Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35 results about "Graphene production techniques" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

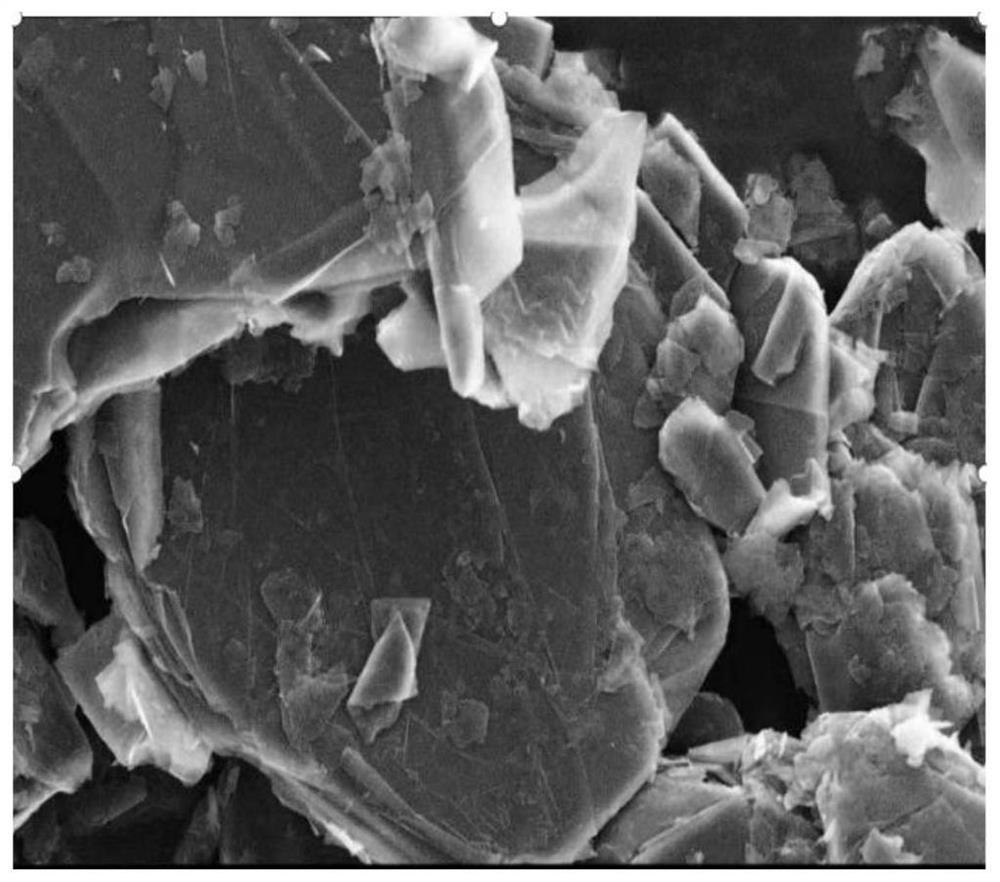

A rapidly increasing list of graphene production techniques have been developed to enable graphene's use in commercial applications. Isolated 2D crystals cannot be grown via chemical synthesis beyond small sizes even in principle, because the rapid growth of phonon density with increasing lateral size forces 2D crystallites to bend into the third dimension.

Production device and production process of graphene thin film coiled material

The invention discloses a production device of a graphene thin film coiled material and a process for producing the graphene thin film coiled material by using the device, and belongs to the technical field of graphene production. The device comprises a cabin body; and an atomic concentrator, a field effect separator, a reformer, a Hall fine arrangement device, a dose-effect fine arrangement device, a fermion enhancer, a film-retracting tension shaft and a guide shaft. The invention discloses the production process of the graphene thin film coiled material. According to the production equipment of the graphene thin film coiled material, the raw material serving as a carbon source is carbon dioxide, and the pollution to the atmosphere environment is close to zero. In addition, discharge of carbon dioxide is reduced, and the atmospheric greenhouse effect can be reduced. The power consumption of the equipment is very low, and the daily power consumption is about 5 degrees.

Owner:张文跃

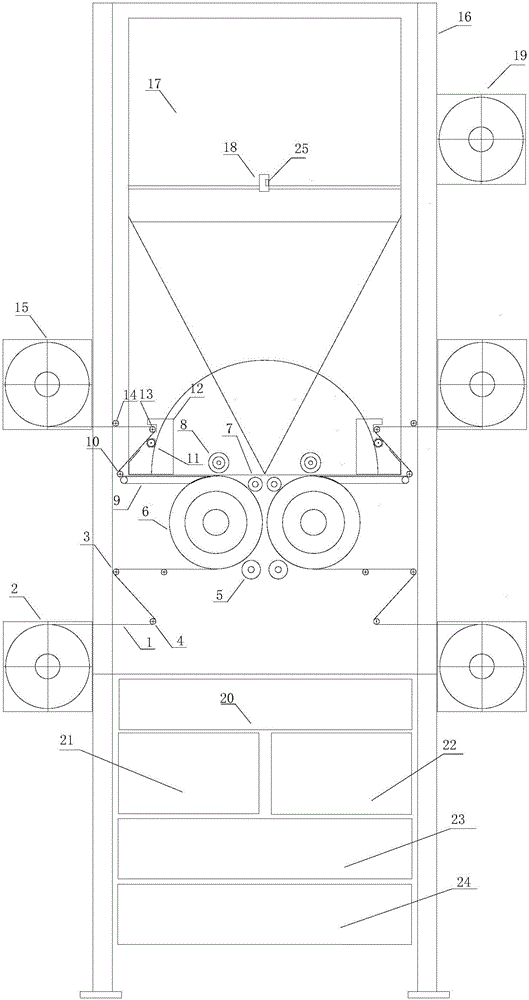

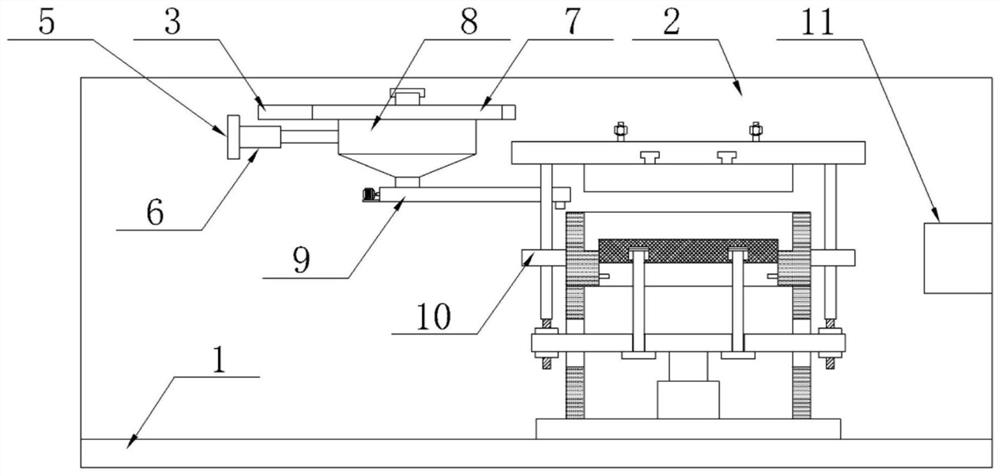

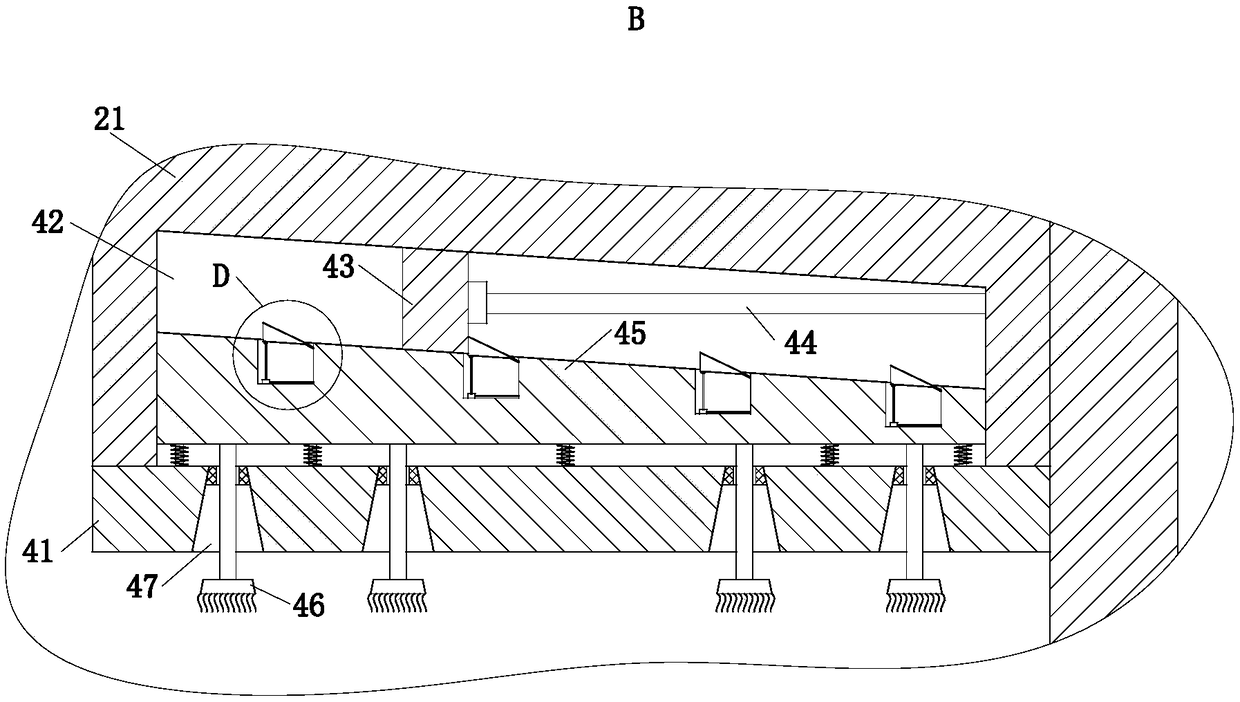

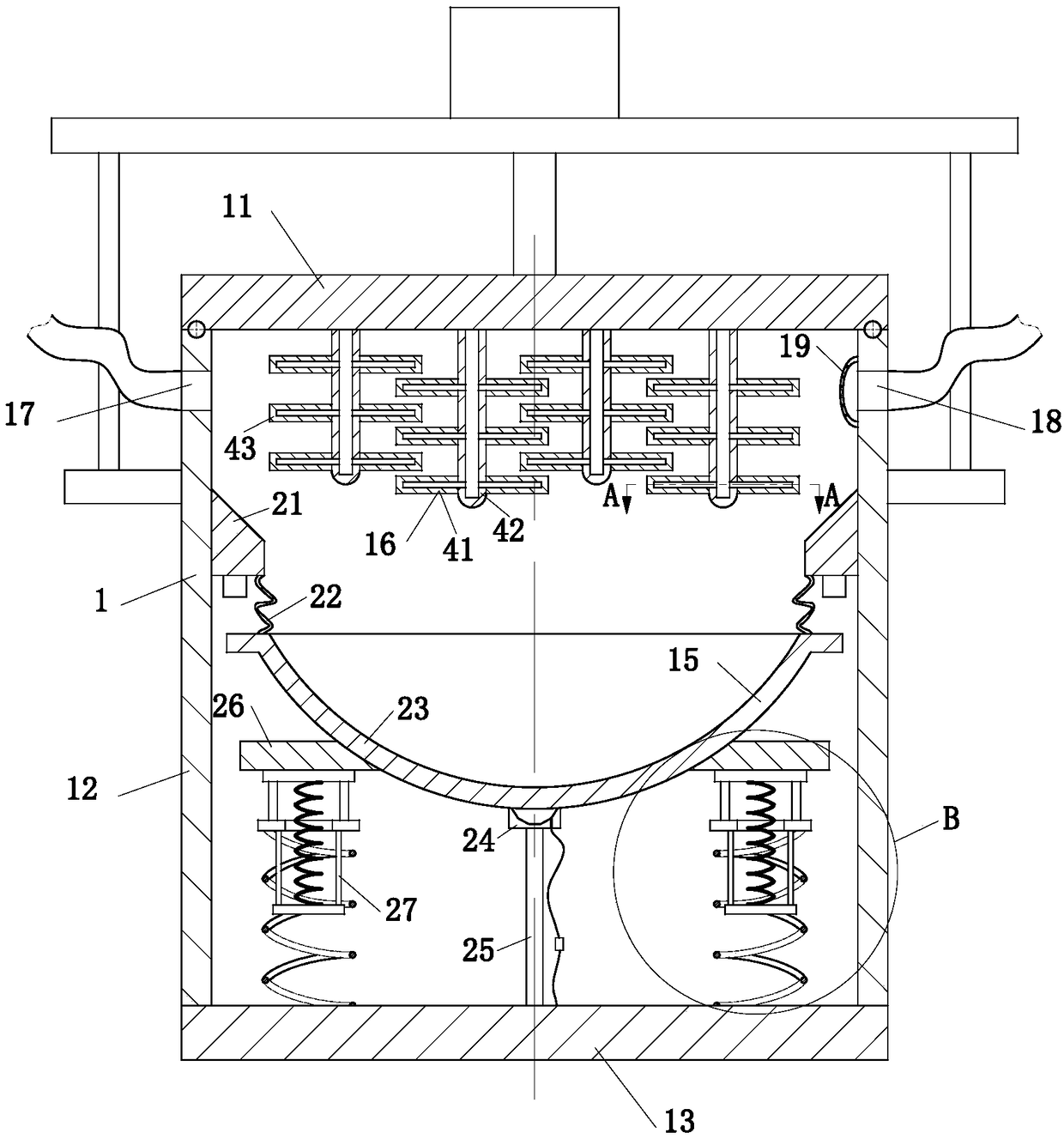

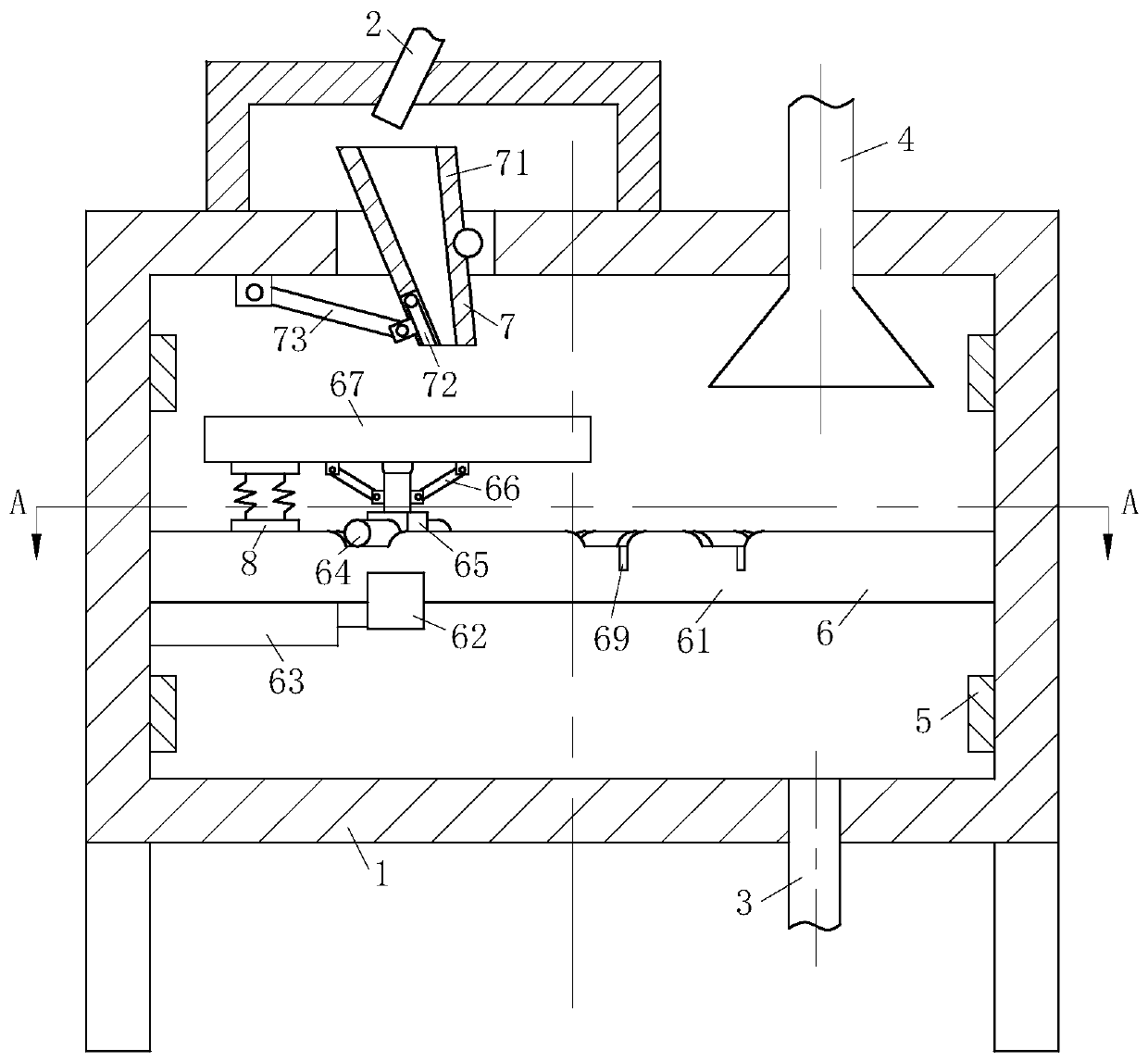

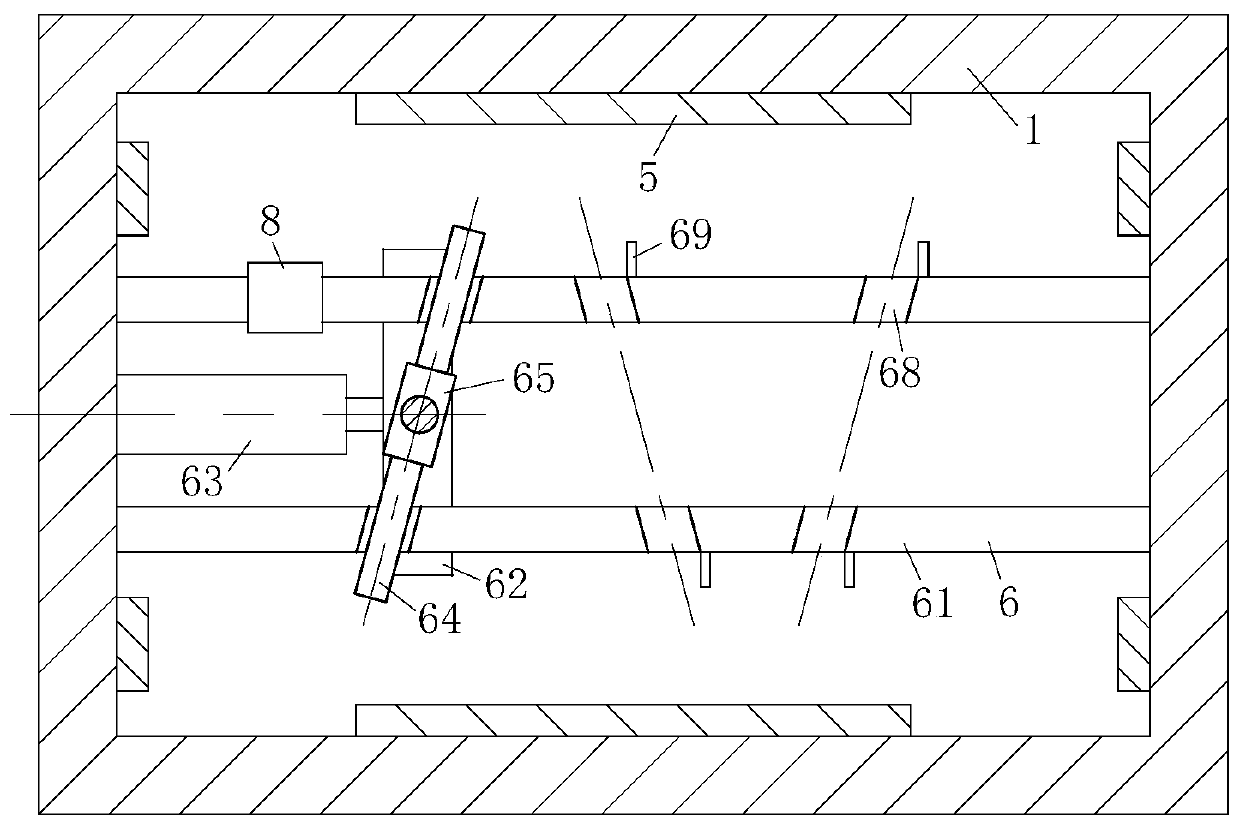

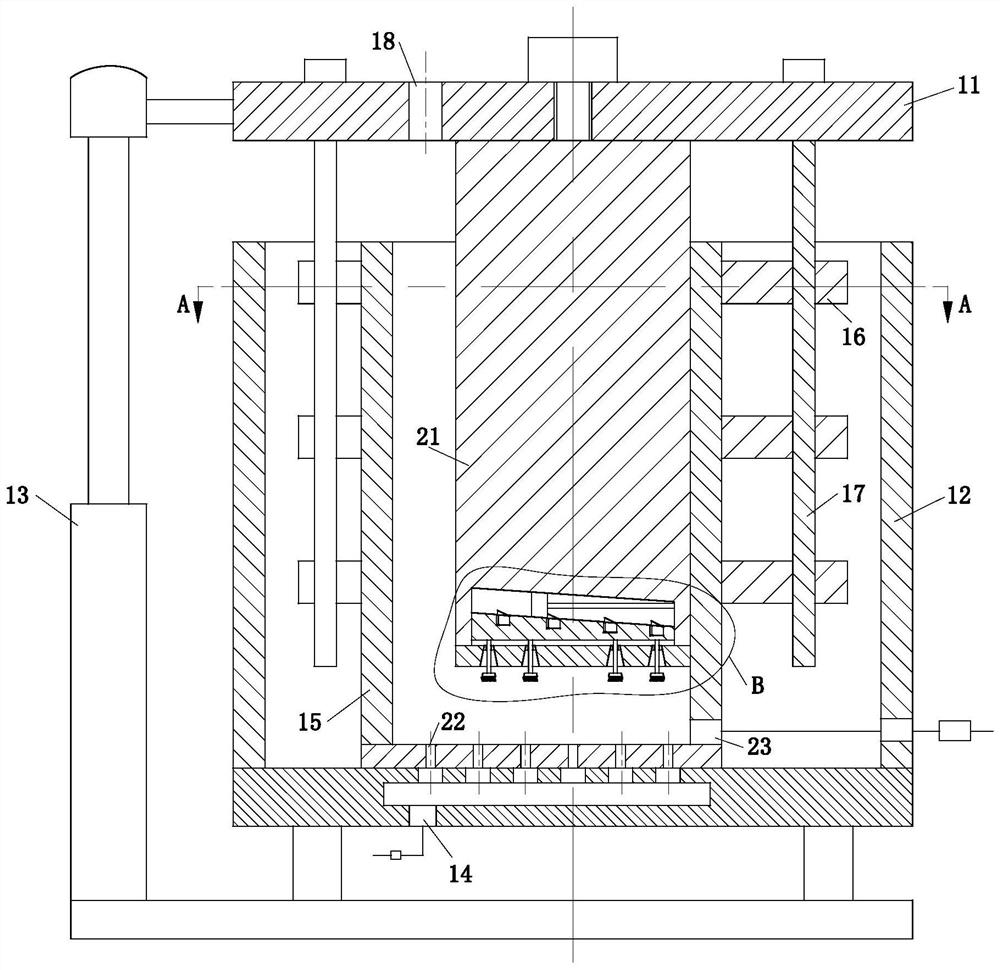

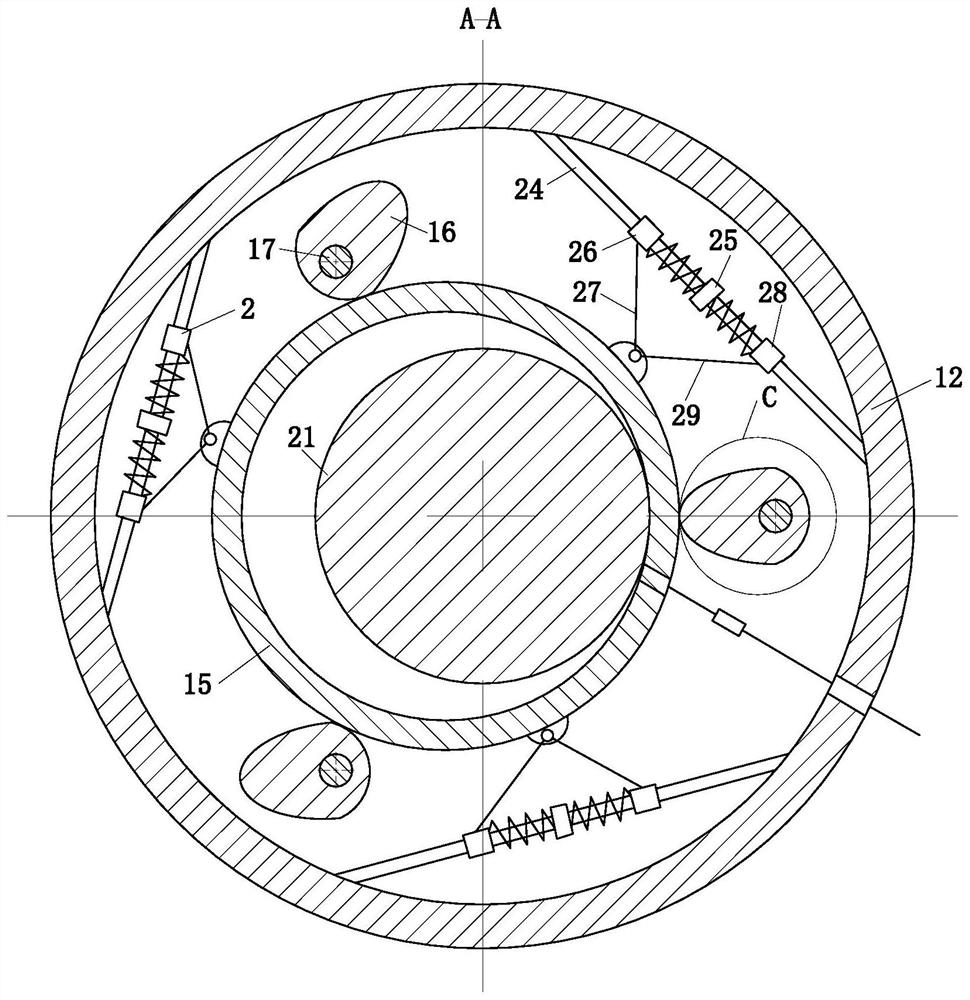

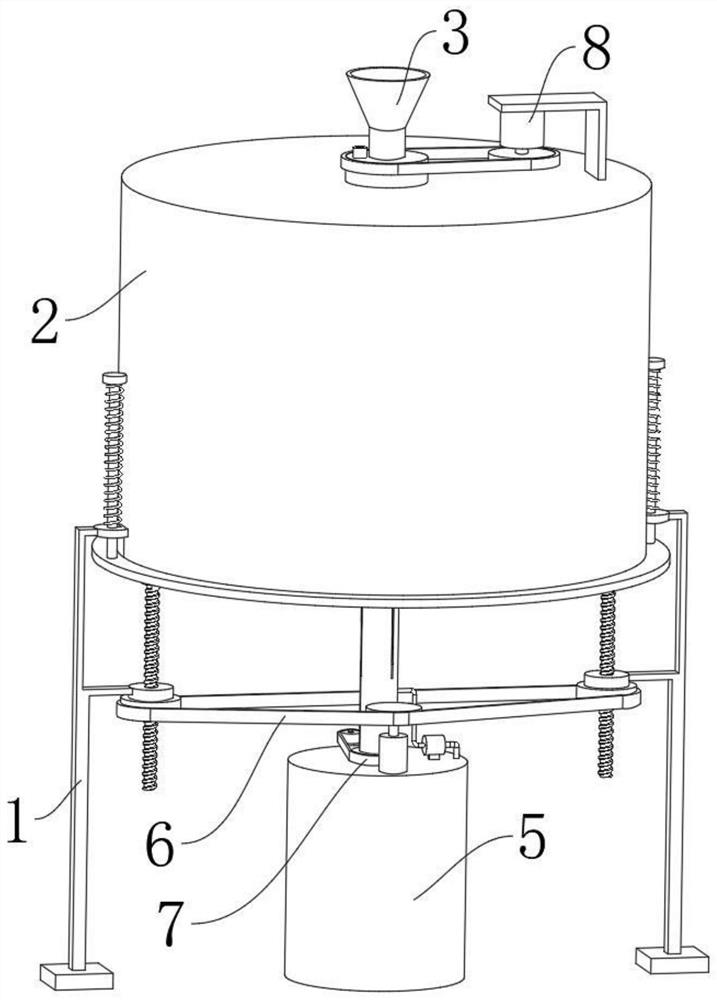

Graphene production and manufacturing system

InactiveCN108675290AAchieve vibrationAchieve hyperconnectivityCarbon compoundsGrain treatmentsDrive motorManufacturing systems

