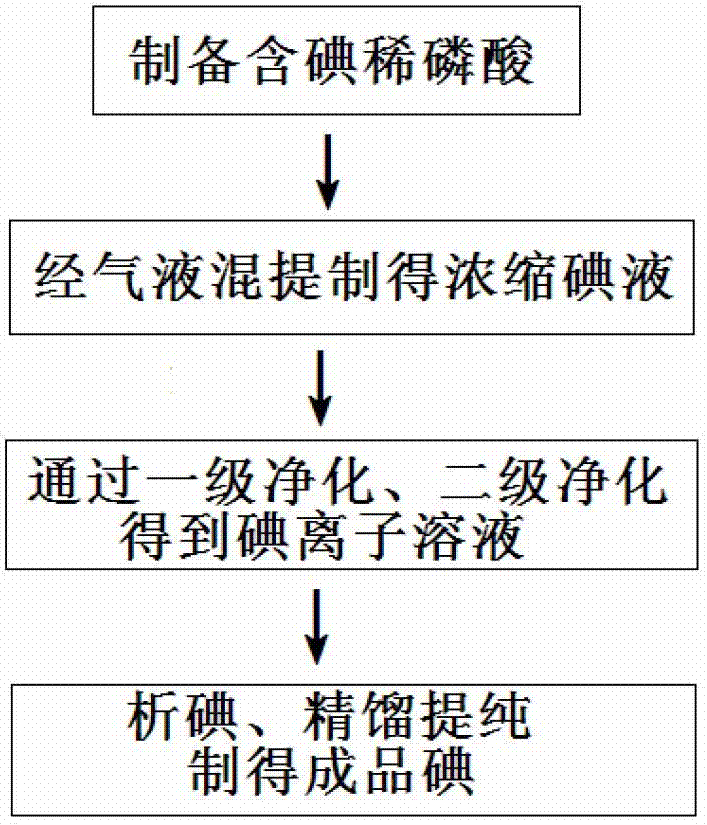

Gas-liquid mixed extraction iodine recovery technology

A gas-liquid mixed extraction and iodine recovery technology, which is applied in the direction of iodine, iodine/hydrogen iodide, etc., can solve the problems that the iodine molecular extraction method of iodine-containing phosphorus rocks has not been explained, and the iodine cannot be extracted simultaneously, and the recovery rate is high. , improve the purity, low economic cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take a total of 1000kg of phosphate rock containing 76ppm of iodine, stir, clarify, and filter to produce iodine-containing dilute phosphoric acid to generate iodine-containing waste gas. The iodine-containing dilute phosphoric acid is introduced into the gas-liquid mixed extraction integrated iodine recovery device, and the iodine-containing waste gas is introduced into the device at the same time. First add hypochlorous acid to iodine-containing dilute phosphoric acid, and under the action of the gas-liquid mixing separator inside the device, the iodine-containing gas and liquid are fully mixed, and the iodine in the acid enters the gas phase state. Then, the iodine-rich gas is introduced into the upper part of the recovery device through the inverted funnel device inside the gas-liquid mixed extraction integrated iodine recovery device, and the temperature is controlled at 39°C. Iodine is recovered with 2% sulfurous acid solution, and the obtained iodine-containing cl...

Embodiment 2

[0026] Take a total of 1000kg of phosphate rock containing 45ppm iodine, stir, clarify, and filter to produce iodine-containing dilute phosphoric acid, and generate iodine-containing waste gas. The iodine-containing dilute phosphoric acid is introduced into the gas-liquid mixed extraction integrated iodine recovery device, and the iodine-containing waste gas is introduced into the device at the same time. First add perchloric acid to iodine-containing dilute phosphoric acid, and under the action of the gas-liquid mixing separator inside the device, the iodine-containing gas and liquid are fully mixed, and the iodine in the acid enters the gas phase state. Then, the iodine-rich gas is introduced into the upper part of the recovery device through the inverted funnel device inside the gas-liquid mixed extraction integrated iodine recovery device, and the temperature is controlled at 36°C. Iodine is recovered with 3% sulfurous acid solution, and the obtained iodine-containing clear...

Embodiment 3

[0028] Take a total of 1000kg of phosphate rock containing 30ppm iodine, stir, clarify, and filter to produce iodine-containing dilute phosphoric acid to generate iodine-containing waste gas. The iodine-containing dilute phosphoric acid is introduced into the gas-liquid mixed extraction integrated iodine recovery device, and the iodine-containing waste gas is introduced into the device at the same time. First add chlorine gas to the iodine-containing dilute phosphoric acid, and under the action of the gas-liquid mixing separator inside the device, the iodine-containing gas and liquid are fully mixed, and the iodine in the acid enters the gas phase state. Then, the iodine-rich gas is introduced into the upper part of the recovery device through the inverted funnel device inside the gas-liquid mixed extraction integrated iodine recovery device, and the temperature is controlled at 33°C, and iodine is recovered with 5% sulfurous acid solution to obtain the iodine-containing clear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com