Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33 results about "Isopropyl chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

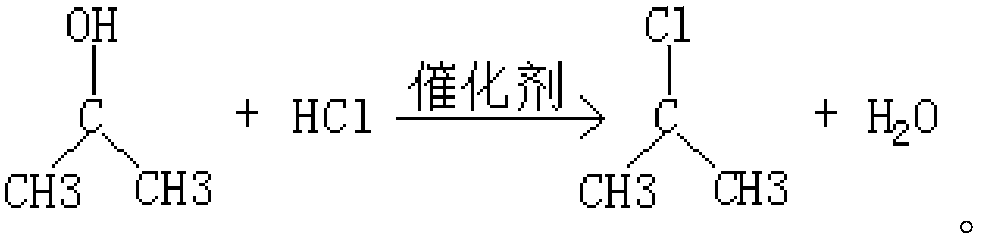

Isopropyl chloride is an organic compound with the chemical formula (CH₃)₂CHCl. A colorless, flammable liquid, it is used industrially as a solvent. It reacts with magnesium to give isopropylmagnesium chloride.

Isopropyl chloride with hydrofluorocarbon or hydrofluoroether as foam blowing agents

InactiveUS6646020B2Combustibility is reduced and eliminatedReduce flammabilityHeat-exchange elementsLiquid soapsPolyisocyanurateHydrofluoroether

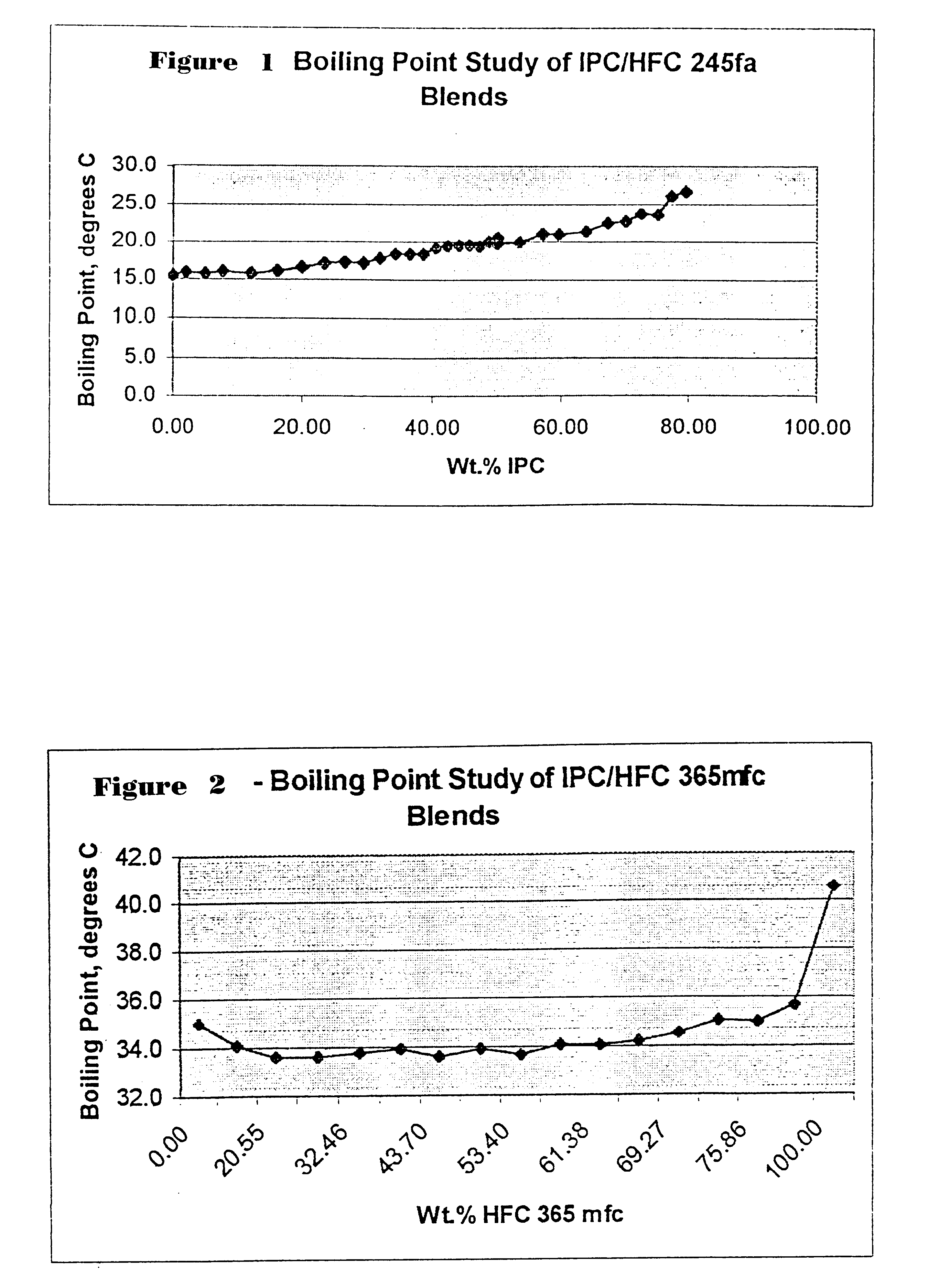

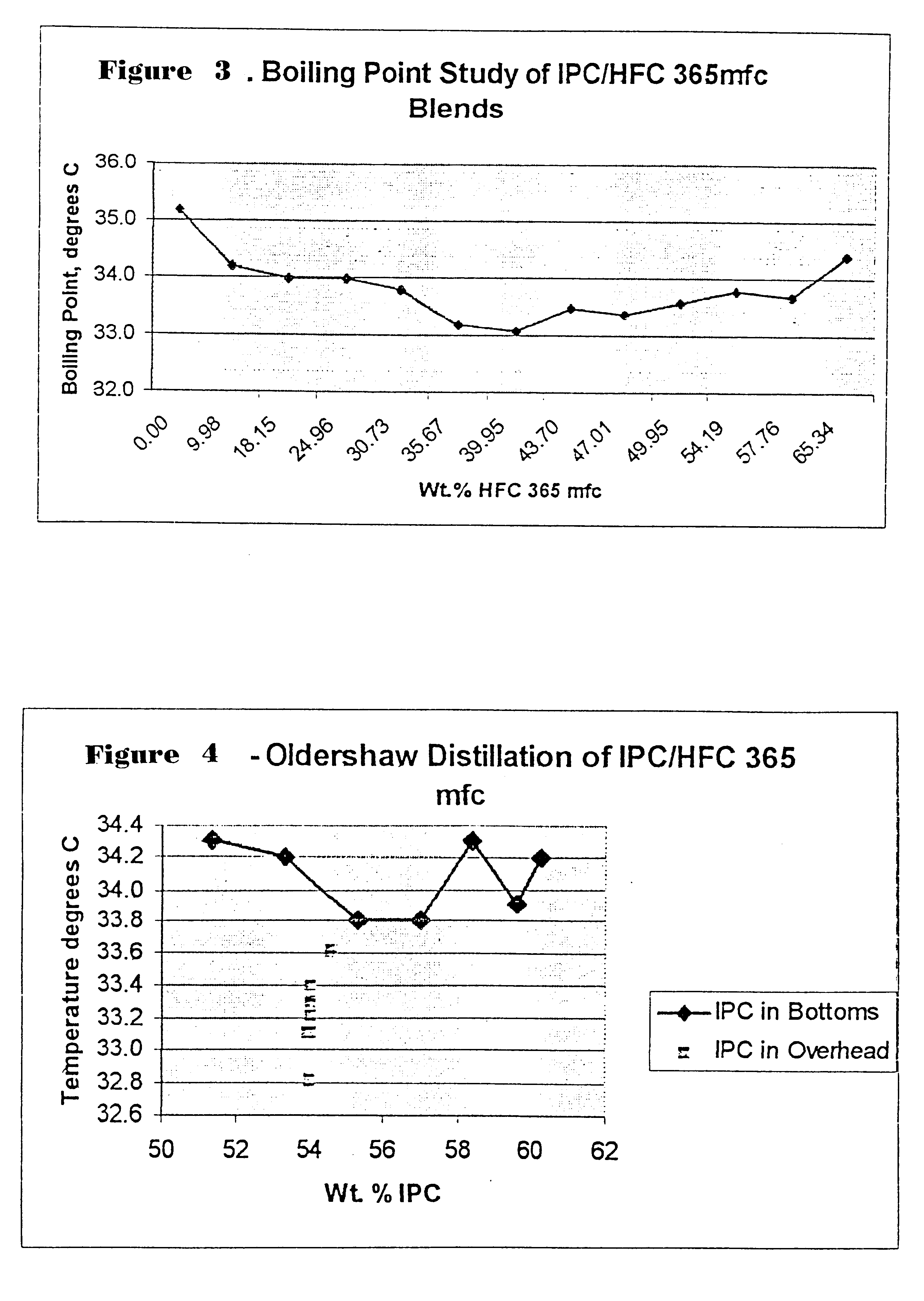

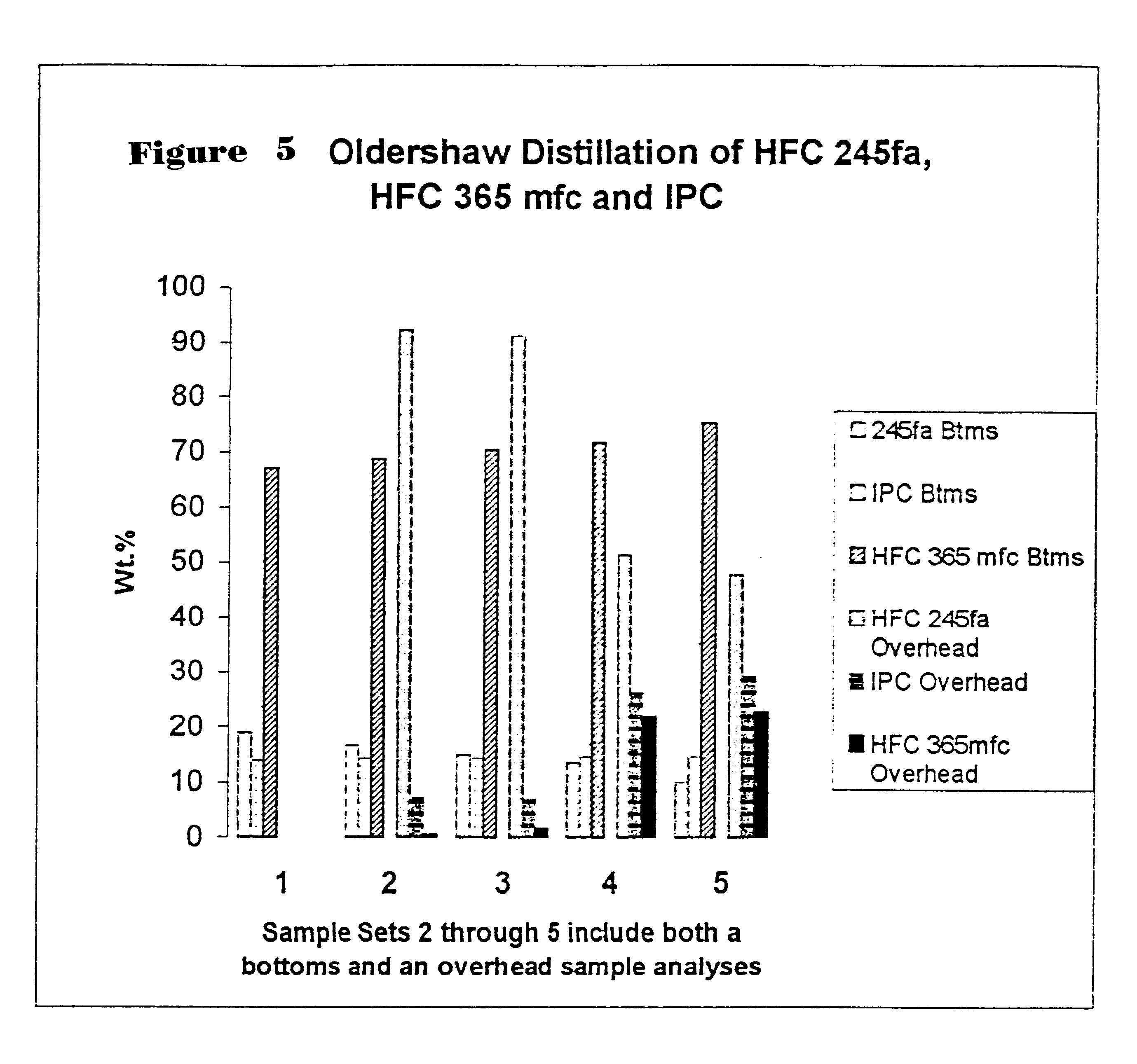

A composition useful as a blowing agent having no flash point or reduced combustibility comprising 2-chloropropane and a gas selected from the group consisting of a fluorohydrocarbon, perfluorocarbons, fluoroethers, hydrofluoropolyethers and mixtures thereof is disclosed. A polyisocyanurate foam or a polyurethane modified polyisocyanurate foam having a mainly closed cell structure and also a method for preparing this foam, the latter comprising closed cells wherein a foam blowing agent consisting of a mixture of 2-chloropropane and one or more HFC compounds including pentafluoropropane, pentafluorobutane, heptafluoropropane, hexafluoropropane or pentafluoroethane are disclosed. Pentanes can be added if desired. Azeotropic mixtures in which 2-chloropropane is an ingredient are disclosed.

