A kind of high-efficiency drying equipment and drying method for graphene production

A drying equipment and high-efficiency technology, which is applied in drying, dryers, lighting and heating equipment, etc., can solve the problems affecting the drying effect of draining, improve the drying effect, reduce the contact area, increase the The effect of large exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

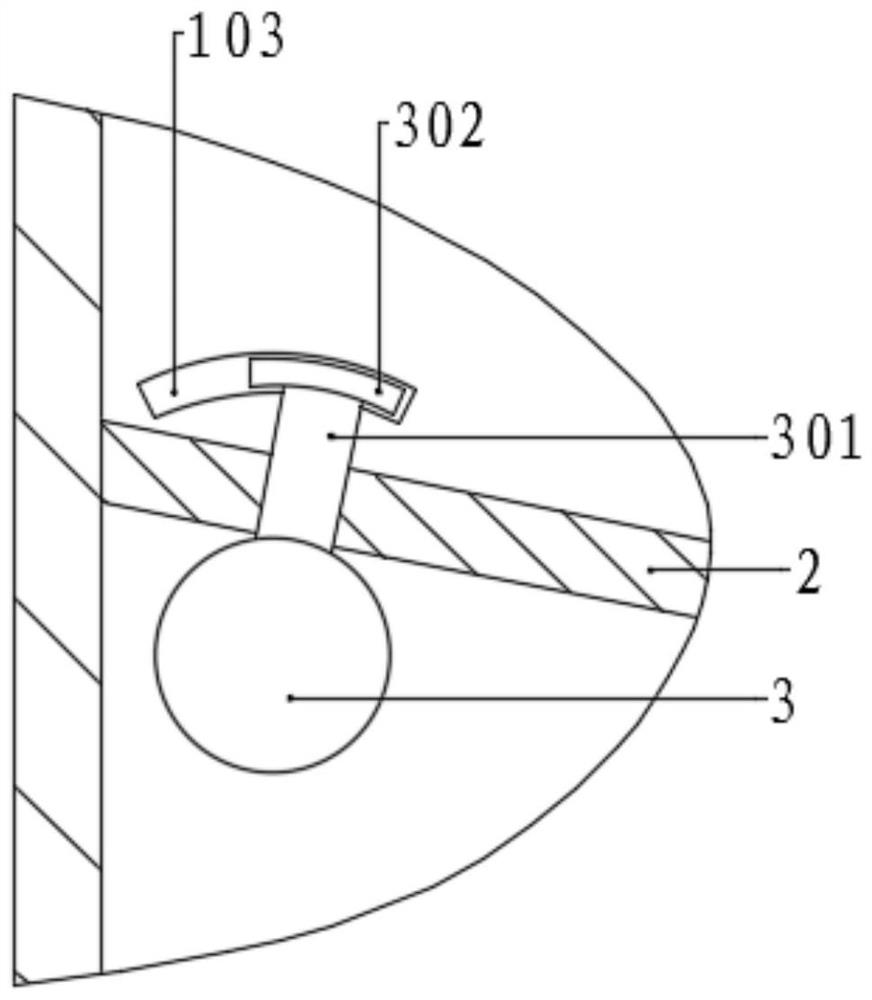

[0058] Please refer to the accompanying drawings, the present invention provides a technical solution: a high-efficiency drying device for graphene production, comprising a drying box 1, and a feeding plate 7 is fixed on the top of the inner cavity of the drying box 1, and the feeding There is a positioning plate 6 below the plate 7, and a material guide plate 2 is fixed at the bottom of the drying box 1. A plurality of material placement mechanisms are evenly arranged between the material guide plate 2 and the positioning plate 6, and the material guide plate 2 is provided with There are drying components. The bottom of the inner cavity of the drying box 1 is provided with a driving component, and the material placing mechanism is connected to the driving component correspondingly. The materials collected are concentrated in the middle of the guide plate 2 for unloading. A plurality of water guide holes 203 are evenly arranged in the middle of the guide plate 2, and a water co...

