Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

132 results about "Methacrylic Acid Polymers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gastric retentive tablet compositions

The present invention relates to a gastric retentive tablet composition comprising: (1) coated particles essentially consisting of a drug and an amino methacrylate copolymer, (2) a methacrylic acid copolymer and (3) an excipient, wherein items 1, 2, and 3 are blended together, and then compressed into a gastric retentive tablet. Thus, the coated particles (item 1), a methacrylic acid copolymer and the excipient are evenly distributed in the tablet. The excipient is selected from a group consisting of a retarding agent, a binder, a filler, a chelating agent, a diluent, a disintegrant, a lubricant, a colorant, a solubilizing agent, or a mixture thereof. The coated particles (item 1) do not contain methacrylic acid polymer.

Owner:WONG DAVID

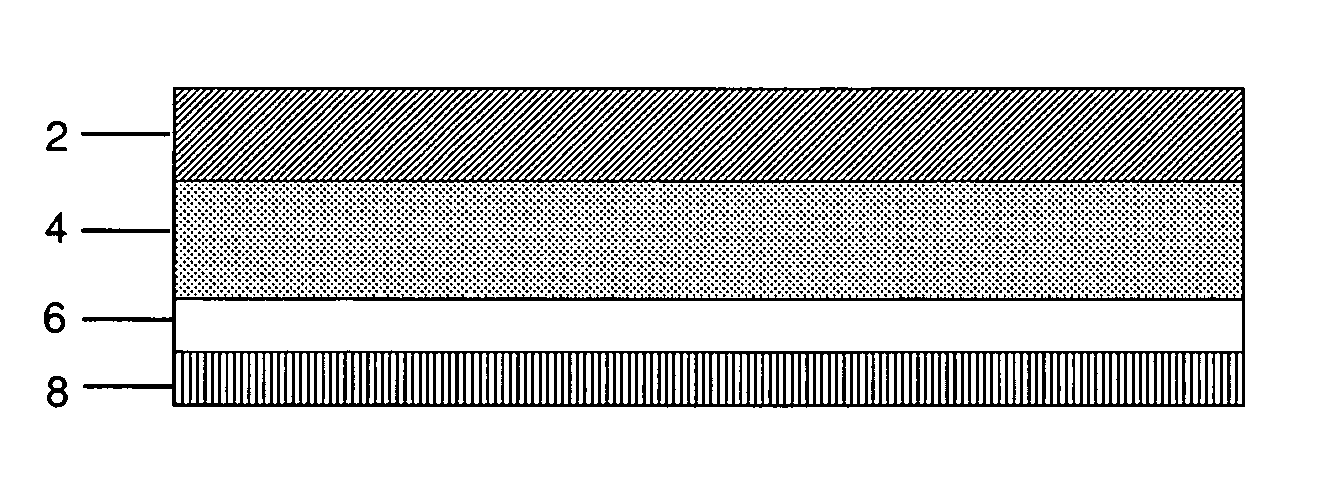

Presssure-sensitive adhesive sheet

ActiveUS20170081557A1Adhesive processesSynthetic resin layered productsAcrylic polymerPressure sensitive

A pressure-sensitive adhesive sheet has a substrate and a pressure-sensitive adhesive layer laminated on at least one side of the substrate. The pressure-sensitive adhesive layer contains a (meth)acrylic polymer having a weight average molecular weight of 10000 or more but less than 50000. Pressure-sensitive adhesive force, occurring after 30 minutes since the pressure-sensitive adhesive layer was attached to an ABS plate, is 1.0 [N / 20 mm] or less, pressure-sensitive adhesive force, occurring after 24 hours since the pressure-sensitive adhesive layer was attached to an ABS plate, is 2.5 [N / 20 mm] or less, and pressure-sensitive adhesive force, occurring after 30 minutes at 23° C. since the pressure-sensitive adhesive layer was attached to an ABS plate and then heated at 80° C. for 5 minutes, is 6.5 [N / 20 mm] or more.

Owner:NITTO DENKO CORP

Pressure-sensitive adhesive composition, pressure-sensitive adhesive layer, process for producing the pressure-sensitive adhesive layer, and optical member with pressure-sensitive adhesive

InactiveUS20090042004A1Excellent pressure-sensitive adhesive propertyIncreased durabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesDisplay deviceLayer thickness

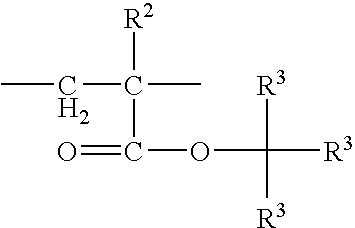

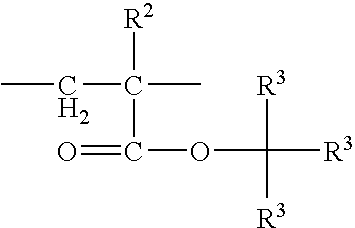

This invention provides a pressure-sensitive adhesive composition that exhibits excellent pressure-sensitive adhesive properties after crosslinking treatment, does not cause lifting or lifting upon heat treatment or treatment under high-humidity conditions particularly even in the case of a pressure-sensitive adhesive layer having a reduced layer thickness, and has excellent durability. A pressure-sensitive adhesive layer formed using the pressure-sensitive adhesive composition, and a process for producing the same are also provided. Further, an optical member with pressure-sensitive adhesive comprising the pressure-sensitive adhesive layer and an image display using the same are provided. The pressure-sensitive adhesive composition is characterized by comprising 100 parts by weight of an (meth)acrylic polymer and 0.02 to 2 parts by weight of a peroxide, and 0.02 to 2 parts by weight of an isocyanate crosslinking agent, the (meth)acrylic polymer comprising as monomer units 50 to 98% by weight of an (meth)acrylic monomer represented by general formula CH2═C(R1)COOR2, wherein R1 represents hydrogen or a methyl group and R2 represents an alkyl group having 2 to 14 carbon atoms, and 0.1 to 35% by weight of a nitrogen-containing monomer.

Owner:NITTO DENKO CORP

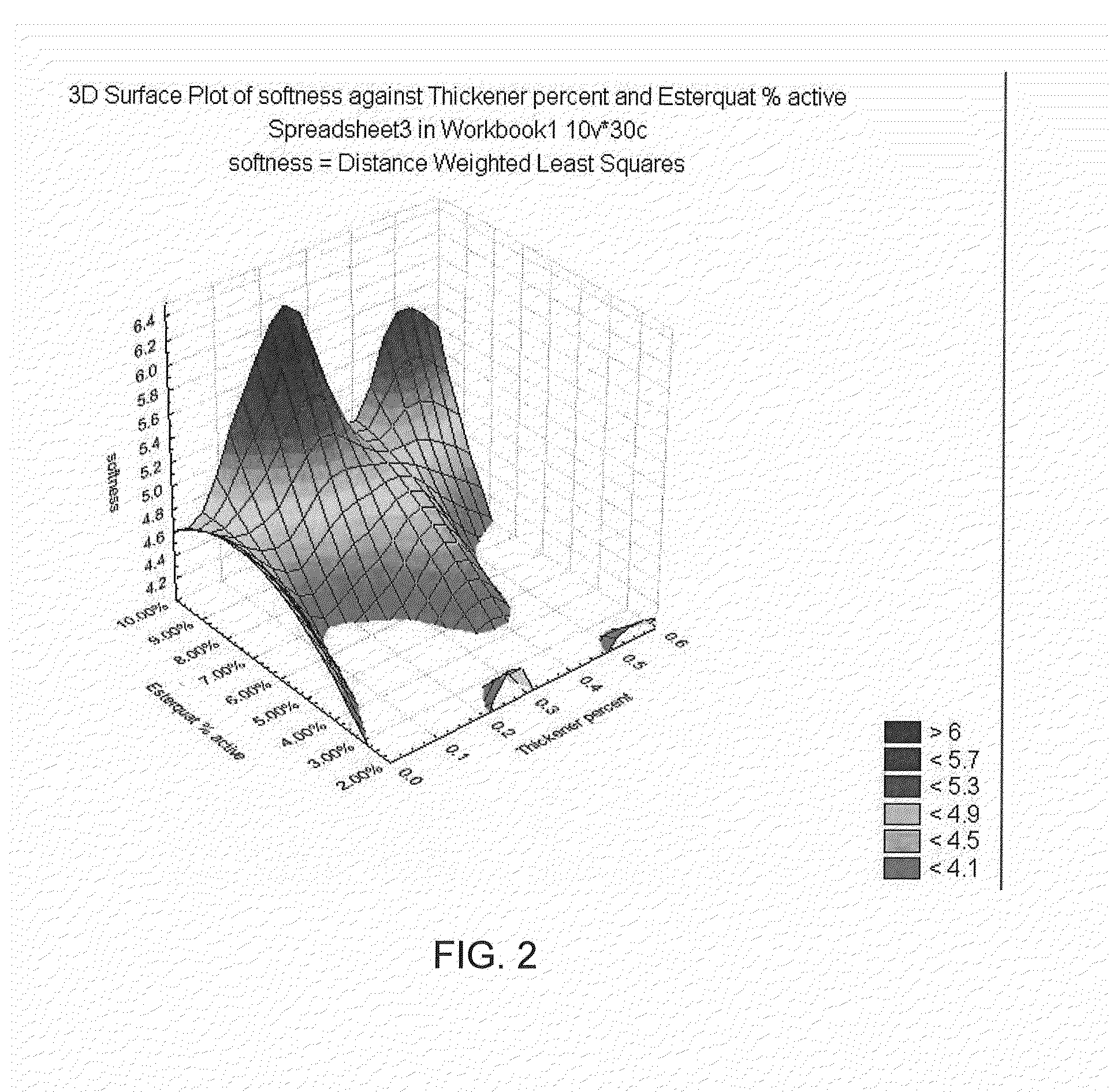

Method of increasing the performance of cationic fabric softeners

ActiveUS20140315779A1Low costLess expensiveCationic surface-active compoundsFibre treatmentChlorideSURFACTANT BLEND

The present invention is method of boosting the performance of a cost-reduced liquid fabric softener comprising a quaternary surfactant fabric softener by adding a quaternary (meth)acrylic polymer that functions dually as a fabric softening active and a rheology modifier. In particular, poly[{2-(methacryloyloxy)ethyl}trimethylammonium chloride], poly[{2-(acryloyloxy)ethyl}trimethylammonium chloride], poly[{3-(methacryloyloxy)propyl}trimethylammonium chloride], and poly[{3-(acryloyloxy)propyl}trimethylammonium chloride] provide synergistic fabric softening with quaternary surfactants to provide superior fabric softening scores from cost-optimized compositions.

Owner:HENKEL KGAA

Aderent, flexible hydrogel and medicated coatings

InactiveCN1261288AImprove toleranceGood flexibilitySurgeryPharmaceutical containersEpoxyActive agent

The adherent coating of the invention comprises a stabilizing polymer together with an active agent (a hydrophilic polymer and / or a bioactive agent) in a layer bonded to the surface of a medical device. This invention encompasses the coating liquids used for coating medical devices, methods of coating the devices, and the coated devices. The stabilizing polymer is selected to entrap the active agent in a coating that has a high degree of flexibility and has improved bonding to a wide variety of substrates. Preferred stabilizing polymers are cross-linkable acrylic and methacrylic polymers, ethylene acrylic acid copolymers, styrene acrylic copolymers, vinyl acetate polymers and copolymers, vinyl acetal polymers and copolymers, epoxy, melamine, other amino resins, phenolic polymers, copolymers thereof, and combinations.

Owner:STS BIOPOLYMERS

Pressure-sensitive adhesive optical film, production method thereof, and image display

InactiveUS20090116111A1Lower dissociation energyPromote decompositionSolid-state devicesSemiconductor/solid-state device manufacturingMeth-Acrylic polymer

A pressure-sensitive adhesive optical film of the present invention comprises an optical film; and a pressure-sensitive adhesive layer laminated on at least one side of the optical film, wherein the pressure-sensitive adhesive layer is formed from an acrylic pressure-sensitive adhesive comprising a (meth)acrylic polymer comprising 30 to 99.99% by weight of an alkyl (meth)acrylate monomer unit and 0.01 to 15% by weight of a functional group-containing monomer unit, and the (meth)acrylic polymer in the acrylic pressure-sensitive adhesive is crosslinked by electron beam irradiation. The pressure-sensitive adhesive optical film has a high level of reworkability, durability and workability.

Owner:NITTO DENKO CORP

Curable Composition

InactiveUS20090118401A1Good weather resistanceExcellent in anti-staining propertyCoatingsAdhesivesMeth-Ultraviolet

Firstly, disclosed is a curable composition which includes an organic polymer containing a crosslinkable silyl group, an ultraviolet ray absorbing agent having a triazine skeleton and a hindered amine based light stabilizer, and thereby, exhibits improved weather resistance both in a thin layer portion and in a thick layer portion. Secondly, disclosed is a curable composition which includes an organic polymer containing a crosslinkable silyl group, a (meth)acrylic polymer containing an epoxy group, a divalent tin organic carboxylate and an organic amine compound, and thereby, exhibits excellent weather resistance, anti-staining property, restoring property and durability. Thirdly, disclosed are an excellent curable composition which includes a reactive organic polymer containing at least one crosslinkable silyl group in one molecule thereof, a reactive organic polymer containing less than one crosslinkable silyl group in one molecule thereof, and thermally expandable hollow spheres as essential components, and thereby, exhibits economical productivity, good physical properties, safety and fire resistance; and a sealing material produced from the curable composition. Further, disclosed is a method for forming a fire-resistant structure with ease and at a low cost.

