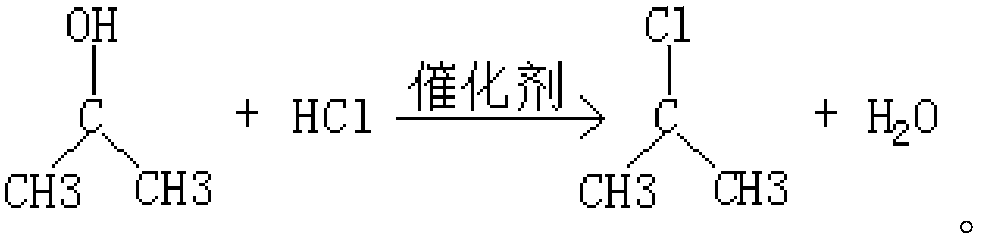

Preparation method of 2-chloropropane

A manufacturing method and technology for chloropropane, which are applied in chemical instruments and methods, halogenated hydrocarbon preparation, organic chemistry and other directions, can solve the problems of reduced service life of the reactor, inability to improve production efficiency, and increased production cost, and achieve improved efficiency, The effect of speeding up the reaction and increasing the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The manufacture method of 2-chloropropane, comprises the following steps:

[0022] S1. Use a vacuum pump to extract the air in the reactor made of stainless steel to form a vacuum inside the reactor, then continue to feed nitrogen into the reactor so that the pressure in the reactor is 120kPa and then stop feeding the protective gas. gas;

[0023] S2. Adding 10g of iron with a purity of 99.99% and a diameter of 0.05mm and 300ml of isopropanol with a purity of 100% to the reactor filled with protective gas, heating the reactor to raise the temperature in the reactor to 110 ℃, and keep the temperature in the reactor constant;

[0024] S3, slowly feed into the hydrogen chloride gas of 310ml in the reactor, and by passing into or extracting protective gas in the reactor, make the pressure in the reactor remain in 180kPa;

[0025] S4, use a thermometer to measure the temperature change in the reactor, after the temperature in the reactor stops rising after feeding hydrogen...

Embodiment 2

[0028] The manufacture method of 2-chloropropane, comprises the following steps:

[0029] S1. Use a vacuum pump to pump out the air in the reactor made of stainless steel to form a vacuum inside the reactor, then continue to feed argon into the reactor so that the pressure in the reactor is 120kPa and then stop the protection. sexual gas;

[0030] S2. Add 10 g of halogenated spherical alumina with a particle size of 3 mm and a pore capacity of 0.7 ml / g and 300 ml of isopropanol with a purity of 100% into a reactor filled with protective gas, and heat the reactor to make the reactor The temperature in the reactor is raised to 120°C, and the temperature in the reactor is kept constant;

[0031] S3, slowly feed 310ml of hydrogen chloride gas into the reactor, and pass into or extract protective gas in the reactor, so that the pressure in the reactor remains within 180kPa;

[0032] S4, use a thermometer to measure the temperature change in the reactor, after the temperature in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com