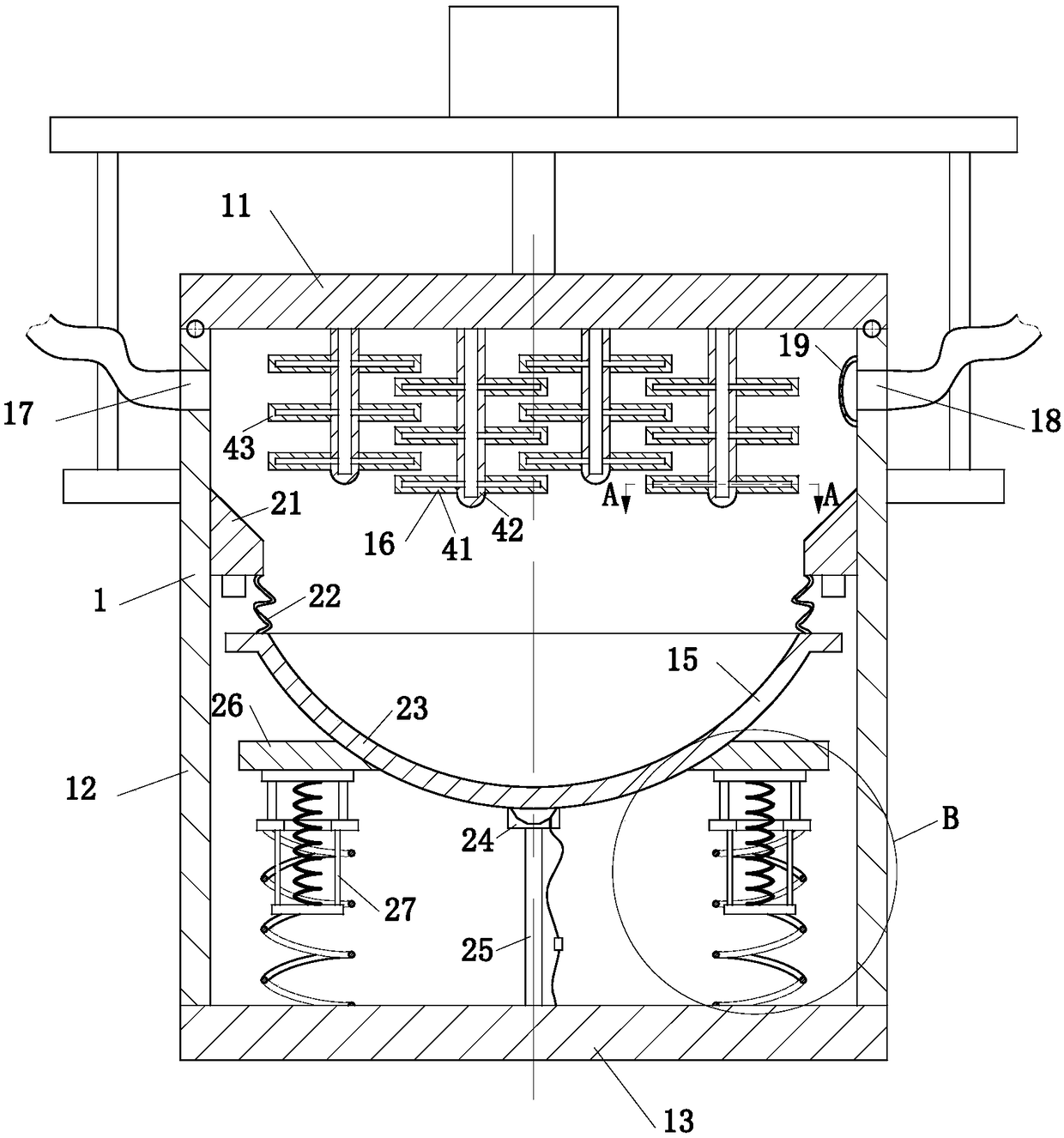

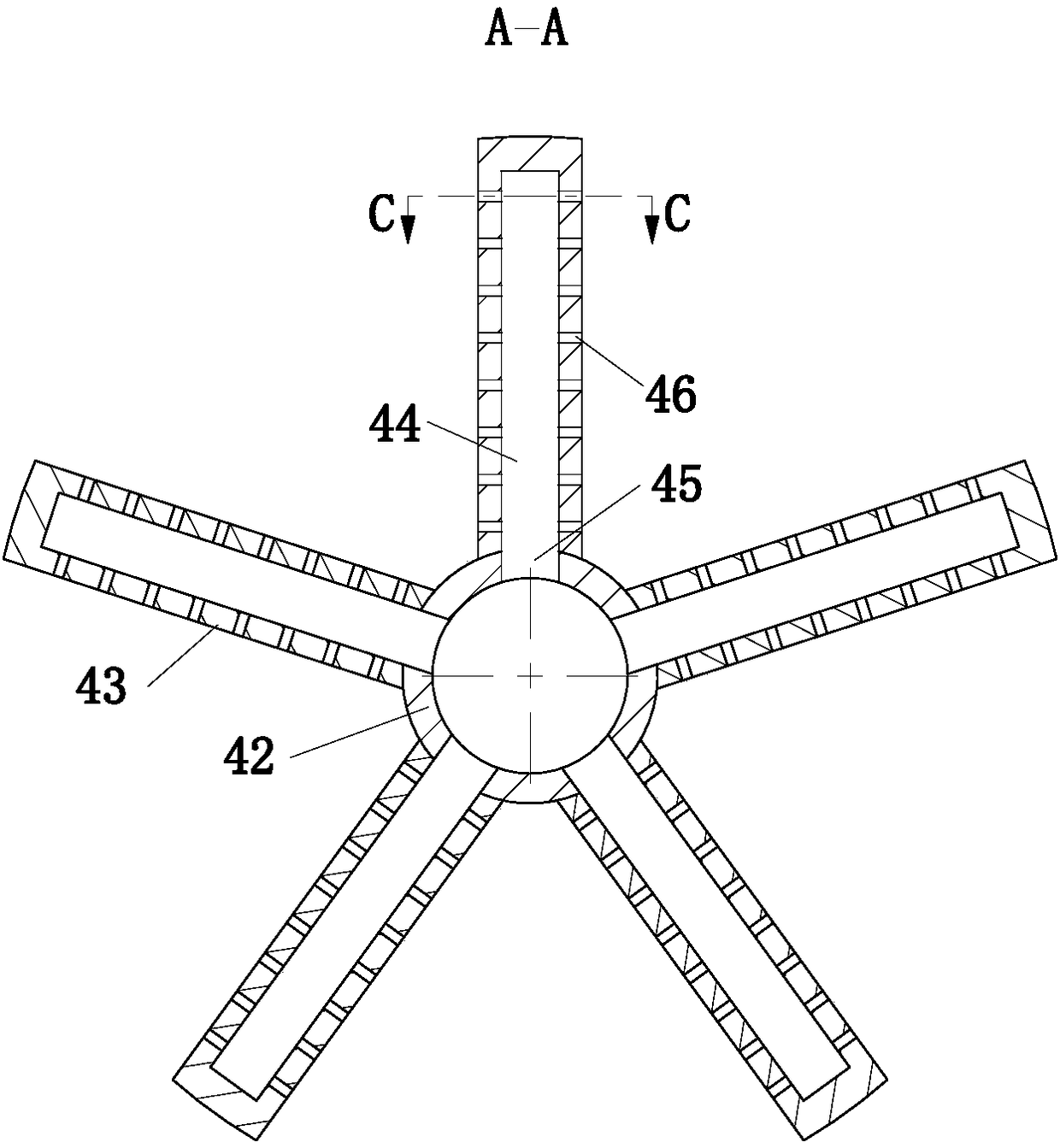

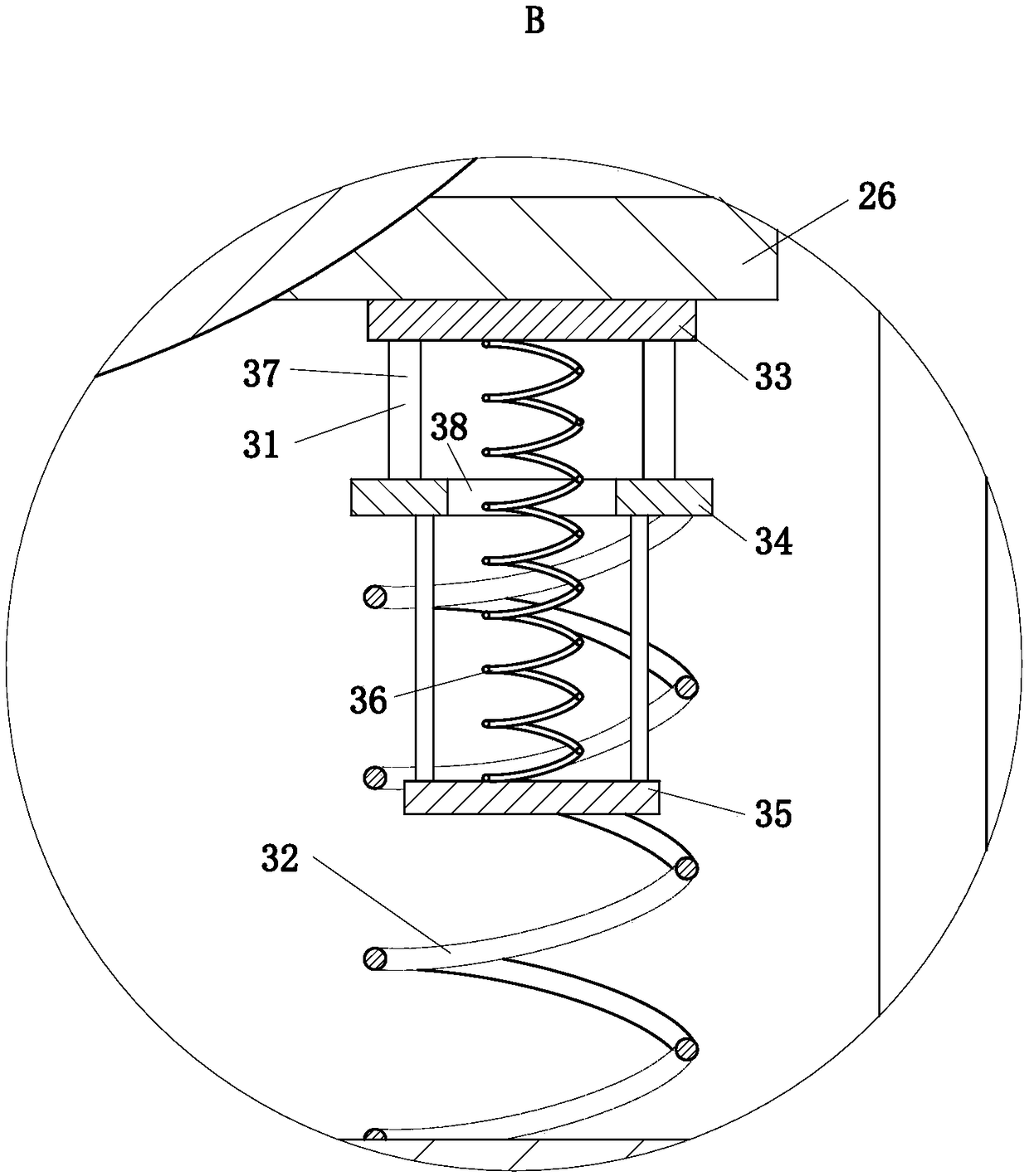

The invention belongs to the technical field of graphene production, and particularly relates to a graphene production and manufacturing system which comprises a drive motor, a support plate, a square-shaped rotary shaft, springs, a vibration vessel, castor supports and castors. The vibration vessel is arranged under a feeding hopper; a square-shaped groove is formed in the bottom end of the vibration vessel; the square-shaped rotary shaft is slidably arranged in the square-shaped groove; a group of springs are arranged at the upper end of the square-shaped rotary shaft; the lower end of the square-shaped rotary shaft is fixedly connected with a rotary shaft of the drive motor; a group of circular arc-shaped inclined slopes are arranged on the upper surface of the support plate; a group ofcastor supports are arranged under the vibration vessel; the upper ends of the castor supports are hinged with the bottom surface of the vibration vessel; the castors are hinged to the lower ends ofthe castor supports; the upper parts of the middle parts of the castor supports are connected with the bottom surface of the vibration vessel through the springs. According to the graphene productionand manufacturing system provided by the invention, through arranging the square-shaped rotary shaft under the vibration vessel, the vibration vessel can be driven to rotate and can be vibrated up anddown; through symmetrically arranged turnover plates, graphene particles can be turned over and stirred uniformly through forward and backward rotation.

