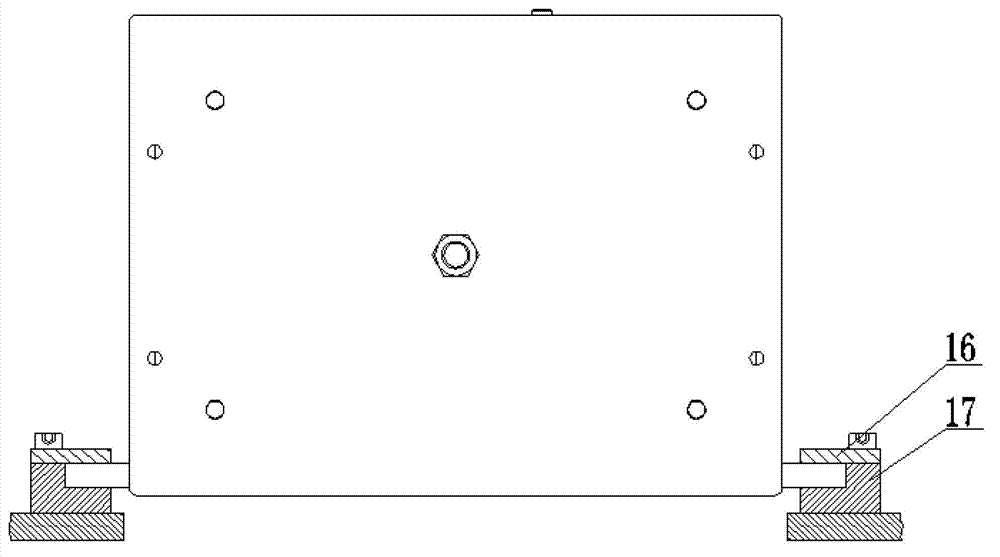

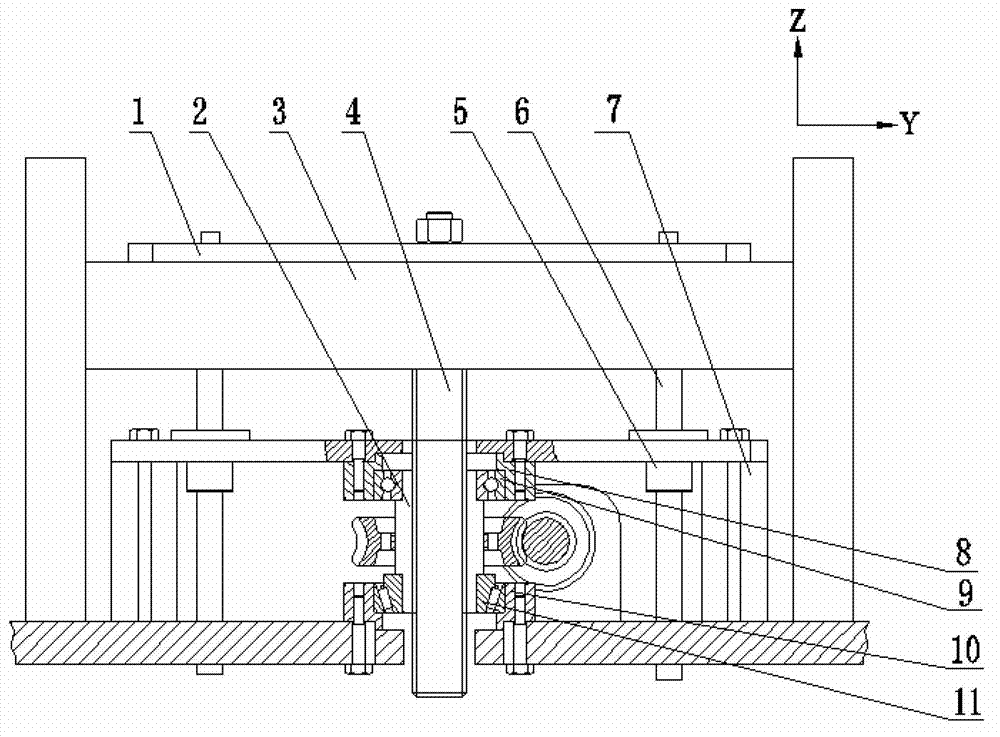

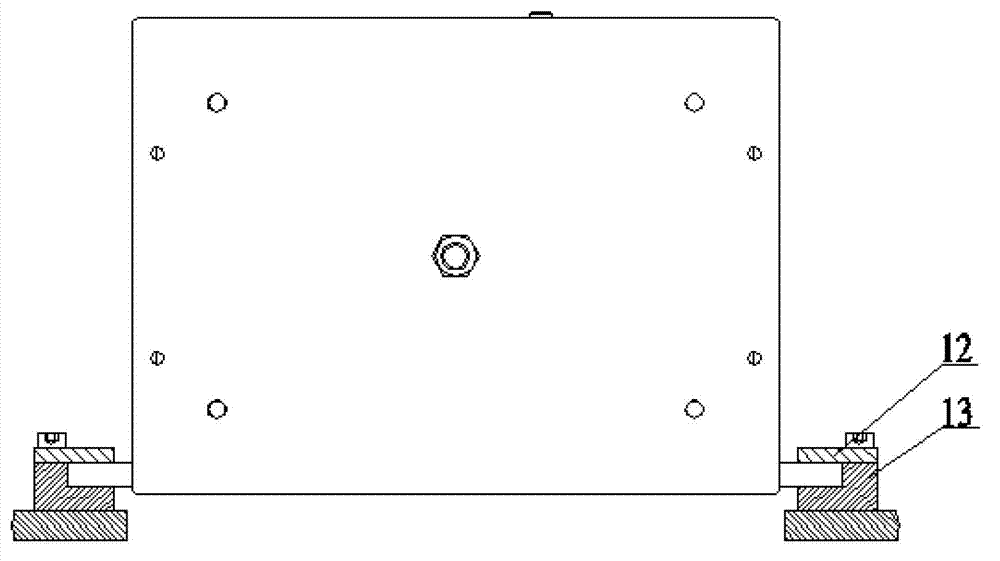

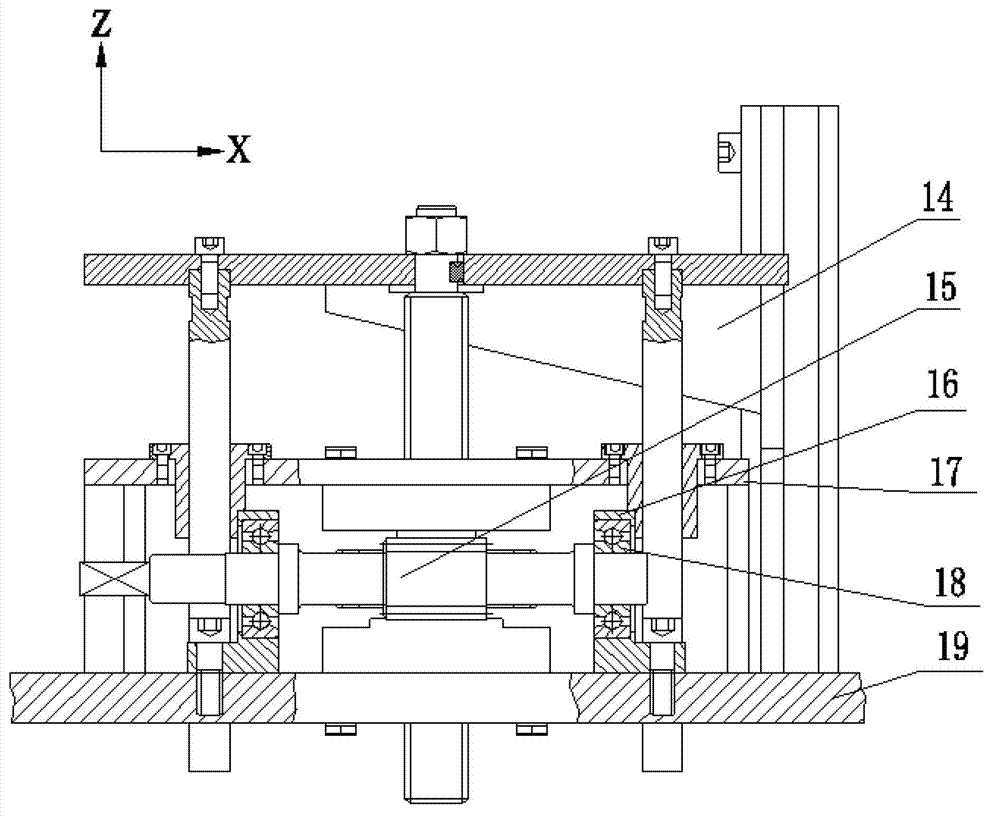

Test bench for comprehensive test of automotive safety airbag

The invention discloses a test bench for the comprehensive test of an automotive safety airbag. The test bench comprises a test bench mechanical part which consists of an automotive safety airbag unfolding speed and acceleration testing buffer device, an automotive safety airbag counteracting force testing device and a test stand. The test stand comprises a test stand lower bracket and an automotive safety airbag static unfolding and lifting device; the automotive safety airbag static unfolding and lifting device is mounted at one side of a test bench face of the test stand lower bracket, the automotive safety airbag unfolding speed and acceleration testing buffer device is mounted at the upper end of the automotive safety airbag static unfolding and lifting device, and the automotive safety airbag counteracting force testing device is mounted on the test bench face in front of the automotive safety airbag static unfolding and lifting device; and locking guide rails and pressing plates are vertically mounted on inner side end faces of a left side supporting frame and a right side supporting frame in the automotive safety airbag counteracting force testing device, and guide plates and locking guide rails in the automotive safety airbag static unfolding and lifting device are in sliding connection with the pressing plates in a matching manner.

