Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

252 results about "Methacrylate polymers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

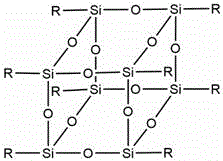

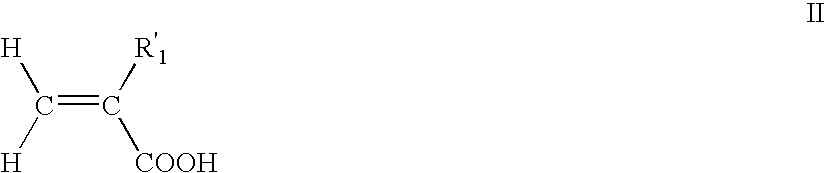

Methacrylate refers to derivatives of methacrylic acid. 2Na +), esters (e.g. CH 2C(CH 3)CO 2CH 3, or methyl methacrylate) and the polymers of these species. Methacrylates are common monomers in polymer plastics, forming the acrylate polymers.

Thermoplastic resin composition and elastomer composition

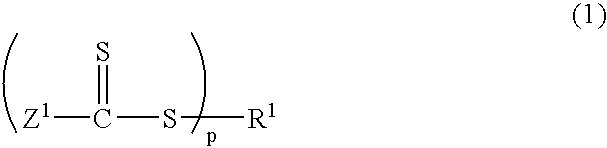

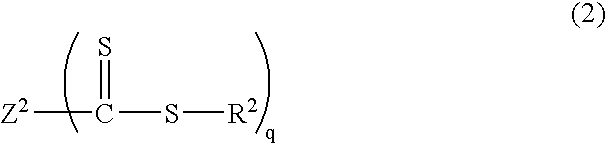

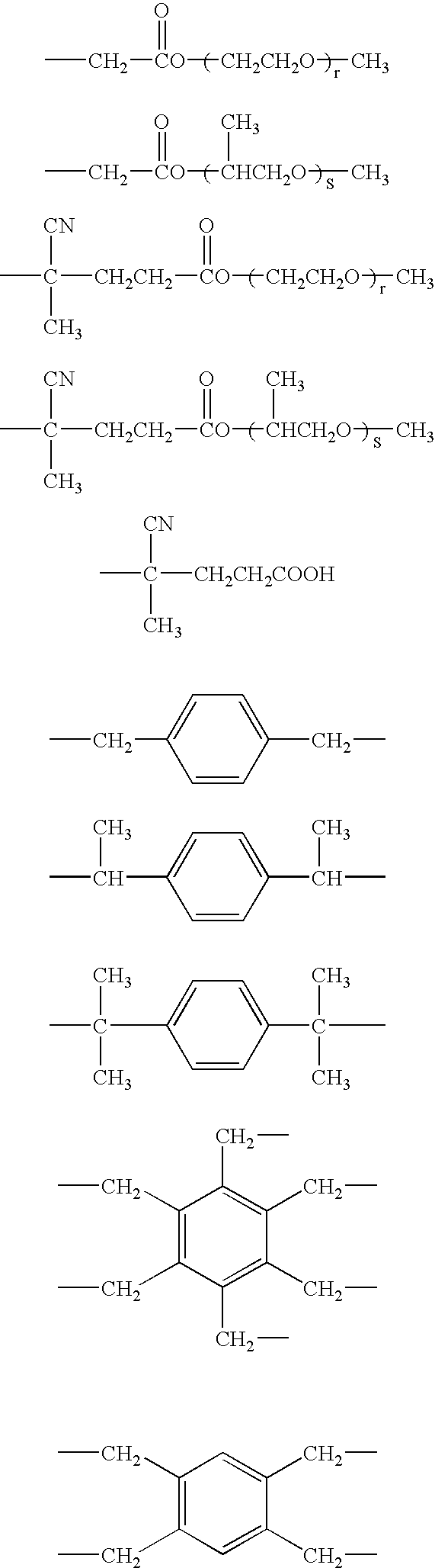

Provided are a thermoplastic resin composition which is excellent in oil resistance, heat resistance, weatherability, impact resistance, transparency, and moldability, and which can be produced economically, an elastomer composition with low hardness and high tensile strength which is excellent in oil resistance and compression set, and a molded object produced by molding the thermoplastic resin composition or elastomer composition. The composition is produced by compounding a thermoplastic resin or an elastomer with a block copolymer having at least one methacrylic ester polymer block and at least one acrylic ester polymer block. Also provided are a process for producing a methacrylic ester-acrylic ester-methacrylic ester block copolymer which requires hardly any purification, which is excellent in heat resistance and weatherability, and in which the molecular weight and the molecular-weight distribution are controlled, and a methacrylic ester-acrylic ester-methacrylic ester block copolymer produced by the process.

Owner:KANEKA CORP

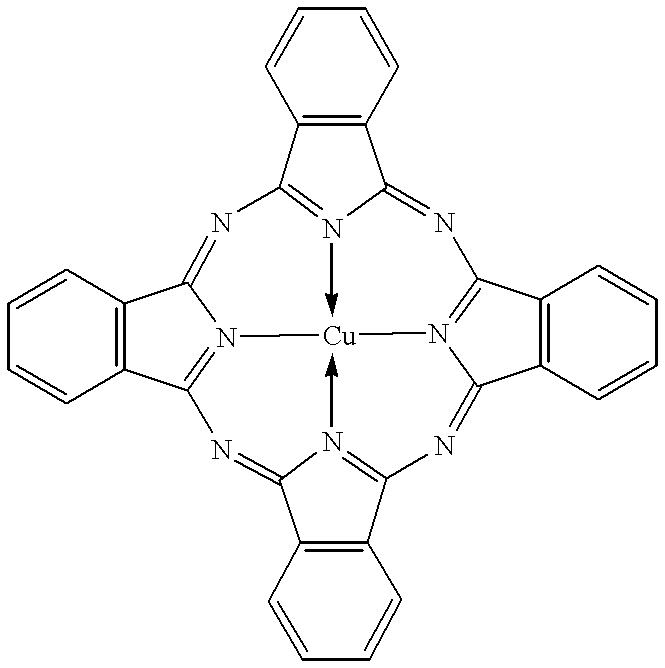

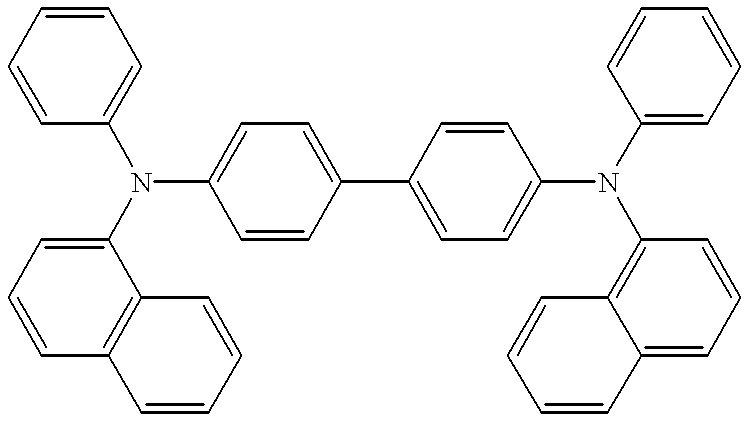

Fluorescent conversion filter and color display device using the same

InactiveUS6249372B1Facilitates its fine patteringImprove the display effectOptical filtersSolid-state devicesDisplay deviceWavelength

A fluorescent conversion filter includes a fluorescent conversion film which facilitates converting light from a wavelength region between near ultraviolet and green to light in the red region which can be finely patterned. A color display device can be produced which includes the fluorescent conversion filter. The fluorescent conversion filter includes a fluorescent conversion film and a light absorption film on the display side surface of the flourescent conversion film. The flourescent conversion film has an absorbance of 1 or less in the wavelength region between 450 nm and 520 nm. The light absorption film has an absorbance of greater than I in the wavelength region between 450 nm and 520 nm. The fluorescent conversion film contains a photo-curing resin or a photo- and thermo-setting resin, that contains an acrylate polymer, a methacrylate polymer or an acrylate-methacrylate copolymer as its main component.

Owner:SHARP KK

Curable Composition

The present invention has its object to provide a curable composition which has good curability and adhesiveness while containing an organotin-free catalyst. The present invention provides a one package curable composition which comprises (A) a polyoxyalkylene polymer having a silicon-containing group capable of crosslinking by forming a siloxane bond, (B) a (meth)acrylic ester polymer having a silicon-containing group capable of crosslinking by forming a siloxane bond and compatible with the component (A), and (C) (c1) a carboxylic acid of which the carbon atom adjacent to a carbonyl group is a quaternary carbon, and / or (c2) a metal carboxylate of which the carbon atom adjacent to a carbonyl group is a quaternary carbon.