Owner:陆挚译

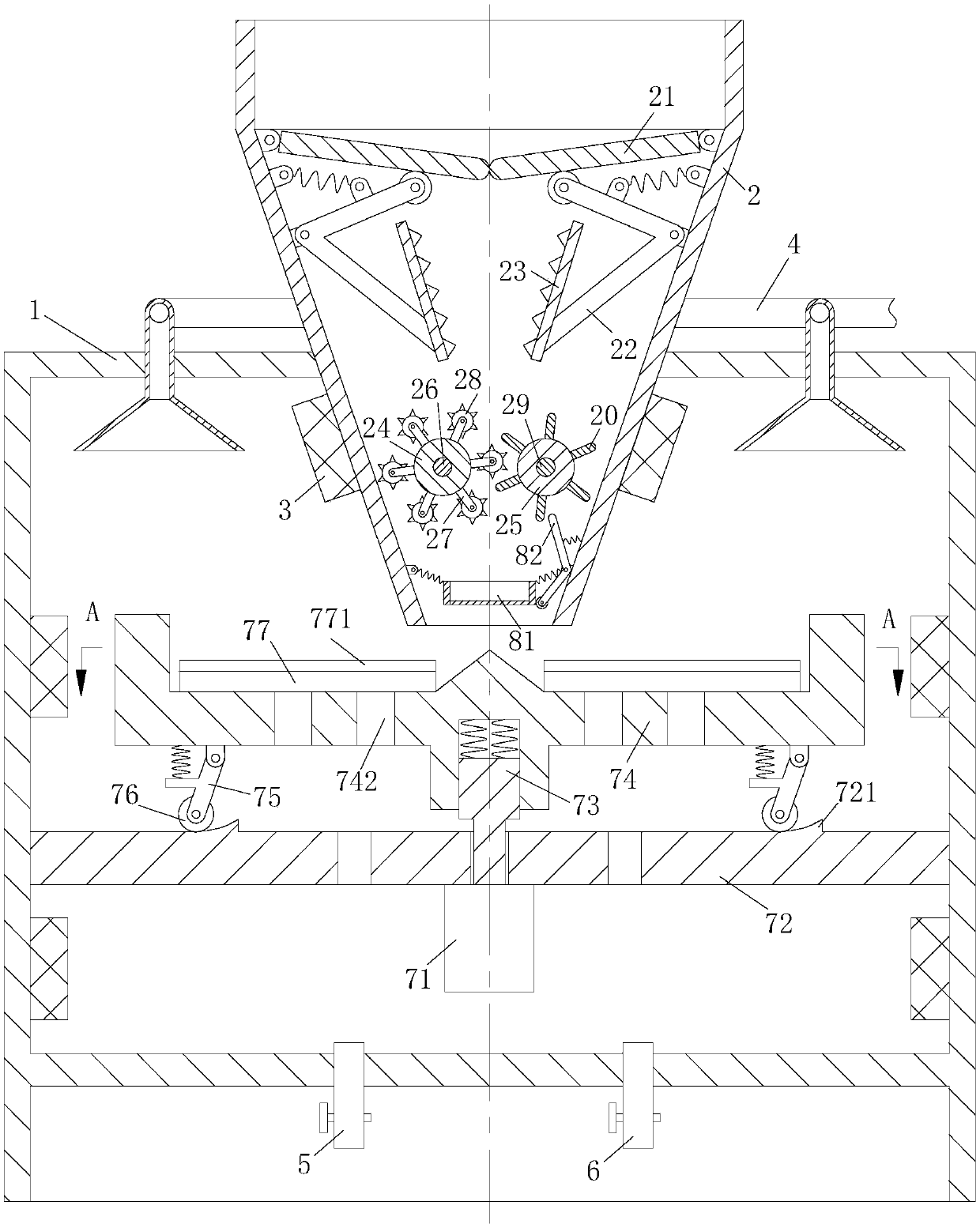

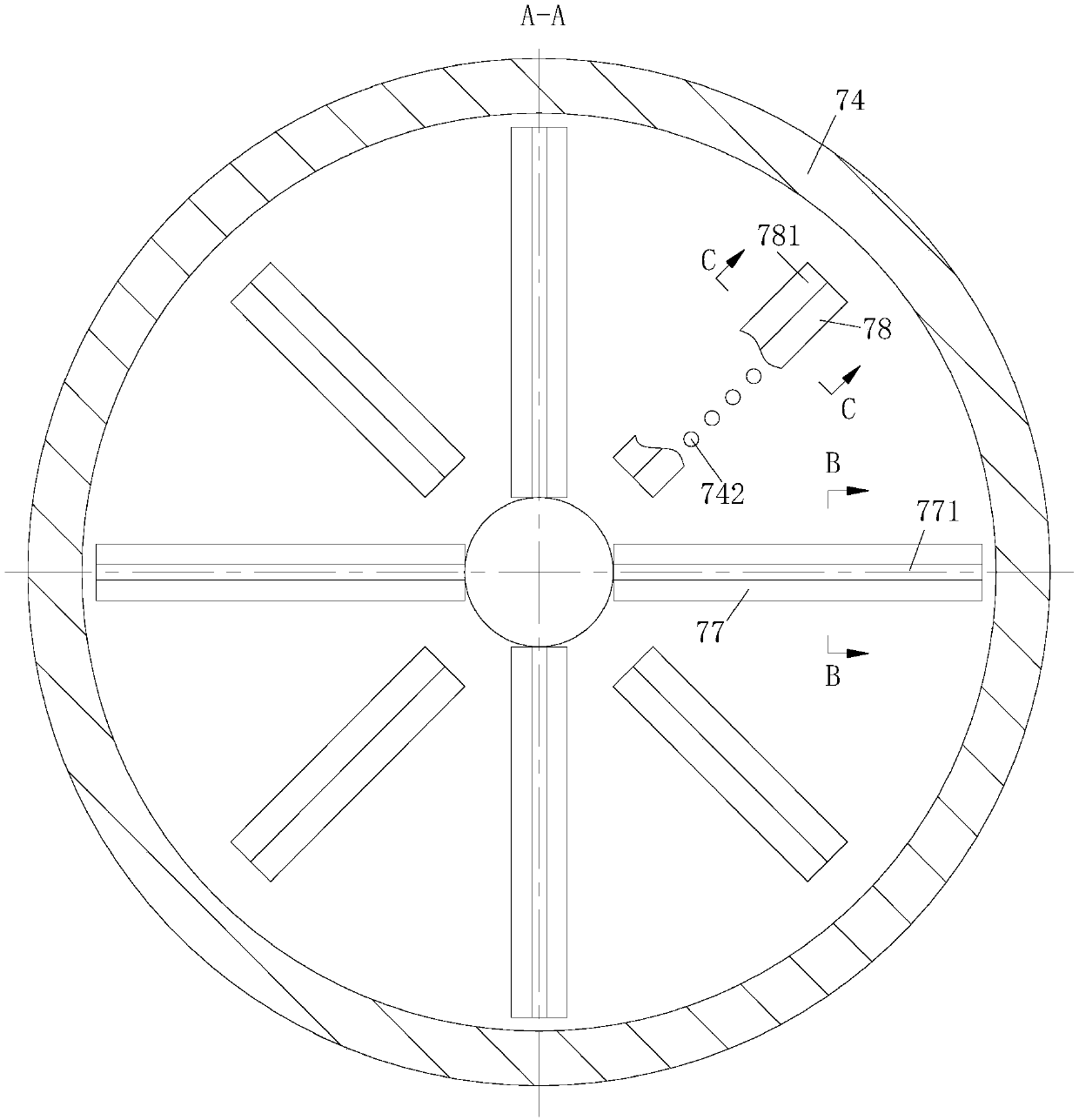

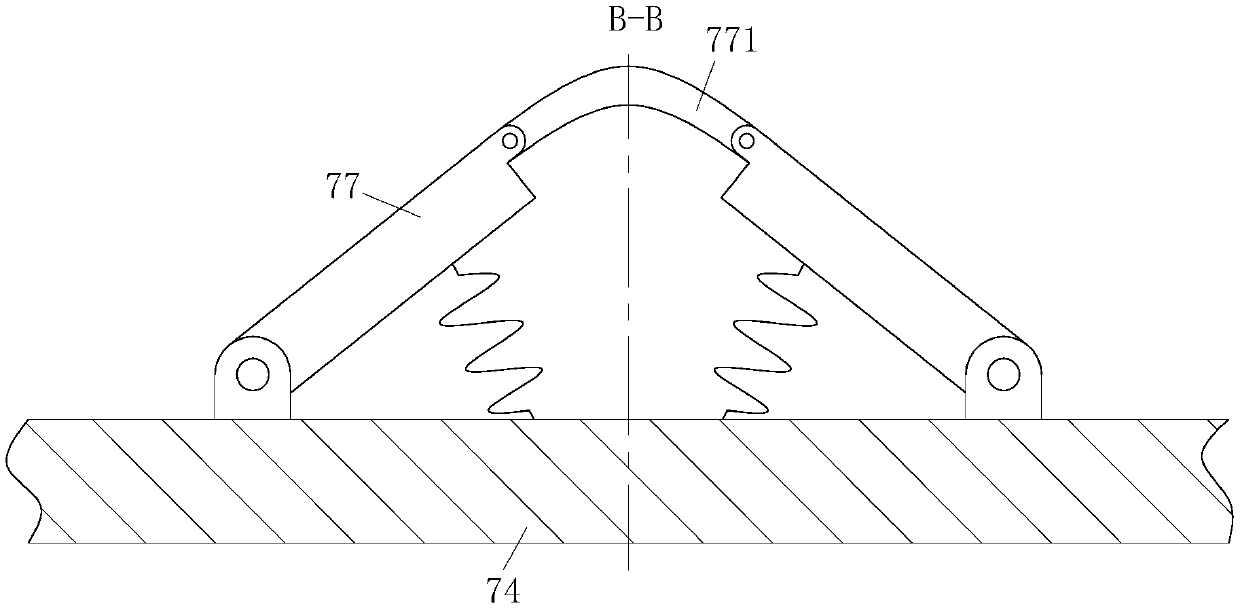

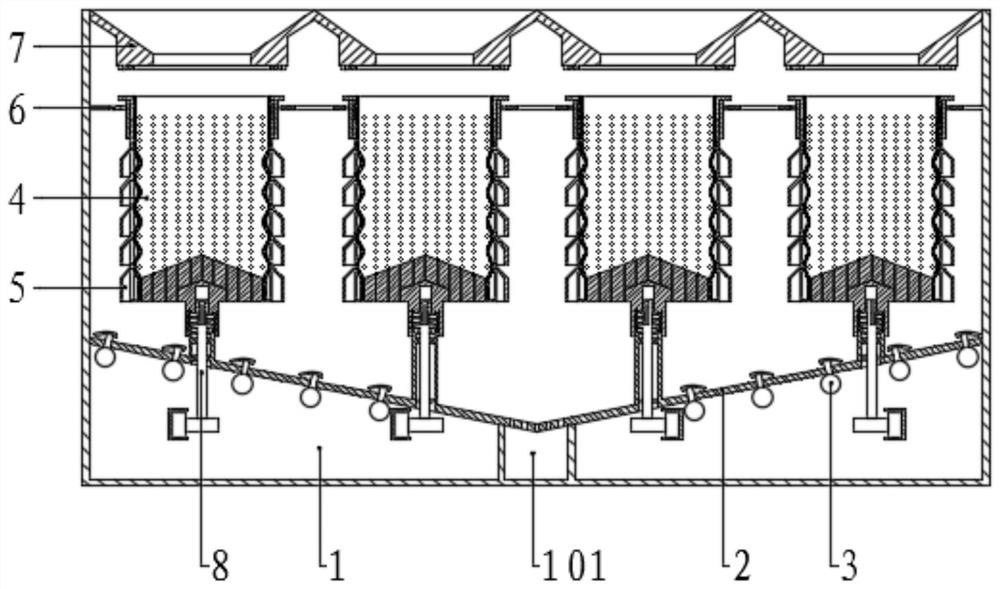

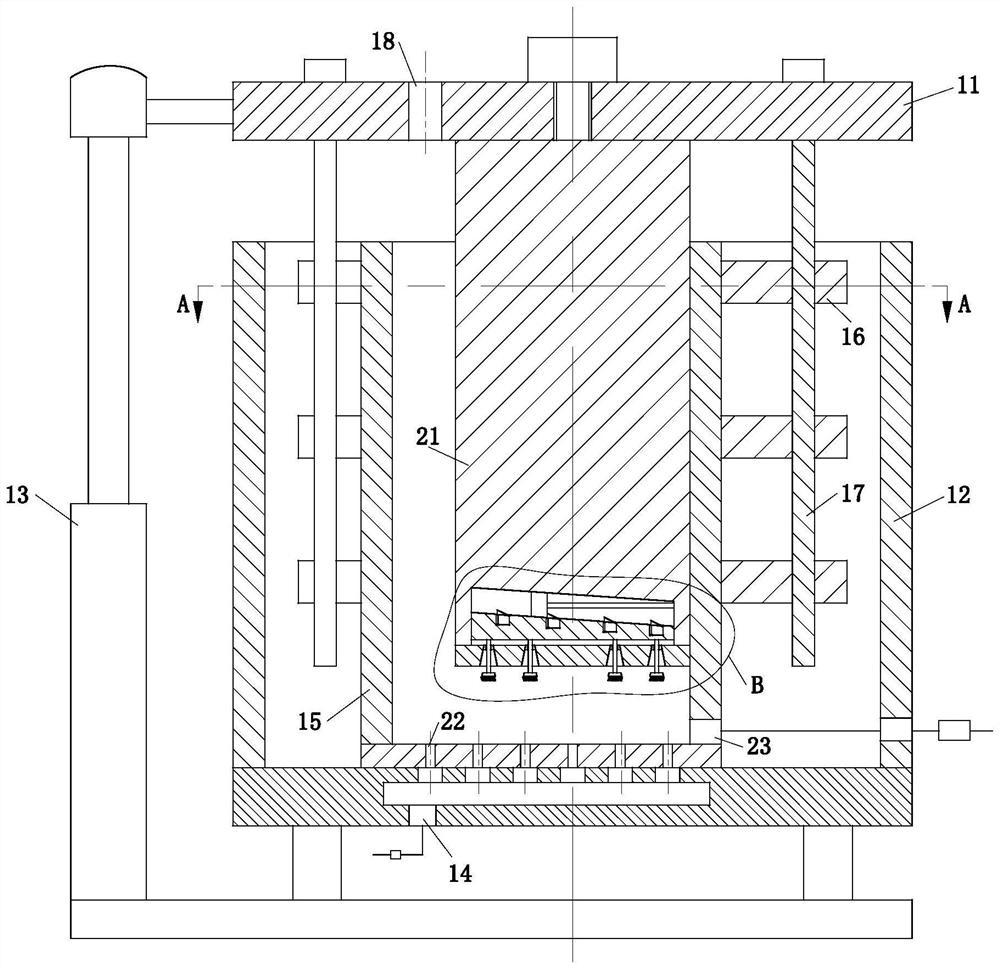

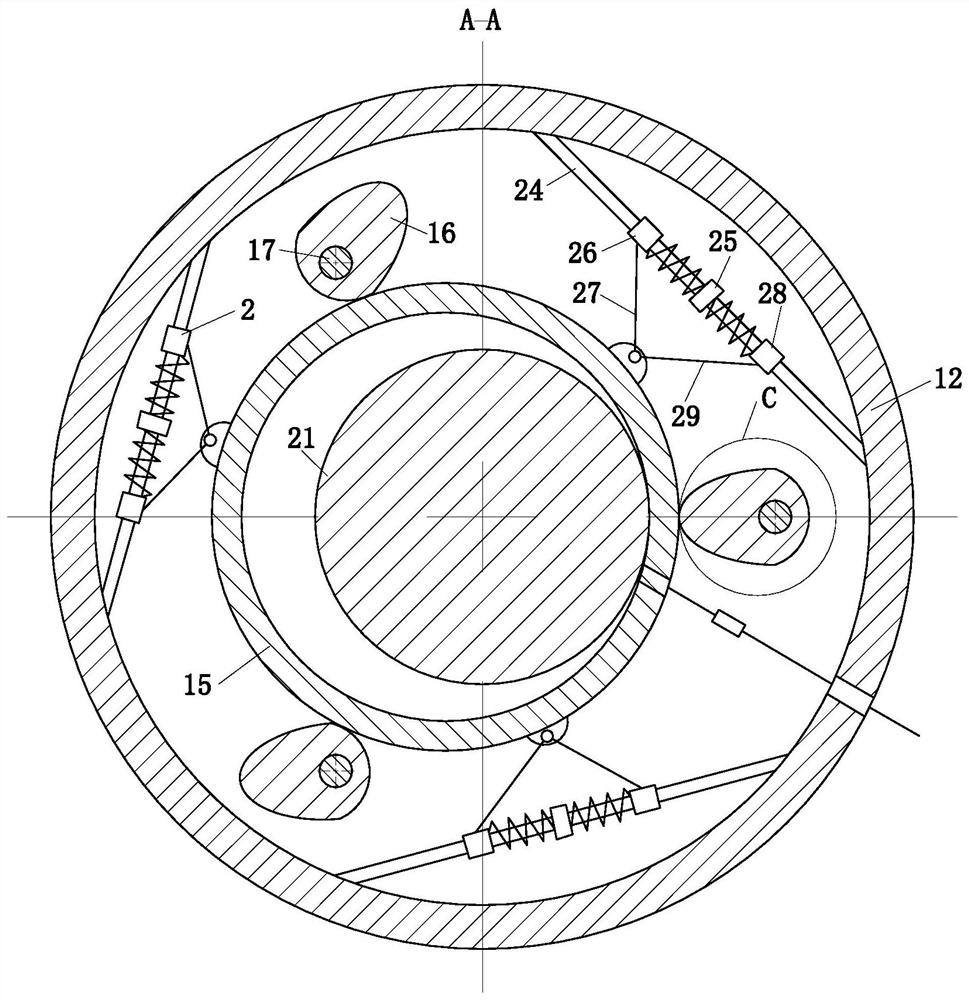

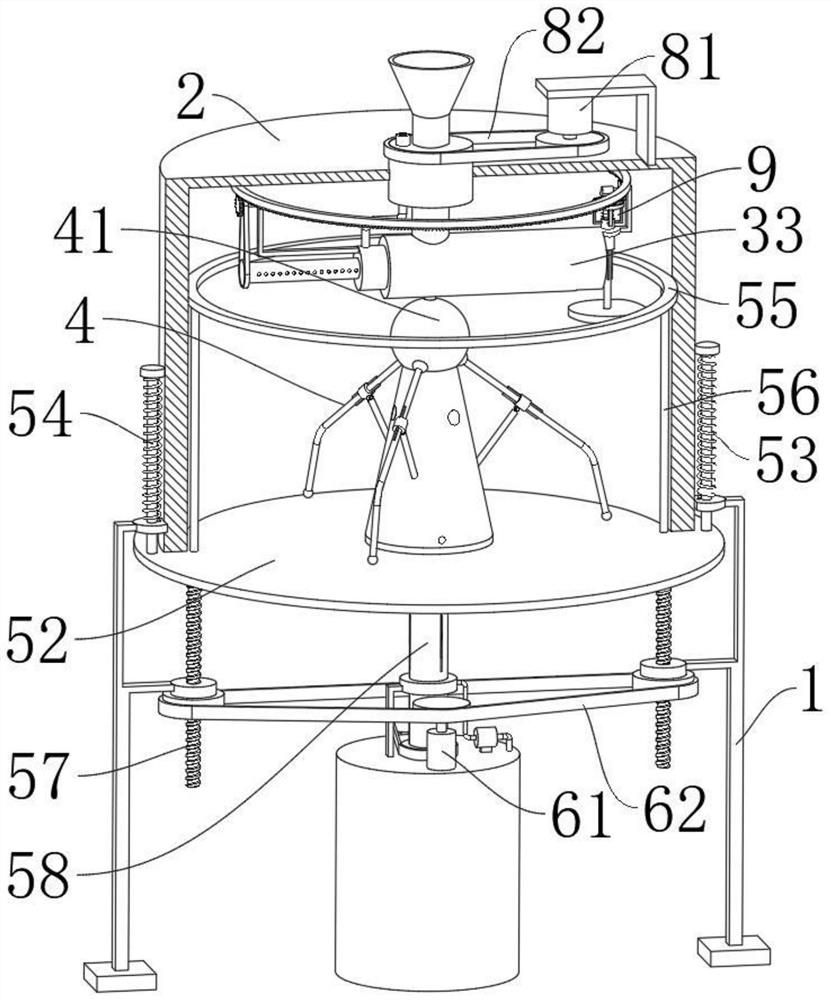

Graphene preparation system

InactiveCN108394891AAchieve strippingSolve the problem of reduced elasticityGrapheneElectric machineryEngineering

The invention belongs to the technical field of graphene production, and particularly relates to a graphene preparation system. The system comprises a material shaking module and a crushing module; the material shaking module and the crushing module are located in a closed bin, and the material shaking module is located below the crushing module; the material shaking module is fixedly arranged onthe inner wall of a side plate; the crushing module is fixedly arranged on the lower surface of an upper bottom plate; the material shaking module is used for raising graphite particles, and the crushing module is used for crushing the raised graphite particles; the upper bottom plate is rotationally arranged at the upper end of the side plate, the upper bottom plate drives the crushing module torotate by being matched with a first motor, and a suction cup is arranged at the lower end of a storage cover; the suction cup is fixedly arranged on the upper surface of a lower bottom plate througha first electric push rod; a rubber pad is fixedly arranged on the lower surface of a first installation block. The system is mainly used for preparing graphene, the graphene can be fully crushed, meanwhile, the fine-particle graphene conforming to the size can be filtered in time, and the production efficiency of the graphene is improved.

Owner:陆挚译

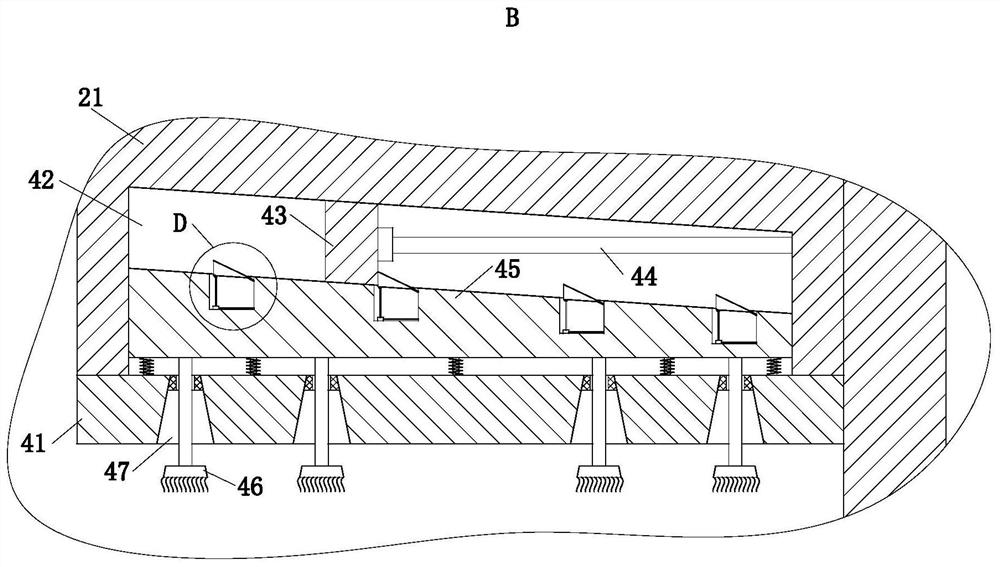

Graphene preparation system

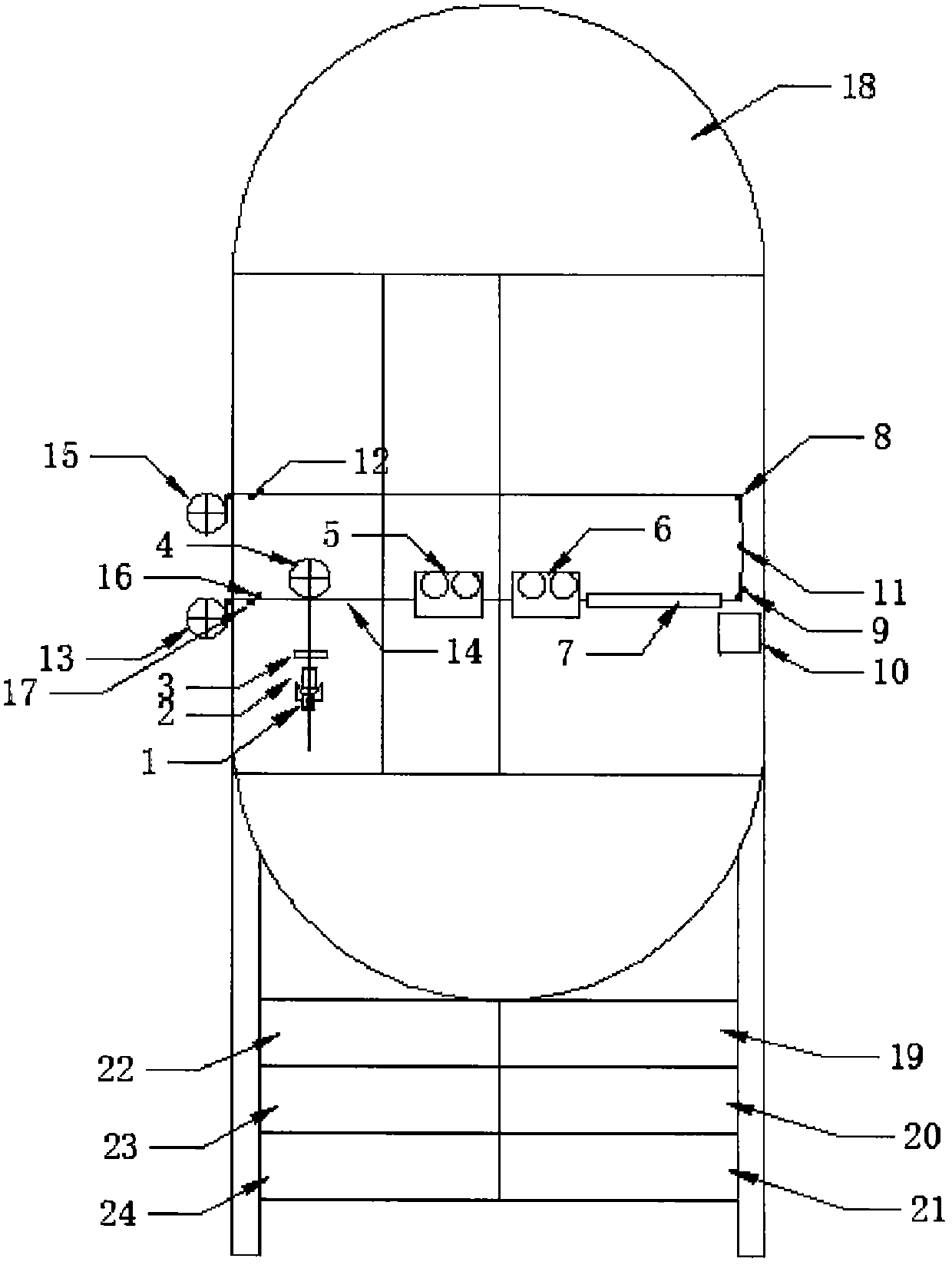

ActiveCN108439388AAvoid cloggingThe generation of influenceCarbon compoundsBiochemical engineeringGraphite particle

The invention belongs to the technical field of graphene production and particularly relates to a graphene preparation system. The graphene preparation system comprises a tank body, a charging pipe, agas inlet pipe, a finished product conveying pipe, a microwave emitter and a swinging module, wherein the charging pipe is arranged at the top of the tank body; the gas inlet pipe is arranged at thebottom of the tank body and can be used for injecting inert gas or compressed air into the tank body; the finished product conveying pipe is arranged at the top of the tank body at one side of the charging pipe; the microwave emitter is arranged on the internal wall of the tank body; the swinging module is arranged at the middle part of the tank body and is used for placing oxidated graphite particles. According to the graphene preparation system, through arranging the swinging module, the swinging module vibrates to avoid the influence on the production of graphene caused by feedstock accumulation; through arranging a vibrating module, the local accumulation of the graphite particles in a placement dish is avoided, and the blockage of a feeding hopper is avoided; through arranging a sloshing module, the graphite particles in the placement dish can slosh, and thus, the influence on the production of the graphene caused by the feedstock accumulation is avoided.

