Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

105 results about "Iodine molecule" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iodine is a diatomic molecule, as it is a molecule made up of two atoms. There are two different types of diatomic molecules. There are hetero nuclear diatomic molecules, and homonuclear diatomic molecules.

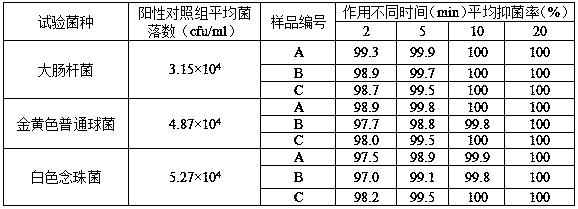

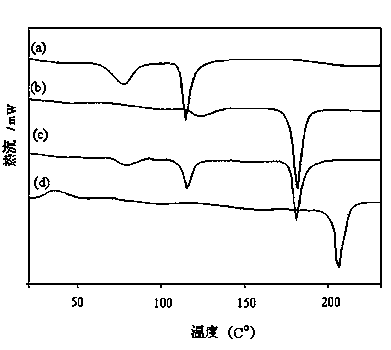

Method for preparing antibacterial film of quaternarized chitosan iodine complex

The invention relates to a method for preparing an antibacterial film of a quaternarized chitosan iodine complex. The method comprises the following steps: inserting quaternary ammonium salt on the hydroxyl group or amino group of a chitosan structure unit to prepare a quaternarized chitosan derivative; soaking a blend film of the quaternarized chitosan derivative and gelatin or poval into a simple substance iodine solution for 4-6 hours to obtain the antibacterial film of the quaternarized chitosan / gelatin or poval iodine complex, or directly preparing a quaternary ammonium salt chitosan iodine complex from the quaternarized chitosan derivative and simple substance iodine, and then mixing the quaternary ammonium salt chitosan iodine complex with gelatin or poval to prepare the blend antibacterial film containing iodine. By using the method, the water solubility and the biological activity of chitosan can be improved; simple substance iodine is stabilized and complexed by utilizing the affinity of a quaternary ammonium salt group and an iodine molecule; according to the different positions of a human body, the prepared antibacterial film can be compounded with other materials; a chitosan base has hemostasis, antiphlogosis and tissue repair functions on human body wound, can reduce the stimulation of iodine on the wound and controls the release of iodine, and the double effects of the chitosan base and iodine provide an ideal curing environment for a wound surface.

Owner:SHANGHAI UNIV OF ENG SCI

One-pack preparation for disinfection, neutralization and cleaning of contact lenses and method of disinfection, neutralization and cleaning

The present invention provides a combined formulation for disinfecting, neutralizing and cleaning a soft contact lens and a method using the same easily, efficiently and safely. The formulation is a one-solution type of combined formulation for disinfecting, neutralizing and cleaning a soft contact lens, which includes a first formulation that contains an iodine-based disinfectant and a proteolytic enzyme and a second formulation that contains a reducing and a foaming agent treated with a delayed release coating, and which contains a nonionic surfactant in at least one of the first and second formulations. A stained soft contact lens can be disinfected, neutralized and cleaned easily by holding it in an aqueous solution colored yellow or brown by iodine molecules and removing it from the aqueous solution after the solution becomes almost colorless.