Owner:KANEKA CORP

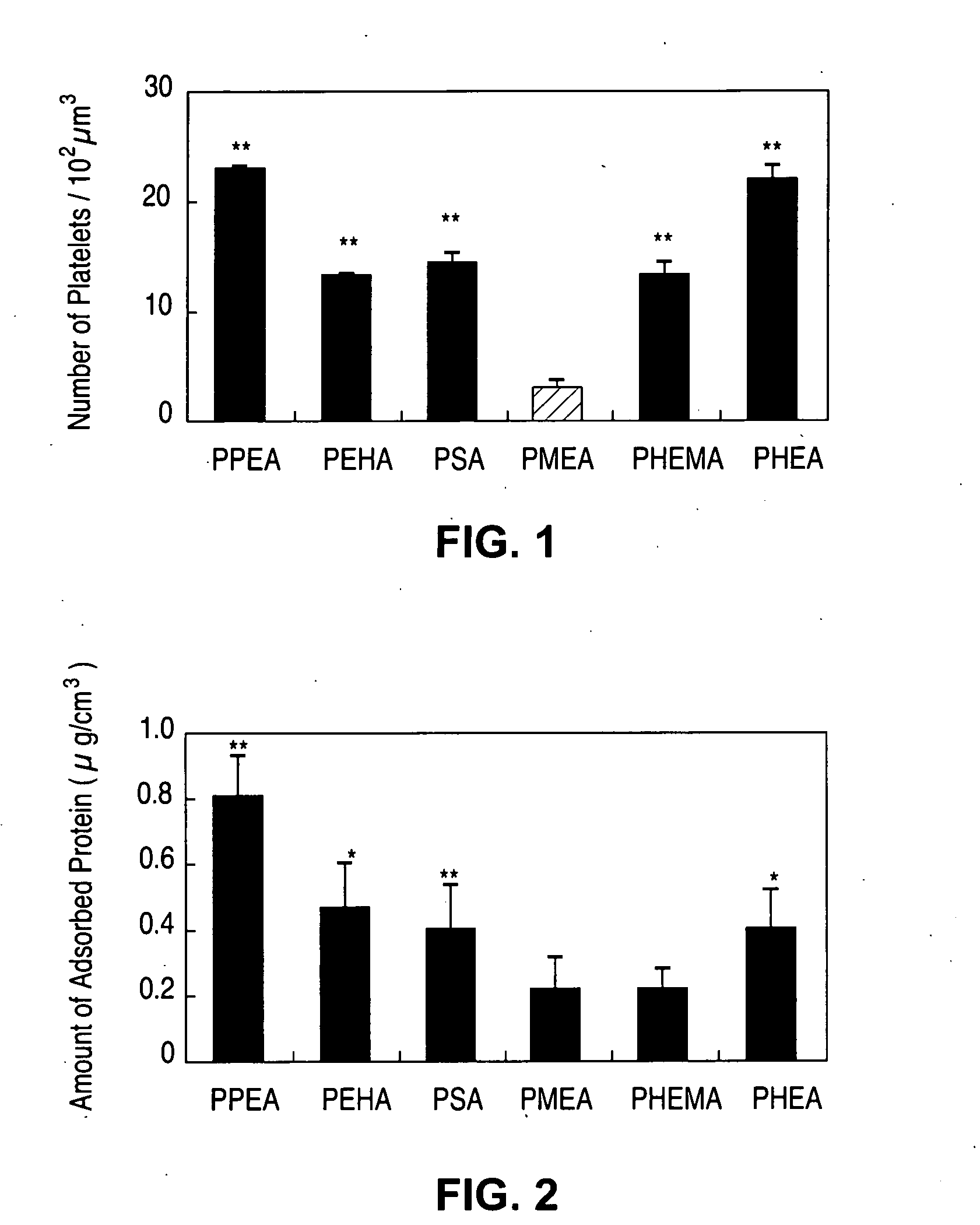

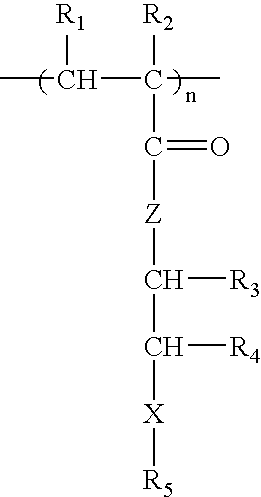

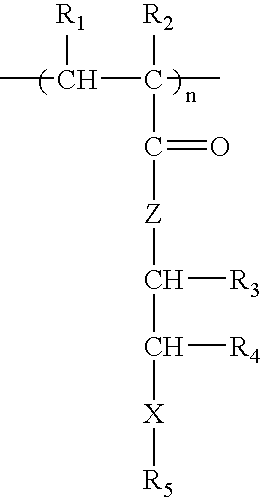

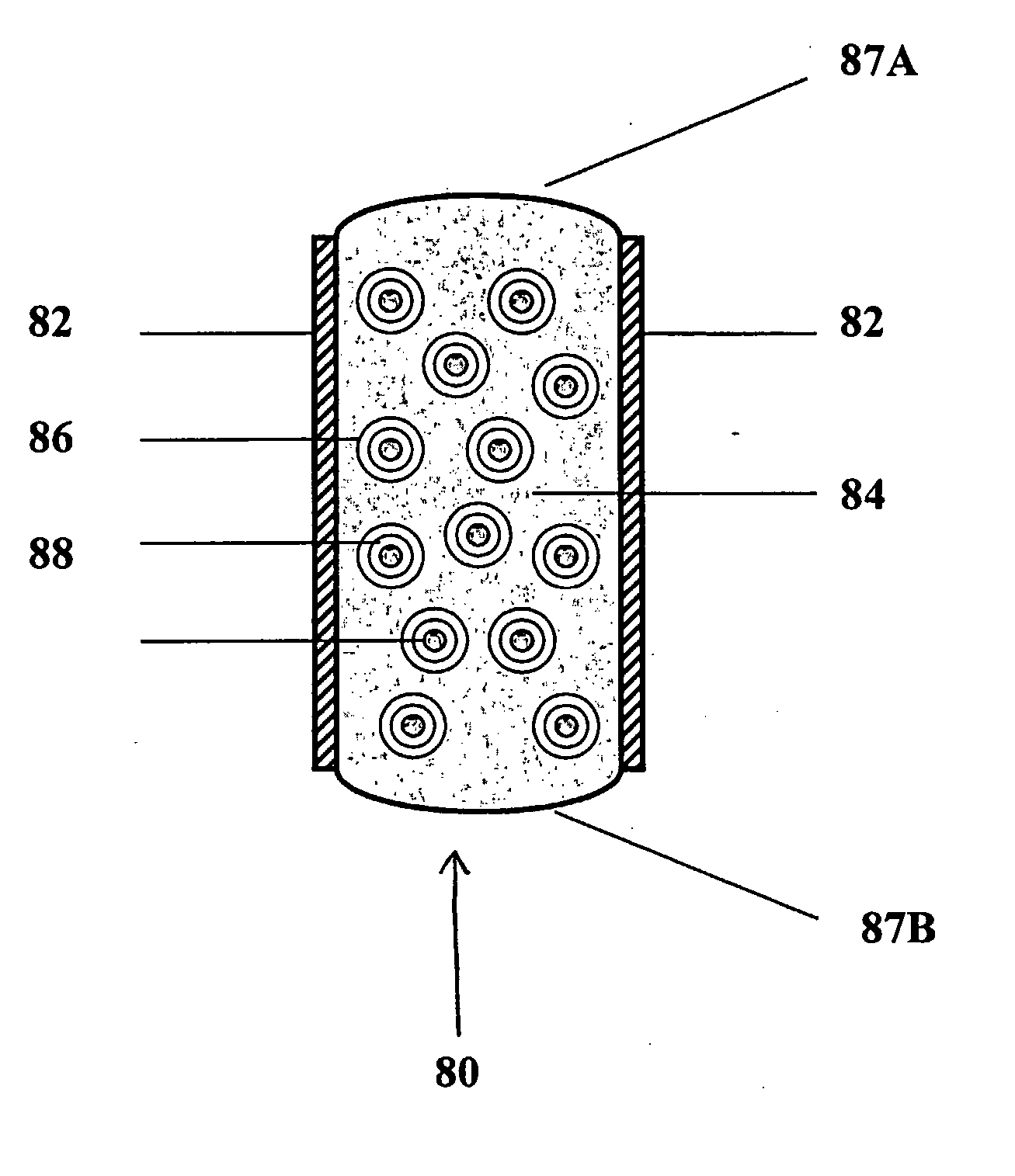

Implantable devices formed of non-fouling methacrylate or acrylate polymers

Implantable devices formed of or coated with a material that includes a polymer having a non-fouling acrylate or methacrylate polymer are provided. The implantable device can be used for treating or preventing a disorder such as atherosclerosis, thrombosis, restenosis, hemorrhage, vascular dissection or perforation, vascular aneurysm, vulnerable plaque, chronic total occlusion, patent foramen ovale, claudication, anastomotic proliferation for vein and artificial grafts, bile duct obstruction, ureter obstruction, tumor obstruction, or combinations thereof.

Owner:ABBOTT CARDIOVASCULAR

Mucoadhesive Oral Formulations of High Permeability, High Solubility Drugs

Solid oral dosage formulations, such as tablet, mini-tab, multiparticulates or osmotic delivery systems, are coated with a mucoadhesive polymeric coating or formed of a mucoadhesive polymer to increase oral bioavailability of Biopharmaceutical Classification System (BCS) Class I drugs. Representative BCS I drugs include valacyclovir, gabapentin, furosemide, levodopa, metformin, and ranitidine HCl. The inclusion of mucoadhesives in the solid oral dosage form brings the dosage form into close proximity with the target epithelium and facilitates diffusion of drug into intestinal tissue. The mucoadhesive polymer may be either dispersed in the matrix of the tablet or applied as a direct compressed coating to the solid oral dosage form. Preferred mucoadhesive polymers include poly(adipic)anhydride “P(AA)” and poly(fumaric-co-sebacic)anhydride “P(FA:SA)”. Other preferred mucoadhesive polymers include non-erodable polymers such as DOPA-maleic anhydride co polymer; isopthalic anhydride polymer; DOPA-methacrylate polymers; and DOPA-cellulosic based polymers.

Owner:JACOB JULES S +4

Light scattering polycarbonate composition for light emitting diode (LED) lighting and use thereof

InactiveCN102134383AHigh transparencyGood light uniformityPoint-like light sourceSemiconductor devices for light sourcesMicrospherePolystyrene

The invention discloses a light scattering polycarbonate composition for LED lighting and use thereof. The composition comprises polycarbonate and a light scattering agent, wherein the light scattering agent is core-shell light scattering powder which takes a glass microsphere, silicon dioxide, a polysiloxane microsphere or polystyrene as a core and acrylate polymer or methacrylate polymer as a shell. The light scattering polycarbonate composition for LED lighting, which is disclosed by the invention, has higher transparency and better light homogenizing effect than other light scattering compositions. The composition disclosed by the invention can be used as a shell material in the field of lighting or display such as LED lamps, fluorescent lamps and incandescent lamps.