Owner:OCCIDENTAL CHEM CORP

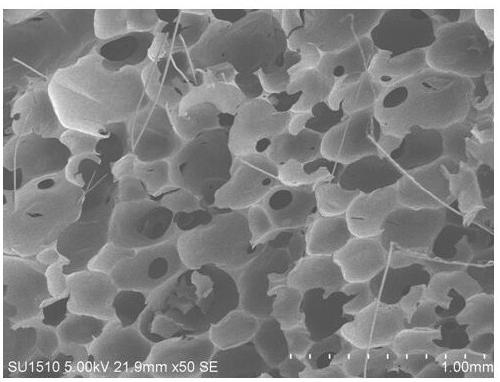

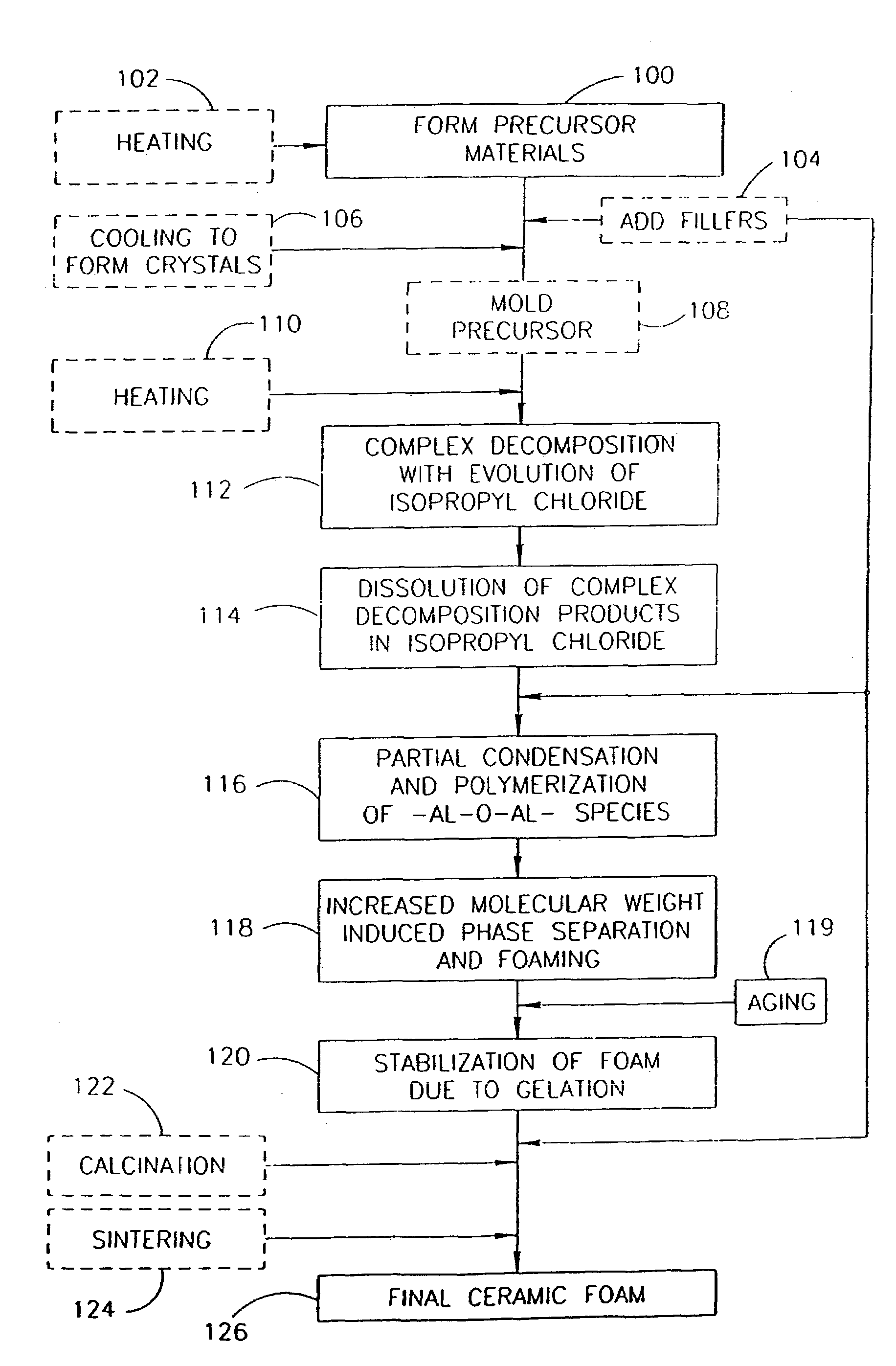

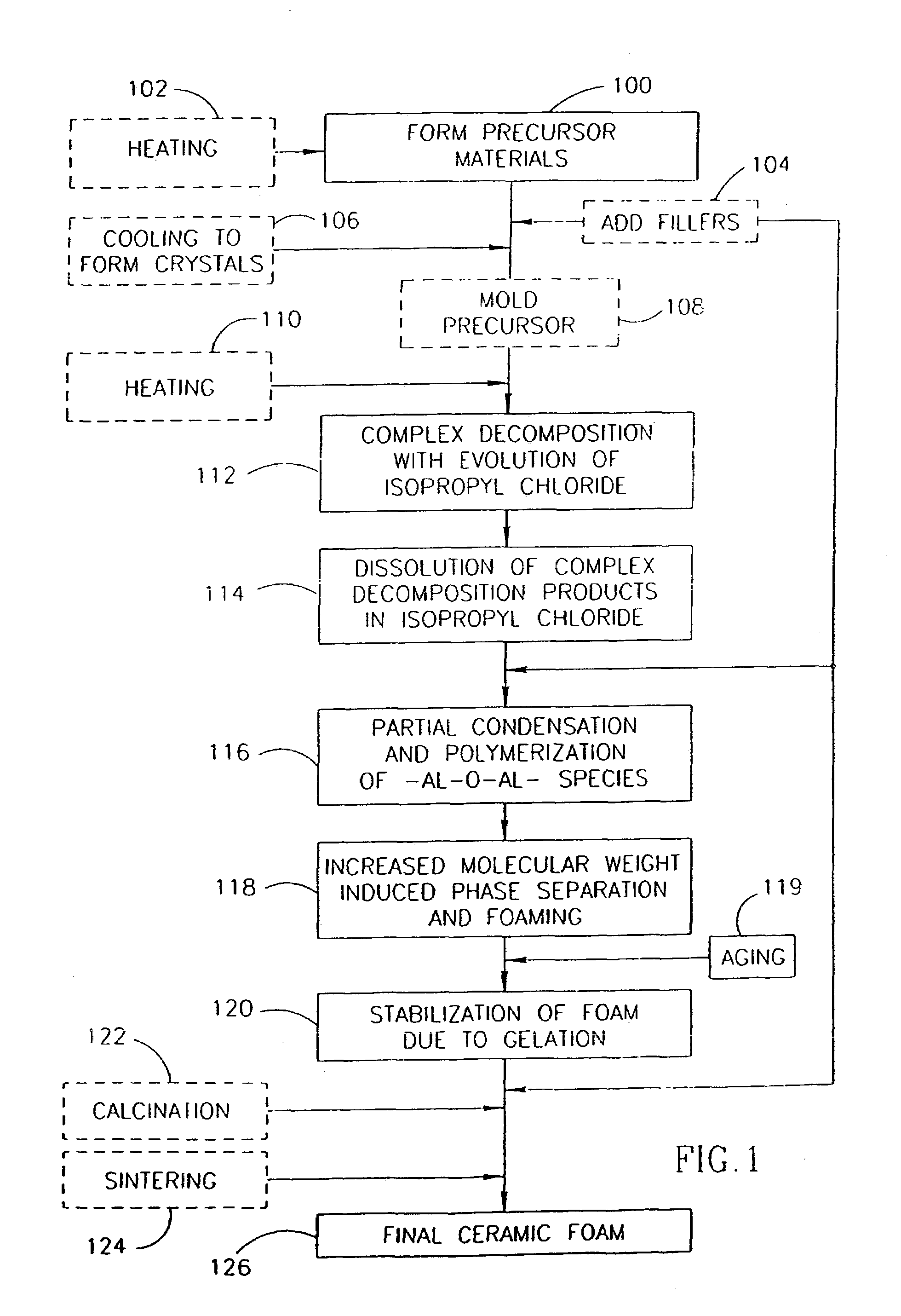

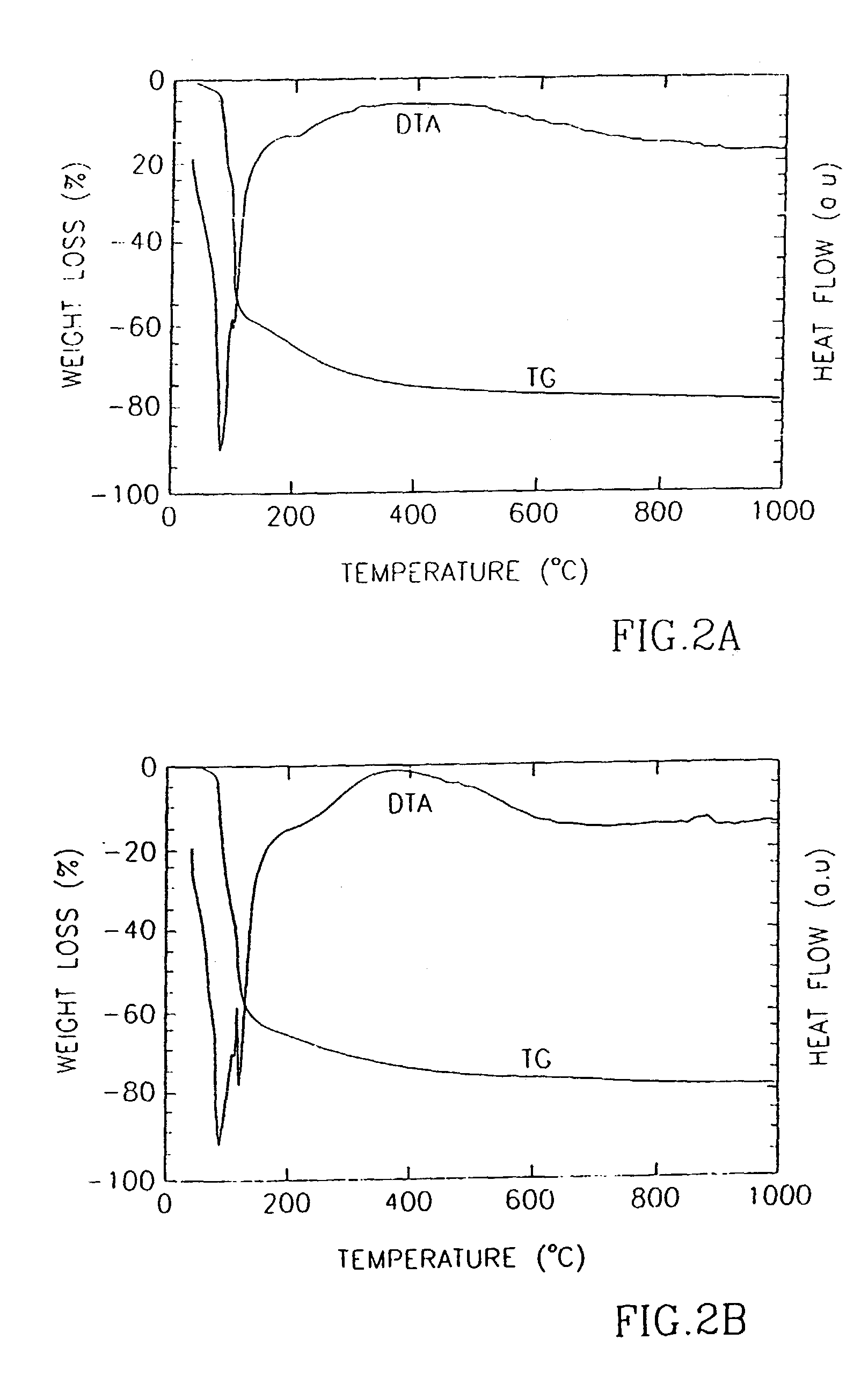

Method of producing ceramic foams

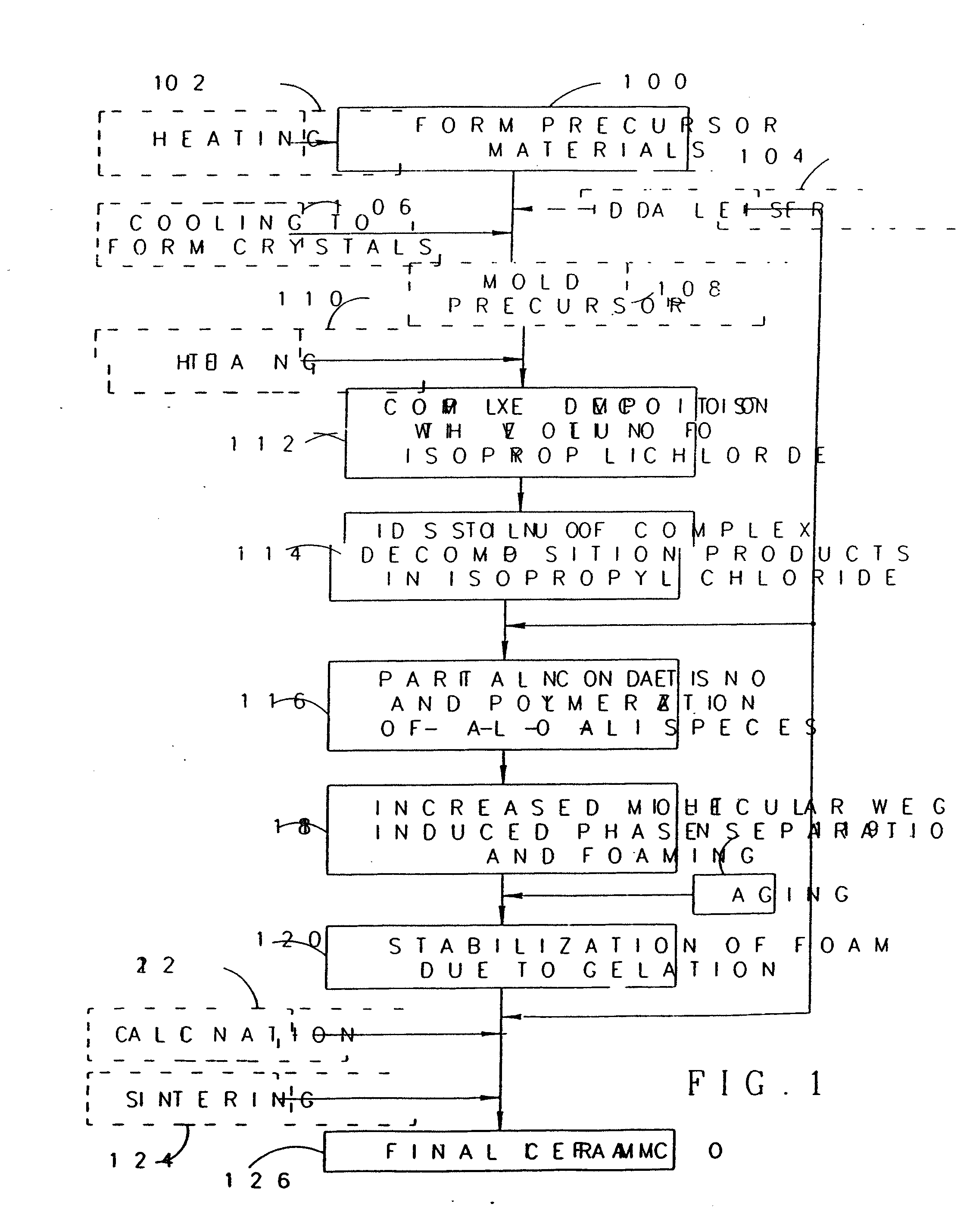

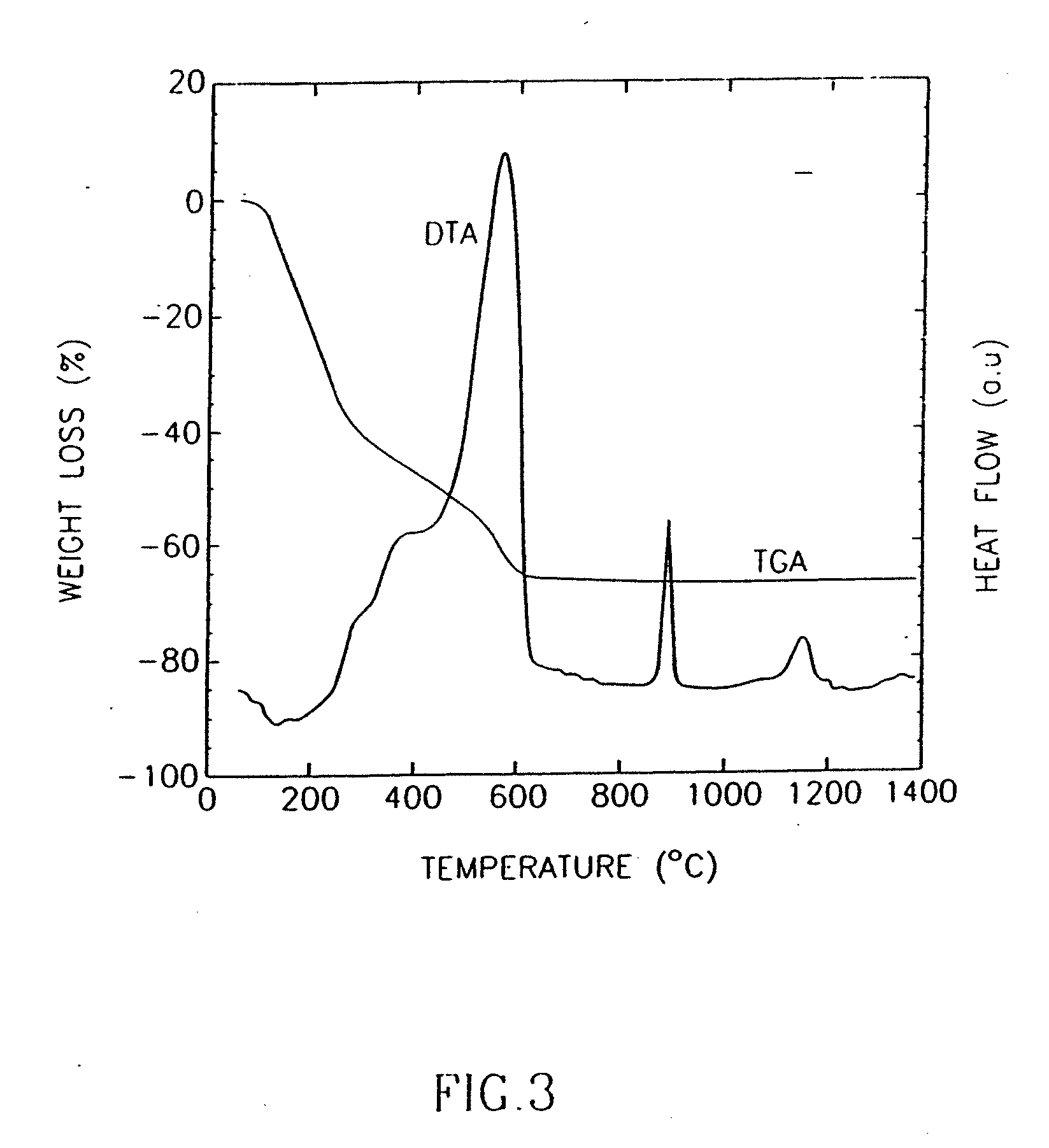

InactiveUS20080058194A1Easy to produceSimple in situ preparationPhysical/chemical process catalystsCeramic shaping apparatusPolymer scienceDecomposition

A process for foaming ceramic foams, in which the ceramic foams are produced from a precursor or a mixture of precursors which contain at least one ceramic-forming element and liberates at least one volatile reaction product during an inorganic gelation process. In one embodiment, foaming is based on a precursor containing crystals of the AICI3(Pri2O) complex. The decomposition of the initial precursor produces polymerizing species dissolved in liquid isopropyl chloride. The solvent and growing AIOxCIy(OPri)z species are mixed homogeneously so that the boiling point of the solution is raised above the boiling point of the pure isopropyl chloride. Polymerization takes place in the liquid until a critical polymer size is attained, whereupon a phase separation into polymer rich and solvent rich regions occurs. Since the expelled solvent is suddenly above its boiling point, bubbles start forming instantly. Foam stabilization takes place as a result of gelation in the polymer rich regions which comprise the cell walls in the foam. The net result of the process is a gelled ultra light foam.