Owner:广州盛门新材料科技有限公司

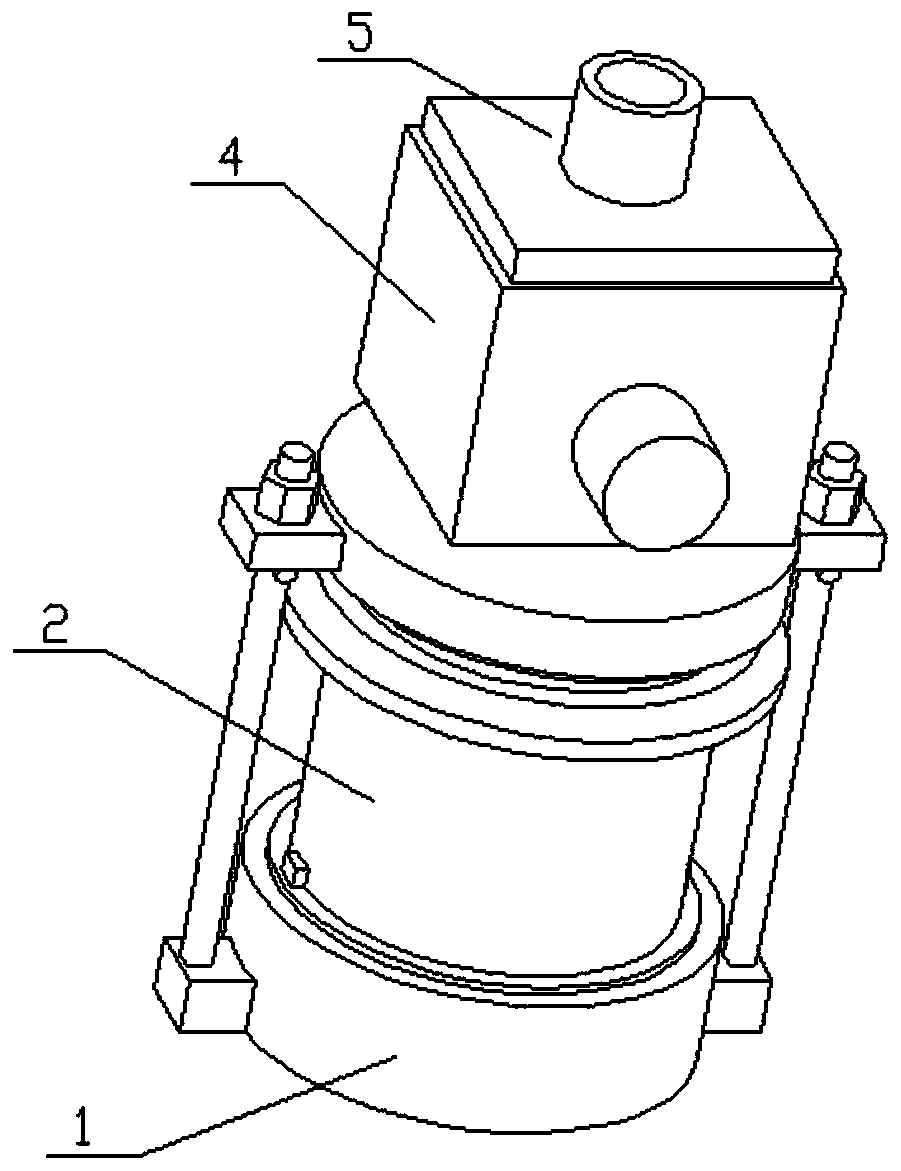

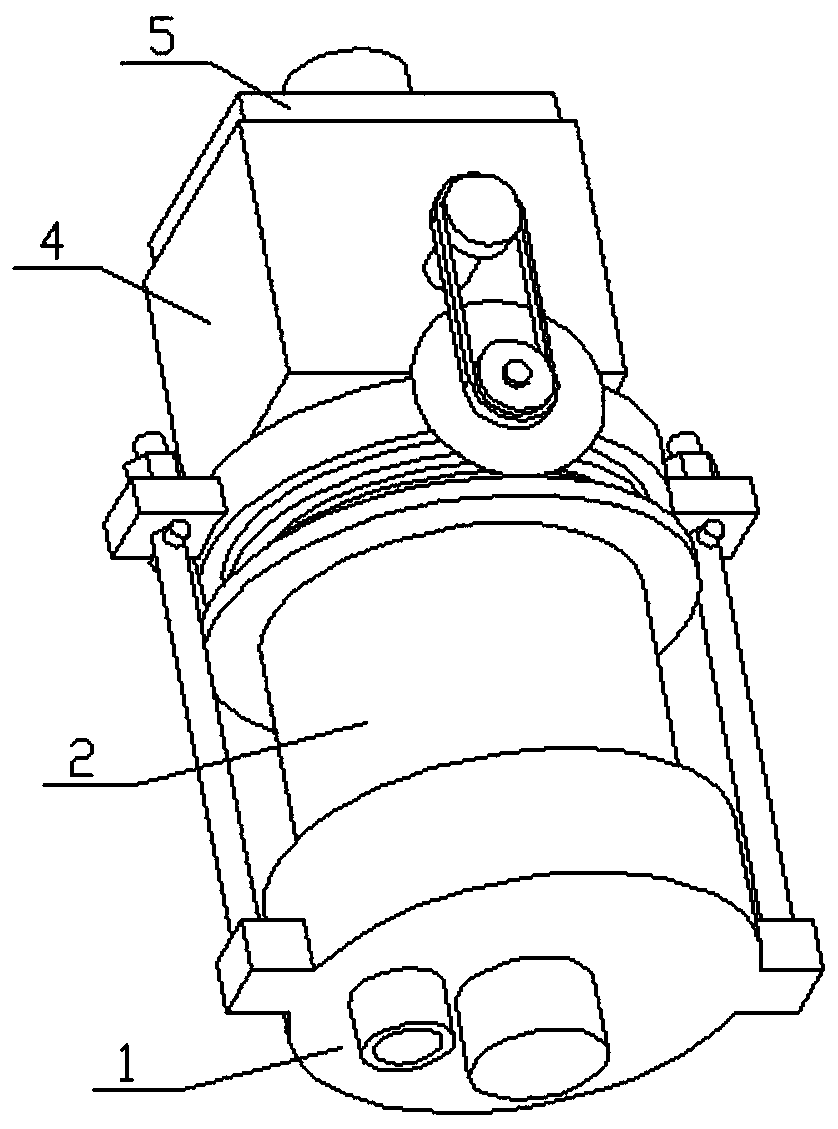

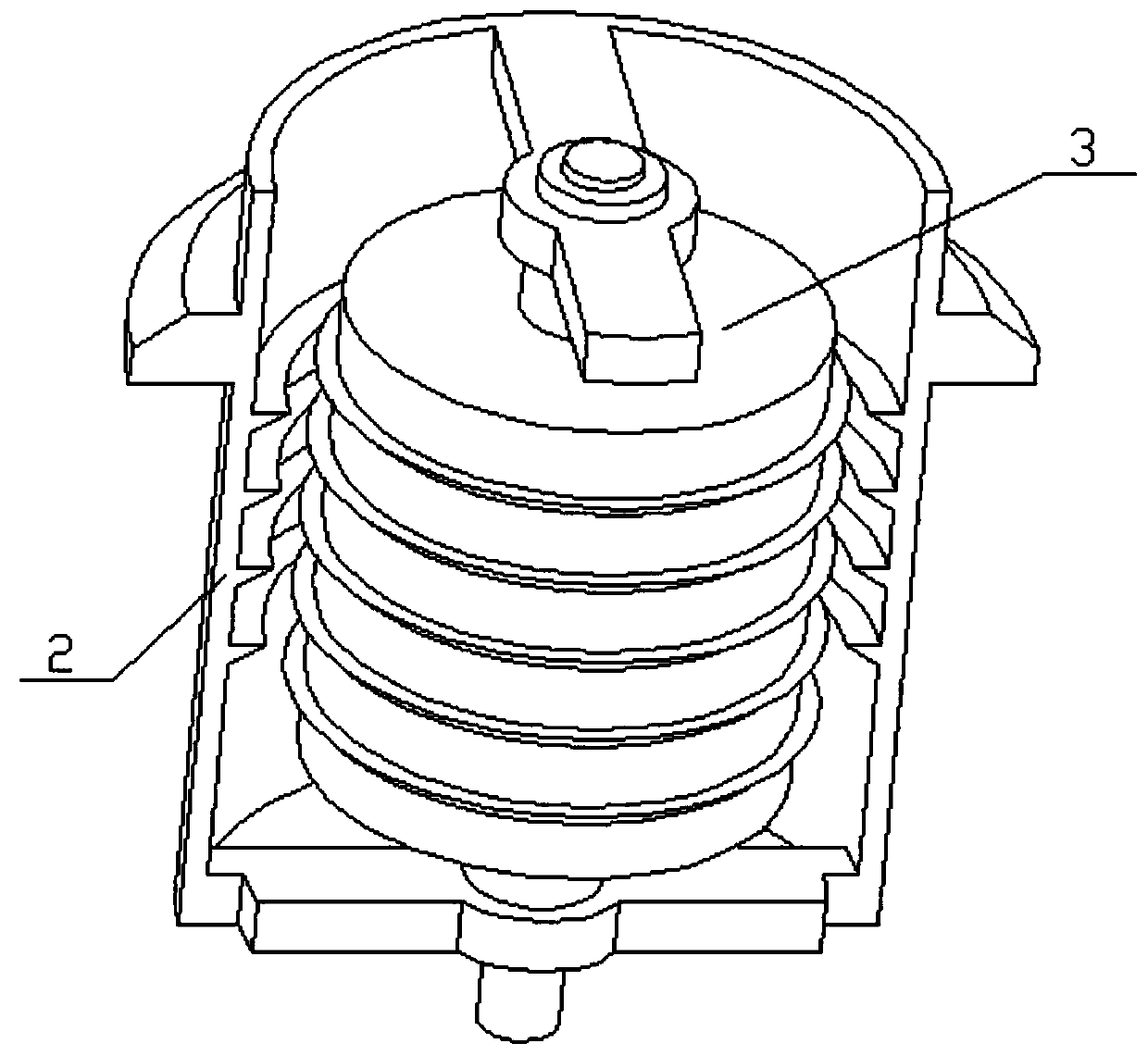

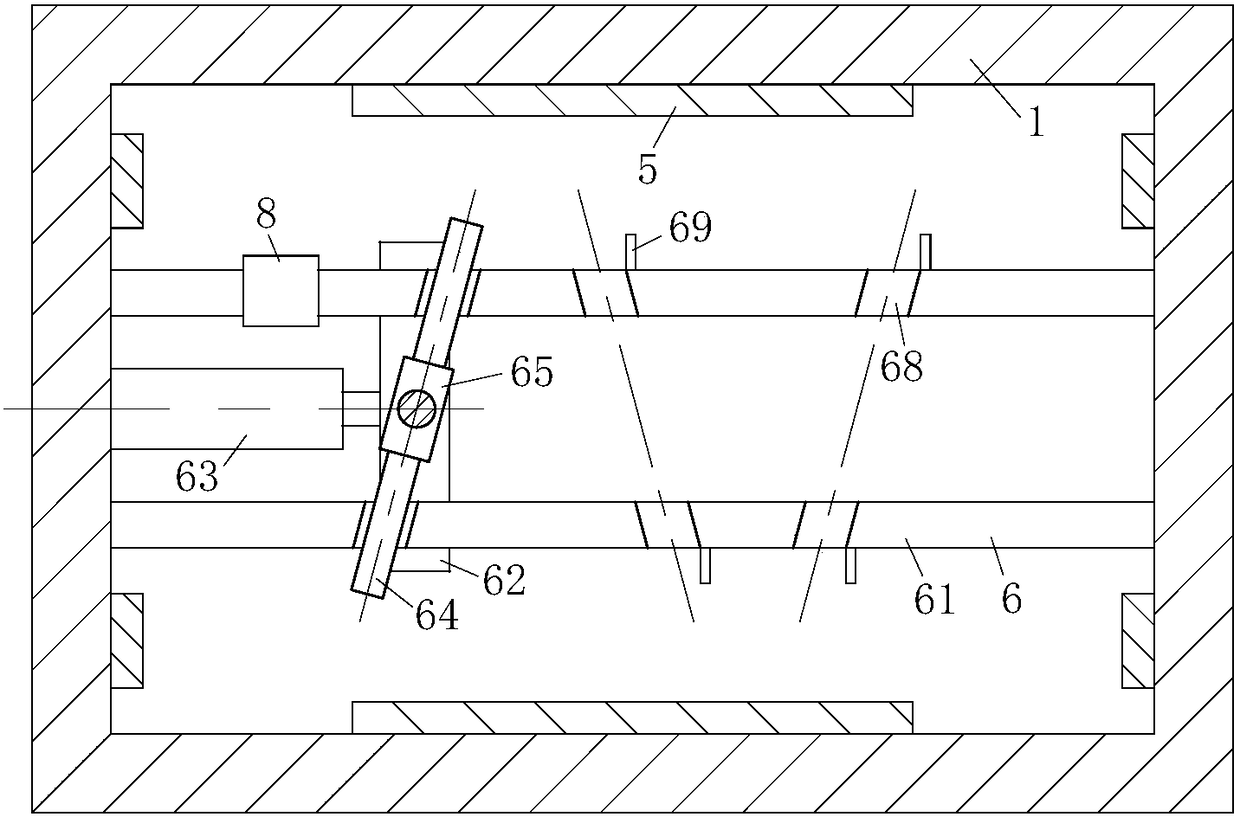

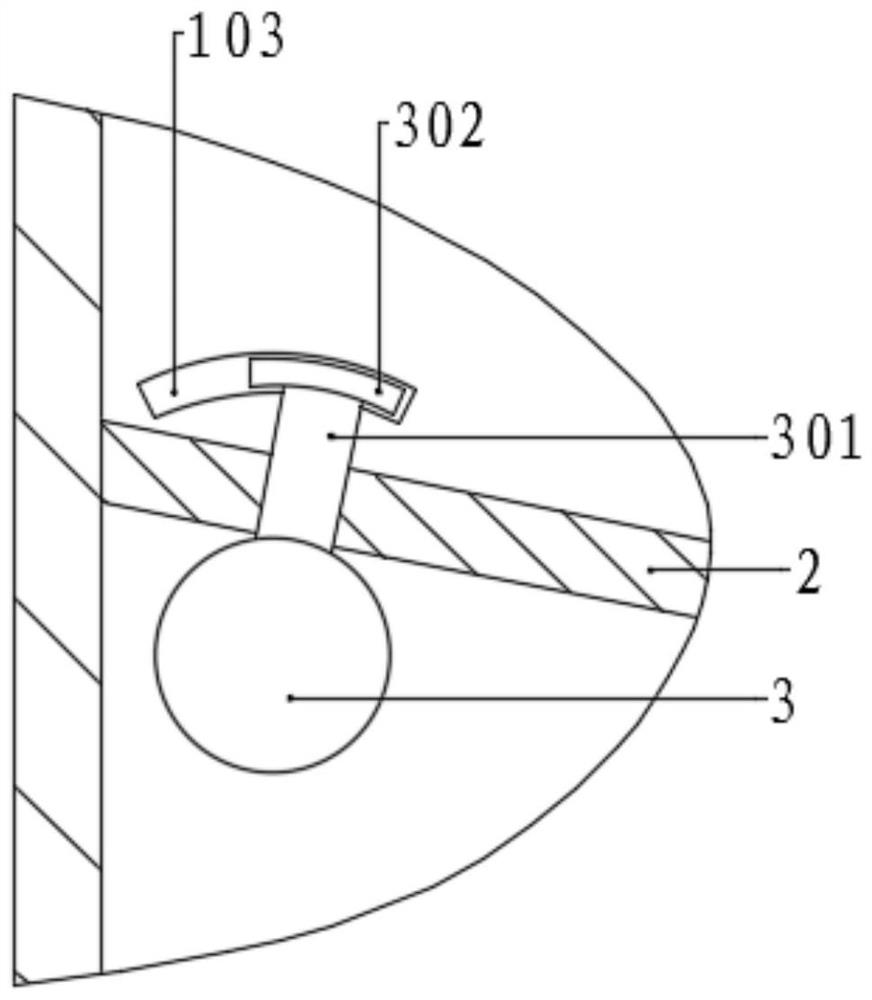

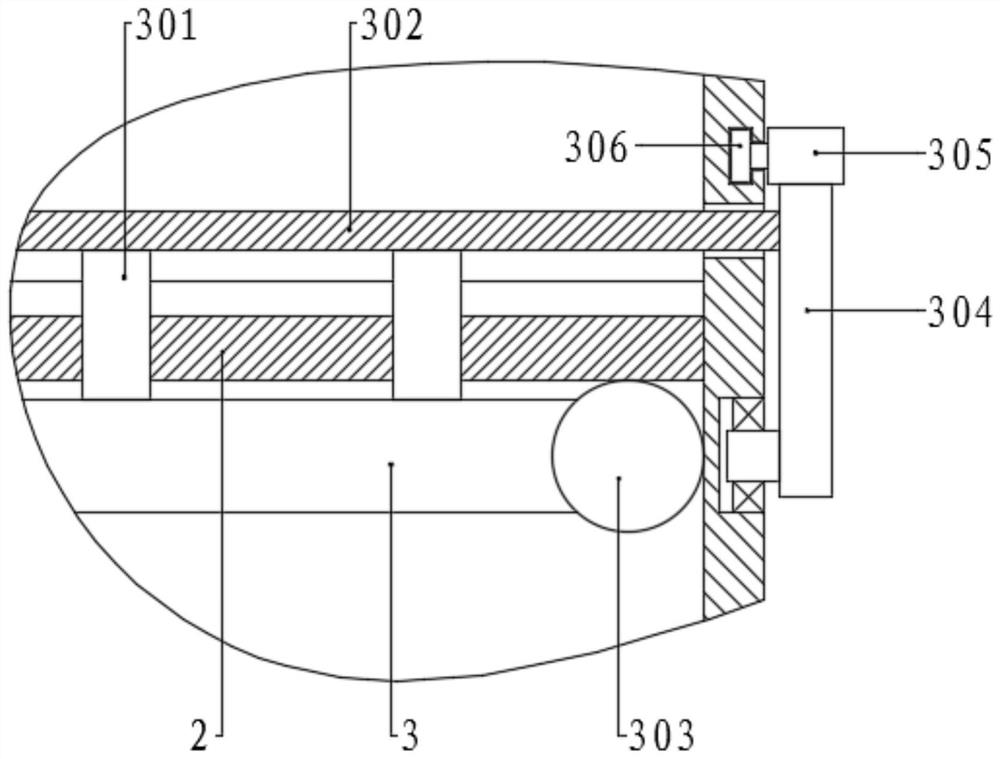

A kind of graphene dry stripping device

The invention relates to the technical field of graphene production, in particular to a dry graphene stripping device. A sucking pump imports an air flow mixed with a graphite dry powder raw materialinto a gap, graphene is dispersed by means of the air flow replacing a conventional solvent, and the graphite flake is sheared transversely first and then sheared longitudinally, so that the probability that the graphite dry powder raw material is sheared and stripped by a shearing edge by no means of solvent is improved greatly. A middle barrel and a vertical rotary column can rotate reversely, so that the relative rotating speed of the vertical rotary column is higher, and the graphite flake is sheared more easily. The lower end of the middle barrel assembly is rotatably connected to the upper end of a bottom assembly, a transverse shearing part is rotatably connected in the middle barrel assembly, the lower end of the transverse shearing part is connected to the bottom assembly, the upper end of the middle barrel assembly is rotatably connected to the lower end of a vertical shearing assembly, the vertical shearing assembly is fixedly connected to the upper end of the bottom assembly, and a top cover assembly is fixedly connected to the upper end of the vertical shearing assembly.

Owner:青岛中天科捷工业科技有限公司

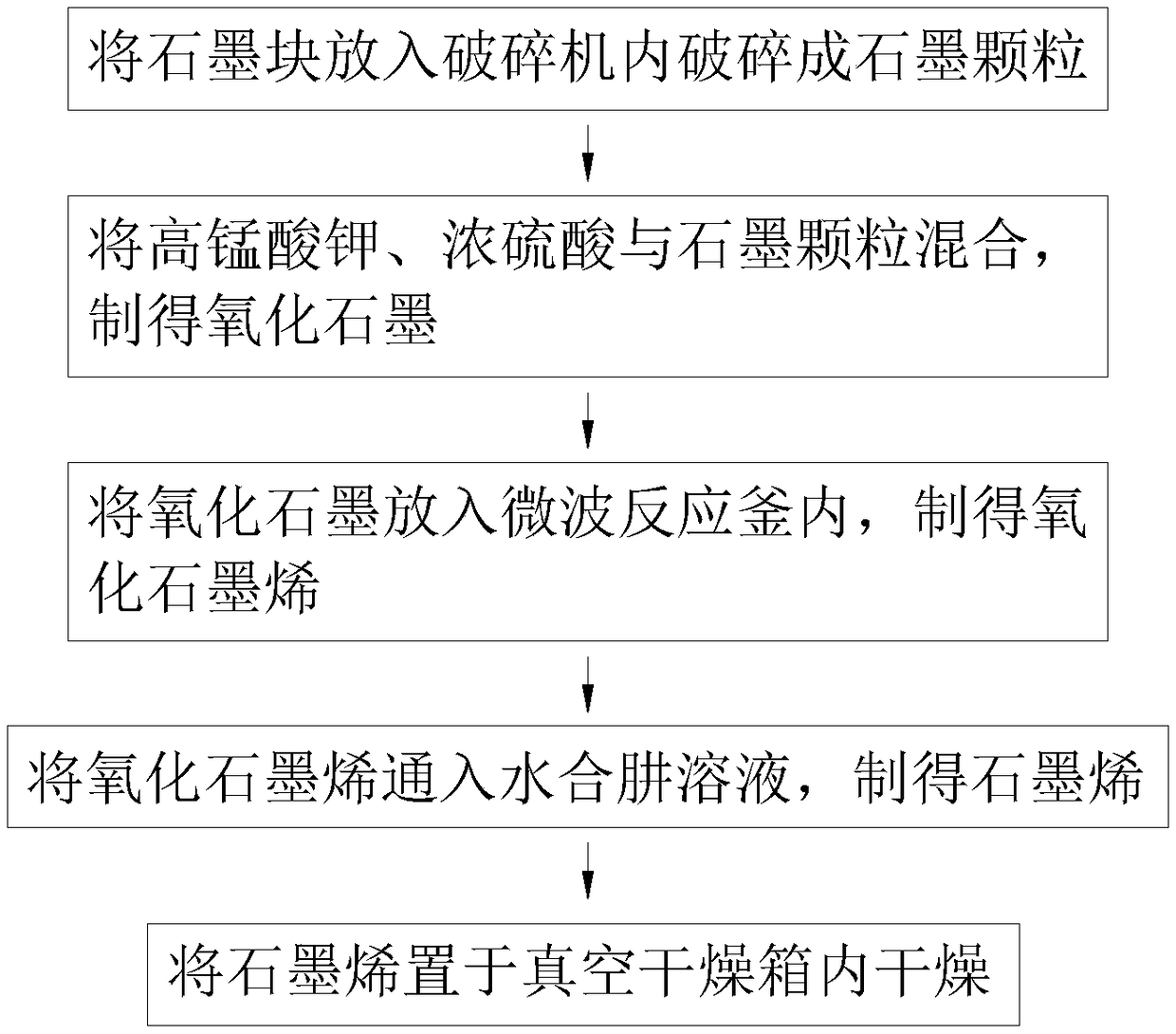

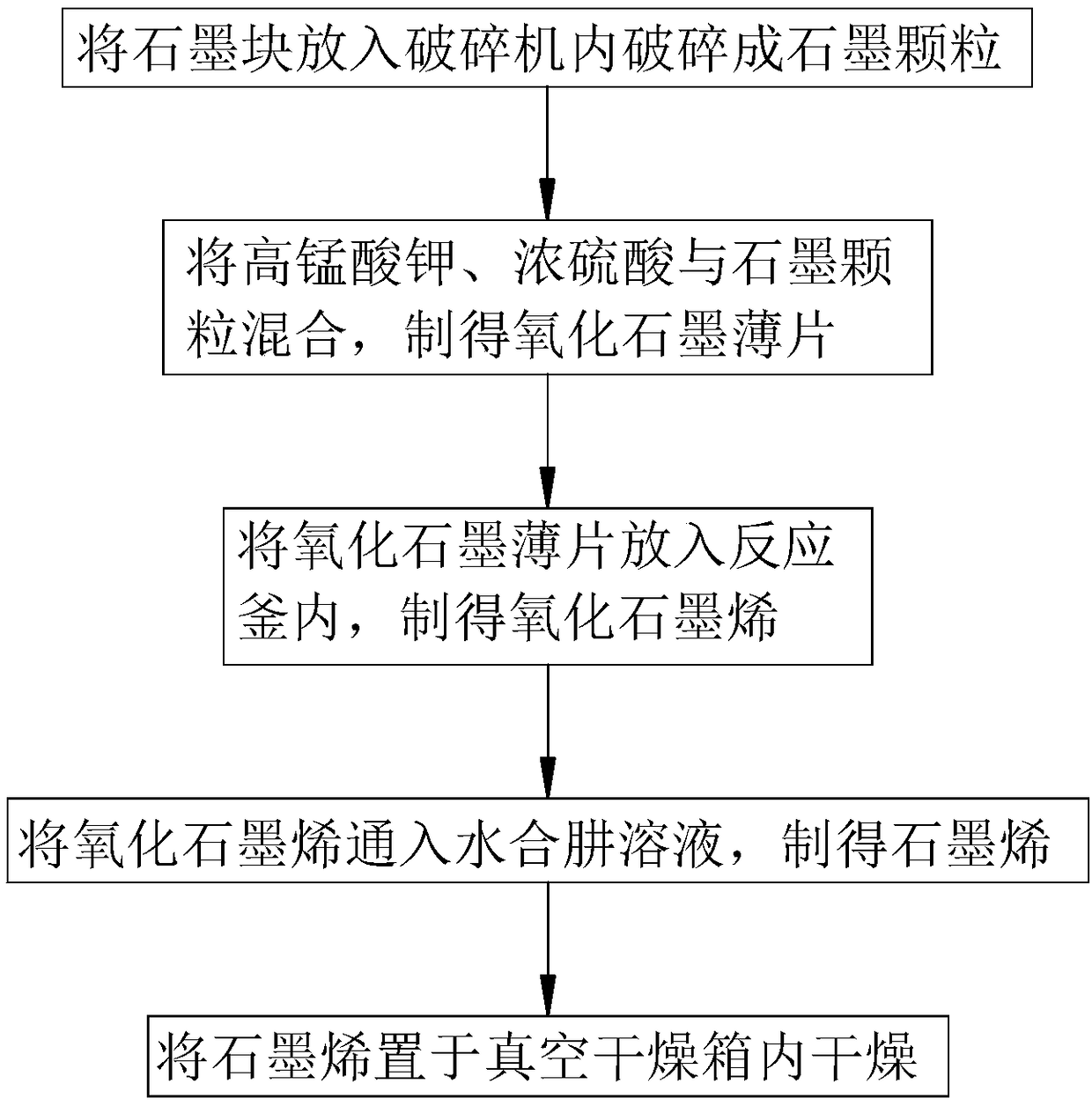

Graphene production and manufacturing process

The invention belongs to the technical field of graphene production, in particular to a graphene production and manufacturing process. A microwave reaction kettle used in the process comprises a driving motor, a support plate, a square rotating shaft, springs, a vibrating dish, caster brackets and casters, wherein a square groove is formed in the bottom end of the vibrating dish; the square rotating shaft is arranged in the square groove in a sliding manner; a set of springs are arranged at the upper end of the square rotating shaft, and the lower end of the square rotating shaft is fixedly connected with a rotating shaft of the driving motor; a set of arc slopes are disposed on the upper surface of the support plate; a set of caster brackets are arranged below the vibrating dish; the upper ends of the caster brackets are hinged to the bottom surface of the vibrating dish, the lower ends of the caster brackets are hinged to the casters, and the upper sides of the middle portions of thecaster brackets are connected to the bottom surface of the vibrating dish by the springs. The square rotating shaft is arranged below the vibrating dish, so that the vibrating dish can be driven to rotate and vibrate up and down; symmetrical turning plates can rotate positively and negatively to stir graphite particles more evenly.

Owner:陆挚译

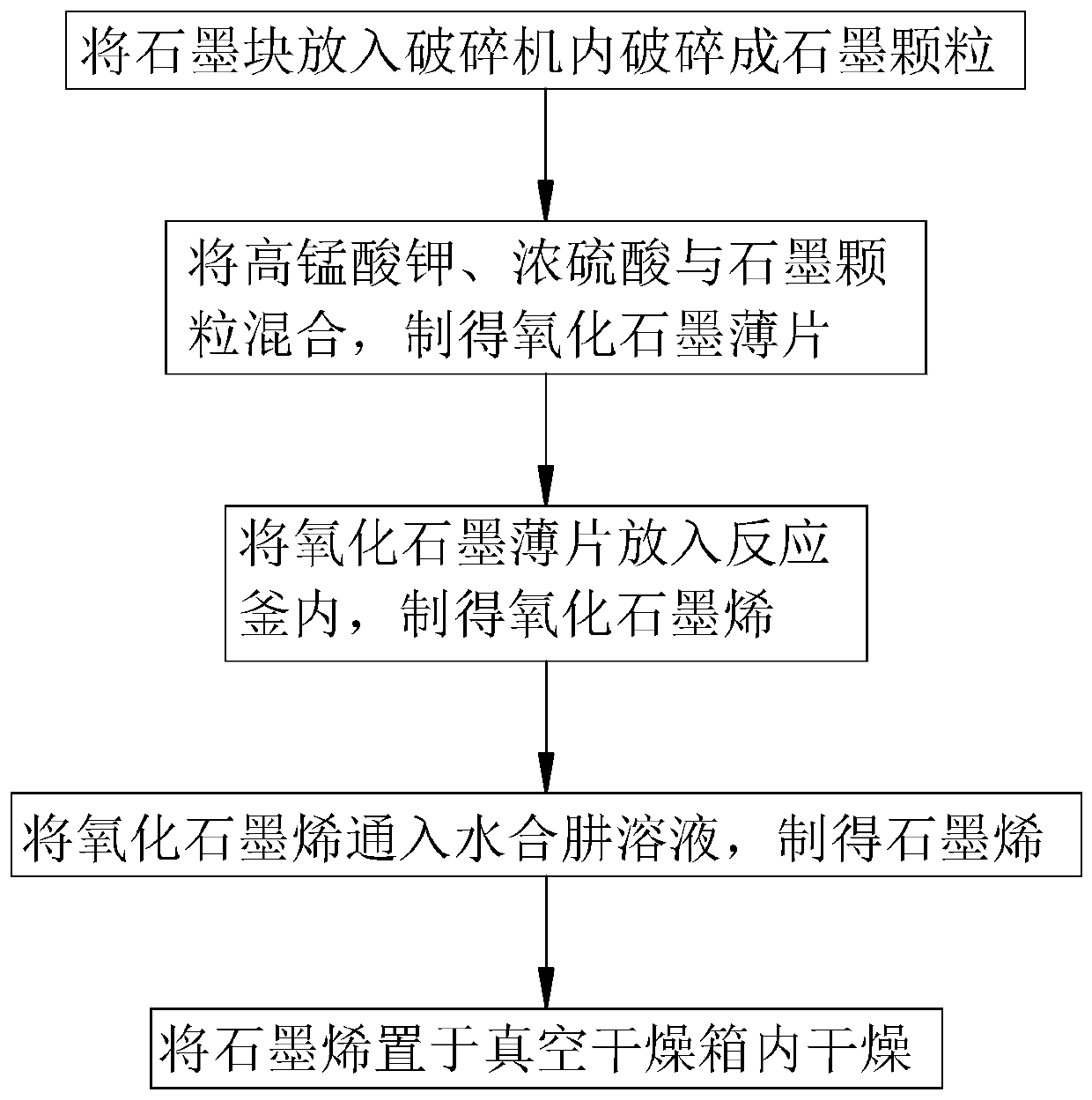

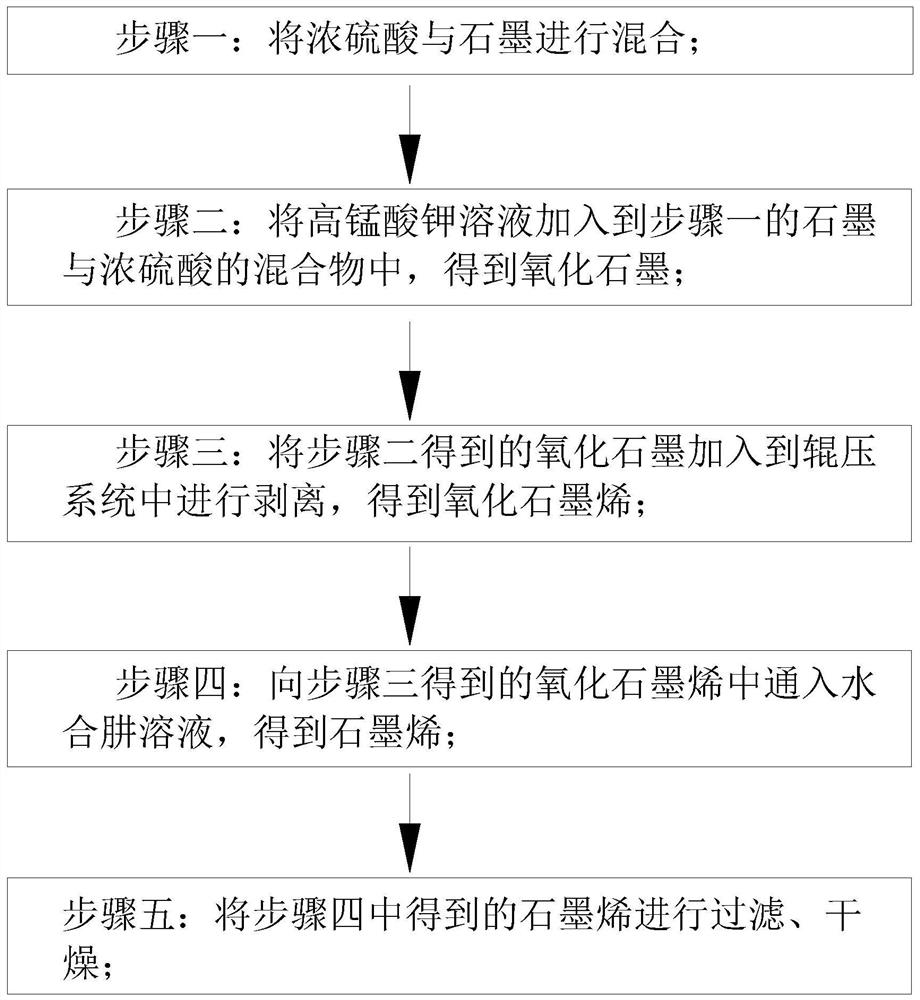

Graphene production process

The invention belongs to the technical field of graphene production and particularly relates to a graphene production process. A reaction kettle is used in the process and comprises a chamber, a feeding pipe, a gas inlet pipe, a finished product conveying pipe, microwave emitters and a swing module. The feeding pipe is arranged at the top of the chamber; the gas inlet pipe is arranged at the bottom of the chamber and used for injecting inert gases or compressed air into the chamber; the finished product conveying pipe is arranged at the top, on one side of the feeding pipe, of the chamber; themicrowave emitters are arranged on the inner wall of the chamber; the swing module is arranged in the middle of the chamber and used for placement of oxidized graphite particles. By arrangement of the swing module, influences on graphene production due to raw material accumulation are avoided under the vibration action of the swing module; by arrangement of a vibration module, local accumulationof graphite particles in a placement vessel is avoided, and blockage of a feeding hopper is avoided; by arrangement of a shaking module, the graphite particles are enabled to shake in the placement vessel, and accordingly influences on graphene production due to raw material accumulation are avoided.