Owner:JINAN UNIVERSITY

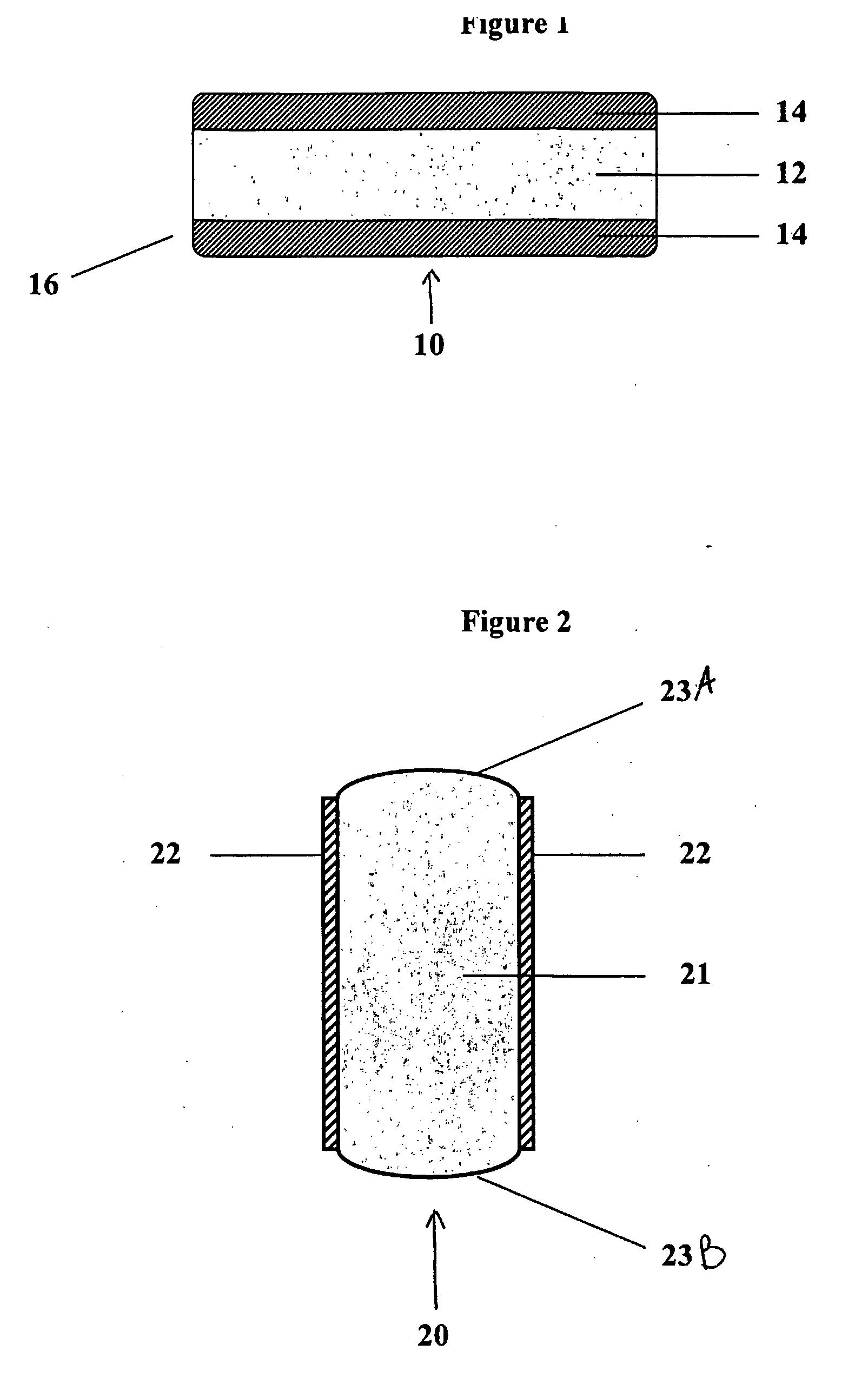

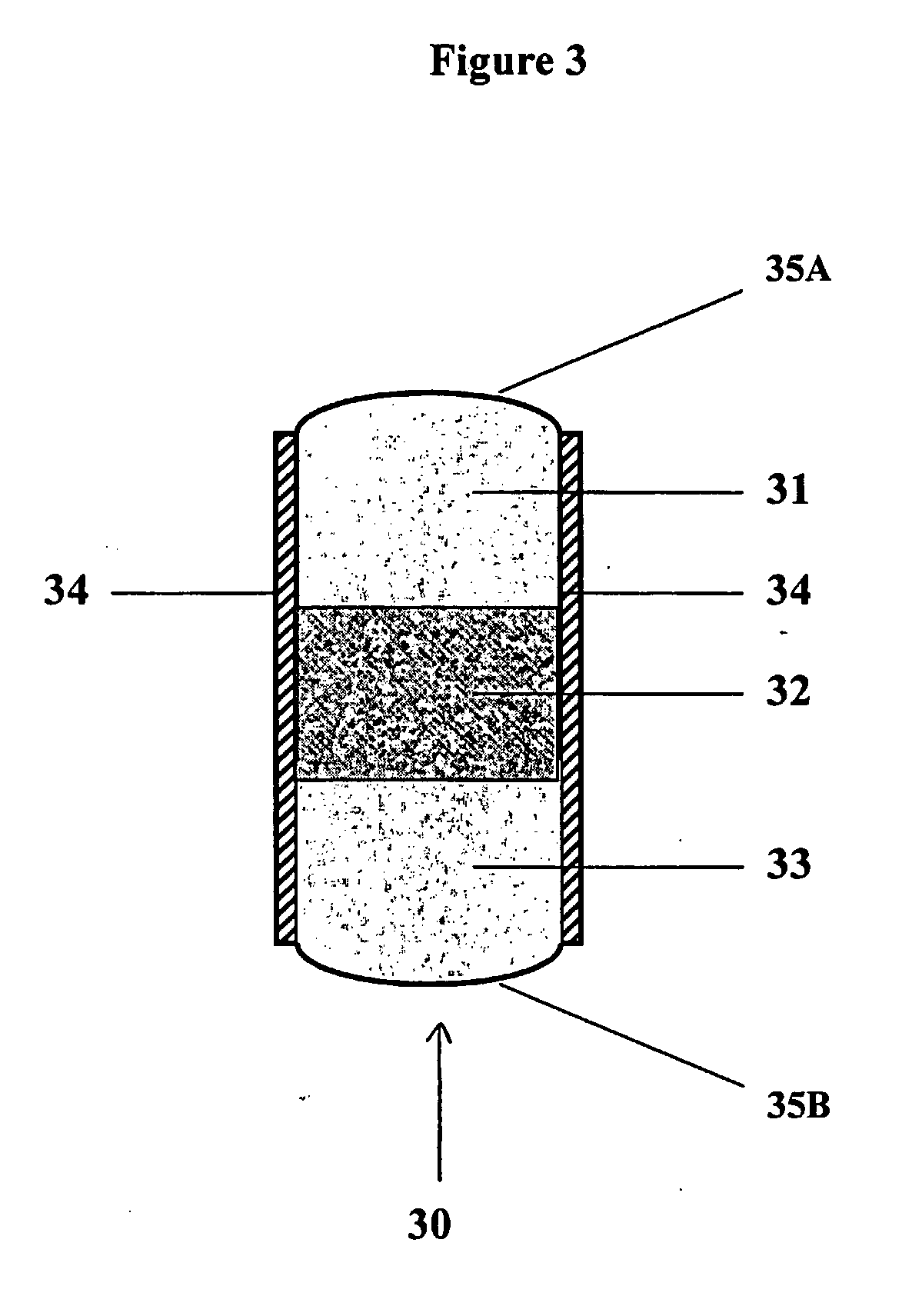

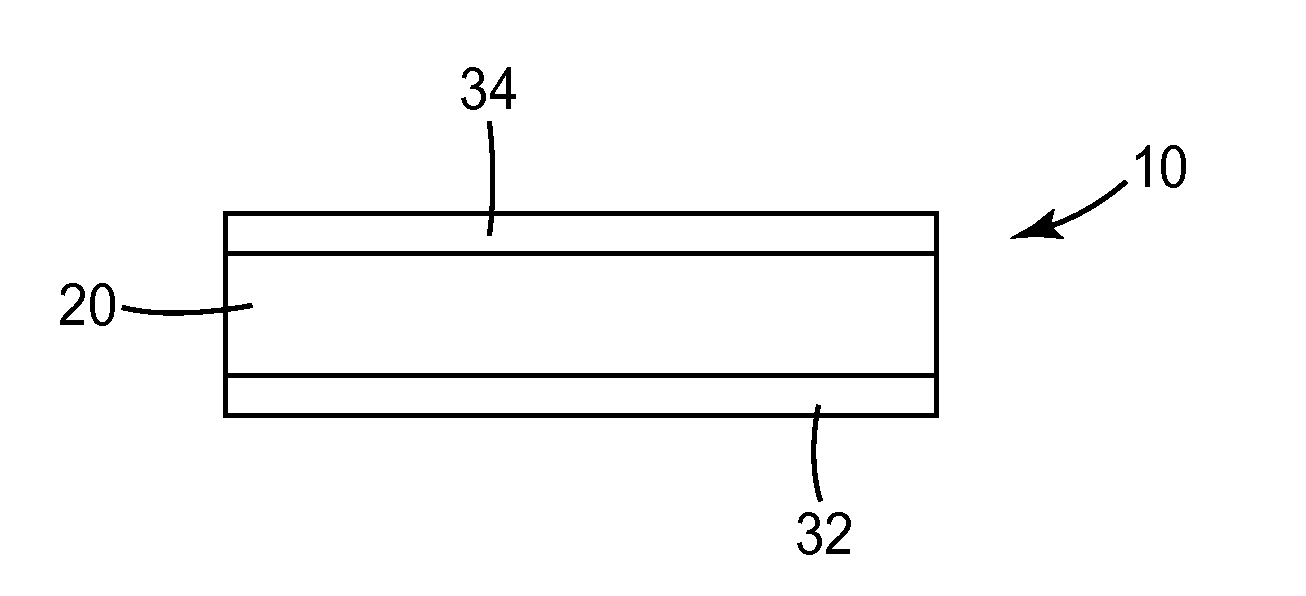

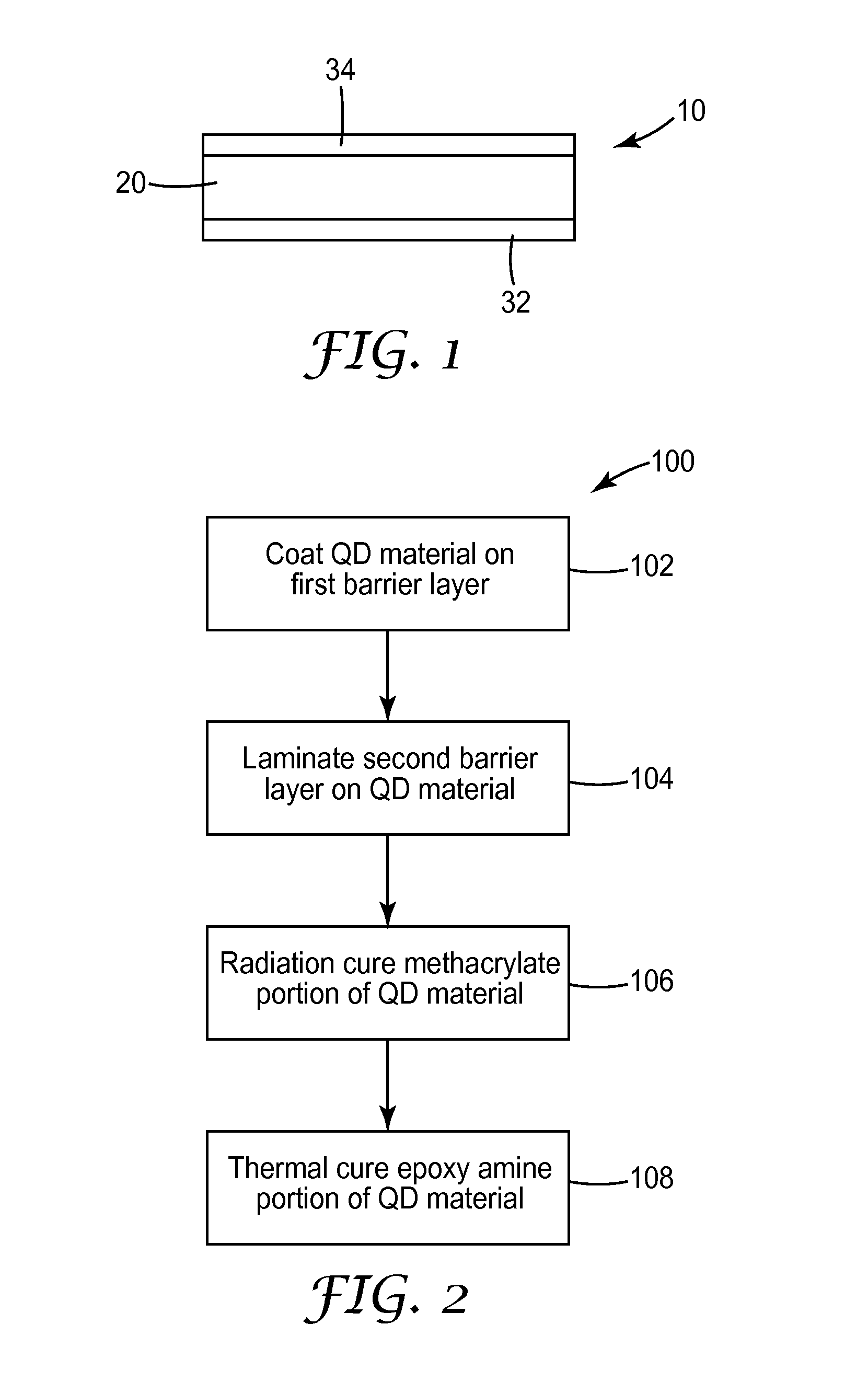

Quantum dot film

ActiveUS20150368553A1Reduce defectsHigh viscositySynthetic resin layered productsOptical articlesQuantum dotMethacrylate polymers

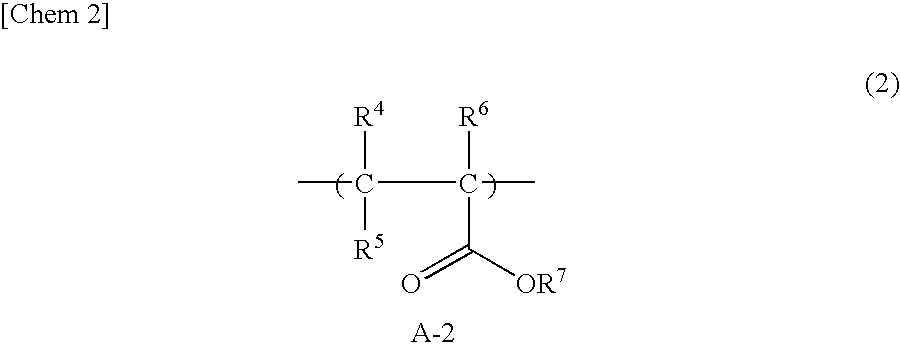

A quantum dot film article includes a first barrier film, a second barrier film, and a quantum dot layer separating the first barrier from the second barrier film. The quantum dot layer includes quantum dots dispersed in a polymer material. The polymer material includes a methacrylate polymer, an epoxy polymer and a photoinitiator.

Owner:3M INNOVATIVE PROPERTIES CO

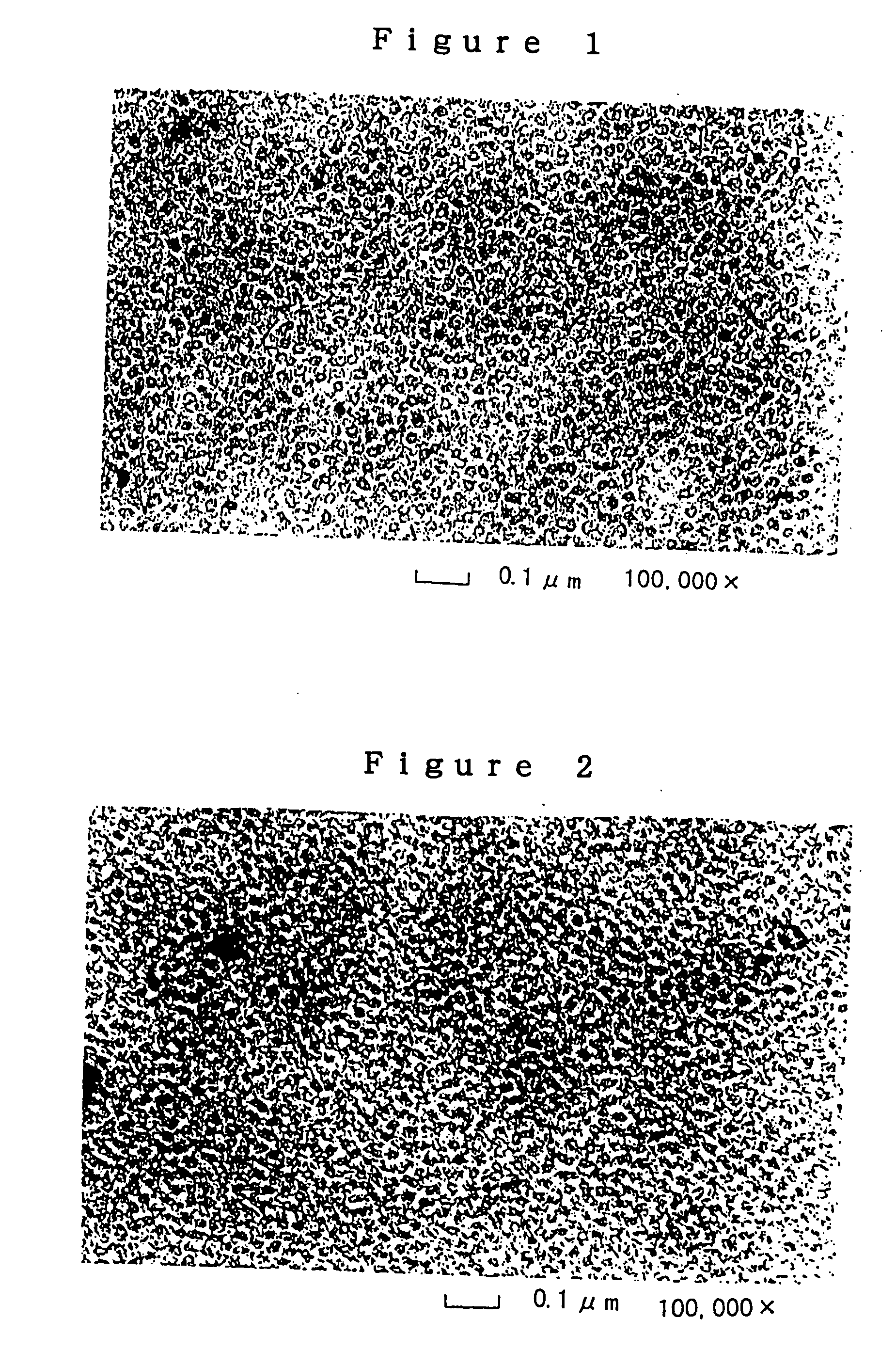

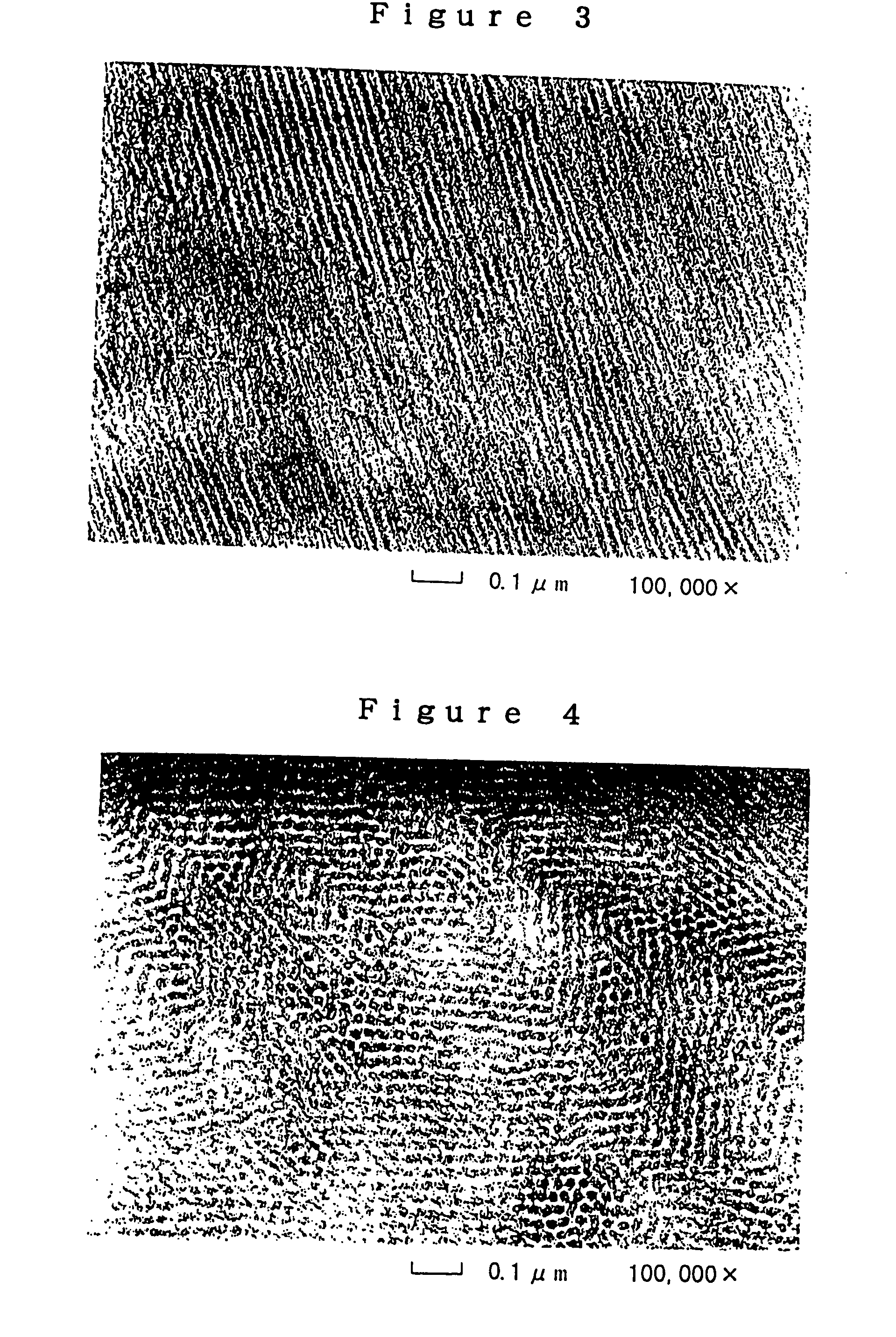

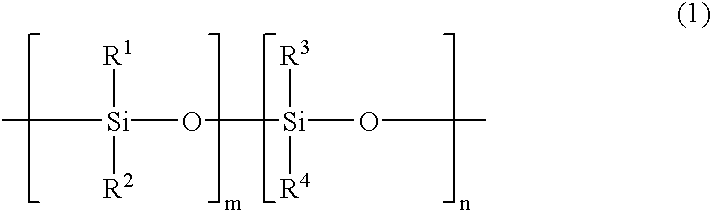

Block copolymer

A block copolymer is obtained by anionic polymerization, includes two or more polymer blocks A miscible with each other, and at least one (meth)acrylic ester polymer block B immiscible with the polymer blocks A, has a ratio [Mn(Amax) / Mn(Amin)] of 2 or more, wherein the ratio [Mn(Amax) / Mn(Amin)] is the ratio of the largest number average molecular weight [Mn(Amax)] to the smallest number average molecular weight [Mn(Amin)] among the polymer blocks A, has at least one block bonding including polymer block Amax-polymer block B-polymer block Amin, and has a total content of the polymer blocks A ranging from 20 wt % to 45 wt % based on the total mass of the block copolymer. This invention provides block copolymers having two or more polymer blocks A miscible with each other and at least one (meth)acrylic ester polymer block B immiscible with the polymer blocks A and exhibiting satisfactory flexibility, melt fluidity, moldability, coatability, mechanical properties, and other properties. The block copolymers of the present invention can yield molded articles having reduced anisotropy and surface stickiness and excellent mechanical properties and pressure-sensitive adhesive compositions having excellent adhesive properties.