Owner:CEMEDAINE CO LTD

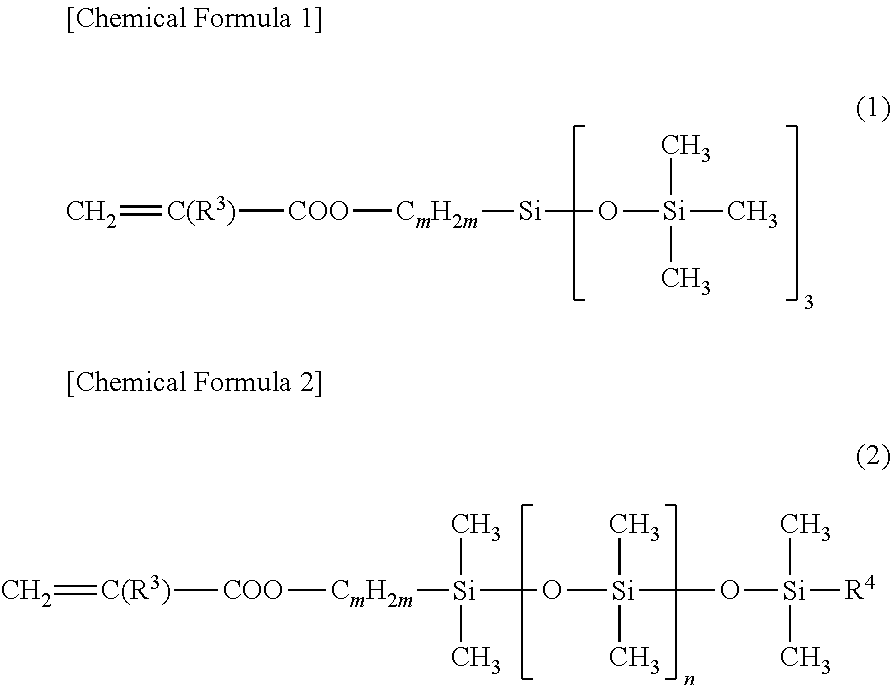

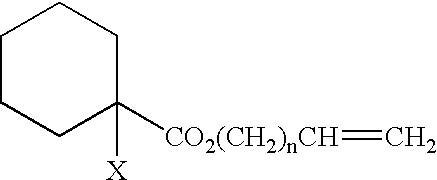

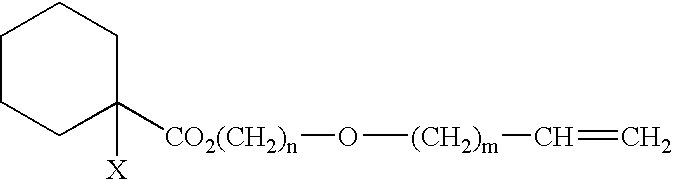

Process for producing (meth)acrylic polymer terminated by crosslinkable silyl group

A method for producing a (meth)acrylic polymer having crosslinkable silyl groups at the termini, comprising a step of adding a hydrosilane compound having a crosslinkable silyl group to an alkenyl-terminated (meth)acrylic polymer (A), which is prepared by atom transfer radical polymerization, in the presence of a platinum hydrosilylation catalyst. The amount of the platinum hydrosilylation catalyst is 0.1 to 10 mg on a platinum metal basis per kilogram of the alkenyl-terminated (meth)acrylic polymer (A). An object of the invention is to provide a method for producing a (meth)acrylic polymer having terminal crosslinkable silyl.