Owner:深圳稀导技术有限公司

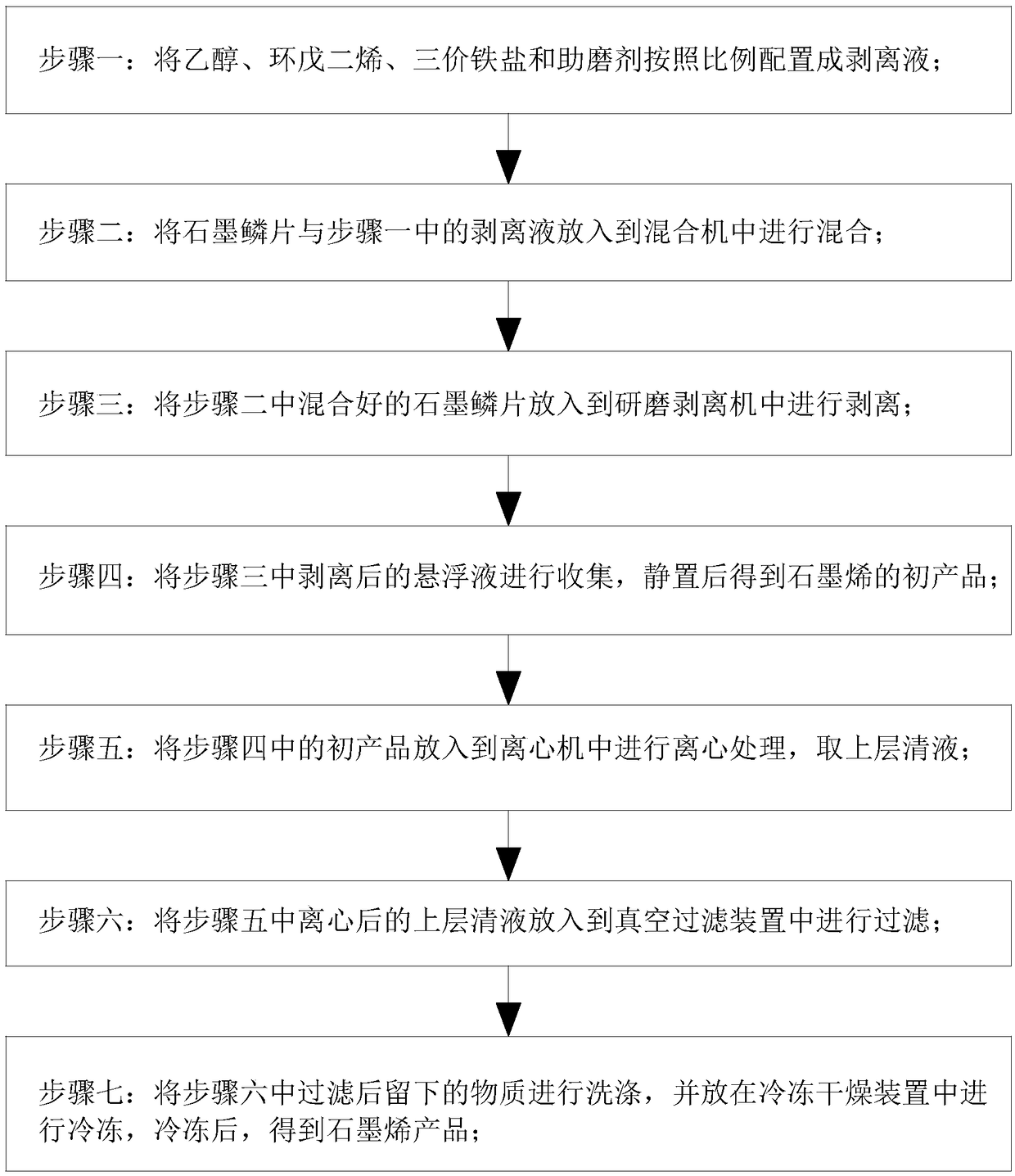

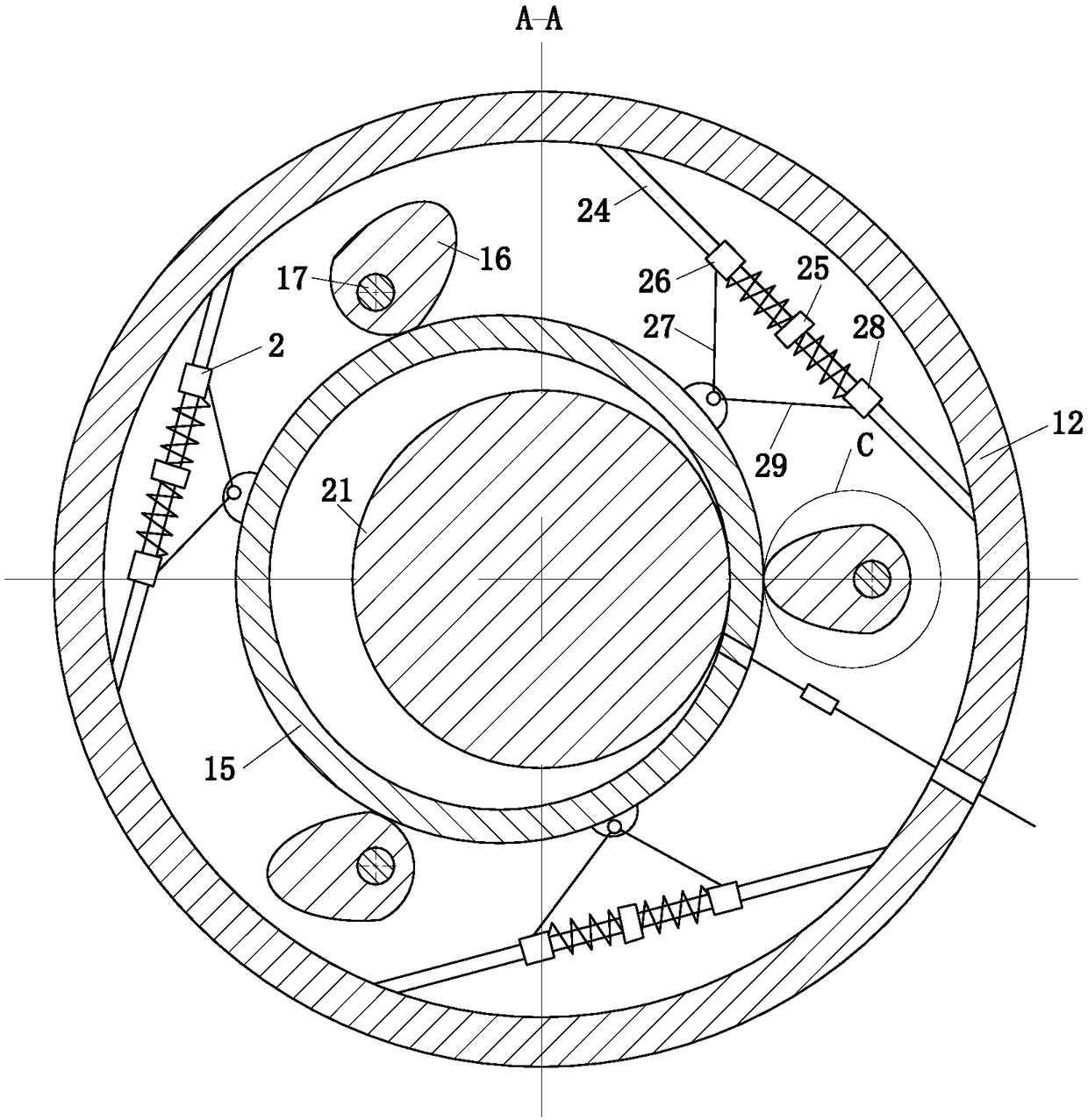

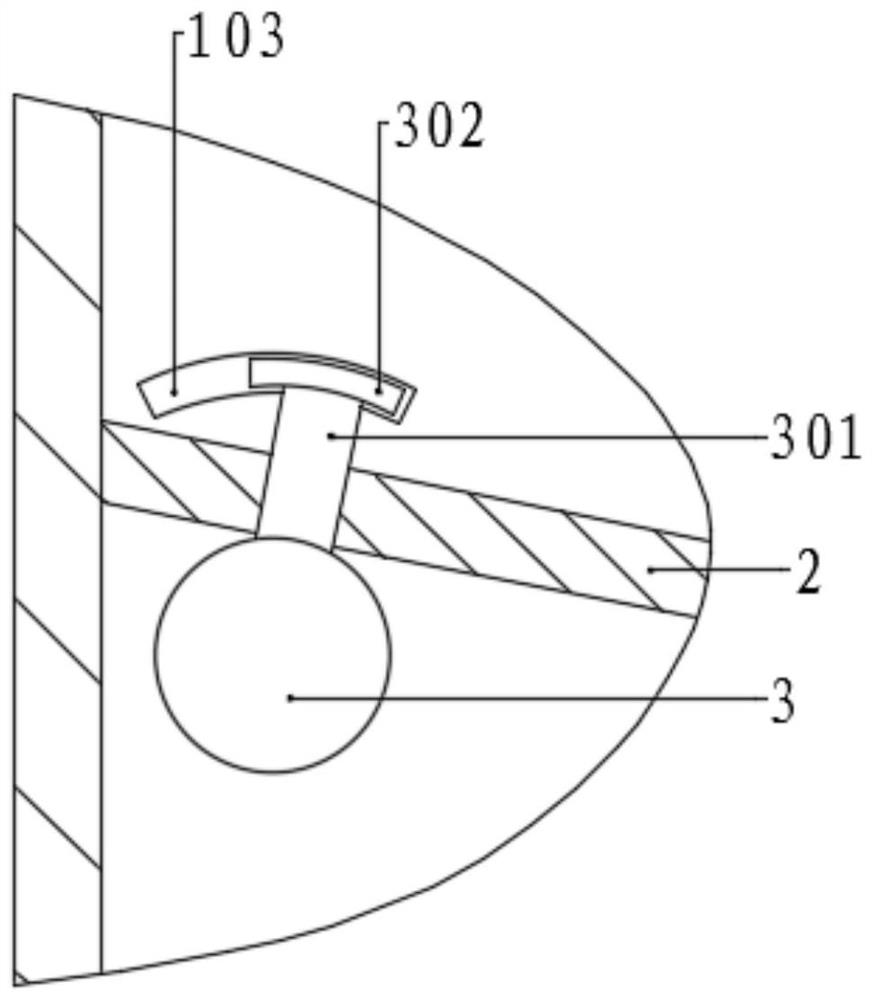

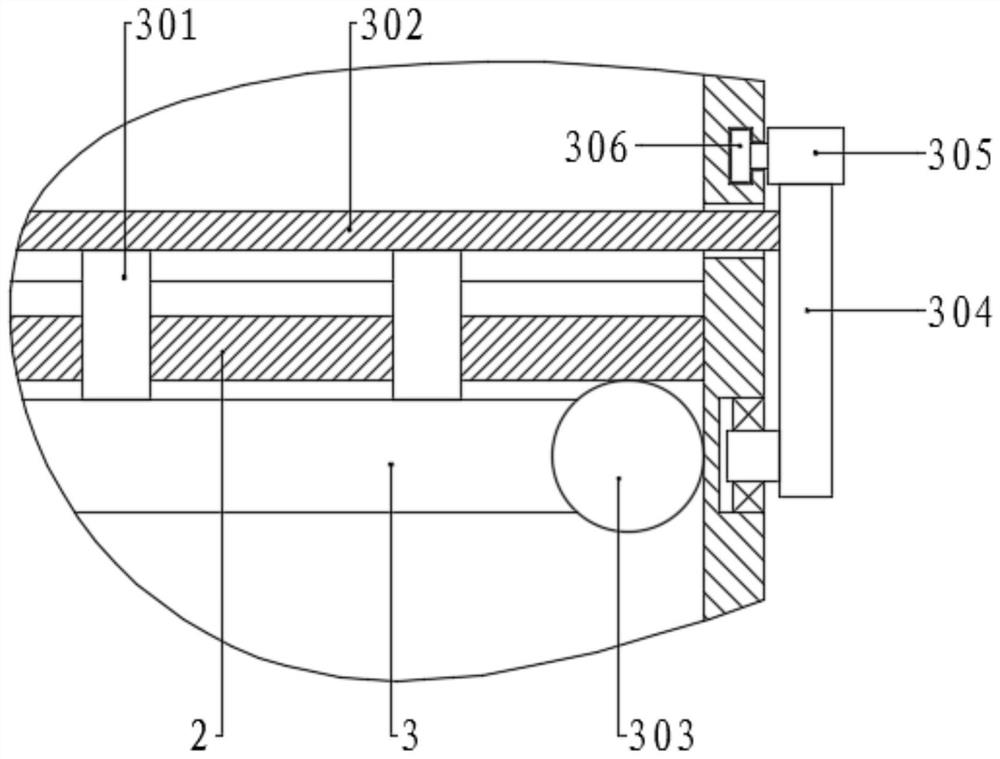

Graphene production technology

The invention belongs to the technical field of graphene production, and particularly discloses a graphene production technology. In the graphene production technology, a grinding and stripping machine is used, and the grinding and stripping machine comprises a machine frame, and further comprises control modules, a grinding module and baffle plates, wherein two baffle plates are provided; the baffle plates are fixedly mounted on the top of the machine frame; the baffle plates are used for matching the shaking of the grinding module; the grinding module is positioned on the middle part of themachine frame; the grinding module is used for grinding graphite powder; two control modules are provided; the control modules are positioned on the outer side of the machine frame; the control modules are used for controlling separation of the grinding module. During rotation of a first motor, through intermeshing rotation of a gear 1, an elliptical gear 1 and an elliptical gear 2, a corresponding rod 1 drives a lower grinding disc and a rod 2 drives an upper grinding disc for closing and separation, graphene is ground and stripped during closing, and the upper grinding disc is cleaned duringseparation, so that the graphene grinding and stripping efficiency and the graphene grinding and stripping quality are improved.

Owner:刘玉婷

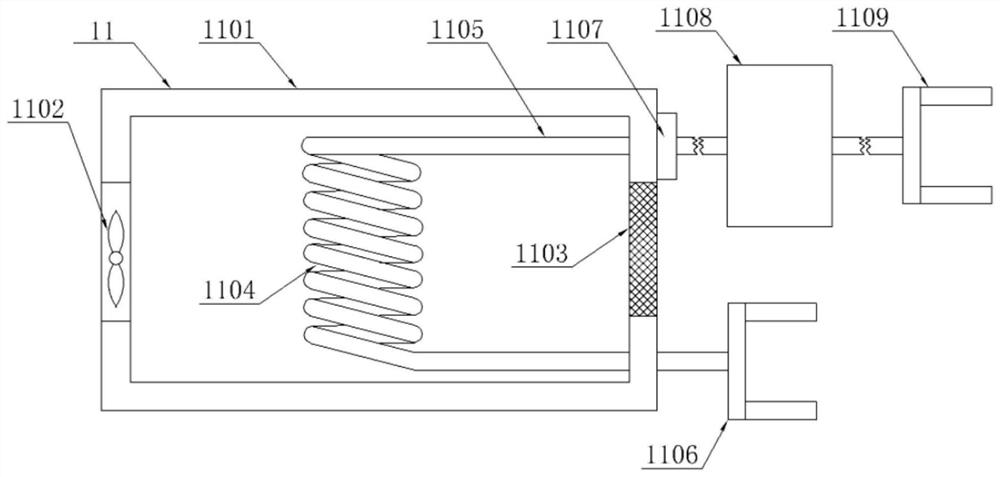

Pressure forming device for automatic graphene production

The invention discloses a pressure forming device for automatic graphene production and belongs to the technical field of graphene production. The pressure forming device for automatic graphene production comprises a base and a horizontal screw feeder, wherein the right end of an electric push rod is fixedly connected with a graphene heating box, the graphene heating box is fixedly arranged at thebottom of a movable plate, and during die casting, a circulating pump pumps low-temperature condensate in an inner cavity of a condensate tank into an inner cavity of a spiral heat exchange tube through a pipeline, and air on an inner cavity of a shell is cooled, so that the air blown to a forming tank body by an exhaust fan is in a low-temperature state, the cooling efficiency of graphene is improved, the low-temperature condensate enters an inner cavity of a cavity through a condensate pipeline to cool the forming tank body, the condensate in the cavity flows back through the pipeline to enter the inner cavity of the condensate tank to be cooled again, the circulating pump conveniently and continuously pumps out, the cooling efficiency of a forming tank is improved, and the utilizationrate of a cold source is improved.

Owner:刘永

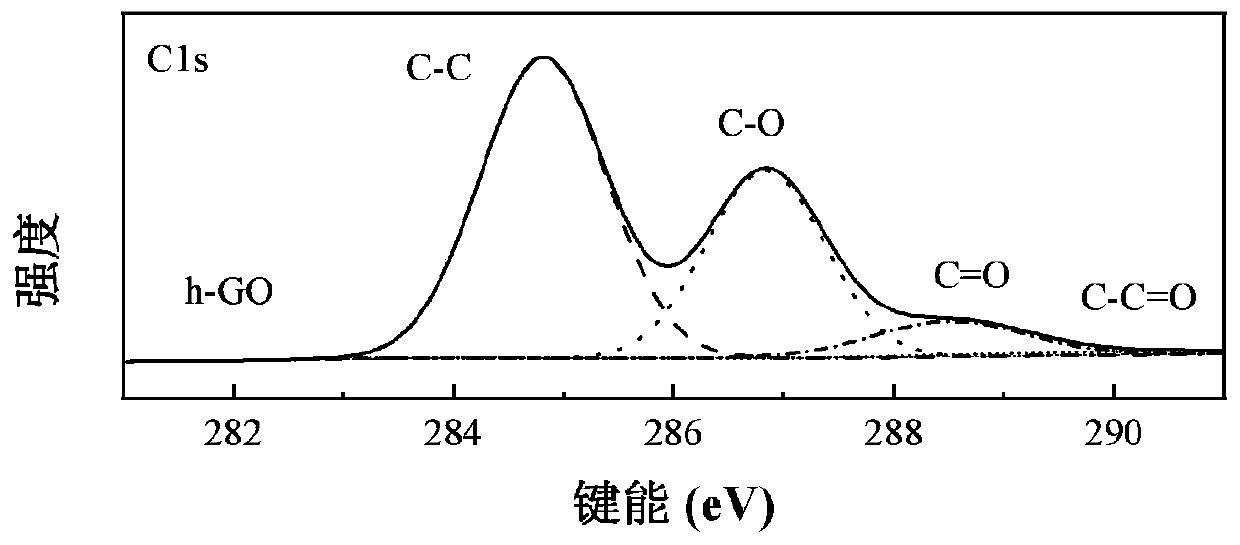

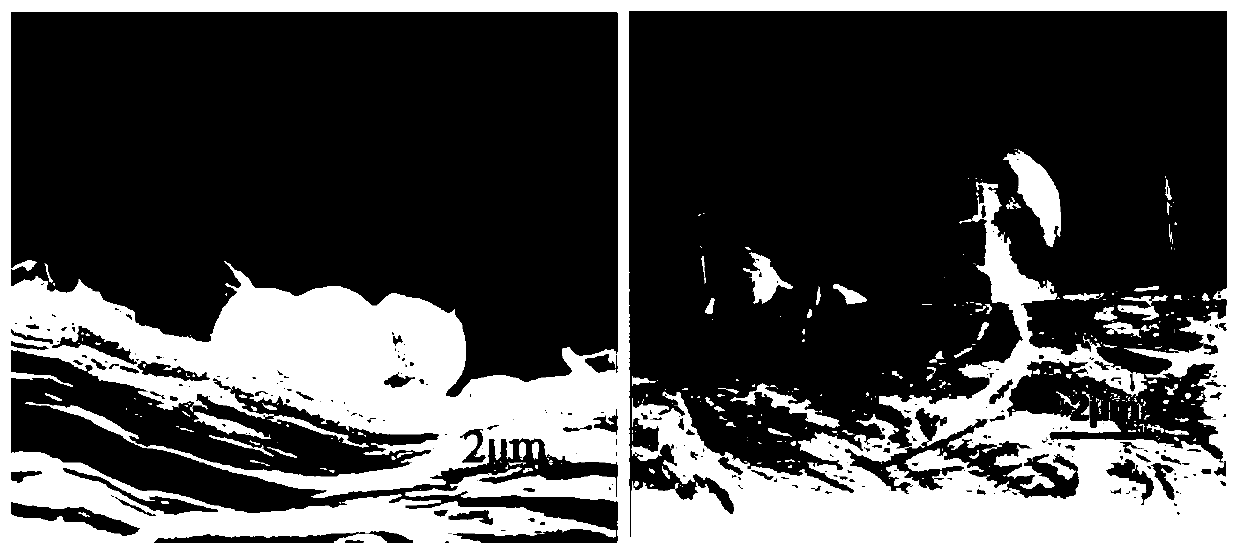

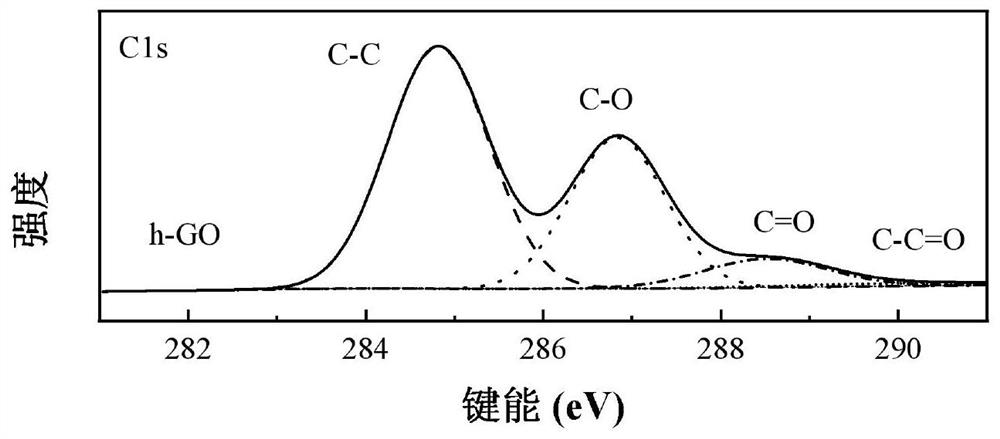

Preparation method of dendritic macromolecule reinforced graphene oxide paper with holes

The invention discloses a preparation method of dendritic macromolecule reinforced graphene oxide paper with holes, and belongs to the technical field of graphene oxide production. The invention aimsto solve the problems of low tensile strength and stress relaxation of a graphene oxide film / paper material and low quality of the finally prepared material due to impermeability of lamellas and the like. An epoxy functional group and adjacent carbon atoms thereof are eroded in a graphene oxide sheet layer through the strong oxidizing property of hydrogen peroxide to form nanoscale holes; polyamide-amine (PAMAM) dendritic polymer is introduced to form covalent cross-linking among graphene oxide sheet layers to improve the interlayer bonding strength of the graphene oxide; and finally, a graphene oxide film / paper material with relatively high strength and relatively good quality is obtained by means of directional filtering. The method is simple to operate, low in cost and high in efficiency, and is expected to realize large-scale preparation.

Owner:HARBIN INST OF TECH

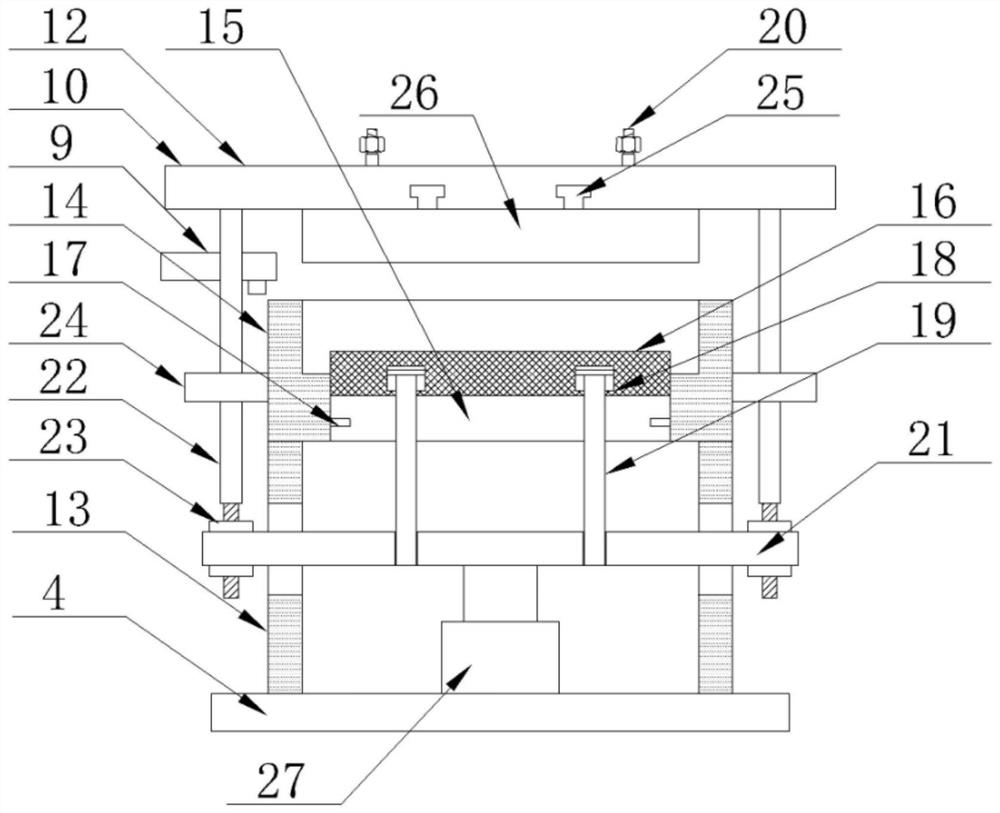

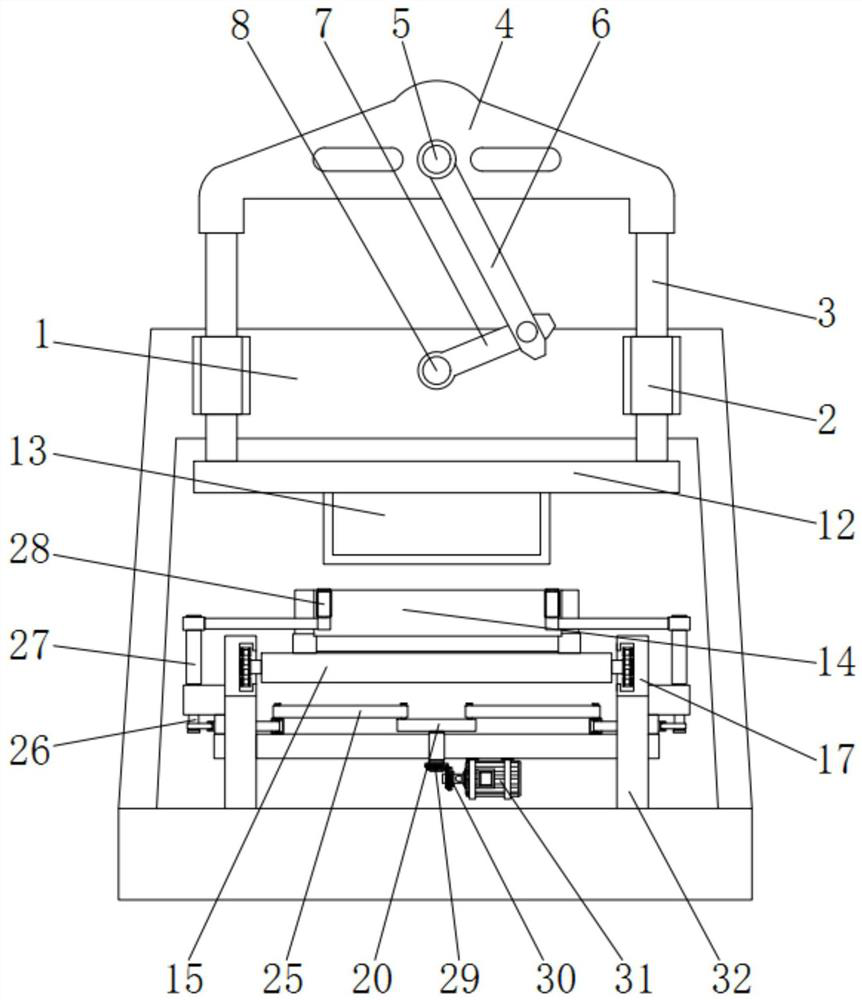

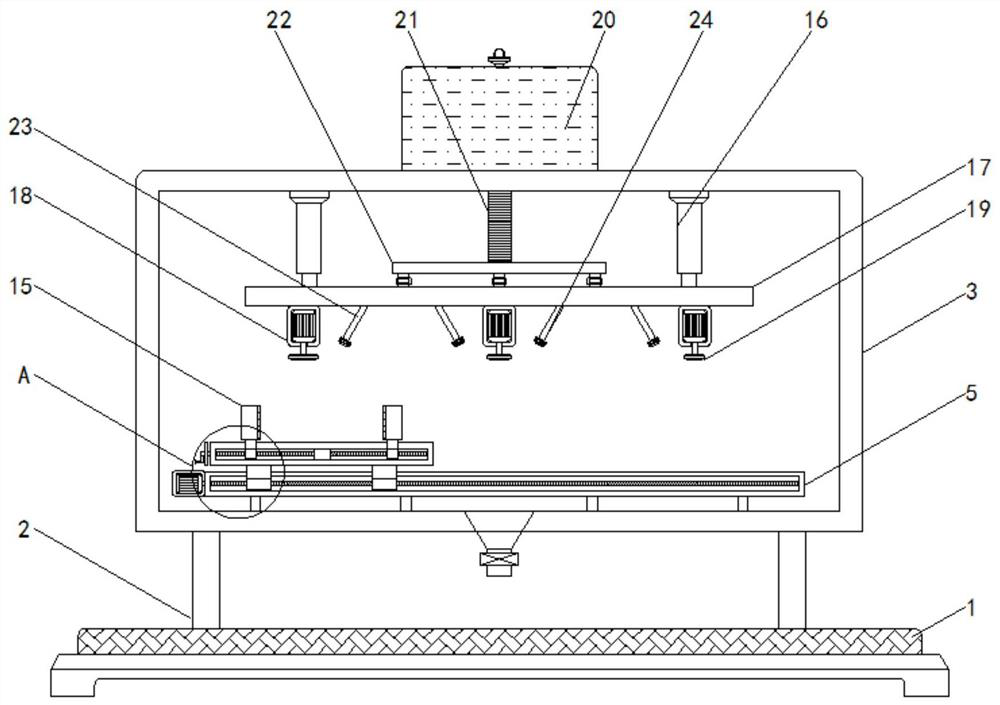

Pressure forming device with positioning mechanism for graphene production

PendingCN112976660AImprove applicabilityAchieve clamping positioningShaping pressElectric machineEngineering

The invention relates to the technical field of graphene production, in particular to a pressure forming device with a positioning mechanism for graphene production. The pressure forming device comprises a fixed frame, a worm, a second motor, supporting legs and a third motor, the top end of the fixed frame is fixedly connected with a fixed block, and an insertion rod is inserted into the fixed block. The top end of the insertion rod is fixedly connected with a connecting plate, and a fixed shaft is inserted into the connecting plate. According to the pressure forming device with the positioning mechanism for the graphene production, a first pressure disc is arranged, a pressure containing mold is conveyed to the bottom of a second pressure disc through a conveying roller, the pressure containing mold is positioned and clamped again through an L-shaped rod, the third motor is started, and a second hinge rod drives the second pressure disc to move up and down; and a pre-pressing blank in the pressure containing mold is pressed again through the second pressure disc, a finally-formed graphene material blank is obtained, graphene powder is subjected to pressure forming in an automatic pressure mode, and the applicability of the graphene production process is improved.