Owner:KURARAY CO LTD

Elastomer composition and thermoplastic resin composition containing the same

InactiveUS6534594B1Improve impact resistanceHigher improvement effect on impact resistanceSkin careThermoplasticElastomer

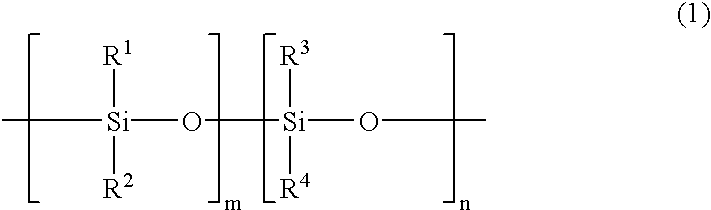

There is provided an elastomer composition for an impact modifier and a thermoplastic resin composition having improved impact resistance using the same. An elastomer composition comprises a block copolymer (a) containing a methacrylate polymer and a siloxane polymer, and a graft copolymer (b) containing a polymer component having a glass transition temperature of lower than 25° C. And the composition is mixed with a thermoplastic resin (c).

Owner:KANEKA CORP

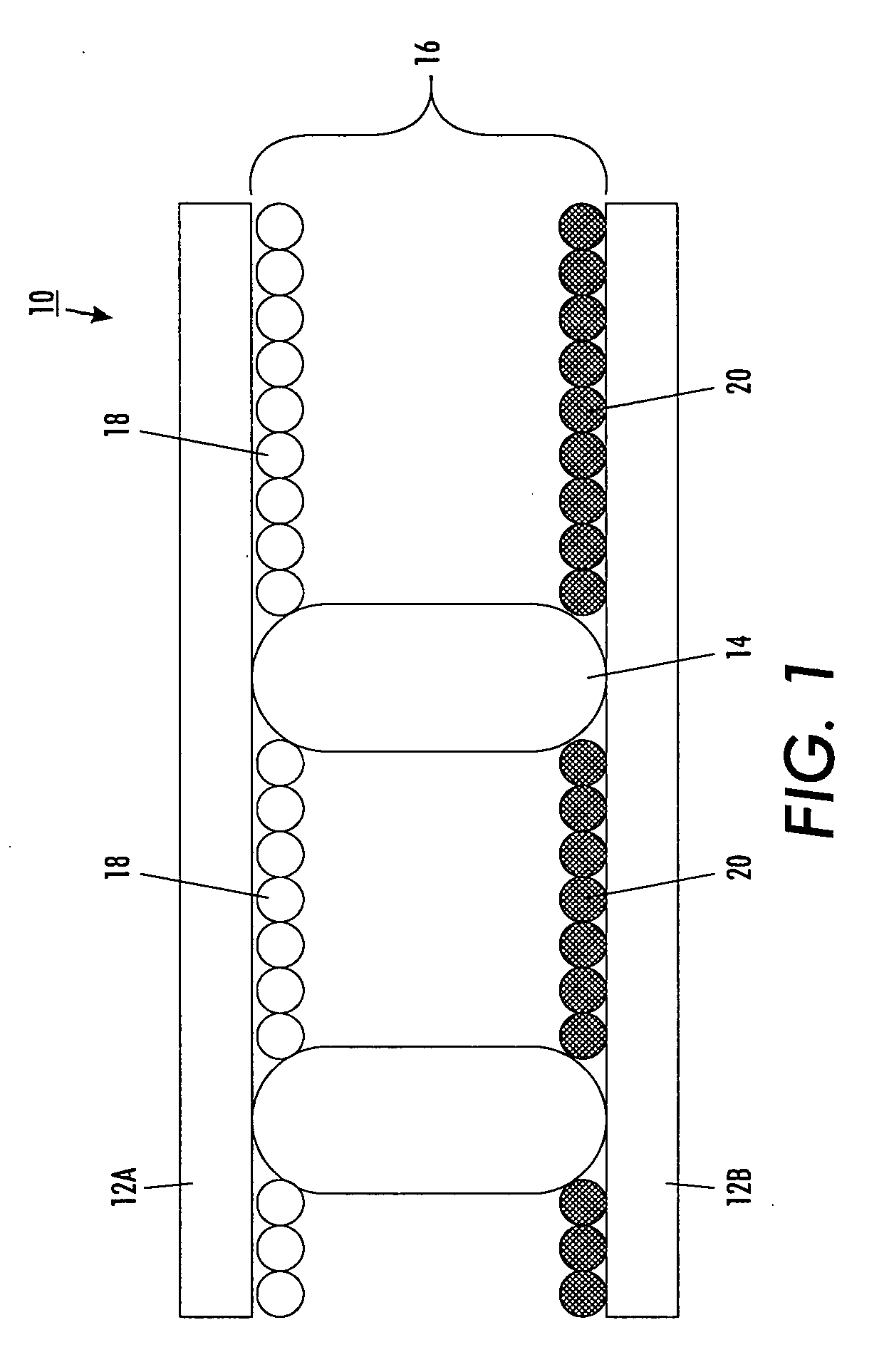

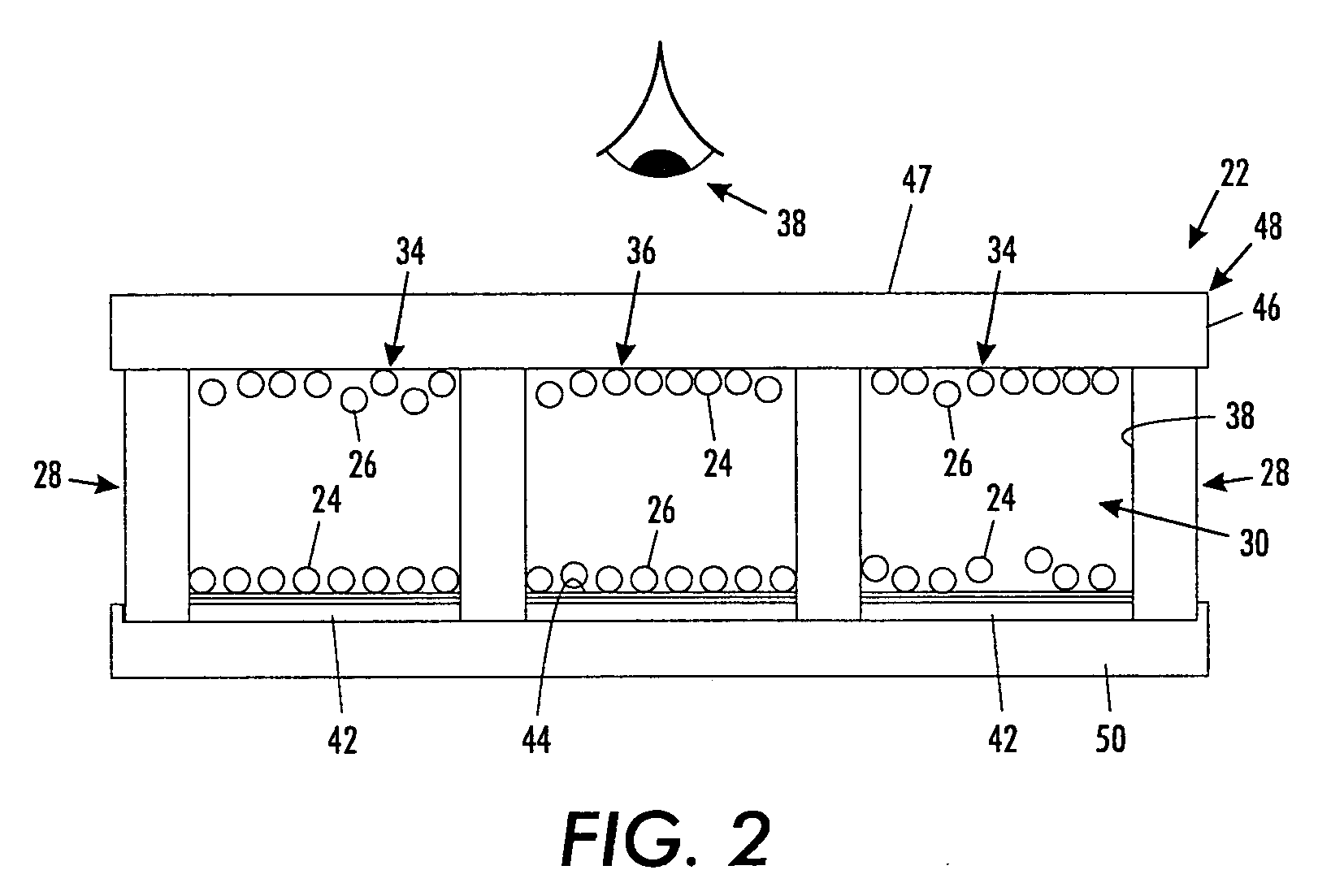

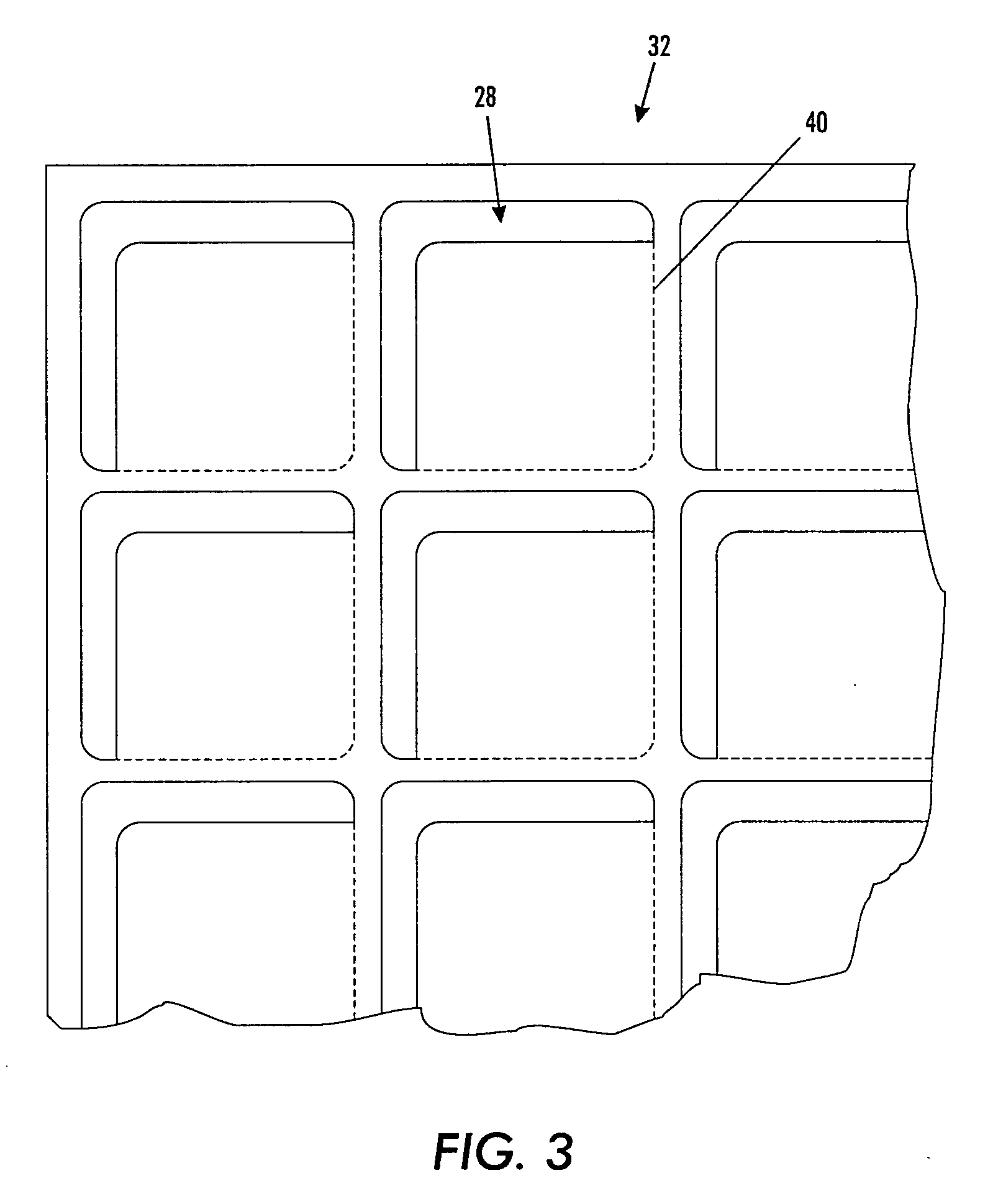

Toner compositions for dry-powder electrophoretic displays

Toner particles and a dry-powder electrophoretic display employing such particles are disclosed herein. The toner particles adapted for a dry-powder electrophoretic display comprise emulsion / aggregation particles having a negative charge. At least a portion of the toner particles include a surface coating, comprising a methacrylate polymer, disposed on the surface of the toner particles to impart a positive charge to a set of toner particles. The emulsion / aggregation toner particles have a particle size generally less than about 10 micrometers that allows for improved image quality as compared to conventional toners utilized in dry-powder electrophoretic displays.