Owner:KANEKA CORP

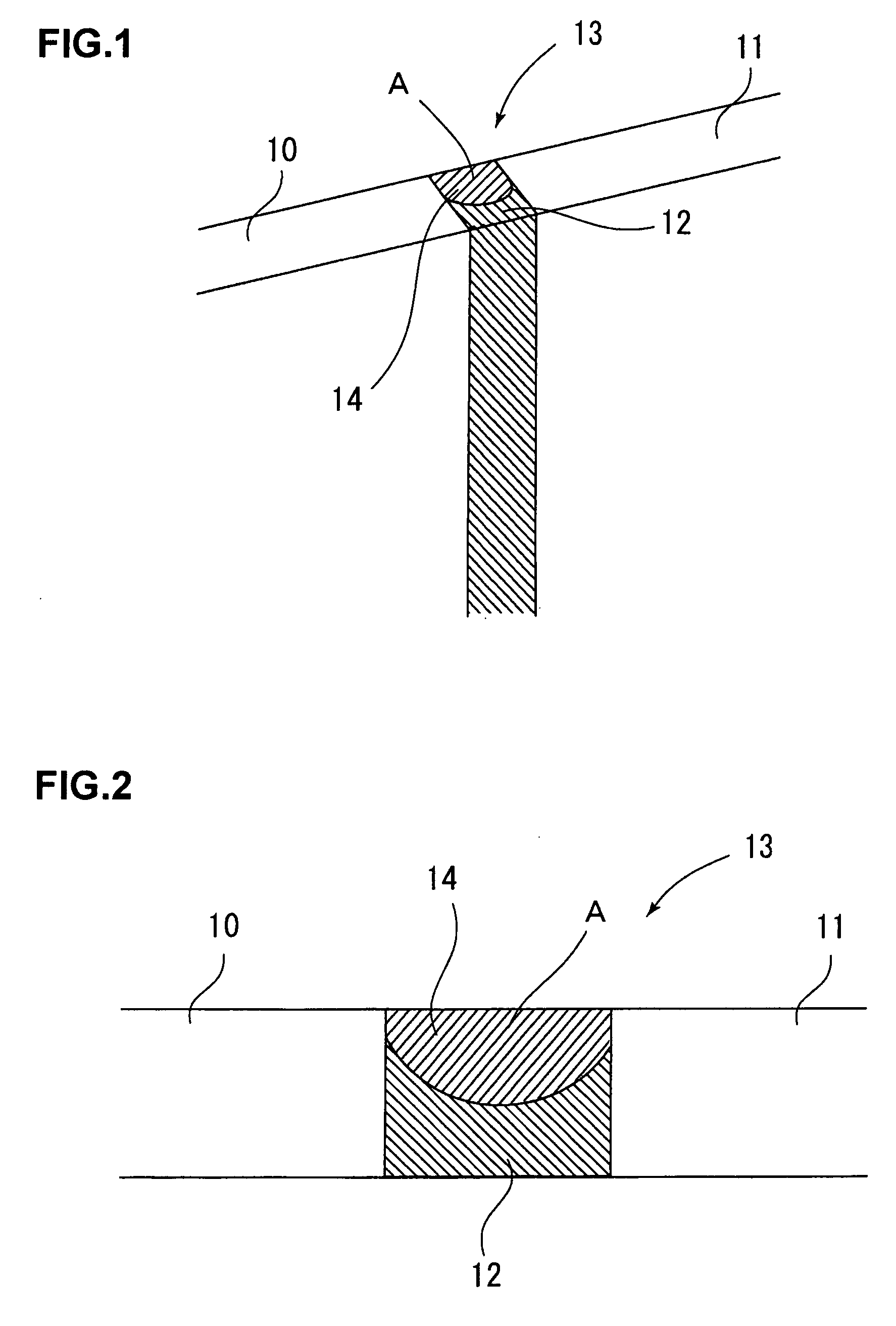

Waterproofing membrane

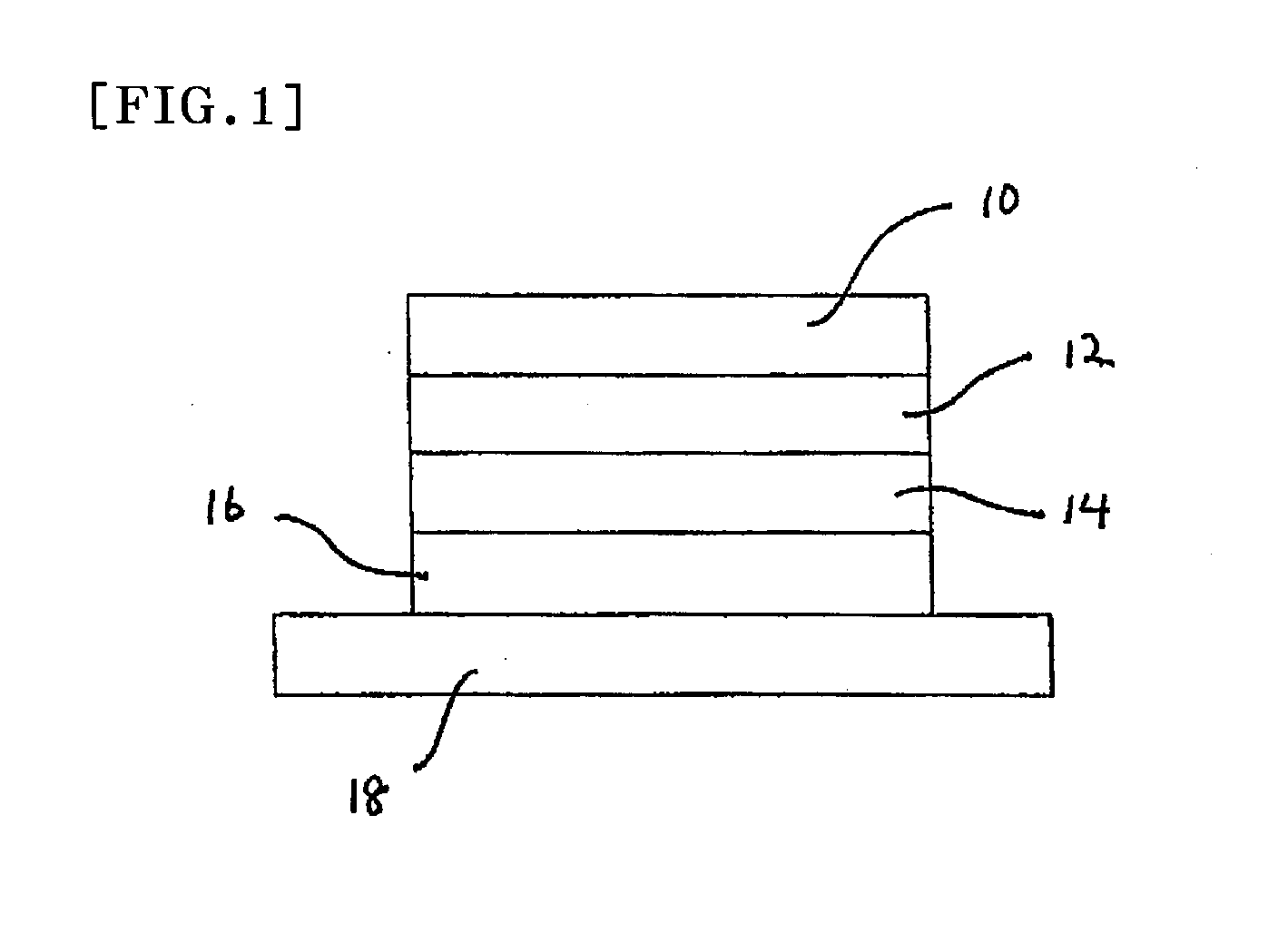

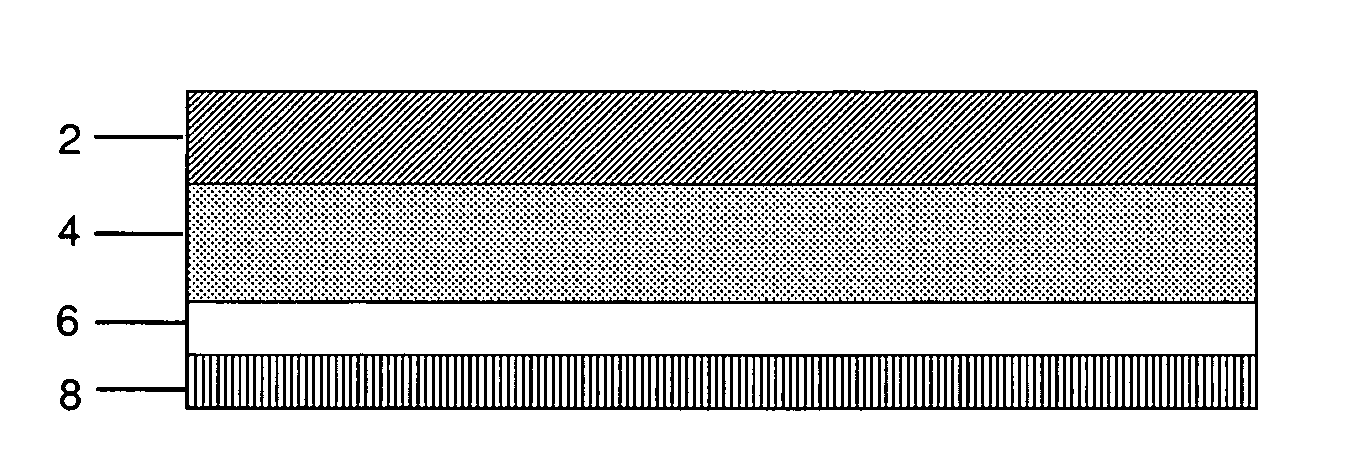

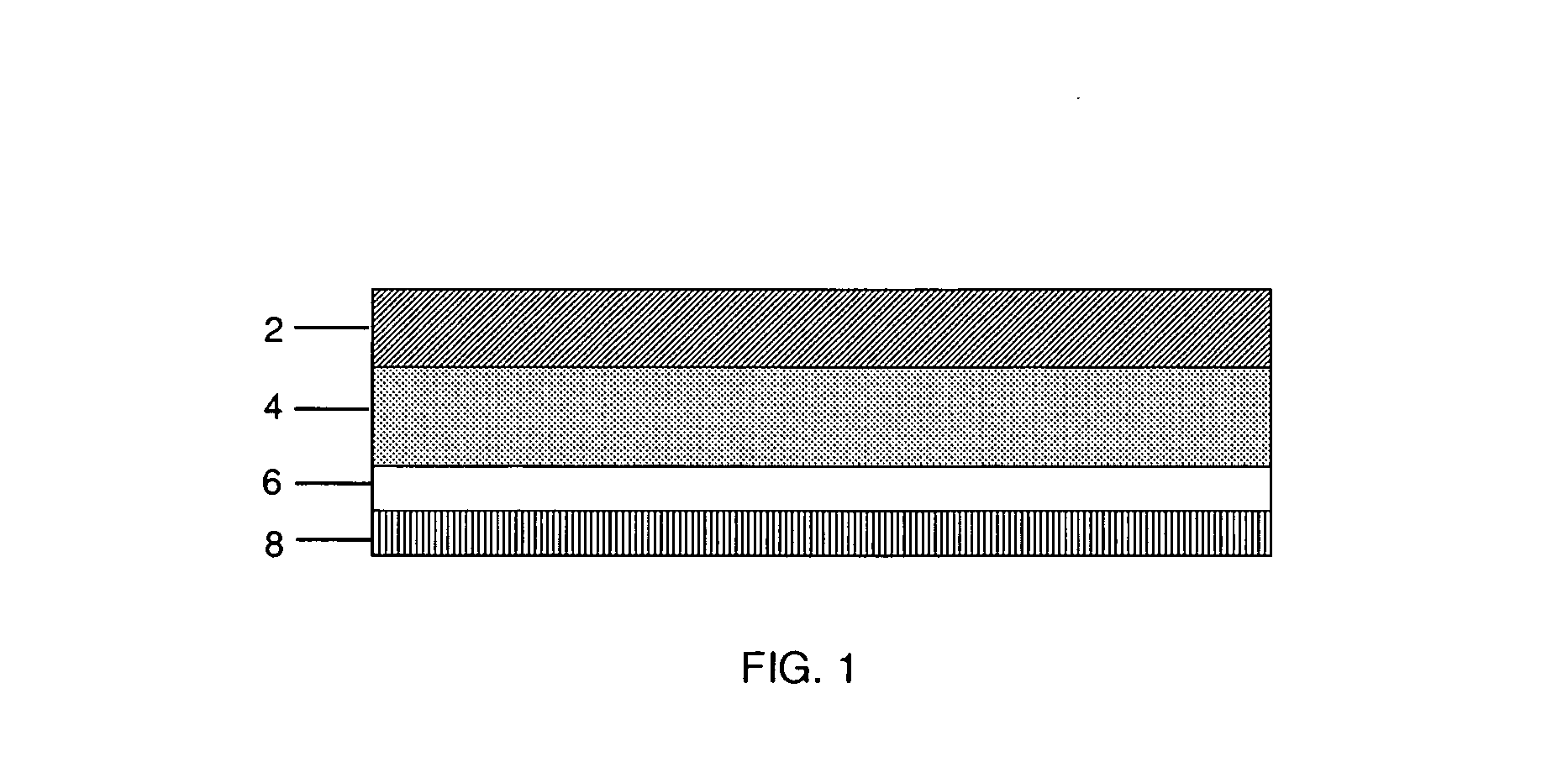

ActiveUS20150052847A1Vinyl aromatic copolymer adhesivesEster polymer adhesivesUltravioletSurfactant free

Disclosed is a waterproofing membrane that comprises a carrier sheet (layer A); a waterproofing adhesive (layer B); a protective coating (layer C), wherein the protective coating is substantially free of surfactant and comprises an acrylic or methacrylic polymer or copolymer, an inorganic filler and a white pigment; and a releasable material (layer D), wherein the releasable material comprises amorphous nanoscale silica and a polymeric binder. The waterproofing membrane does not require a release liner, binds strongly to concrete cast against it (even after UV exposure), tolerates foot traffic, and withstands immersion in water over an extended period.

Owner:GCP APPL TECH INC

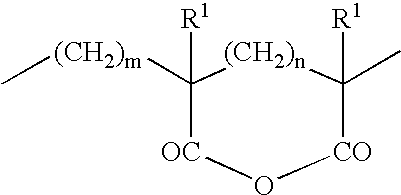

Photocurable resin composition and cured product of same, resin sheet and production method for same, and display device

InactiveUS20120114953A1Excellent reliabilityExcellent stress relaxation propertyPolyureas/polyurethane adhesivesSynthetic resin layered productsChemistryIsocyanate compound

A photocurable resin composition including: (A) a urethane (meth)acrylate oligomer having a polyoxyalkylene structure, (B) a (meth)acrylic polymer, (C) a (meth)acrylic monomer, and (D) a photopolymerization initiator, wherein the component (A) is produced using monomer components including (a1) a polyoxyalkylene polyol, (a2) a polyisocyanate, and (a3) a hydroxyl group-containing mono(meth)acrylate compound, a relationship N (=n1 / n2) between the total mass n1 of the monomer components and the total equivalent weight n2 of acryloyl groups within the all monomer components is 4,000 or greater, and the component (A) is substantially free of unreacted isocyanate groups.

Owner:HITACHI CHEM CO LTD

Thermoplastic resin composition

A thermoplastic resin composition which comprises a thermoplastic resin (a) and a block copolymer (b) comprising a methacrylic polymer block (A) and an acrylic polymer block (B).