Owner:邹小婧

Water-soluble graphene production equipment and method based on electric field melting

The invention discloses water-soluble graphene production equipment and method based on electric field melting, and particularly relates to the technical field of graphene production. An existing graphene production technology has certain pollution to the environment, all-weather long-time non-stop production cannot be achieved, and the inner wall of a separation cylinder cannot be cleaned. The production equipment comprises a feeding mechanism, and the feeding mechanism comprises a storage box. A material storage barrel is installed on one side of the material storage box, and a piston is arranged in the material storage barrel in a sliding mode. And a processing device is mounted on one side of the storage barrel. And the processing device comprises a separating cylinder. And a movable grinding head, a fixed grinding head and a scraping plate are mounted in the separation cylinder. According to the invention, the effect of automatically adding the mixed liquid is achieved through lifting of the piston; attachments on the inner wall of the separation cylinder are cleaned by utilizing rotation of the scraper; and continuously breaking and melting graphite particles in the graphite mixed solution by using an electric arc in an external electric field to produce graphene.

Owner:哈尔滨盛世康虹生物技术有限公司

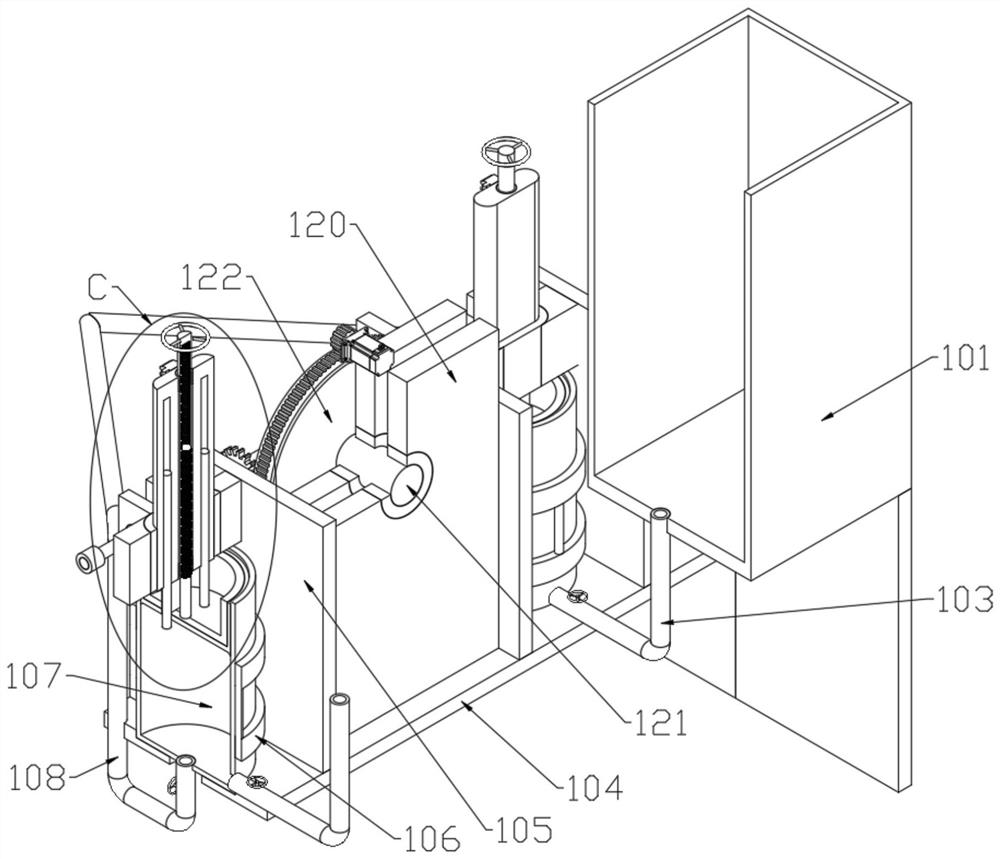

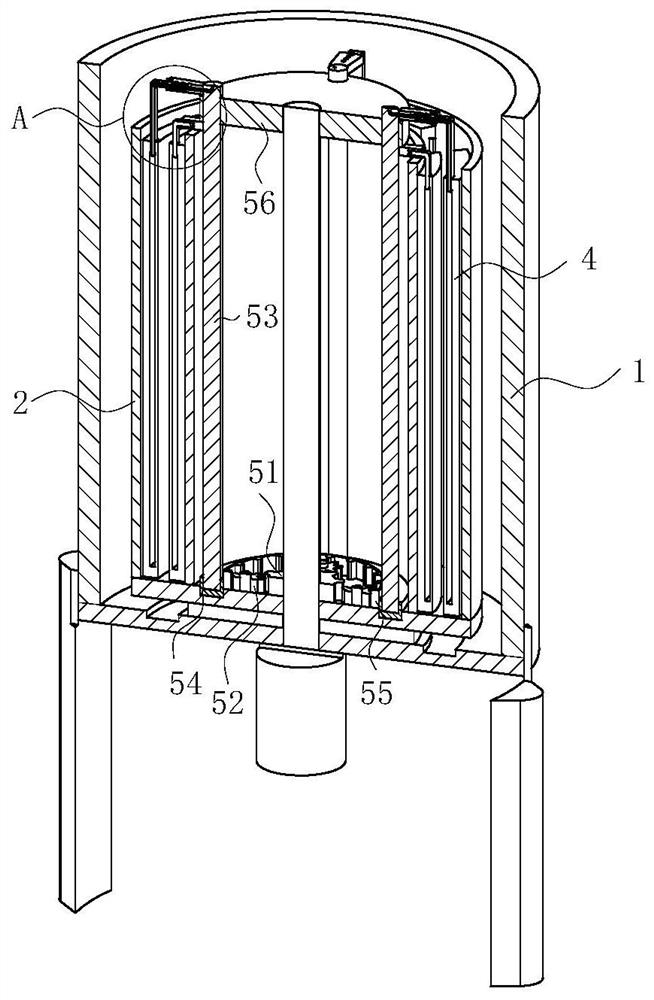

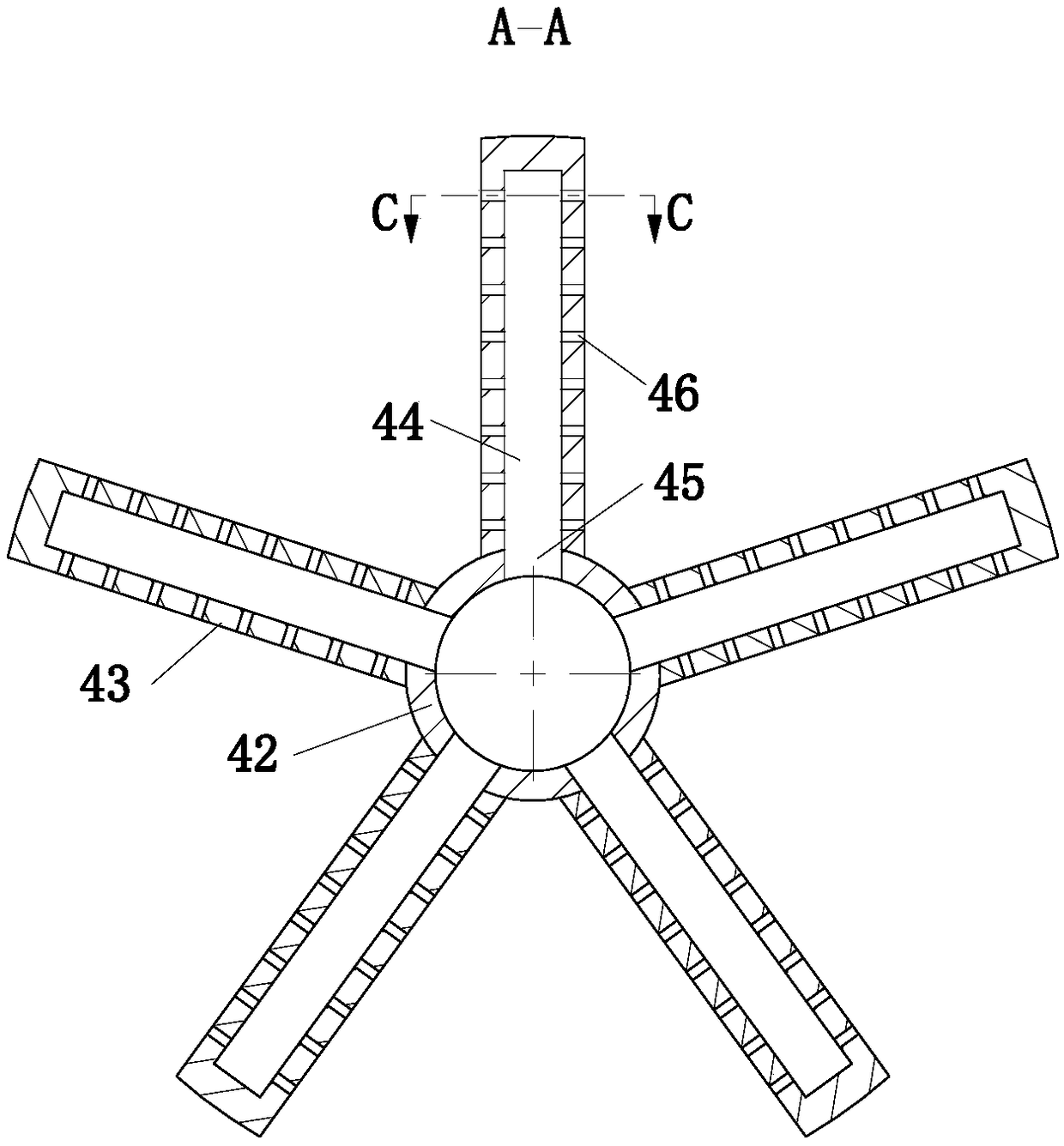

Graphene PVD coated coiled material production device and production process

InactiveCN110373650AReduce power consumptionSolve the need for ultra-high speedChemical vapor deposition coatingAtomic fountainCvd graphene

The invention discloses a graphene PVD coated coiled material production device and a production process adopting the same and belongs to the technical field of graphene production. The device comprises a reaction still. An atomic fountain device, a field-effect separator, an atomic disperser, a reformer, a Hall precision wiring device, a dose-effect precision assembler, a fermion intensifier anda quality inspection device are arranged in the reaction still according to the graphene PVD coated coiled material production process flow in sequence. The invention further discloses the graphene PVD coated coiled material production process. According to the graphene PVD coated coiled material production equipment and process, raw materials used as a carbon source is acetylene, the equipment power consumption is quite small, and the power consumption per day is around 24 kw / h.

Owner:张文跃

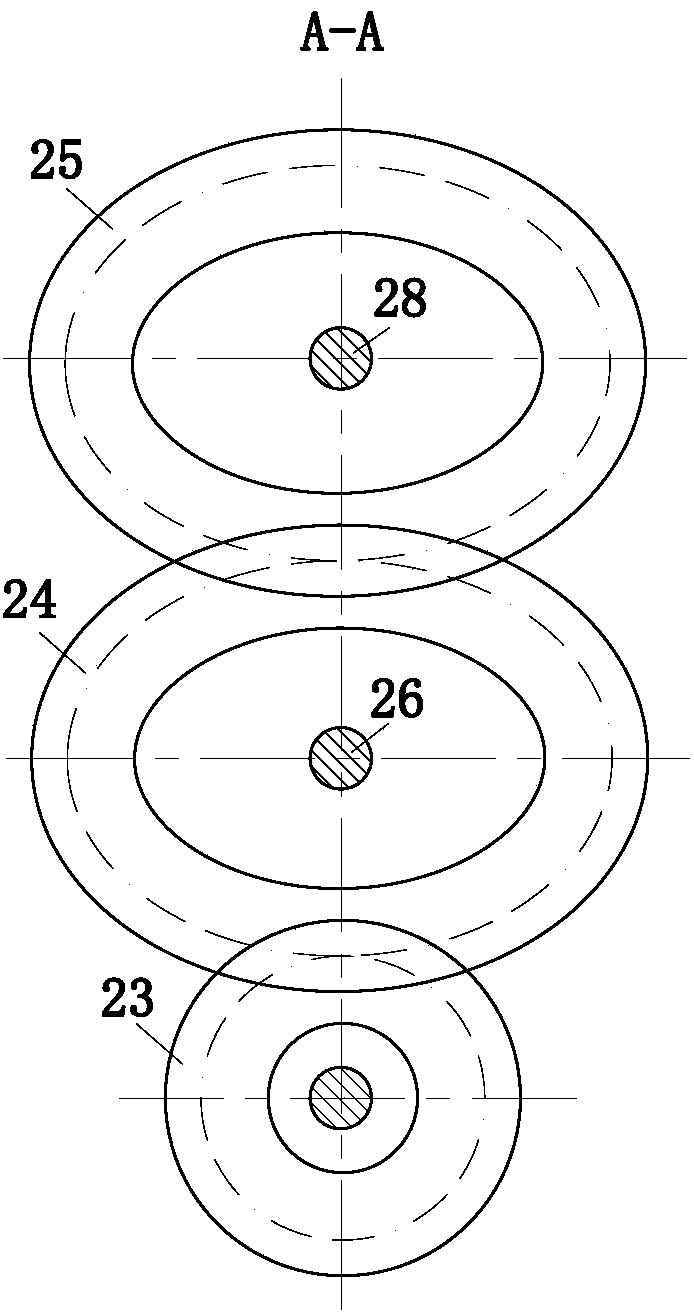

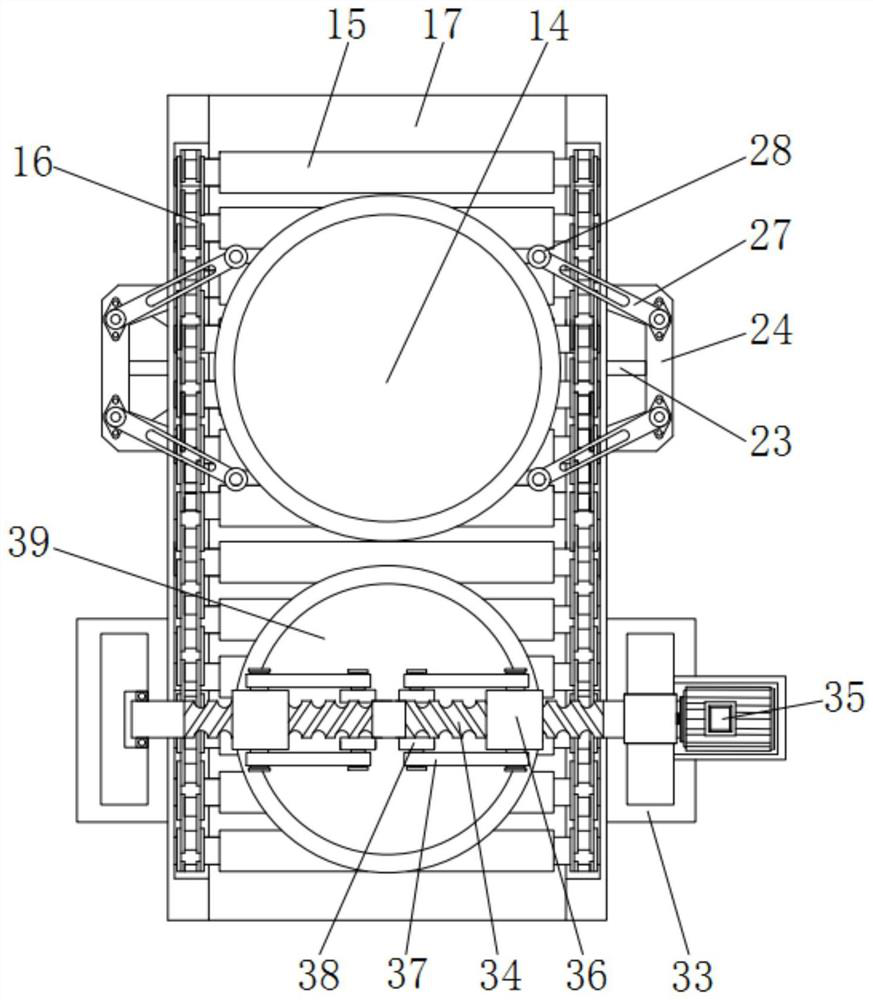

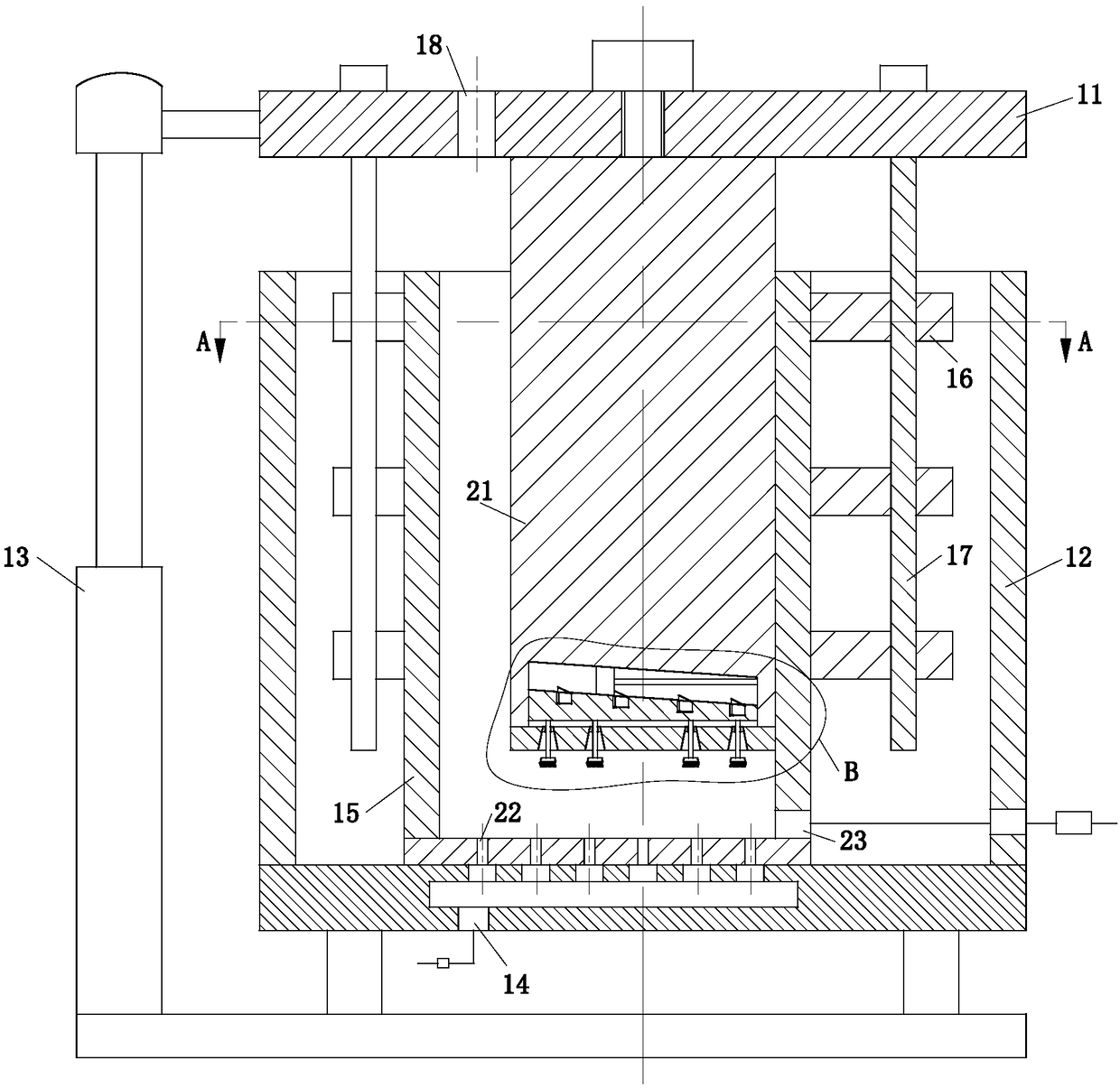

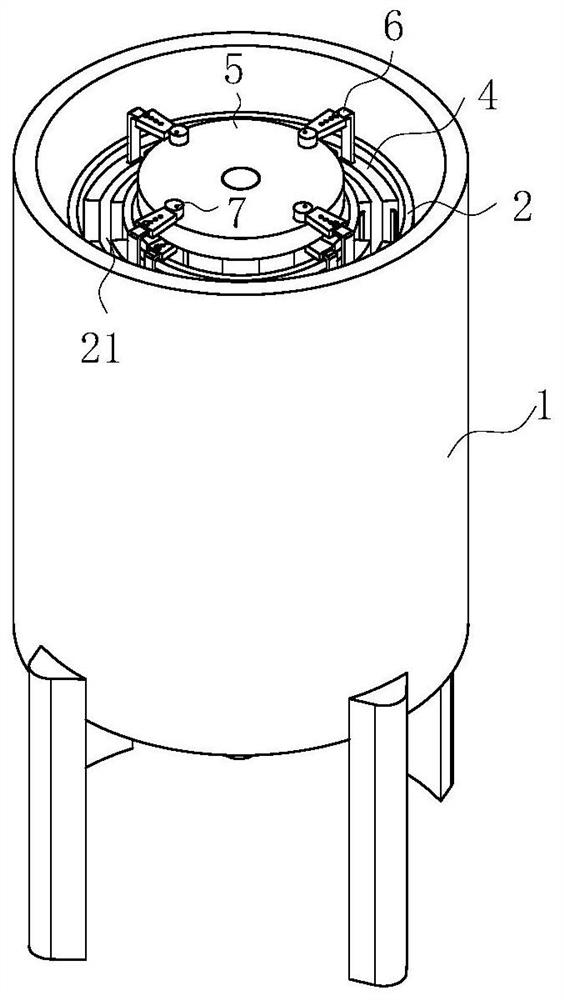

Graphene roll stripping system

The invention belongs to the technical field of graphene production, in particular to a graphene roll stripping system. A squeeze cylinder is arranged in a closed cylinder, cam sets are rotatably mounted on an upper bottom plate through a rotating rod, a squeeze roller is arranged in the squeeze cylinder, and the squeeze roller is rotatably mounted on the upper bottom plate; the three cam sets cooperate with each other such that the squeeze roller is in contact with the inner wall of the squeeze cylinder; graphite particles are transported from a feed port to the squeeze cylinder, a motor drives the squeeze roller to rotate, at the same time, a controller controls the three cam sets to cooperatively rotate through the motor, and the inner wall of the squeeze cylinder is in full contact with the squeeze roller, thereby improving the stripping efficiency of graphene; and the stripped graphene is collected through filter holes and a discharge port. The system is mainly used for preparinggraphene and can be used for fully grinding the graphene, and at the same time, the fine graphene particles meeting the size can be filtered in time, so that the production efficiency of graphene is improved.

Owner:德汇新材料科技南通有限公司

High-efficiency drying equipment for graphene production and drying method

ActiveCN112944852AHigh speedReduce contact areaDrying solid materials without heatDrying gas arrangementsStructural engineeringProcess engineering

The invention discloses high-efficiency drying equipment for graphene production and a drying method in the technical field of graphene production. The high-efficiency drying equipment comprises a drying box, wherein feeding plates, positioning plates and a material guide plate are sequentially arranged in an inner cavity of the drying box from top to bottom; a plurality of material placing mechanisms are evenly arranged between the material guide plate and the positioning plates; a driving assembly is connected to the bottom of each material placing mechanism; and a drying assembly is arranged on the material guide plate. According to the high-efficiency drying equipment and the drying method, materials are drained through draining barrels, the draining speed is increased through the centrifugal effect during rotation, and drained water cannot be thrown into the adjacent draining barrels through the effect of annular baffles; and under the action of a first electromagnet and adsorption plates in connecting cylinders, water retaining cylinders move downwards, dewatering tanks and the concave positions of the draining barrels are staggered, then drying is carried out through the drying assembly, after drying is finished, the draining barrels move upwards, the bottom ends of the draining barrels are separated from sealing tables, and the materials move outwards along the top surfaces of the sealing tables and fall onto the material guide plate.

Owner:福建烯望新材料科技有限公司

Graded grinding and crushing device for graphene production

The invention relates to the technical field of graphene production, and discloses a graded grinding and crushing device for graphene production. The graded grinding and crushing device comprises a base, two support rods are fixedly installed on each of the left side and the right side of the top of the base, and the tops of the four support rods are fixedly connected with a grinding box. According to the graded grinding and crushing device for graphene production, by arranging a first motor, a lead screw and sliding blocks, when graphene powder of different thicknesses needs to be ground, thefirst motor can be started, so that the first motor drives the lead screw to rotate, and thus the two sliding blocks move left and right; when graphene blocks move to positions below different grinding discs, rotation of the first motor is stopped, so that an electric push rod is started to push the grinding discs to move downwards, and then a second motor can be started to grind the graphene blocks; and the structure can achieve the effect of graded grinding, and it is avoided that different grinding devices need to be used when the graphene powder of different thicknesses needs to be ground.