Owner:CELLARIS LTD

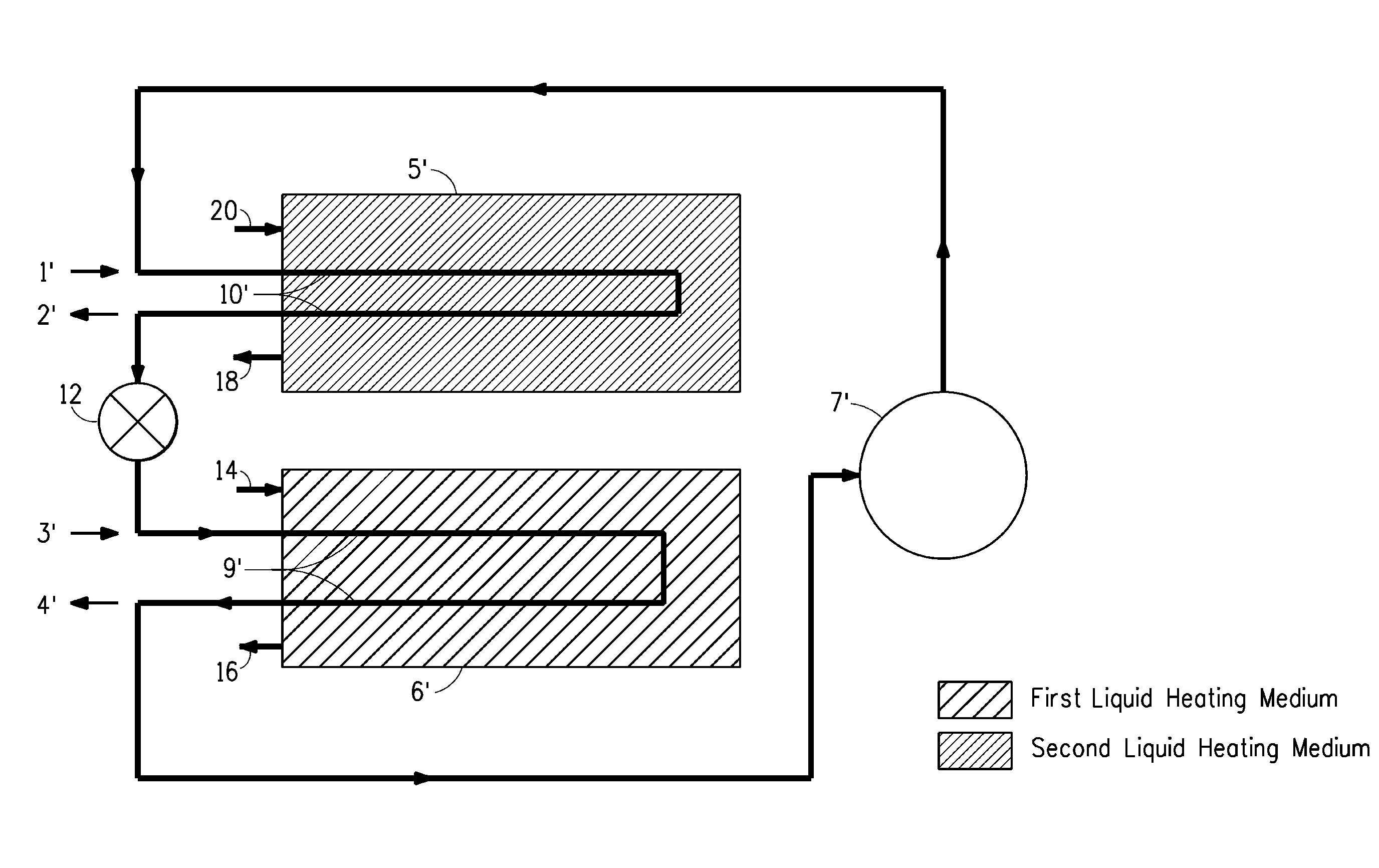

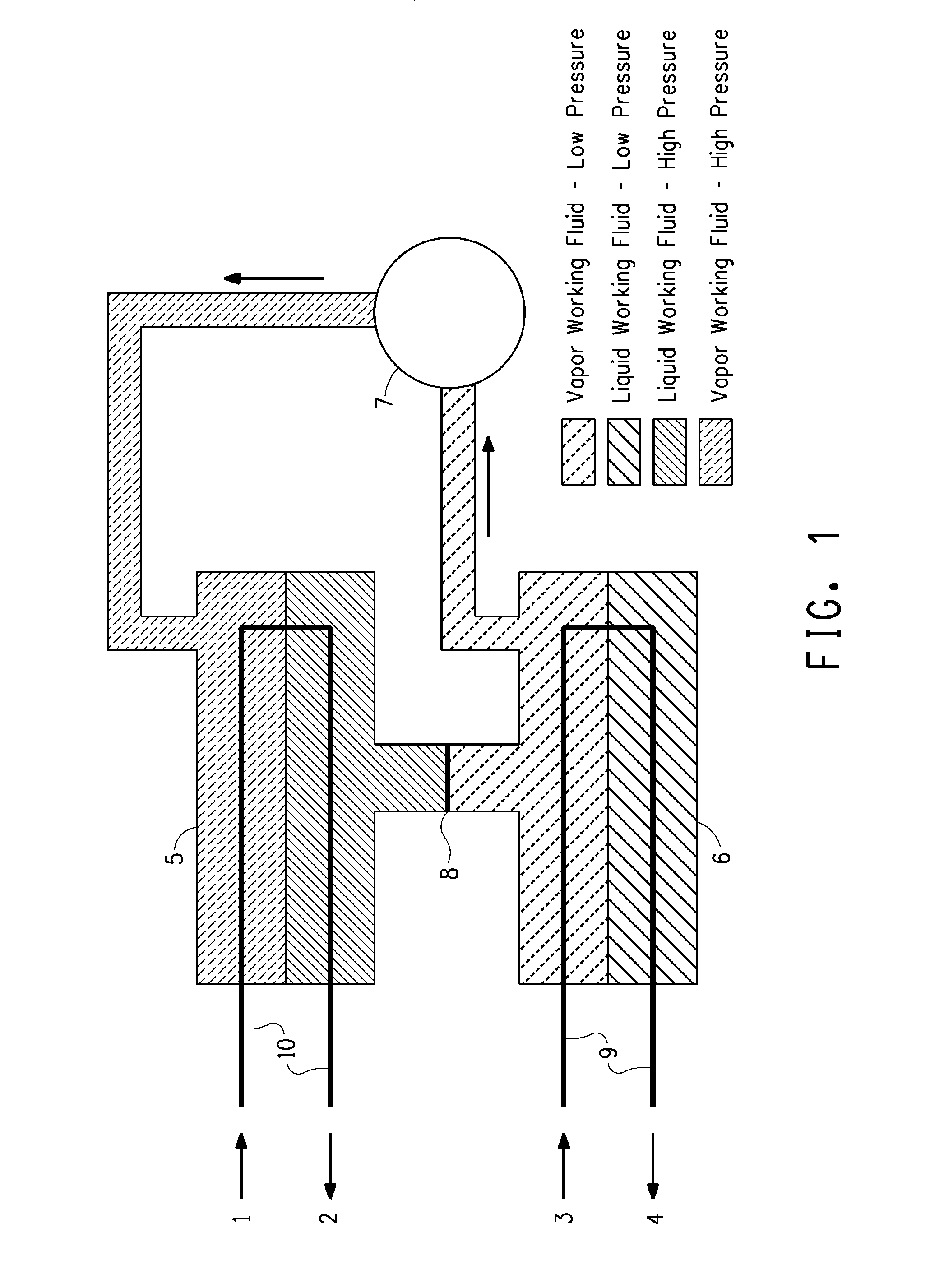

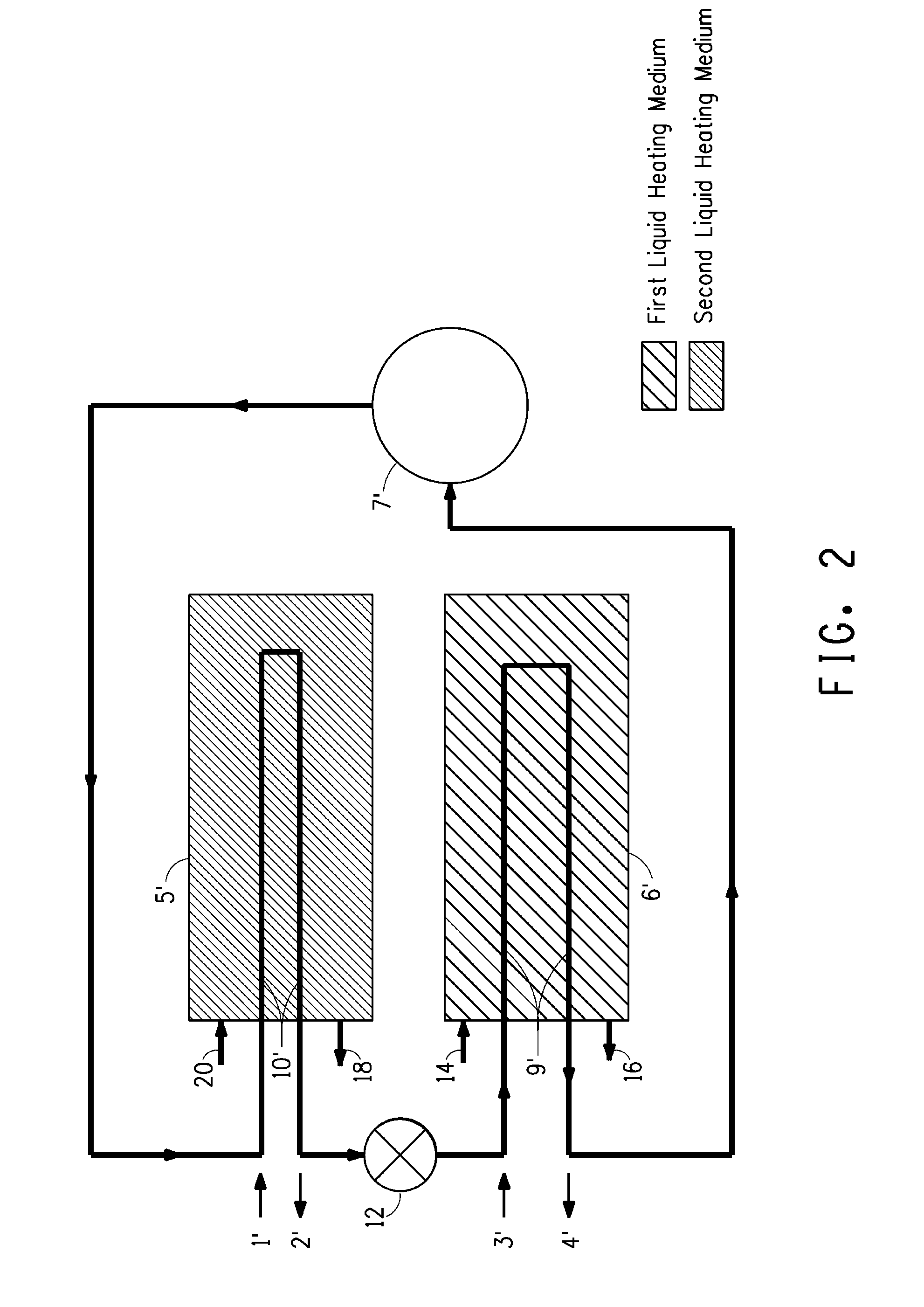

Producing heating using working fluids comprising z-1,1,1,4,4,4-hexafluoro-2-butene

ActiveUS20130298581A1Improve the heating effectHeat pumpsHeat-exchange elementsWorking fluidEngineering

Disclosed herein is a method for producing heating in a high temperature heat pump comprising condensing a vapor working fluid comprising Z-1,1,1,4,4,4-hexafluoro-2-butene, in a condenser, thereby producing a liquid working fluid. Also disclosed herein is a method of raising the maximum feasible condenser operating temperature in a high temperature heat pump apparatus comprising charging the high temperature heat pump with a working fluid comprising Z-1,1,1,4,4,4-hexafluoro-2-butene. Also disclosed herein is a composition comprising: (a) Z-1,1,1,4,4,4-hexafluoro-2-butene; (b) 2-chloropropane; and (c) at least one lubricant suitable for use at a temperature of at least about 150° C.; is wherein the 2-chloropropane is present in an amount effective to form an azeotrope or azeotrope-like combination with the Z-1,1,1,4,4,4-hexafluoro-2-butene. Also disclosed herein is a high temperature heat pump apparatus containing a working fluid comprising Z-1,1,1,4,4,4-hexafluoro-2-butene.

Owner:THE CHEMOURS CO FC LLC

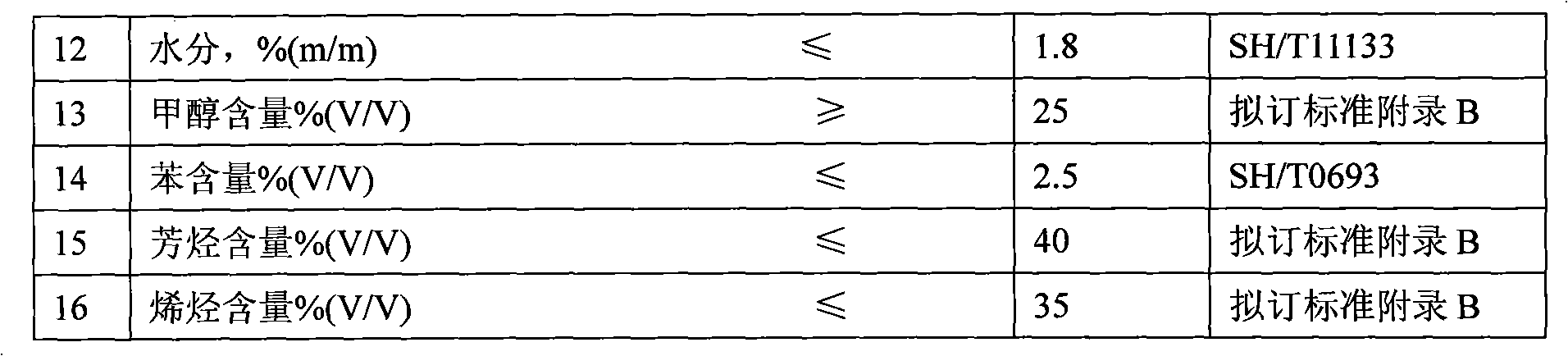

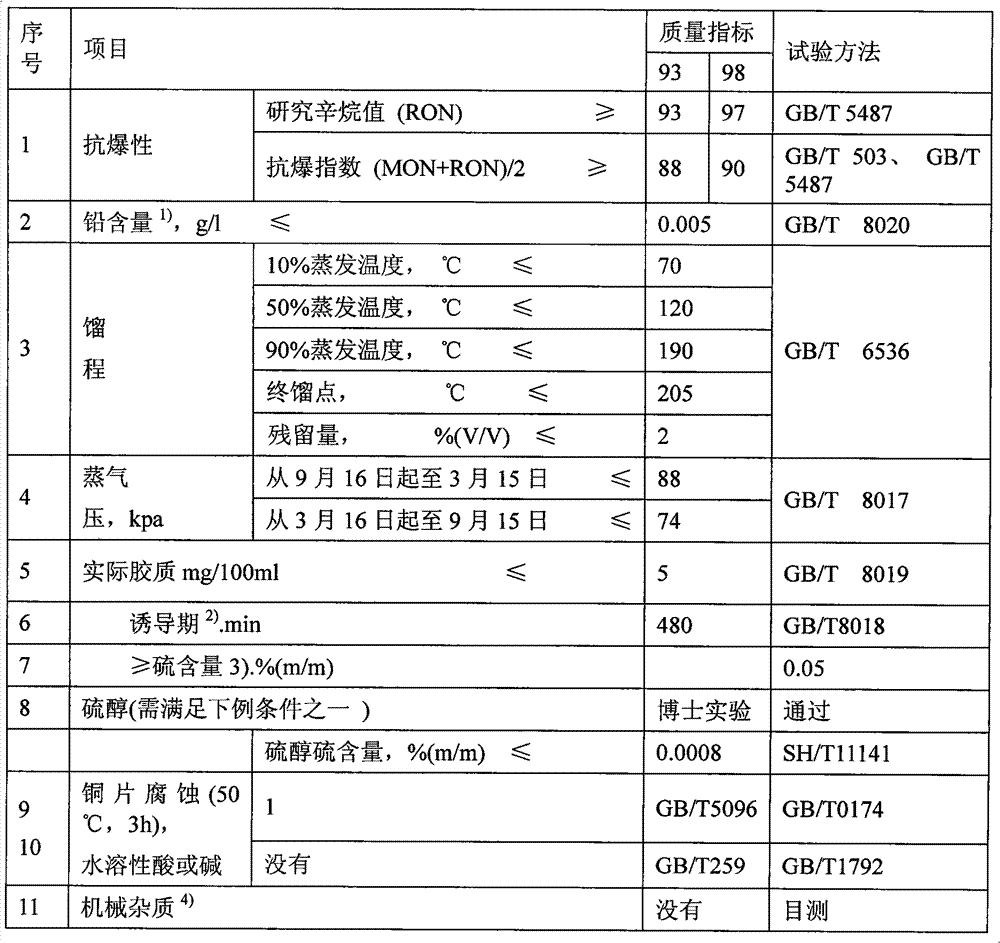

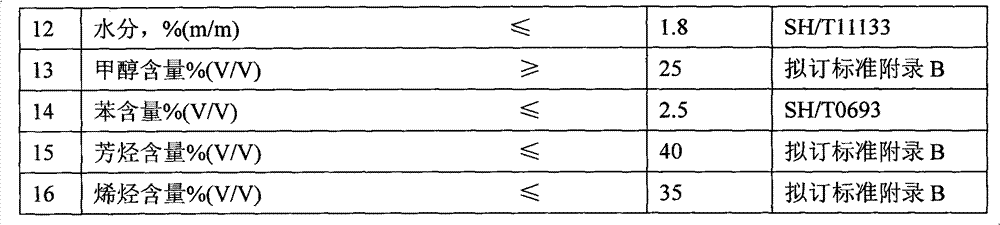

Alcohol ether gasoline used in new energy vehicles

InactiveCN101538491AReduce consumptionReduce pollutionLiquid carbonaceous fuelsNew energyLiquid fuel

The invention relates to a liquid fuel, and particularly a liquid carbonaceous fuel of the mixture of hydrocarbons and alcohol ether. The alcohol ether gasoline used in new energy vehicles comprises 25 to 85 percent of gasoline constituents and 15 to 75 percent of alcohol ether-major other chemical raw materials by weight percentage, wherein the components of the alcohol ether-major other chemical raw materials and the weight proportions thereof in the alcohol ether gasoline used in new energy vehicles are as follows: industrial methanol: 10 to 60 percent, n-hexane: 0 to 3 percent, isopropyl chloride: 0 to 1 percent, trichloroethylene: 0 to 1 percent, epichlorohydrin: 0.2 to 3 percent, bromoethanol: 0.2 to 2 percent, isodibutyl ether: 0.5 to 2 percent, ethylene glycol monobutyl ether: 0 to 1 percent, lauric acid : 0.4 to 2 percent, methyl chloroacetate: 0 to 4 percent, isopropyl nitrate: 0.2 to 4 percent, trimethyl phosphate: 0 to 3 percent, nitromethane: 0.1 to 1 percent, nitroethane: 0 to 1 percent, nitroguanidine: 0 to 3 percent, cyclopentadiene: 0 to 4 percent, and n-butylamine: 0 to 1 percent.

