Graphene powder gas-phase physical stripping method and produced graphene

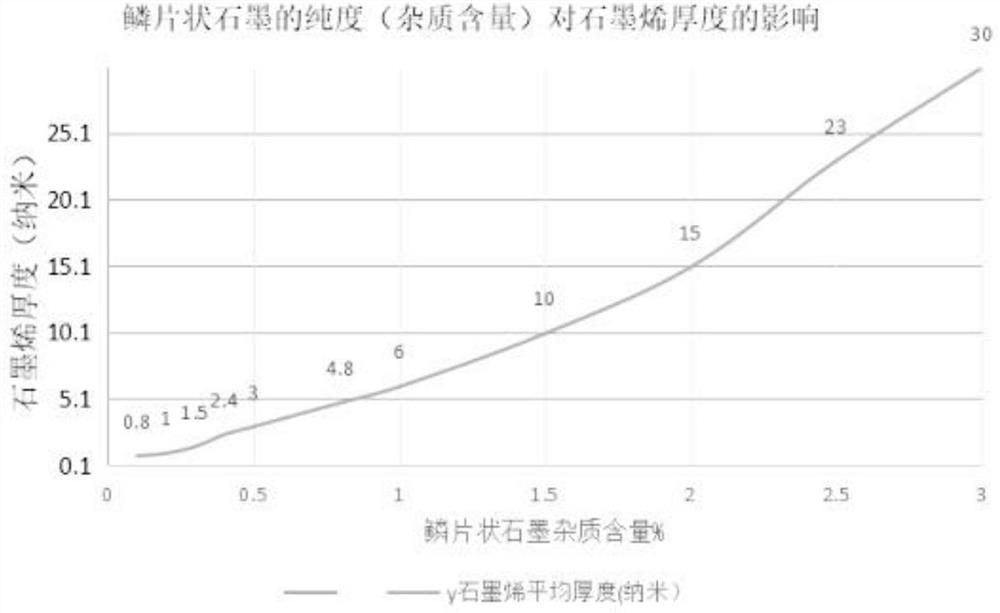

A technology of physical exfoliation and graphene powder, applied in the field of graphene, can solve the problems of high production cost, waste liquid pollution, high production cost, etc., and achieve the effects of long service life, large specific surface area and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