Owner:高密市盛德新能源科技有限公司

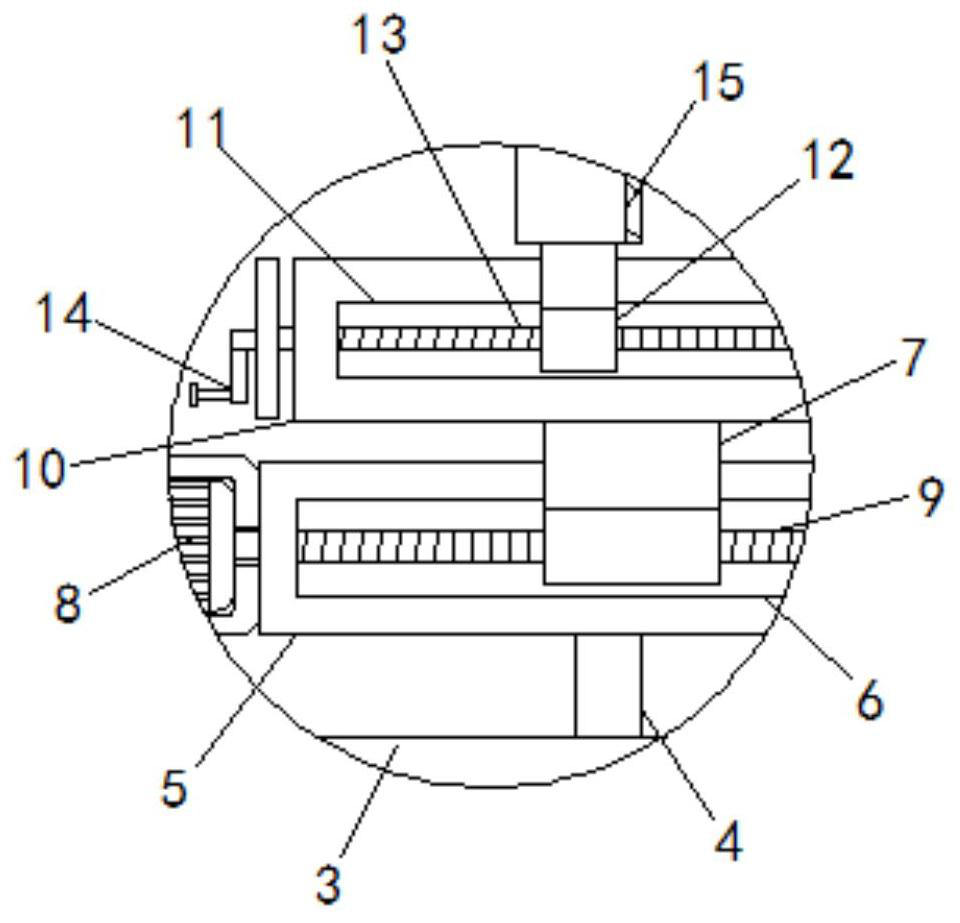

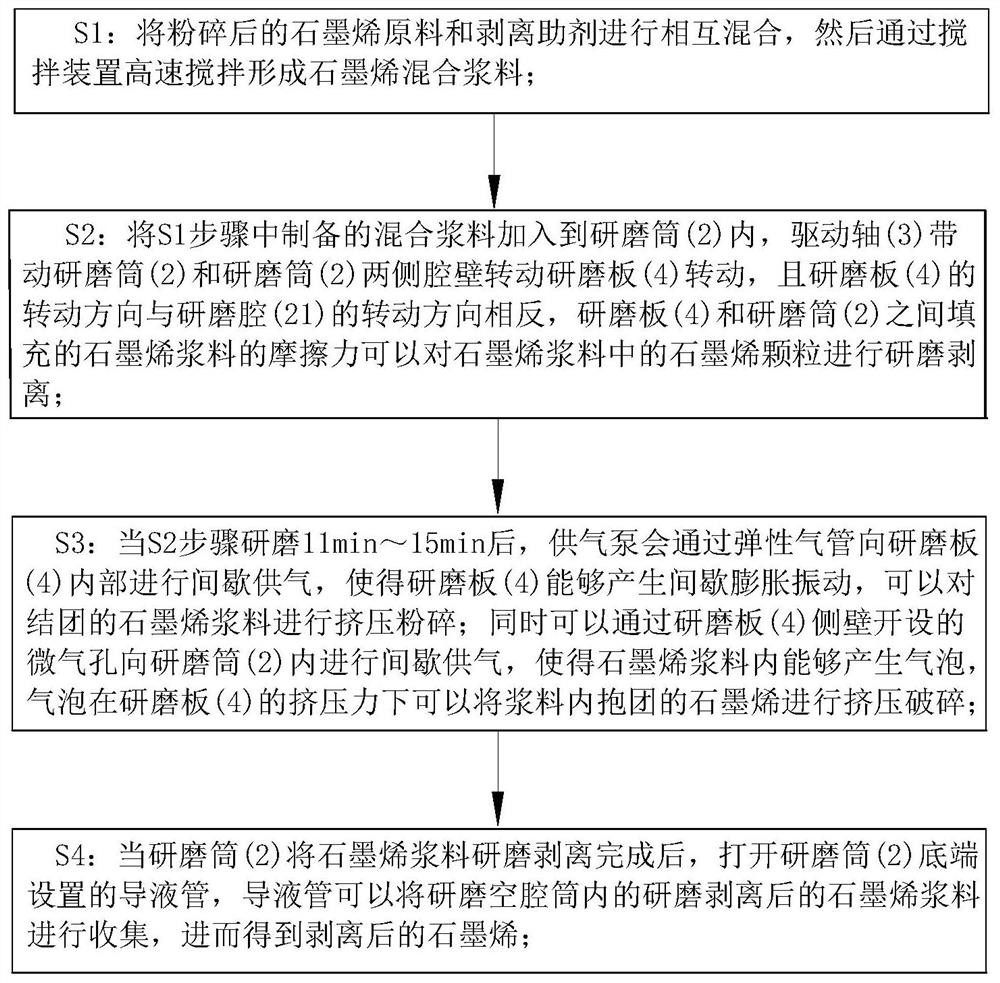

Preparation method of graphene

The invention belongs to the technical field of graphene production, and particularly relates to a graphene preparation method. The preparation method comprises the following steps: S1, a crushed graphene raw material is mixed with a stripping aid, and then the mixture is stirred at a high speed through a stirring device to form graphene mixed slurry; s2, the mixed slurry prepared in the step S1 is added into a grinding cylinder, wherein a driving shaft drives grinding plates at the grinding cylinder and cavity walls on the two sides to rotate, the rotating direction of the grinding plate being opposite to the rotating direction of a grinding cavity; S3, after the graphene slurry is ground in the step S2 for 11-15 min, an air supply pump can intermittently supply air into a grinding platethrough an elastic air pipe, so that the grinding plate can generate intermittent expansion vibration, and the caked graphene slurry can be extruded and crushed, wherein gas introduced into the expansion cavity in a clearance mode can enable the expansion cavity to generate clearance expansion, expansion of the grinding plate can extrude the inner wall of the grinding cylinder, then graphene slurry agglomerated during grinding can be extruded and crushed, and thereby the efficient grinding and stripping effect of graphene is improved.

Owner:牛安逸

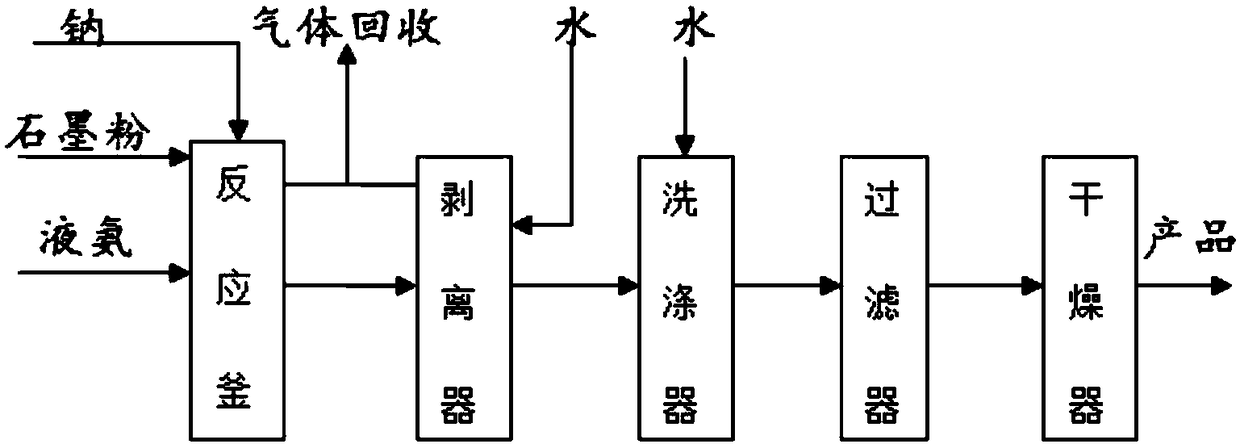

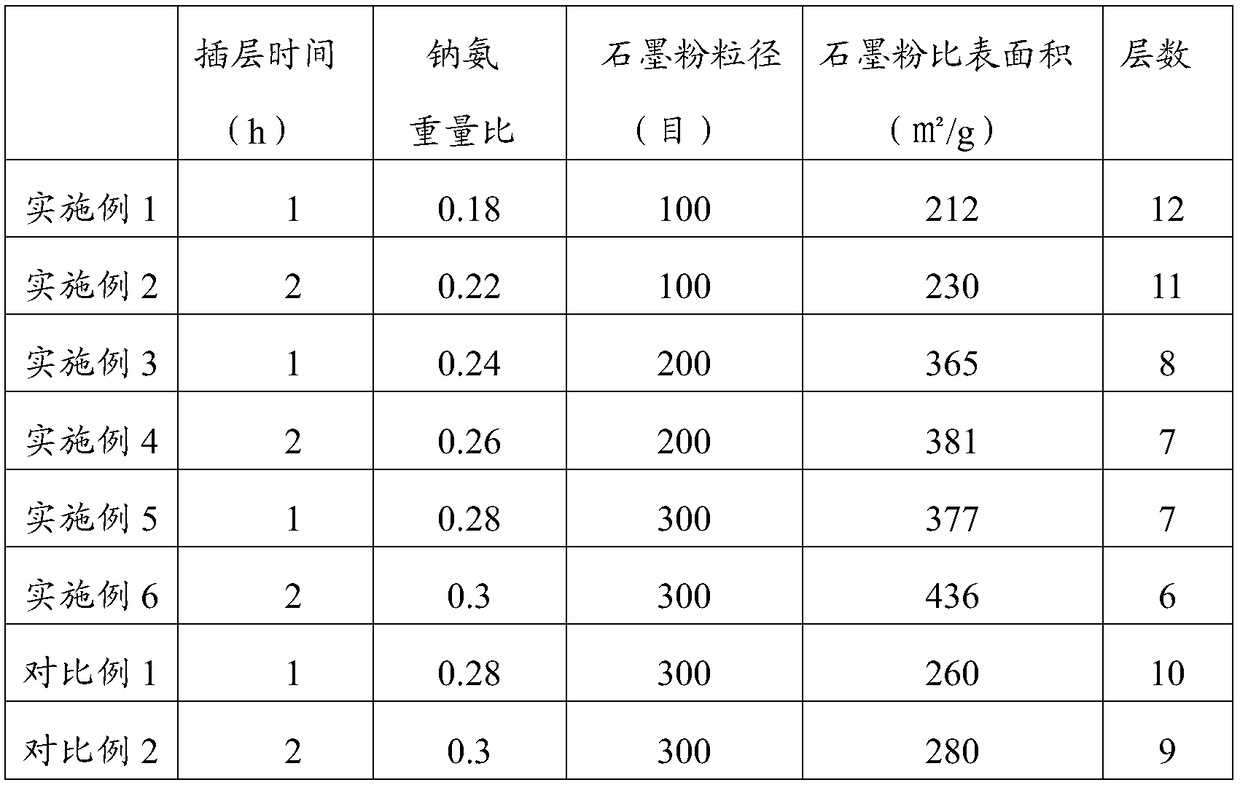

Batch production method of high quality graphene

The invention discloses a batch production method of high quality graphene, and belongs to the technical field of graphene production. The method comprises the following steps: 1, adding natural graphite powder to a reactor fully filled with ammonia gas; 2, sequentially adding sodium metal and liquid ammonia to the reactor of the step 1 to obtain a mixed liquid, maintaining at normal temperature for 1 to 2 hours, and controlling pressure to 1.0 to 1.5 MPa; 3, heating the reactor of the step 2 until the liquid ammonia is evaporated completely to obtain sodium-intercalated graphite powder; step4, placing the sodium intercalated graphite powder into a stripper, and introducing water for reaction; and step 5, washing a material obtained in the step 4 with water, filtering and drying to obtaina graphene product. The method has the advantages of using of the natural graphite powder as a raw material, no changing in the graphene structure, short graphene forming time, mass production and the like.

Owner:山东恒华新材料有限公司

Graphene heavy-duty anti-corrosion wear-resistant coating and preparation process thereof

InactiveCN114539882AExtended pathImprove anti-corrosion and wear-resistant effectAnti-corrosive paintsEpoxy resin coatingsEpoxyXylylene

The invention belongs to the technical field of graphene production, and particularly discloses a graphene heavy-duty anti-corrosion wear-resistant coating and a preparation process, and the graphene heavy-duty anti-corrosion wear-resistant coating comprises the following components in parts by weight: 20-30 parts of graphene, 50-70 parts of an epoxy resin emulsion, 30-45 parts of a standard carrier solvent, 15-20 parts of silicon dioxide, 20-30 parts of deionized water, 5-10 parts of ferrotitanium powder, 5-8 parts of a surface modifier, 1-3 parts of a dispersant and 1-3 parts of barium sulfate. The standard carrier solvent can be selected from one of butyl acetate, xylene, MEK and ethyl acetate, and the surface modifier comprises a silane coupling agent, an aluminate coupling agent and a surfactant; according to the invention, the graphene is added into the epoxy resin coating, and a path for a corrosive medium to be conducted to a base material is prolonged by utilizing a labyrinth effect generated by a lamellar structure of a graphene material, so that the corrosion process is delayed, and the graphene anti-corrosion and wear-resistant coating has better anti-corrosion and wear-resistant properties.

Owner:SHANGHAI JIANYE TECH ENG

Graphene preparation method

InactiveCN108793142AAdjust lift heightSolve the problem of reduced elasticityCarbon compoundsEngineeringGraphite particle

The invention belongs to the technical field of graphene production, in particular to a graphene preparation method. A graphene preparation device used in the method comprises a dithering module and acrushing module, which are both located in a closed bin, wherein the dithering module is located below the crushing module and is fixedly mounted on the inner wall of a side plate; the crushing module is fixedly mounted on the lower surface of an upper bottom plate; the dithering module is used for raising graphite particles, and the crushing module is used for crushing the raised graphite particles; the upper bottom plate is rotatably mounted on the upper end of the side plate, and cooperates with a motor I to drive the crushing module to rotate; a sucker is arranged at the lower end of a storage cover and is fixedly mounted on the upper surface of a lower bottom plate through an electric push rod I; a rubber pad is fixedly mounted on the lower surface of a mounting block I. The method is mainly used for preparing graphene, and can be used for fully crushing graphene to improve the production efficiency of graphene.

Owner:陆挚译

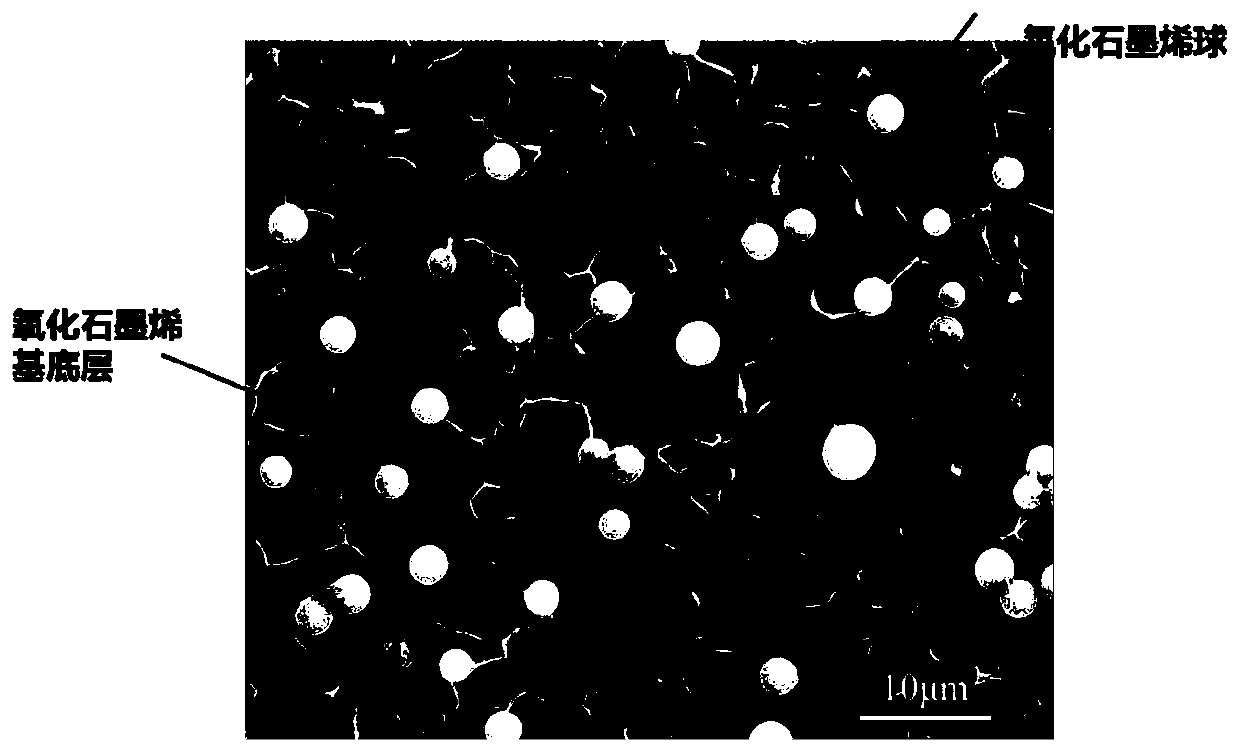

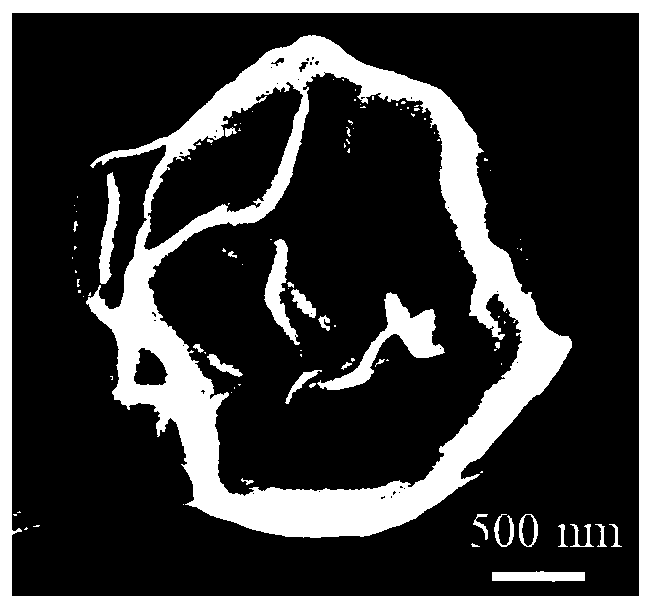

Graphene oxide paper with surface microsphere structure and preparation method thereof

ActiveCN111017918ALarge specific surface areaGreat application potentialGrapheneMicrosphereGraphene flake

The invention discloses graphene oxide paper with a surface microsphere structure and a preparation method thereof, which belong to the technical field of graphene oxide production. The micron-scale graphene oxide spheres are evenly distributed on the upper surface of the graphene oxide paper, the bottoms of the graphene oxide spheres are tightly connected with the graphene oxide paper on the lower portions of the graphene oxide spheres through graphene sheet layers, and the interiors of the graphene oxide spheres are of a hollow structure. The particle size distribution of the graphene oxidespheres is 2.3 [mu] m to 2.8 [mu] m. The bottom of the graphene oxide paper is formed by stacking graphene sheet layers, the thickness of the graphene oxide paper is 50-80 [mu] m, and wrinkles are formed on the surface of the graphene oxide paper. The micron-sized graphene oxide spheres are uniformly distributed on the surface of the prepared graphene oxide paper, and the unique structure endows the graphene oxide paper with higher specific surface area than common graphene oxide paper. By regulating and controlling the pH value and concentration of the graphene oxide dispersion liquid and thecontent of graphene oxide, the size and distribution of surface microspheres can be regulated and controlled at a micron scale.

Owner:HARBIN INST OF TECH

A kind of graphene production process

The invention belongs to the technical field of graphene production and particularly relates to a graphene production process. A reaction kettle is used in the process and comprises a chamber, a feeding pipe, a gas inlet pipe, a finished product conveying pipe, microwave emitters and a swing module. The feeding pipe is arranged at the top of the chamber; the gas inlet pipe is arranged at the bottom of the chamber and used for injecting inert gases or compressed air into the chamber; the finished product conveying pipe is arranged at the top, on one side of the feeding pipe, of the chamber; themicrowave emitters are arranged on the inner wall of the chamber; the swing module is arranged in the middle of the chamber and used for placement of oxidized graphite particles. By arrangement of the swing module, influences on graphene production due to raw material accumulation are avoided under the vibration action of the swing module; by arrangement of a vibration module, local accumulationof graphite particles in a placement vessel is avoided, and blockage of a feeding hopper is avoided; by arrangement of a shaking module, the graphite particles are enabled to shake in the placement vessel, and accordingly influences on graphene production due to raw material accumulation are avoided.

Owner:深圳稀导技术有限公司

Graphene feed liquid deacidification method and device

InactiveCN113526499AReduced sulfuric acid contentReduce running timeCarbon compoundsUltrafiltrationGraphiteCeramic membrane

The invention discloses a graphene feed liquid deacidification method and device, and belongs to the technical field of graphene production, wherein the graphene feed liquid deacidification method specifically comprises the following steps: S101, feeding to-be-treated graphene feed liquid into a storage tank for preliminary precipitation; S102, removing impurities from the bottom of the precipitated graphene feed liquid, pressurizing the graphene feed liquid through a pressurizing pump, and feeding the graphene feed liquid into ceramic membrane equipment; and S103, carrying out nanofiltration filtration deacidification on the graphene feed liquid entering the ceramic membrane equipment through a ceramic membrane, and fully filtering to obtain a ceramic membrane concentrated solution. According to the method, the graphene feed liquid is subjected to ceramic membrane deacidification, the ceramic membrane concentrated solution is obtained, the molecular weight cutoff of a ceramic membrane used in the ceramic membrane deacidification is 10-50 nm, the pressure intensity of the ceramic membrane deacidification is 0.3-0.6 MPa, and the content of sulfuric acid in the concentrated solution treated through the ceramic membrane is greatly reduced; and through effective concentration and filtration of the graphene feed liquid, the operation time is shortened, the water consumption is reduced, and the production cost is reduced.

Owner:同舟众横厦门流体技术有限公司

A kind of graphene rolling peeling method

The invention belongs to the technical field of graphene production, and specifically relates to a graphene rolling peeling method. In the rolling system adopted in the method, an extrusion cylinder is arranged in a closed cylinder, and a cam group is installed on the upper cylinder by rotating a rod. On the bottom plate, there is an extrusion roller in the extrusion cylinder, which is installed on the upper bottom plate in rotation; three cam groups cooperate with each other to make the extrusion roller contact with the inner wall of the extrusion cylinder; graphite particles are transported from the feed port to the extrusion cylinder. In the press cylinder, the motor drives the extrusion roller to rotate, and at the same time, the controller uses the motor to make the three cam sets rotate in coordination, so that the inner wall of the extrusion cylinder is in full contact with the extrusion roller, thereby improving the stripping efficiency of graphene; the graphite after stripping Graphene is collected through a filter hole and a discharge port; the present invention is mainly used for preparing graphene, which can fully grind graphene, and meanwhile fine particle graphene meeting the size can be filtered in time; improves the production efficiency of graphene.

Owner:江苏希诚新材料科技有限公司

A kind of preparation method of graphene oxide paper with holes reinforced by dendrimers

ActiveCN110903506BEffective resizingEfficient dischargeCarbon compoundsPorous graphenePolymer science

The invention discloses a preparation method of dendritic macromolecule reinforced graphene oxide paper with holes, and belongs to the technical field of graphene oxide production. The invention aimsto solve the problems of low tensile strength and stress relaxation of a graphene oxide film / paper material and low quality of the finally prepared material due to impermeability of lamellas and the like. An epoxy functional group and adjacent carbon atoms thereof are eroded in a graphene oxide sheet layer through the strong oxidizing property of hydrogen peroxide to form nanoscale holes; polyamide-amine (PAMAM) dendritic polymer is introduced to form covalent cross-linking among graphene oxide sheet layers to improve the interlayer bonding strength of the graphene oxide; and finally, a graphene oxide film / paper material with relatively high strength and relatively good quality is obtained by means of directional filtering. The method is simple to operate, low in cost and high in efficiency, and is expected to realize large-scale preparation.