Owner:陈斌

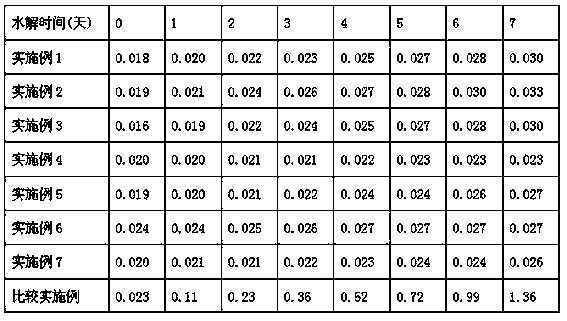

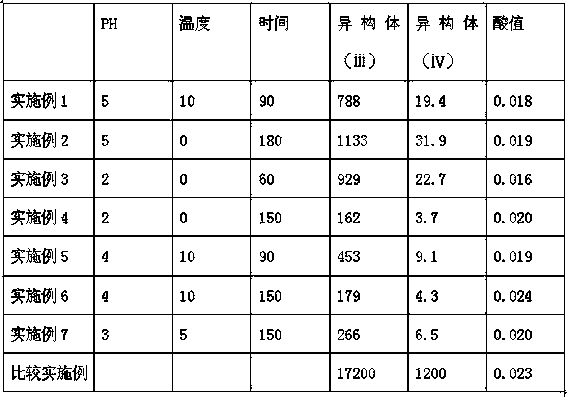

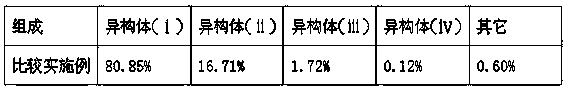

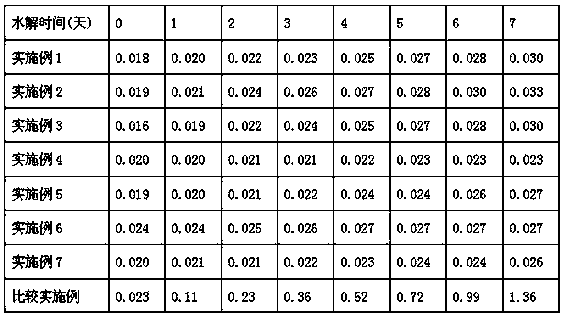

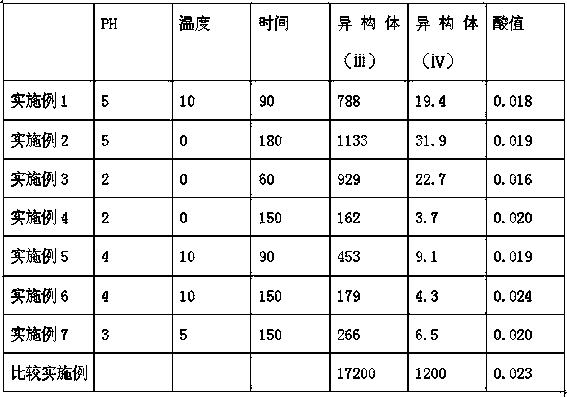

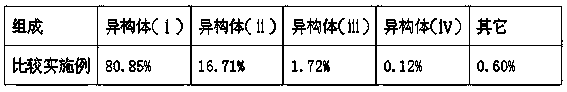

Preparation method for 3-(2-isopropyl chloride) phosphate ester fire-retardant with high resistance to hydrolysis

ActiveCN103408584AImprove water resistanceReasonable designPhosphorus organic compoundsHigh resistancePhosphate

A preparation method for a 3-(2-isopropyl chloride) phosphate ester fire-retardant with high resistance to hydrolysis belongs to the technical field of chemical engineering. The method comprises the following steps: allowing phosphorus oxychloride and epoxypropare to react under the action of a Lewis acid catalyst to synthesize a TCPP crude product; allowing the TCPP crude product to be subjected to hydrolytic treatment under the acidic condition, washing, dehydrating and filtering so as to prepare the 3-(2-isopropyl chloride) phosphate ester fire retardant with high resistance to hydrolysis. Due to the adoption of the method, the content of the 3-(2-isopropyl chloride) phosphate ester in the TCPP crude product can be reduced to 100 ppm, even 10 ppm, the content of the 2-(2-propyl chloride) (2-isopropyl chloride) phosphate ester can be reduced to 5000 ppm, even 500 ppm, and accordingly, the hydrolysis resistance of the 3-(2-isopropyl chloride) phosphate ester is finally improved.

Owner:ZHEJIANG WANSHENG

Cleaning treatment technology for isopropyl chloride cyanuric acid production waste water

ActiveCN102897948AAchieving zero emissionsMaximize resource utilizationMultistage water/sewage treatmentNature of treatment waterChemical industryElectrolysis

The invention belongs to the technical field of chemical industry production waste water treatment and discloses cleaning treatment technology for isopropyl chloride cyanuric acid production waste water; a treatment method of this technology comprises the following steps: chloridizing sodium dichloro isocyanurate mother liquor to recycle trichloroisocyanuric acid; acidizing mother liquid, blowing chlorine and by-producing sodium chlorate; alkalifying and reducing the mother liquid so as to recycle cyanuric acid monosodium salt, reducing mother liquid total ammonium; after acidizing the mother liquid, reacting tripolycyanamide with residual cyanuric acid of the mother liquid so as to generate sparingly-soluble melamine cyanurate sediment; separating sediment so as to reduce mother liquid total ammonium; then, absorbing the mother liquid total ammonium by special active carbon so as to further reduce the mother liquid total ammonium; desorbing saturated active carbon by dilute liquid alkali, recycling cyanuric acid trisodium salt; and oxidizing absorbed mother liquid by sodium hypochlorite solution so as to dispel residual cyanuric acid, wherein the total ammonium content of the mother liquid is less than or equal to 2mg / L; treated qualified saline is transferred to a chlor-alkali plant so as to test salt; after tested saline is refined, the tested saline is used for electrolytically producing caustic soda and chorine; isopropyl chloride cyanuric acid is produced again by the caustic soda and the chorine so as to form a circular economic industry chain; and waste water zero emission is realized.

Owner:河北冀衡化学股份有限公司

After-treatment method of crude tris-(2-isopropyl chloride) phosphate

ActiveCN102002068AEliminate odorEasy to removePhosphorus organic compoundsPhosphoric Acid EstersAlkaline water

The invention relates to an after-treatment method of crude tris-(2-isopropyl chloride) phosphate, in particular to a treatment method which can effectively remove the stinky 2-methyl-pentanal in the tris-(2-isopropyl chloride) phosphate. The method is characterized by comprising the steps of: introducing a certain amount of ozone in the crude tris-(2-isopropyl chloride) phosphate obtained by reaction; directly oxidizing the insoluble 2-methyl-pentanal generated by reaction into acidic materials such as 2- methyl-valeric acid and the like soluble in an alkaline solution; and conveniently removing the acidic materials in the subsequent washing process to ensure that the obtained tris-(2-isopropyl chloride) phosphate does not contain the 2-methyl-pentanal which stinks. The method of the invention reduces the content of the stinky 2-methyl-pentanal in the tris-(2-isopropyl chloride) phosphate from about 200-300ppm to less than 5ppm; and when the product is applied to the interior materials of automobiles or furniture and the like, the stink is eliminated, and therefore, the product is in the favor of consumers.

Owner:ZHEJIANG WANSHENG

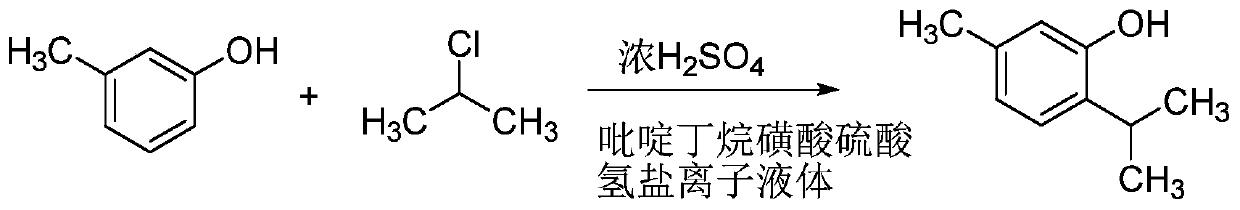

Preparation method of 3-methyl-4-isopropylphenol

InactiveCN103044205AMild reaction conditionsHigh yieldOrganic chemistryOrganic compound preparationHigh pressure4-isopropylphenol

The invention discloses a preparation method of 3-methyl-4-isopropylphenol. The method comprises the following steps of: (1) dissolving m-toluidine into sulfuric acid to react with an isopropylation reagent to obtain 3-methyl-4-isopropylaniline, wherein the isopropylation reagent is isopropanol, propylene or 2-chloropropane; (2) hydrolyzing the 3-methyl-4-isopropylaniline to obtain a reaction solution containing the 3-methyl-4-isopropylphenol, wherein the hydrolysis is diazo hydrolysis or high-temperature high-pressure hydrolysis by using the sulfuric acid as a solvent; and (3) distilling the reaction solution containing the 3-methyl-4-isopropylphenol and performing solvent refining to obtain needle-like crystalline 3-methyl-4-isopropylphenol. The method disclosed by the invention has the characteristics of mild reaction condition, high yield, few by-products and little pollution; and the preparation method effectively solves difficulties such as many by-products, severe condition and great pollution in the existing preparation process of the 3-methyl-4-isopropylphenol.

Owner:ZHEJIANG DINGLONG TECH

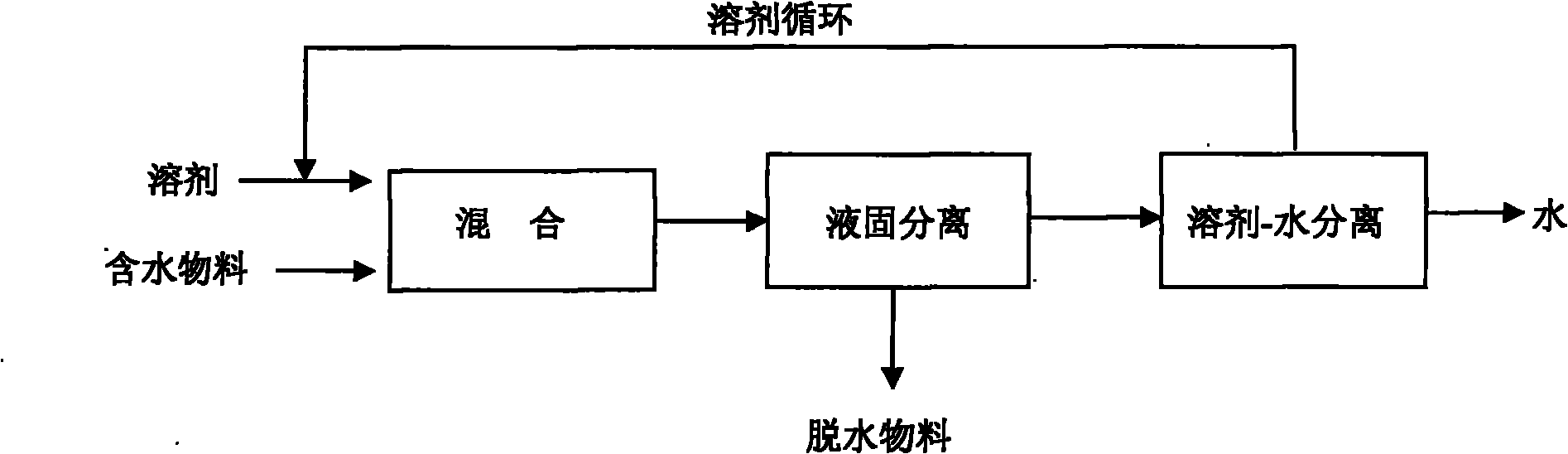

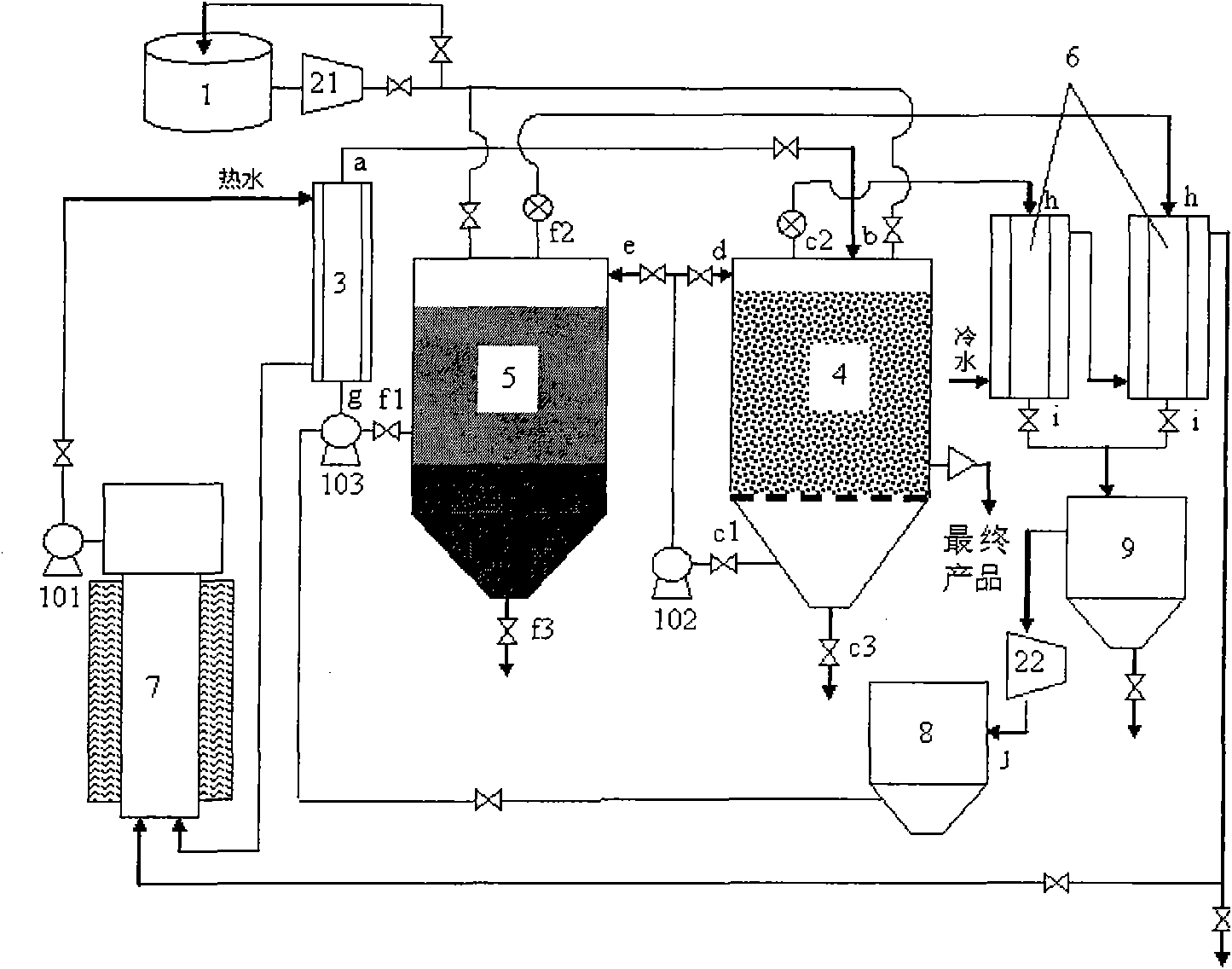

Substitution and dehydration method for water contained solid materials and device

InactiveCN101780390AAchieve recyclingReduce moisture contentGas-gas reaction processesDichloropropaneEpoxy

The invention provides a substitution and dehydration method for water contained solid materials and a device. In the method, the material is dehydrated by organic solvents with low boiling point and low latent heat, which are liquid at 0 DEG C to 60 DEG C and 0.1 MPa to 3 MPa, such as propane, dichloropropane, epoxy ethane, dimethyl ether, dimethyl sulphide and a mixture thereof or a mixture of the organic solvents and a surface active agent with low adsorbability and low latent heat, in dehydration equipment through the action of leaching, absorbing, substituting and the like and liquid-solid separation. The solvents and water can be separated and recycled by evaporating water bearing solvents in separation equipment and condensating the solvents in condensation recovery equipment or layering the solvents and water. Because the latent heat of the solvents is far less than that of the water, the solvent substitution and dehydration method and the device thereof of the invention can obviously reduce power consumption in the dehydration process, solve the problems of burning, wall built-up and the like through low operation temperature, and are suitable for dehydration of solid materials with different water contents.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