Owner:OPHTECS CORP

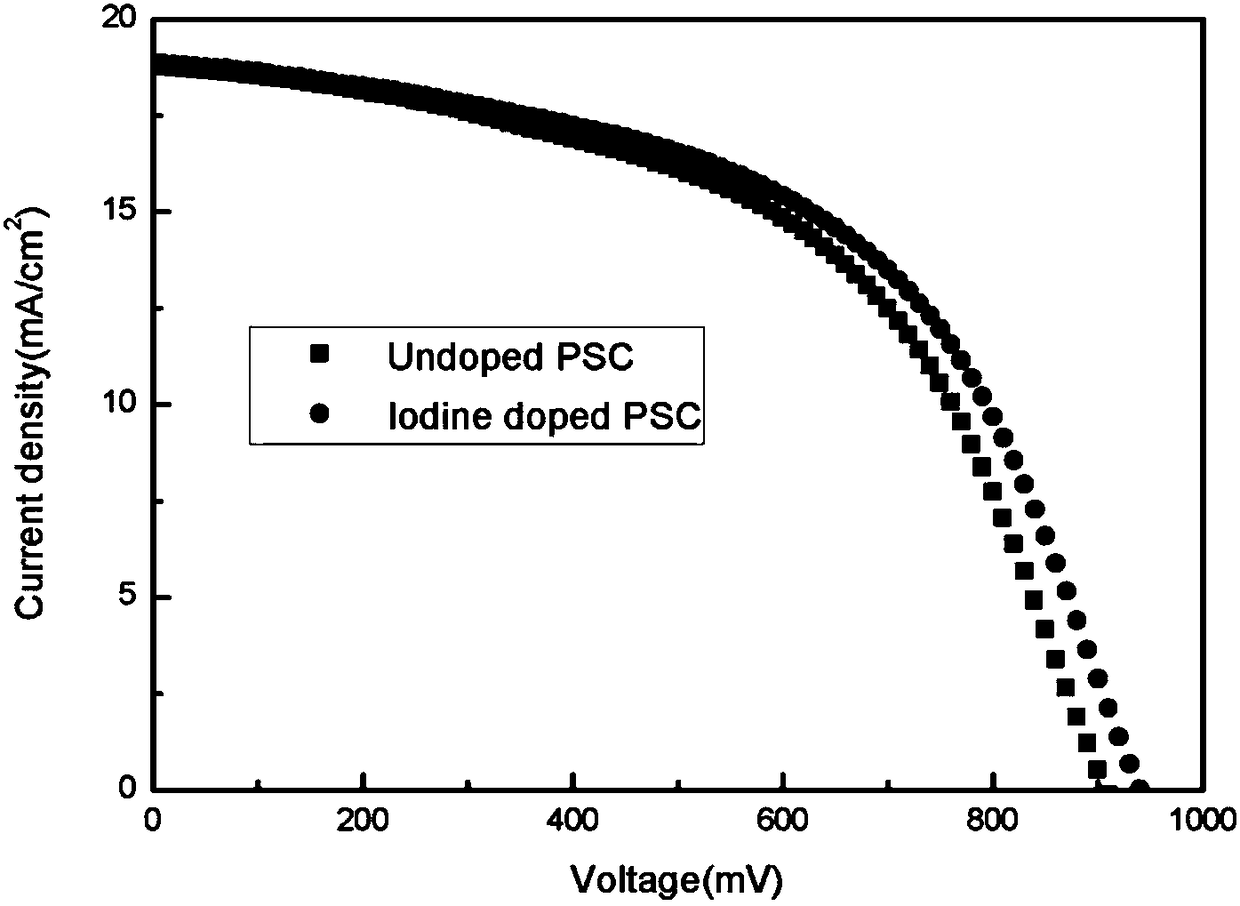

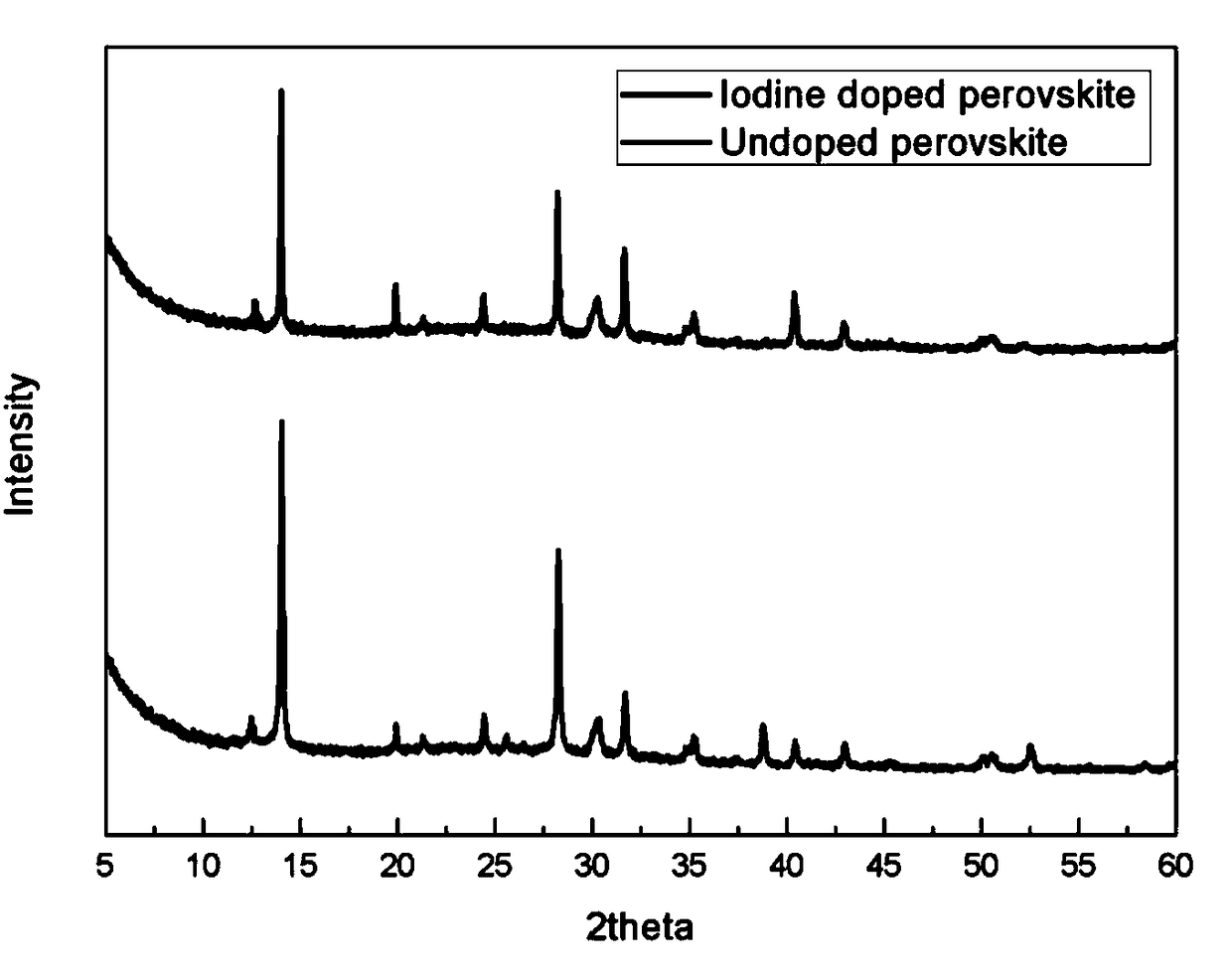

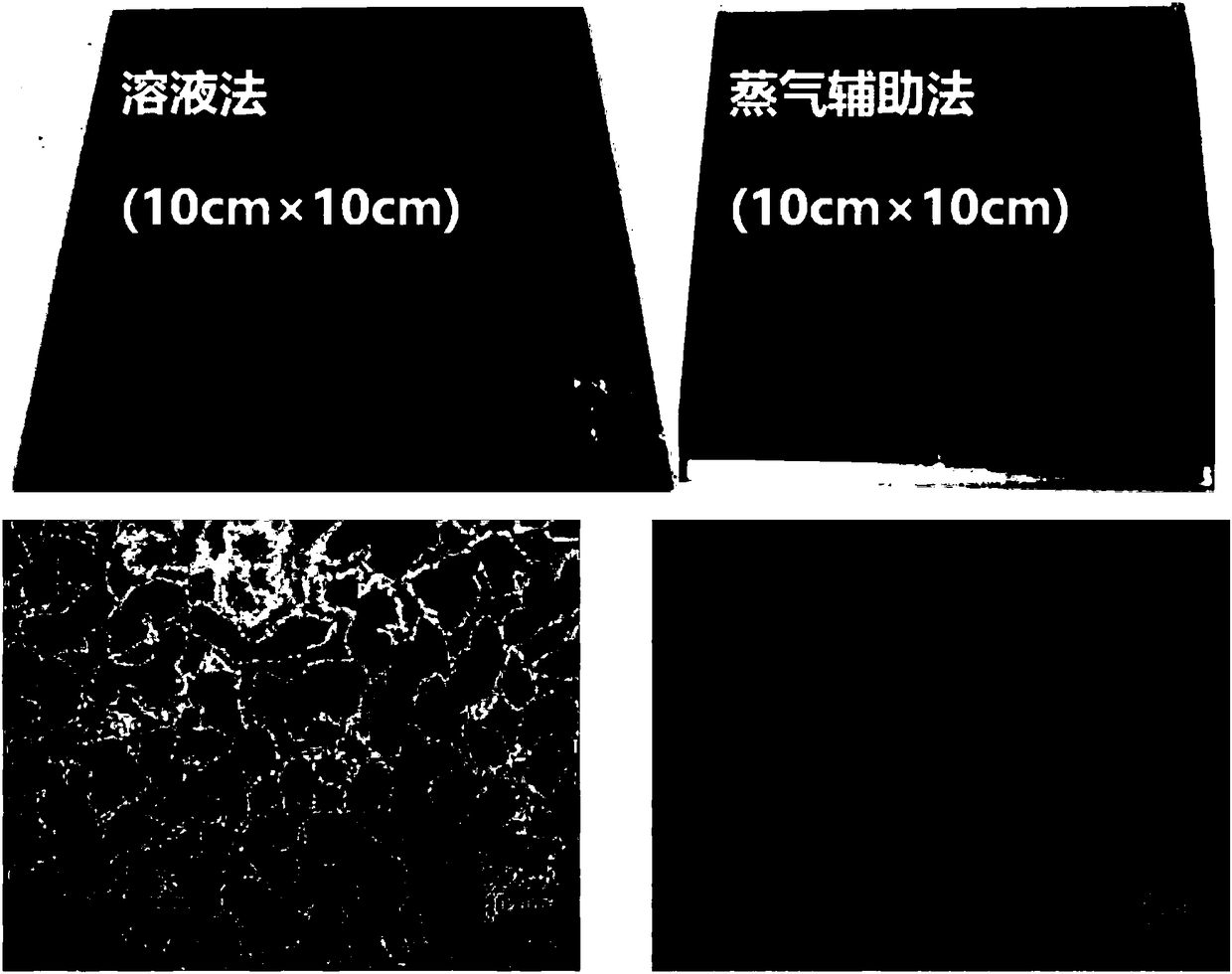

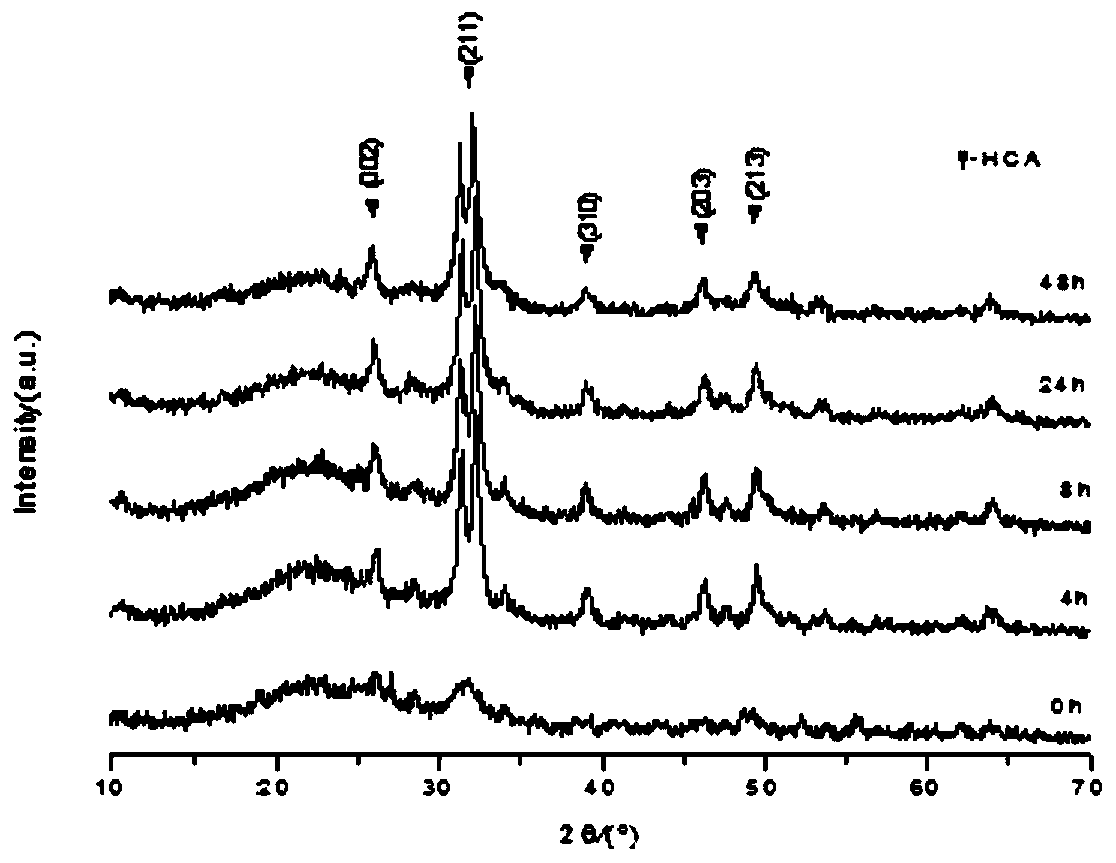

Method for preparing perovskite solar cell by steam assistance

InactiveCN108493340AQuality improvementRaise the ratioSolid-state devicesSemiconductor/solid-state device manufacturingHole transport layerCrystallographic defect

The invention belongs to the field of solar cells, and particularly relates to a method for preparing a perovskite solar cell by steam assistance. The method comprises the steps of evaporating an electron transmission layer on a substrate; evaporating a PbI2 layer on the electron transmission layer; dissolving FAI and I2 in isopropyl alcohol, placing the isopropyl alcohol opposite to the PbI2 layer after another one piece of glass is coated, heating in a vacuum environment so that FAI and iodine molecules are sublimed to a surface of the PbI2 plating layer and react to form a perovskite crystal, and obtaining a perovskite light absorption layer after annealing; and sequentially spin-coating a hole transmission layer and evaporating a metal counter electrode to prepare the perovskite solarcell. A continuous, uniform, compact and high-quality perovskite thin film can be obtained by slow phase reaction between a vapor phase and a solid phase and by a steam assistance method; and meanwhile, excessive amount of iodine is added and doped in the perovskite light absorption layer, thus, the proportion of Alpha-FAPbI3 with photosensitivity in perovskite is increased, the crystal defect concentration is reduced, and the photoelectric conversion efficiency of the cell is improved.

Owner:WUHAN UNIV OF TECH

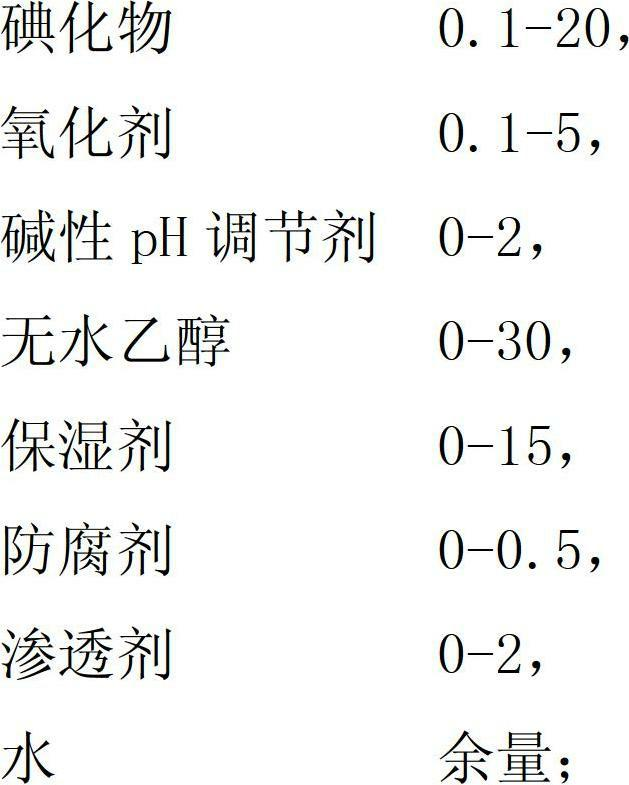

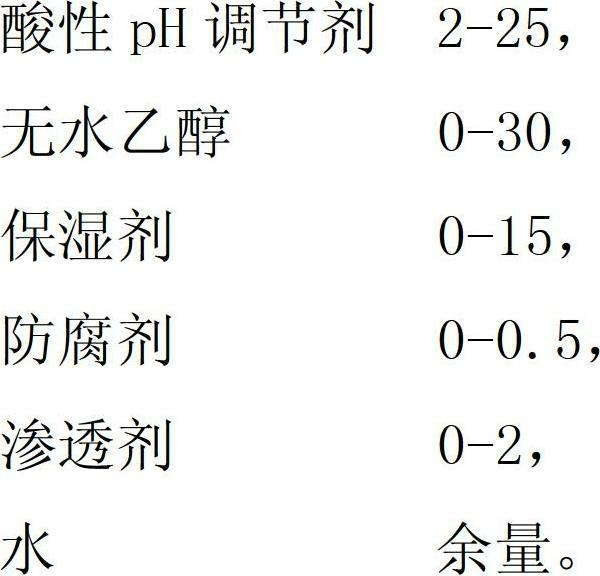

Liquid iodine disinfectant, preparation method and used container thereof

ActiveCN102670648ALess irritatingImprove stabilityAerosol deliveryOintment deliveryDisinfectantIrritation

The invention discloses a liquid iodine disinfectant, a preparation method and a used container thereof. The liquid iodine disinfectant comprises iodide, an oxidant capable of oxidizing the iodide to generate iodine molecules, and a pH regulator used for regulating the mixture of the iodide and the oxidant to be acidic, the disinfectant consists of a preparation I containing the iodide and a preparation II containing the oxidant and the pH regulator, and the preparation I and the preparation II are both liquid. The liquid iodine disinfectant disclosed by the invention is good in stability, can be stored for a long time, has little skin irritation, can permeate fast and volatilize quickly, does not need deiodination, and is light in coloring, excellent in sterilization effect, and safe and convenient to use and carry. The liquid iodine disinfectant disclosed by the invention has broad spectrum bactericidal action and low irritation to the skin mucosa, so that the liquid iodine disinfectant can be applied to various skin diseases caused by bacteria, funguses and viruses.

Owner:山东沙多普生物科技有限公司

Method for producing compound having colorant structure at main chain terminal of polymer, and pigment dispersant, pigment composition, pigment dispersion and toner containing compound obtained by the production method

ActiveUS20150274853A1Increase chanceHigh affinityMonoazo dyesTransportation and packagingHydrogen atomWater insoluble

To provide a method for producing a compound that enhances dispersibility of a pigment of respective colors in a water-insoluble solvent, as well as a pigment dispersant, and a pigment composition, a pigment dispersion and a toner having a good tinting power. A method for producing a compound, including the following:(i): subjecting a polymerizable monomer forming a monomer unit represented by formula (1) to radical polymerization in the presence of a radical polymerization initiator and an iodine molecule to provide a polymer; and(ii): binding a colorant to a terminal of a main chain of the polymer:whereinR1 represents a hydrogen atom and an alkyl group, andR2 represents a phenyl group, a carboxyl group, an alkoxycarbonyl group or a carboxamide group.