Embodiment 2

[0066] The structure of this embodiment is basically the same as that of the first embodiment, the difference is that the feeding plate 7 is evenly provided with a plurality of bucket-shaped feeding troughs 701 along the rectangular array, and the bottom end of the feeding trough 701 is provided with a feeding material in the middle. A ring-shaped third electromagnet 703 is provided on the bottom surface of the feeding plate 7 corresponding to the outer side of the feeding port 702. The third electromagnet 703 is electrically connected with a power supply and a switch, and the positioning plate 6 includes a plurality of evenly arranged positioning rings. 601, the positions of the positioning rings 601 and the feeding chute 701 correspond one-to-one, the two adjacent positioning rings 601 are fixedly connected by a fixing rod 602, and the positioning ring 601 located on the outer side is connected to the side of the drying box 1 through the fixing rod 602. The walls are fixedly ...

Embodiment 3

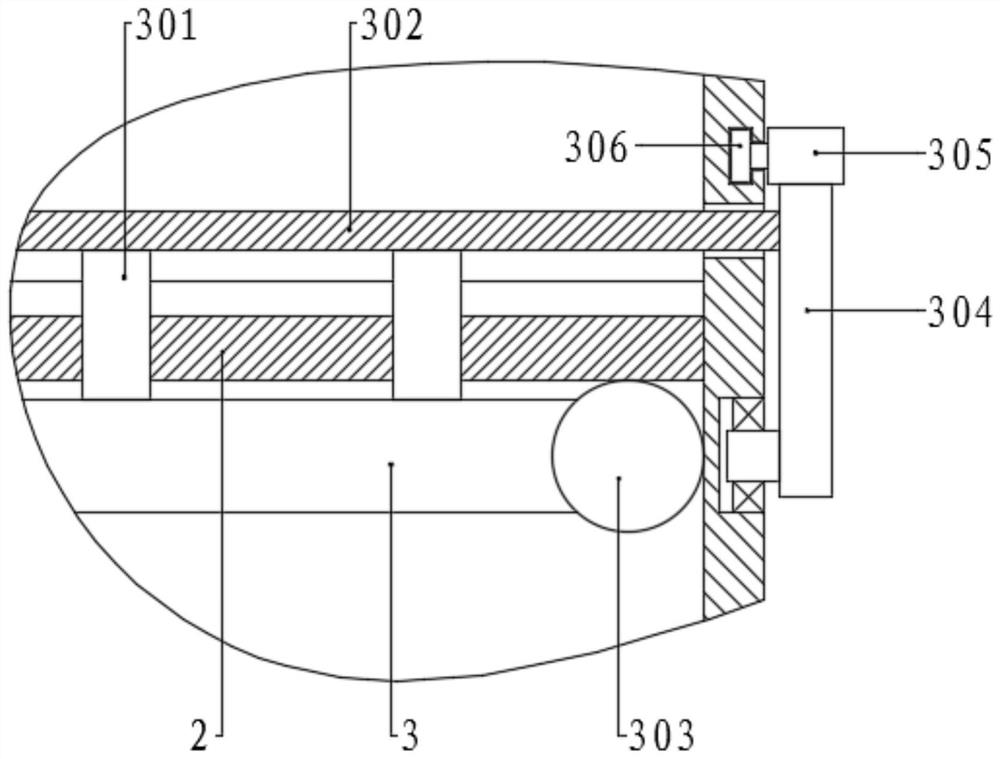

[0079] The structure of this embodiment is basically the same as that of the second embodiment, the difference is that the top of the air outlet duct 301 is set to be arc-shaped, and the top of the air outlet duct 301 located on the same drying duct 3 is jointly provided with an arc-shaped seal The bottom arc surface of the sealing plate 302 is slidably connected to the top arc surface of the air outlet duct 301, the two side walls of the drying box 1 are provided with arc grooves 103, and the two ends of the sealing plate 302 are slidably connected to the arc shape slot 103, and one end of it extends out of the drying box 1, and a fan-shaped plate 304 is fixed. A plurality of sector plates 304 located on the same side are meshed with the same first rack 305 through the teeth. The inclination angle of the first rack 305 and the corresponding side of the guide plate 2 is the same, and the top of the first rack 305 There are mobile components on the surface.

[0080] The moving...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com