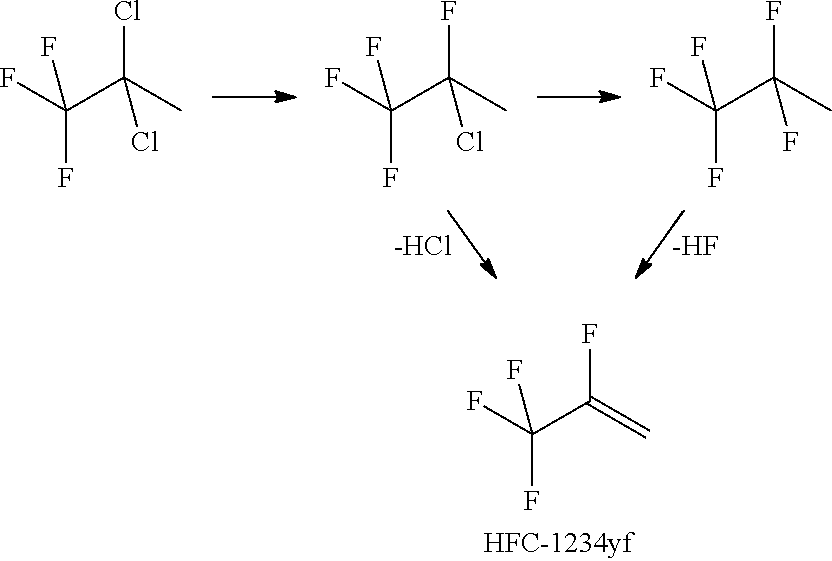

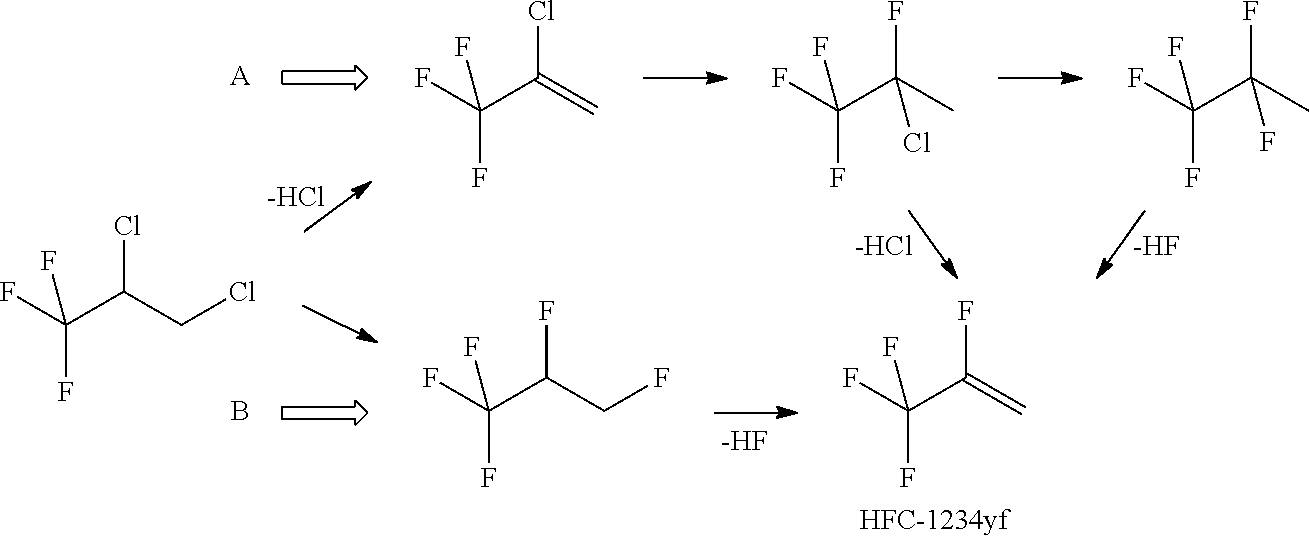

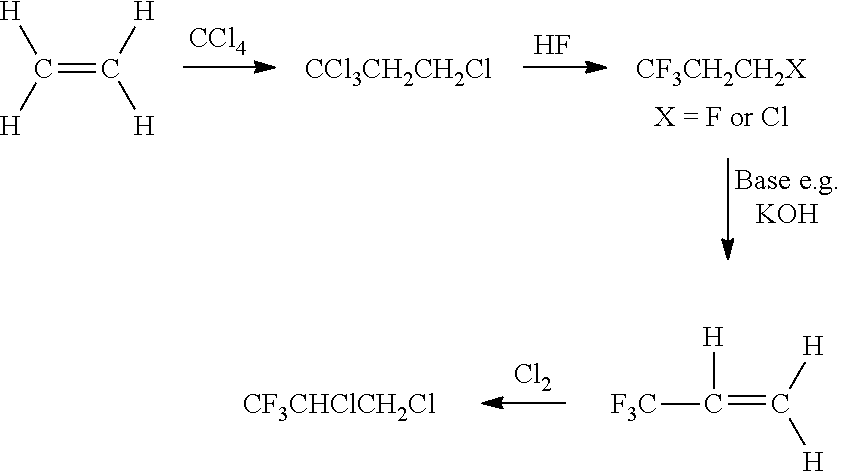

Process for dehydrochlorinating 1,1,1,2-tetrafluoro-2-chloropropane to 2,3,3,3-tetrafluoropropene in the presence of an alkali metal-doped magnesium oxyfluoride catalyst and methods for making the catalyst

ActiveUS8053612B2Preparation by dehalogenationPreparation by hydrogen halide split-offDivalent metal ionsOxygen

Owner:HONEYWELL INT INC

Polyester fabric foamed flame-retardant coating adhesive

InactiveCN105507004AMeet the new demands of finishingMeet the technical requirements of foam finishingHeat resistant fibresPolyesterPhosphate

The invention relates to a polyester fabric foamed flame-retardant coating adhesive which comprises 100 parts of matrix emulsion composed of 20-50 parts of vinyl acetate polymer and 50-80 parts of ethylene-vinyl acetate copolymer resin, 10-23 parts of tri(2, 3-dibromopropyl) isocyanuric acid ester, 5-8 parts of tri(isopropyl chloride) phosphate, 1-3 parts of associative waterborne polyurethane emulsion, 5-10 parts of polyacrylate emulsion, 2-4 parts of fumed silica, 0.5-1.0 part of organic silicone emulsion and 0.5-2 parts of straight chain alcohol sulfate. The polyester fabric foamed flame-retardant coating adhesive has the advantages that a composite foamed flame-retardant coating adhesive system which has good flame-retardant effect is provided, and washing durability and mechanical resistance of the flame-retardant coating adhesive on fabric are improved.

Owner:HANGZHOU FUYANG HONGXIANG TECH SERVICES CO LTD

Process for Preparing R-1234yf By Base Mediated Dehydrohalogenation

ActiveUS20130274528A1Preparation by hydrogen halide split-offOrganic compound preparationPolymer scienceDehydrohalogenation

Owner:MEXICHEM AMANCO HLDG DE C V

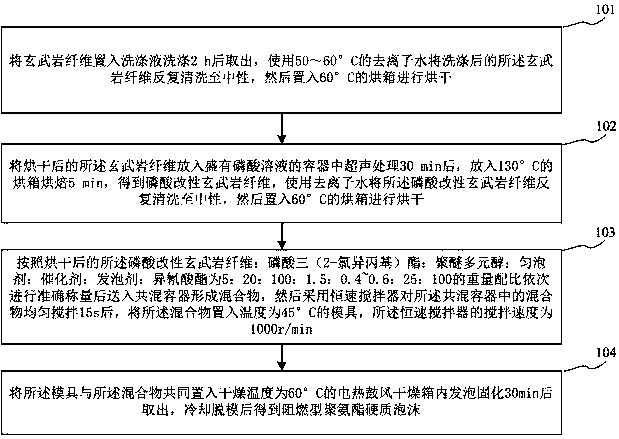

Flame-retardant type polyurethane rigid foam and preparation method thereof

InactiveCN109054355AImprove mechanical propertiesImprove flame retardant and smoke suppression performancePhosphoric acidBasalt fiber

The invention discloses a flame-retardant type polyurethane rigid foam and a preparation method thereof, and relates to the technical field of processing of materials. The flame-retardant type polyurethane rigid foam and the preparation method have the advantages that the surface of basalt fiber is modified by phosphoric acid to obtain the phosphoric acid-modified basalt fiber, so that the surfaceactivity of the basalt fiber is improved; the phosphoric acid-modified basalt fiber is mixed with phosphotriester-(2-isopropyl chloride) to form a flame-retardant agent for preparing the flame-retardant type polyurethane rigid foam, so as to solve the problems of poor compatibility and low mechanical property due to direct compounding of the basalt fiber and the polyurethane rigid foam matrix, and reach the technical effects of accelerating the formation of a crosslinking network of a polyurethane foam system and improving the mechanical property of the flame-retardant type polyurethane rigidfoam; the phosphoric acid-modified basalt fiber and the phosphotriester-(2-isopropyl chloride) as the flame-retardant agent can be uniformly dispersed into the flame-retardant type polyurethane rigidfoam matrix, so as to reduce the heat release rate and smoke production amount of the polyurethane foam, and reach better flame-retardant and smoke-inhibiting properties of the polyurethane foam.

Owner:JIAXING UNIV

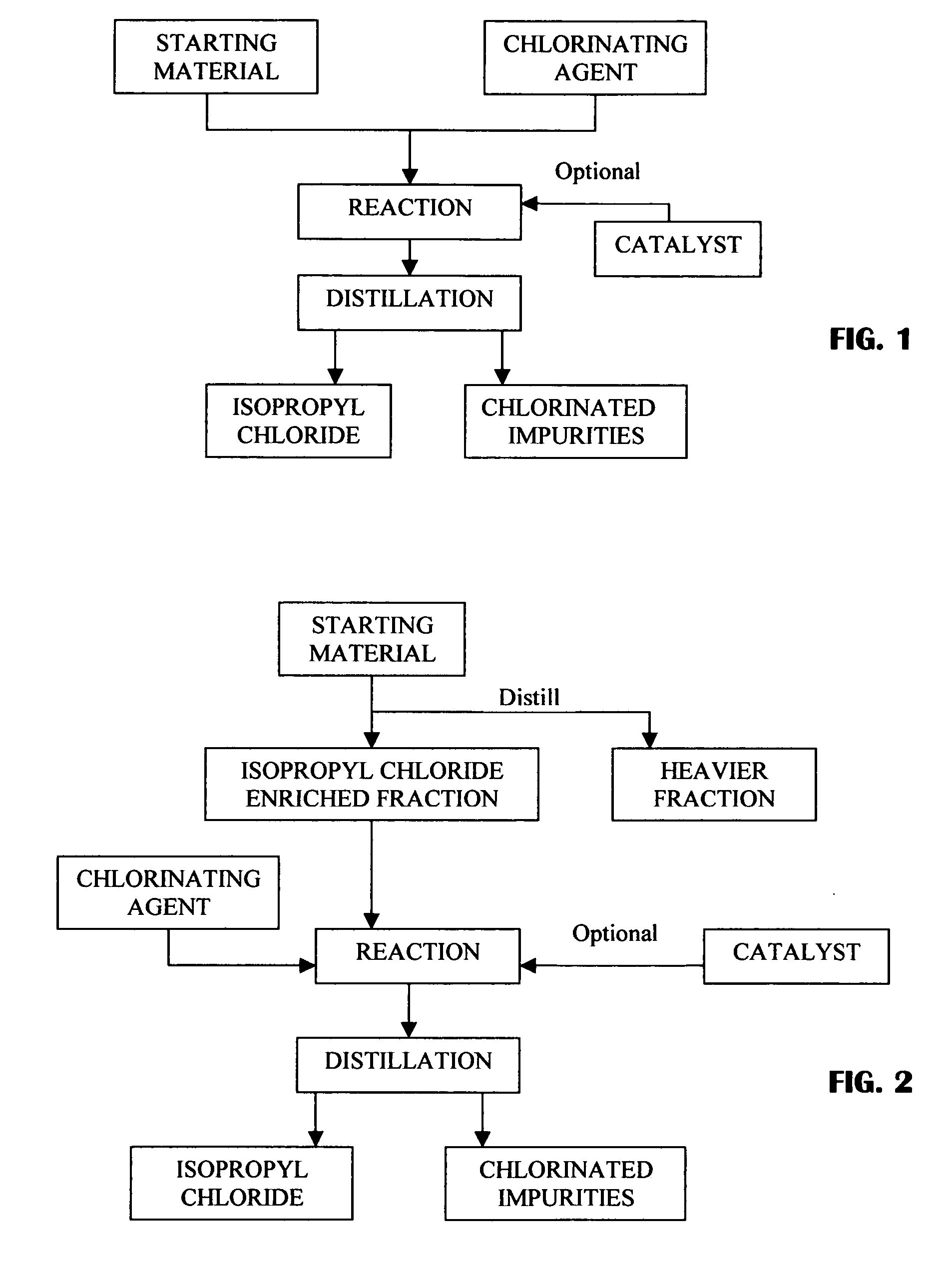

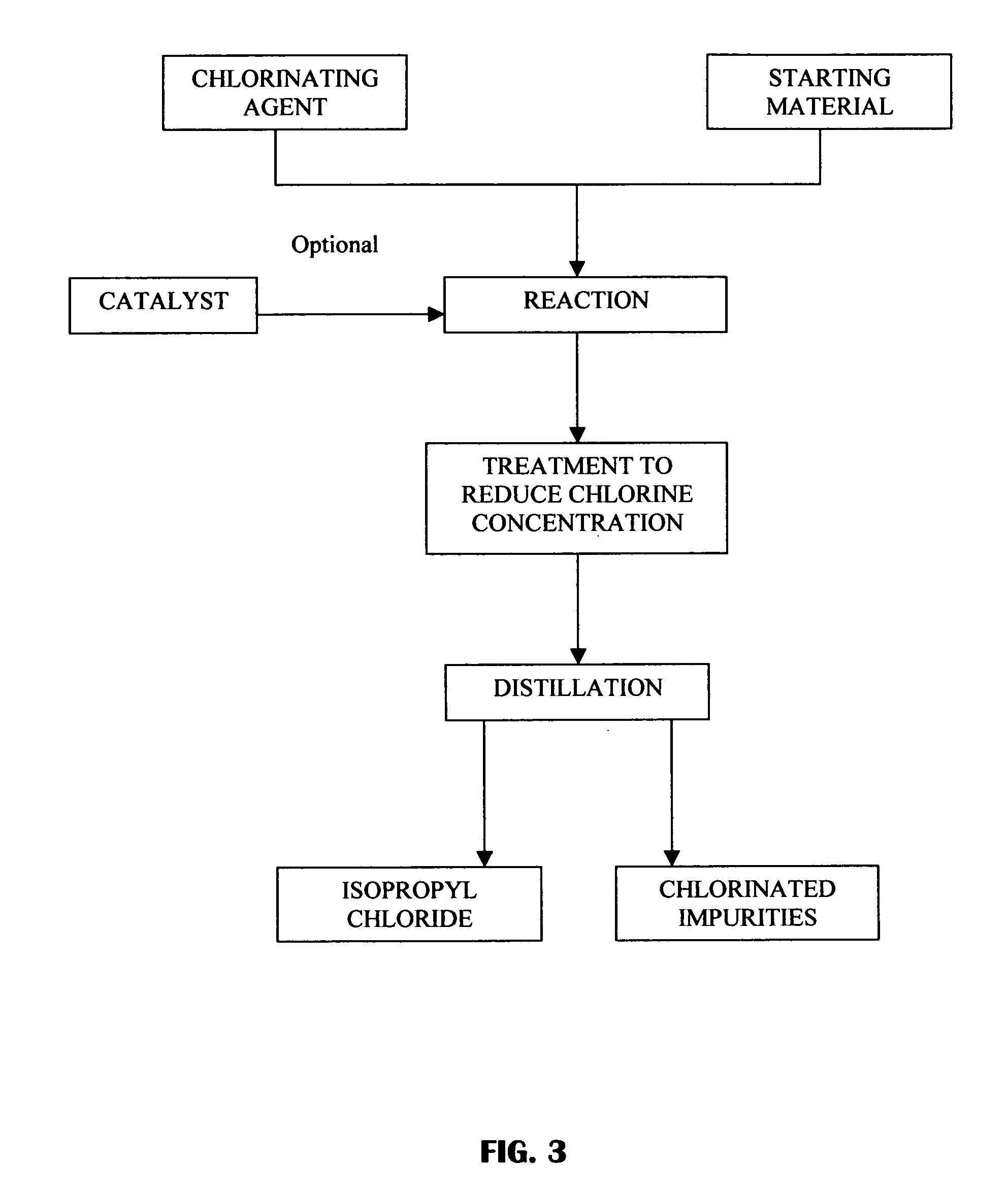

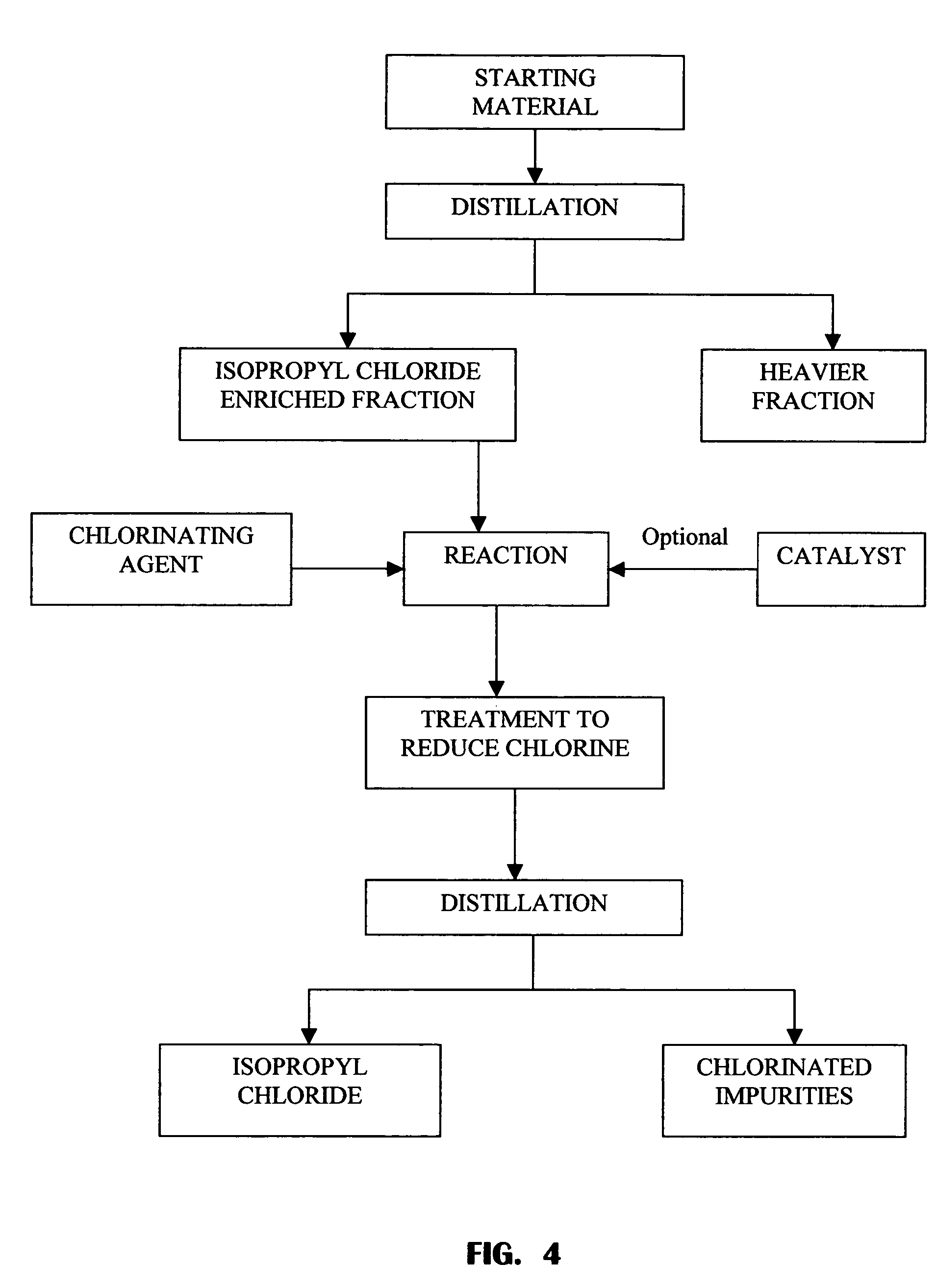

Method for producing isopropyl chloride for use as a foam-blowing agent

Isopropyl chloride (IPC) is prepared by the chlorination of propane or propene or propyne, or by any other means resulting in an IPC product containing significant amounts of undesired olefins. Such impure product may be purified by chlorination followed by distillation, by distillation followed by chlorination followed by distillation, by chlorination followed by treatment to reduce chlorine concentration followed by distillation, or by distillation followed by chlorination followed by treatment followed by distillation.