Owner:CANON KK

Method for producing compound having colorant structure at main chain terminal of polymer, and pigment dispersant, pigment composition, pigment dispersion and toner containing compound obtained by the production method

ActiveUS9556290B2Good dispersionHigh tinting strengthMonoazo dyesTransportation and packagingHydrogen atomWater insoluble

To provide a method for producing a compound that enhances dispersibility of a pigment of respective colors in a water-insoluble solvent, as well as a pigment dispersant, and a pigment composition, a pigment dispersion and a toner having a good tinting power. A method for producing a compound, including the following:(i): subjecting a polymerizable monomer forming a monomer unit represented by formula (1) to radical polymerization in the presence of a radical polymerization initiator and an iodine molecule to provide a polymer; and(ii): binding a colorant to a terminal of a main chain of the polymer:whereinR1 represents a hydrogen atom and an alkyl group, andR2 represents a phenyl group, a carboxyl group, an alkoxycarbonyl group or a carboxamide group.

Owner:CANON KK

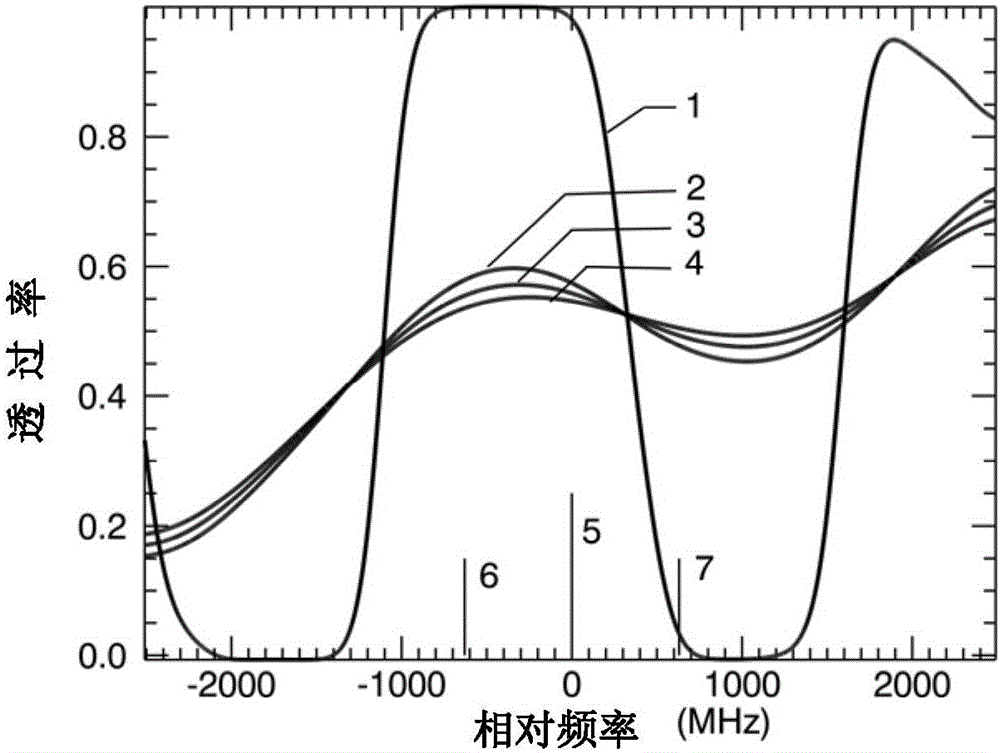

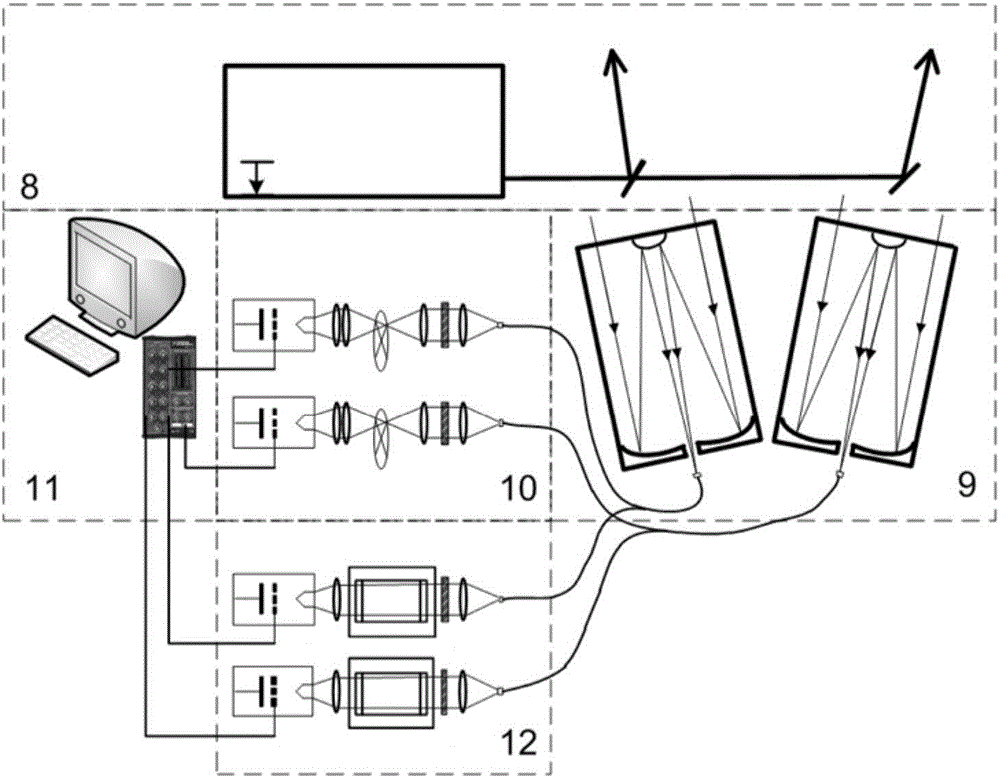

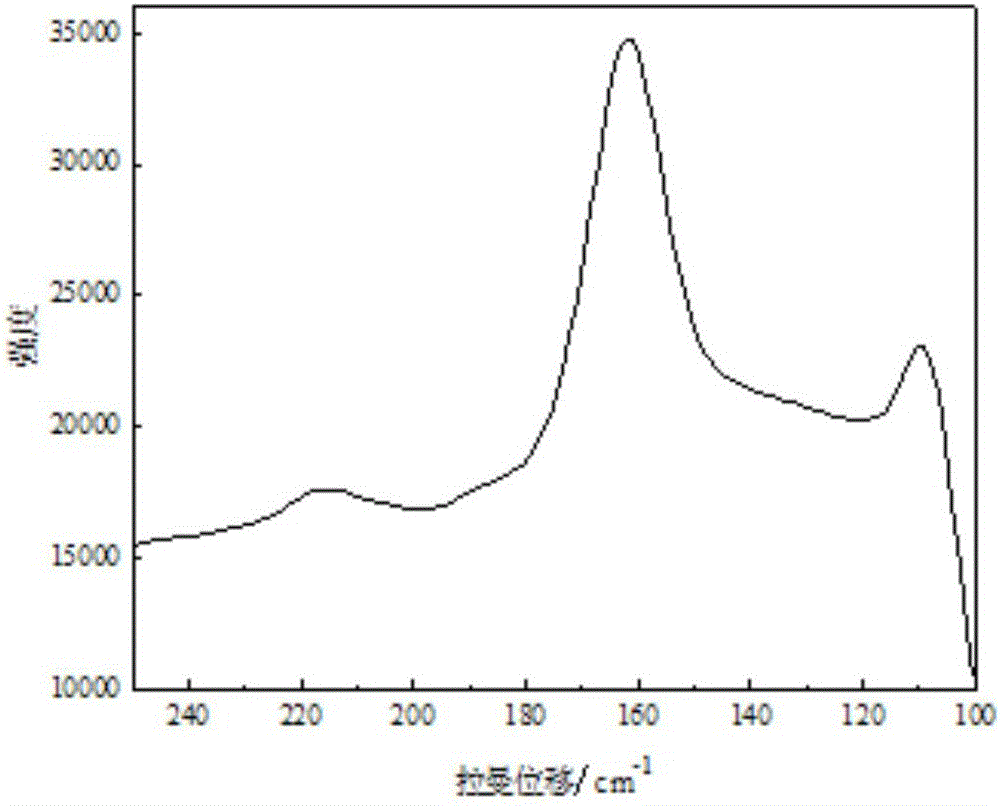

Method for measuring ocean inherent optical parameter by using laser radar system

InactiveCN106526611AEnables separate measurementsHyperspectral resolution characteristicsColor/spectral properties measurementsElectromagnetic wave reradiationRadar systemsAbsorption filter

The invention discloses a method for measuring an ocean inherent optical parameter by using a laser radar system. 532nm wavelength output is employed by the laser emitting system in the laser radar system, a receiving system is used to carry out signal receiving, received atmosphere and ocean scattering signals are divided into two paths according to 1:1 in a receiving system, one path is used as a reference channel, the other path goes through an iodine molecule absorption filter as a measurement channel. The photoelectric conversion of two paths of optical signals is realized through a photoelectric detector, and the signals are inputted to a processing system for processing computing via a signal collection system. According to the method, the iodine molecule absorption filter is used, the back scattering signal spectrum of a laser sea water body is considered, the separate measurement of the narrow linewidth suspended matter scattering and broadband water molecule scattering is realized, the spectral resolution characteristic is high, and the detection range of ocean information by the laser radar system is expanded.

Owner:LUDONG UNIVERSITY

Antibacterial gel containing iodine tincture, and preparation method thereof

ActiveCN107744524AReduce RingwormPromote wound healingAntibacterial agentsOrganic active ingredientsEscherichia coliIrritation

The invention discloses an antibacterial gel containing iodine tincture, and a preparation method thereof, wherein the antibacterial gel containing iodine tincture comprises, by mass, 0.5-10% of iodine tincture, 0.1-3% of a polymer thickener, 0.1-5% of a chitosan or chitin derivative, 0.05-2% of a zinc salt, 10-75% of alcohol, and 20-80% of pure water. According to the present invention, by complexing iodine tincture and the chitosan / chitin derivative, the iodine molecule is embedded into the axial center position of the spiral body of the chitosan / chitin derivative to form the slight yellow or colorless transparent inclusion compound, such that the iodine in the system can stably exist in the gel, the wound surface can be protected after the antibacterial gel is coated and forms the film,the antibacterial / sterilization effect can be continuously provided, the chitosan / chitin derivative can promote the wound healing so as to provide a good wound healing environment, the irritation andthe corrosion of the product can be effectively reduced, the yellowing can be avoided, and deiodination is not required after the use; and the antibacterial gel can strongly inhibit Escherichia coli,Staphylococcus aureus, Candida albicans and other pathogenic bacteria, can be used for antibacterial / bacterial inhibition of bacteria and fungi, and can further be used for providing antibacterial effects on mosquito bites, skin itching, red swelling of skin, acne and other conditions.

