Quality traceability system for bag-folding process of automobile safety air bag production line

A traceability system and automobile safety technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems of lack of quality traceability technology in the airbag production line, and achieve the effect of convenient browsing mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

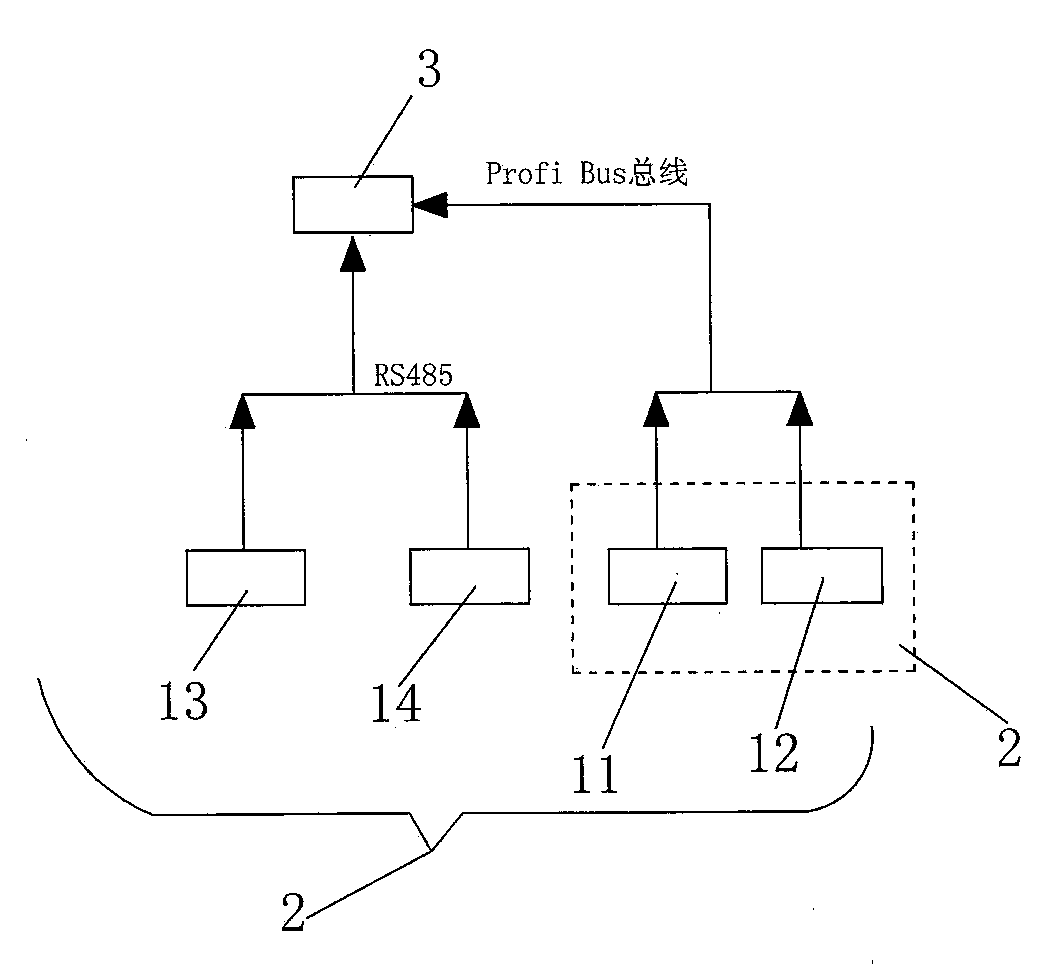

[0014] Such as figure 1 As shown, the present invention is made of information collection device 1, PLC system 2 and computer processing system 3, and described information collection device 1 includes magnetic switch sensor 11, proximity switch sensor 12, torque sensor 13 and speed sensor 14, magnetic The switch sensor 11 and the proximity switch sensor 12 are installed in the bag rolling and bag pressing stations in the assembly process of the airbag production line, and are used to detect whether the bag rolling and bag pressing operations are in place in the assembly process of the airbag production line. The magnetic switch sensor 11 and the proximity switch Sensor 12 is connected with PLC system 2, and PLC system 2 is connected with computer processing system 3 by Profi Bus bus line, realizes the transmission of data; Torque sensor 13 and speed sensor 14 are installed on the rolling bag motor, for detecting the rotating speed of bag rolling motor and Torque, the torque s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com