Owner:OCCIDENTAL CHEM CORP

Method of producing ceramic foams

InactiveUS7306762B2Inherent simplicityEasy to producePhysical/chemical process catalystsCeramic shaping apparatusPolymer scienceBoiling point

A process for foaming ceramic foams, in which the ceramic foams are produced from a precursor or a mixture of precursors which contain at least one ceramic-forming element and liberates at least one volatile reaction product during an inorganic gelation process. In one embodiment, foaming is based on a precursor containing crystals of the AlCl3(Pri2O) complex. The decomposition of the initial precursor produces polymerizing species dissolved in liquid isopropyl chloride. The solvent and growing AlOxCly(OPri)z species are mixed homogeneously so that the boiling point of the solution is raised above the boiling point of the pure isopropyl chloride. Polymerization takes place in the liquid until a critical polymer size is attained, whereupon a phase separation into polymer rich and solvent rich regions occurs. Since the expelled solvent is suddenly above its boiling point, bubbles start forming instantly. Foam stabilization takes place as a result of gelation in the polymer rich regions which comprise the cell walls in the foam. The net result of the process is a gelled ultra light foam.

Owner:CELLARIS LTD

Alcohol ether gasoline used in new energy vehicles

InactiveCN101538491BEasy to startImprove latent heat of evaporationLiquid carbonaceous fuelsLiquid fuelTrichloroethylene

Owner:陈斌

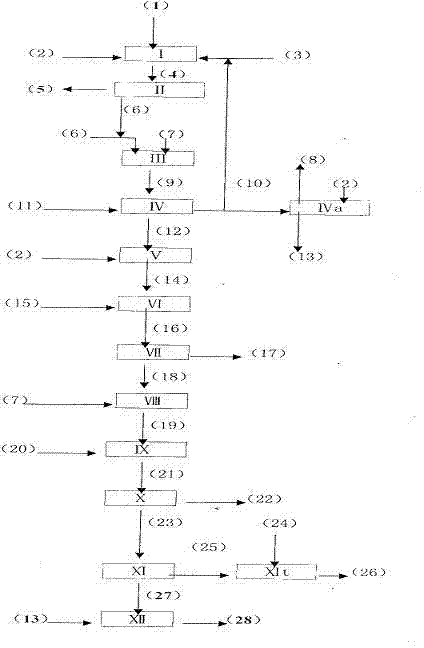

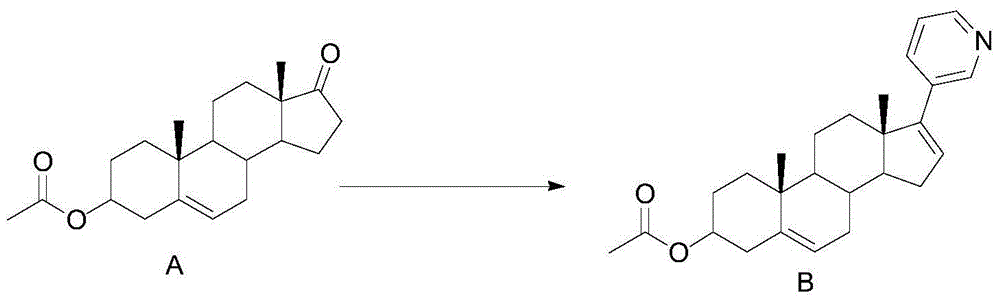

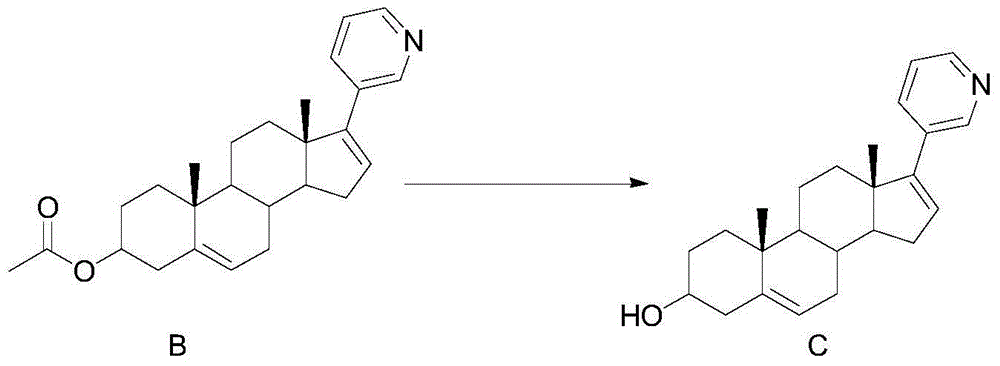

Synthesis method of 17-(3-pyridyl)-androst-4, 16-diene-3beta-ol acetate

InactiveCN105646636AHigh purityReaction raw materials are cheap and easy to obtainSteroidsSynthesis methodsGrignard reagent

The invention discloses a synthesis method of 17-(3-pyridyl)-androst-4, 16-diene-3beta-ol acetate. The reaction route is shown as the following: preparing a Grignard reagent from isopropyl chloride and magnesium powder, and then conducting Grignard exchange with 3-bromopyridine to obtain a 3-bromopyridine Grignard reagent; in the presence of isopropyl ether as a solvent, adding dehydroepiandrosterone acetate to carry out condensation reaction, then adding a Burgess reagent to perform dehydration so as to obtain an Abiraterone acetate crude product; then carrying out hydrolysis to obtain 17-(3-pyridyl)-androst-4, 16-diene-3beta-ol and performing recrystallization; and then adding an acetylation reagent to carry out reaction so as to obtain the target compound. The method provided by the invention has the advantages of simple operation, cheap and easily available raw materials, mild reaction conditions, low equipment requirement and high total yield, synchronous recovery of the used solvent and the like, and is low in production cost and easy for large-scale production, thus having significant industrial application value.

Owner:重庆瑞泊莱医药科技有限公司

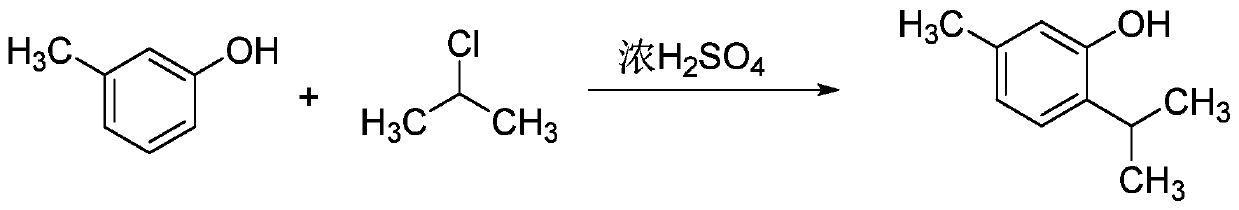

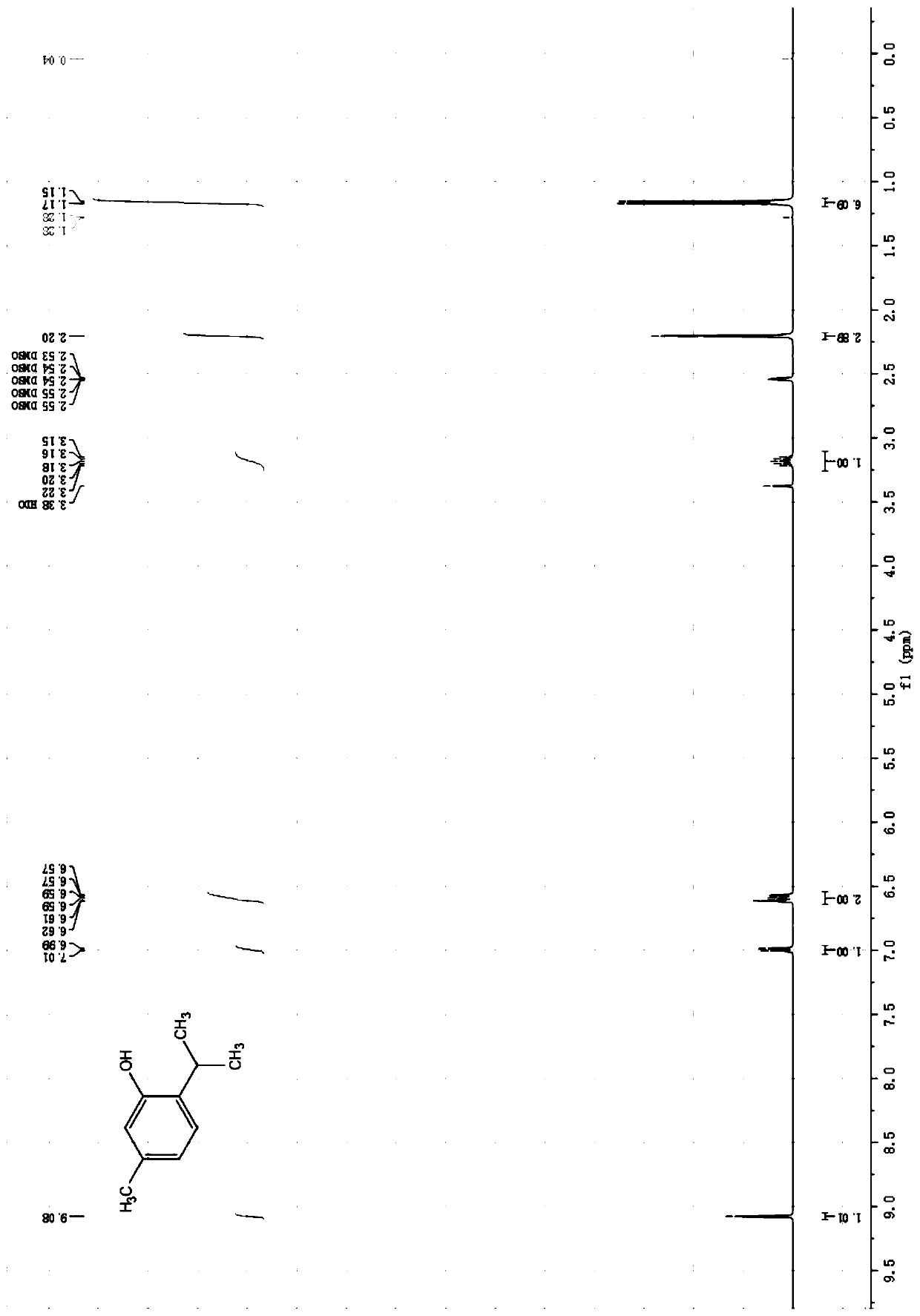

Preparation method of thymol

ActiveCN111499497AEasy to removeAvoid pollutionOrganic chemistryOrganic compound preparationPtru catalystIsopropyl

The invention relates to a preparation method of thymol, and belongs to the technical field of medicine synthesis. The preparation method comprises the steps: carrying out coupling promotion on m-cresol and isopropyl chloride by adding a reaction auxiliary agent concentrated sulfuric acid and an ionic liquid, sealing a tube, carrying out a reaction at the temperature of 120-130 DEG C for 2 h, carrying out a reaction, cooling, dissolving the product in n-heptane, washing with water, concentrating and crystallizing to obtain the target product. The byproduct obtained by the method is easy to separate from the product, the production cost of the product is reduced, an expensive catalyst is not needed, the reaction time is short, the method is environment-friendly, the conversion rate of the target product is effectively improved, the purification is easy, the purity of the obtained product is high, and the method can be applied to reference substance research.

Owner:ZHANGZHOU SHUIXIAN PHARMA CO LTD

Preparation method for 3-(2-isopropyl chloride) phosphate ester fire-retardant with high resistance to hydrolysis

ActiveCN103408584BImprove water resistanceReasonable designPhosphorus organic compoundsHigh resistancePhosphate

A preparation method for a 3-(2-isopropyl chloride) phosphate ester fire-retardant with high resistance to hydrolysis belongs to the technical field of chemical engineering. The method comprises the following steps: allowing phosphorus oxychloride and epoxypropare to react under the action of a Lewis acid catalyst to synthesize a TCPP crude product; allowing the TCPP crude product to be subjected to hydrolytic treatment under the acidic condition, washing, dehydrating and filtering so as to prepare the 3-(2-isopropyl chloride) phosphate ester fire retardant with high resistance to hydrolysis. Due to the adoption of the method, the content of the 3-(2-isopropyl chloride) phosphate ester in the TCPP crude product can be reduced to 100 ppm, even 10 ppm, the content of the 2-(2-propyl chloride) (2-isopropyl chloride) phosphate ester can be reduced to 5000 ppm, even 500 ppm, and accordingly, the hydrolysis resistance of the 3-(2-isopropyl chloride) phosphate ester is finally improved.

Owner:ZHEJIANG WANSHENG

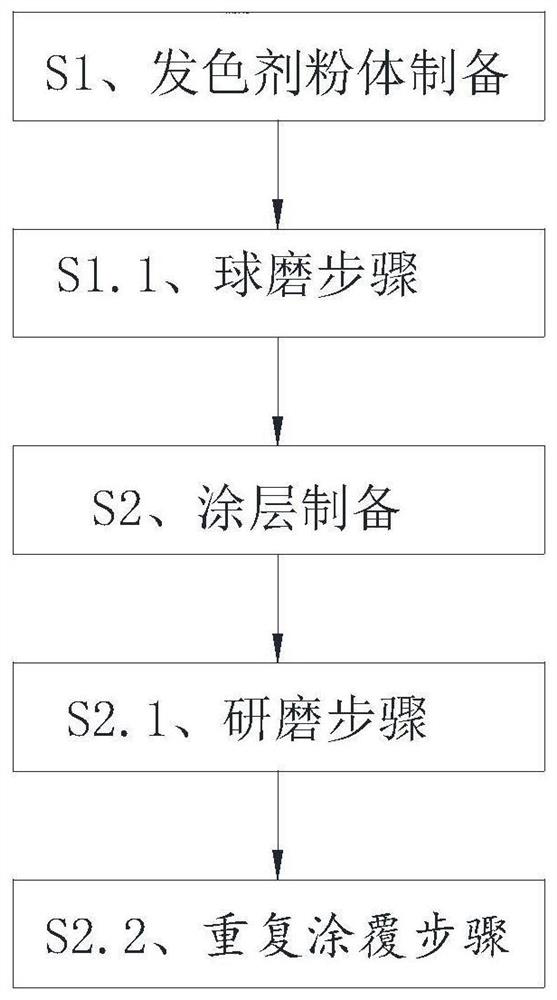

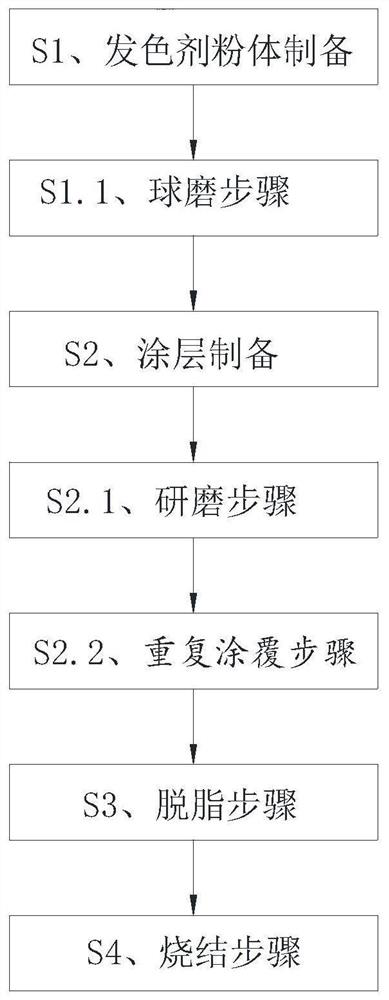

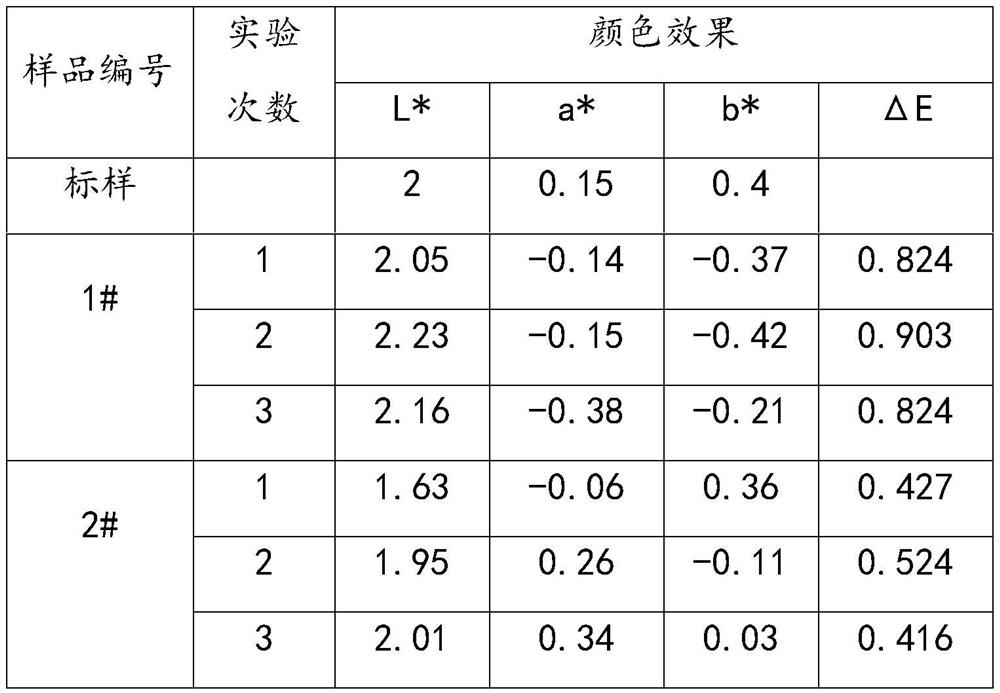

A kind of preparation method of black zirconia pigment and ceramics

ActiveCN112280331BExcellent mechanical propertiesLower sintering temperaturePigment physical treatmentXylyleneZirconia ceramic