Owner:青岛健康海洋生物制药有限公司

Sodium fluorescence Doppler laser radar and method for measuring wind field and temperature of atmosphere

ActiveCN106093964AExtended Atmospheric Detection RangeElectromagnetic wave reradiationICT adaptationTroposphereIodine molecule

The invention provides a sodium fluorescence Doppler laser radar and method for measuring the wind field and temperature of the atmosphere. According to the invention, part of the scattering signals of the atmosphere that are received by the sodium fluorescence Doppler laser radar are separated and permeate an iodine molecule absorption spectrometer, and the light intensity of the Rayleigh scattering signals of the atmosphere is detected by using the absorption lines at 589 nm of the iodine molecules so as to measure the wind velocity and temperature information of the atmosphere corresponding to the Rayleigh scattering signals of the atmosphere, such that the exploration height of the sodium fluorescence Doppler laser radar is expanded from the mesopause of the atmosphere to the stratosphere and the troposphere, which expands the exploration range of the sodium fluorescence Doppler laser radar to the atmosphere.

Owner:NAT SPACE SCI CENT CAS

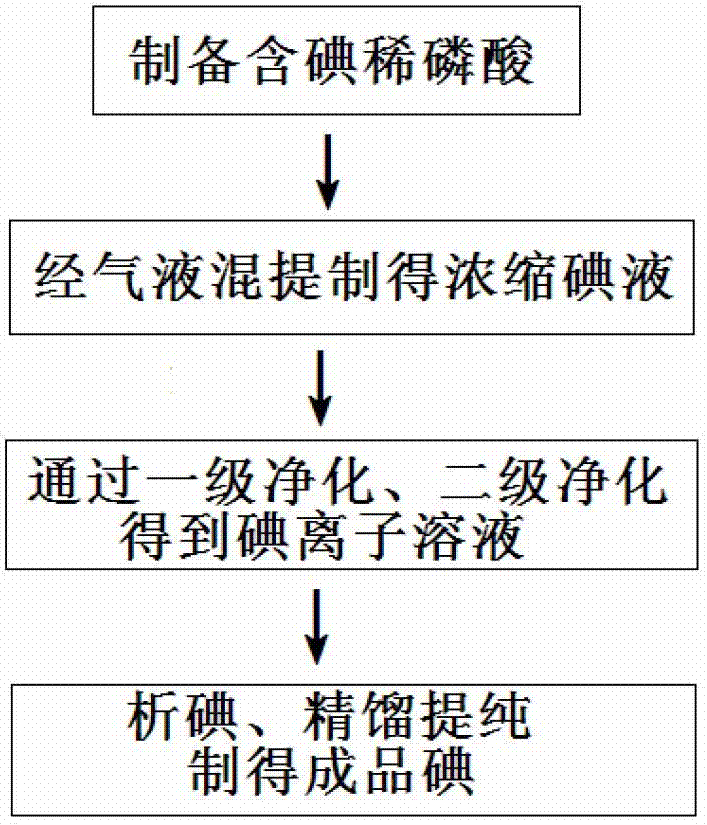

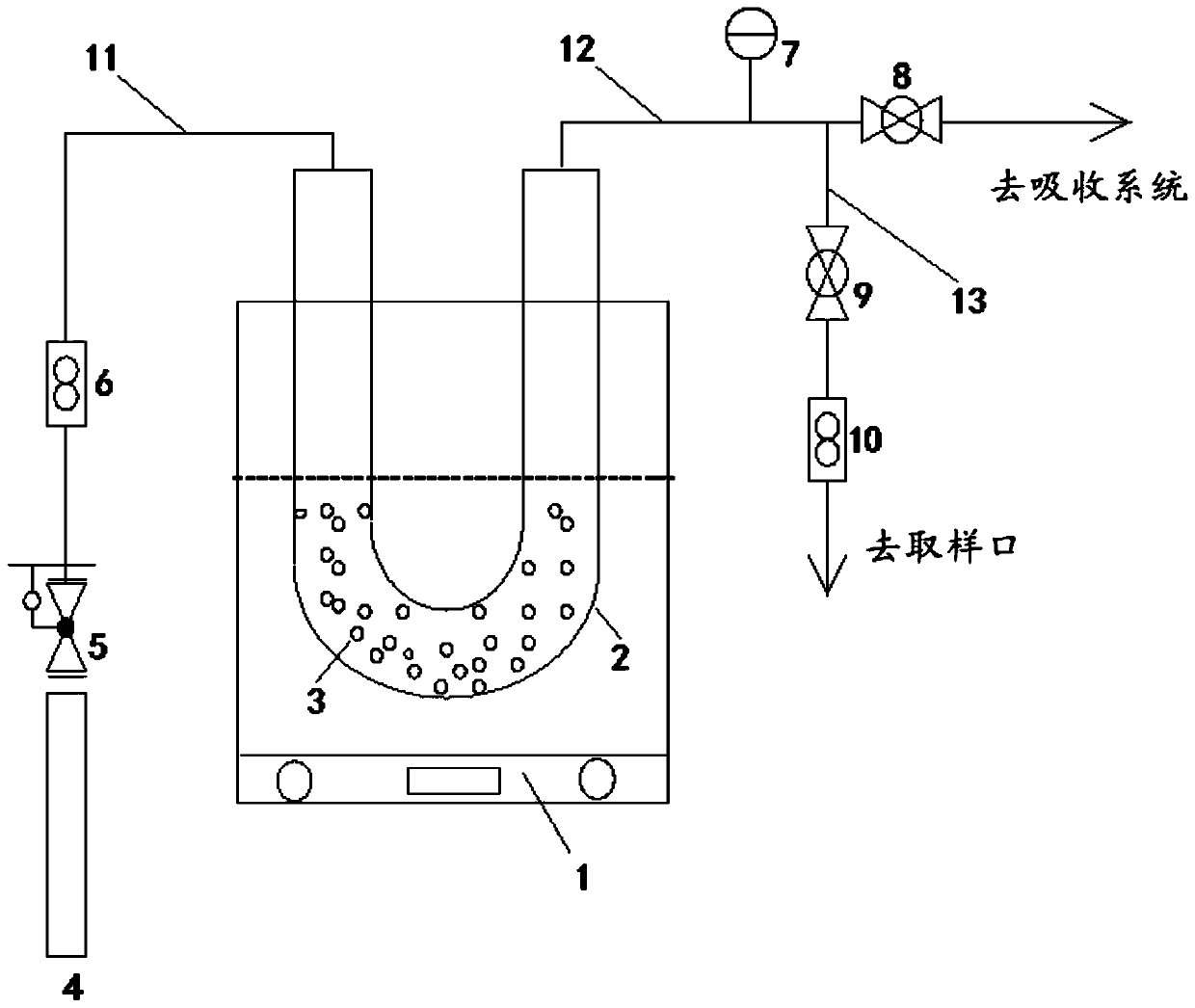

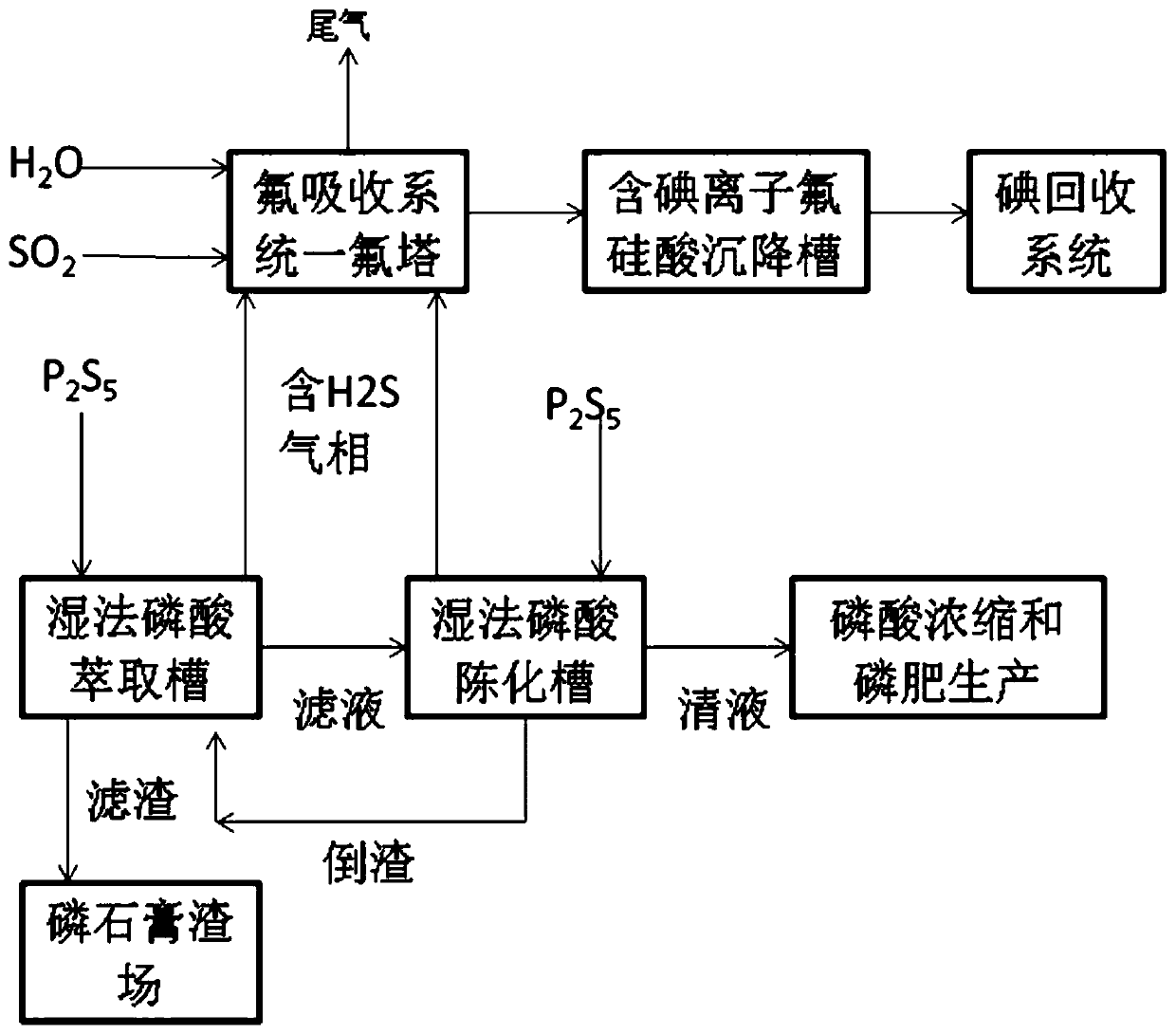

Gas-liquid mixed extraction iodine recovery technology

The invention discloses a gas-liquid mixed extraction iodine recovery technology. According to the invention, phosphate rock is soaked in sulfuric acid, and iodine-containing dilute phosphoric acid is obtained; an oxidizing agent is added into the dilute phosphoric acid, such that gas-phase iodine is obtained; the gas-phase iodine is subjected to a reaction with a reducing agent, such that iodine is precipitated. The invention is characterized in that: iodine-containing dilute phosphoric acid obtained by the reaction of phosphate rock and sulfuric acid and iodine-containing exhaust gas are simultaneously delivered into and sufficiently mixed in a gas-liquid mixed extraction integral iodine recovery apparatus; the oxidizing agent is added and a reaction is carried out, such that iodine molecules are obtained; the reducing agent is added under a condition of a controlled temperature, such that a concentrated iodine liquid is obtained; two-stage clarification, precipitation, filtration, and rectification purification are carried out, such that finished product iodine is obtained. The technology provided by the invention makes up for the defects of a method for extracting iodine from wastes produced in the process for producing phosphorus products from iodine-containing phosphorite. With the technology, iodine in iodine-containing dilute phosphoric acid and iodine-containing exhaust gas can be recovered simultaneously. Through two-stage clarification, defluoridation is realized, and floccule and impurities are removed, such that the purity of iodine is improved. The technology is also advantaged in simple technology, high recovery rate, and low economic cost. With the technology, iodine-containing exhaust gas can be fully utilized, and the pollution of tail-gas discharging to the environment can be reduced.