Owner:PALO ALTO RES CENT INC

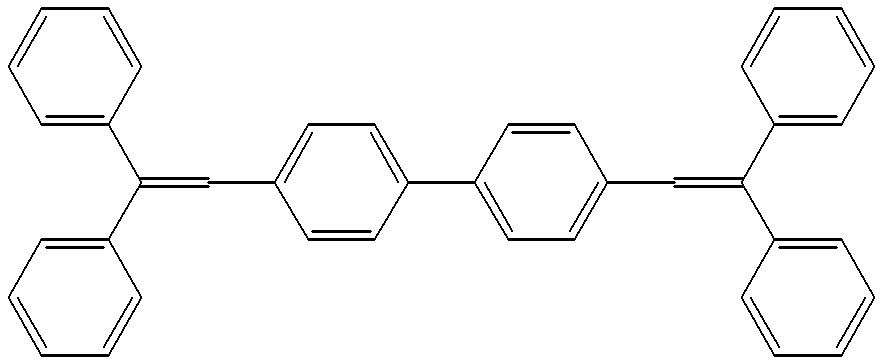

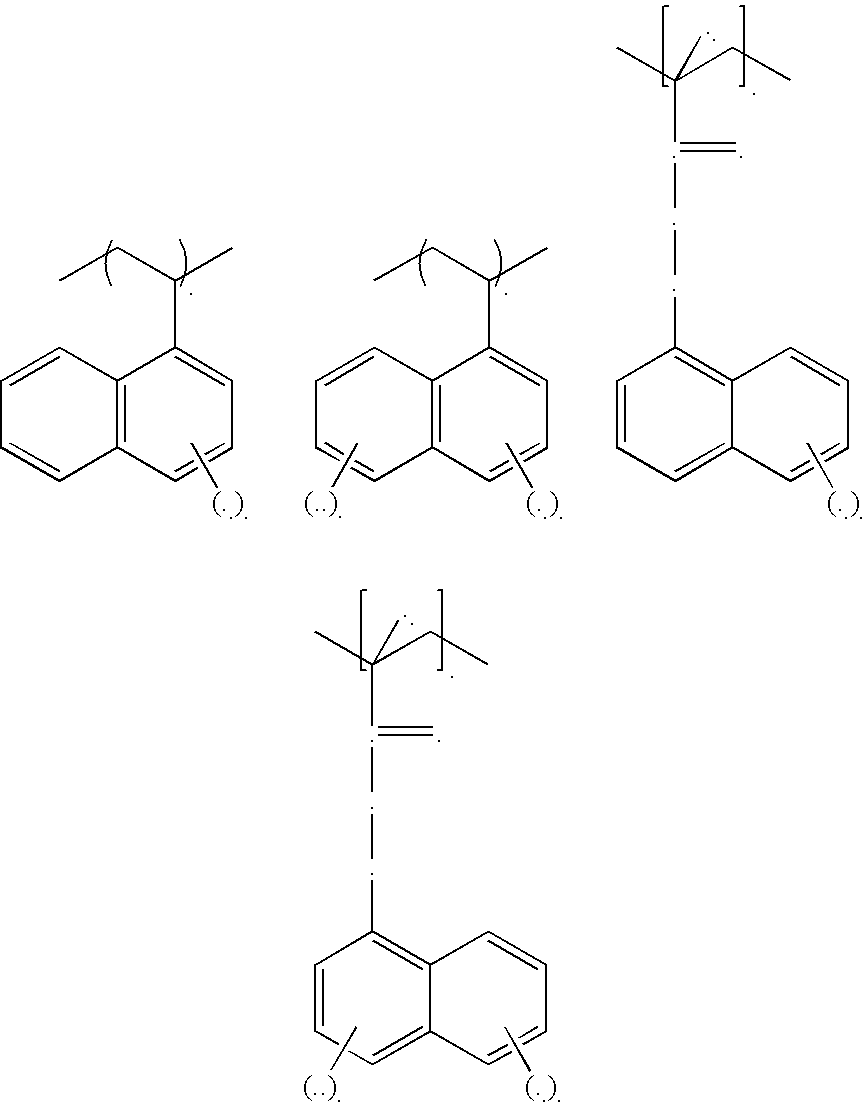

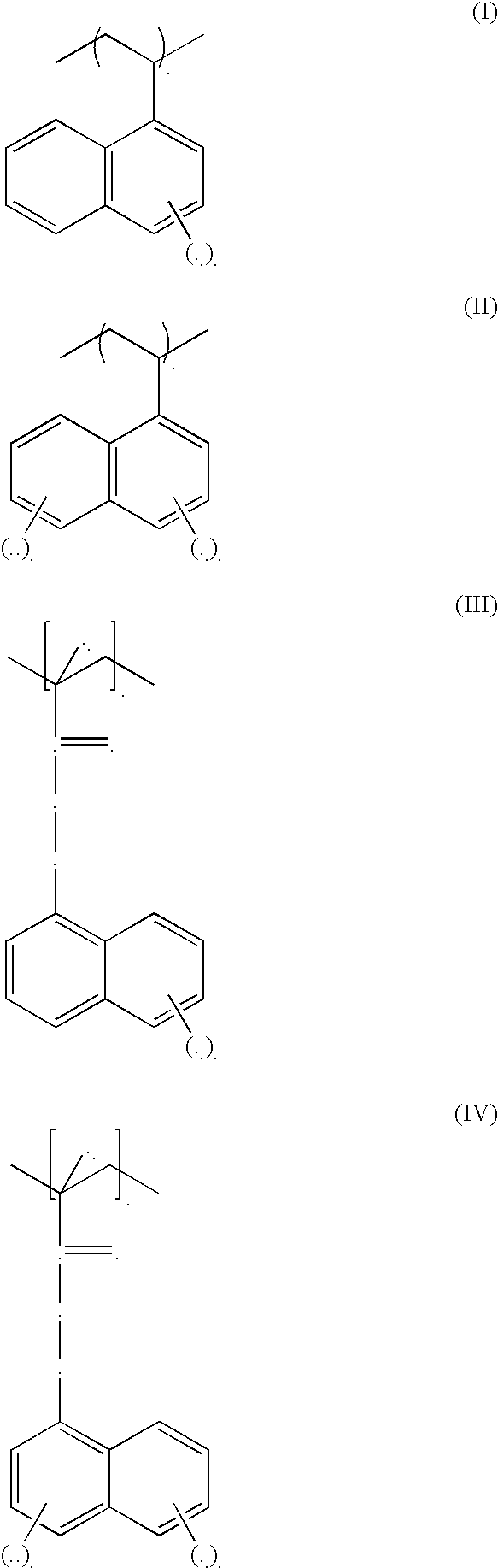

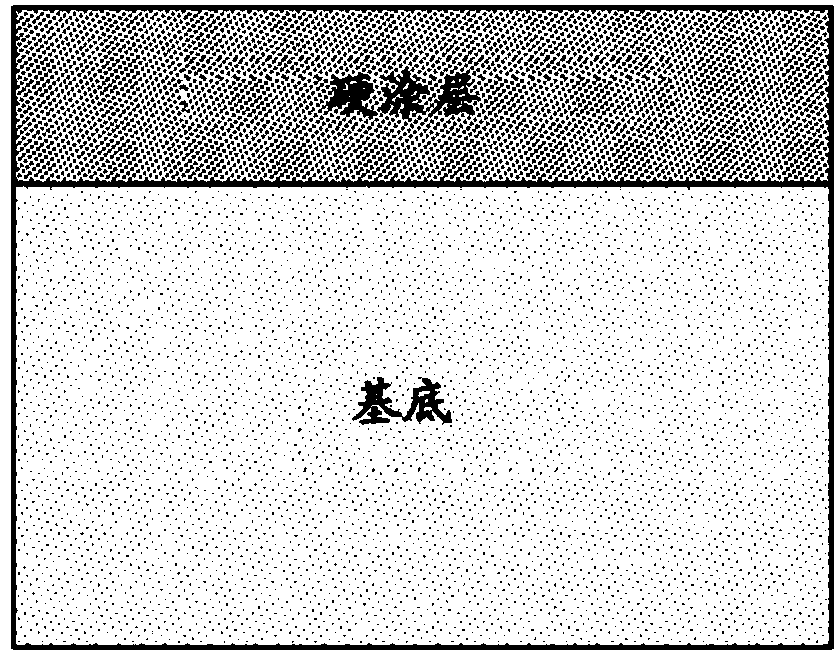

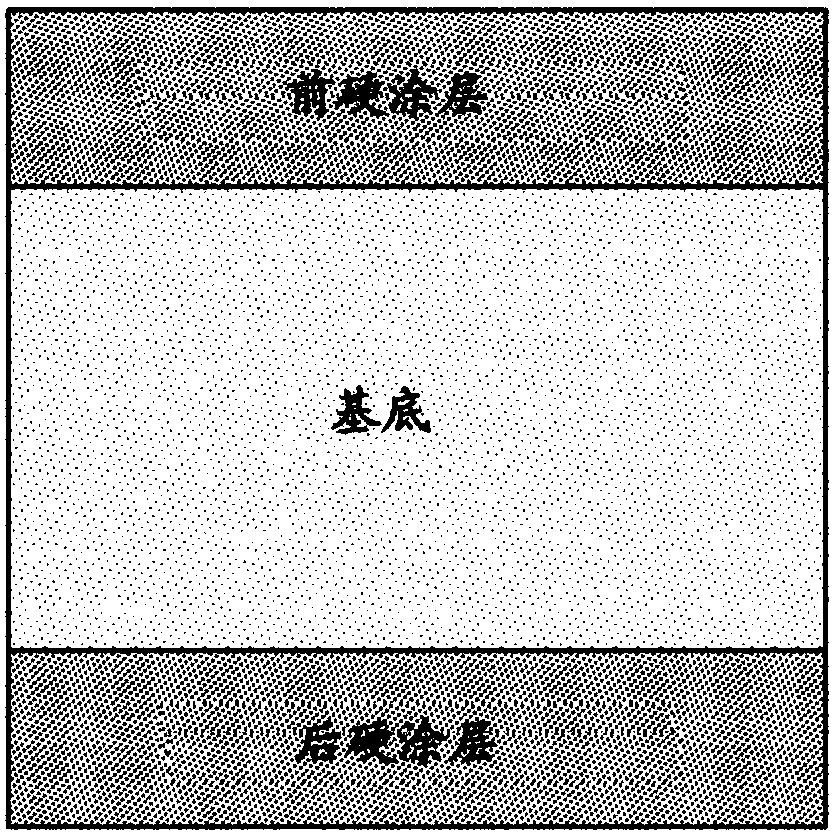

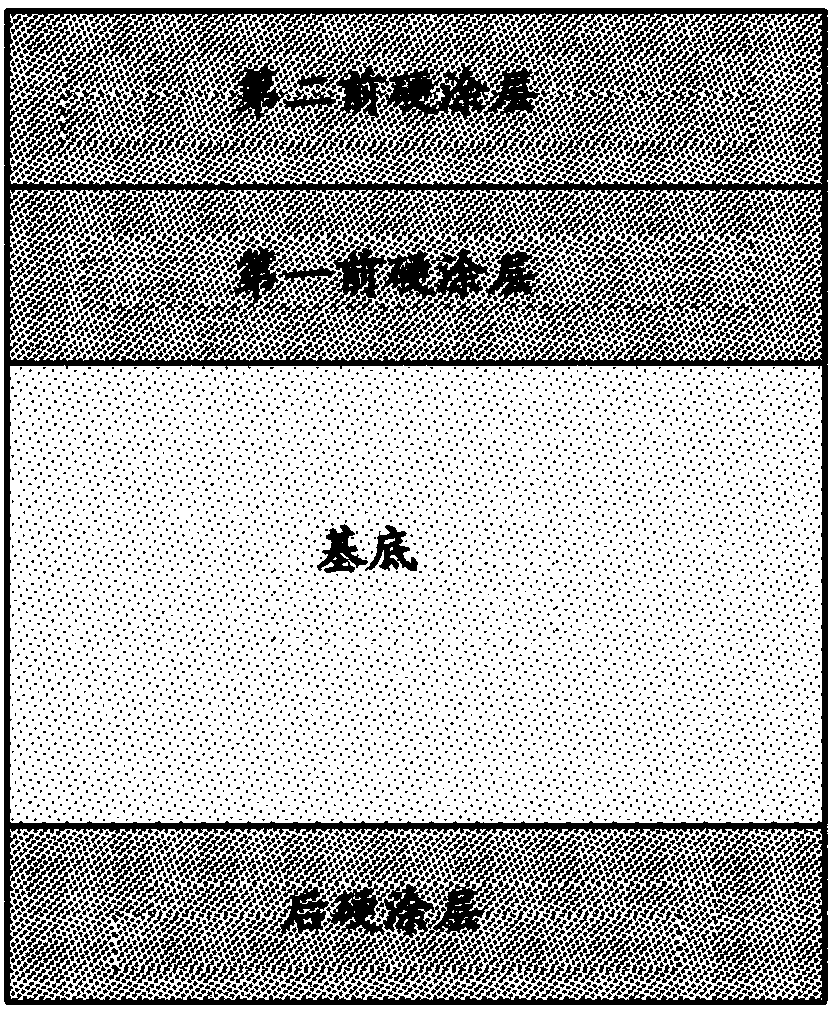

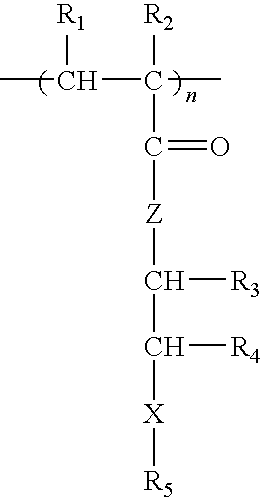

Low refractive index polymers as underlayers for silicon-containing photoresists

InactiveUS20060134546A1Improve corrosion resistanceGood optical performancePhotomechanical apparatusSemiconductor/solid-state device manufacturingRefractive indexAcrylate polymer

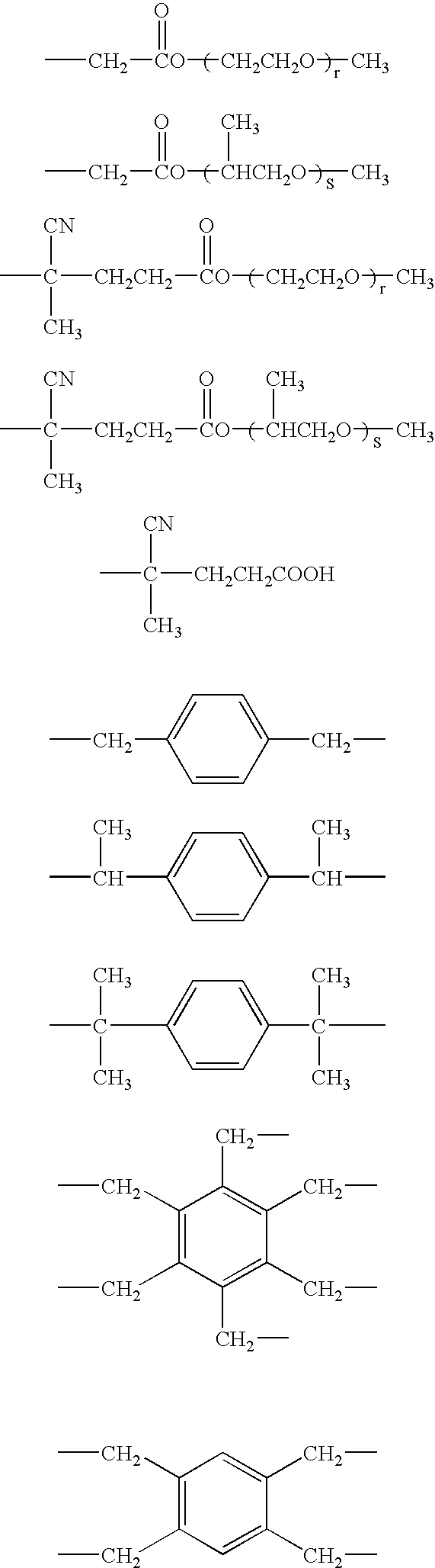

A new underlayer composition that exhibits high etch resistance and improved optical properties is disclosed. The underlayer composition comprises a vinyl or acrylate polymer, such as a methacrylate polymer, the polymer comprising at least one substituted or unsubstituted naphthalene or naphthol moiety, including mixtures thereof. Examples of the polymer of this invention include: where each R1 is independently selected from an organic moiety or a halogen; each A is independently a single bond or an organic moiety; R2 is hydrogen or a methyl group; and each X, Y and Z is an integer of 0 to 7, and Y+Z is 7 or less. The organic moiety mentioned above may be a substituted or unsubstituted hydrocarbon selected from the group consisting of a linear or branched alkyl, halogenated linear or branched alkyl, aryl, halogenated aryl, cyclic alkyl, and halogenated cyclic alkyl, and any combination thereof. The compositions are suitable for use as a planarizing underlayer in a multilayer lithographic process, including a trilayer lithographic process.