The invention provides a method for preparing a black zirconia pigment, which includes the following steps: S1. Preparation of color developing agent powder: mixing ferric nitrate nonahydrate and cobalt nitrate hexahydrate, heating and melting, and performing pyrolysis to cool down to obtain Chromogenic agent CFO powder. S2. Coating preparation: after dispersing and stirring the CFO powder, absolute ethanol and xylene; adding zirconium isopropoxide and stirring to obtain the first mixture; A solvent is added dropwise into a mixture, and the solvent is a mixture of water and ethanol, and the second mixture is pyrolyzed to obtain a black zirconia pigment powder. The present invention also provides a method for preparing black zirconia ceramics, adding S3 degreasing step and S4 sintering step on the basis of the above method to obtain black zirconia ceramics. The preparation method of the black zirconia pigment and ceramics of the present invention has uniform color of the ceramics, effectively suppresses the volatilization of the color developing agent, and has good mechanical properties.

Owner:SHENZHEN TAOTAO TECH CO LTD

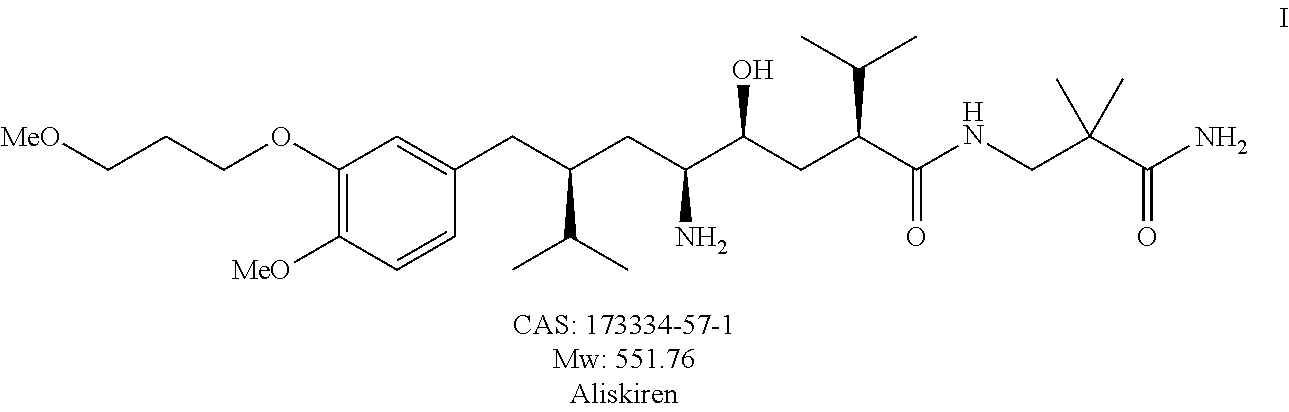

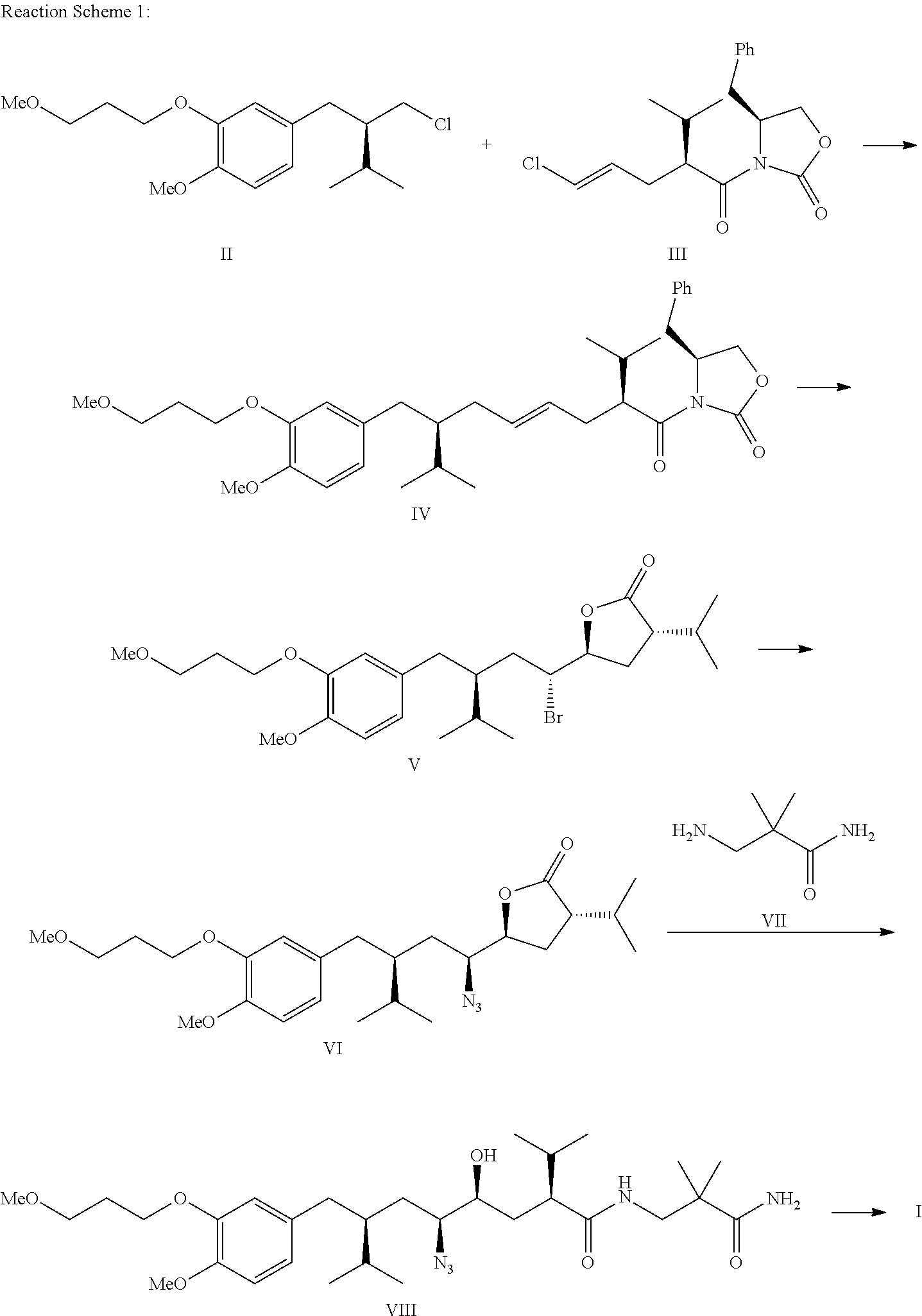

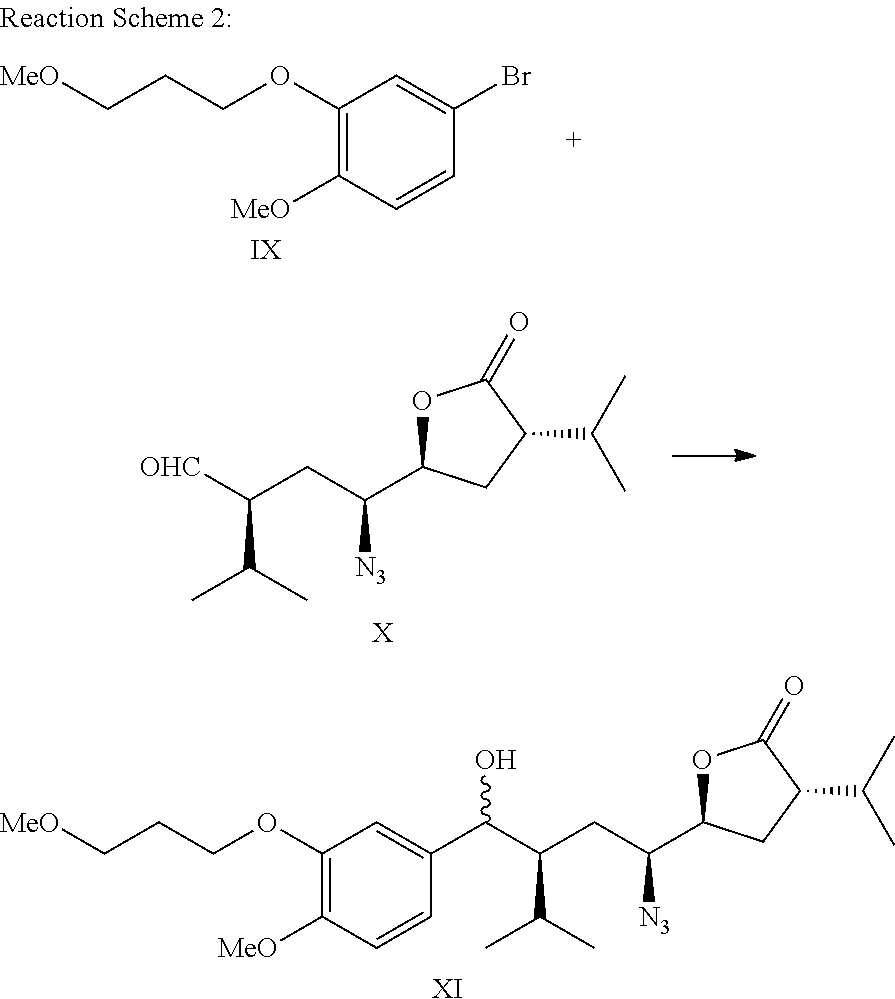

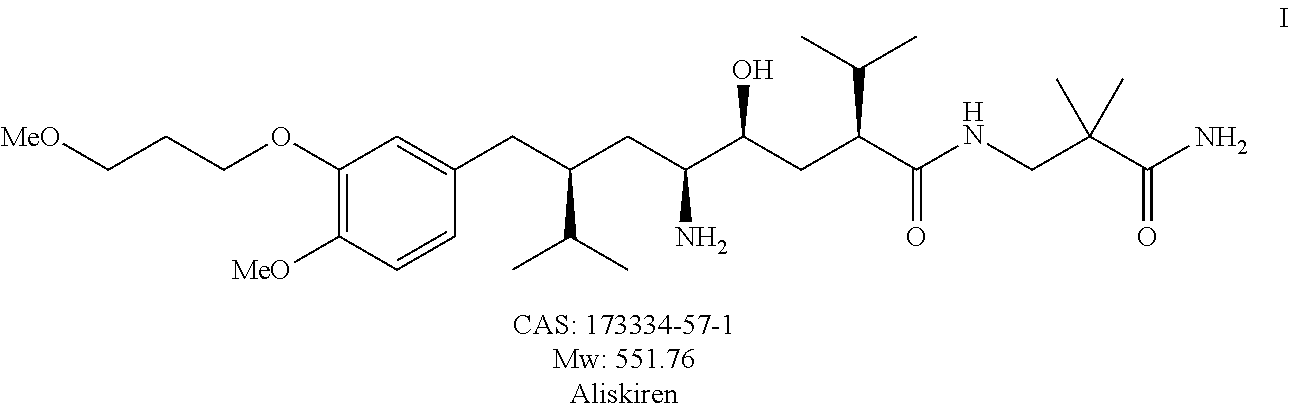

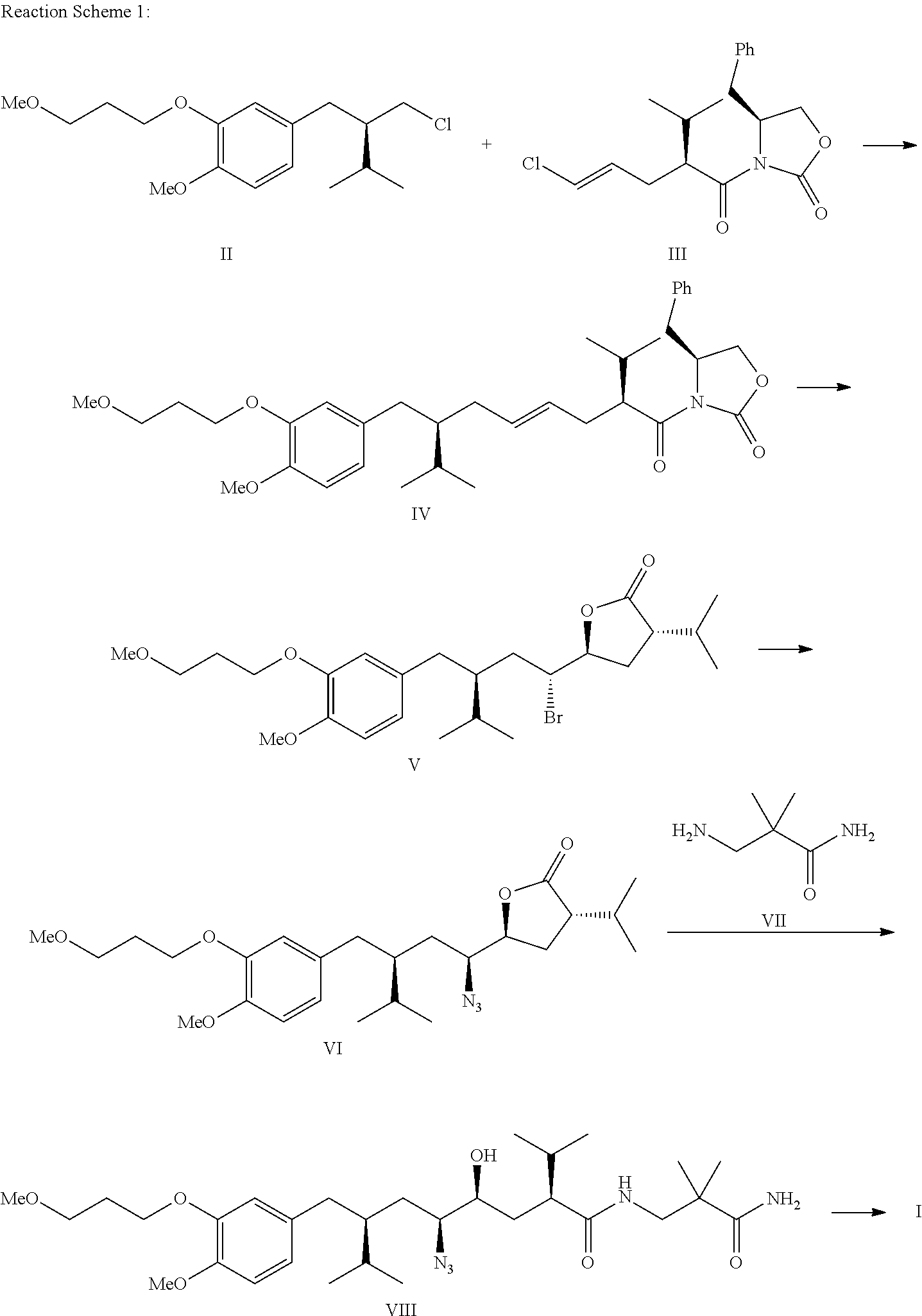

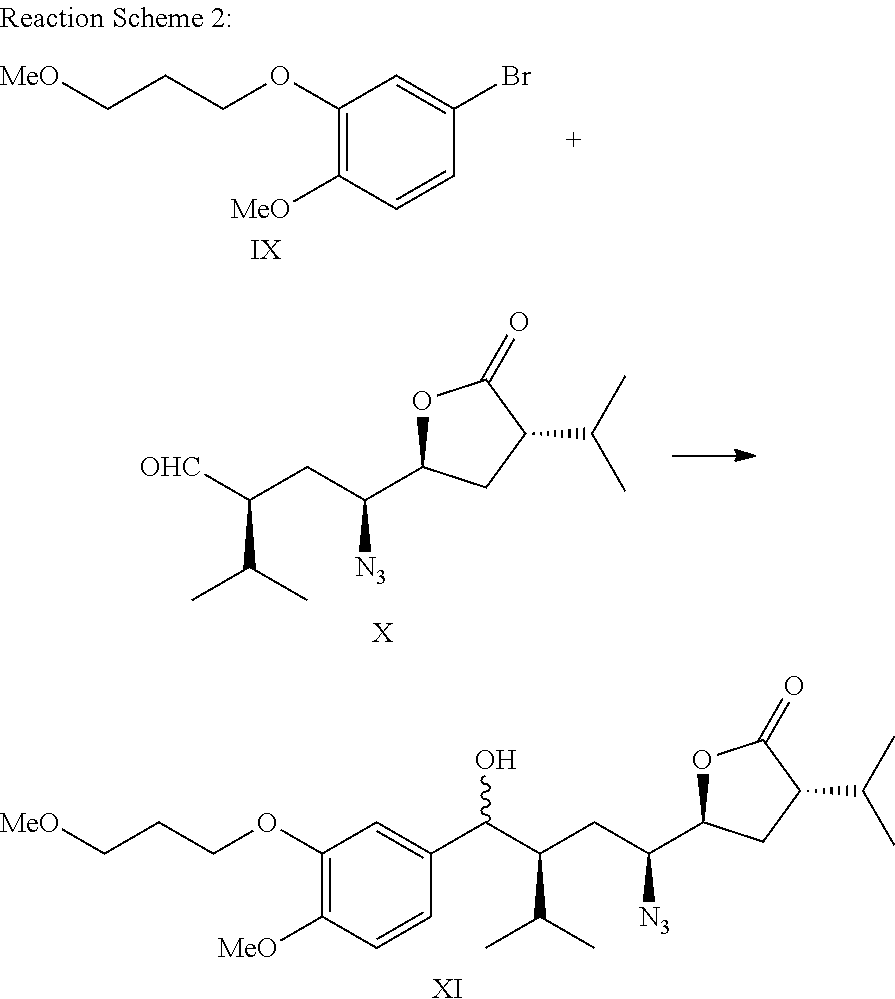

Method for preparing aliskiren and its intermediates thereof

ActiveUS20130225841A1Complicated reaction operationLow costCarbamic acid derivatives preparationOrganic compound preparationBenzeneBromine

A method for preparing Aliskiren and intermediate thereof, which comprises the following steps: reacting 4-bromo-1-methoxy-2-(3-methoxypropoxy)benzene with magnesium isopropyl chloride and n-BuLi to obtain the compound of formula XXII; reacting the product of methylsulfonylation of the compound of formula XIX with anhydrous LiBr to obtain the compound of formula XXI; obtaining the intermediate of Aliskiren shown as formula XV by reacting the compound of formula XXII with the compound of formula XXI in an ether as the solvent and in the presence of a catalyst containing iron; then reacting the compound of formula XV with the compound of formula VII to obtain the compound of formula XXIII, following removing R1 from the amino group and obtaining Aliskiren shown as formula I.