Owner:GUIYANG KAILIN FERTILIZER CO LTD

Iodine-Type Polarizer, Polarizing Place and Method for Producing Thereof

ActiveUS20090290215A1Increase brightnessImproved brightness ratioPolarising elementsOptical articlesIodine solutionsPhosphate

There is provided a method for producing a polarizer having improved cross transmittance. The method for producing a polarizer includes: dyeing a polyvinyl alcohol (PVA)-based film with molecular iodine by immersing the PVA-based film in an aqueous iodine solution (a dyeing step); absorbing the molecular iodine into the PVA-based film using an aqueous boric acid solution (a cross-linking step); arranging the molecular iodine in the certain direction by stretching the PVA-based film in a certain direction (an stretching step); and drying, in an oven, the PVA-based film in which the molecular iodine is oriented; wherein a phosphate compound is added to the iodine aqueous solution (the dyeing step) or the aqueous boric acid solution(the stretching step) so that a weight ratio of the boric acid:the phosphate compound is in a range of 1:0.1 to 1:10.

Owner:LG CHEM LTD

Organo-iodine complex

InactiveCN1834087AComprehensive ecological nutritional medicineGood for healthOrganic chemistryPeptide/protein ingredientsCoccidiosisDisease

This invention relates to an organic iodine complex, in which iodine serves as coordination center and functional group-containing organics serve as chelating reagent. The functional groups can be amino and / or hydroxyl and / or carboxyl, and the representatives of hydroxyl- and carboxyl-containing organics are 2-hydroxy-4-methylthiobutanoic acid and 2-hydroxypropanoic acid, respectively. This invention also relates to a combination of organic iodine complex and its application in pharmacy. The combination comprises 0.3~40% organic iodine complex as active ingredient and one or more ingredients chosen from the following ones: natural aminoacyl iodine, solvent, surfactant, food additives, food and synthesized drugs. This combination can be used in preparation of drug against AIDS, white spot syndrome virus in penaeid shrimp, Taura syndrome virus; grass carp hemorrhage virus, stomatitis, pharyngitis, colpitis, tumor, digestive tract diseases in poultry, histomoniasis, coccidiosis, human digestive tract diseases and iodine deficiency diseases.

Owner:曾雄飞

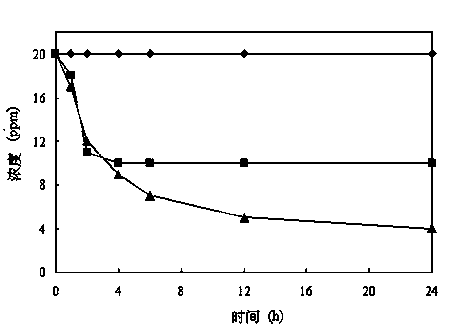

Liquid molecular iodine disinfectant, preparation method and used container

InactiveCN102688257ARapid sterilizationImprove the bactericidal effectClosuresAntisepticsDisinfectantIrritation

The invention discloses a liquid molecular iodine disinfectant, which comprises an iodide, an oxidant and an acidity pH regulator, wherein the oxidant can be used for oxidizing the iodide to generate iodine molecules, and the acidity pH regulator is used for regulating a mixture of the iodide and the oxidant to be acid. The disinfectant consists of a composition of a preparation 1 containing the iodide and the oxidant and a preparation 2 containing the acidity pH regulator; the preparation 1 and the preparation 2 are in a liquid state respectively; and the pH value of the preparation I is greater than 6.5. The liquid molecular iodine disinfectant disclosed by the invention not only is high in stability, can be stored for a long time, is light in irritation to skins, rapid in penetration and volatilization, light in coloring and obvious in sterilizing effect and does not need to be de-iodinated but also is safe and convenient in use and carrying. The liquid molecular iodine disinfectant disclosed by the invention has a broad-spectrum sterilizing effect and is light in irritation to skin mucosae and can be used for various skin diseases caused by bacteria, fungi and viruses.

Owner:WINERGEN TECH WEIFANG

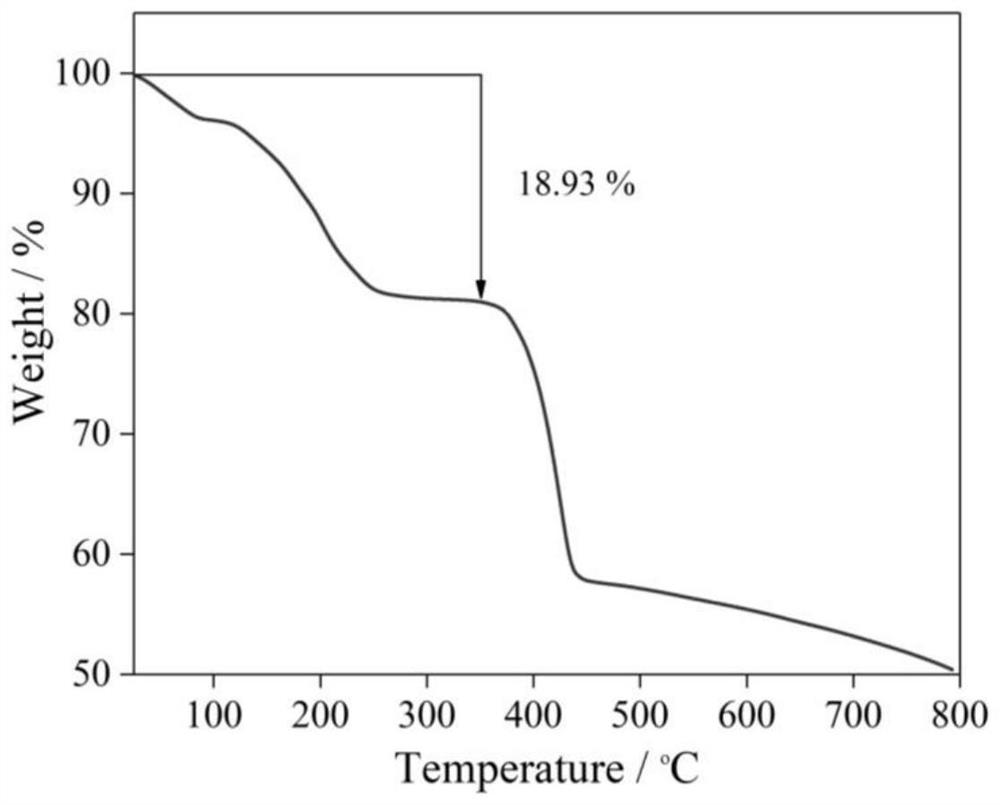

Silver ion-doped azo conjugated microporous polymer, preparation method and application

InactiveCN108355628AImprove anti-interference abilityImprove adsorption capacityOther chemical processesWater contaminantsPolymer scienceAzo coupling

The invention discloses a silver ion-doped azo conjugated microporous polymer, a preparation method and application, which belong to the technical field of polymer material preparation. Specifically,with 4-(1,2,2-tri(4-aminophenyl)vinyl)aniline and phloroglucinol as comonomers, under the catalysis of concentrated hydrochloric acid, coupling is carried out by diazo-coupling reaction, silver ions are then loaded, and thereby the silver ion-doped azo conjugated microporous polymer is prepared. The polymer prepared by the invention shows excellent adsorption capability on iodine molecules, moreover, the performance of the polymer is excellent in aspects such as detecting heavy metal ions Cu<2+>, Hg<2+>, Cr<3+> and Ni<2+>, and the polymer has potential application value in fields such as iodine adsorption and heavy metal ion detection.

Owner:JILIN NORMAL UNIV

Enhanced bioavailable iodine molecules

ActiveUS20120225161A1Increase supplementImprove the level ofIron group organic compounds without C-metal linkagesAnimal feeding stuffIodideCalcium iodate

This invention relates to supplementation of the diets of domesticated animals (livestock and poultry) with iodine in an enhanced bioavailable manner, that is to say the iodine is more available to the animal than when using conventional sources of iodine, such as calcium iodate. The supplementary compound are alpha amino acid metal iodide complexes.

Owner:ZINPRO

Iodine-loaded bioactive glass for wound care and application of iodine-loaded bioactive glass

InactiveCN110151784ABroad-spectrum antibacterialQuick fixAntibacterial agentsAntimycoticsSide effectWound care

The invention discloses iodine-loaded bioactive glass for wound care and application of the iodine-loaded bioactive glass. The properties that chitosan is not dissolved in an alkaline medium and formscondensation / precipitation when meeting an alkaline medium are utilized to obtain a chitosan microsphere template, and hollow bioactive glass is prepared from a compound containing various inorganicelements (silicon, calcium, sodium, phosphorus and the like) through a sol-gel-template method. The iodine-loaded bioactive glass is prepared by adopting a sealing temperature control sublimation andadsorption technology, and the composition has both bioactive glass particles and iodine molecules, can effectively promote healing of hard and soft tissue injuries of the human body, can also play along-lasting role of inhibiting / killing bacteria, has strong effects, low toxic and side effects and little immune inflammation response, and is convenient to store, carry and use.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