Owner:KANEKA CORP

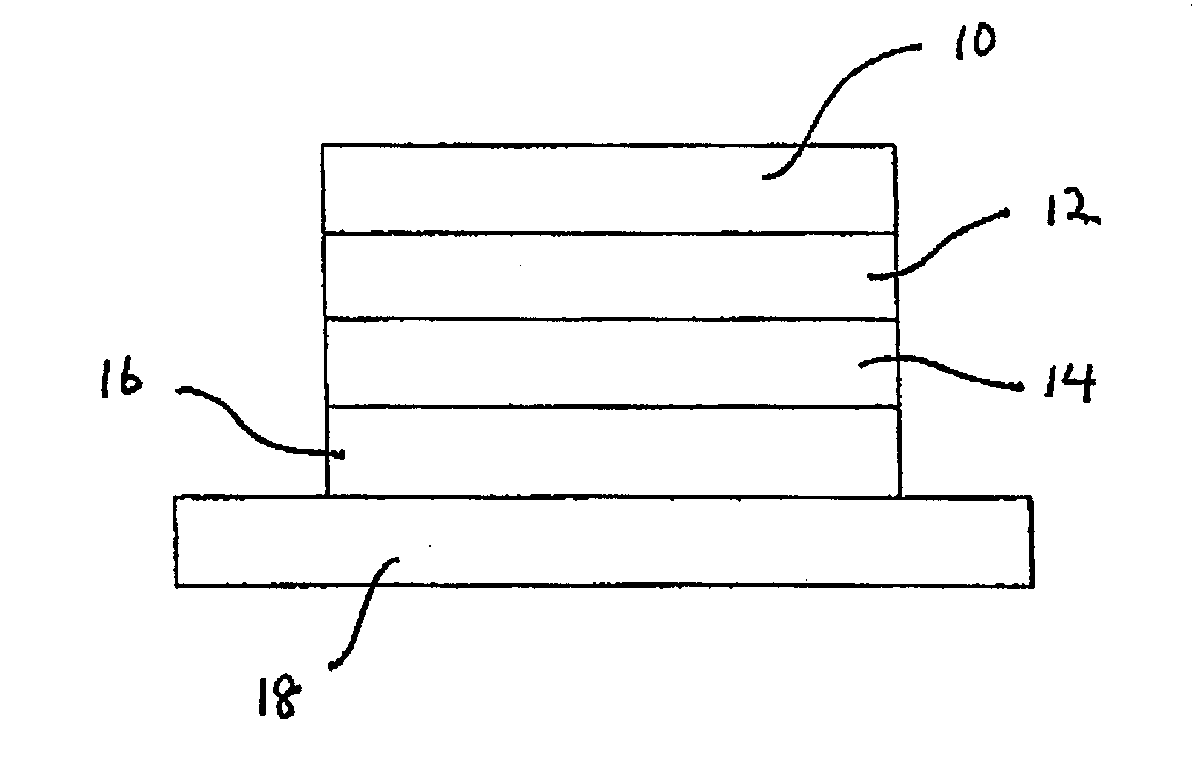

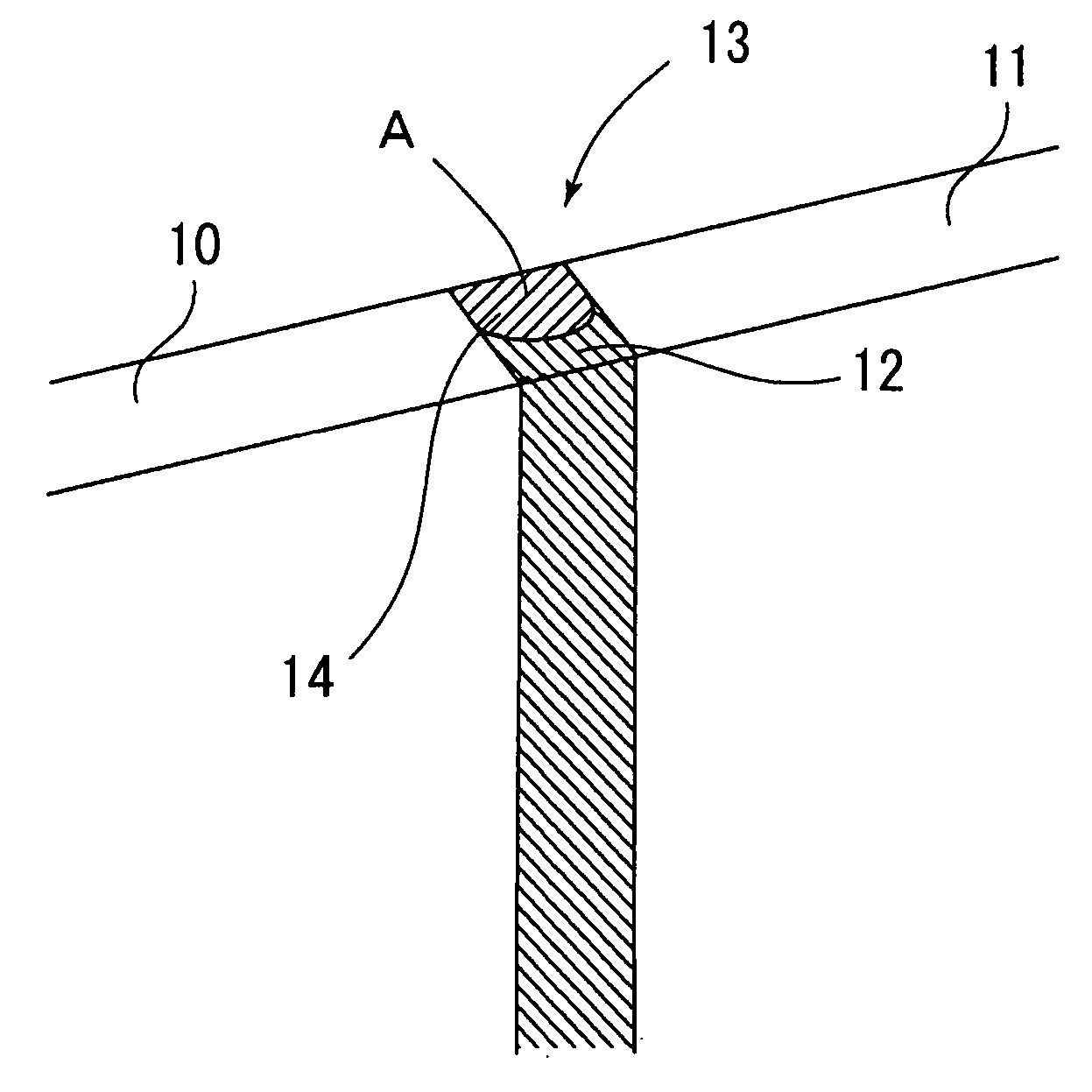

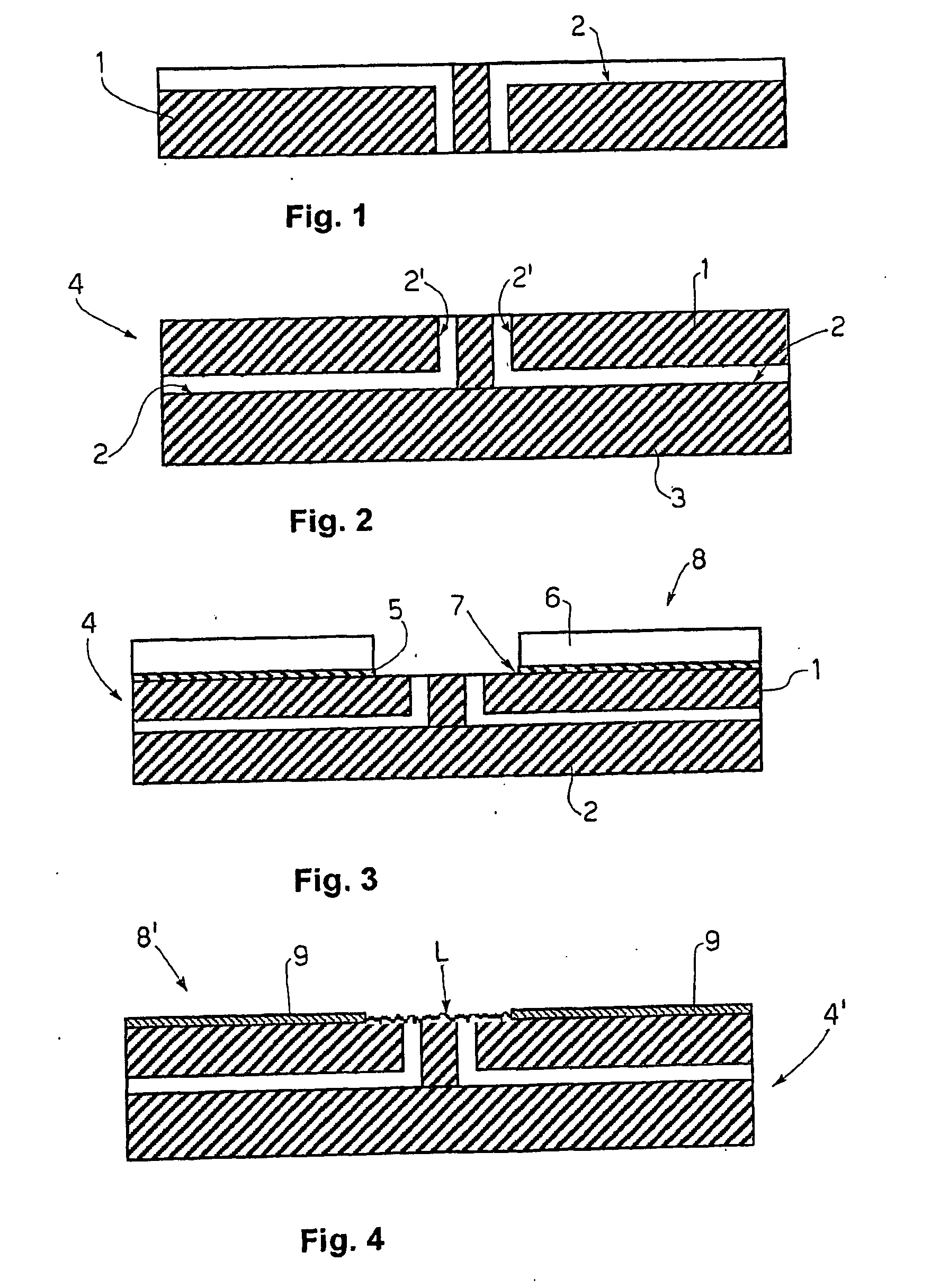

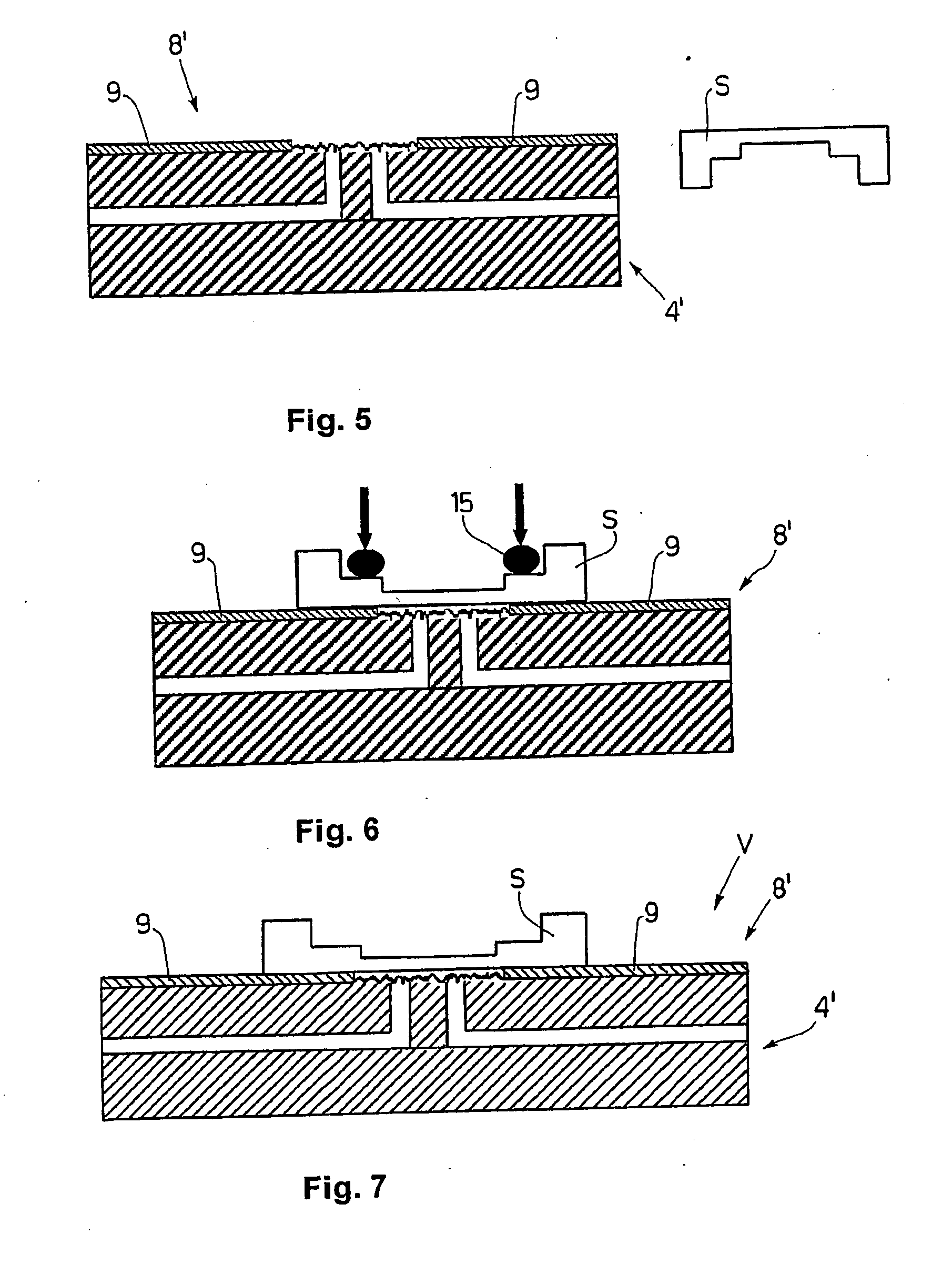

Method for Bonding a Layer of Silicone to a Substrate of Methacrylate Polymer

ActiveUS20110193006A1Easy and inexpensive to produceOvercomes drawbackLamination ancillary operationsDecorative surface effectsMethacrylate polymersMethacrylic Acid Polymers

Method of bonding a layer (S) of silicone to a substrate (4′) of methacrylic polymer; the method involves positioning between the methacrylate polymer and the silicone a layer (9) of an organosilane having the formula R1Si(R2)3, in which R2 is OH and R1 is a methacrylic residue.

Owner:MENARINI SILICON BIOSYSTEMS SPA

Curable composition and method for producing the same

Disclosed herein is a curable composition excellent in workability, adhesion properties, rubber-like properties, storage stability, and quick curability. The curable composition comprises (A) a crosslinkable silyl group-containing organic polymer and (B) a (meth)acrylic polymer obtained by polymerizing a (meth)acrylic monomer having a polymerizable unsaturated bond in the presence of a metallocene compound and a crosslinkable silyl group-containing thiol compound, at least one end of the (meth)acrylic polymer being bonded to a residue, —S—R3 (where R3 represents a group having a crosslinkable silyl group) obtained by removing a hydrogen atom from the crosslinkable silyl group-containing thiol compound.

Owner:CEMEDAINE CO LTD

Methacrylate polymer solid-phase micro-extraction fibre and method of producing the same

InactiveCN101279145AAvoid interferenceHigh sensitivityOther chemical processesAlkali metal oxides/hydroxidesCross-linkFiber

The invention relates to a methacrylate polymer solid phase micro extraction fiber and a preparation method thereof, in particular to a solid phase micro extraction. A fiber is provided with a stainless steel substrate which is a stainless steel wire, and one end of the stainless steel wire is provided with a methacrylate polymer coating. The preparation steps of the invention are that: one end of the stainless steel wire is cleaned with water and dried after being ultrasonically cleaned by an acetone solvent and an ethanol solvent; trimethylolpropane trimethacrylate, toluol and azodiisobutyronitrile are added to the methacrylate in sequence, then ultrasonic blending process and nitrogen flushing and deoxygenizing process are conducted, and then a prepolymerization blended solution is obtained; the prepolymerization blended solution is injected to a glass point sampling capillary by a microliter syringe, then the stainless steel wire is vertically inserted into the central part of the point sampling tube, and the two ends of the point sampling tube are sealed by rubber, then the point sampling tube is placed into an oven for polymerizing and cross linked at a certain temperature. After a polymer solution is solidified at the surface of the fiber, the point sampling tube is soaked in a hydrofluoric acid solution for a certain period, then the glass tube wall is removed, and then the solid phase micro extraction fiber is obtained.

Owner:XIAMEN UNIV

Methacrylic resin composition

ActiveUS20090012215A1High hardnessImprove impact resistanceSynthetic resin layered productsRecord information storageCrack resistanceAcrylic resin

Owner:KANEKA CORP

Inorganic particle dispersoid, energy ray-curable resin composition and film

The invention provides an inorganic particle dispersoid, an energy ray-curable resin composition and a film. The dispersoid of a cured product has high hardness and dispersion stability and is characterized in that the dispersoid is obtained by dispersing inorganic particles (A) for surface treatment into reactive dispersant. The inorganic particles (A) for surface treatment are obtained by treating surfaces of inorganic particles (C) with a compound (B) containing (methyl) acryloyl. The reactive dispersant is a reaction product generated during an additive reaction between monomers containing (methyl) acryloyl and carboxyl and (methyl) acrylic polymers containing epoxy radical; or a reaction product generated during an additive reaction between monomers containing (methyl) acryloyl and epoxy radical and acrylic polymers containing carboxyl (methyl) acrylic; wherein the content of the (methyl) acryloyl is 200-600, and the hydroxyl value is 90-280mg / KOH.

Owner:DIC CORP

Biofilm growth prevention

A biostatic coating comprising a coating composition which on drying produces an intrinsically hydrophobic film. The coating composition includes a biocidal complex A-B in which A is a phenolic biocide and B is selected from polyvinylpyrrolidone (“PVP”), PVP polymers, PVP copolymers and mixtures thereof. The coating composition for example is selected from acrylic and methacrylic polymer based compositions, acrylic and methacrylic copolymer based compositions, vinyl polymer based compositions, vinyl copolymer based compositions, epoxy resins, epoxy esters, and mixtures thereof. Suitable biocides for use in the invention include, but are not limited to complexes of PVP or PVP copolymer with triclosan; diclosan; dichlorophen; orthophenylphenol; orthobenzylparachlorophenol, cresols, xylols, and substituted diphenyl ethers.

Owner:NOVAPHARM RES AUSTRALIA

Waterproofing membrane

ActiveUS9476196B2Vinyl aromatic copolymer adhesivesEster polymer adhesivesUltravioletSurfactant free

Disclosed is a waterproofing membrane that comprises a carrier sheet (layer A); a waterproofing adhesive (layer B); a protective coating (layer C), wherein the protective coating is substantially free of surfactant and comprises an acrylic or methacrylic polymer or copolymer, an inorganic filler and a white pigment; and a releasable material (layer D), wherein the releasable material comprises amorphous nanoscale silica and a polymeric binder. The waterproofing membrane does not require a release liner, binds strongly to concrete cast against it (even after UV exposure), tolerates foot traffic, and withstands immersion in water over an extended period.