Owner:GLOBALFOUNDRIES INC

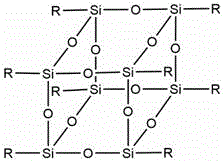

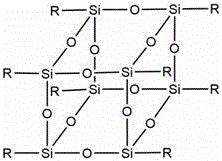

POSS and silicone oil modified fluorinated acrylate building waterproof paint

InactiveCN106752628AImprove permeabilityImprove mechanical propertiesCoatingsWeather resistanceSilsesquioxane

The invention belongs to the technical field of polymer fine chemicals, and discloses a POSS and silicone oil modified fluorinated acrylate building waterproof paint and a preparation method thereof. The preparation method comprises adopting POSS, silicone oil and fluorinated methacrylate to perform the copolymerization to obtain POSS-containing silicone oil modified fluorinated methacrylate polymer, wherein the selected alkenyl-containing POSS is polyhedral polysilsesquioxane containing alkenyl. The polymer disclosed by the invention has good weather resistance, has good adhesive force and permeation to concrete and other building materials, has a good waterproof effect, and is suitable for the waterproof work of various concrete constructions.

Owner:UNIT 61489 OF PLA

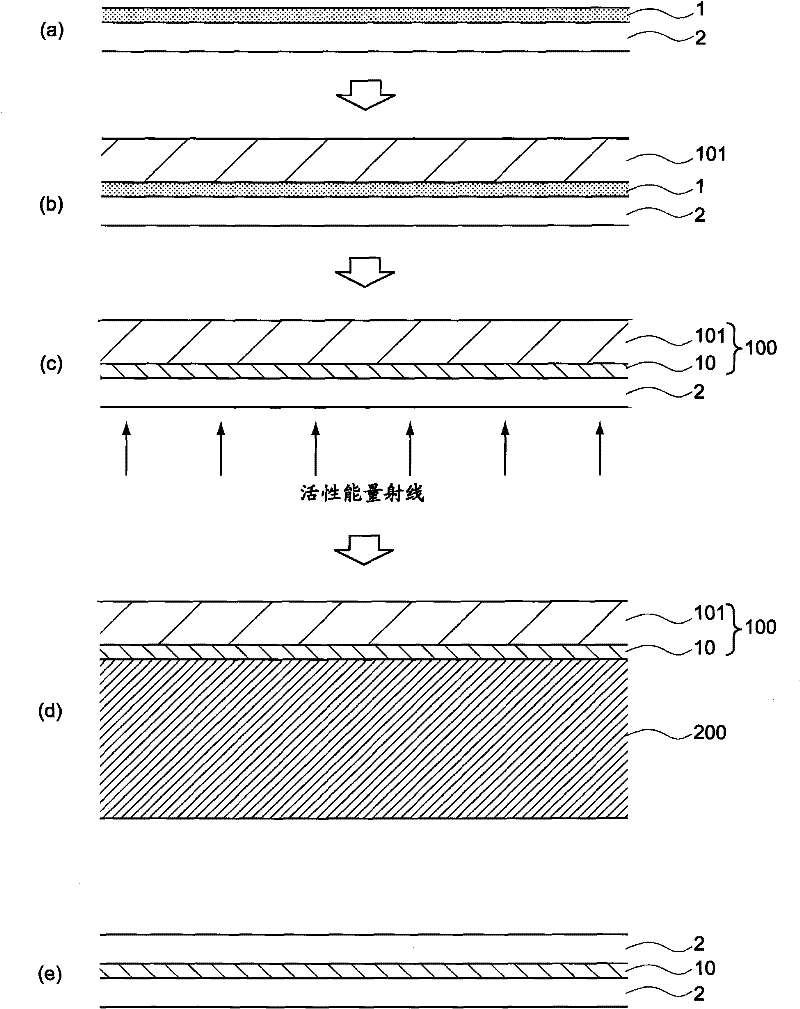

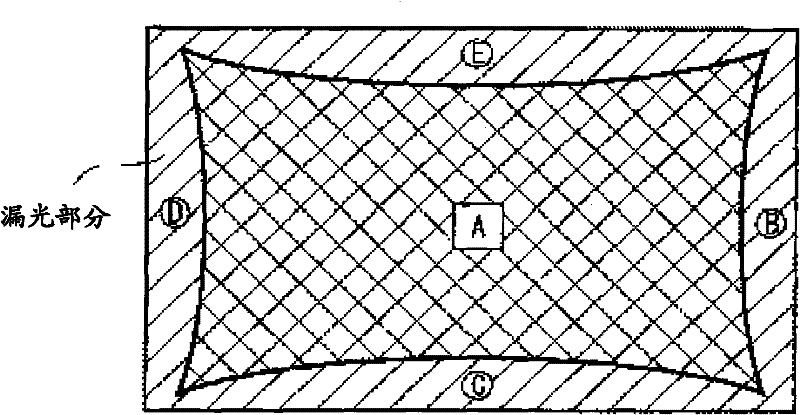

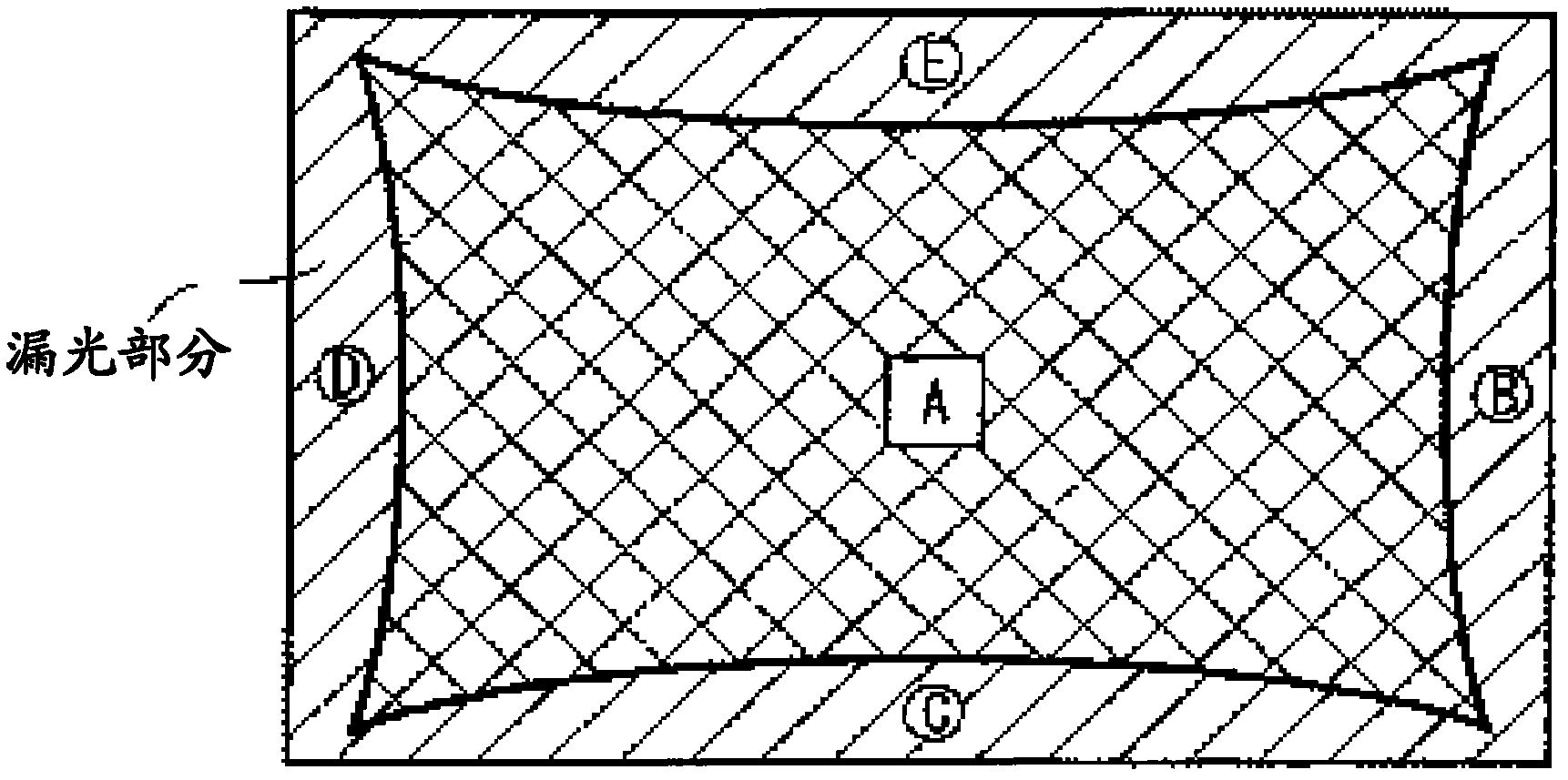

Optical adhesive composition, optical adhesive and optical film

ActiveCN102051131AHigh transparencyIncreased durabilityNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceSide chain

The invention relates to an optical adhesive composition, an optical adhesive and an optical film, which do not require an aging treatment, can effectively prevent the occurring of light leak even during the exposure to environment change, and have excellent transparency. The invention provides an optical adhesive composition comprising (A) 100 parts by weight of (methyl) acrylic acid ester polymer whose weight average molecular weight is 200 thousand to 2.5 million, (B) 1 to 50 parts by weight of (methyl) acrylic acid ester polymer whose side chain has the reactivity of an ethylene double bond and whose weight average molecular weight is 30 thousand to 1.5 million, (C) 0.1 to 50 parts by weight of multifunctional (methyl) acrylic acid ester compound, (D) 0.01 to 10 parts by weight of photopolymerization initiator.

Owner:LINTEC CORP

Hot sealing compound for aluminum foils applied to polypropylene and polystyrene

InactiveUS7498373B2Improve adhesionImprove heat resistanceLiquid surface applicatorsOther chemical processesPolystyreneThermal stability

The invention relates to a hot sealing system comprised of an olefin polymer or of an olefin polymer A, of a methacrylate polymer B, of a graft polymer A-X consisting of the above-mentioned constituents and of a solvent or solvent mixture. The hot sealing system is characterized by having a high thermal stability and short sealing times.

Owner:EVONIK OPERATIONS GMBH

Thermoplastic resin composition and elastomer composition

Provided are a thermoplastic resin composition which is excellent in oil resistance, heat resistance, weatherability, impact resistance, transparency, and moldability, and which can be produced economically, an elastomer composition with low hardness and high tensile strength which is excellent in oil resistance and compression set, and a molded object produced by molding the thermoplastic resin composition or elastomer composition. The composition is produced by compounding a thermoplastic resin or an elastomer with a block copolymer having at least one methacrylic ester polymer block and at least one acrylic ester polymer block. Also provided are a process for producing a methacrylic ester-acrylic ester-methacrylic ester block copolymer which requires hardly any purification, which is excellent in heat resistance and weatherability, and in which the molecular weight and the molecular-weight distribution are controlled, and a methacrylic ester-acrylic ester-methacrylic ester block copolymer produced by the process.

Owner:KANEKA CORP

Hard-coating film for display device, and display device comprising same

Provided is a hard-coating film for a display device comprising: a plastic substrate of which the modulus of elasticity is 2.5 GPa and the glass transition temperature is at least 150 degrees; and a hard-coating layer provided on at least one surface of the plastic substrate, and, in the present invention, the plastic substrate has a thickness of no more than 100 mum and comprises: an active energy ray curable resin composition containing a (meth)acrylate polymer (A) having a hydroxyl group and a (meth)acryloyl group and having a weight-average molecular weight (Mw) in a range of between 3,000to 100,000, and an isocyanate compound (B); and, optionally, nano-sized inorganic particles dispersed in the resin composition, while the hard-coating film has a pencil hardness of 4H as measured byASTM D3363 under a weight of 1 kg and has a flexibility of a radius of curvature of 10 mm. Also provided is a display device comprising the hard-coating film.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Thermoplastic polymer powder

InactiveUS20060036030A1Improve compatibilityImprove liquidityCoatingsRubber elasticityMethacrylate polymers

A thermoplastic polymer powder which (i) consists mainly of an acrylic block copolymer comprising one or more acrylic ester polymer blocks (A) and bonded thereto at least one polymer block selected among methacrylic ester polymer blocks (B) and acrylic ester polymer blocks (C) differing in structure from the blocks (A); (ii) has a complex dynamic viscosity η*(5) of 5.0×103 Pa.s or lower as measured under the conditions of a temperature of 250° C. and an oscillation frequency of 5 rad / sec; (iii) has a Newtonian viscosity index n represented by the equation n=log η*(5)-log η*(50) [wherein η*(5) and η*(50) indicate the complex dynamic viscosities (unit, Pa.s) as measured under the conditions of a temperature of 250° C. and oscillation frequencies of 5 and 50 rad / sec, respectively] of 0.50 or smaller; and (iv) has an average particle diameter of 1 mm or smaller. The thermoplastic polymer powder is suitable for use in molding techniques employing a powder, such as slush molding and in powder coating. A molding, skin material, and the like which are excellent in weatherability, flexibility, mechanical strength, low-temperature properties, adhesion to polar resins, rubber elasticity, safety, etc. can be smoothly produced from the powder.

Owner:KURARAY CO LTD

Implantable devices formed of non-fouling methacrylate or acrylate polymers

Implantable devices formed of or coated with a material that includes a polymer having a non-fouling acrylate or methacrylate polymer are provided. The implantable device can be used for treating or preventing a disorder such as atherosclerosis, thrombosis, restenosis, hemorrhage, vascular dissection or perforation, vascular aneurysm, vulnerable plaque, chronic total occlusion, patent foramen ovale, claudication, anastomotic proliferation for vein and artificial grafts, bile duct obstruction, ureter obstruction, tumor obstruction, or combinations thereof.

Owner:ABBOTT CARDIOVASCULAR

Resin Composition for Optical Materials, Resin Film for Optical Material, and Optical Waveguide

InactiveUS20090196559A1Improve heat resistanceHigh transparencyOptical fibre with multilayer core/claddingSynthetic resin layered productsImidePolymer science

A resin composition for an optical material, which is excellent in heat resistance and transparency and is soluble in an aqueous alkali solution, a resin film for an optical material made of the resin composition, and an optical waveguide using the same are provided. The resin composition for an optical material includes: (A) an alkali-soluble (meth)acrylate polymer containing a maleimide skeleton in a main chain; (B) a polymerizable compound; and (C) a polymerization initiator. The resin film for an optical material is made of the resin composition for an optical material. The optical waveguide has a core part and / or a clad layer formed using the resin composition for an optical material or the resin film for an optical material.