Owner:ZHEJIANG TIANYU PHARMA

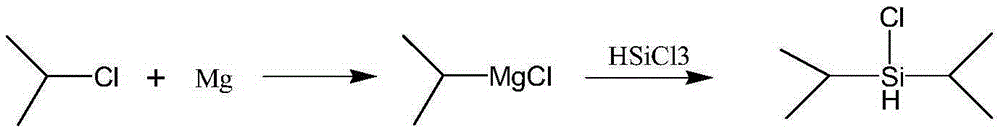

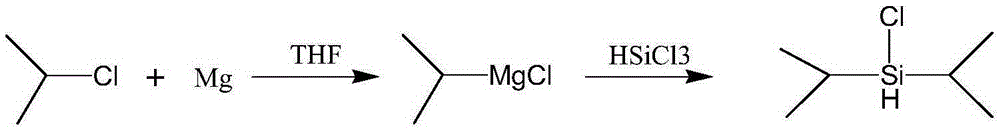

A kind of synthetic method of diisopropyl chlorosilane

ActiveCN103588805BReasonable choiceGood choiceGroup 4/14 element organic compoundsChemical synthesisTetrahydrofuran

The invention relates to a synthetic method of diisopropyl chlorosilane, and belongs to the field of chemical synthesis of organic silicon halide in organic chemistry. According to the synthetic method, magnesium chips and part of tetrahydrofuran are added into a four-neck flask equipped with a mechanical stirrer, a thermometer, a reflux condensing tube and a constant-pressure dropwise adding funnel under the protection of N2 and heated to the temperature of 40-65 DEG C for initiation reaction; after initiation, a residual mixed solution of 2-chloropropane and tetrahydrofura is dropwise added at the temperature of 40-65 DEG C; after dropwise adding, the mixture reacts at the temperature of 40-65 DEG C for 0.5-3.0 h and then is cooled to subzero 10-30 DEG C; a mixed solution of trichlorosilane and n-hexane is dropwise added, a system releases heat violently and produces a large quantity of white solids; and after dropwise adding, the mixture reacts for 0.5-3.0 h and finishes the reaction, suction filtration is performed, a filter cake is washed with n-hexane, filtrates are combined, most of solvents are concentrated, rectification is performed, cut fraction at the temperature of 110-140 DEG C is collected and serves as a product, the yield is 50%-75%, and the purity is 95.0%-99.0%. According to the synthetic method, the technical route is reasonable, simple and convenient to select and easy to operate.

Owner:内蒙古佳瑞米精细化工有限公司

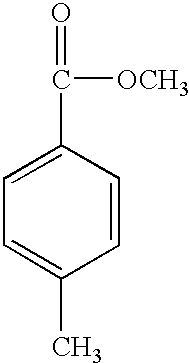

Polyol containing glycol adduct for use in producing rigid foam

A polyol composition containing a polyester polyol, at least 5 weight % of a compatibilizing agent, based on the weight of the polyol and compatibilizing agent, and a hydrocarbon blowing agent. The compatibilizing agent is one or a combination of a benzoate glycol adduct, a substituted benzoate glycol adduct, a naphthenate glycol adduct, a substituted naphthenate glycol adduct, a toluate glycol adduct, or a substituted toluate glycol adduct. The hydrocarbon blowing agent is selected from cyclopentane, isopentane, n-pentane, 2-chloropropane; 1,1,1,2-tetrafluoroethane (HFC-134a); 1,1,1,3,3-pentafluoropropane (HFC-245fa); and n-propylbromide, or mixtures thereof. The compatibilizing agent improves the miscibility of conventional polyester polyols with hydrocarbon blowing agents. The polyol composition can be reacted with a polyisocyanate to form a foam. Foams prepared from the mixture have superior thermal conductivity, lower flammability, and higher stability of the emulsified liquid reactants prior to polymerization.

Owner:INVISTA NORTH AMERICA S A R L

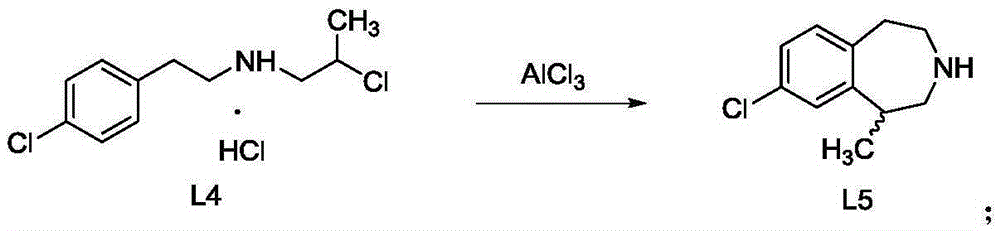

Method for preparing lorcaserin

ActiveCN105924396ARealize industrial applicationQuality assuranceOrganic chemistryChlorobenzeneSolvent free

The present invention provides a method for preparing lorcaserin. The method is as below: A) synthesizing a lorcaserin racemate by using 1-[[2-(4-chlorphenyl) ethyl] amino]-2-chloropropane hydrochloride as a raw material by a solvent-free method; B) cooling the reaction system to 70-80 DEG C, adding an organic solvent, stirring well and cooling to 0 to 5 DEG C, wherein the organic solvent is tetrachloroethylene, chlorobenzene, toluene or cyclohexane; C) adding hydrochloric acid solution in the reaction system, dispensing the liquid, and removing an organic phase to obtain a water phase; and D) adding NaOH solution to the water phase, then adding cyclohexane or heptanes, and extracting and concentrating the organic phase to obtain a lorcaserin racemic pure product. After the solvent-free alkylation reaction, the organic solvent of tetrachloroethylene, chlorobenzene, toluene or cyclohexane is added, so as to solve the safety problem caused by rapid heat release due to direct addition of water; and the posttreatment process is simple and safe. The invention realizes industrial application of solvent-free synthesis of lorcaserin, at the same time ensures the quality of prepared lorcaserin.

Owner:LIANGJIANG MEDICINE CO LTD

Process for producing isopropyl chloride

The present invention is an industrially advantageous process for isopropyl chloride production in which the catalytic activity can be maintained under the milder reaction conditions than in the conventional processes, and which requires no special reactor.Propylene and hydrogen chloride is reacted in a gas phase, in the presence of iron or a halogenated aluminum oxide (preferably, aluminum oxide reacted with hydrogen chloride). Preferably, a temperature during the reaction is 20 to 100° C., and a pressure of the reaction is 1013 to 3039 hPa (absolute pressure).

Owner:KASHIMA CHEM +1

Cleaning treatment technology for isopropyl chloride cyanuric acid production waste water

ActiveCN102897948BAchieving zero emissionsMaximize resource utilizationMultistage water/sewage treatmentNature of treatment waterChemical industryElectrolysis

The invention belongs to the technical field of chemical industry production waste water treatment and discloses cleaning treatment technology for isopropyl chloride cyanuric acid production waste water; a treatment method of this technology comprises the following steps: chloridizing sodium dichloro isocyanurate mother liquor to recycle trichloroisocyanuric acid; acidizing mother liquid, blowing chlorine and by-producing sodium chlorate; alkalifying and reducing the mother liquid so as to recycle cyanuric acid monosodium salt, reducing mother liquid total ammonium; after acidizing the mother liquid, reacting tripolycyanamide with residual cyanuric acid of the mother liquid so as to generate sparingly-soluble melamine cyanurate sediment; separating sediment so as to reduce mother liquid total ammonium; then, absorbing the mother liquid total ammonium by special active carbon so as to further reduce the mother liquid total ammonium; desorbing saturated active carbon by dilute liquid alkali, recycling cyanuric acid trisodium salt; and oxidizing absorbed mother liquid by sodium hypochlorite solution so as to dispel residual cyanuric acid, wherein the total ammonium content of the mother liquid is less than or equal to 2mg / L; treated qualified saline is transferred to a chlor-alkali plant so as to test salt; after tested saline is refined, the tested saline is used for electrolytically producing caustic soda and chorine; isopropyl chloride cyanuric acid is produced again by the caustic soda and the chorine so as to form a circular economic industry chain; and waste water zero emission is realized.

Owner:河北冀衡化学股份有限公司

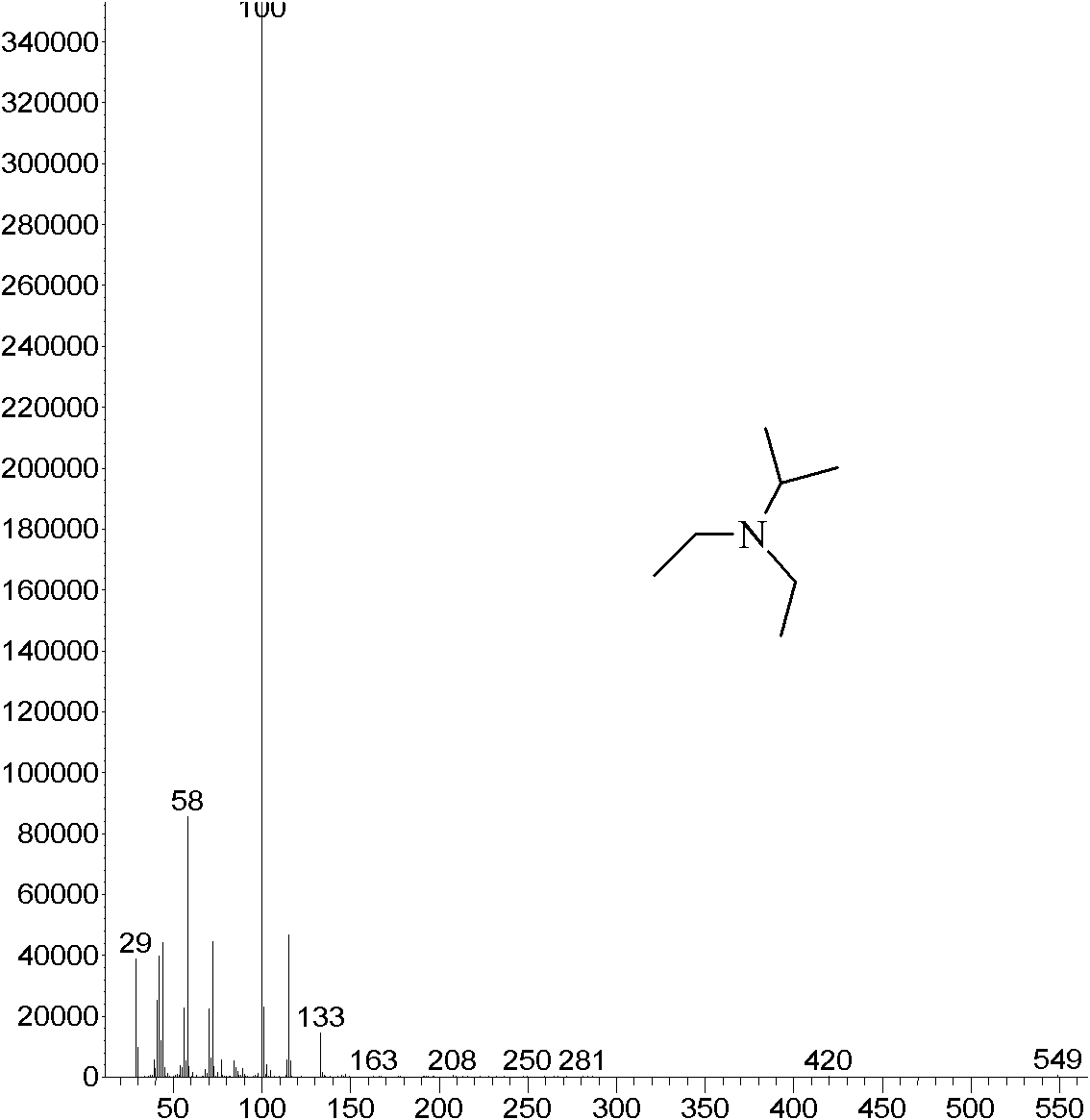

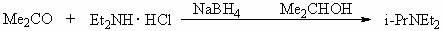

Synthesis method of N,N-diethyl isopropylamine

InactiveCN102180797ARelieve pressureReduce pollutionOrganic compound preparationAmino compound preparationSynthesis methodsReaction temperature

The invention discloses a synthesis method of N,N-diethyl isopropylamine. The synthesis method comprises the following steps of: making diethylamine and isopropyl chloride serving as raw materials react in a high-pressure kettle in the absence of a solvent and a catalyst at the reaction temperature of 100-200 DEG C under the reaction pressure of 0.2-1.1 Mpa for 4-10 hours, wherein the molar ratio of the diethylamine to the isopropyl chloride is (2-5):1; and adding an inorganic alkaline solution into an obtained reaction product until the pH is 11.5-13.5, separating liquid and fractionating to obtain the N,N-diethyl isopropylamine. The synthesis method of N,N-diethyl isopropylamine has the characteristics of environmental friendliness, simple process, high yield and the like.

Owner:ZHEJIANG UNIV

Method for preparing aliskiren and its intermediates thereof

ActiveUS8664440B2Complicated reaction operationLow costBiocideCarbamic acid derivatives preparationBenzeneBromine

Owner:ZHEJIANG TIANYU PHARMA

Preparation method of 2-chloropropane

InactiveCN109053364ANot corrosiveGuaranteed stabilityHalogenated hydrocarbon preparationGaseous hydrogenOxygen

The invention discloses a preparation method of 2-chloropropane. The preparation method of the 2-chloropropane comprises the following steps: S1, after a vacuum state is formed in a reaction kettle, introducing protective gas into the reaction kettle; S2, adding a catalyst and isopropanol into the reaction kettle full of protective gas and heating the reaction kettle; S3, slowly introducing hydrogen chloride gas into the reaction kettle; and S4, after the hydrogen chloride gas is introduced and the temperature of the reaction kettle stops being increased, stopping introducing the hydrogen chloride gas to obtain the 2-chloropropane. Reaction is conducted by using the gaseous hydrogen chloride and the gaseous hydrogen chloride does not have corrosion effect, so that corrosion to the reactionkettle is avoided; furthermore, oxygen does not exist in the reaction kettle and only inert gas exists in the reaction kettle, and the temperature of the reaction kettle is not less than 100 DEG C, so that water in the reaction kettle exists in the form of gas, the fact that the hydrogen chloride exists in the form of gas all the time is guaranteed, the stability and the safety of the productionflow are guaranteed and occurrence of production accidents is reduced.

Owner:浙江胡涂硅科技有限公司

After-treatment method of crude tris-(2-isopropyl chloride) phosphate

ActiveCN102002068BEliminate odorEasy to removePhosphorus organic compoundsPhosphoric Acid EstersAlkaline water

The invention relates to an after-treatment method of crude tris-(2-isopropyl chloride) phosphate, in particular to a treatment method which can effectively remove the stinky 2-methyl-pentanal in the tris-(2-isopropyl chloride) phosphate. The method is characterized by comprising the steps of: introducing a certain amount of ozone in the crude tris-(2-isopropyl chloride) phosphate obtained by reaction; directly oxidizing the insoluble 2-methyl-pentanal generated by reaction into acidic materials such as 2- methyl-valeric acid and the like soluble in an alkaline solution; and conveniently removing the acidic materials in the subsequent washing process to ensure that the obtained tris-(2-isopropyl chloride) phosphate does not contain the 2-methyl-pentanal which stinks. The method of the invention reduces the content of the stinky 2-methyl-pentanal in the tris-(2-isopropyl chloride) phosphate from about 200-300ppm to less than 5ppm; and when the product is applied to the interior materials of automobiles or furniture and the like, the stink is eliminated, and therefore, the product is in the favor of consumers.

Owner:ZHEJIANG WANSHENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com