Owner:GCP APPL TECH INC

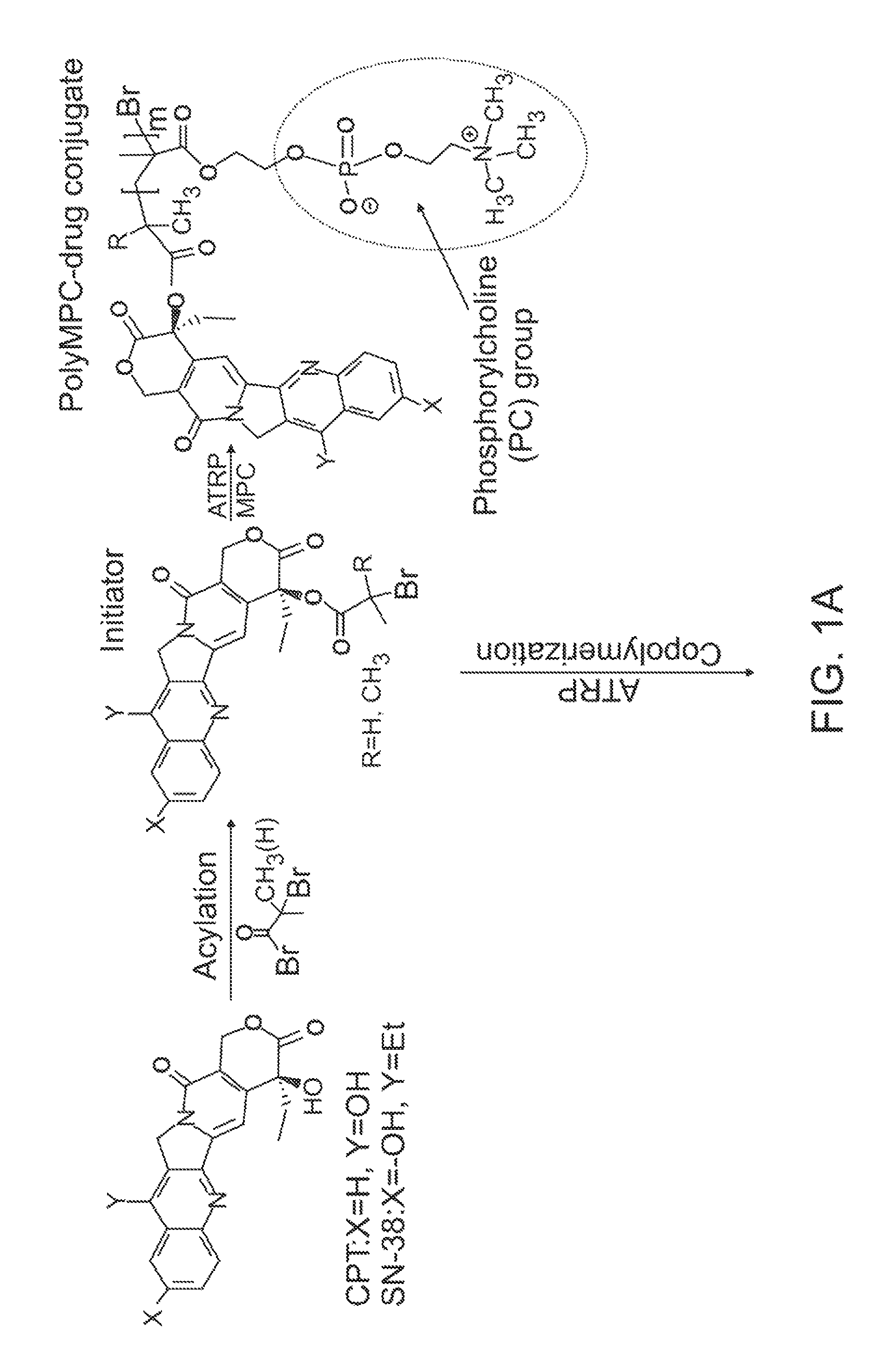

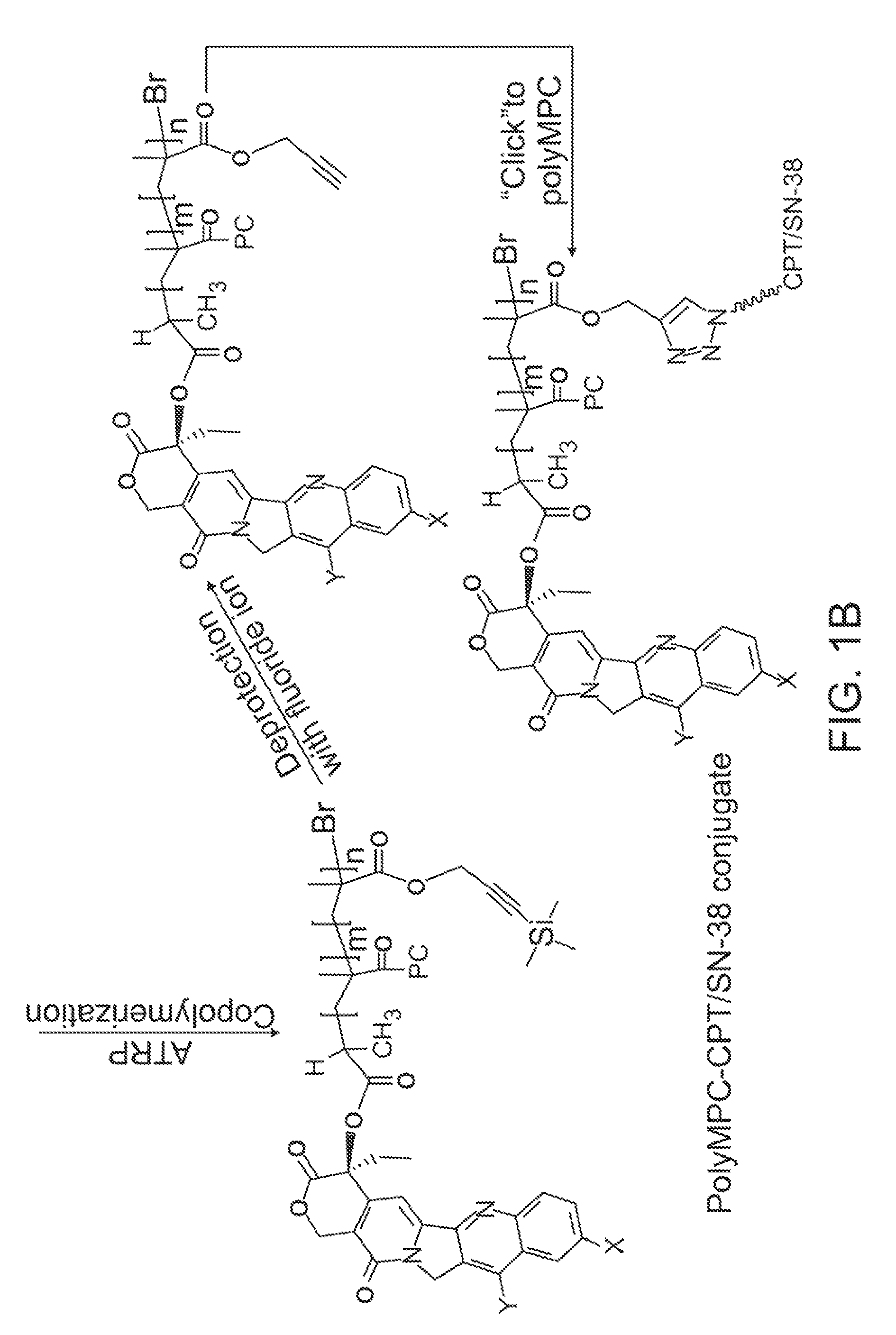

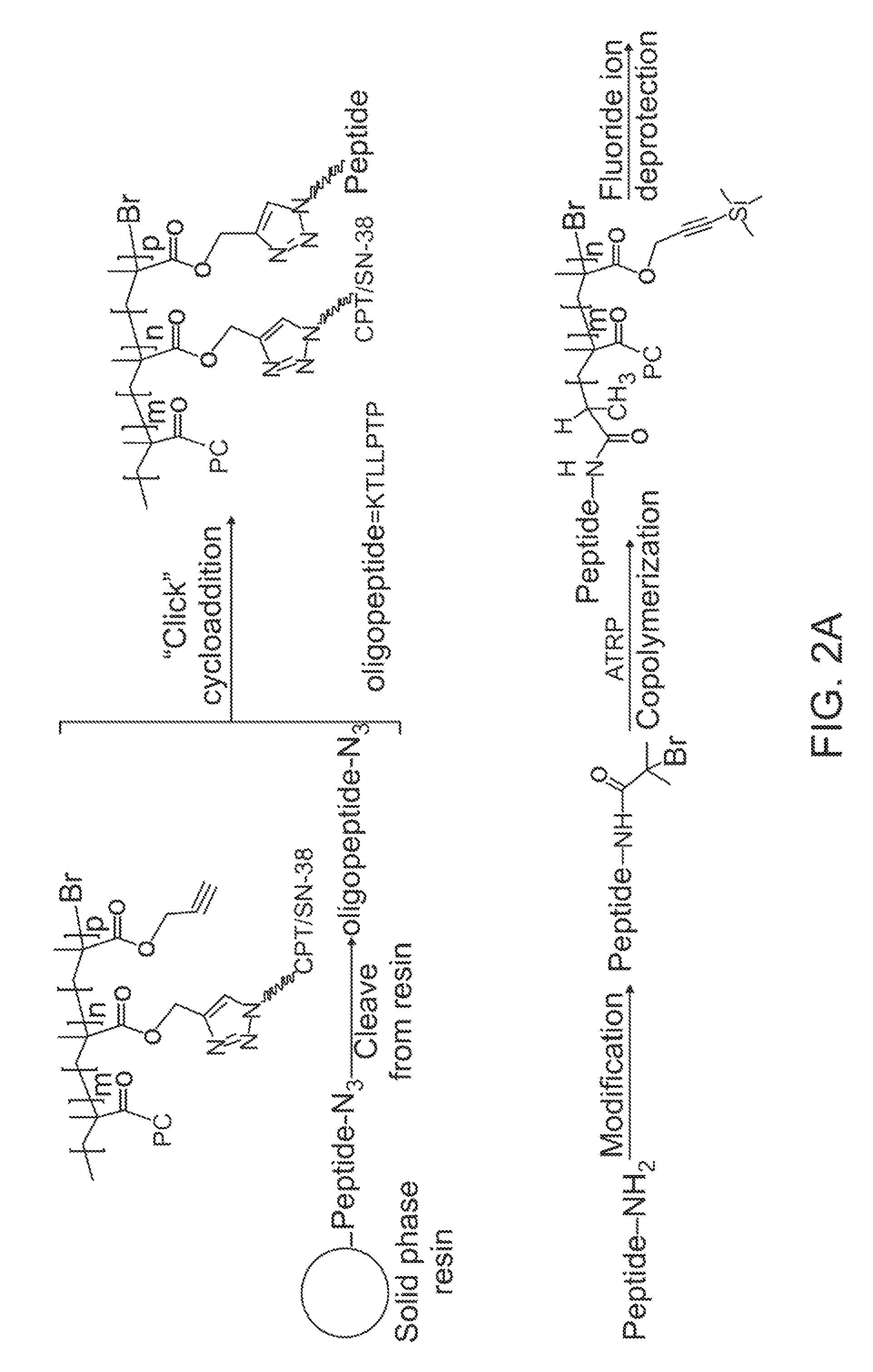

Zwitterionic polymers with therapeutic moieties

ActiveUS9416210B2Robust triazole cycloadductHigh yieldOrganic active ingredientsPharmaceutical non-active ingredientsClick chemistryZwitterion

Owner:UNIV OF MASSACHUSETTS

Posttreatment method of protein fiber fabric dyed by natural dyestuff

InactiveCN107574693AImprove acid and alkali resistanceImprove color fastness to soapingDyeing processAnimal fibresPerspirationAlum

The invention discloses a posttreatment method of a protein fiber fabric dyed by natural dyestuff. The posttreatment method comprises the following steps: adding the protein fiber fabric dyed by the natural dyestuff into a treatment bath containing 0.5 to 5g / L of a chitosan-methacrylate polymer and 0.2 to 1.0g / L of a nonionic surfactant AEO9, controlling the bath ratio to 1 to 50, raising the temperature to 80 DEG C, treating for 45 minutes, taking out the fabric and dewatering; then adding the fabric into the treatment bath which contains 0.2 to 1.5 g / L of alum and has a pH value equal to 5,treating the fabric at the temperature of 50 DEG C for 30 minutes, taking out the fabric and dewatering; washing the fabric with hot water and cold water to neutral, dewatering and then drying at thetemperature of 100 to 120 DEG C. The method has the advantages that fastness indexes related to the pH value such as the stability of acid and alkali resistance, the color fastness to soaping, the color fastness to perspiration of the dyed fabric can be improved.