Owner:HITACHI CHEM CO LTD

Method for preparing polymer brush films with multiple stimulation responses

The invention relates to a method for preparing polymer brush films with multiple stimulation responses by homogeneous phase atom transfer radical polymerization (ATRP). According to the method, the polymer brush films are N,N-diamido ethyl methacrylate polymers and have multiple stimulation responses on temperature, pH value, salt and a solvent. The homogeneous phase ATRP preparation method comprises the following steps of: synthesizing an initiator omega-(2-bromoisobutyramide)alkyl silane coupling agent; assembling the initiator on the clean surface of a substrate; and performing surface-initiated atom transfer radical polymerization in a homogeneous system. According to the method, the grafting density and film thickness of a polymer brush can be regulated and controlled by regulating the assembly density and the content of bulk phase monomers of the initiator on the surface of the substrate, so that the polymer brush films which have different structures and multiple stimulation responses can be obtained. The method is mild in reaction condition, easy to control, adjustable in grafting density, high in polymerization efficiency and wide in applicability.

Owner:EAST CHINA UNIV OF SCI & TECH

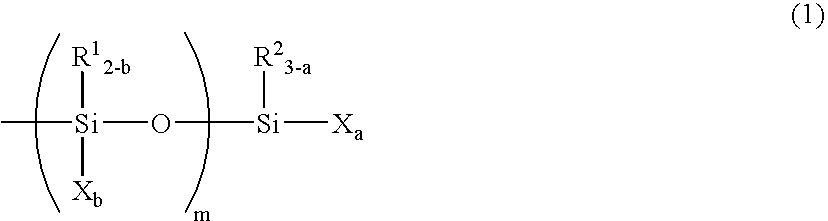

Room temperature-curable composition and cured product thereof

InactiveUS20110098410A1High hardnessGood adhesivenessEster polymer adhesivesPolyether coatingsPolymer chemistryAcrylate polymer

The present invention provides a novel acrylic / modified silicone room temperature-curable resin composition that serves as a material for sealants having high modulus and high strength after curing, and a cured product thereof. The room temperature-curable composition includes: a (meth)acrylate ester polymer (A) having a specific silicon-containing functional group and having an alkyl (meth)acrylate ester monomer unit in its molecular chain; and a polyoxyalkylene polymer (B) having a specific silicon functional group.

Owner:KANEKA CORP

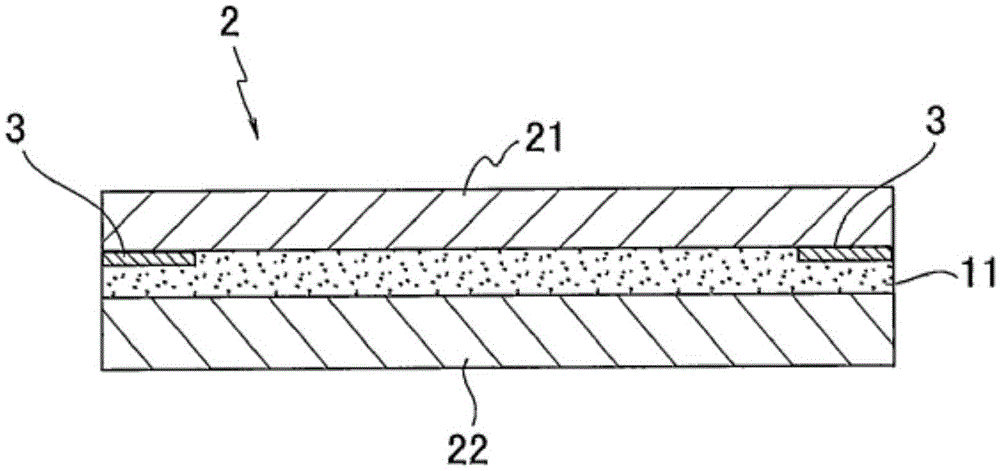

Adhesive sheet and display

PendingCN106010326AGood anti-foamNon-macromolecular adhesive additivesEster polymer adhesivesPolymer scienceAdhesive

The invention provides an adhesive sheet and a display which are not liable to be subjected to adverse influence of UV light and have excellent anti-foaming performance. The adhesive sheet (1) has an adhesive layer (11) which bonds a display forming component (21) to another display forming component (22), which have section difference at least on to-be-laminated sides. The adhesive layer (11) is composed of an adhesive that is formed by thremal-crosslinking an adhesive composition including (methyl)acrylate polymer (a), a thermal-crosslinker (b) and a ultraviolet absrober (c). The adhesive layer (11) is lower than 2% in haze and is lower than 1% in light transmittance under wavelength of 360 nm.

Owner:LINTEC CORP

Thermoplastic elastomer composition and composite molded article manufactured from the same

ActiveUS20090105396A1Increase elasticityIncrease flexibilityFilm/foil adhesivesSynthetic resin layered productsPolymer scienceAdhesive

[Problems] To provide a thermoplastic elastomer composition which can tightly adhere to a resin having a polar group without the need of using any adhesive and is excellent in water resistance, rubber properties and moldability, or to provide a composite molded article manufactured from the composition.[Means for Solving Problems] A thermoplastic elastomer composition comprising: (a) 100 parts by mass of a styrene block copolymer constituted by a [vinyl aromatic polymer block (A1)]-[hydrogenated conjugated diene polymer block (A2)]-[vinyl aromatic polymer block (A1)]; (b) 2 to 1000 parts by mass of an acrylic block copolymer having a methacrylic acid ester polymer block (B3) and an acrylic acid ester polymer block (B1); and (c) 2 to 200 parts by mass of a block copolymer containing a hydrophilic group; and a composite resin molded article manufactured by compositing the thermoplastic elastomer composition with a thermoplastic resin.

Owner:KURARAY CO LTD

Manufacturing method of oil absorbing fiber felt

ActiveCN103437067AImprove performanceSimple processNon-woven fabricsCross-linkManufacturing technology

The invention discloses a manufacturing method of oil absorbing fiber felt, belonging to the technical field of manufacturing of fiber felts. By simultaneously adopting a semi-interpenetrating polymer network technique and an electrostatic spinning technique, the manufacturing method comprises the following steps: firstly, synthesizing monomers, which are unlikely to form cross-linked structures, to linear non-crosslinking methacrylate polymers by suspension polymerization; dissolving the polymers in a solvent suitable for electrostatic spinning to prepare liquor, and adding monomers, which are likely to form cross-linked structures and contain an initiator, into the liquor; preparing polymer liquor containing the semi-interpenetrating network structure by liquor polymerization; after insulating and defoaming, spraying the liquor to a receiving roller by an electrostatic spinning method; and along with volatilization of the solvent, after fibers are cured, fixing the semi-interpenetrating network structure inside the fibers so as to form the fiber felt with an intrinsic oil absorbing function. Compared with existing polypropylene fiber felt, the fiber felt disclosed by the invention has the advantages of higher adsorption rate, stronger oil keeping capacity and the like, and satisfies the industrial practical demands.

Owner:TIANJIN POLYTECHNIC UNIV

Adhesive composition, adhesive and optical film

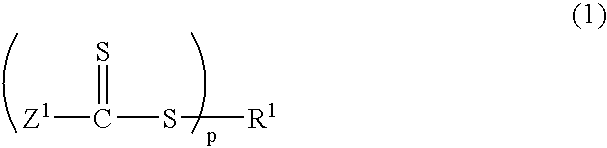

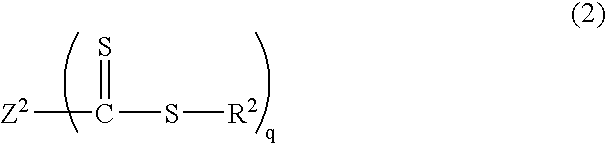

ActiveCN102040929AEfficient ene-thiol reactionIncreased durabilityFilm/foil adhesivesPolarising elementsPolymer scienceChemical compound

The present invention provides an adhesive composition, an adhesive and an optical film. An aging treatment period when the adhesive composition is prepared to the adhesive is not required, and performance change of the adhesive is prevented when the adhesive is exposed in a severe environment for a long time period. Furthermore the expansion of the substrate suitable for the adhesive can be restricted thereby preventing performance change. The adhesive composition provided by the invention can settle the problems and is characterized by comprising the components of (A), (B1) and (C); or the components of (A), (B2) and (C); or the components of (A), (B1), (B2) and (C), wherein each component is described as follows: (A) 100 by weight parts of (methyl)acrylate polymer with a weight average molecular ratio of 200 thousand to 2.5 million; (B1) 1-100 by weight parts of reactive (methyl)acrylate polymer which has a weight average molecular ratio of 30 thousand to 1.5 million and has ethylene double bonds at a side chain; (B2) 1-50 by weight parts of polyenic compound which has more than two ethylene double bonds in one module; and (C) 0.01-50 by weight parts of polythiol compound which has more than two sulfhydryl groups in one module.

Owner:LINTEC CORP

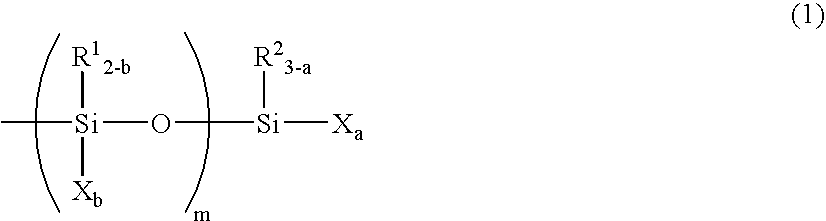

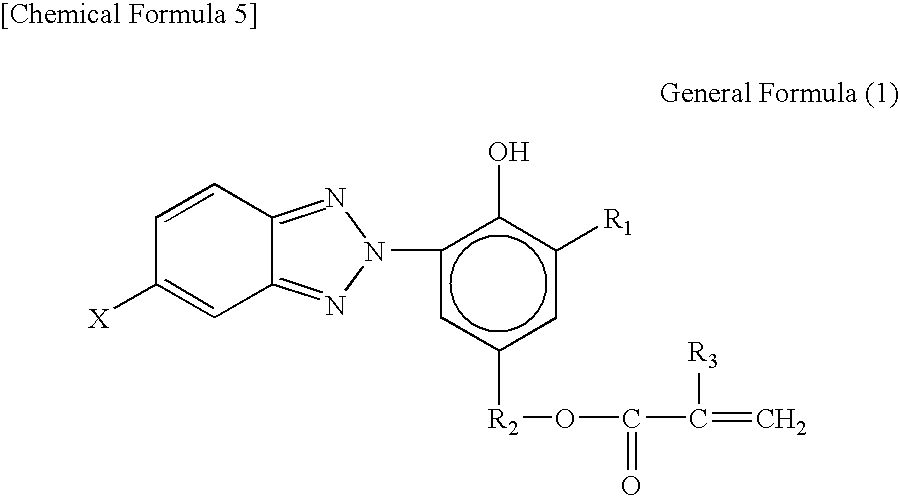

Methacrylic Resin Composition, Methacrylic Resin Film, and Vinyl Chloride Molded Article with the Film Layered

ActiveUS20070212561A1High transparencyGood weather resistanceSynthetic resin layered productsConstructions elementsPlasticizerShock resistance

A resin composition suitable for forming a film excellent in transparency, weatherability, hardness, shock resistance, bending-fracturing resistance, and moldability; and a film excellent in weatherability even when laminated on a molded body comprising a PVC resin composition containing a plasticizer is provided. The film having the above characteristics can be obtained by making a methacrylic resin composition into a film, the methacrylic resin composition comprising a methacrylic resin composition (C) obtained by polymerizing a methacrylate polymer (A) obtained by polymerizing a monomer mixture mainly composed of alkyl methacrylate in the presence of acrylic crosslinked elastic particles (B) obtained by copolymerizing a monomer mixture mainly composed of alkyl acrylate and a polyfunctional monomer with two or more non-conjugated double bonds per a molecule; and being copolymerized with 0.01 to 50 parts by weight of an ultraviolet absorber represented by the general formula (1).

Owner:KANEKA CORP

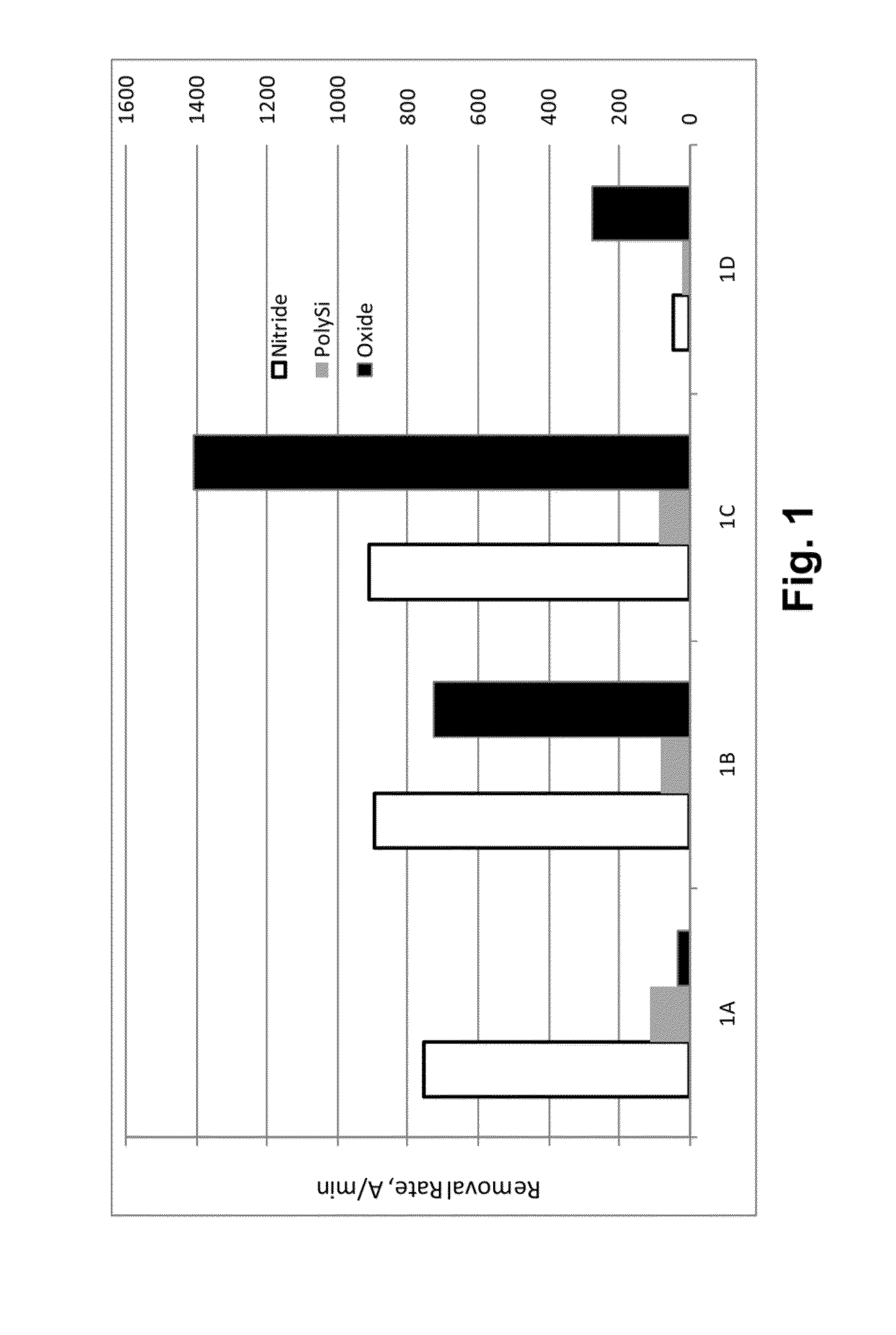

Compositions and methods for selective polishing of silicon nitride materials

ActiveUS20140017892A1High silicon nitride removal rateLow polysilicon removal rateOther chemical processesSemiconductor/solid-state device manufacturingParticulatesCerium(IV) oxide

The present invention provides an acidic aqueous polishing composition suitable for polishing a silicon nitride-containing substrate in a chemical-mechanical polishing (CMP) process. The composition, at point of use, preferably comprises about 0.01 to about 2 percent by weight of at least one particulate ceria abrasive, about 10 to about 1000 ppm of at least one non-polymeric unsaturated nitrogen heterocycle compound, 0 to about 1000 ppm of at least one cationic polymer, optionally, 0 to about 2000 ppm of at least one polyoxyalkylene polymer, and an aqueous carrier therefor. The cationic polymer preferably is selected from a poly(vinylpyridine) polymer, a quaternary ammonium-substituted acrylate polymer, a quaternary ammonium-substituted methacrylate polymer, or a combination thereof. Methods of polishing substrates and of selectively removing silicon nitride from a substrate in preference to removal of polysilicon using the compositions are also provided.

