Curable Composition

a composition and cure technology, applied in the direction of coatings, adhesives, etc., can solve the problems of no technology for solving the whitening phenomenon of thin layer parts, poor appearance of a structure, and inability to solve the whitening phenomenon of those thin layer parts, etc., to achieve excellent anti-staining property and weather resistance, improve weather resistance, and high elongation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

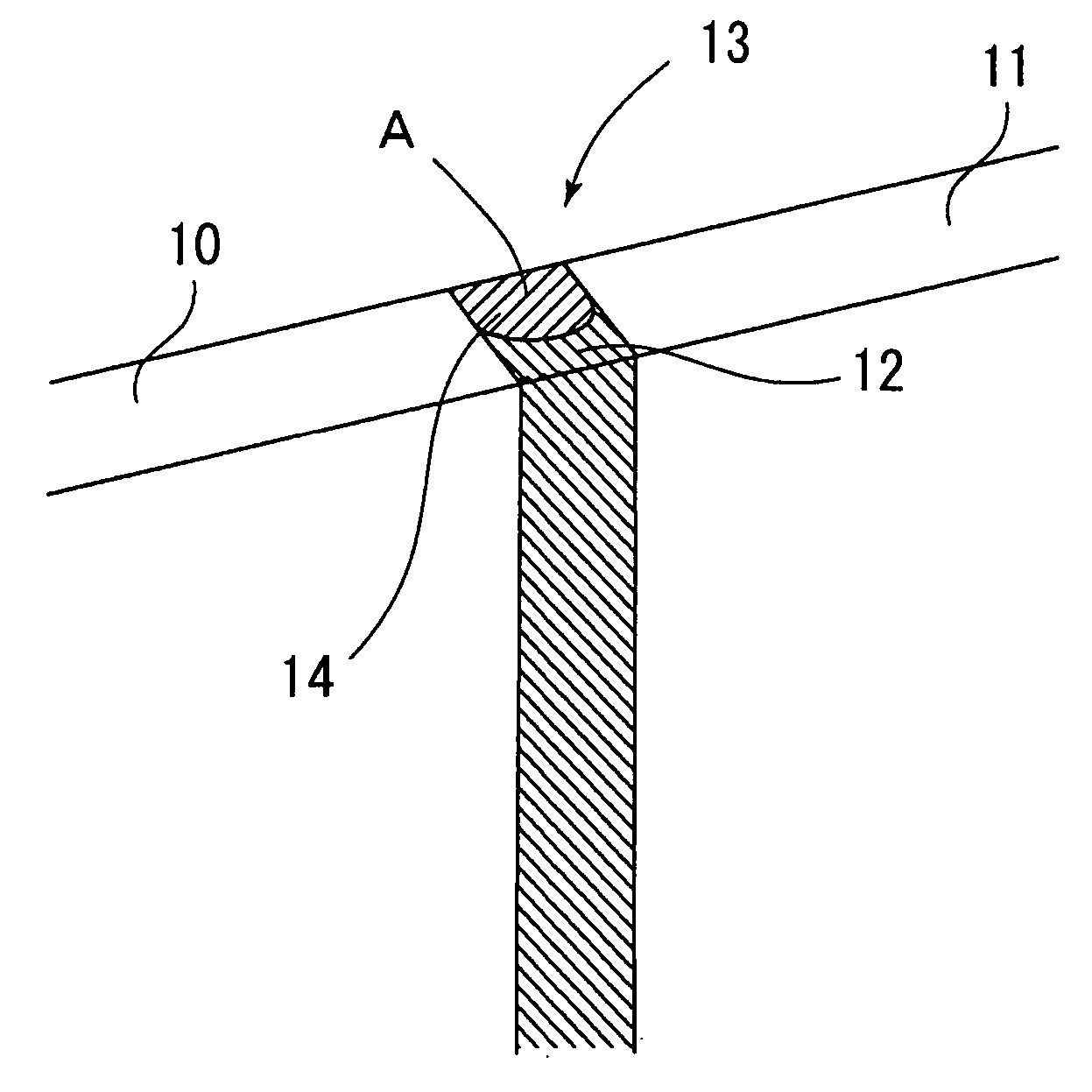

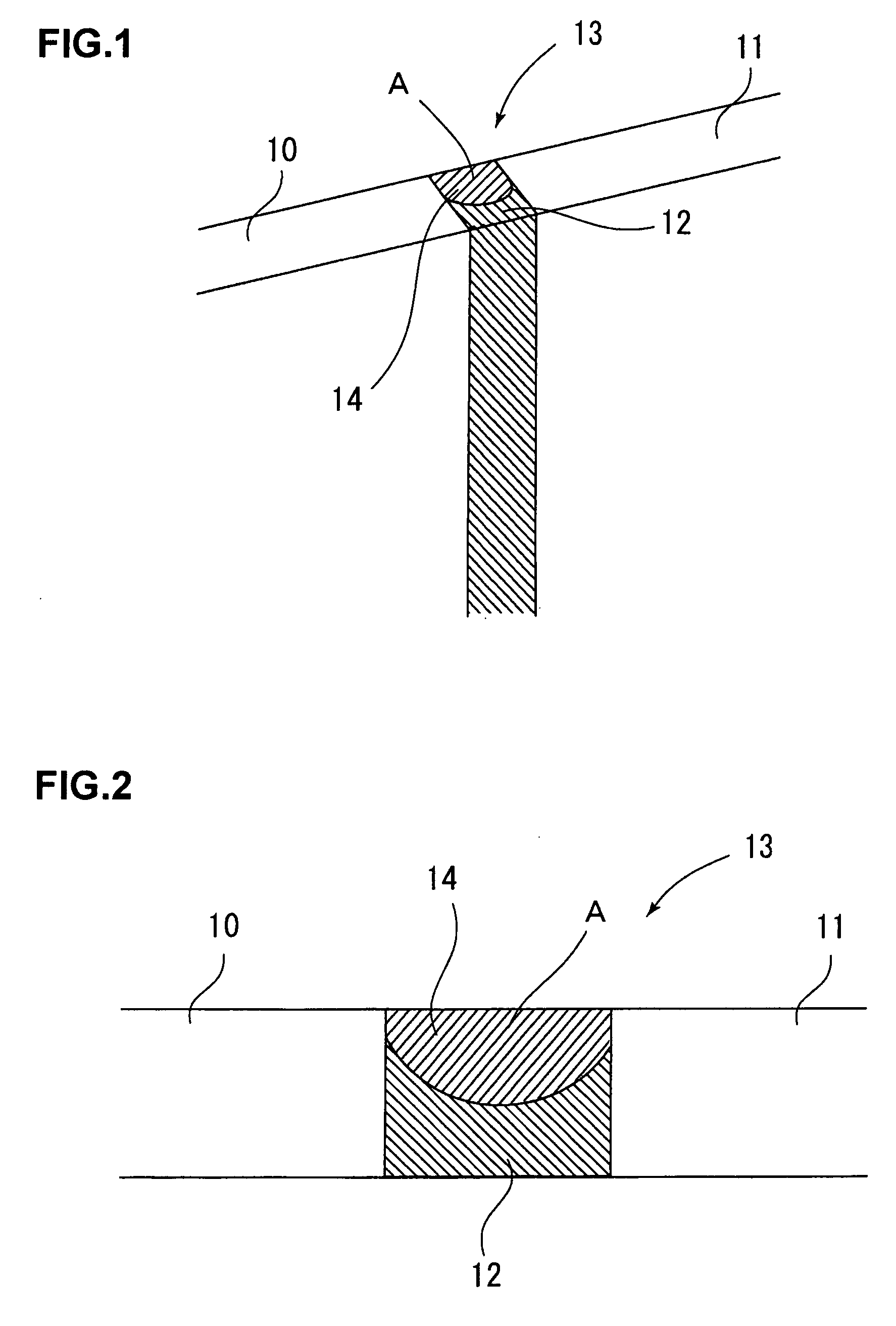

Image

Examples

examples

[0140]Hereinafter, the present invention will be described more specifically by way of examples. Needless to say, however, these examples are exemplary, and should not be construed as being limitative.

synthesis example 2

Synthesis of Acrylic Polymer 1 Containing Crosslinkable Silyl Group

[0142]The temperature of a pressure stirring tank type reactor provided with an electrothermal heater and having a volume of 1,000 ml was kept at 200° C. Next, while the pressure in the reactor was kept constant, a monomer mixture composed of 84 parts of butyl acrylate as an acrylate monomer, 16 parts of γ-methacryloxypropyltrimethoxysilane as a hydrolyzable silyl group-containing monomer, and 1 part of di-t-butyl peroxide as a polymerization initiator started to be continuously supplied from a raw material tank to the reactor at a constant supply speed (80 g / min, residence time: 12 minutes), and a reaction liquid corresponding to the supplied amount of the monomer mixture was continuously pulled out from the outlet of the reactor.

[0143]Immediately after the initiation of the reaction, the reaction temperature reduced once, and then an increase in temperature due to heat of polymerization was observed. The reaction t...

example 1

[0144]As shown in Table 1, predetermined amounts of a modified silicone polymer SA 100S (manufactured by Kaneka Corporation) as the component (A), that is, the organic polymer containing a crosslinkable silyl group, a 1577 FF (manufactured by Ciba Specialty Chemicals) as the component (B), that is, the triazine based ultraviolet ray absorbing agent, a CHIMASSORB 119FL (manufactured by Ciba Specialty Chemicals) as the component (C), that is, the light stabilizer, a plasticizer, a filler, and a dehydration treatment agent were loaded, and the blended substances were mixed and stirred under heat and reduced pressure at 110° C. for 2 hours, whereby the blended substances were dehydrated. Further, predetermined amounts of the ketimine compound obtained in Synthesis Example 1 as the component (D), dibutyltin diacetylacetonate as a curing catalyst, and an aminosilane compound as a silane coupling agent were added to and blended in the resultant under stirring, whereby a curing composition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com