Owner:苏州虹锦生态纺织科技有限公司

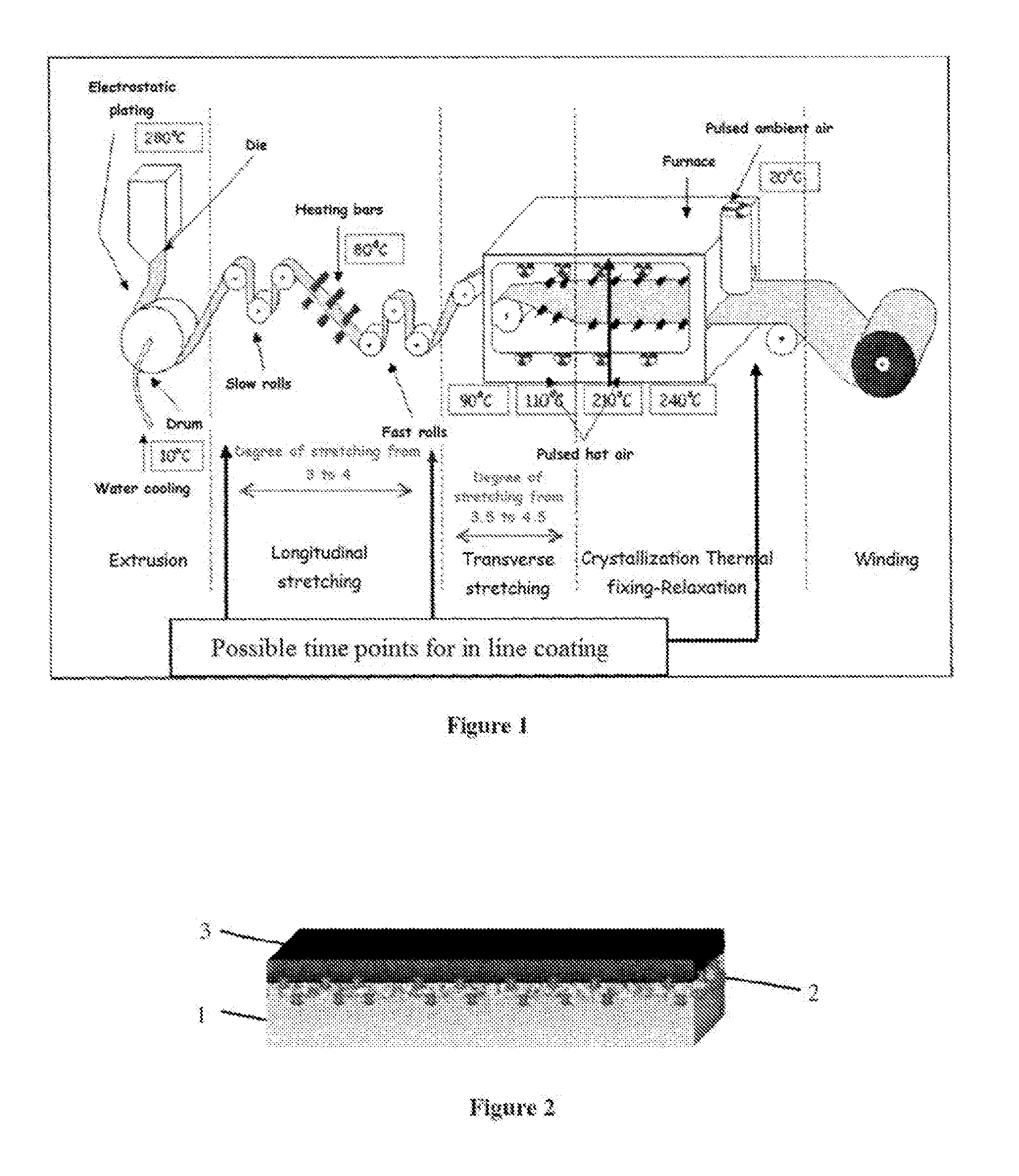

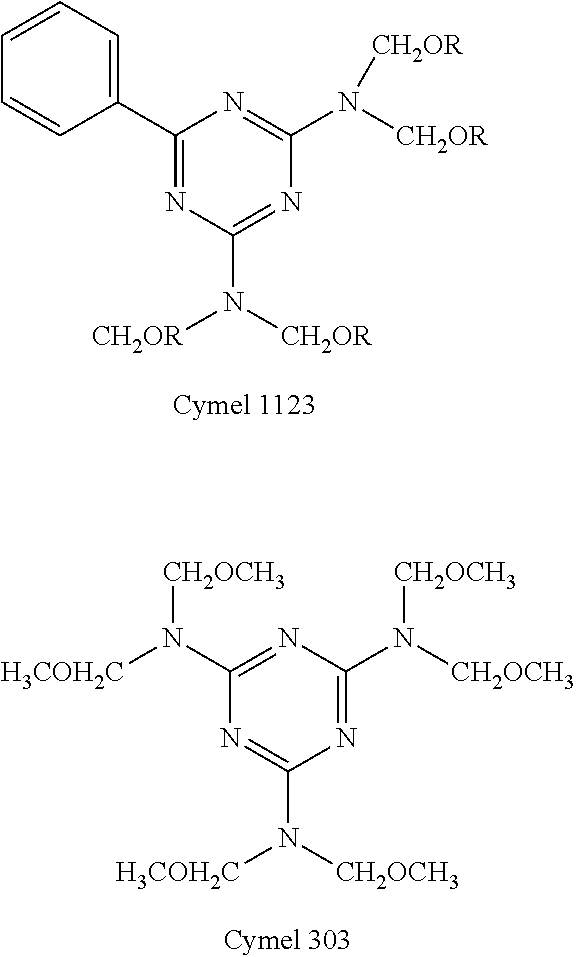

Composition for coating polymer films, coating process and composite materials obtained

The invention relates to a composition intended for coating polymer films, making it possible to improve the adhesion between the film and a final coating, and to confer good barrier properties on the coated film. The coating composition comprises at least one acrylic and / or methacrylic polymer which has a gel content of at least 50% by weight, relative to the total weight of acrylic and / or methacryclic polymer, at least one crosslinking agent and at least one polyester comprising sulphonyloxy groups, which is water-soluble or water-dispersible.