Owner:JILIN UNIV

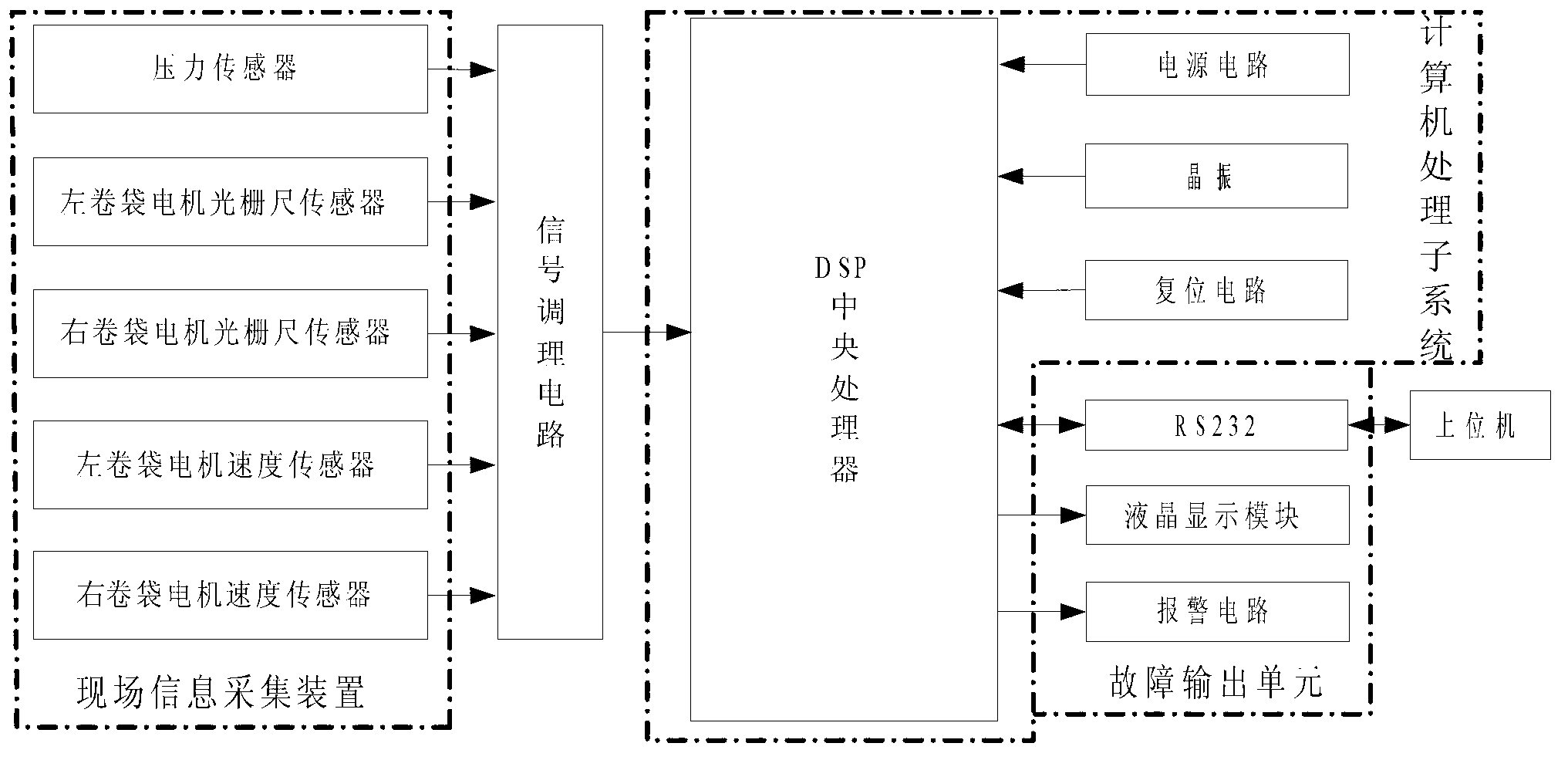

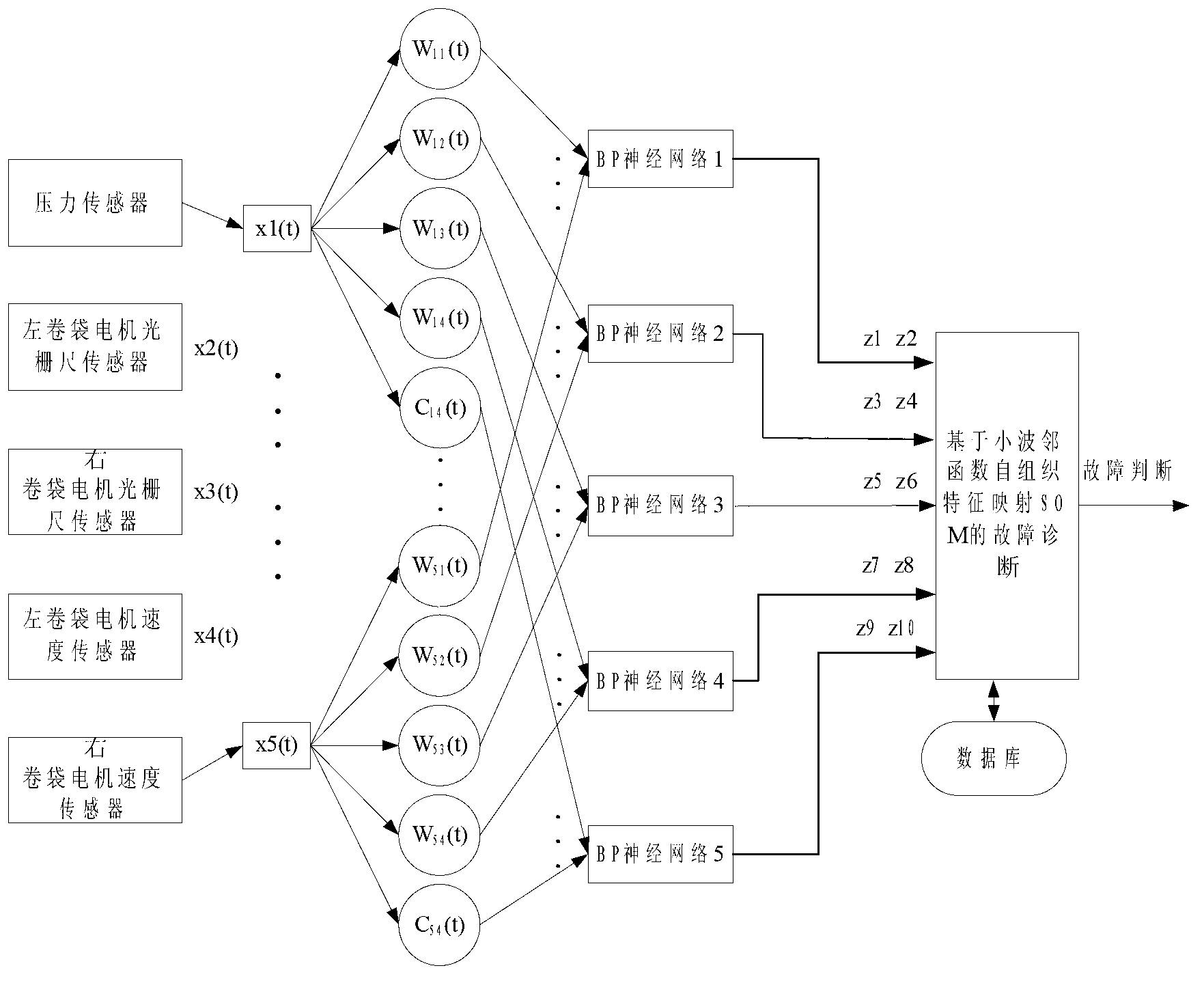

Fault diagnosis system and method for automobile safety air bag assembly working procedure

InactiveCN102707713AAchieve compression and simplificationTimely discovery of special working conditionsElectric testing/monitoringBiological neural network modelsSignal conditioning circuitsData information

The invention discloses a fault diagnosis system and a fault diagnosis method for an automobile safety air bag assembly working procedure, and relates to the field of detection for automobile air bags. The system comprises a field information acquisition device, a signal conditioning circuit, a computer processing subsystem, a fault output unit and an upper computer, wherein the field information acquisition device acquires data information required by fault diagnosis for the air bag assembly working procedure and transmits the acquired data information to the signal conditioning circuit for conditioning; then the computer processing subsystem performs processing and fusion analysis on the received data information and transmits a diagnosis result obtained through processing and analysis to the fault output unit for displaying and outputting; and the fault diagnosis result is transmitted to the upper computer for storage, so that a fault data sample base is updated. According to the system and the method, the accuracy rate of fault diagnosis for the automobile safety air bag assembly working procedure is effectively improved; phenomena of false alarming and leaked alarming are avoided; and therefore, the fault diagnosis result is relatively rational and relatively practical.