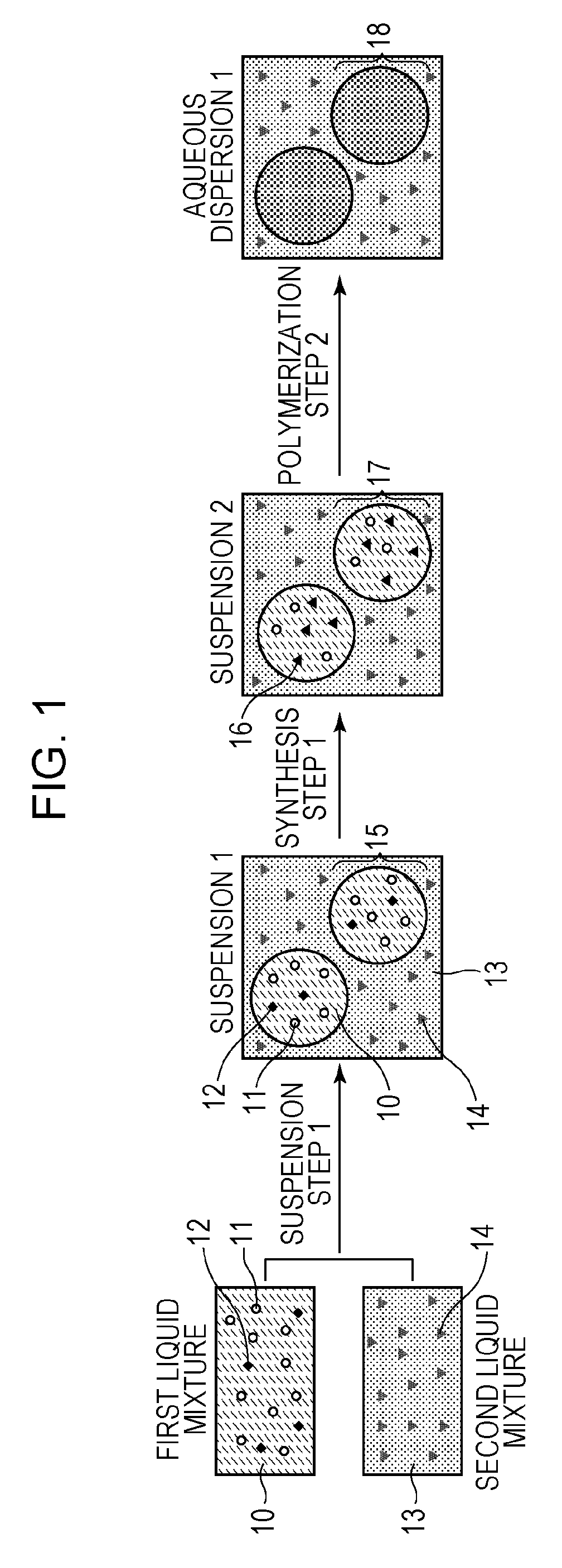

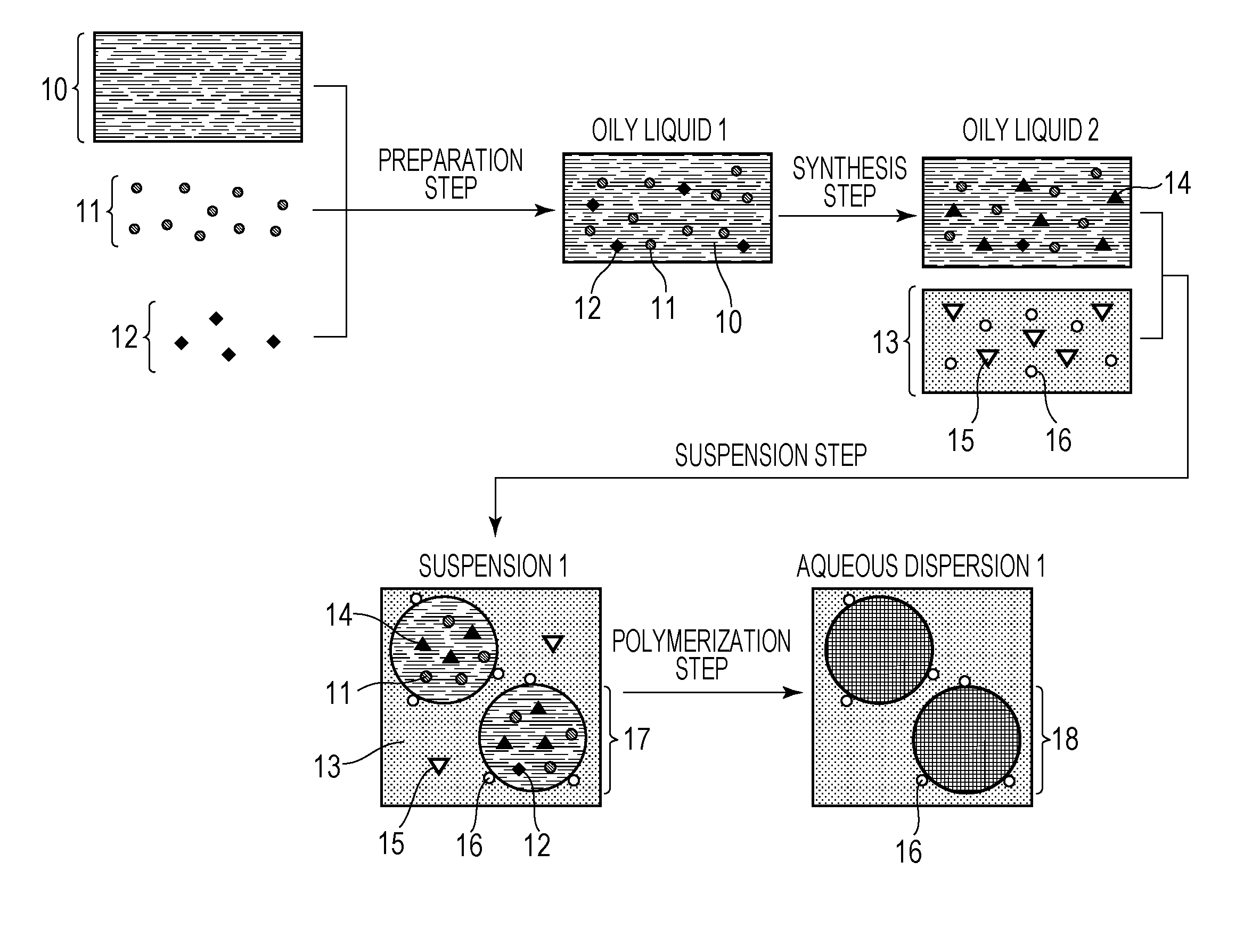

Method for producing polymer particles

InactiveUS20120277390A1Satisfactory molecular-weight controllabilitySatisfactory polymerization conversion ratePhotochemistryOil droplet

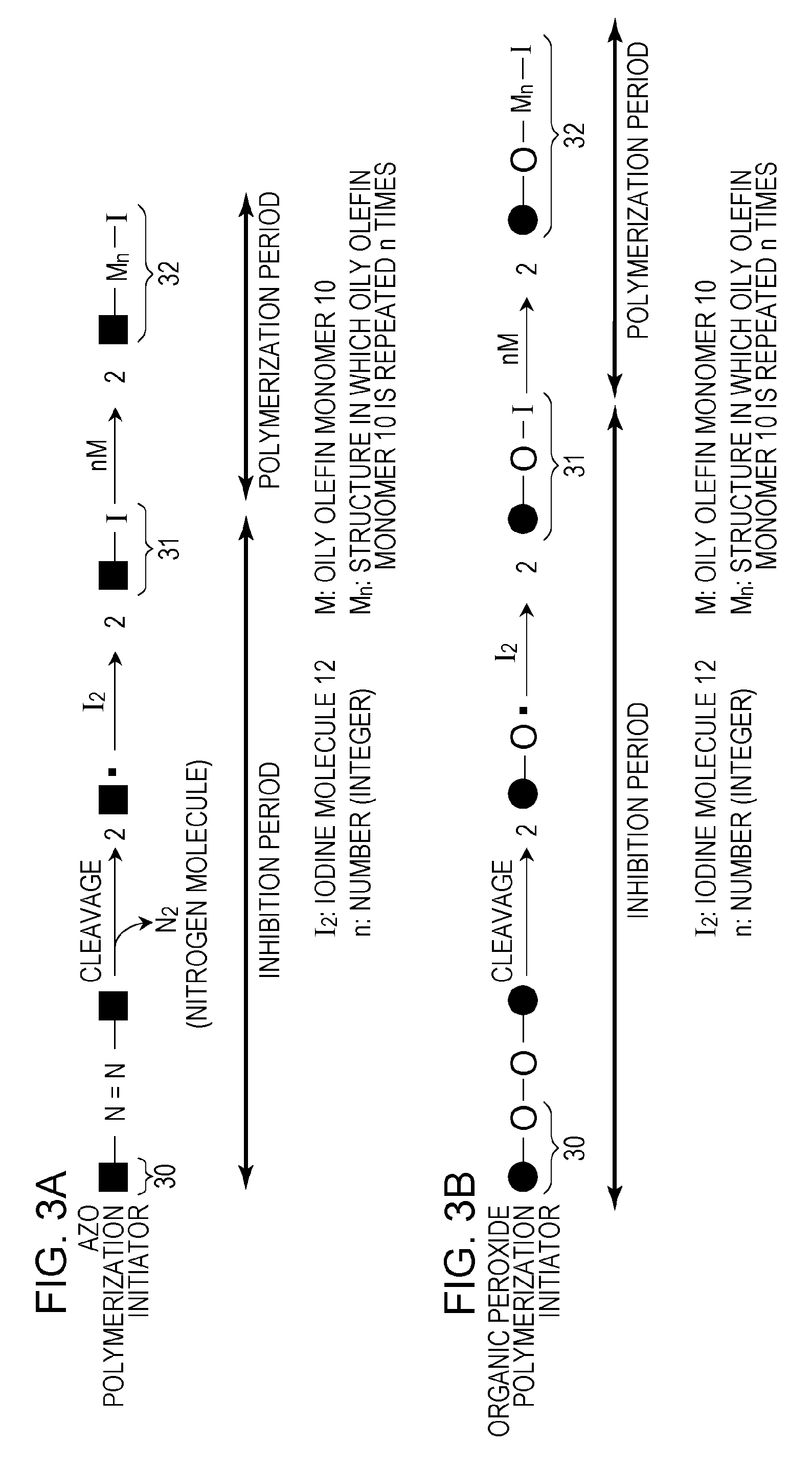

A method for producing polymer particles includes a suspension step of suspending a first liquid mixture containing an oily olefin monomer, a radical polymerization initiator, and an iodine molecule in a second liquid mixture containing water and an iodide ion to prepare a suspension containing an oil droplet having the first liquid mixture; a synthesis step of synthesizing an iodine compound by allowing a radical generated by cleavage of the radical polymerization initiator to react with the iodine molecule in the oil droplet; and a polymerization step of polymerizing the oily olefin monomer in the oil droplet.

Owner:CANON KK

A method of measuring an oxygen atom concentration by utilizing a titration technology

A method of measuring an oxygen atom concentration by utilizing a titration technology is provided. The method adopts nitric oxide as a fluorescent indicator, wherein the nitric oxide and an oxygen atom are subjected to a three-body recombination reaction to generate a nitrogen dioxide excited state molecule, and the excited state molecule emits wide-spectrum fluorescence during spontaneous radiation. The method adopts iodine molecules or mercury atoms, and the like as a titrant. The titrant rapidly reacts with oxygen atoms, the nitrogen dioxide molecule fluorescence quenches when the oxygen atoms are completely consumed through the titrant, and quenching of the nitrogen dioxide molecule fluorescence during titration is adopted as a titration end point. The method only needs to measure the concentration of the titrant, can determine the titration end point by observing the fluorescence of the indicator through naked eyes, and is advantaged by being simple, direct, rapid and convenient.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

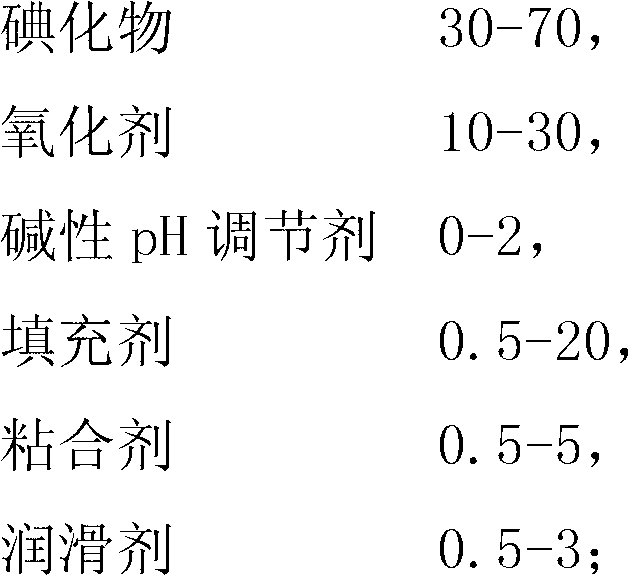

Solid molecular iodine disinfectant and preparation method thereof

ActiveCN102697804ALess irritatingImprove stabilityPowder deliveryAntiinfectivesSolubilityDisinfectant

The invention discloses a solid molecular iodine disinfectant and a preparation method thereof. The disinfectant comprises an iodide, an oxidant capable of oxidizing the iodide into iodine molecules, and a pH regulator for regulating the mixture of the iodide and the oxidant to be acidic; the disinfectant consists of a preparation 1 containing the iodide and the oxidant and a preparation 2 containing the pH regulator; and the preparation 1 and the preparation 2 are in a solid state. The disinfectant is high in stability and remarkable in disinfection effect; and due to high water solubility of main agents and auxiliary materials, the disinfectant can be quickly dissolved in water and is safe and convenient to use and carry. Because the raw materials are nontoxic, the disinfectant can be used for soaking disinfection of skin and can also be used for treating various skin diseases caused by bacteria, fungi and viruses.

