Water-soluble graphene production equipment and method based on electric field melting

A kind of production equipment and graphene technology, applied in the field of water-soluble graphene production equipment, can solve problems such as inconvenient cleaning, achieve the effect of increasing production and improving the probability of breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

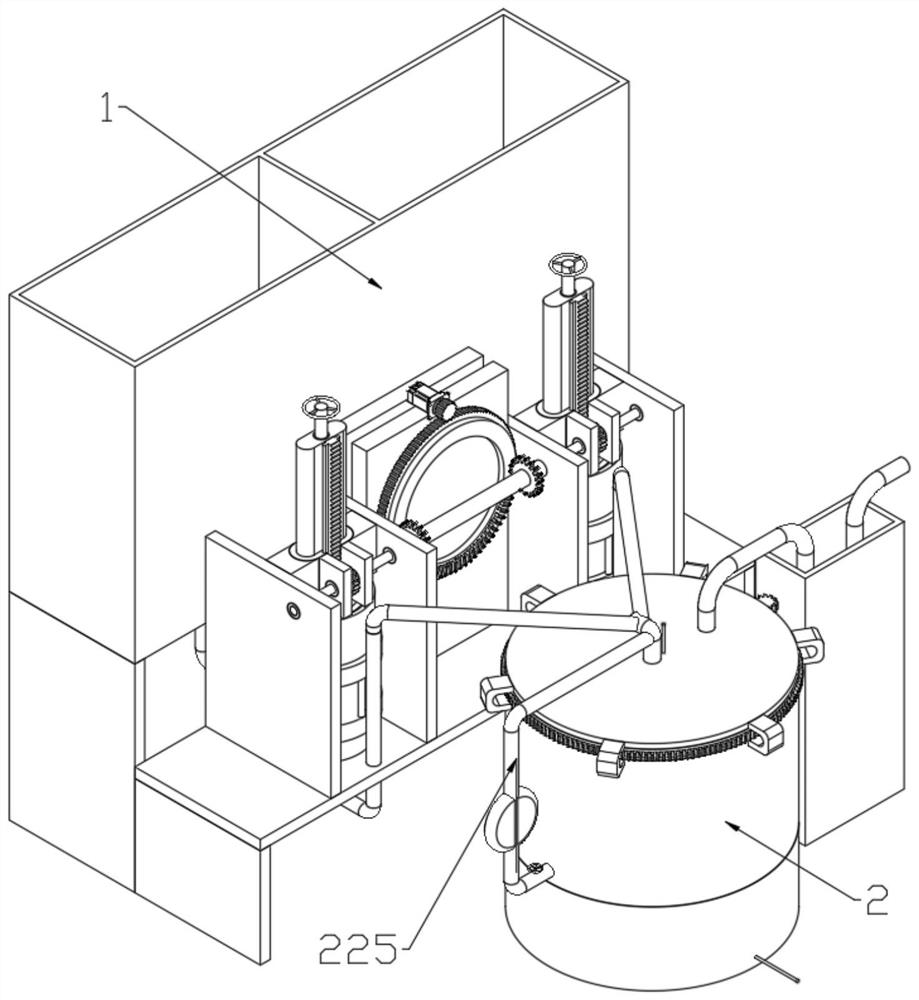

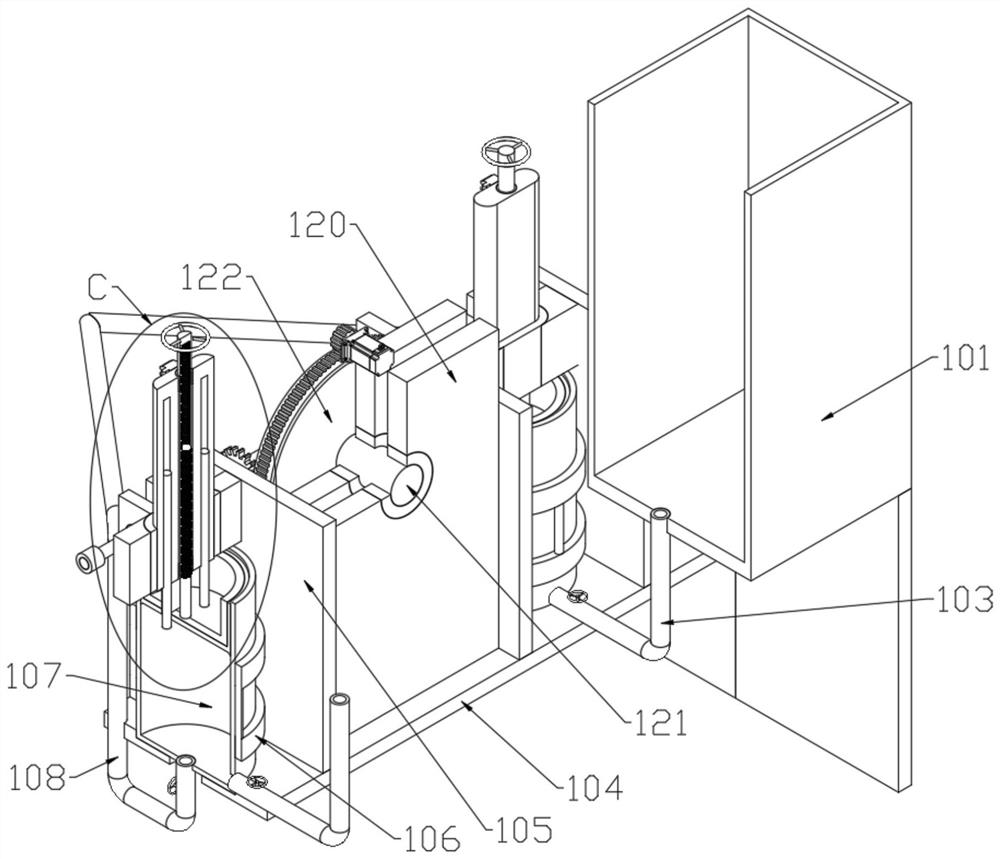

[0055] Example: Figure 1-9 , The present invention provides an aqueous graphene device based on an electric field produced molten, comprising a feed mechanism, the feed mechanism comprises a feed storage tank 101, a storage bin 101 attached to a side of the base plate 104, the said bottom plate is mounted to the top 104 of the magazine 107 symmetrically above the storage cartridge 107 is attached to the arc-shaped locking blocks 110, 110 inside the arcuate block slide card is provided with an arc column 111, the arc column 111 the inner rotor 113 provided with a threaded cylinder, the threaded cylinder 113 is provided with an internal screw thread 114, the screw 114 is attached to the bottom end of the piston 115, the arc-shaped locking block 110 is attached to one side of rack 116, the rack 116 mesh with the first gear 119, the first gear 119 is attached to the center of the rotating lever 118, the rotor 122 is mounted symmetrically between the reservoir cartridge 107, the turnta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com