Owner:CMC MATERIALS INC

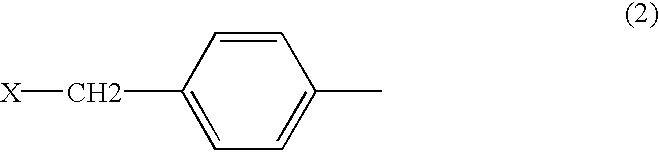

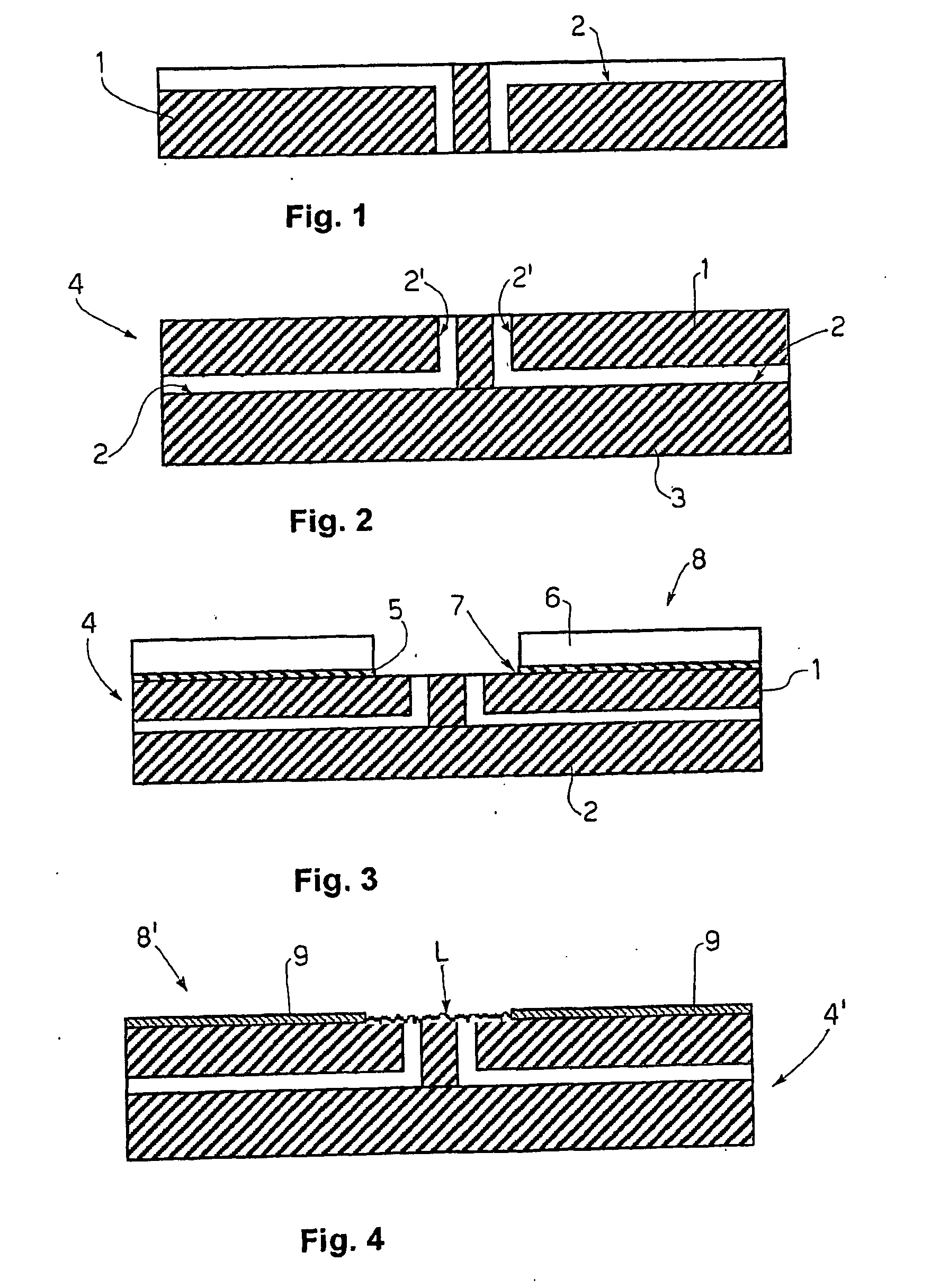

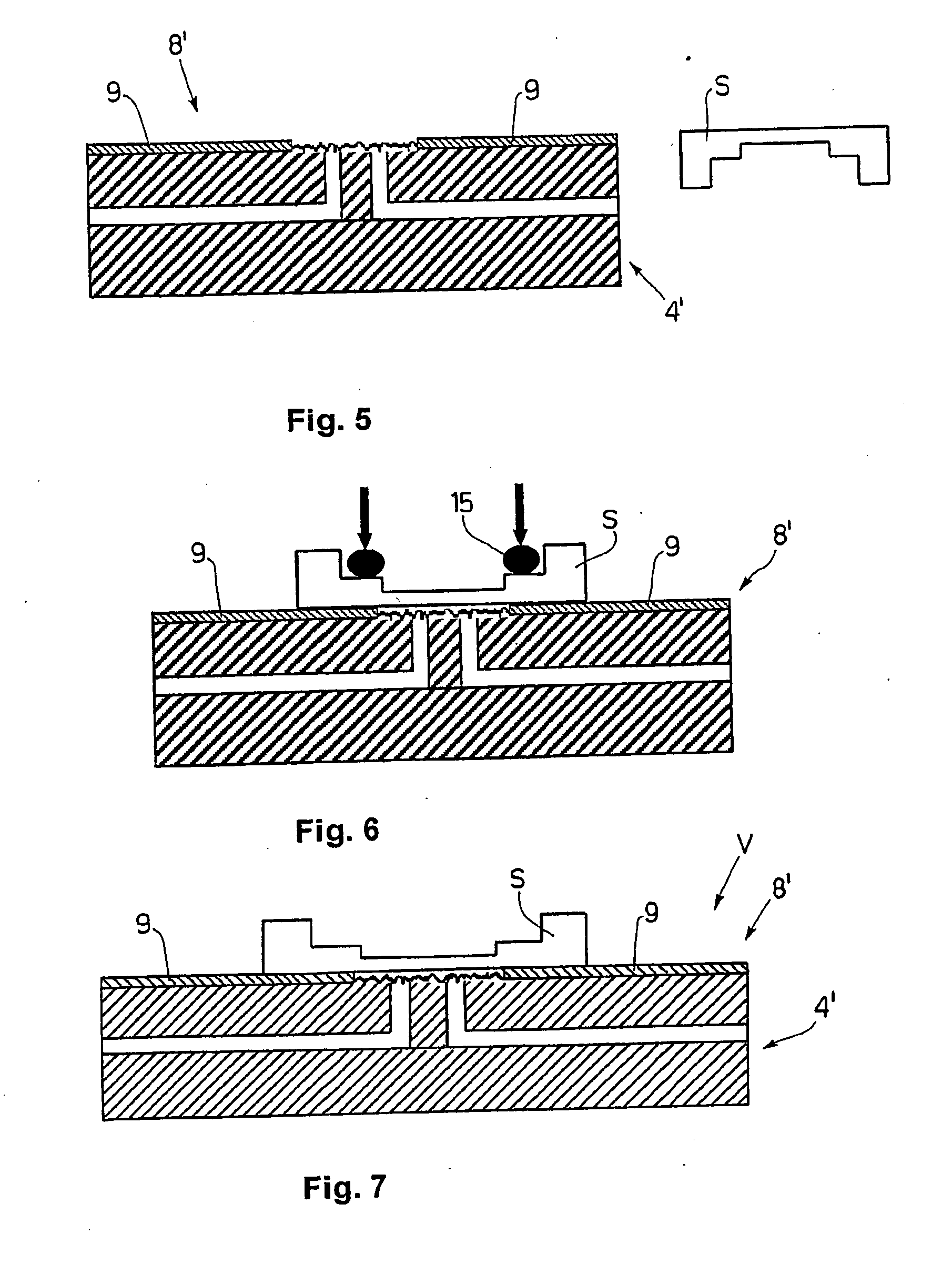

Method for Bonding a Layer of Silicone to a Substrate of Methacrylate Polymer

ActiveUS20110193006A1Easy and inexpensive to produceOvercomes drawbackLamination ancillary operationsDecorative surface effectsMethacrylate polymersMethacrylic Acid Polymers

Method of bonding a layer (S) of silicone to a substrate (4′) of methacrylic polymer; the method involves positioning between the methacrylate polymer and the silicone a layer (9) of an organosilane having the formula R1Si(R2)3, in which R2 is OH and R1 is a methacrylic residue.

Owner:MENARINI SILICON BIOSYSTEMS SPA

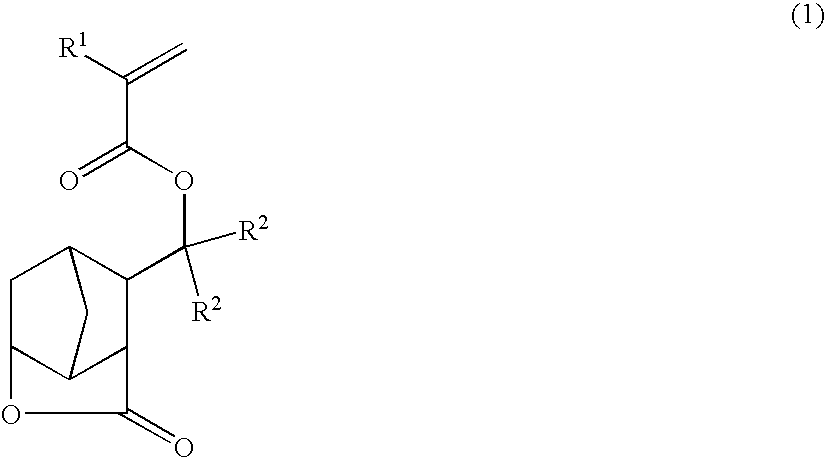

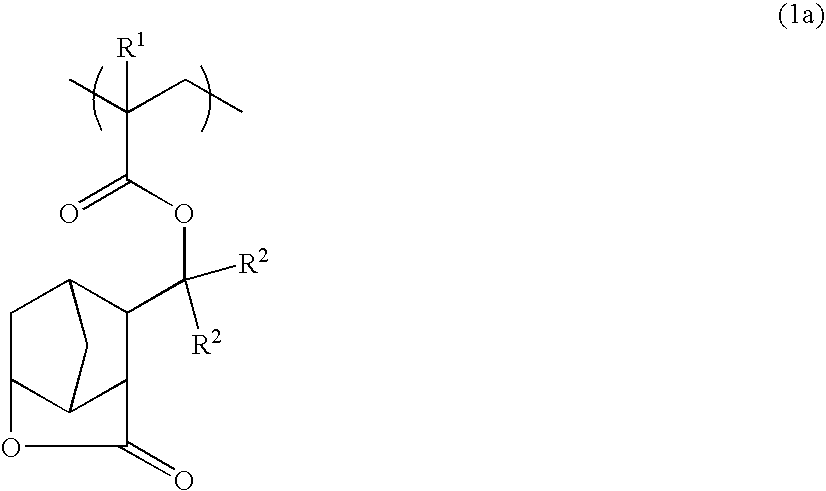

Novel tertiary (meth)acrylates having lactone structure, polymers, resist compositions and patterning process

ActiveUS20050250924A1Improve adhesionHigh transparencyOrganic chemistryPhotosensitive materialsResistMeth-

Novel tertiary (meth)acrylate compounds having a lactone structure are polymerizable into polymers having improved transparency, especially at the exposure wavelength of an excimer laser and dry etching resistance. Resist compositions comprising the polymers are sensitive to high-energy radiation, have a high resolution, and lend themselves to micropatterning with electron beams or deep-UV rays.

Owner:SHIN ETSU CHEM IND CO LTD

Dental polymerizable composition and kit therefor

InactiveUS20110028589A1Easy to operateFew air bubblesImpression capsSurgical adhesivesMeth-Denture base

The present invention provides a dental polymerizable composition which has excellent handling property by the brush-dip technique and the bulk-mix technique, particularly excellent handling property by the brush-dip technique, contains few air bubbles, is excellent in color tone, polishability, mechanical properties and the discoloration resistance of a cured product at the time of curing and is used for many purposes such as the repair of a denture base or artificial tooth, a tooth crown prosthetic restoration and a temporary prosthetic restoration which is used until a bridge is completed when it is a two-composition type self-curing resin.The dental polymerizable composition comprises three different types of (meth)acrylate polymer particles, each having specific particle size characteristics and specific molecular weight characteristics.

Owner:SUN MEDICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com