Owner:山东沙多普生物科技有限公司

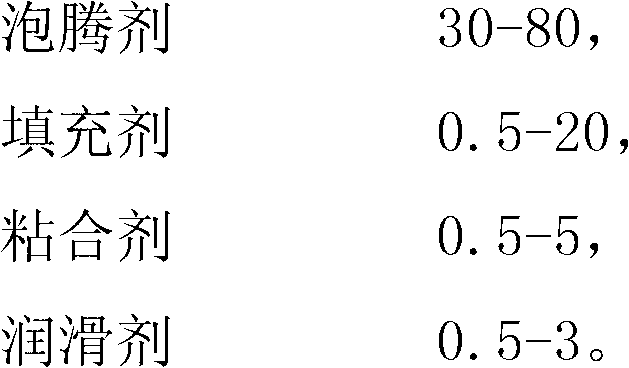

Organic functional material and preparation method and application in iodine adsorption thereof

InactiveCN109603764AEasy accessLarge molecular pore sizeOther chemical processesSynthesis methodsPollution

The invention belongs to the field of synthesis and application of organic functional materials, in particular to a synthesis method and application of an organic functional material formed through aself-assembly function based on citrazinic acid and cytosine. The method adopts the citrazinic acid and the cytosine as raw materials, and specifically comprises the steps that a certain proportion ofcitrazinic acid and cytosine solid are grinded; the grinded mixture is mixed with a certain proportion of an acetonitrile and water mixed solution to be subjected to ultrasound for several seconds and then naturally dried, and the organic functional material is obtained. The method has the advantages that the material synthesis method is simple and easy to operate, pi electrons enriched in the framework of the synthesized material and the larger pore diameter of the material enable the material to adsorb iodine molecules in air and an organic solvent, and a method for adsorbing radioactive iodine in nuclear waste pollution is provided.

Owner:ZHEJIANG NORMAL UNIVERSITY

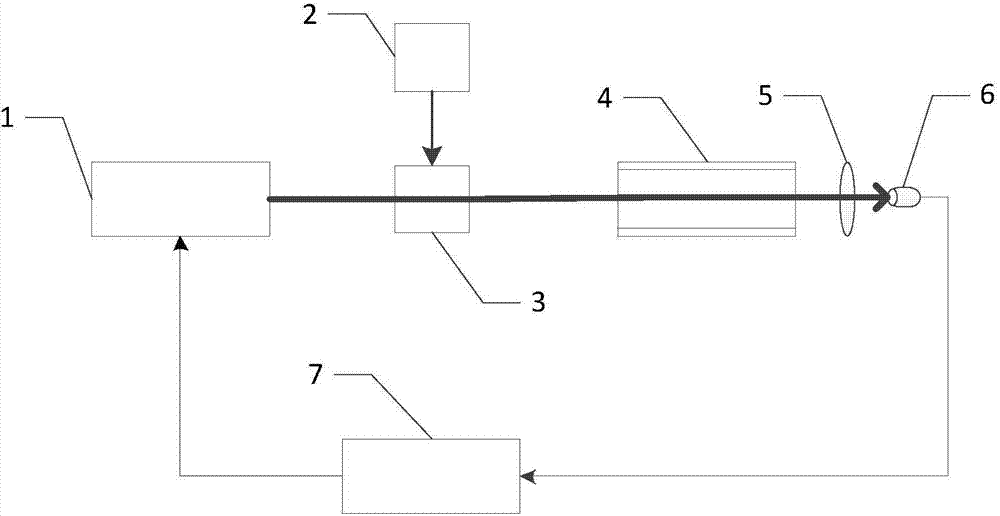

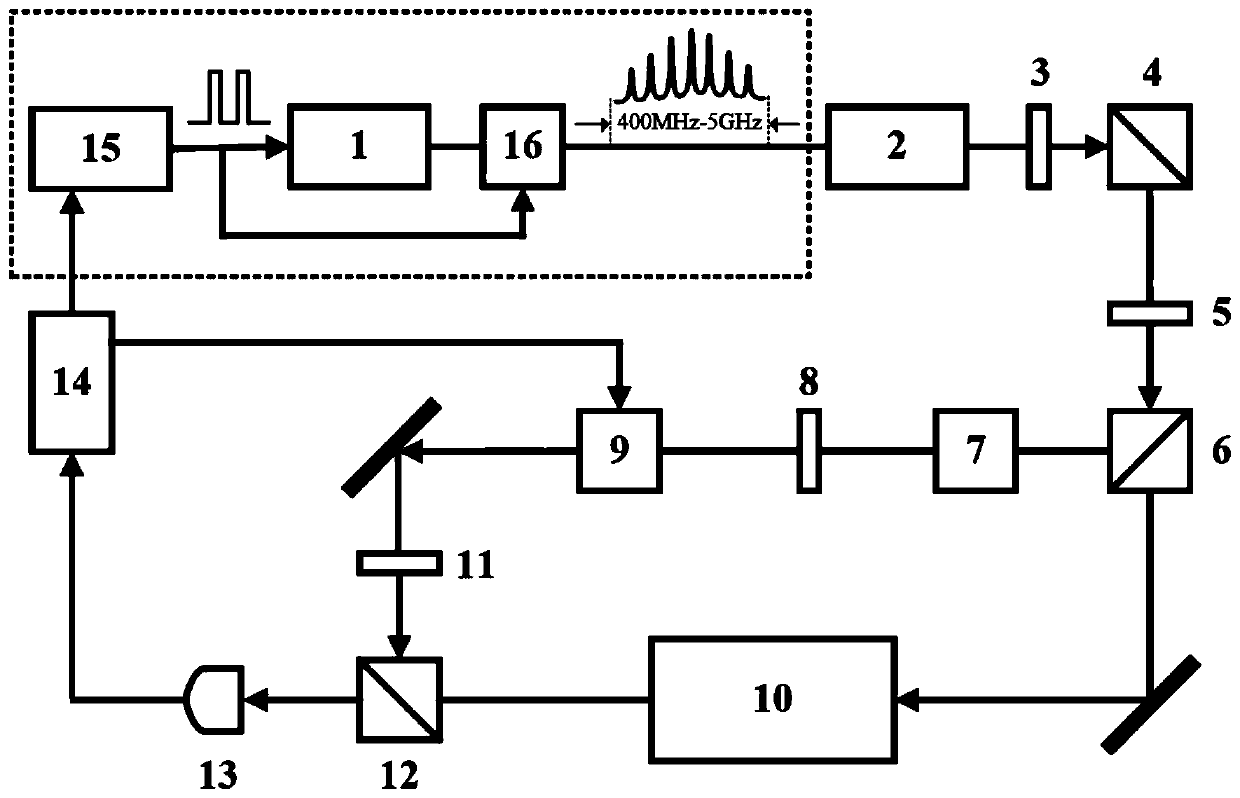

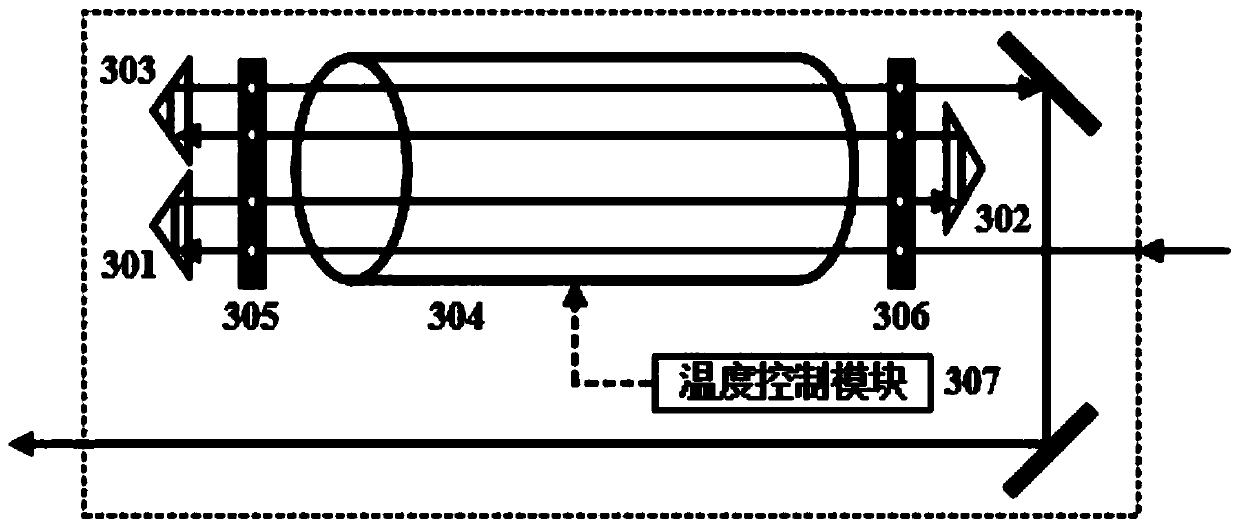

Laser phase locking frequency stabilizing device and method based on iodine molecule filter

ActiveCN104733996ALow divergence angle requirementsSimple structureLaser detailsFrequency stabilizationOptoelectronics

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Iodine/hydrophobic cyclodextrin clathrate and its preparation method and use

InactiveCN103785366AQuick killHas broad-spectrum antibacterial propertiesBiocideOther chemical processesToxic gasCyclodextrin