Owner:TORAY FILMS EURO

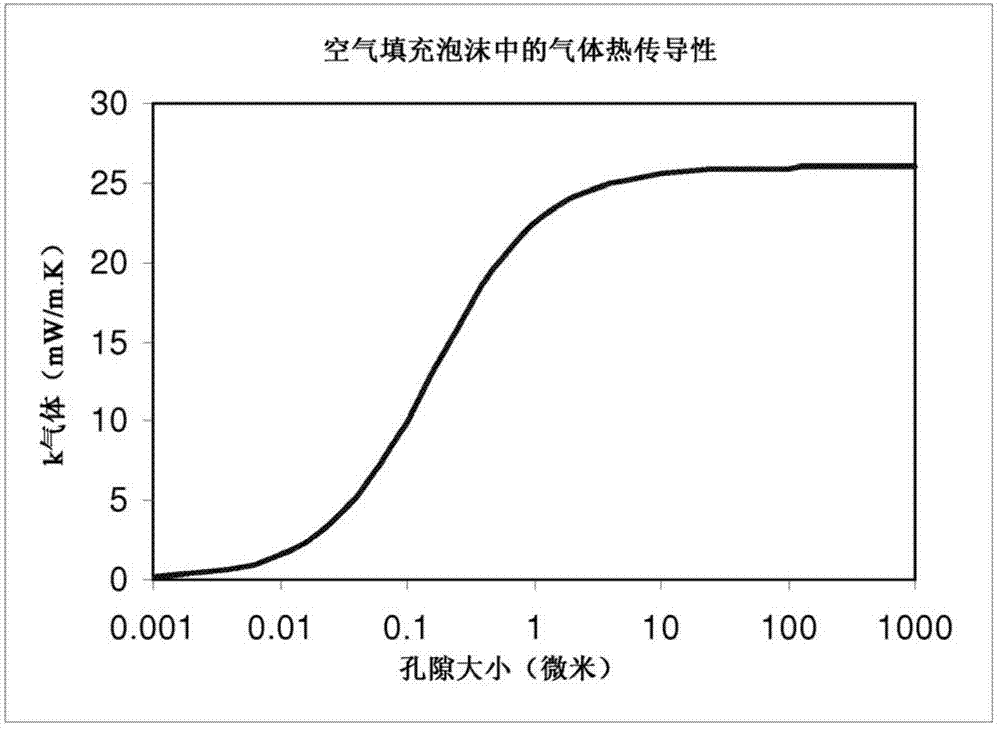

Nanocellular thermoplastic foam and process for making the same

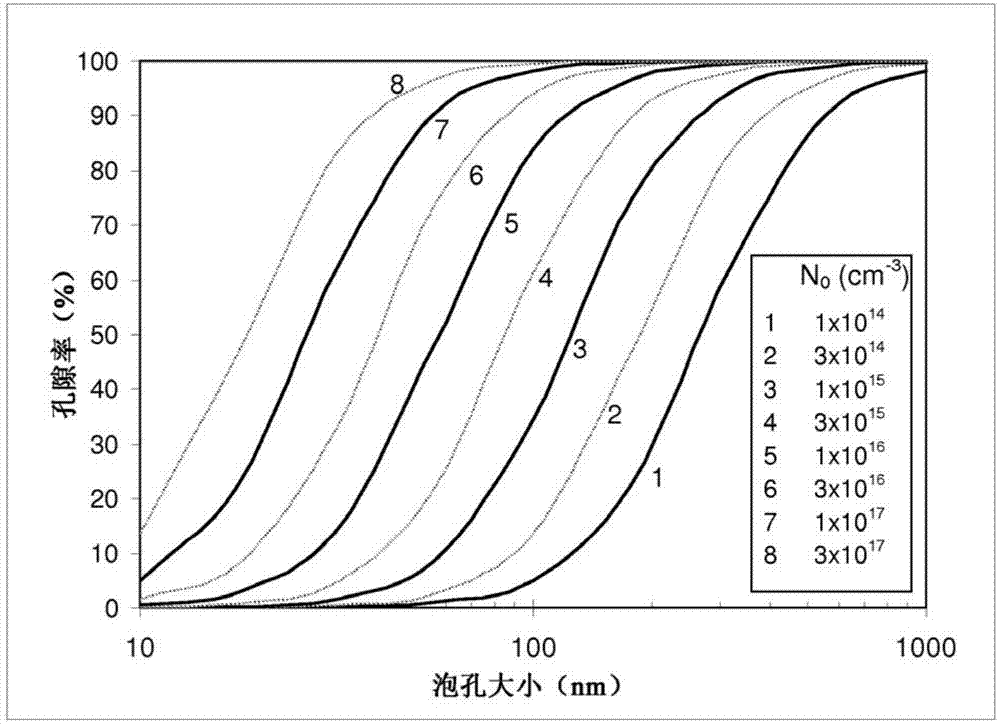

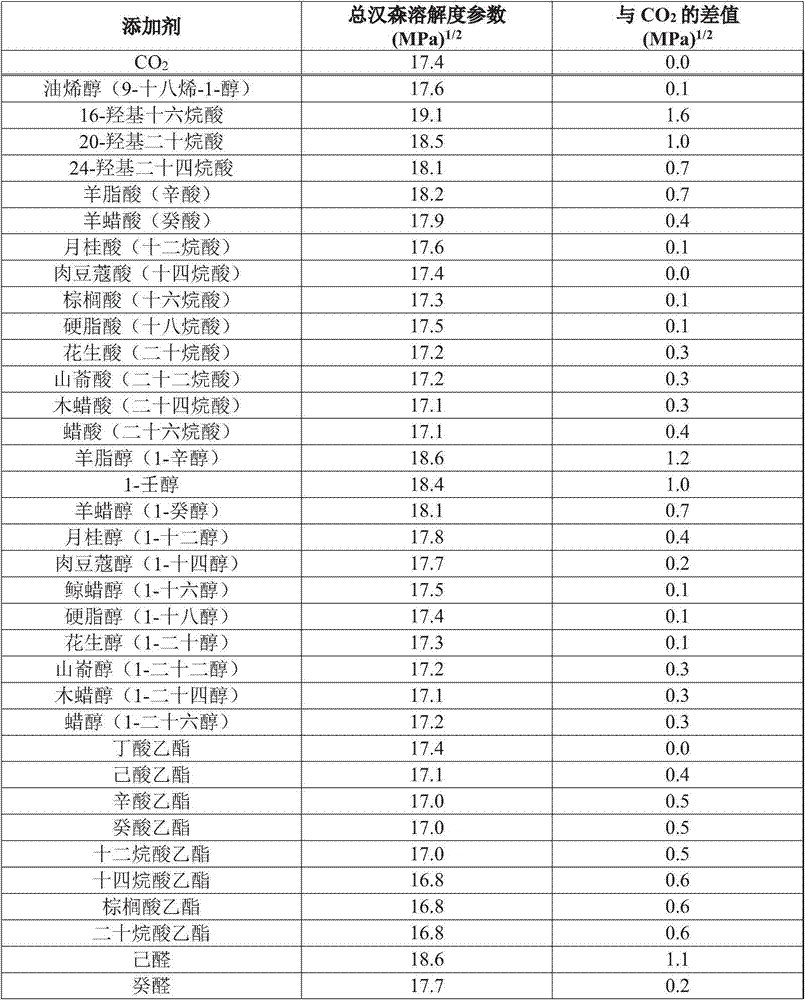

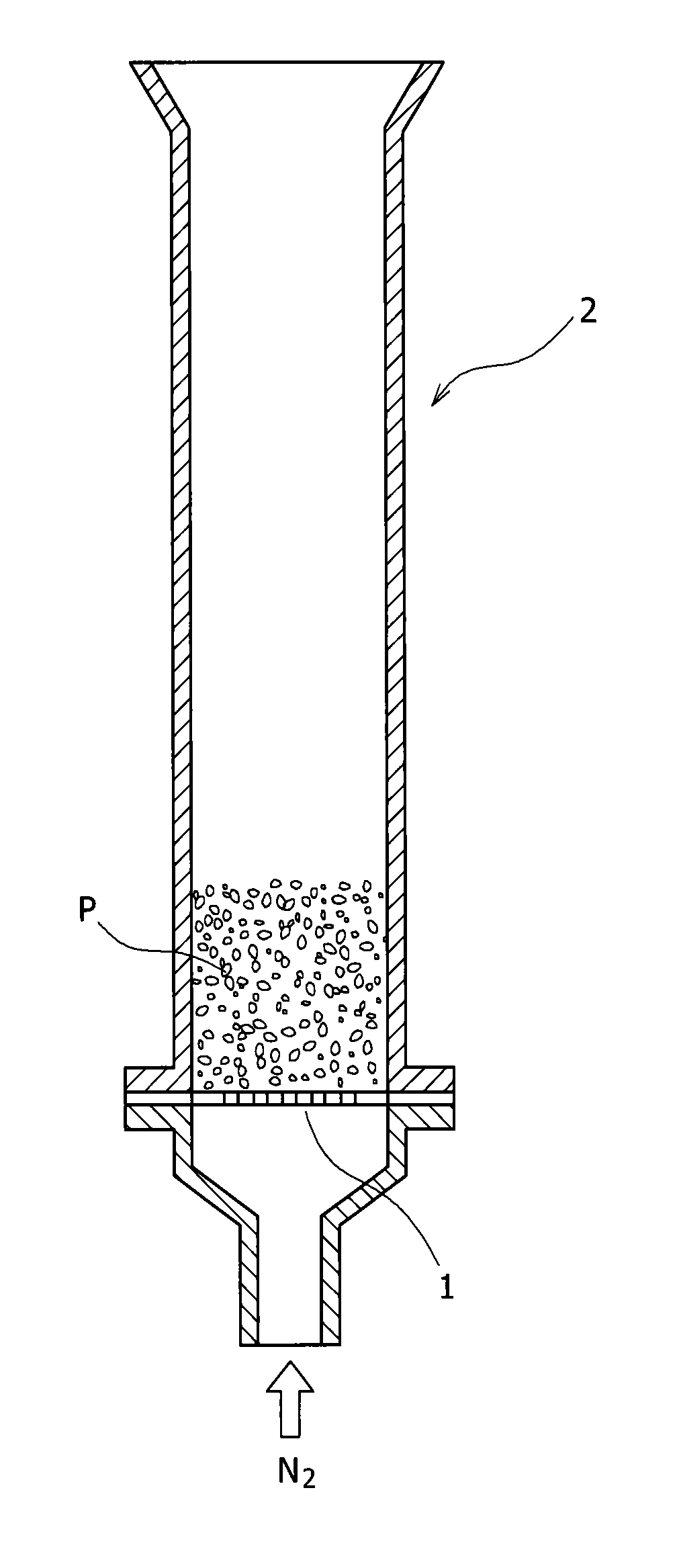

Prepare a thermoplastic polymer foam having a porosity of 70% or more and at least one of: (i) an average cell size of 200 nanometers or less; and (ii) a nucleation density of at least 1x1015 effective nucleation sites per cubic centimeter of foamable polymer composition not including blowing agent using a foamable polymer composition containing a thermoplastic polymer selected from styrenic polymer and (meth)acrylic polymers, a blowing agent comprising at least 20 mole-percent carbon dioxide based on moles of blowing agent and an additive having a Total Hansen Solubility Parameter that differs from that of carbon dioxide by less than 2 and that is present at a concentration of 0.01 to 1.5 weight parts per hundred weight parts thermoplastic polymer.

Owner:DDP SPECIALTY ELECTRONICS MATERIALS US 8 LLC

Binder for powder metallurgy, mixed powder for powder metallurgy, and sintered body

ActiveUS20150361255A1Inhibition of segregationAvoid scatterTransportation and packagingMetal-working apparatusDust emissionHot Temperature

The present invention provides a binder which has excellent effect on suppression of segregation or dust emission, while exhibiting excellent fluidity both at ordinary temperatures and at high temperatures. The present invention is a binder which is blended for use in a mixed powder for powder metallurgy, said mixed powder containing an iron-based powder and an auxiliary starting material powder. This binder is characterized by being composed of one or more polymers that are selected from among butene polymers having a melting point of from 50° C. to 85° C. (inclusive) and a heated melt fluidity at 190° C. of from 2.0 g / 10 minutes to 3.6 g / 10 minutes (inclusive) and methacrylic acid polymers having a weight average molecular weight of 1,000,000 or less.

Owner:KOBE STEEL LTD

Dispersible powder and cosmetic

PendingCN112386504AGood dispersionImprove dispersion stabilityCosmetic preparationsHair cosmeticsPolymer scienceMeth-

An object of the present invention is to provide a dispersible powder having excellent dispersibility and high dispersion stability particularly in an aqueous medium. Another object is to provide a cosmetic blended with this powder, the cosmetic being capable of forming a uniform cosmetic film and having favorable spreadability upon application, stretchability, adhesiveness, and feeling on use aswell as high stability. The dispersible powder is obtained by treating powder with a surface treating agent. The surface treatment agent comprises a (meth)acrylic polymer containing a repeating unit having a phosphorylcholine group.

Owner:SHIN ETSU CHEM IND CO LTD

Non-aqueous composition comprising partially fluorinated methacrylic polymers

ActiveUS20110200829A1Synthetic resin layered productsLiquid/solution decomposition chemical coatingSolvent basedMethacrylate polymers

A solvent-based non-aqueous fluorinated methacrylate polymer comprising repeating units in any sequence from (1) at least one fluorinated methacrylate, and (2) at least one non-fluorinated alkyl acrylate and (3) at least one non-fluorinated hydroxyalkyl methacrylate,provided thata) the repeating unit of fluorinated methacrylate is present in a range of about 40%-80% by weight of total monomers added,b) the repeating unit of non-fluorinated alkyl acrylate is present in a range of about 10%-35% by weight of total monomers added, andc) the repeating unit of non-fluorinated hydroxyalkyl methacrylate is present in a range of about 5%-25% by weight of total monomers added, andd) the total of all repeating units is 100% by weight.

Owner:THE CHEMOURS CO FC LLC

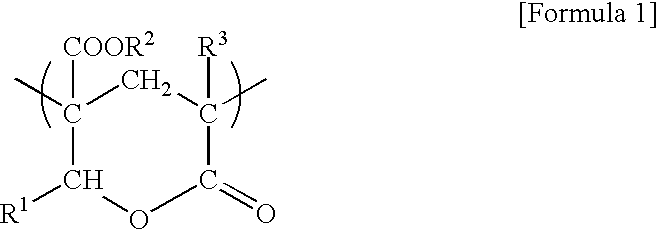

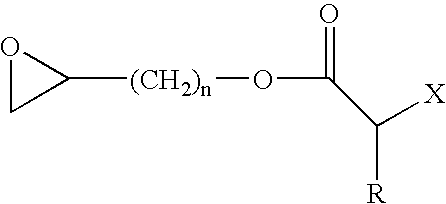

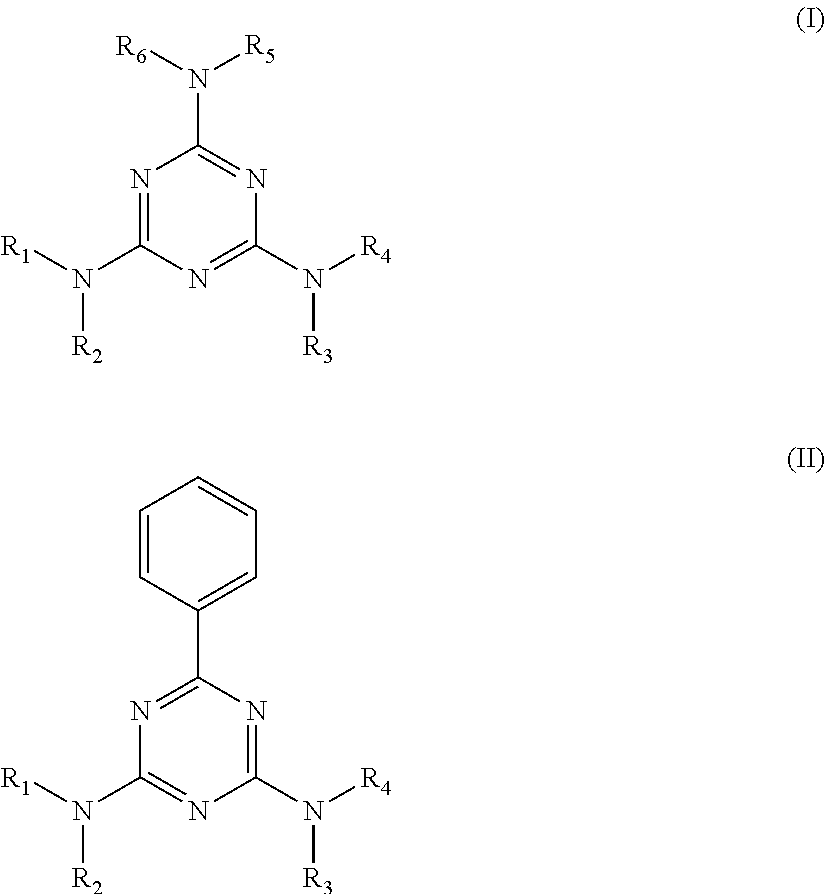

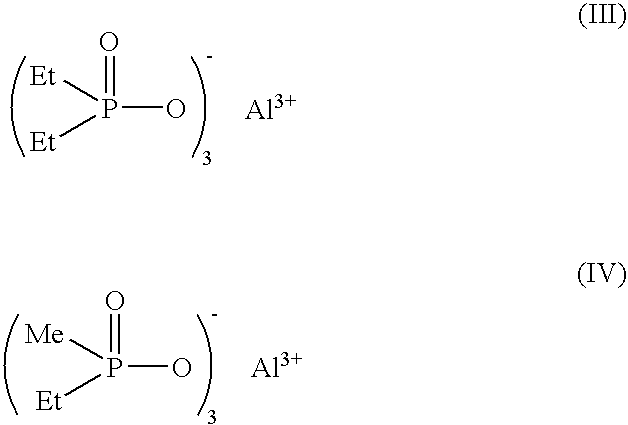

Flame-retardant methacrylic composition

InactiveUS20070149659A1Improve flame retardant performanceImprove surface conditionSynthetic resin layered productsCoatingsFire retardantPolymer