Owner:HARBIN INST OF TECH

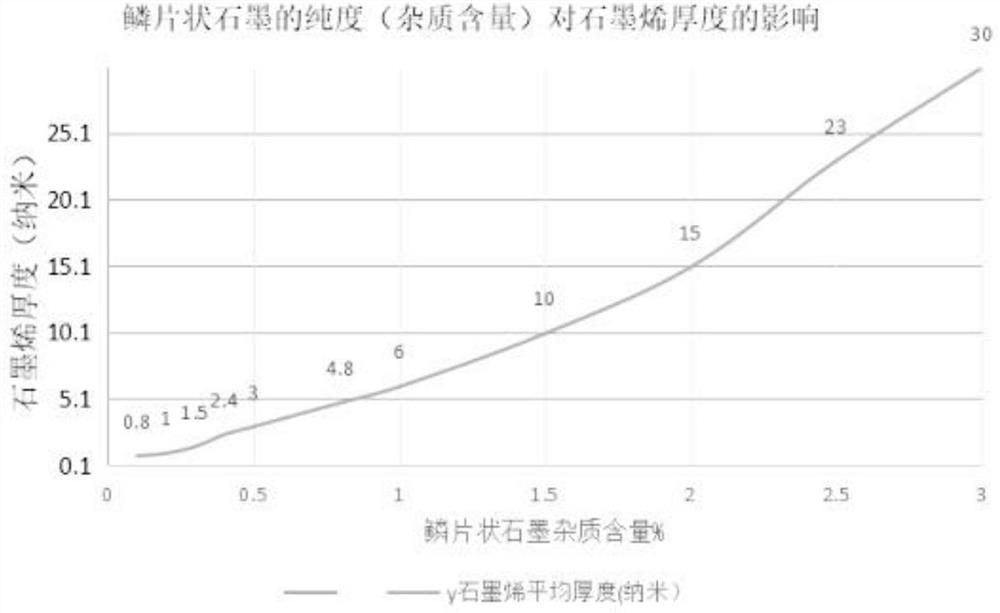

Graphene powder gas-phase physical stripping method and produced graphene

PendingCN113620280ALarge specific surface areaImprove stripping efficiencyMaterial nanotechnologySingle layer graphenePolyvinyl alcoholPyrrolidinones

The invention relates to the technical field of graphene production, and concretely relates to a graphene powder gas-phase physical stripping method. The method comprises the following steps: selecting high-purity flaky graphite as a raw material for producing graphene, mixing the flaky graphite with a ball-milling stripping medium, feeding the mixture into a ball mill, adding polyvinylpyrrolidone, polyvinyl alcohol and oleamide, carrying out ball-milling stripping under the protection of inert gas, and separating the graphene sheets subjected to ball-milling stripping through airflow classification under the protection of the inert gas after stripping is finished. Graphene production is completed through a physical method, the graphene sheets exist in a complete powder form, the storage and use environment is not limited, the industrial production cost is low, and graphene can be more widely applied to all walks of life.

Owner:湖南晨智纳米材料科技有限公司

A graphene roll peeling system

The invention belongs to the technical field of graphene production, and specifically relates to a graphene roll peeling system. An extrusion cylinder is arranged in a closed cylinder, and a cam group is rotated and installed on an upper base plate through a rotating rod. An extrusion cylinder is arranged in the extrusion cylinder. The extrusion roller rotates and is installed on the upper bottom plate; the three cam groups cooperate with each other to make the extrusion roller contact the inner wall of the extrusion cylinder; graphite particles are transported from the feed port to the extrusion cylinder, and the motor drives the extrusion roller to rotate. At the same time, the controller uses the motor to make the three cam sets rotate together, and the inner wall of the extrusion cylinder is in full contact with the extrusion roller, thereby improving the stripping efficiency of graphene; the stripped graphene is collected through the filter hole and the discharge port ; The present invention is mainly used for preparing graphene, which can fully grind graphene, and simultaneously meet the size of fine particle graphene can be filtered in time; improve the production efficiency of graphene.

Owner:德汇新材料科技南通有限公司

A kind of high-efficiency drying equipment and drying method for graphene production

ActiveCN112944852BHigh speedReduce contact areaDrying solid materials without heatDrying gas arrangementsStructural engineeringProcess engineering

Owner:福建烯望新材料科技有限公司

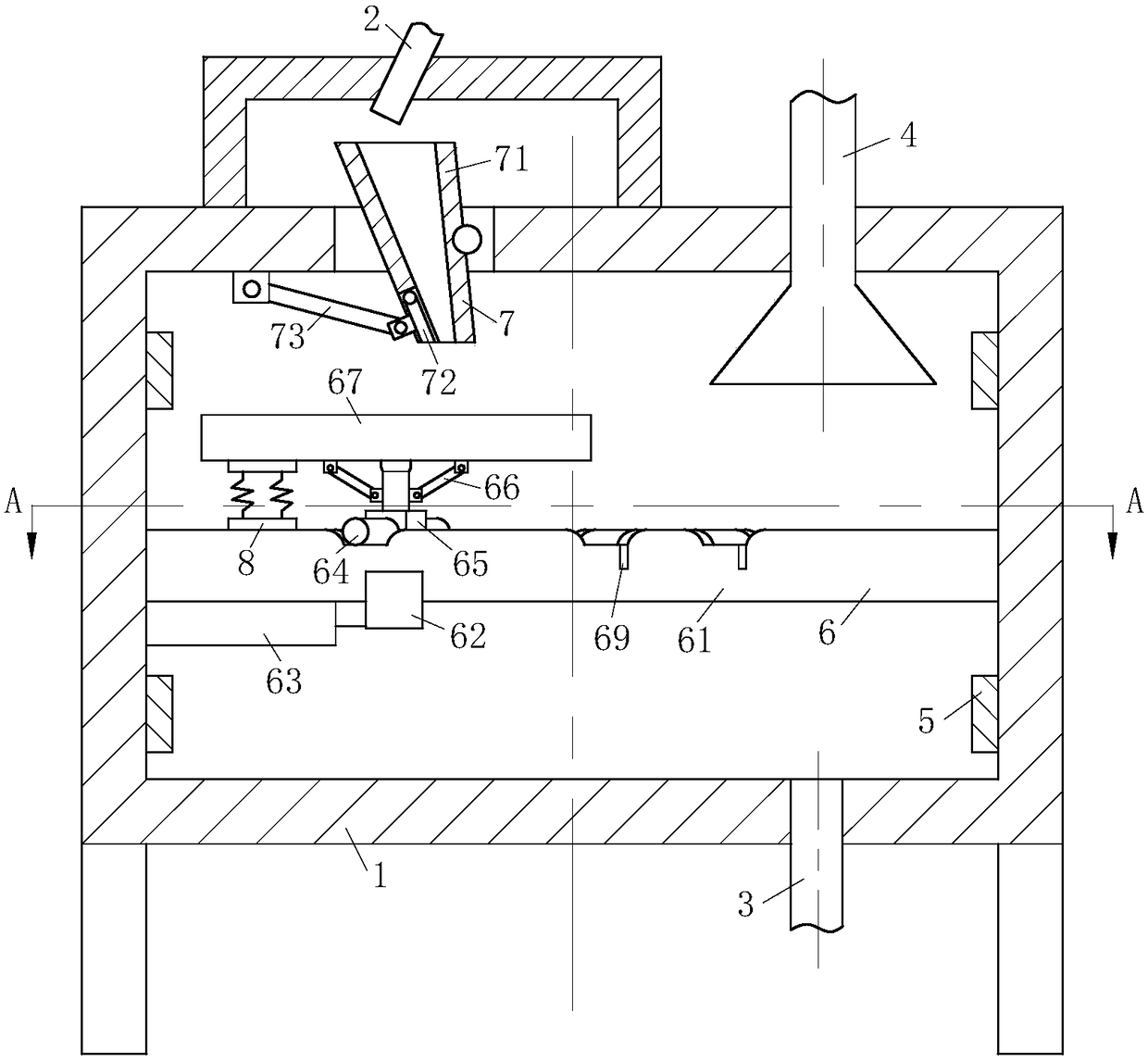

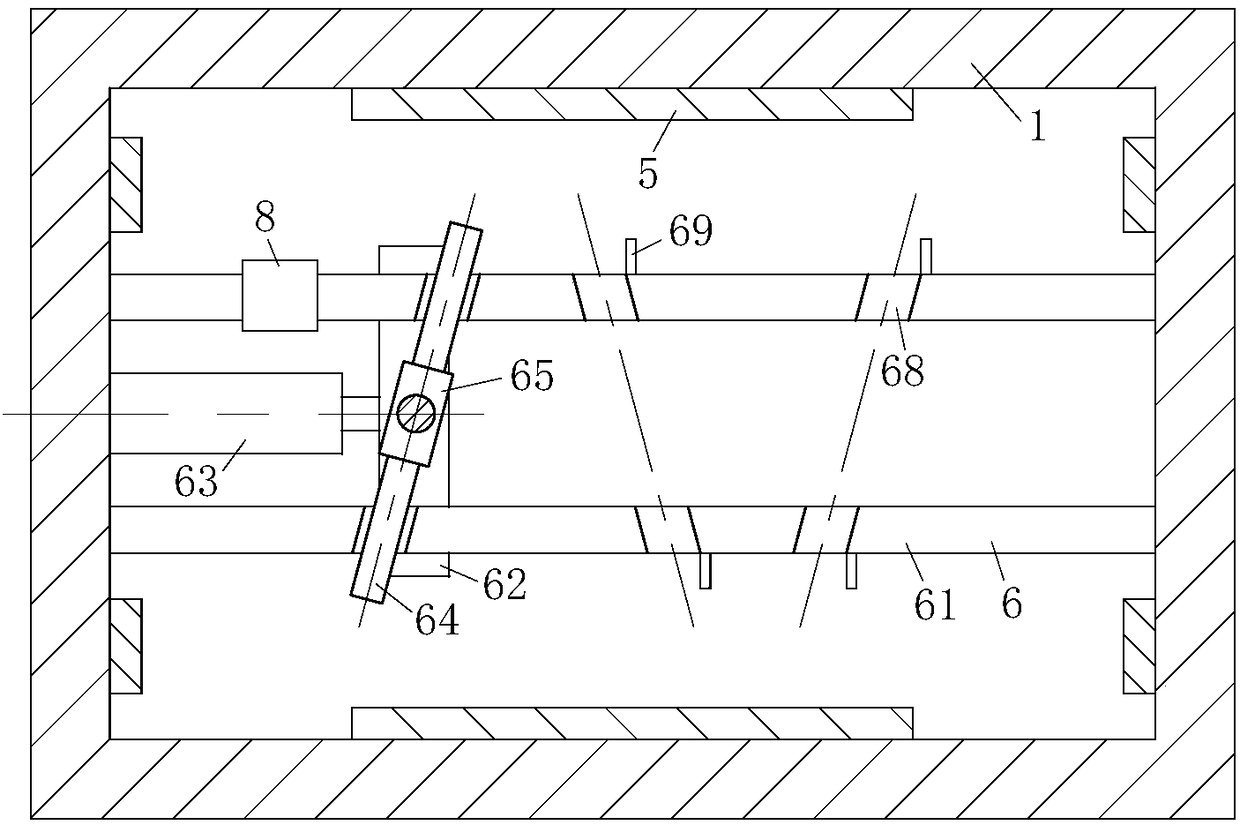

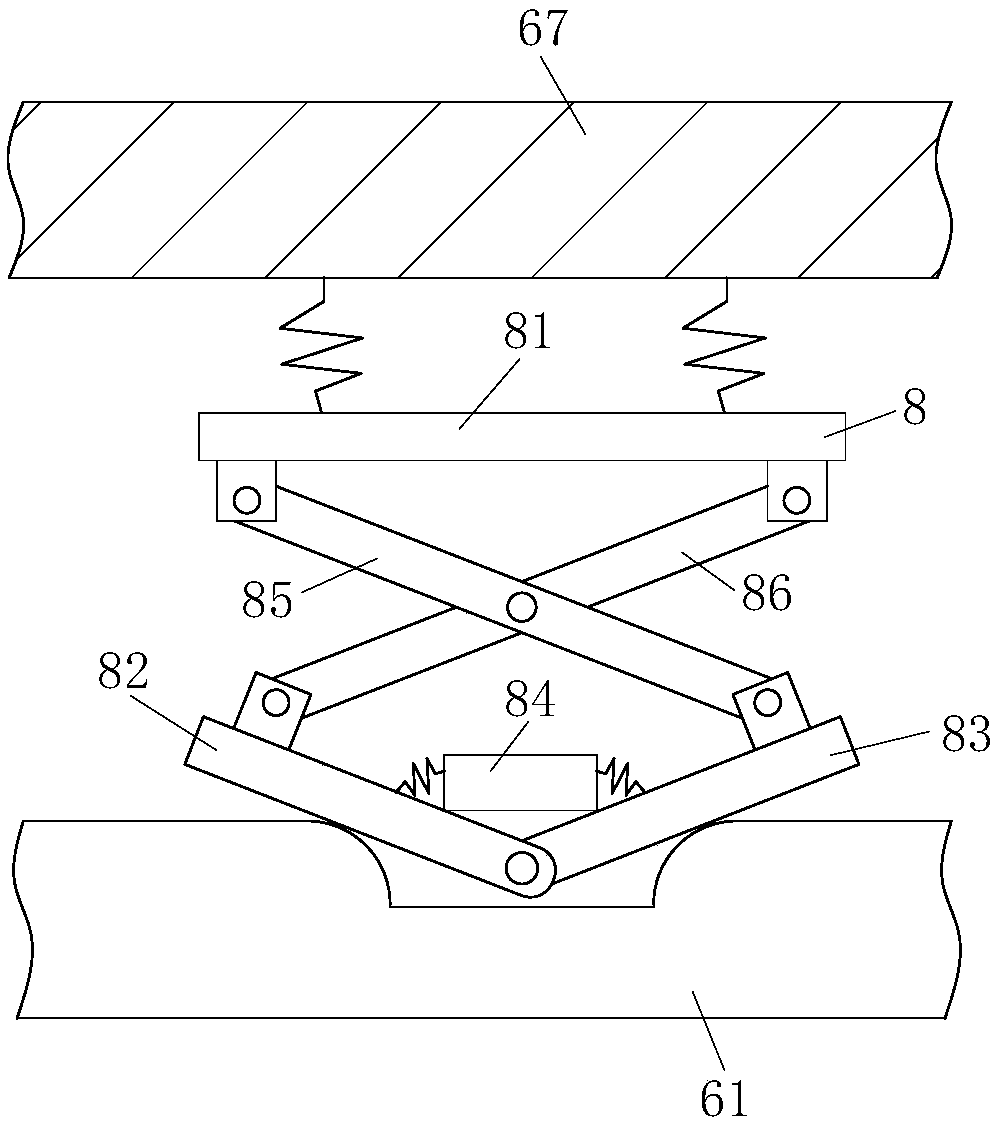

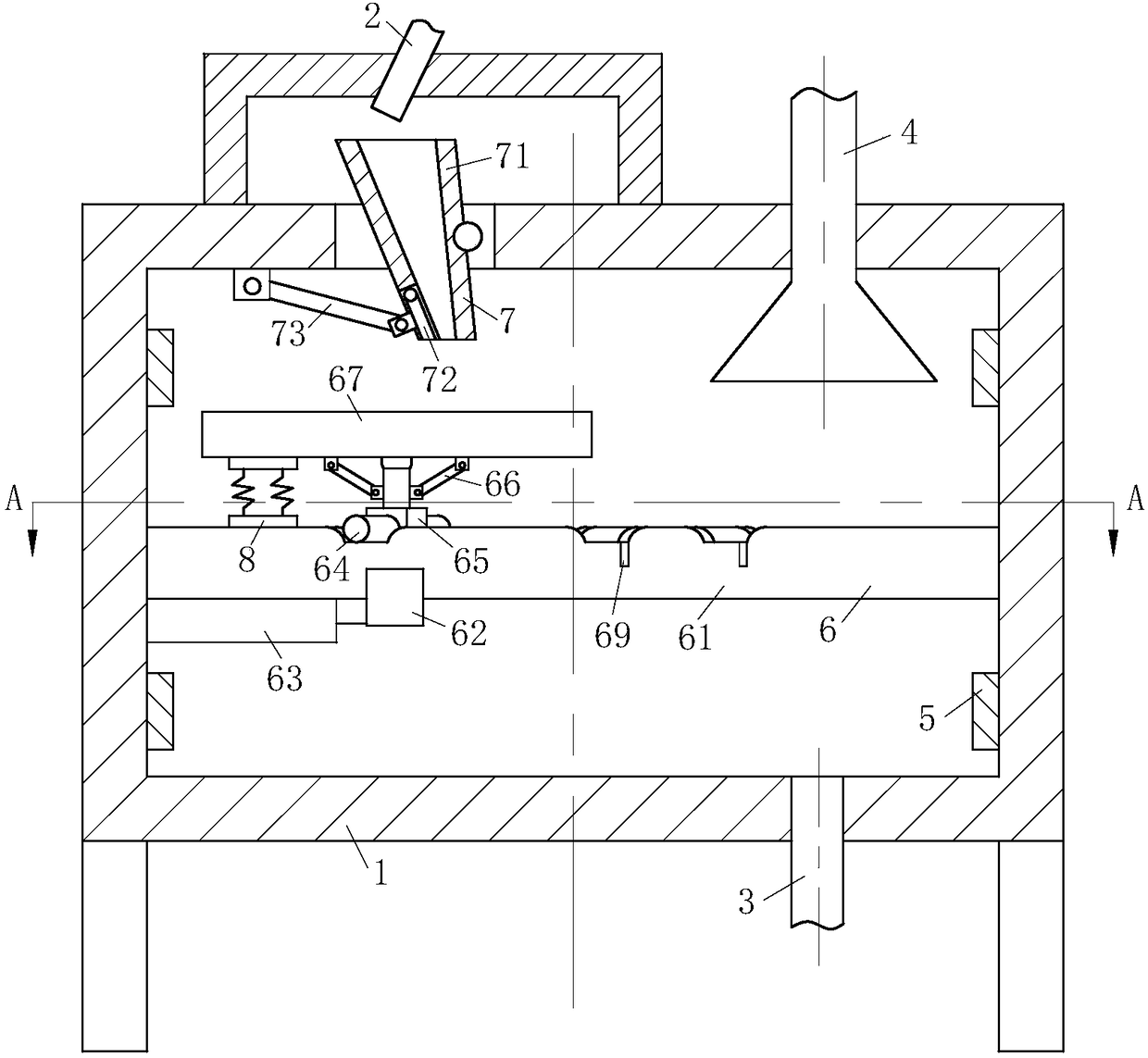

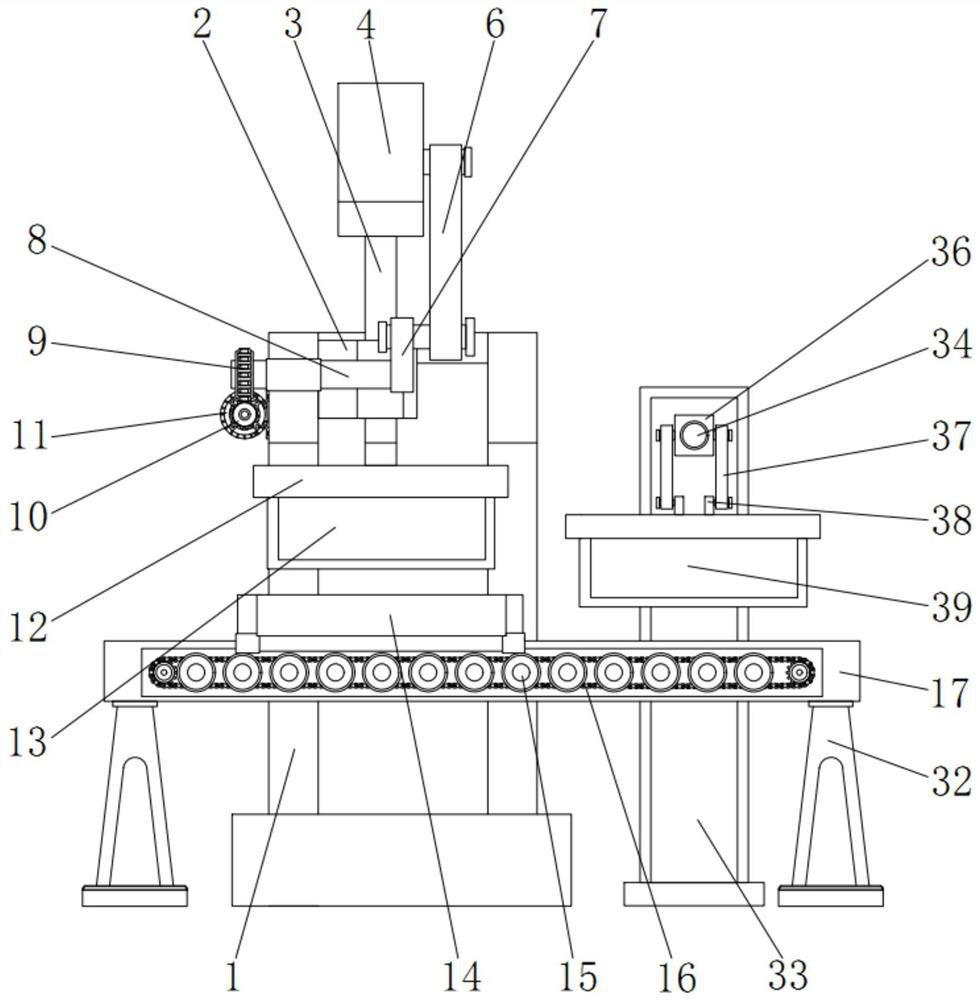

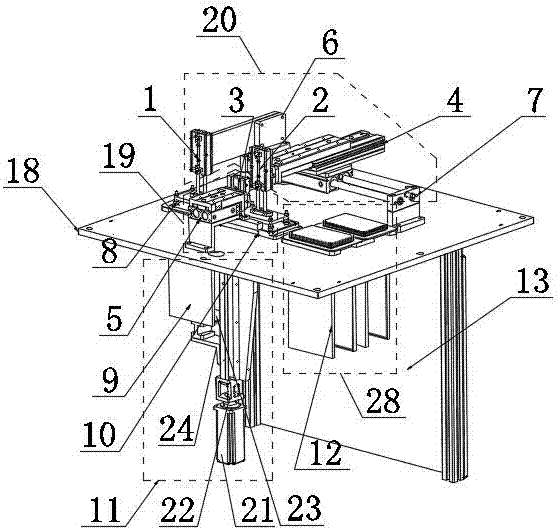

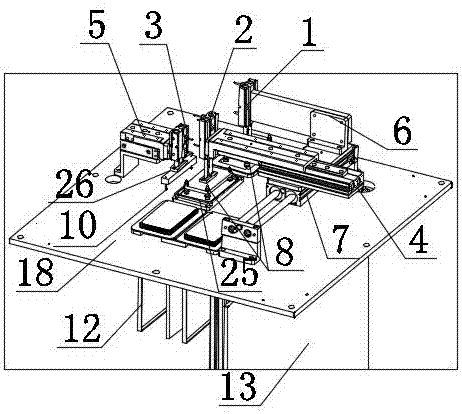

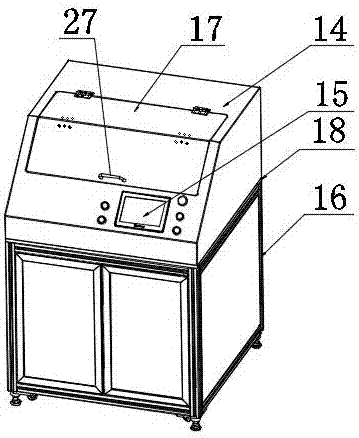

Graphene heating film detection and sorting automation device

InactiveCN106890803ALow experience requirementImprove work efficiencySortingEngineeringUltimate tensile strength

The invention relates to the technical field of graphene production, in particular to a graphene heating film detection and sorting automation device. In the graphene heating film detection and sorting automation device, a box body structure consisting of an aluminum profile frame of the device is connected with a metal plate shell by a bolt; and a deck plate is fixed at the middle upper section of the aluminum profile frame through a bolt, and is fixedly provided with a loading module, a detecting module, a sorting module and an unloading module through bolts. The graphene heating film detection and sorting automation device can automatically detect resistance values of heating films, classifies and places the heating films according to detecting results, greatly improves the working efficiency, saves the detecting time, relieves the labor intensity, reduces the experience and quality requirements on operators, is stable in workpiece quality, and largely increases the yield.

Owner:常州烯旺新材料科技有限公司

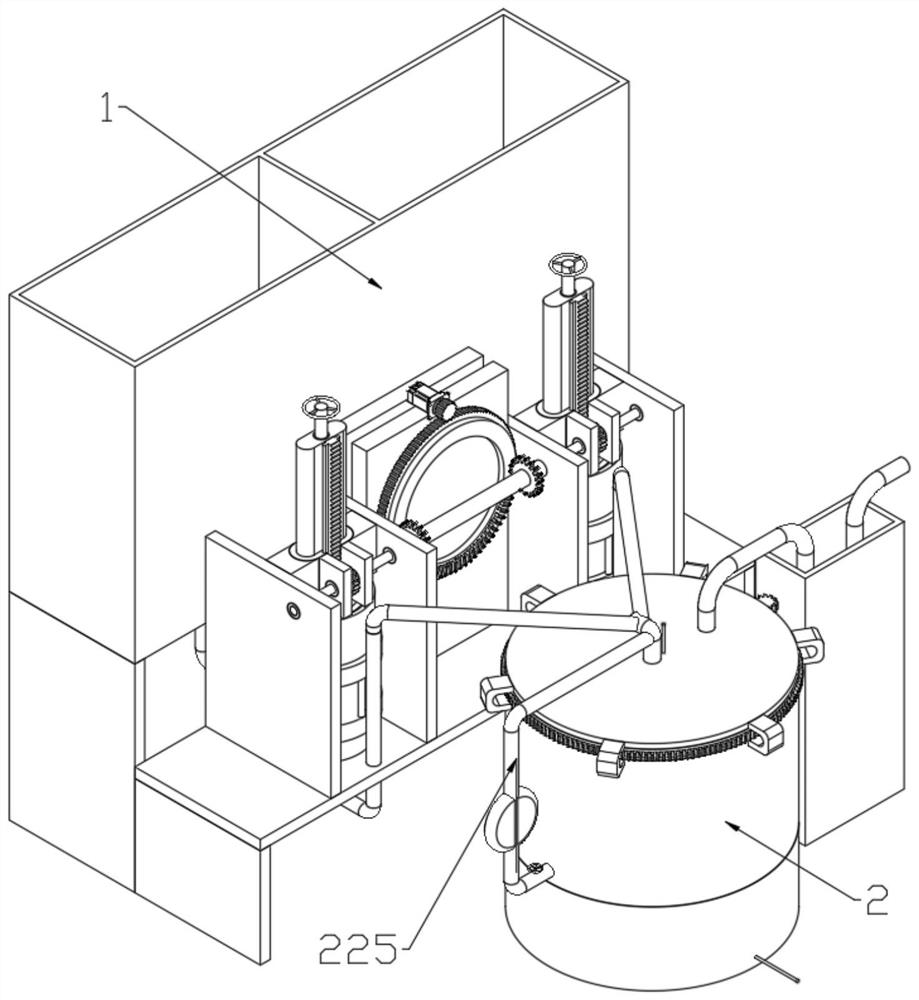

Automatic stirring device for graphene production

PendingCN114870734AEffective flushingEffective scraping operationShaking/oscillating/vibrating mixersCarbon compoundsBLENDER/MIXERProcess engineering

The invention discloses an automatic stirring device for graphene production, and relates to the technical field of graphene production, the automatic stirring device comprises a support and a mixing barrel, the mixing barrel is mounted on the support, and a dispersion feeding mechanism is arranged on the upper side of the mixing barrel and is used for dispersion feeding operation of graphene raw materials and solutions; a vibration stirring mechanism is arranged in the mixing barrel and used for vibration stirring operation of a mixture, and the vibration stirring mechanism is linked with the dispersion feeding mechanism; an opening is formed in the lower side of the mixing barrel, and a cleaning mechanism is arranged at the opening in the lower side of the mixing barrel and used for cleaning the inner wall of the mixing barrel. By arranging the cleaning mechanism, after stirring operation is completed, a mixture attached to the inner wall of the mixing barrel can be effectively washed and scraped, and the situation that the attached mixture influences the stirring device and hinders next stirring operation is prevented.

Owner:西安新三力复合材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com