Owner:SHENYANG PHARMA UNIVERSITY

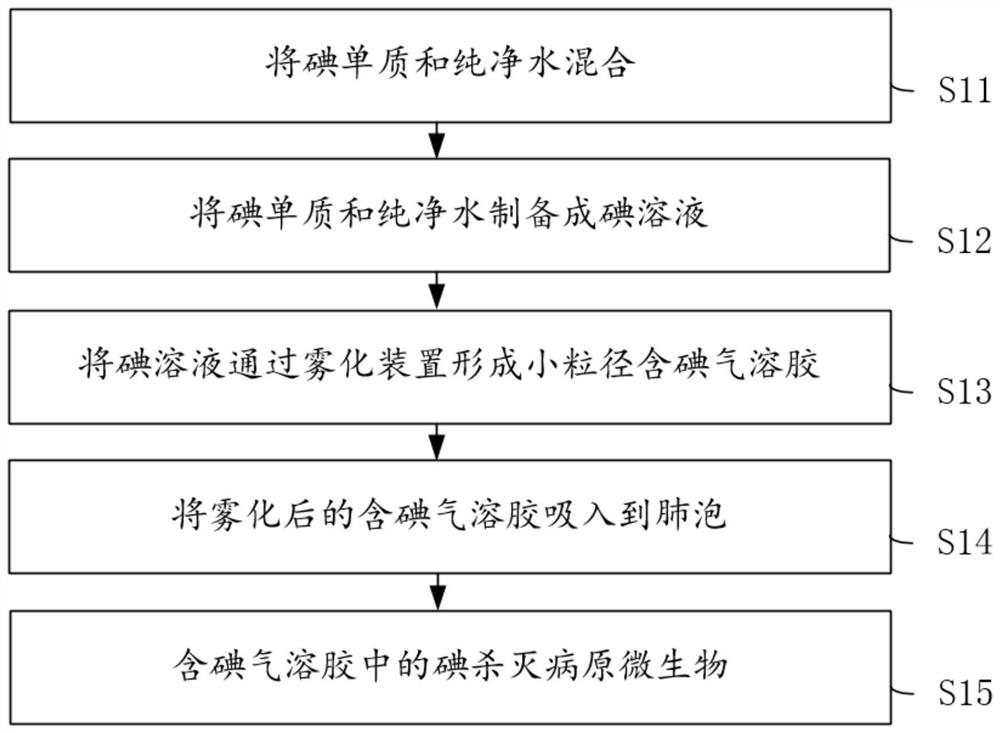

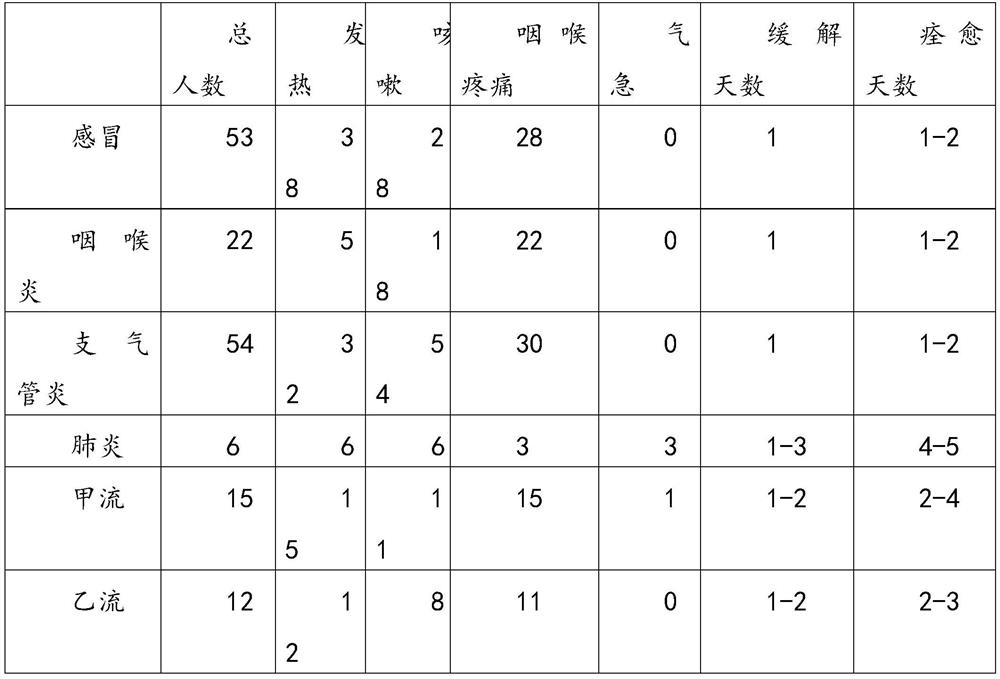

Application of iodine in preparation of medicine for preventing and treating respiratory tract infectious diseases and method for preparing iodine-containing aerosol with low particle size

PendingCN112791097AEfficient killingKill easilyAntibacterial agentsAntimycoticsPulmonary infectionLung alveolus

The invention discloses an application of iodine in preparation of a medicine for preventing and treating respiratory tract infectious diseases and a method for preparing iodine-containing aerosol with low particle size. According to the invention, iodine is dissolved in pure water and an oily solvent to respectively prepare two iodine solution atomizing agents, and the two iodine solution atomizing agents are atomized into iodine-containing aerosol by an atomizer to be inhaled into the respiratory tract, so that pathogens are quickly and efficiently killed, and the iodine-containing aerosol becomes the only specific medicine for treating respiratory virus infection lacking effective treatment medicines; and more effective and convenient treatment medicines are provided for infection of respiratory bacteria, mycoplasmas, fungi and the like. The method is mainly characterized in that iodine is prepared into a low-concentration iodine solution and atomized into iodine-containing aerosol, so that the density of iodine is greatly reduced, the irritation is greatly reduced, and iodine molecules enter the respiratory tract to kill pathogens; the iodine-containing aerosol with low particle size can reach pulmonary alveoli to directly screen and kill viruses in the pulmonary alveoli, so that critical and severe pulmonary infection patients can be quickly out of danger, and mild diseases can be quickly cured.

Owner:金玉东

Device and method for continuously generating iodine vapor

ActiveCN110544544APrevent overflowEvenly heatedNuclear energy generationNuclear monitoringEngineeringNuclear fuel

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method for producing polymer particles

InactiveUS20120322965A1Improving molecular-weight controllabilityContainment leakAqueous solutionAlkene

A method for producing polymer particles includes a preparation step for preparing a first oily liquid containing an oily olefin monomer, a radical polymerization initiator, and an iodine molecule; a synthesis step for obtaining a second oily liquid containing at least an iodine compound produced by a reaction between a radical generated by cleavage of the radical polymerization initiator and the iodine molecule in the first oily liquid; a suspension step for obtaining an oil droplet of the second oily liquid by suspending the second oily liquid in an aqueous solution containing an oxidizing agent, an acid, and a dispersant; and a polymerization step for polymerizing the oily olefin monomer in the oil droplet.

Owner:CANON KK

MOF (Metal Organic Framework) porous adsorption material as well as preparation method and application thereof

PendingCN114405482AImprove applicabilityGuaranteed application effectOther chemical processesAlkali metal oxides/hydroxidesAlkaneMetal-organic framework

The invention belongs to the technical field of complex application, and discloses an MOF (Metal Organic Framework) porous adsorption material, a preparation method thereof and application of the MOF porous adsorption material in the aspects of efficiently adsorbing iodine vapor and capturing iodine molecules in an iodine aqueous solution. The MOF iodine adsorption material is prepared through solvothermal reaction of lead ions and 5-(4-pyridine) isophthalic acid (pi), the chemical formula is [Pb2 (pia) 2 (DMA)]. DMA, the compound is of a column-chain structure, Pb < 2 + > ions and ligand carboxylic acid groups form a defective double-cube alkane [Pb4O6]-based metal carboxyl chain, and the defect double-cube alkane [Pb4O6]-based metal carboxyl chain is used for adsorbing iodine. Adjacent chains are expanded into a three-dimensional porous network structure with a square window one-dimensional nano pore channel through pia ligands which are arranged in parallel. The MOF can be used for efficiently capturing iodine vapor and iodine molecules in an aqueous solution after being replaced with a low-boiling-point solvent and subjected to heating, vacuumizing and activating treatment, and the material keeps high structural stability in the iodine adsorption process.

Owner:SHAANXI UNIV OF SCI & TECH

Starch polyiodide and preparation method and application thereof

The invention relates to starch polyiodide and a preparation method and application thereof. The starch polyiodide is a polymer complex formed by the coordination of oxygen-containing groups in starch molecules with polyiodide molecules; the preparation method includes: (1), gelatinizing starch; (2), coordinating the gelatinized starch with iodine, iodides and a stabilizer to produce liquid starch polyiodide; (3), adding a precipitant to precipitate and separate the liquid starch polyiodide, filtering, and drying with filter cakes to obtain powdery starch polyiodide; (4), reusing filtrate. As a disinfectant, the starch polyiodide has the characteristics such as water solution controllability, high sterilizing efficiency, good stability, good safety and convenience of use, good degradability and low sterilizing cost and is a green new-generation disinfectant; by means of adding, spraying, impregnating, applying, washing or fumigating, the disinfectant may be used in disinfection of drinking water and aquaculture water, medical disinfection, environmental disinfection, vegetable and fruit disinfection, food preservation, mold prevention, plant disease prevention and treatment and the like.

Owner:CHANGZHOU GARDENSUN ANTI BACTERIAL MATERIALS TECH

Iodine molecular optical clock based on pulse modulation wide-spectrum comb-tooth-type laser and control method of iodine molecular optical clock

ActiveCN111413859AImprove effective utilizationImprove signal-to-noise ratioApparatus using atomic clocksPower control systemControl system

The invention relates to an iodine molecular optical clock based on pulse modulation wide-spectrum comb-tooth-type laser and a control method. A power supply control system of the iodine molecule optical clock generates a pulse modulation signal and transmits the pulse modulation signal to a laser system to generate a pulse signal, optical feedback isolation is performed on a rear optical path through an isolator, and a first half-wave plate and a first polarization splitting prism are sequentially connected behind the isolator; a laser frequency stabilization light path comprises a second half-wave plate and a second polarization splitting prism which are connected in sequence and divide the laser for the laser frequency stabilization light path into two beams; one beam with stronger light intensity is used as a pump laser, passes through a Glan-Taylor prism, a third half-wave plate and an electro-optic phase modulator in sequence, and is reflected to a light path multiplication system by a third polarization splitting prism; and the beam with weaker light intensity is used as a detection laser to pass through the light path multiplication system and the third polarization splitting prism, is received by a high-speed photoelectric detector and then is input into a laser phase discrimination and high-speed servo feedback control circuit to generate a servo signal of the power supply control system.

Owner:PKU HKUST SHENZHEN HONGKONG INSTITUTION

Method for removing harmful elements of wet-process phosphoric acid and derivative products thereof and equipment

PendingCN110540179AImprove qualityReduce visual pollutionIodinePhosphorus compoundsPhosphorus pentasulfideO-Phosphoric Acid

The invention relates to the technical field of treatment of wet-process phosphoric acids, in particular to a method for removing harmful elements of a wet-process phosphoric acid and derivative products thereof and equipment. According to the method for removing the harmful elements of the wet-process phosphoric acid and the derivative products thereof and the equipment, phosphorus pentasulfide is selected as an arsenic removal catalyst, and is added into a wet-process phosphoric acid extracting groove and a wet-process phosphoric acid ageing groove separately, a two-stage harmful element removing reaction is carried out to make arsenic in the wet-process phosphoric acid and the derivative products thereof enter a phosphogypsum stack finally in a form of an insoluble compound As2S3, not only is the arsenic removed, but also heavy metal cations of the harmful elements of Cr, Pb, Cu and the like in the wet-process phosphoric acid and the derivative products thereof are removed at the same time, the quality of the wet-process phosphoric acid and the derivative products thereof is improved, harmful elements in an obtained phosphate fertilizer are reduced, and a by-product hydrogen sulfide gas is used as a reducer of iodine molecules in extracted tail gas, so that consumption of a liquid SO2 raw material in an iodine recovery system is reduced, visual pollution of red smoke from the extracted tail gas is reduced, and iodine molecule resources are recovered.

Owner:GUIZHOU KAILIN GRP CO LTD

Sum-frequency and modulation transfer spectrum-based 1,572nm frequency stabilization system and method

The invention discloses a sum-frequency and modulation transfer spectrum-based 1,572nm frequency stabilization system apparatus which can be applied to CO<2> gas concentration detection laser radar. The frequency stabilization system comprises a 1,064nm laser, a 1,064nm beam splitter, 532nm frequency doubling crystal, a 532nm beam splitter, a 532nm electric-optical phase modulator, a 532nm first collimation lens, a 532nm polarized beam-splitting prism, a first iodine pool, a 532nm first collimation lens, a 532nm focusing lens, a 532nm photoelectric detector, a first frequency mixer, a first signal generator, a first electronic servo system, a 1,572nm laser, a 1,572nm beam splitter, a wavelength division multiplexer, 634nm sum-frequency crystal, a 634nm beam splitter, a 634nm electric-optical phase modulator, a 634nm first collimation lens, a 634nm polarized beam-splitting prism, a second iodine pool, a 634nm second collimation lens, a 634nm focusing lens, a 634nm photoelectric detector, a second frequency mixer, a second signal generator and a second electronic servo system. Direct utilization of a CO<2> long-absorption-pool frequency stabilization system is avoided, so that the size is reduced; and in addition, the iodine molecule fine absorption spectrum is narrower than CO<2> molecule absorption line, so that frequency stability is improved.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com