Owner:CHANGCHUN UNIV OF TECH

Static expanding lifting device of automobile air bag

Owner:JILIN UNIV

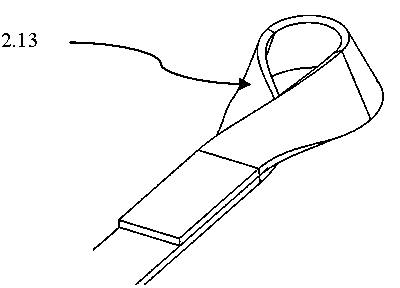

Automobile airbag shell structure

ActiveCN104015684AIn line with the development trend of lightweightImprove rigidityPedestrian/occupant safety arrangementMetal frameworkEngineering

An automobile airbag shell structure is composed of a metal framework, a fabric tape net, a bracket and a U-shaped steel wire, wherein the fabric tape net is formed by weaving fabric tapes. The fabric tape tail end located on the inner side of the fabric tape net is provided with circular collars. The fabric tape tail end located on the outer side of the fabric tape net is provided with angular hanging rings. The U-shaped steel wire penetrates through all the collars on the inner side of the fabric tape net and then is fixed on the inner side of the bracket. The periphery of the metal framework is provided with hooks corresponding to all the fabric tapes. The hanging rings on the outer side of the fabric tape net penetrate through the metal framework and then are hung on the hooks on the periphery of the metal framework. The netty structure is formed by sewing the fabric tapes, one end of the netty structure is hung on the metal framework, the other end of the netty structure is fixed on the bracket through the U-shaped steel wire, and therefore a hollow netty container structure is formed. The automobile airbag shell structure is high in rigidity, low in cost and light in weight, thereby being in accordance with the light weight development trend of automobiles.

Owner:JINZHOU JINHENG AUTOMOTIVE SAFETY SYST

Automobile airbag door

InactiveUS20140333052A1High strengthLow tensile strengthPedestrian/occupant safety arrangementCushionMotor vehicle airbag

An automobile airbag door includes a base member, a three-dimensionally knitted inner cushion layer, which is arranged on one side of the base member, and a covering arranged on a side of the inner cushion layer that is opposite to the base member. The base member and the inner cushion layer each have a plurality of cleavage grooves, which serve as starting points of breaking action when the airbag door is pressed by the airbag being deployed and inflated. An outer cushion layer is located between the inner cushion layer and the covering.

Owner:TOYODA GOSEI CO LTD

Gas generating powder used for gas generator of automobile safety airbag and preparation method thereof

InactiveCN1544271ASimplified Filtration SystemImprove gas production efficiencyPedestrian/occupant safety arrangementAdhesiveFilter system

The invention discloses an aerogenic drug used in gas generator of automobile safety gas cell and its preparing method, composed of negative oxygen combustible agent, oxidant, slagging agent, and adhesive; it adopts a wet-mixing extrusion molding technique for preparing and the drug has very weak toxicity; suitable for large-scale low-cost production, and has a little dust in producing course, high safety; and has high gas generating efficiency, 1.7 times about as high as that of sodium azide aerogenic drug; etc. It simplifies the filter system of the gas generator and creates important conditions for the development of miniaturizing and lightening the gas generator. It can meet the requirements, is a non-azide aerogenic drug and can replace the sodium azide aerogenic drug and is used in the current popular multiple gas generators of automobile safety gas cells.

Owner:西安北方庆华电器(集团)有限责任公司

Automotive Airbag Device

InactiveUS20070257475A1Stabilize flowGas flow is smoothPedestrian/occupant safety arrangementForming gasEngineering

An airbag is formed from fabric layers joined at a seam, and gas generator inflates the airbag by means of gas expelled from the gas generator's insertion end which has been inserted into the airbag. A gas guide is formed in the airbag in order to direct gas from the gas generator into the airbag and includes a pouch-shaped gas guide member in which are formed gas injection nozzles and an attachment orifice. The insertion end of the gas generator is inserted into the attachment orifice with the gas injection nozzles facing an interior of the airbag. A convex-shaped seam is included where the fabric layers are joined, and is disposed in opposition to the gas guide member. The gas guide member comes into contact with the convex-shaped seam as a result of the pressure of the flow of gas from the gas generator through the gas guide member.

Owner:AUTOLIV DEV AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com