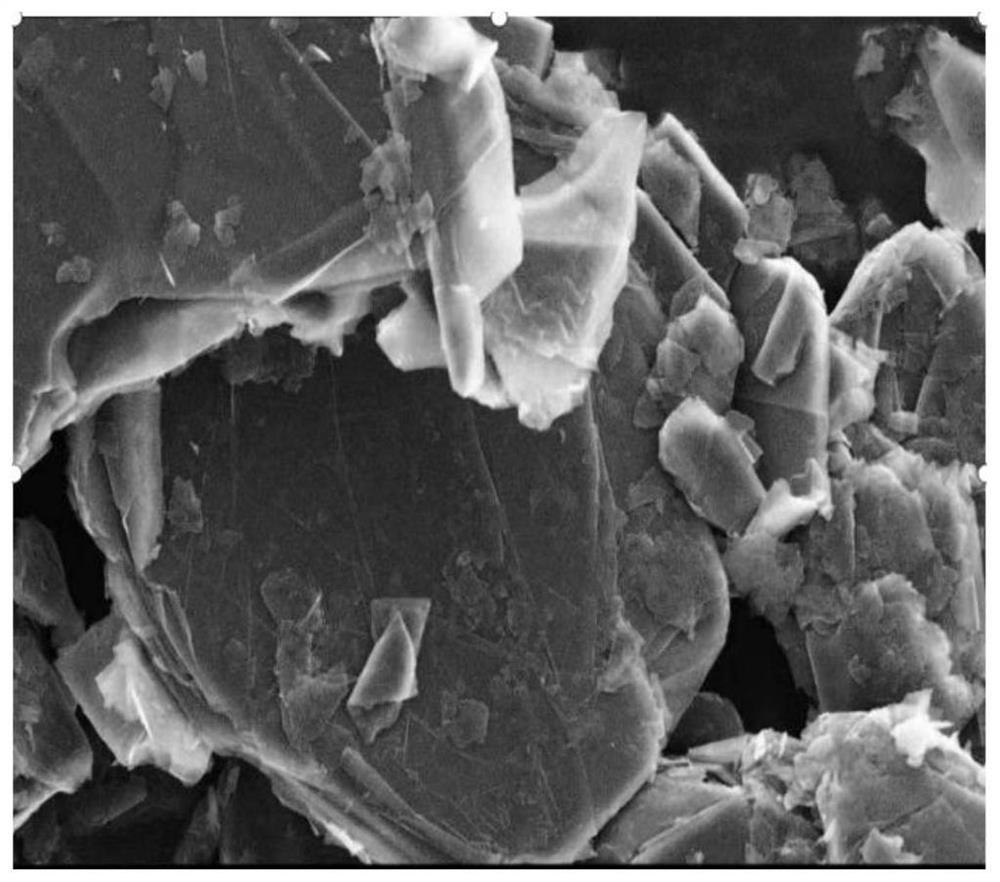

Image

Examples

Embodiment 1

[0060] A kind of graphene powder vapor phase physical stripping method of the present embodiment comprises the following steps:

[0061] The average particle size D50=2-7μm, D100<25μm, flake graphite with impurity content≤0.1%, is made of 18-45μm aluminum-magnesium-silicon alloy powder (in the aluminum-magnesium-silicon alloy, the aluminum content is 65wt%, the magnesium content is 25wt%, Silicon content 10wt%,) and stainless steel balls with a diameter of 0.5mm-0.9mm and stainless steel powder with a diameter of 20-40μm are added to the ball mill. The weight of stainless steel balls, stainless steel powder and aluminum-magnesium-silicon alloy powder The proportion is shown in Table 1 below. The weight of flake graphite is 3.5% of the ball mill exfoliation medium (the sum of steel balls, stainless steel powder and aluminum-magnesium-silicon alloy powder). The ball mill speed is 60-80 rpm and the temperature is 100-110 ℃, the ball milling stripping is carried out in a nitrogen ...

Embodiment 2

[0067] Flake graphite with an average particle size of D50=2-7μm, D100<25μm, impurity content≤0.1%, spherical aluminum-magnesium-silicon alloy powder with a diameter of 18-45μm, stainless steel balls with a diameter of 0.5mm-0.9mm, and 20- The ball mill exfoliation medium composed of 40 μm stainless steel powder is added in the ball mill, wherein relative to the total weight of the ball mill medium, the weight of steel balls is 10%, the weight of stainless steel powder is 42%, and the weight of aluminum-magnesium-silicon alloy powder is 48%, In the aluminum-magnesium-silicon alloy, the aluminum content is 65wt%, the magnesium content is 25wt%, and the silicon content is 10wt%. The weight of flaky graphite and the weight of ball milling stripping medium (the sum of steel ball, stainless steel powder and aluminum-magnesium-silicon alloy powder) are as shown in Table 2. In the ball mill, add polyvinylpyrrolidone, polyvinyl alcohol, oleic acid amide in the The ball milling strippi...

Embodiment 3

[0073] The average particle size D50=2-7μm, D100<25μm, flake graphite with impurity content≤0.1%, is made of 18-45μm aluminum-magnesium-silicon alloy powder (in the aluminum-magnesium-silicon alloy, the aluminum content is 65wt%, the magnesium content is 25wt%, Silicon content 10wt%,) and the stripping medium that diameter is 0.5mm-0.9mm stainless steel ball and the stainless steel powder of 20-40 μm is added in the ball mill, wherein, relative to the total weight of ball milling medium, steel ball weight is 10 %, the weight of the stainless steel powder is 48%, the weight of the Al-Mg-Si alloy powder is 42%, and the mass ratio of Al-Mg-Si in the Al-Mg-Si alloy is shown in the following table 3, and the weight of the flaky graphite is the ball milling exfoliation medium ( Steel balls, stainless steel powder and aluminum-magnesium-silicon alloy powder) about 3.5%, in the ball mill, add polyvinylpyrrolidone, polyvinyl alcohol, oleic acid amide to perform ball milling and peeling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com