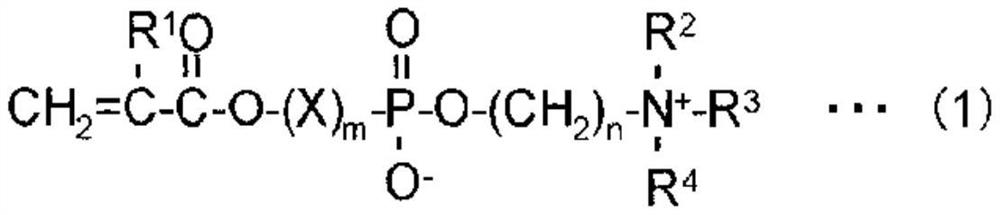

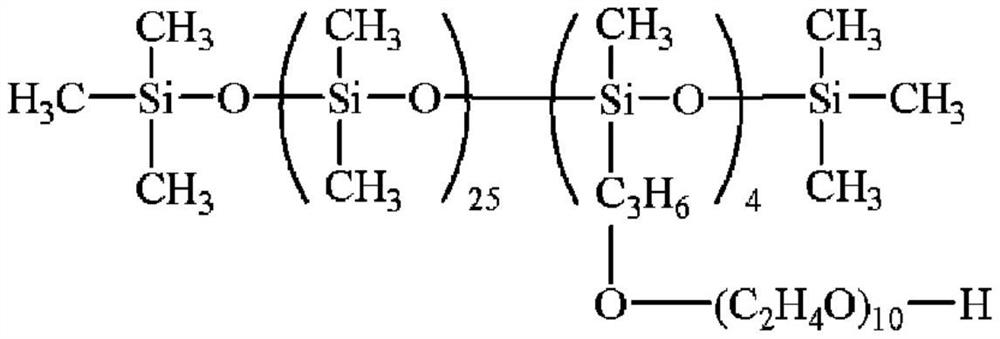

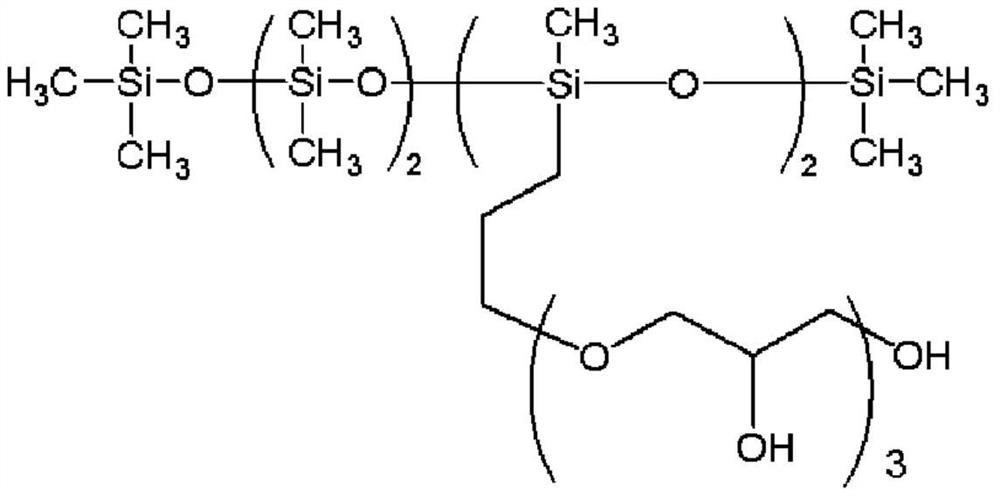

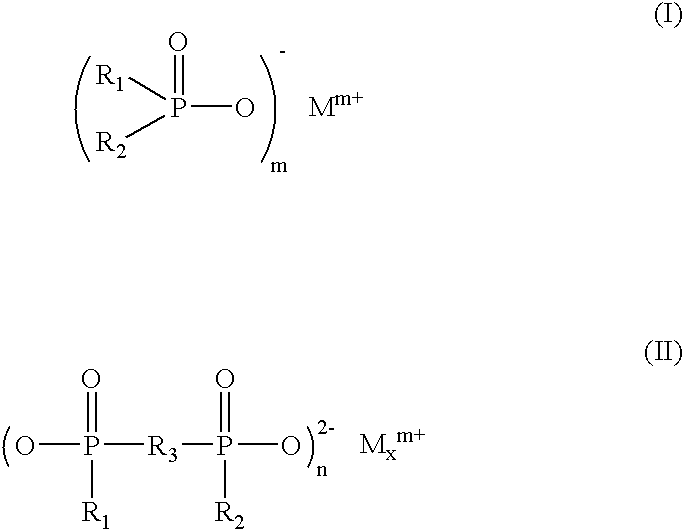

The invention relates to a flame-retardant methacrylic composition based on a methacrylic polymer comprising, per 100 parts of methacrylic polymer, from 15 to 25 parts, advantageously from 17 to 25 parts, preferably from 17 to 23 parts, more preferentially still from 19 to 22 parts, of at least one flame-retardant agent of formula (I) or (II): in which: R1 and R2 denote linear or branched C1-C6 alkyl groups and / or aryl groups; R3 denotes a linear or branched C1-C10 alkylene group, a C6-C10 arylene group, an alkylarylene group or an arylalkylene group; M denotes Mg, Ca, Al, Sb, Sn, Ge, Ti, Zn, Fe, Zr, Ce, Bi, Sr, Mn, Li, Na or K; m is an integer between 1 and 4; n is an integer between 1 and 4; x is an integer between 1 and 4.

Owner:ARKEMA FRANCE SA

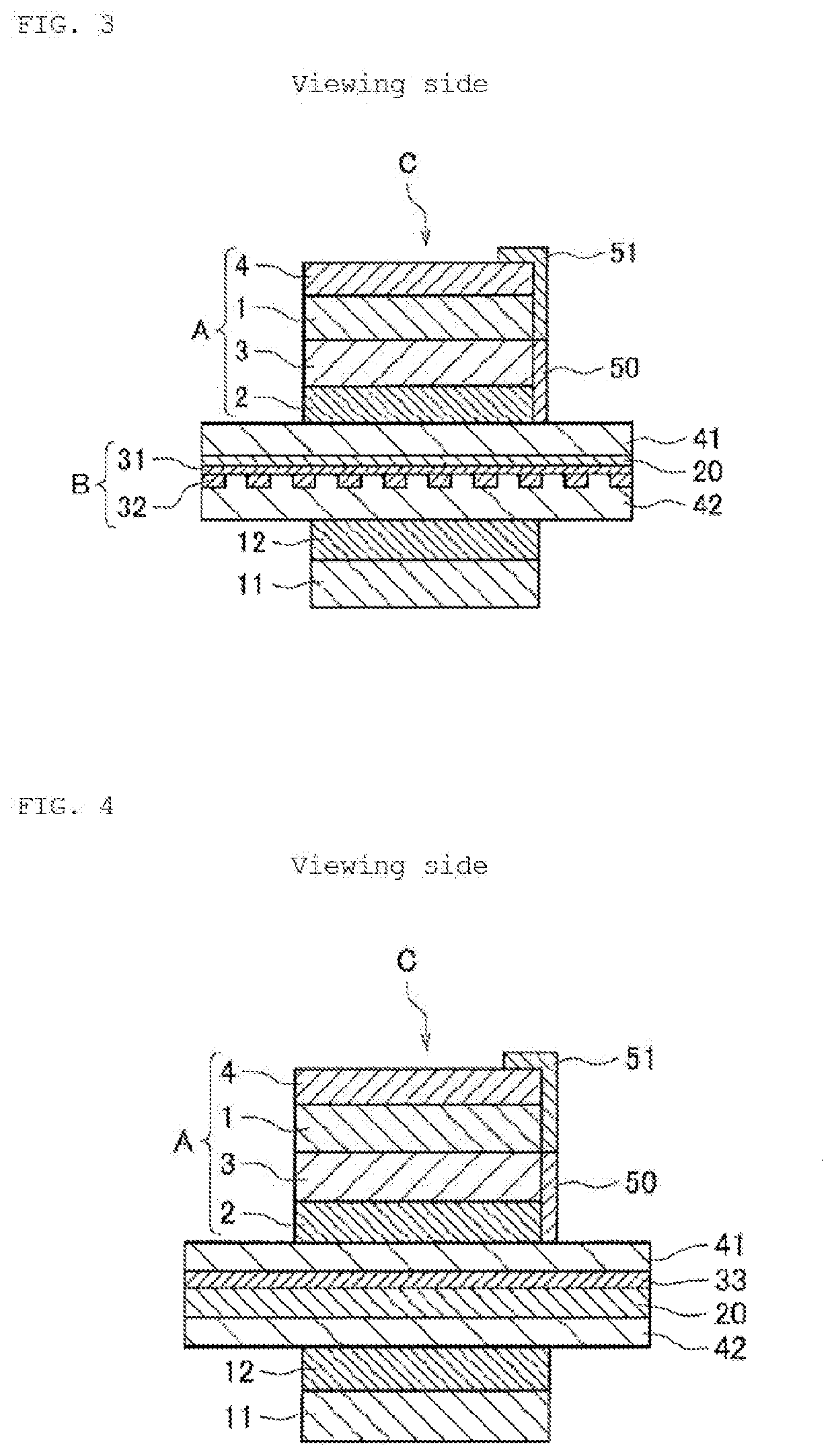

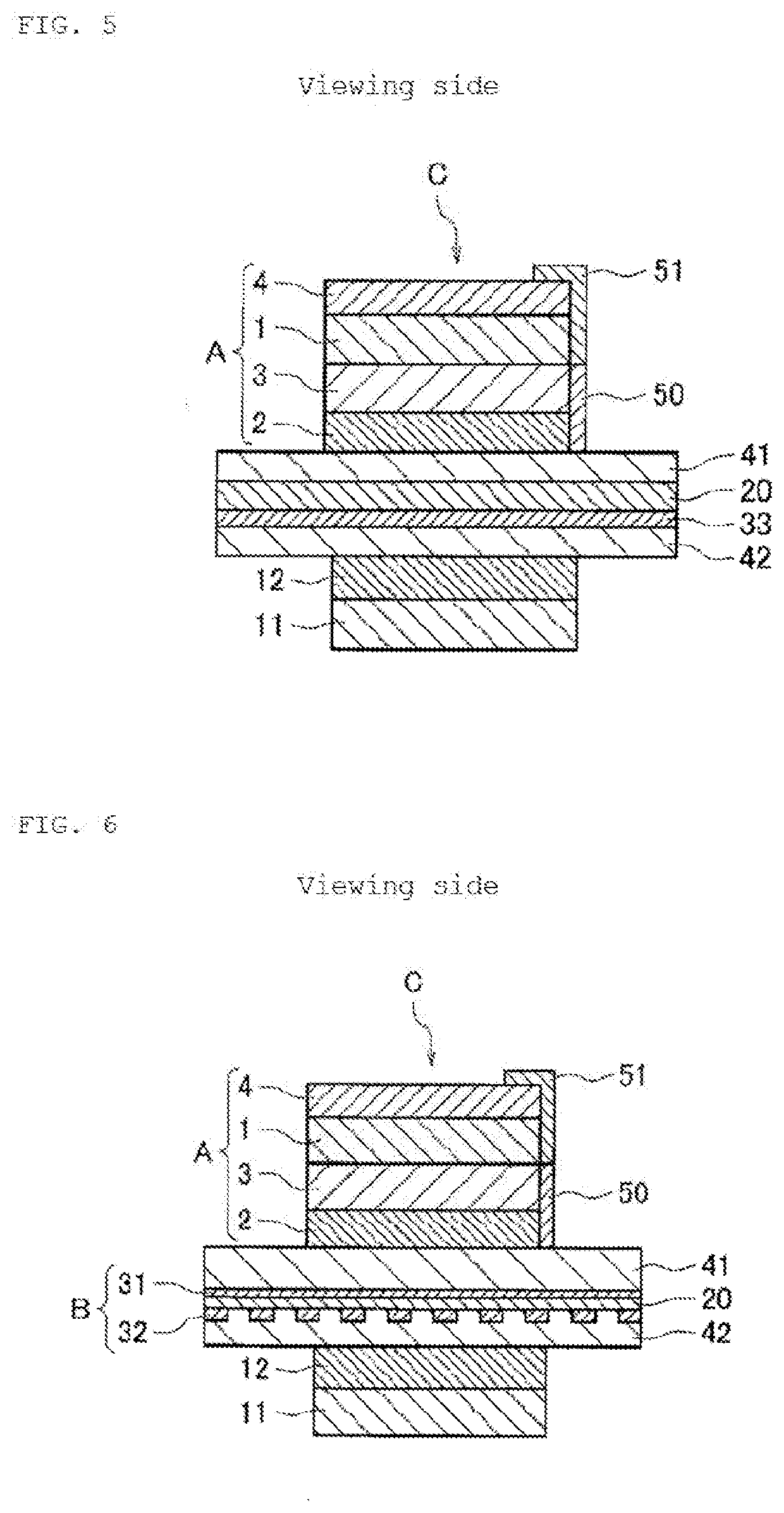

Polarizing film with added adhesive layer, polarizing film with added adhesive layer for in-cell liquid crystal panel, in-cell liquid crystal panel, and liquid crystal display device

InactiveUS20200033673A1Conduction failureAvoid turbidityLayered productsPolarising elementsPolymer scienceMeth-

The present invention provides a pressure-sensitive adhesive layer attached polarizing film far realizing an in-cell type liquid crystal panel in which it is possible to prevent clouding attributable to the pressure-sensitive adhesive layer even in a humidified environment, and it is also possible to satisfy a stable antistatic function and touch sensor sensitivity. This pressure-sensitive adhesive layer attached polarizing film is provided with a pressure-sensitive adhesive layer and a polarizing film, and is characterized in that: the pressure-sensitive adhesive layer is formed from a pressure-sensitive adhesive composition comprising an organic cation-anion salt and a (meth)acrylic polymer containing, as monomer units, an alkyl (meth)acrylate and a polar functional group-containing monomer; and the ratio (b / a) of the variation in the surface resistances value of the pressure-sensitive adhesive layer-side before and after humidification is 5 or less.

Owner:NITTO DENKO CORP

Method for preparing leather retanning fat-liquoring agent

InactiveCN101457262ARealize cleaner productionReduce dosageTanning treatmentEmulsionCarvacryl acetate

The invention discloses a method for preparing a leather retanning fat-liquoring agent which is a long chain aliphatic alcohol n-butyl alcohol maleic diester methacrylate polymer prepared by a water emulsion copolymerized reaction of a long chain aliphatic alcohol n-butyl alcohol maleic diester and a methacrylic acid. The leather retanning fat-liquoring agent of the invention is a high molecule material with an amphipathic structure, is suitable for the leather processing, has multifunction of retanning, fat-liquoring, water proof and wash resistance or the like, reduces the leather chemical material amount and the tanning process and is useful for implementing leather cleaning production.

Owner:WENZHOU UNIVERSITY

Thermoplastic elastomer composition and molded article

InactiveUS20070173604A1Improve heat resistanceGood moldabilitySuperstructure subunitsDomestic articlesPolymer scienceWeather resistance

The present invention provides an acrylic block copolymer composition improving melt flowability at molding and being excellent in heat resistance in addition to maintain weather resistance, chemical resistance, adhesivity, flexibility and abrasion resistance which are the characteristics of the acrylic block copolymer. It is attained by a thermoplastic elastomer composition comprising an acrylic block copolymer (A) which comprises a methacrylic polymer block (a) and an acrylic polymer block (b), wherein at least one of polymer blocks among the methacrylic polymer block (a) and the acrylic polymer block (b) has a functional group (X), and a compound (B) containing 1.1 or more of functional groups (Y) in one molecule.

Owner:KANEKA CORP

Multiple component coating composition utilizing dilution stable polyisocyanates

The present invention is directed to a multiple component coating composition comprising (a) a film forming binder component having isocyanate reactive groups; (b) a stable polyisocyanate solution comprising organic liquid and up to 30% by weight, based on the weight of the polyisocyanate solution, of a polyisocyanate having reactive isocyanate groups selected from an aromatic polyisocyanate having tertiary isocyanate groups or a (meth)acrylic polymer containing reactive isocyanate groups; and (c) optionally, a tinting composition comprising pigment, a dispersing agent and an organic liquid carrier; whereby components (a), (b) and (c) are blended together before application to a substrate and after application to a substrate the composition is cured to form a finish. The present invention is also directed to a method of producing a finish on a substrate and to the resulting coated substrate.

Owner:AXALTA COATING SYST IP CO LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com